Evaluation of Changes in Protein, Amino Acids, and Flavor during Mixed Fermentation of Chicken and Soybean

-

摘要: 以纯黄豆发酵为对照,分析了鸡肉与黄豆混合发酵过程中蛋白质、氨基酸态氮、蛋白酶活力、游离氨基酸和挥发性风味物质的变化规律。结果表明,发酵过程中,样品的蛋白质含量呈下降趋势,氨基酸态氮、蛋白酶活力和游离氨基酸含量则呈上升趋势。不同发酵时期,鸡肉和黄豆混合发酵组中鲜味氨基酸和总游离氨基酸含量均显著高于纯黄豆发酵(P<0.05),挥发性风味物质的积累也较纯黄豆发酵多。通过正交偏最小二乘判别分析(orthogonal partial least squares discriminant analysis,OPLS-DA)结合气味活性值(odor activity value,OAV)进一步分析得出,3-甲硫基丙醛、苯甲醛、苯乙醛和1-辛烯-3-醇是鸡肉与黄豆混合发酵过程中的关键差异挥发性风味物质。该研究结果为高品质豆基发酵调味品的开发和品质调控提供了理论参考。Abstract: In this study, the model of mixed fermentation was constructed using the chicken and soybean, in order to explore its differences (on the content of protein, amino acid nitrogen, free amino acids, volatile flavor substances and on the activity of protease) from a single fermented soybean product. The results showed that fermentation induced a decline of the content of protein, but an increase in amino acid nitrogen, free amino acids and the activity of protease, respectively. Compared with the soybean fermentation group, the mixed fermentation group had significantly higher concentrations of umami amino acids and total free amino acids, and richer volatile flavor substances during fermentation, in which 3-methylthiopropionaldehyde, benzaldehyde, phenylacetaldehyde, and 1-octen-3-ol were regarded as the key differential compounds by means of orthogonal partial least squares discriminant analysis (OPLS-DA) and odor activity value (OAV). The current study contributed to the development of new soybean-based condiment and provided a theoretical reference for quality control of soybean fermentation products.

-

Keywords:

- chicken-soybean pastes /

- fermentation /

- free amino acids /

- volatile flavor substances

-

发酵调味品能赋予食品良好的色、香、味,被广泛应用于佐餐与调味。近年来,为顺应消费者对食品营养健康日益增长的需求,以黄豆与其他原料复合发酵的调味品逐渐被研发,如蟹味黄豆酱[1]、柑橘黄豆酱[2]、牛肉黄豆酱[3]、鳀鱼酱油[4]、猴头菇酱油[5]等。相比于传统发酵调味品,复合发酵调味品更具营养和风味[6],受到了广大消费者的喜爱。

在复合发酵过程中,发酵基料中新增加的原料可能会影响微生物的丰富度和多样性,从而导致调味品具有不同风味[7]。此外,新增加原料本身含有的蛋白质、脂肪等营养成分通过微生物的降解,会产生氨基酸以及脂肪酸等风味前体物质,从而改变发酵调味品的特征风味和滋味[8]。豆基发酵调味品中丰富的游离氨基酸和挥发性风味物质是决定其品质的重要物质基础。其中,大豆蛋白的降解对游离氨基酸和风味物质的形成具有重要作用[9]。通过添加一些富含蛋白质的原料可以有效提升产品的营养价值和风味。如肖泽源[3]和郭丽平[8]等分别将富含蛋白的牛肉、贻贝与黄豆混合发酵制成豆酱,发现成品中具有更丰富的游离氨基酸和香气物质。与牛肉、贻贝等原料相比,鸡胸肉中同样富含蛋白质(24.31 g/100 g)[10],将其与黄豆混合发酵有望提升体系中蛋白质的降解程度,从而提高产品的营养与风味。然而目前鸡肉与黄豆混合发酵过程中的蛋白质、氨基酸以及风味变化规律尚不清楚,了解发酵过程中物质的变化规律有助于指导产品的实际生产[8,11]。

因此,本研究以纯黄豆发酵为对照组(soybean paste,SP),探究鸡肉与黄豆混合发酵(chicken-soybean paste,CSP)过程中的蛋白质、蛋白酶活力、氨基酸态氮、游离氨基酸和挥发性风味物质的变化规律,结合OPLS-DA模型和OAV值进一步比较两种黄豆酱发酵过程中关键差异挥发性风味物质的变化,旨在阐明鸡肉与黄豆混合发酵过程中蛋白质、氨基酸与风味变化规律,为高品质豆基发酵调味品的开发和品质调控提供理论参考。

1. 材料与方法

1.1 材料与仪器

黄豆 购于当地市场;新鲜鸡胸肉、面粉、盐 购于当地超市;米曲霉As3.042孢子粉 沂水锦润生物科技有限公司;植物乳杆菌(ATCC 8014)、戊糖片球菌(ATCC 33316) 购于广东省微生物菌种保藏中心;硼酸、甲基红、磷酸二氢钠、磷酸氢二钠 福晨(天津)化学试剂有限公司;溴甲酚绿 天津市天新精细化工开发中心;氢氧化钠 广东广试试剂科技有限公司;甲醛、三氯乙酸 天津市大茂化学试剂厂;碳酸钠、氯化钠、硫酸、盐酸 广州化学试剂厂;磺基水杨酸、福林酚 上海源叶生物科技有限公司;以上均为分析纯;酪蛋白 中国食品药品检定研究院。

电热鼓风干燥箱、HWS-26电热恒温水浴锅 上海一恒科学仪器有限公司;BSC-250恒温恒湿培养箱 上海博迅实业有限公司医疗设备厂;TGL-16M台式高速冷冻离心机 湖南湘仪实验室仪器开发有限公司;HM-6300全自动智能均质仪 莱谱(北京)科技有限公司;Kjeltec 8400蛋白质分析仪 瑞典Foss Analytical Ab公司;PB-10台式pH计 赛多利斯科学仪器(北京)有限公司;DF-101S集热式恒温加热磁力搅拌器 巩义市英峪高科仪器厂;UV-1800紫外可见分光光度计 日本岛津企业管理(中国)有限公司;6890N-5975B气相色谱-质谱联用仪 美国Agilent公司;固相微萃取装置50/30 μm DVB/CAR/PDMS萃取头 美国Sigma-Aldrich公司;L-8900全自动氨基酸分析仪 日本Hitachi公司。

1.2 实验方法

1.2.1 样品的制备

1.2.1.1 发酵剂的制备

将植物乳杆菌和戊糖片球菌菌种分别接种于100 mL MRS肉汤液体培养基中,37 ℃培养48 h得到菌悬液,吸取适量混匀后的菌悬液于无菌生理盐水中,调整菌悬液中的菌落数量达到106 CFU/mL备用。

1.2.1.2 发酵工艺流程和操作要点

工艺流程:

操作要点:

黄豆与面粉预处理:黄豆在室温下浸泡12 h(豆:水=1:3)后常压蒸煮50 min,面粉经180 ℃烘烤30 min,然后二者分别冷却至室温。

制曲:先将冷却的面粉接入108 CFU/g的米曲霉孢子粉,接种量为预处理后的黄豆与面粉总质量的0.15%,再与冷却的黄豆按质量比为8:2混合,然后放入恒温培养箱中培养,在30 ℃、80%相对湿度的条件下发酵72 h完成制曲,每隔8 h定期进行翻曲,得到曲坯。

鸡胸肉预处理:鸡胸肉洗净后切成黄豆颗粒大小的肉丁,常压蒸煮20 min后冷却至室温。

发酵:曲坯与鸡肉按质量比为6:4混合后装入陶瓷罐(只装入曲坯为纯黄豆发酵),加入与发酵基料(陶瓷罐中所加入的物料)质量比为1:1的盐水(浓度为10%),并接种植物乳杆菌与戊糖片球菌菌悬液(接种量为2%,浓度为106 CFU/mL,体积比为1:1),在37 ℃的恒温培养箱中培养42 d后完成发酵,期间每隔一周定期进行搅拌。

1.2.2 样品收集

分别在不同的发酵时间段,在干净环境下对纯黄豆酱(未添加鸡胸肉,记为SP)和鸡肉黄豆酱(40%鸡胸肉添加量,记为CSP)醪糟进行搅拌。前一周分别在发酵第0、3、7 d搅拌,之后每隔一周(14、21、28、35、42 d)搅拌一次直到发酵结束,每次搅拌后立即收集样品,并分别标记为SP0、CSP0(未发酵期),SP3、CSP3、SP7、CSP7、SP14、CSP14(发酵前期),SP21、CSP21、SP28、CSP28(发酵中期),SP35、CSP35、SP42、CSP42(发酵后期)。收集的样品用均质机均质成糊状后装在无菌取样袋中,分析前储存在−80 ℃,并在一周内进行分析。

1.2.3 理化指标的测定

参照国标GB 5009.5-2016《食品安全国家标准 食品中蛋白质的测定》中的凯氏定氮法测定蛋白质含量;参照国标GB/T 23527-2009《蛋白酶制剂》中的福林法测定蛋白酶活力;参照国标GB 5009.235-2016《食品安全国家标准 食品中氨基酸态氮的测定》中的酸度计法测定氨基酸态氮含量。

1.2.4 游离氨基酸的测定

根据Gao等[12]的方法,并稍加修改。称取2 g样品和10 mL质量分数为10%的磺基水杨酸混匀,7000 r/min均质40 s,将均质后的混合液于4 ℃、10000 r/min离心15 min,取4 mL上清液并与4 mL石油醚混合振荡,之后去除有机层,取1 mL样品液稀释10倍,过0.22 μm水相滤膜,取1 mL滤液于进样瓶中,用全自动氨基酸分析仪进行测定。味觉活性值(taste activity value,TAV)按下式计算[13]:

1.2.5 挥发性风味物质的测定

使用顶空固相微萃取(headspace solid phase microextraction,HS-SPME)-气质联用(gas chromatography-mass spectrometry,GC-MS),参照Zhao等[14]的方法稍加改动测定样品中的挥发性风味物质。

样品处理与萃取:称取2 g充分混匀的黄豆酱样品于20 mL顶空瓶中,加入0.5 g氯化钠、2 mL蒸馏水,并添加100 μL 2-甲基-3-庚酮溶液(8.16 μg/mL)作为内标,将装有样品的顶空瓶放置于55 ℃水浴锅中平衡10 min,把预先在250 ℃条件下老化30 min的萃取头(50/30 μm)插入顶空瓶中,55 ℃恒温萃取30 min,在进样器中解吸附5 min后进样。

色谱条件:J&W HP-5MS UI 毛细管色谱柱(30 m×250 μm×0.25 μm);升温程序:40 ℃保持3 min,4 ℃/min升温至150 ℃,保持0 min,8 ℃/min升温至240 ℃,保持6 min;进样方式:不分流;进样口温度250 ℃;载气为He,流速1.0 mL/min。

质谱条件:传输线温度280 ℃,离子源温度230 ℃,四极杆温度150 ℃,离子能量70 eV,检测电压350 V,质量扫描范围35~550 m/z。

定性与定量分析:利用安捷伦MassHunter Workststion Software对原始数据进行处理和分析,结合NIST 11谱库对挥发性成分进行初步判定,选择挥发性成分匹配度大于80的物质,去除萃取纤维柱流失的硅烷化杂质,再结合保留时间和参考有关文献完成挥发性风味物质的最终定性。以2-甲基-3-庚酮为内标物,采用内标法对样品的挥发性成分进行定量分析。按下式计算样品中挥发性风味物质的含量:

式中:C1为挥发性风味物质含量,mg/kg;C2为内标物含量,μg;A1为挥发性风味物质的峰面积;A2为内标物的峰面积;m为样品质量,g。

气味活性值的计算:气味活性值(OAV)用于评估每种化合物对样品整体香气的贡献[15]。OAV按下式计算:

1.3 数据处理

实验数据采用Excel 2016进行数据统计,利用SPSS Statistics 27.0进行数据计算与分析,用Origin 2022作图,SIMCA 14.1进行多变量分析。

2. 结果与分析

2.1 发酵过程中蛋白质、氨基酸态氮含量及蛋白酶活力的变化

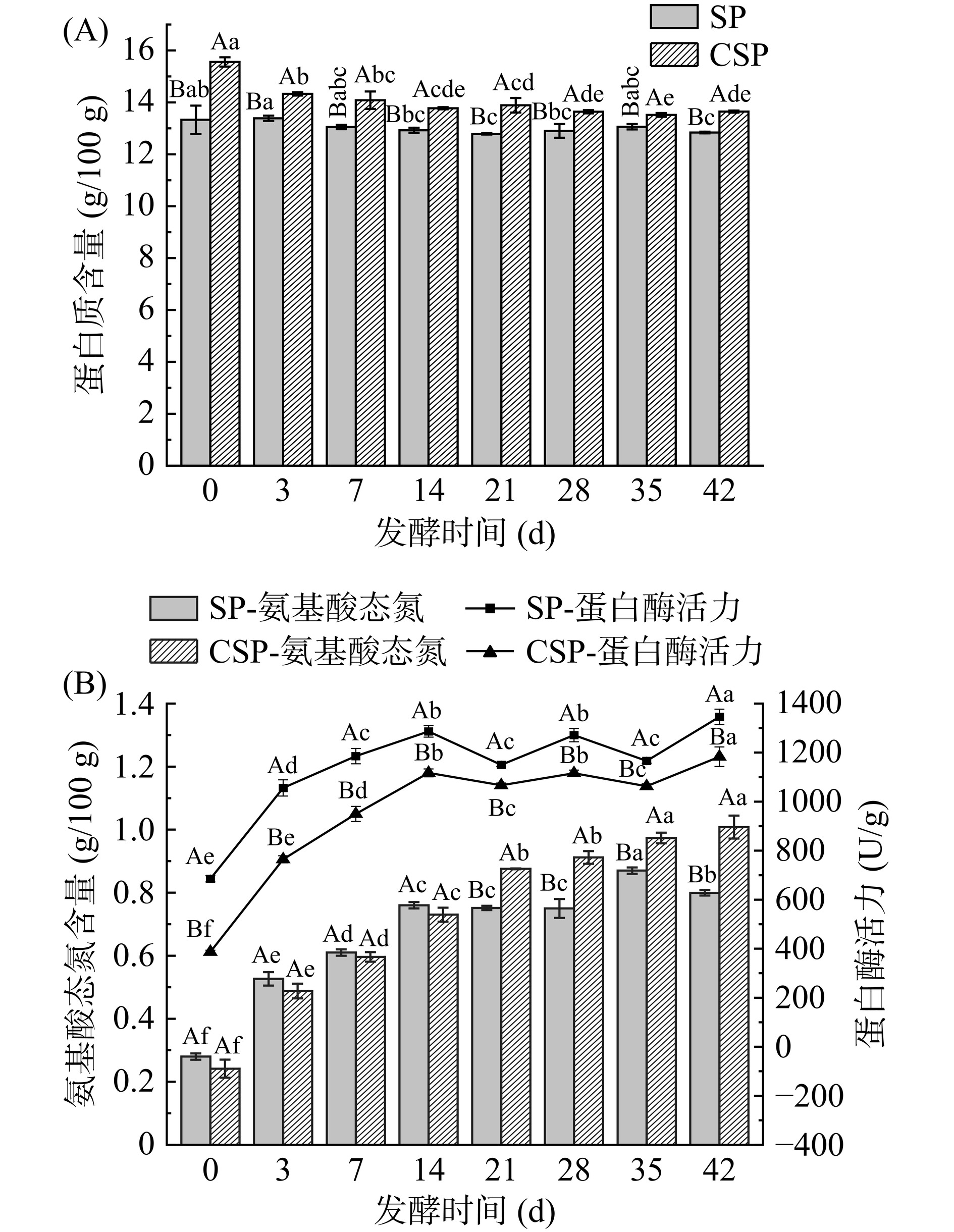

蛋白质是豆酱中重要的营养物质之一,分解产生的氨基酸态氮反映了豆酱的发酵程度,且与蛋白酶活性有关[16]。图1显示了两种黄豆酱发酵过程中蛋白质、氨基酸态氮含量与蛋白酶活力的变化。从图1(A)中可以看出,发酵过程中,两种黄豆酱的蛋白质含量均呈下降趋势,在发酵21 d后趋于平稳。从发酵0 d到42 d的过程中,鸡肉黄豆酱(CSP组)和纯黄豆酱(SP组)的蛋白质含量分别下降了12.28%和3.68%,这表明蛋白质在发酵过程中发生了降解,且CSP组中蛋白质降解作用更明显。此外,CSP组在整个发酵过程中的蛋白质含量均显著高于SP组(P<0.05),这是由于鸡胸肉中含有更丰富的蛋白质,使得CSP组的蛋白质含量更高。

由图1(B)可知,两种黄豆酱的氨基酸态氮与蛋白酶活力呈先上升(0~21 d)后趋于平稳的趋势。这说明发酵前期微生物代谢活跃,产生了大量的蛋白酶分解蛋白质,使氨基酸态氮含量迅速增加[17]。而在发酵中后期,乳酸菌产生的有机酸抑制了微生物的生长及酶的活性,蛋白质水解作用减弱,因此氨基酸态氮含量增速减缓[18]。同时,微生物需要利用氮源生长,这也可能是发酵中后期氨基酸态氮含量增加缓慢的原因之一[19]。由图1(B)还可知,在整个发酵过程中,CSP组的蛋白酶活力显著低于SP组(P<0.05),然而,CSP组的氨基酸态氮含量在发酵前14 d时与SP组差异不显著(P>0.05),21 d后显著高于SP组(P<0.05)。这可能是由于在发酵中后期,SP组中含有更丰富的微生物和更剧烈的美拉德反应,使得SP组消耗更多的氨基酸态氮[19]。发酵0 d到42 d,CSP组的氨基酸态氮含量与蛋白酶活力分别增加了4.21倍和3.06倍,相应的SP组的氨基酸态氮含量与蛋白酶活力分别增加了2.86倍和1.96倍,这说明鸡肉黄豆酱发酵过程中微生物对蛋白质的降解作用强于黄豆单独发酵,有利于提高黄豆酱的品质。

2.2 发酵过程中游离氨基酸组成的变化

游离氨基酸组成是评价豆酱营养价值的重要指标,并影响着豆酱的特征风味和滋味。表1显示了两种黄豆酱发酵过程中游离氨基酸含量的变化。随着发酵时间的延长,两种黄豆酱的鲜味、甜味、苦味、必需氨基酸和总游离氨基酸含量均显著上升(P<0.05),与郭丽平[8]的研究结果一致,说明发酵基料中的蛋白质被分解成了游离氨基酸[20]。整个发酵过程中,鸡肉黄豆酱(CSP组)的鲜味氨基酸和总游离氨基酸含量显著高于纯黄豆酱(SP组)(P<0.05),说明鸡胸肉中丰富的蛋白质有利于豆酱鲜味氨基酸和总游离氨基酸的积累。在发酵过程中,CSP组和SP组中游离氨基酸(除精氨酸和半胱氨酸外)含量都呈现增加的趋势,且谷氨酸和天冬氨酸的含量最高,其次为赖氨酸、亮氨酸、丙氨酸,这与Yang等[16]和Tian等[21]的研究结果一致。从未发酵到发酵后期,CSP组中谷氨酸和天冬氨酸的含量均显著高于SP组(P<0.05),这是由于鸡肉蛋白被水解[22]。谷氨酸和天冬氨酸可以赋予豆酱强烈的鲜味特征,丙氨酸和赖氨酸则主要贡献甜味,亮氨酸主要贡献苦味,它们相互作用,共同形成豆酱的良好滋味[23]。此外,发酵后期,SP组中的异亮氨酸和缬氨酸含量分别比未发酵期增加了1.52 mg/g和1.57 mg/g,而CSP组中则分别比未发酵期增加了1.69 mg/g和1.74 mg/g,这两种氨基酸具有支链结构,是重要的风味前体物,对风味形成有重要影响[8]。

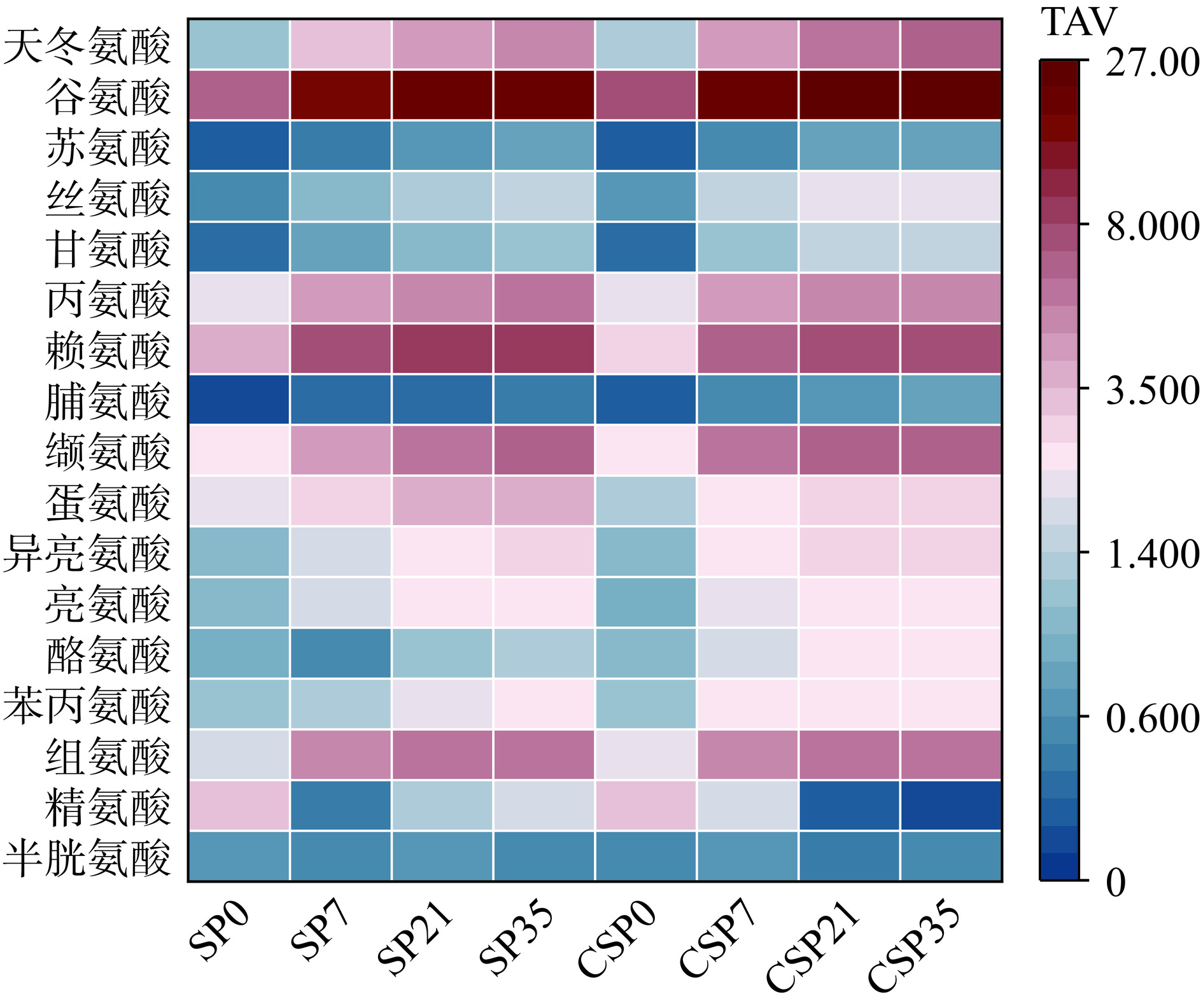

表 1 发酵过程中游离氨基酸含量的变化Table 1. Changes in free amino acid content during the fermentation味感 名称 游离氨基酸含量(mg/g) SP0 SP7 SP21 SP35 CSP0 CSP7 CSP21 CSP35 鲜味 天冬氨酸(Asp) 1.02±0.01Bd 3.00±0.02Bc 4.25±0.13Bb 4.68±0.01Ba 1.26±0.01Ad 4.18±0.31Ac 5.73±0.09Ab 6.20±0.02Aa 谷氨酸(Glu) 1.85±0.02Bc 5.25±0.02Bb 6.67±0.11Ba 6.66±0.01Ba 2.26±0.03Ac 7.27±0.53Ab 8.07±0.11Aa 8.08±0.04Aa 甜味 苏氨酸*(Thr) 0.62±0.01Ad 1.08±0.01Bc 1.66±0.06Bb 1.86±0.01Ba 0.65±0.01Ac 1.46±0.11Ab 1.93±0.03Aa 2.06±0.01Aa 丝氨酸(Ser) 0.89±0.02Bd 1.44±0.01Bc 2.08±0.06Bb 2.30±0.00Ba 0.97±0.01Ac 2.16±0.16Ab 2.82±0.04Aa 2.99±0.00Aa 甘氨酸(Gly) 0.43±0.01Bd 0.98±0.01Bc 1.26±0.01Bb 1.36±0.00Ba 0.47±0.01Ac 1.32±0.10Ab 1.83±0.03Aa 1.94±0.01Aa 丙氨酸(Ala) 1.18±0.02Ad 2.46±0.02Ac 3.00±0.03Ab 3.17±0.01Aa 1.10±0.01Bc 2.40±0.18Ab 2.79±0.04Ba 2.92±0.01Ba 赖氨酸*(Lys) 1.75±0.00Ad 3.67±0.05Ac 4.33±0.03Ab 4.47±0.02Aa 1.39±0.05Bc 3.32±0.23Ab 3.67±0.07Ba 3.74±0.07Ba 脯氨酸(Pro) 0.58±0.01Bc 1.00±0.01Bb 1.08±0.18Bab 1.33±0.00Ba 0.70±0.01Ac 1.60±0.12Ab 1.96±0.03Aab 2.12±0.01Aa 苦味 缬氨酸*(Val) 0.90±0.02Ad 1.70±0.01Ac 2.21±0.03Bb 2.47±0.01Ba 0.95±0.01Ac 2.09±0.15Ab 2.48±0.03Aa 2.69±0.01Aa 蛋氨酸*(Met) 0.58±0.01Ad 0.89±0.00Ac 1.12±0.01Ab 1.19±0.00Aa 0.37±0.01Bc 0.71±0.05Bb 0.79±0.01Ba 0.82±0.01Ba 异亮氨酸*(Ile) 0.84±0.02Ad 1.61±0.00Ac 2.17±0.01Bb 2.36±0.01Ba 0.84±0.01Ac 2.01±0.14Ab 2.36±0.04Aa 2.53±0.02Aa 亮氨酸*(Leu) 1.78±0.03Ad 3.25±0.01Ac 4.11±0.11Ab 4.41±0.05Aa 1.53±0.02Bc 3.53±0.25Ab 4.02±0.06Aa 4.19±0.03Ba 酪氨酸(Tyr) 0.76±0.02Ad 0.50±0.01Bc 1.02±0.05Bb 1.17±0.01Ba 0.81±0.01Ad 1.61±0.11Ac 1.83±0.02Ab 2.06±0.06Aa 苯丙氨酸*(Phe) 0.98±0.03Ad 1.21±0.00Bc 1.71±0.01Bb 1.90±0.02Ba 1.06±0.01Ac 1.85±0.13Ab 2.14±0.04Aa 2.24±0.02Aa 组氨酸(His) 0.35±0.01Ac 0.91±0.14Ab 1.09±0.01Aab 1.19±0.00Ba 0.38±0.01Ac 0.98±0.07Ab 1.17±0.02Aa 1.20±0.02Aa 精氨酸(Arg) 1.52±0.04Ad 0.22±0.00Bc 0.61±0.00Ab 0.88±0.00Aa 1.55±0.02Aa 0.87±0.06Ab 0.14±0.00Bc 0.07±0.00Bc 无味 半胱氨酸(Cys) 0.15±0.01Aa 0.14±0.00Aa 0.15±0.01Aa 0.12±0.00Ab 0.14±0.01Ab 0.16±0.01Aa 0.11±0.00Bc 0.12±0.00Ac 鲜味氨基酸 2.87±0.04Bd 8.25±0.04Bc 10.93±0.02Bb 11.34±0.01Ba 3.52±0.05Ac 11.45±0.84Ab 13.80±0.20Aa 14.28±0.06Aa 甜味氨基酸 5.43±0.08Ad 10.63±0.11Ac 13.41±0.01Bb 14.51±0.01Ba 5.28±0.10Ac 12.26±0.90Ab 15.01±0.23Aa 15.77±0.05Aa 苦味氨基酸 7.72±0.17Ad 10.29±0.16Bc 14.03±0.23Ab 15.58±0.03Aa 7.50±0.11Ac 13.63±0.98Ab 14.94±0.22Aab 15.79±0.18Aa 必需氨基酸 7.46±0.12Ad 13.41±0.085Ac 17.31±0.27Ab 18.68±0.06Aa 6.80±0.11Bc 14.96±1.07Ab 17.40±0.28Aa 18.27±0.18Aa 总游离氨基酸 16.17±0.28Ad 29.31±0.30Bc 38.51±0.23Bb 41.54±0.04Ba 16.43±0.25Ac 37.50±2.71Ab 43.85±0.64Aa 45.96±0.21Aa 注:*表示必需氨基酸;同行大写字母不同表示同一发酵时间不同样品的游离氨基酸含量差异显著(P<0.05);同行小写字母不同表示同一样品不同发酵时间游离氨基酸含量差异显著(P<0.05)。 TAV是指样品中所含呈味氨基酸与其阈值之间的比率[13],当某种滋味物质的TAV≥1时,说明其对整体滋味有贡献[24]。图2显示了各呈味游离氨基酸TVA值的变化。整个发酵过程中,所有氨基酸(除精氨酸和半胱氨酸外)的TAV值呈现增大的趋势。其中,TAV值大于1的氨基酸包括天冬氨酸、谷氨酸、丙氨酸、赖氨酸、缬氨酸、蛋氨酸、苯丙氨酸和组氨酸,这些氨基酸对形成豆酱的特征滋味具有重要的贡献。两种豆酱中谷氨酸的TAV值最大,其次是赖氨酸,这说明鲜味和甜味对黄豆酱的滋味贡献最大。此外,CSP组中天冬氨酸、谷氨酸、缬氨酸、苯丙氨酸、组氨酸的TAV值均大于SP组。结合各类呈味氨基酸含量的变化,说明鸡胸肉的添加促进了黄豆酱中鲜味氨基酸的积累,使其味道更加鲜美。

2.3 发酵过程中挥发性风味物质的变化

2.3.1 通过HS-SPME-GC-MS鉴定的挥发性风味物质

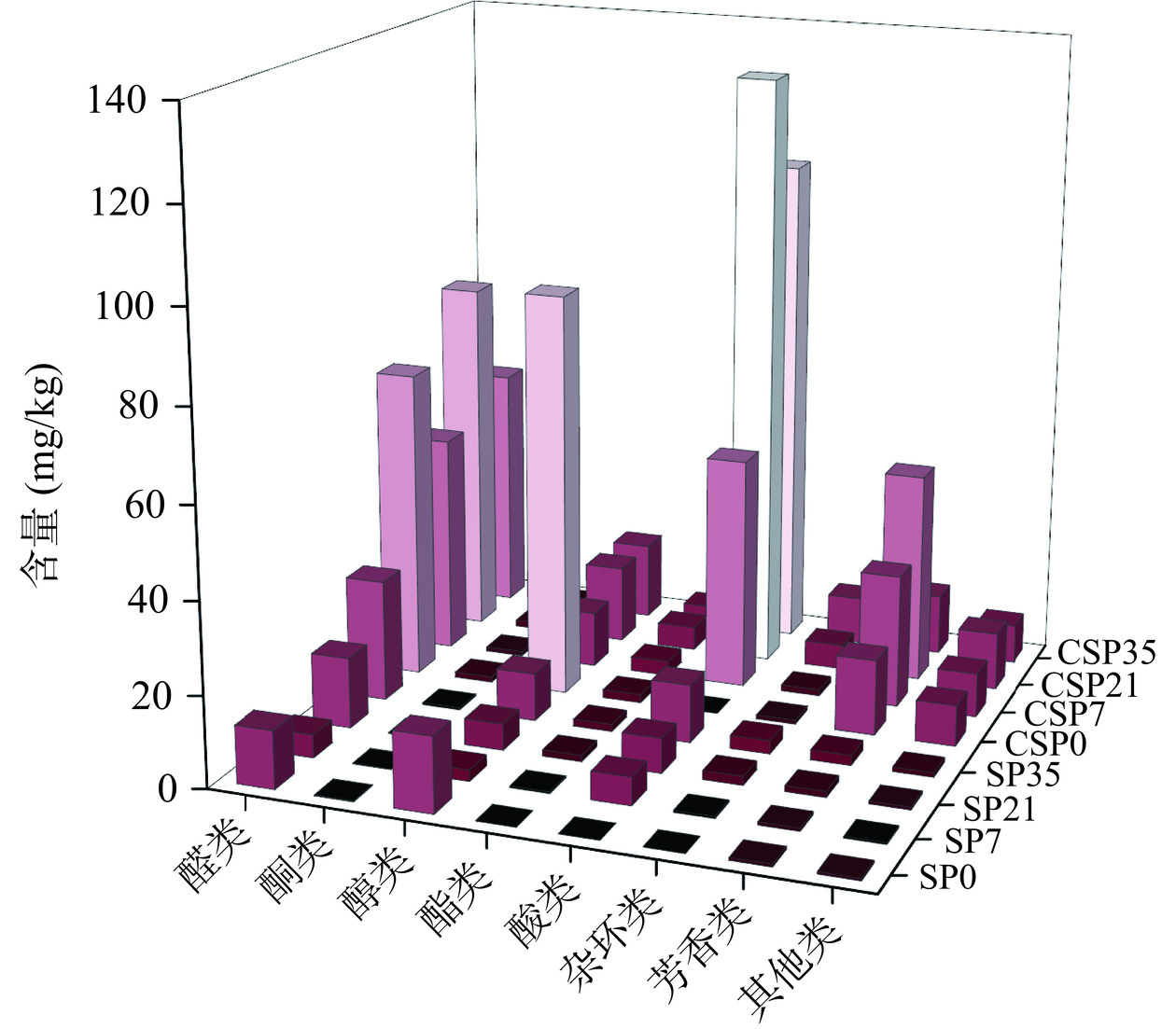

挥发性风味物质的组成决定了消费者对产品整体风味的感官。利用HS-SPME-GC-MS对两种黄豆酱发酵过程中挥发性风味物质的组成进行分析,结果如表2和图3所示。整个发酵过程中共检测出66种挥发性风味物质,包括17种醛类、1种酮类、7种醇类、12种酯类、5种酸类、5种杂环类和8种芳香类,且醛类、醇类、酸类、芳香类的含量较高。其中,鸡肉黄豆酱(CSP组)的醛类和芳香类物质数量最丰富,纯黄豆酱(SP组)的醛类和醇类物质数量最丰富。在发酵过程中,两种黄豆酱的挥发性风味物质动态变化存在差异,CSP组的大部分挥发性风味物质含量高于SP组。发酵第35 d时,CSP组中的醛类、醇类、酸类和芳香类的含量分别是SP组的2.03、1.61、8.51倍和5.87倍,这主要是由于发酵过程中挥发性风味物质的形成与变化与豆酱原料中的蛋白质密切相关[25]。在CSP组发酵过程中,鸡肉蛋白被分解为氨基酸,促进了芳香族、支链醛、支链醇等物质的积累[26−27]。

表 2 发酵过程中挥发性风味物质的组成与含量Table 2. Composition and content of volatile flavor substances during the fermentation类别 序号 名称 保留时间(min) 挥发性风味物质含量(mg/kg) SP0 SP7 SP21 SP35 CSP0 CSP7 CSP21 CSP35 醛类 A1 异戊醛 3.43 3.93±0.86Ba 0.55±0.03Ab 2.29±1.54Aa 2.62±0.41Ba 26.88±3.63Aa ND 8.10±1.11Ab 8.92±2.56Ab A2 己醛 6.78 0.98±0.83Ba 0.41±0.12Bab ND ND 5.51±1.44Aa 6.83±1.48Aa 7.61±1.05Aa ND A3 3-甲硫基丙醛 10.65 0.69±0.08Bbc 0.23±0.11Bc 0.83±0.19Bb 1.65±0.44Ba 5.66±1.01Ac 6.52±1.41Abc 15.72±2.04Aa 12.18±2.22Aab A4 苯甲醛 12.82 0.63±0.14Bd 1.36±0.11Bc 2.18±0.39Bb 4.05±0.51Ba 2.84±0.62Ab 16.21±5.37Aa 24.33±3.69Aa 15.49±3.31Aa A5 苯乙醛 16.09 4.83±0.89Ba 1.10±0.05Bc 2.80±0.39Bb 4.96±0.81Ba 16.11±3.45Aa 6.26±3.98Ab 13.41±1.60Aa 11.17±2.58Aab A6 2-苯基丙醛 18.35 0.16±0.04Ab ND ND ND ND ND ND ND A7 壬醛 18.47 0.98±0.73Ba 0.38±0.23Bab 0.19±0.12Bb 0.50±0.12Aab 1.84±0.19Aa 2.99±1.52Aa 2.00±0.30Aa 0.76±0.22Ab A8 阿托醛 20.38 0.12±0.03Aa ND ND ND ND ND ND ND A9 2-苯基巴豆醛 24.43 0.42±0.16Aa ND ND 0.39±0.05Aa 0.68±0.16Aa ND ND ND A10 糠醛 7.83 ND 1.09±0.08Bc 5.44±1.57Ab 9.14±0.87Aa ND 2.70±1.26Ab 6.72±1.41Aa 5.44±1.09Ba A11 2-甲基丁醛 3.56 ND ND 1.82±0.58Ab 3.45±0.68Aa 8.55±3.33Aa ND ND ND A12 3-甲基巴豆醛 6.29 ND ND 0.09±0.01Ab ND ND ND ND ND A13 可卡醛 31.46 ND ND ND 0.05±0.01Aa ND ND ND ND A14 正辛醛 14.5 ND ND ND ND ND 0.59±0.15Ab 1.22±0.05Aa ND A15 十六烷醛 37.96 ND ND ND ND ND 3.13±1.90Aa ND ND A16 月桂醛 29.17 ND ND ND ND ND ND ND 0.35±0.15Aa A17 肉豆蔻醛 37.97 ND ND ND ND ND ND 0.63±0.20Aa ND 酮类 B1 2-甲基-3-甲氧基-4H-吡喃-4-酮 21.47 0.23±0.10Bb 0.11±0.02Bb 0.22±0.09Bb 0.47±0.17Aa 1.23±0.72Aa 0.96±0.41Aab 1.47±0.85Aa ND 醇类 C1 异戊醇 4.95 2.90±0.60Ba 0.49±0.03Bb 0.50±0.15Bb 0.65±0.12Bb 5.49±0.88Aa 2.22±0.91Ab 3.14±0.84Ab 2.58±0.49Ab C2 2,3-丁二醇 6.28 0.97±0.35Ba ND ND ND 4.30±1.16Aa 1.07±0.19Ab ND ND C3 1-辛烯-3-醇 13.63 11.04±2.08Ba 1.56±0.11Bb 1.77±0.35Bb 3.08±0.46Bb 74.39±14.45Aa 6.8±5.03Ab 10.10±2.09Ab 7.19±1.44Ab C4 苯乙醇 18.75 0.48±0.13Ab 0.20±0.01Bc 0.48±0.03Ab 1.05±0.21Ba 1.00±0.35Abc 2.21±1.39Ab ND 4.84±1.66Aa C5 2-甲基-1-丁醇 5.04 ND 0.28±0.03Aa 0.27±0.14Aa 0.35±0.05Aa ND ND ND ND C6 糠醇 8.66 ND ND 1.42±0.66Ab 3.70±0.59Aa ND ND ND ND C7 麦芽醇 18.56 ND ND 0.45±0.21Bb 1.73±0.59Aa ND ND 3.91±2.88Aa 2.37±1.29Aab 酯类 D1 正己酸乙酯 14.32 ND 0.11±0.02Ab ND 0.16±0.03Aa ND ND ND ND D2 苯甲酸乙酯 20.93 ND 0.19±0.04Ab 0.30±0.03Bb 0.51±0.19Ba ND ND 2.64±0.76Aa 1.31±0.52Ab D3 苯乙酸乙酯 23.52 ND 0.10±0.01Ac 0.22±0.03Bb 0.28±0.04Aa ND 0.46±0.37Aa 0.88±0.15Aa 0.66±0.19Aa D4 棕榈酸乙酯 40.36 ND ND 0.25±0.06Ba 0.32±0.07Ba 0.44±0.19Ab 1.59±0.79Aa 1.18±0.05Aab 0.95±0.50Aab D5 辛酸乙酯 21.87 ND ND ND 0.07±0.01Ba ND 0.37±0.27Aa 0.50±0.08Aa 0.30±0.07Aa D6 油酸乙酯 42.5 ND ND 0.10±0.04Aa 0.12±0.03Aa ND 0.61±0.23Aa ND ND D7 异丁酸乙酯 5.54 ND ND 0.12±0.03Aa ND ND ND ND 0.86±0.19Aa D8 2-甲基丁酸乙酯 8.48 ND ND 0.29±0.17Aa ND ND ND ND ND D9 乙酸异戊酯 9.51 ND ND 0.16±0.05Aa ND ND ND ND ND D10 乙酸糠酯 14.06 ND ND ND 0.17±0.03Aa ND ND ND ND D11 乙酸乙酯 2.89 ND ND ND ND 1.45±0.27Aa ND ND ND D12 亚油酸乙酯 42.42 ND ND ND ND ND 0.22±0.08Aa ND ND 酸类 E1 乙酸 3.16 ND 6.20±0.37Bb 7.70±1.88Bb 11.25±2.08Ba ND 43.33±16.75Ab 82.69±8.99Aa 62.84±15.67Aab E2 2-甲基丁酸 9.73 ND ND ND 1.56±0.54Ba ND 3.49±2.76Ab ND 8.60±2.12Aa E3 异戊酸 8.92 ND ND ND ND ND 4.45±3.68Ab 17.64±3.86Aa 15.72±1.88Aa E4 壬酸 24.88 ND ND ND ND ND ND 31.17±7.11Aa 20.24±3.42Aab E5 异丁酸 6.01 ND ND ND ND ND ND ND 1.62±0.92Aa 杂环类 F1 2-正戊基呋喃 13.96 ND ND 0.11±0.05Bb 0.27±0.05Ba ND 1.38±0.37Aab 1.73±0.34Aa 1.51±0.39Aa F2 2,3-二氢苯并呋喃 22.73 ND 0.10±0.05Aa ND ND 0.90±0.49Aa ND ND ND F3 2-乙基呋喃 4.13 ND ND 0.20±0.13Aa ND ND ND ND 3.04±1.28Aa F4 2,6-二甲基吡嗪 10.86 ND 0.35±0.03Ac 1.68±0.42Bb 2.55±0.42Ba ND ND 3.79±1.30Aa 4.24±1.54Aa F5 2,3,5-三甲基吡嗪 14.38 ND ND ND 0.17±0.02Ba ND ND ND 1.76±0.74Aa 芳香类 G1 愈创木酚 17.69 ND ND 0.11±0.01Ab 0.14±0.02Ba ND 1.50±1.32Aa ND 0.93±0.36Aab G2 对乙烯基愈疮木酚 25.89 0.37±0.08Ba 0.19±0.01Bbc 0.22±0.03Bb 0.13±0.02Bc 2.31±0.54Aa 1.35±1.07Aab 1.01±0.21Ab 0.62±0.32Ab G3 2,6-二叔丁基对甲酚 31.96 0.08±0.02Ba ND ND ND 0.39±0.07Aa ND ND ND G4 2,4-二叔丁基苯酚 32.04 ND ND ND ND 0.51±0.10Aa 0.53±0.37Aa ND ND G5 4-甲氧基苯酚 17.7 ND ND ND ND ND ND 1.85±0.12Aa ND G6 甲氧基苯肟 10.47 0.19±0.08Bb 0.11±0.02Ab 0.40±0.13Ba 0.53±0.10Ba 1.22±0.26Aa ND 2.21±0.85Aa 1.22±0.83Aa G7 1,3-二叔丁基苯 23.72 ND 0.41±0.09Bb 0.62±0.34Bb 1.02±0.09Ba 11.10±2.04Ab 23.93±9.72Aab 37.24±7.75Aa 7.84±2.15Ab G8 甲苯 5.77 ND ND ND 0.45±0.15Ba 1.17±0.16Ab 2.16±1.34Aab 4.22±0.15Aa 2.74±0.53Aab 其他类 H1 十二烷 22.03 0.17±0.03Bbc 0.12±0.02Bc 0.19±0.04Bb 0.32±0.02Ba 1.49±0.32Aa 2.69±2.26Aa 3.98±0.96Aa 2.33±1.17Aa H2 十三烷 25.56 0.35±0.09Bab 0.21±0.03Bb 0.36±0.12Bab 0.40±0.06Ba 1.87±0.46Ab 1.74±1.03Ab 4.14±1.21Aa 2.38±0.77Ab H3 十一烷 18.29 ND 0.05±0.00Bb 0.07±0.02Ba ND ND 0.96±0.91Aa 0.90±0.08Aa 1.02±0.73Aa H4 十四烷 28.88 ND ND ND 0.05±0.00Ba 0.31±0.05Ab 0.84±0.60Aab 1.41±0.52Aa 0.44±0.14Ab H5 十九烷 18.27 ND ND ND 0.26±0.02Aa ND ND ND ND H6 十五烷 31.91 ND ND ND ND ND 0.24±0.19Aa ND ND H7 3-甲基十一烷 20.93 ND ND ND ND 0.66±0.23Aa ND ND ND H8 3-甲基十三烷 27.9 ND ND ND ND ND 0.41±0.30Aa 0.71±0.24Aa ND H9 癸烷 14.36 ND ND ND ND 0.50±0.10Aab 1.57±0.54Aa ND ND H10 苯乙烯 10.04 ND ND ND ND 1.80±0.45Aa ND ND 1.43±0.71Aa H11 右旋萜二烯 15.5 ND ND ND ND 2.46±0.52Aa 1.36±0.31Aa 1.62±0.25Aa 1.03±0.26Aa 注:ND表示未检出;同行大写字母不同表示同一发酵时间不同样品的挥发性风味物质含量差异显著(P<0.05);同行小写字母不同表示同一样品不同发酵时间挥发性风味物质含量差异显著(P<0.05)。 醛类的阈值较低,通常表现出强烈的坚果味或焦糖味。图3中显示,不同发酵时间CSP组的醛类物质含量均高于SP组。由表2可知,在发酵过程中都检测出的醛类物质包括异戊醛、3-甲硫基丙醛、苯甲醛、苯乙醛和壬醛等,其中苯甲醛和苯乙醛的含量较高。整个发酵过程中,CSP组中苯甲醛含量从2.84 mg/kg提高到了15.49 mg/kg,SP组从0.63 mg/kg提高到了4.05 mg/kg,CSP组的增加量高于SP组。两种黄豆酱中的苯乙醛均呈现先降低后增加的趋势,发酵第7 d时的含量最低,发酵前后含量无明显变化。先前已有报道显示,苯甲醛和苯乙醛具有传统大酱的独特风味[28],这对黄豆酱风味的形成起到积极的作用。

醇类和酯类都被描述为具有花香,由于其低阈值而对产品的风味有显著贡献[22]。从表2中可知,在整个发酵过程中都检测到的醇类为异戊醇和1-辛烯-3-醇。其中,1-辛烯-3-醇的含量最高,且整个发酵过程中CSP组的1-辛烯-3-醇的含量明显高于SP组。有文献报道,1-辛烯-3-醇和异戊醇是构成酱油风味的关键物质[29],同时,1-辛烯-3-醇也是肉制品中的主要醇类物质[30]。异戊醇和1-辛烯-3-醇分别具有令人愉悦的蘑菇香[31]和浓郁的麦芽香[29],这说明鸡肉的添加对黄豆酱的风味具有促进作用。在酯类物质中,未发酵期,CSP组只检测到棕榈酸乙酯和乙酸乙酯,SP组中并未检测出酯类物质。随着发酵的进行,苯乙酸乙酯变化比较明显,在CSP组中呈现先增加后降低的趋势,SP组则呈上升趋势,发酵35 d(发酵后期)时两组样品中的含量均比发酵7 d(发酵前期)时有所增加。

发酵豆酱中的酸类物质是由于微生物代谢过程中氨基酸或长链脂肪酸的酶促分解而产生的[32],它的积累对豆酱的整体香气具有重要影响。CSP组中的酸类物质主要是乙酸和异戊酸,二者均随着发酵的进行呈现先增加后降低的趋势;SP组中的酸类物质主要是乙酸,其含量随着发酵的进行逐渐增加。在芳香类物质中,比较有代表性的是1,3-二叔丁基苯,其在CSP组中的含量随发酵时间的增加呈先上升后下降的趋势(发酵21 d时含量最大),在SP组中则与发酵时间成正比,且整个发酵过程中CSP组的含量高于SP组。

其他类物质中,酮类只检测出了2-甲基-3-甲氧基-4H-吡喃-4-酮,杂环类中的2,6-二甲基吡嗪在发酵过程中含量逐渐增加,对乙烯基愈疮木酚是所有阶段均检测出的唯一芳香类物质,其余物质并未有明显的变化趋势。

2.3.2 发酵过程中挥发性风味物质的差异性分析

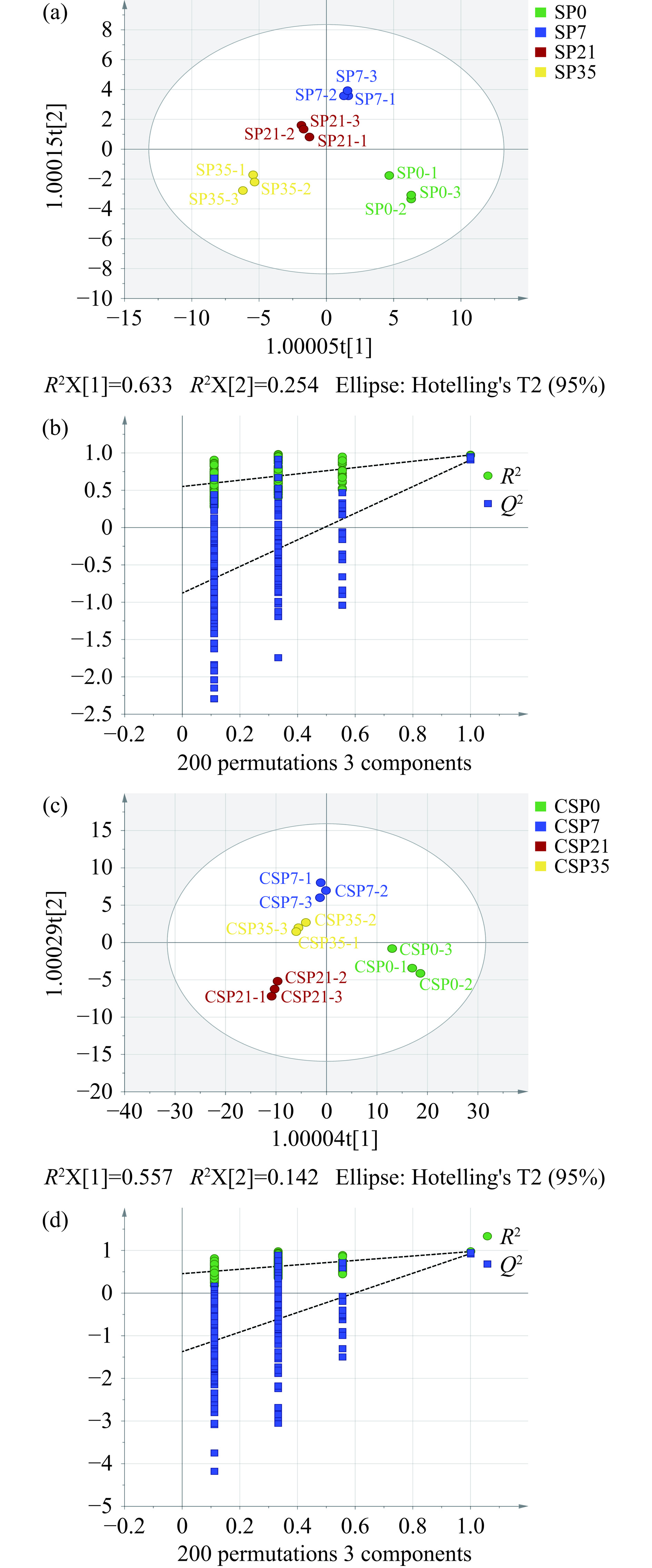

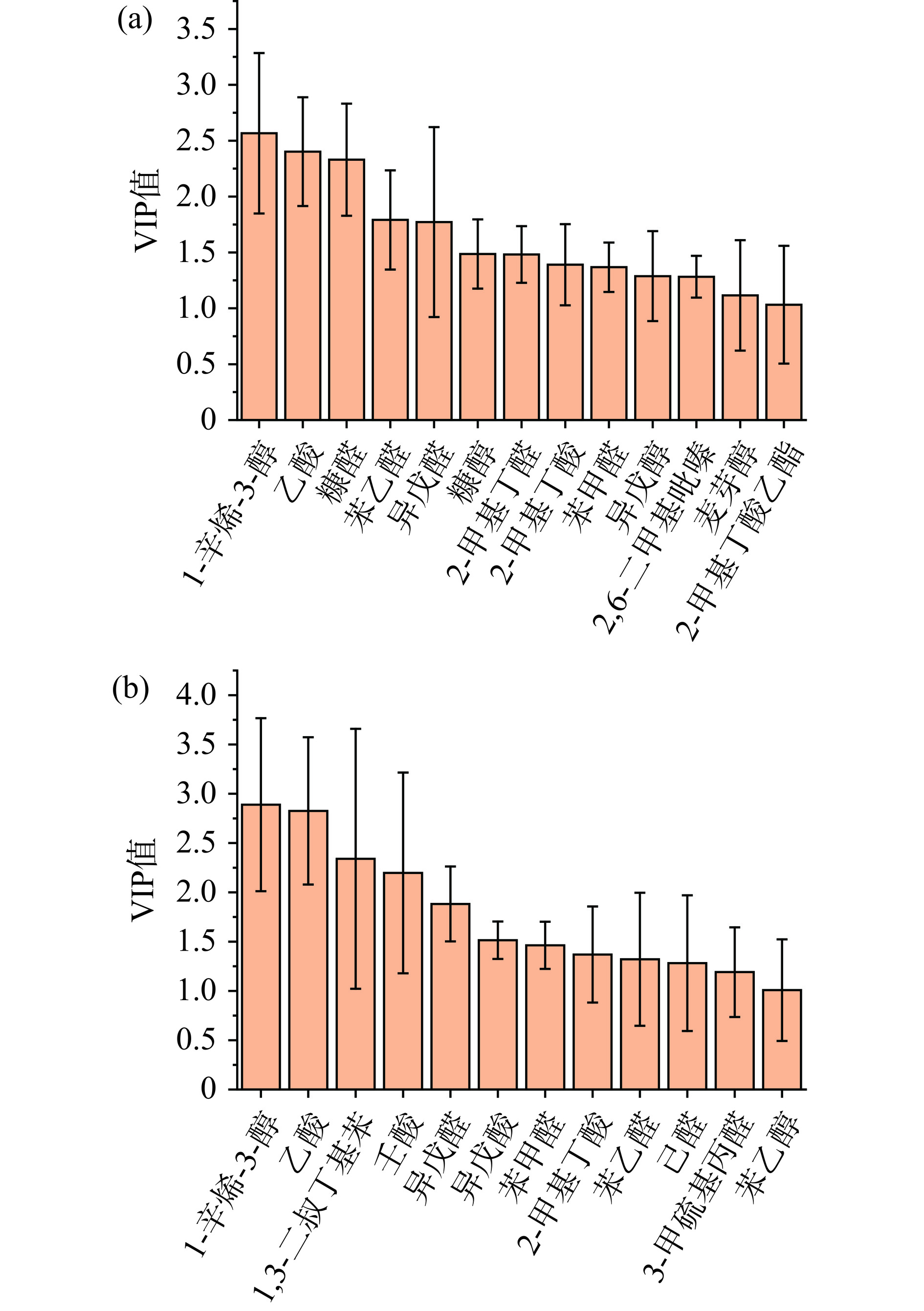

为了更好地观察鸡肉黄豆酱发酵过程中挥发性风味物质的具体差异,采用OPLS-DA模型进一步分析。OPLS-DA是有监督的判别分析方法,通过对大量数据进行降维处理,实现数据可视化及判别分析[33]。在SP的OPLS-DA模型中,自变量拟合指数(R2X)=0.977,因变量拟合指数(R2Y)=0.975,模拟预测指数(Q2)=0.885(如图4(a)所示),CSP的OPLS-DA模型中,R2X=0.981,R2Y=0.968,Q2=0.884(如图4(c)所示),均处于0.5~1之间,表明两种黄豆酱的OPLS-DA模型均具有较高的可解释度和拟合度,可以用于区分样品发酵过程中挥发性风味物质的变化[34]。通过对模型进行200次交叉置换检验,结果如图4(b)和图4(d)所示,R2均位于横轴0的上方,Q2回归线是负数,说明两个模型均稳定可靠,不存在过拟合,可直接用于样品的判别分析。基于OPLS-DA模型中的变量重要性投影(variable importance in the projection,VIP)将每个变量的贡献进行量化,使得分析组间的差异变量更加准确可靠,其中VIP值>1的挥发性风味物质可作为关键差异物质,且VIP值越大,变量差异越明显[35]。根据VIP值>1,SP中共筛选出13种关键挥发性风味物质(如图5(a)所示),而CSP中共筛选出12种关键挥发性风味物质(如图5(b)所示),其中1-辛烯-3-醇、乙酸、糠醛是SP发酵过程中差异性最大的物质,1-辛烯-3-醇、乙酸、1,3-二叔丁基苯、壬酸是CSP发酵过程中差异性最大的物质。

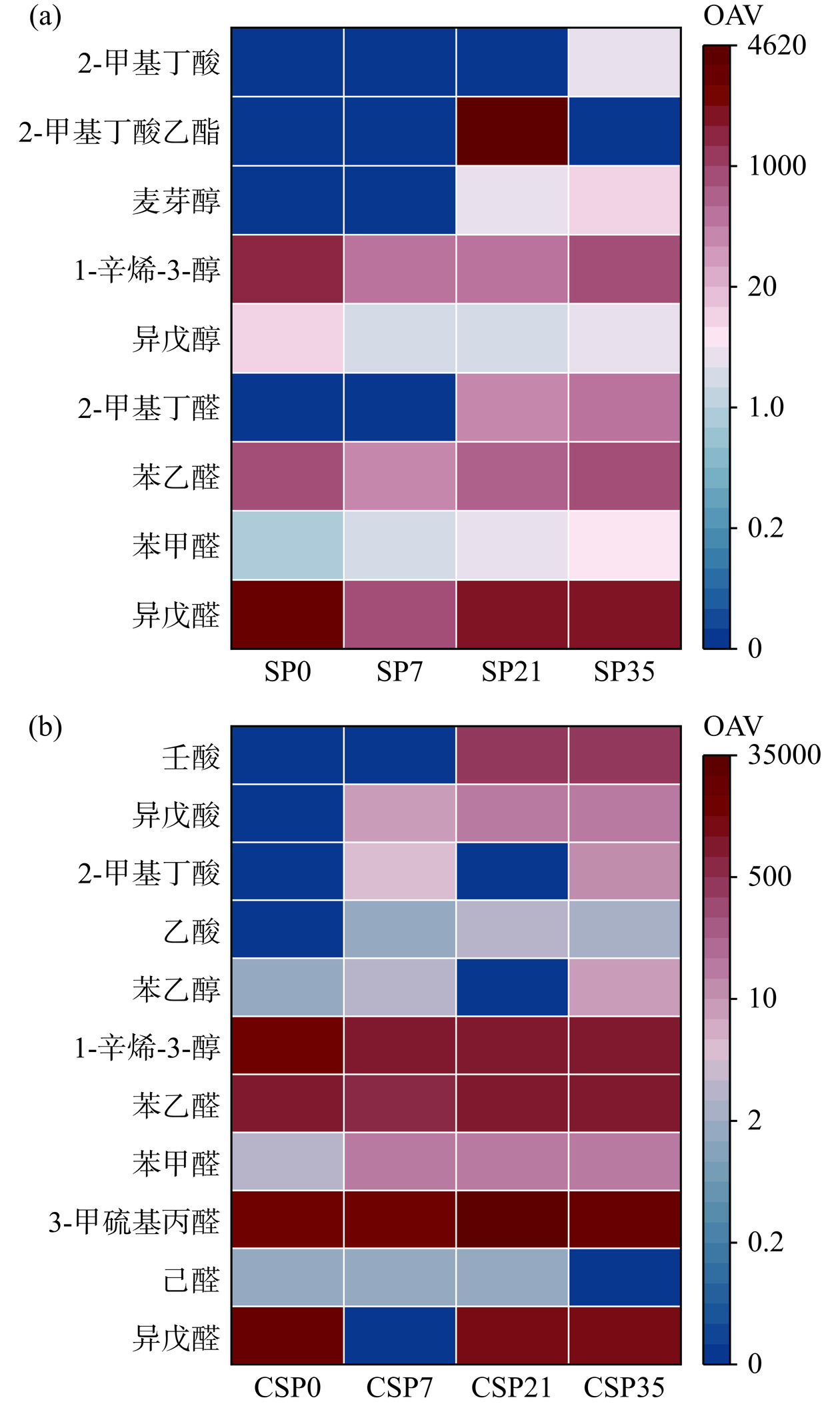

2.3.3 关键差异挥发性物质OAV分析

挥发性风味物质对黄豆酱风味的影响取决于其含量和阈值的大小[35]。OAV为化合物的浓度与该化合物阈值的比值,可用于评估单一挥发性风味物质对黄豆酱发酵过程中整体香气的贡献,OAV≥1表示该挥发性风味物质具有贡献,被认定为样品的关键香气物质[15]。故基于两种黄豆酱中VIP值>1的差异挥发性风味物质,结合其阈值进行OAV计算,确定两种黄豆酱在发酵过程中的特征风味差异。由图6(a)可知,SP发酵过程中共有9种挥发性风味物质的OAV>1,其中异戊醛、苯乙醛、异戊醇和1-辛烯-3-醇在整个发酵过程中的OAV>1,因此这4种物质可视为SP发酵过程中的关键差异挥发性风味物质,对SP的风味具有重要贡献。由图6(b)可知,CSP发酵过程中共有11种挥发性风味物质的OAV>1,其中3-甲硫基丙醛、苯甲醛、苯乙醛和1-辛烯-3-醇在整个发酵过程中的OAV>1,可被认为是CSP发酵过程中的关键差异挥发性风味物质。

与SP相比,CSP的发酵过程中新增了3-甲硫基丙醛和苯甲醛这两种关键差异挥发性风味物质,说明3-甲硫基丙醛和苯甲醛在CSP的发酵过程中变化较大,这可能与添加鸡肉后蛋白质降解程度增大,影响了游离氨基酸的组成有关。3-甲硫基丙醛有醇厚的酱香和红烧肉香味,主要来源于蛋氨酸Strecker降解反应[36]。在整个发酵过程中,CSP的3-甲硫基丙醛含量显著高于SP(P<0.05),而蛋氨酸的含量明显低于SP,这说明鸡肉黄豆酱中蛋氨酸可能更多的被转化成了3-甲硫基丙醛[36]。除此之外,整个发酵过程中,CSP的苯甲醛、苯乙醛和1-辛烯-3-醇的OAV值也显著高于SP,这可能与CSP中苯丙氨酸含量高于SP有关。Chen等[37]的研究表明,苯甲醛和苯乙醛都是由苯丙氨酸降解而产生,苯甲醛可赋予食品杏仁和焦糖味,苯乙醛则具有蜂蜜和可可香气。Shen等[38]的研究表明,1-辛烯-3-醇通常由脂肪酸的氧化形成,是鸡肉中的特征风味物质,具有令人愉悦的蘑菇状香气。在整个发酵过程中,CSP中1-辛烯-3-醇的OAV值均高于SP,说明鸡肉的添加可能也促进了脂肪酸的氧化。综上所述,鸡肉的添加可能促进了氨基酸的降解和脂肪酸的氧化,从而提高了关键差异挥发性风味物质的OAV值,使得产品的风味发生了变化。

3. 结论

以纯黄豆酱(SP组)为对照组,测定了鸡肉黄豆酱(CSP组)发酵过程中的蛋白质、氨基酸态氮含量、蛋白酶活力、游离氨基酸和挥发性风味物质的变化。结果表明,随着发酵时间的延长,鸡肉黄豆酱的氨基酸态氮和蛋白酶活力分别增加了4.21倍和3.06倍,纯黄豆酱中分别增加了2.86倍和1.96倍,蛋白质含量分别下降了12.28%和3.68%。整个发酵过程中,两种黄豆酱的游离氨基酸逐渐积累,且鸡肉黄豆酱的鲜味、甜味和总游离氨基酸含量均显著高于纯黄豆酱(P<0.05)。两种黄豆酱发酵过程中共检测出66种挥发性风味物质,其中以醛类、醇类、酸类和芳香类的含量较高,且鸡肉黄豆酱中的风味物质含量明显高于纯黄豆酱。根据OPLS-DA和OAV分析得出3-甲硫基丙醛、苯甲醛、苯乙醛和1-辛烯-3-醇是鸡肉黄豆酱发酵过程中的关键差异挥发性风味物质。综合来看,鸡胸肉的添加提高了发酵基料中的蛋白质含量和氨基酸态氮含量,促进了游离氨基酸的积累,有助于黄豆酱特征风味的形成。

-

表 1 发酵过程中游离氨基酸含量的变化

Table 1 Changes in free amino acid content during the fermentation

味感 名称 游离氨基酸含量(mg/g) SP0 SP7 SP21 SP35 CSP0 CSP7 CSP21 CSP35 鲜味 天冬氨酸(Asp) 1.02±0.01Bd 3.00±0.02Bc 4.25±0.13Bb 4.68±0.01Ba 1.26±0.01Ad 4.18±0.31Ac 5.73±0.09Ab 6.20±0.02Aa 谷氨酸(Glu) 1.85±0.02Bc 5.25±0.02Bb 6.67±0.11Ba 6.66±0.01Ba 2.26±0.03Ac 7.27±0.53Ab 8.07±0.11Aa 8.08±0.04Aa 甜味 苏氨酸*(Thr) 0.62±0.01Ad 1.08±0.01Bc 1.66±0.06Bb 1.86±0.01Ba 0.65±0.01Ac 1.46±0.11Ab 1.93±0.03Aa 2.06±0.01Aa 丝氨酸(Ser) 0.89±0.02Bd 1.44±0.01Bc 2.08±0.06Bb 2.30±0.00Ba 0.97±0.01Ac 2.16±0.16Ab 2.82±0.04Aa 2.99±0.00Aa 甘氨酸(Gly) 0.43±0.01Bd 0.98±0.01Bc 1.26±0.01Bb 1.36±0.00Ba 0.47±0.01Ac 1.32±0.10Ab 1.83±0.03Aa 1.94±0.01Aa 丙氨酸(Ala) 1.18±0.02Ad 2.46±0.02Ac 3.00±0.03Ab 3.17±0.01Aa 1.10±0.01Bc 2.40±0.18Ab 2.79±0.04Ba 2.92±0.01Ba 赖氨酸*(Lys) 1.75±0.00Ad 3.67±0.05Ac 4.33±0.03Ab 4.47±0.02Aa 1.39±0.05Bc 3.32±0.23Ab 3.67±0.07Ba 3.74±0.07Ba 脯氨酸(Pro) 0.58±0.01Bc 1.00±0.01Bb 1.08±0.18Bab 1.33±0.00Ba 0.70±0.01Ac 1.60±0.12Ab 1.96±0.03Aab 2.12±0.01Aa 苦味 缬氨酸*(Val) 0.90±0.02Ad 1.70±0.01Ac 2.21±0.03Bb 2.47±0.01Ba 0.95±0.01Ac 2.09±0.15Ab 2.48±0.03Aa 2.69±0.01Aa 蛋氨酸*(Met) 0.58±0.01Ad 0.89±0.00Ac 1.12±0.01Ab 1.19±0.00Aa 0.37±0.01Bc 0.71±0.05Bb 0.79±0.01Ba 0.82±0.01Ba 异亮氨酸*(Ile) 0.84±0.02Ad 1.61±0.00Ac 2.17±0.01Bb 2.36±0.01Ba 0.84±0.01Ac 2.01±0.14Ab 2.36±0.04Aa 2.53±0.02Aa 亮氨酸*(Leu) 1.78±0.03Ad 3.25±0.01Ac 4.11±0.11Ab 4.41±0.05Aa 1.53±0.02Bc 3.53±0.25Ab 4.02±0.06Aa 4.19±0.03Ba 酪氨酸(Tyr) 0.76±0.02Ad 0.50±0.01Bc 1.02±0.05Bb 1.17±0.01Ba 0.81±0.01Ad 1.61±0.11Ac 1.83±0.02Ab 2.06±0.06Aa 苯丙氨酸*(Phe) 0.98±0.03Ad 1.21±0.00Bc 1.71±0.01Bb 1.90±0.02Ba 1.06±0.01Ac 1.85±0.13Ab 2.14±0.04Aa 2.24±0.02Aa 组氨酸(His) 0.35±0.01Ac 0.91±0.14Ab 1.09±0.01Aab 1.19±0.00Ba 0.38±0.01Ac 0.98±0.07Ab 1.17±0.02Aa 1.20±0.02Aa 精氨酸(Arg) 1.52±0.04Ad 0.22±0.00Bc 0.61±0.00Ab 0.88±0.00Aa 1.55±0.02Aa 0.87±0.06Ab 0.14±0.00Bc 0.07±0.00Bc 无味 半胱氨酸(Cys) 0.15±0.01Aa 0.14±0.00Aa 0.15±0.01Aa 0.12±0.00Ab 0.14±0.01Ab 0.16±0.01Aa 0.11±0.00Bc 0.12±0.00Ac 鲜味氨基酸 2.87±0.04Bd 8.25±0.04Bc 10.93±0.02Bb 11.34±0.01Ba 3.52±0.05Ac 11.45±0.84Ab 13.80±0.20Aa 14.28±0.06Aa 甜味氨基酸 5.43±0.08Ad 10.63±0.11Ac 13.41±0.01Bb 14.51±0.01Ba 5.28±0.10Ac 12.26±0.90Ab 15.01±0.23Aa 15.77±0.05Aa 苦味氨基酸 7.72±0.17Ad 10.29±0.16Bc 14.03±0.23Ab 15.58±0.03Aa 7.50±0.11Ac 13.63±0.98Ab 14.94±0.22Aab 15.79±0.18Aa 必需氨基酸 7.46±0.12Ad 13.41±0.085Ac 17.31±0.27Ab 18.68±0.06Aa 6.80±0.11Bc 14.96±1.07Ab 17.40±0.28Aa 18.27±0.18Aa 总游离氨基酸 16.17±0.28Ad 29.31±0.30Bc 38.51±0.23Bb 41.54±0.04Ba 16.43±0.25Ac 37.50±2.71Ab 43.85±0.64Aa 45.96±0.21Aa 注:*表示必需氨基酸;同行大写字母不同表示同一发酵时间不同样品的游离氨基酸含量差异显著(P<0.05);同行小写字母不同表示同一样品不同发酵时间游离氨基酸含量差异显著(P<0.05)。 表 2 发酵过程中挥发性风味物质的组成与含量

Table 2 Composition and content of volatile flavor substances during the fermentation

类别 序号 名称 保留时间(min) 挥发性风味物质含量(mg/kg) SP0 SP7 SP21 SP35 CSP0 CSP7 CSP21 CSP35 醛类 A1 异戊醛 3.43 3.93±0.86Ba 0.55±0.03Ab 2.29±1.54Aa 2.62±0.41Ba 26.88±3.63Aa ND 8.10±1.11Ab 8.92±2.56Ab A2 己醛 6.78 0.98±0.83Ba 0.41±0.12Bab ND ND 5.51±1.44Aa 6.83±1.48Aa 7.61±1.05Aa ND A3 3-甲硫基丙醛 10.65 0.69±0.08Bbc 0.23±0.11Bc 0.83±0.19Bb 1.65±0.44Ba 5.66±1.01Ac 6.52±1.41Abc 15.72±2.04Aa 12.18±2.22Aab A4 苯甲醛 12.82 0.63±0.14Bd 1.36±0.11Bc 2.18±0.39Bb 4.05±0.51Ba 2.84±0.62Ab 16.21±5.37Aa 24.33±3.69Aa 15.49±3.31Aa A5 苯乙醛 16.09 4.83±0.89Ba 1.10±0.05Bc 2.80±0.39Bb 4.96±0.81Ba 16.11±3.45Aa 6.26±3.98Ab 13.41±1.60Aa 11.17±2.58Aab A6 2-苯基丙醛 18.35 0.16±0.04Ab ND ND ND ND ND ND ND A7 壬醛 18.47 0.98±0.73Ba 0.38±0.23Bab 0.19±0.12Bb 0.50±0.12Aab 1.84±0.19Aa 2.99±1.52Aa 2.00±0.30Aa 0.76±0.22Ab A8 阿托醛 20.38 0.12±0.03Aa ND ND ND ND ND ND ND A9 2-苯基巴豆醛 24.43 0.42±0.16Aa ND ND 0.39±0.05Aa 0.68±0.16Aa ND ND ND A10 糠醛 7.83 ND 1.09±0.08Bc 5.44±1.57Ab 9.14±0.87Aa ND 2.70±1.26Ab 6.72±1.41Aa 5.44±1.09Ba A11 2-甲基丁醛 3.56 ND ND 1.82±0.58Ab 3.45±0.68Aa 8.55±3.33Aa ND ND ND A12 3-甲基巴豆醛 6.29 ND ND 0.09±0.01Ab ND ND ND ND ND A13 可卡醛 31.46 ND ND ND 0.05±0.01Aa ND ND ND ND A14 正辛醛 14.5 ND ND ND ND ND 0.59±0.15Ab 1.22±0.05Aa ND A15 十六烷醛 37.96 ND ND ND ND ND 3.13±1.90Aa ND ND A16 月桂醛 29.17 ND ND ND ND ND ND ND 0.35±0.15Aa A17 肉豆蔻醛 37.97 ND ND ND ND ND ND 0.63±0.20Aa ND 酮类 B1 2-甲基-3-甲氧基-4H-吡喃-4-酮 21.47 0.23±0.10Bb 0.11±0.02Bb 0.22±0.09Bb 0.47±0.17Aa 1.23±0.72Aa 0.96±0.41Aab 1.47±0.85Aa ND 醇类 C1 异戊醇 4.95 2.90±0.60Ba 0.49±0.03Bb 0.50±0.15Bb 0.65±0.12Bb 5.49±0.88Aa 2.22±0.91Ab 3.14±0.84Ab 2.58±0.49Ab C2 2,3-丁二醇 6.28 0.97±0.35Ba ND ND ND 4.30±1.16Aa 1.07±0.19Ab ND ND C3 1-辛烯-3-醇 13.63 11.04±2.08Ba 1.56±0.11Bb 1.77±0.35Bb 3.08±0.46Bb 74.39±14.45Aa 6.8±5.03Ab 10.10±2.09Ab 7.19±1.44Ab C4 苯乙醇 18.75 0.48±0.13Ab 0.20±0.01Bc 0.48±0.03Ab 1.05±0.21Ba 1.00±0.35Abc 2.21±1.39Ab ND 4.84±1.66Aa C5 2-甲基-1-丁醇 5.04 ND 0.28±0.03Aa 0.27±0.14Aa 0.35±0.05Aa ND ND ND ND C6 糠醇 8.66 ND ND 1.42±0.66Ab 3.70±0.59Aa ND ND ND ND C7 麦芽醇 18.56 ND ND 0.45±0.21Bb 1.73±0.59Aa ND ND 3.91±2.88Aa 2.37±1.29Aab 酯类 D1 正己酸乙酯 14.32 ND 0.11±0.02Ab ND 0.16±0.03Aa ND ND ND ND D2 苯甲酸乙酯 20.93 ND 0.19±0.04Ab 0.30±0.03Bb 0.51±0.19Ba ND ND 2.64±0.76Aa 1.31±0.52Ab D3 苯乙酸乙酯 23.52 ND 0.10±0.01Ac 0.22±0.03Bb 0.28±0.04Aa ND 0.46±0.37Aa 0.88±0.15Aa 0.66±0.19Aa D4 棕榈酸乙酯 40.36 ND ND 0.25±0.06Ba 0.32±0.07Ba 0.44±0.19Ab 1.59±0.79Aa 1.18±0.05Aab 0.95±0.50Aab D5 辛酸乙酯 21.87 ND ND ND 0.07±0.01Ba ND 0.37±0.27Aa 0.50±0.08Aa 0.30±0.07Aa D6 油酸乙酯 42.5 ND ND 0.10±0.04Aa 0.12±0.03Aa ND 0.61±0.23Aa ND ND D7 异丁酸乙酯 5.54 ND ND 0.12±0.03Aa ND ND ND ND 0.86±0.19Aa D8 2-甲基丁酸乙酯 8.48 ND ND 0.29±0.17Aa ND ND ND ND ND D9 乙酸异戊酯 9.51 ND ND 0.16±0.05Aa ND ND ND ND ND D10 乙酸糠酯 14.06 ND ND ND 0.17±0.03Aa ND ND ND ND D11 乙酸乙酯 2.89 ND ND ND ND 1.45±0.27Aa ND ND ND D12 亚油酸乙酯 42.42 ND ND ND ND ND 0.22±0.08Aa ND ND 酸类 E1 乙酸 3.16 ND 6.20±0.37Bb 7.70±1.88Bb 11.25±2.08Ba ND 43.33±16.75Ab 82.69±8.99Aa 62.84±15.67Aab E2 2-甲基丁酸 9.73 ND ND ND 1.56±0.54Ba ND 3.49±2.76Ab ND 8.60±2.12Aa E3 异戊酸 8.92 ND ND ND ND ND 4.45±3.68Ab 17.64±3.86Aa 15.72±1.88Aa E4 壬酸 24.88 ND ND ND ND ND ND 31.17±7.11Aa 20.24±3.42Aab E5 异丁酸 6.01 ND ND ND ND ND ND ND 1.62±0.92Aa 杂环类 F1 2-正戊基呋喃 13.96 ND ND 0.11±0.05Bb 0.27±0.05Ba ND 1.38±0.37Aab 1.73±0.34Aa 1.51±0.39Aa F2 2,3-二氢苯并呋喃 22.73 ND 0.10±0.05Aa ND ND 0.90±0.49Aa ND ND ND F3 2-乙基呋喃 4.13 ND ND 0.20±0.13Aa ND ND ND ND 3.04±1.28Aa F4 2,6-二甲基吡嗪 10.86 ND 0.35±0.03Ac 1.68±0.42Bb 2.55±0.42Ba ND ND 3.79±1.30Aa 4.24±1.54Aa F5 2,3,5-三甲基吡嗪 14.38 ND ND ND 0.17±0.02Ba ND ND ND 1.76±0.74Aa 芳香类 G1 愈创木酚 17.69 ND ND 0.11±0.01Ab 0.14±0.02Ba ND 1.50±1.32Aa ND 0.93±0.36Aab G2 对乙烯基愈疮木酚 25.89 0.37±0.08Ba 0.19±0.01Bbc 0.22±0.03Bb 0.13±0.02Bc 2.31±0.54Aa 1.35±1.07Aab 1.01±0.21Ab 0.62±0.32Ab G3 2,6-二叔丁基对甲酚 31.96 0.08±0.02Ba ND ND ND 0.39±0.07Aa ND ND ND G4 2,4-二叔丁基苯酚 32.04 ND ND ND ND 0.51±0.10Aa 0.53±0.37Aa ND ND G5 4-甲氧基苯酚 17.7 ND ND ND ND ND ND 1.85±0.12Aa ND G6 甲氧基苯肟 10.47 0.19±0.08Bb 0.11±0.02Ab 0.40±0.13Ba 0.53±0.10Ba 1.22±0.26Aa ND 2.21±0.85Aa 1.22±0.83Aa G7 1,3-二叔丁基苯 23.72 ND 0.41±0.09Bb 0.62±0.34Bb 1.02±0.09Ba 11.10±2.04Ab 23.93±9.72Aab 37.24±7.75Aa 7.84±2.15Ab G8 甲苯 5.77 ND ND ND 0.45±0.15Ba 1.17±0.16Ab 2.16±1.34Aab 4.22±0.15Aa 2.74±0.53Aab 其他类 H1 十二烷 22.03 0.17±0.03Bbc 0.12±0.02Bc 0.19±0.04Bb 0.32±0.02Ba 1.49±0.32Aa 2.69±2.26Aa 3.98±0.96Aa 2.33±1.17Aa H2 十三烷 25.56 0.35±0.09Bab 0.21±0.03Bb 0.36±0.12Bab 0.40±0.06Ba 1.87±0.46Ab 1.74±1.03Ab 4.14±1.21Aa 2.38±0.77Ab H3 十一烷 18.29 ND 0.05±0.00Bb 0.07±0.02Ba ND ND 0.96±0.91Aa 0.90±0.08Aa 1.02±0.73Aa H4 十四烷 28.88 ND ND ND 0.05±0.00Ba 0.31±0.05Ab 0.84±0.60Aab 1.41±0.52Aa 0.44±0.14Ab H5 十九烷 18.27 ND ND ND 0.26±0.02Aa ND ND ND ND H6 十五烷 31.91 ND ND ND ND ND 0.24±0.19Aa ND ND H7 3-甲基十一烷 20.93 ND ND ND ND 0.66±0.23Aa ND ND ND H8 3-甲基十三烷 27.9 ND ND ND ND ND 0.41±0.30Aa 0.71±0.24Aa ND H9 癸烷 14.36 ND ND ND ND 0.50±0.10Aab 1.57±0.54Aa ND ND H10 苯乙烯 10.04 ND ND ND ND 1.80±0.45Aa ND ND 1.43±0.71Aa H11 右旋萜二烯 15.5 ND ND ND ND 2.46±0.52Aa 1.36±0.31Aa 1.62±0.25Aa 1.03±0.26Aa 注:ND表示未检出;同行大写字母不同表示同一发酵时间不同样品的挥发性风味物质含量差异显著(P<0.05);同行小写字母不同表示同一样品不同发酵时间挥发性风味物质含量差异显著(P<0.05)。 -

[1] 贺羽, 王帅, 冯小刚, 等. 蟹味黄豆酱的研制及其理化分析[J]. 中国调味品,2018,43(10):52−57. [HE Y, WANG S, FENG X G, et al. Development and physicochemical analysis of crab flavored soybean paste[J]. China Condiment,2018,43(10):52−57.] doi: 10.3969/j.issn.1000-9973.2018.10.011 HE Y, WANG S, FENG X G, et al. Development and physicochemical analysis of crab flavored soybean paste[J]. China Condiment, 2018, 43(10): 52−57. doi: 10.3969/j.issn.1000-9973.2018.10.011

[2] 彭铭烨, 周梦舟, 付彩霞, 等. 响应面法优化柑橘黄豆酱的制曲工艺[J]. 中国调味品,2017,42(7):6−10. [PENG M Y, ZHOU M Z, FU C X, et al. Optimization of koji-making process of citrus soybean paste by response surface methodology[J]. China Condiment,2017,42(7):6−10.] doi: 10.3969/j.issn.1000-9973.2017.07.002 PENG M Y, ZHOU M Z, FU C X, et al. Optimization of koji-making process of citrus soybean paste by response surface methodology[J]. China Condiment, 2017, 42(7): 6−10. doi: 10.3969/j.issn.1000-9973.2017.07.002

[3] 肖泽源. 发酵型牛肉黄豆酱的研制[D]. 长沙:中南林业科技大学, 2023. [XIAO Z Y. Preparation of fermented beef soybean paste[D]. Changsha:Central South University of Forestry and Technology, 2023.] XIAO Z Y. Preparation of fermented beef soybean paste[D]. Changsha: Central South University of Forestry and Technology, 2023.

[4] 于小航. 鳀鱼调味品及抗氧化肽的研究与制备[D]. 青岛:中国海洋大学, 2014. [YU X H. The study and production of anchovy condiments and antioxidant peptides[D]. Qingdao:Ocean University of China, 2014.] YU X H. The study and production of anchovy condiments and antioxidant peptides[D]. Qingdao: Ocean University of China, 2014.

[5] ZHAO G Z, LIU C, HADIATULLAH H, et al. Effect of Hericium erinaceus on bacterial diversity and volatile flavor changes of soy sauce[J]. Food Science and Technology,2020,139:110543.

[6] 卢慧芳, 上官玲玲, 夏会丽, 等. 发酵玉米粉酶解液制备天然鲜味料[J]. 食品工业科技,2022,43(17):158−166. [LU H F, SHANGGUAN L L, XIA H L, et al. Enzymolysis of fermented corn meal to prepare natural umami flavoring[J]. Science and Technology of Food Industry,2022,43(17):158−166.] LU H F, SHANGGUAN L L, XIA H L, et al. Enzymolysis of fermented corn meal to prepare natural umami flavoring[J]. Science and Technology of Food Industry, 2022, 43(17): 158−166.

[7] XIAO L Q, LAPU M L Z, KANG S, et al. Effects of tartary buckwheat on physicochemical properties and microbial community of low salt natural fermented soybean paste[J]. Food Control,2022,138:108953. doi: 10.1016/j.foodcont.2022.108953

[8] 郭丽平. 贻贝酱加工工艺及其品质和风味变化研究[D]. 杭州:浙江工商大学, 2022. [GUO L P. Study on processing technology, quality and flavor of mussel sauce[D]. Hangzhou:Zhejiang Gongshang University, 2022.] GUO L P. Study on processing technology, quality and flavor of mussel sauce[D]. Hangzhou: Zhejiang Gongshang University, 2022.

[9] 朱秀清, 张宾洋, 孙冰玉, 等. 大豆蛋白素肉风味影响研究进展[J]. 食品科学,2023,44(5):18−28. [ZHU X Q, ZHANG B Y, SUN B Y, et al. Research progress on flavor formation in soy protein-based meat analogs[J]. Food Science,2023,44(5):18−28.] doi: 10.7506/spkx1002-6630-20220623-247 ZHU X Q, ZHANG B Y, SUN B Y, et al. Research progress on flavor formation in soy protein-based meat analogs[J]. Food Science, 2023, 44(5): 18−28. doi: 10.7506/spkx1002-6630-20220623-247

[10] 周磊. 不同品种畜禽肉品质参数的比较研究[D]. 乌鲁木齐:新疆农业大学, 2007. [ZHOU L. The comparison study of meat quality parameter on differents domastic livestock and poultry breeds[D]. Urumqi:Xinjiang Agricultural University, 2007.] ZHOU L. The comparison study of meat quality parameter on differents domastic livestock and poultry breeds[D]. Urumqi: Xinjiang Agricultural University, 2007.

[11] 武俊瑞, 顾采东, 田甜, 等. 豆酱自然发酵过程中蛋白质和氨基酸的变化规律[J]. 食品科学,2017,38(8):139−144. [WU J R, GU C D, TIAN T, et al. Evaluation of changes in protein and amino acids in naturally fermented soybean pastes with different fermentation periods[J]. Food Science,2017,38(8):139−144.] doi: 10.7506/spkx1002-6630-201708022 WU J R, GU C D, TIAN T, et al. Evaluation of changes in protein and amino acids in naturally fermented soybean pastes with different fermentation periods[J]. Food Science, 2017, 38(8): 139−144. doi: 10.7506/spkx1002-6630-201708022

[12] GAO R C, LIU H J, LI Y, et al. Correlation between dominant bacterial community and non-volatile organic compounds during the fermentation of shrimp sauces[J]. Food Science and Human Wellness,2023,12(1):233−241. doi: 10.1016/j.fshw.2022.07.002

[13] LI X, WANG Y, SUN Y Q, et al. Nutritional evaluation, flavor characteristics and microbial community of shrimp paste made from different materials and variance analysis[J]. Food Chemistry Advances,2023,2:100268. doi: 10.1016/j.focha.2023.100268

[14] ZHAO C C, TIAN Z Y, YI J J, et al. Characterization and correlation of bacterial community and volatile flavor compounds in Xiguajiang, a Chinese traditional fermented condiment[J]. Food Research International,2022,162:111904. doi: 10.1016/j.foodres.2022.111904

[15] WANG Y Q, LI C S, ZHAO Y Q, et al. Novel insight into the formation mechanism of volatile flavor in Chinese fish sauce (Yu-lu) based on molecular sensory and metagenomics analyses[J]. Food Chemistry,2020,323:126839. doi: 10.1016/j.foodchem.2020.126839

[16] YANG Y, NIU C T, SHAN W X, et al. Physicochemical, flavor and microbial dynamic changes during low-salt Doubanjiang (broad bean paste) fermentation[J]. Food Chemistry,2021,351:128454. doi: 10.1016/j.foodchem.2020.128454

[17] 刘丹, 葛予宁, 徐晗, 等. 混菌制曲和酱渣添加对黄豆酱理化指标动态变化的影响[J]. 中国酿造,2020,39(7):125−130. [LIU D, GE Y N, XU H, et al. Effects of mixed starter-making and sauce residue addition on the dynamic changes of physical and chemical indexes of soybean paste[J]. Brewing in China,2020,39(7):125−130.] doi: 10.11882/j.issn.0254-5071.2020.07.025 LIU D, GE Y N, XU H, et al. Effects of mixed starter-making and sauce residue addition on the dynamic changes of physical and chemical indexes of soybean paste[J]. Brewing in China, 2020, 39(7): 125−130. doi: 10.11882/j.issn.0254-5071.2020.07.025

[18] 周旭, 曾涛, 王洪伟, 等. 不同制曲工艺对速成永川豆豉后发酵过程和产品品质的影响[J]. 微生物学报,2023,63(6):2385−2400. [ZHOU X, ZENG T, WANG H W, et al. Effect of different koji-making processes on the post-fermentation process and product quality of rapid Yongchuan Douchi[J]. Acta Microbiologica Sinica,2023,63(6):2385−2400.] ZHOU X, ZENG T, WANG H W, et al. Effect of different koji-making processes on the post-fermentation process and product quality of rapid Yongchuan Douchi[J]. Acta Microbiologica Sinica, 2023, 63(6): 2385−2400.

[19] 于松峰. 传统豆瓣辣椒酱发酵过程细菌群落演替及其与风味物质变化的对应分析[D]. 天津:天津科技大学, 2017. [YU S F. The analysis of bacterial community succession and the correspondence of flavor compounds change during the fermentation process of traditional broad bean paste with chili[D]. Tianjin:Tianjin University of Science and Technology, 2017.] YU S F. The analysis of bacterial community succession and the correspondence of flavor compounds change during the fermentation process of traditional broad bean paste with chili[D]. Tianjin: Tianjin University of Science and Technology, 2017.

[20] LIU P, XIANG Q, SUN W J, et al. Correlation between microbial communities and key flavors during post-fermentation of Pixian broad bean paste[J]. Food Research International,2020,137:109513. doi: 10.1016/j.foodres.2020.109513

[21] TIAN Z Y, AMEER K, SHI Y L, et al. Characterization of physicochemical properties, microbial diversity and volatile compounds of traditional fermented soybean paste in Henan Province of China[J]. Food Bioscience,2022,50:102045. doi: 10.1016/j.fbio.2022.102045

[22] LIU P, XIANG Q, CHEN G, et al. Consumer preference of Chinese traditional fermented fava pastes[J]. International Journal of Food Properties,2018,21(1):2469−2490. doi: 10.1080/10942912.2018.1528271

[23] 覃芳丽, 邹宇晓, 王思远, 等. 发酵食品的滋味特性及其形成机制研究进展[J]. 食品与发酵工业,2024,50(10):388−396. [QIN F L, ZOU Y X, WANG S Y, et al. Taste characteristics and related formation mechanism during food[J]. Food and Fermentation Industries,2024,50(10):388−396.] QIN F L, ZOU Y X, WANG S Y, et al. Taste characteristics and related formation mechanism during food[J]. Food and Fermentation Industries, 2024, 50(10): 388−396.

[24] 杨心怡, 赵那娜, 刘荔, 等. 贻贝(Mytilus edulis)酶解液酵母发酵法脱腥工艺探究及其风味变化分析[J]. 食品工业科技,2023,44(12):319−327. [YANG X Y, ZHAO N N, LIU L, et al. Optimization of deodorization and analysis of flavor change of blue mussel (Mytilus edulis) hydrolysate by yeast fermentation[J]. Science and Technology of Food Industry,2023,44(12):319−327.] YANG X Y, ZHAO N N, LIU L, et al. Optimization of deodorization and analysis of flavor change of blue mussel (Mytilus edulis) hydrolysate by yeast fermentation[J]. Science and Technology of Food Industry, 2023, 44(12): 319−327.

[25] LU Y H, CHI Y L, LÜ Y P, et al. Evolution of the volatile flavor compounds of Chinese horse bean-chili-paste[J]. Food Science and Technology,2019,102:131−135.

[26] 孔维洲, 卜宁霞, 马浩然, 等. 不同发酵剂及其组合对发酵鸡肉干品质的影响[J]. 江苏农业学报,2019,35(2):453−460. [KONG W Z, BU N X, MA H R, et al. Effect of different starter cultures and their combinations on the quality of fermented chicken meat[J]. Jiangsu Journal of Agricultural Sciences,2019,35(2):453−460.] doi: 10.3969/j.issn.1000-4440.2019.02.028 KONG W Z, BU N X, MA H R, et al. Effect of different starter cultures and their combinations on the quality of fermented chicken meat[J]. Jiangsu Journal of Agricultural Sciences, 2019, 35(2): 453−460. doi: 10.3969/j.issn.1000-4440.2019.02.028

[27] 高芳, 包亚莉, 华晓青, 等. 乳酸菌对发酵肉制品抑菌作用及风味特征的影响研究进展[J]. 食品科学,2023,44(9):194−201. [GAO F, BAO Y L, HUA X Q, et al. Lactic acid bacteria:A review of their inhibitory effect on harmful microbes and effect on flavor characteristics of fermented meat products[J]. Food Science,2023,44(9):194−201.] doi: 10.7506/spkx1002-6630-20220411-116 GAO F, BAO Y L, HUA X Q, et al. Lactic acid bacteria: A review of their inhibitory effect on harmful microbes and effect on flavor characteristics of fermented meat products[J]. Food Science, 2023, 44(9): 194−201. doi: 10.7506/spkx1002-6630-20220411-116

[28] 贾云, 钮成拓, 郑飞云, 等. 传统豆瓣酱微生物群落发酵演替规律及其功能分析[J]. 微生物学报,2021,61(9):2749−2764. [JIA Y, NIU C T, ZHENG F Y, et al. Succession and function analysis of microbial community during traditional broad bean paste fermentation[J]. Acta Microbiologica Sinica,2021,61(9):2749−2764.] JIA Y, NIU C T, ZHENG F Y, et al. Succession and function analysis of microbial community during traditional broad bean paste fermentation[J]. Acta Microbiologica Sinica, 2021, 61(9): 2749−2764.

[29] 丁婷婷, 赵悦, 张梦丽, 等. 不同盐度对酱油发酵中酵母自溶及酱油风味的影响[J]. 中国调味品,2023,48(7):14−19. [DING T T, ZHAO Y, ZHANG M L, et al. Effect of different salinity on yeast autolysis and soy sauce flavor in soy sauce fermentation[J]. China Condiment,2023,48(7):14−19.] doi: 10.3969/j.issn.1000-9973.2023.07.003 DING T T, ZHAO Y, ZHANG M L, et al. Effect of different salinity on yeast autolysis and soy sauce flavor in soy sauce fermentation[J]. China Condiment, 2023, 48(7): 14−19. doi: 10.3969/j.issn.1000-9973.2023.07.003

[30] THAIS C M, JOSE M L, ERICK S, et al. Relationship between volatile organic compounds, free amino acids, and sensory profile of smoked bacon[J]. Meat Science,2021,181:108596. doi: 10.1016/j.meatsci.2021.108596

[31] XIE C Z, ZENG H Y, WANG C X, et al. Volatile flavour components, microbiota and their correlations in different sufu, a Chinese fermented soybean food[J]. Journal of Applied Microbiology,2018,125(6):1761−1773. doi: 10.1111/jam.14078

[32] GAO X L, FENG T, SHENG M J, et al. Characterization of the aroma-active compounds in black soybean sauce, a distinctive soy sauce[J]. Food Chemistry,2021,364:130334. doi: 10.1016/j.foodchem.2021.130334

[33] 李想, 邓静, 易宇文, 等. 电子舌和气相色谱-离子迁移谱技术分析炖煮时间对松茸鸡汤风味的影响[J]. 中国食品学报,2024,24(1):336−348. [LI X, DENG J, YI Y W, et al. Analysis of the effect of stewed time on the flavor of fresh matsutake chicken soup using electronic tongue and gas chromatography-ion mobility spectrometry techniques[J]. Journal of Chinese Institute of Food Science and Technology,2024,24(1):336−348.] LI X, DENG J, YI Y W, et al. Analysis of the effect of stewed time on the flavor of fresh matsutake chicken soup using electronic tongue and gas chromatography-ion mobility spectrometry techniques[J]. Journal of Chinese Institute of Food Science and Technology, 2024, 24(1): 336−348.

[34] 徐永霞, 白旭婷, 冯媛, 等. 基于GC-IMS和化学计量学分析海鲈鱼肉蒸制过程中风味物质的变化[J]. 食品科学,2021,42(22):270−275. [XU Y X, BAI X T, FENG Y, et al. Changes of flavor compounds in sea bass during steaming process as analyzed by gas chromatography-ion mobility spectroscopy and chemometrics[J]. Food Science,2021,42(22):270−275.] doi: 10.7506/spkx1002-6630-20201219-221 XU Y X, BAI X T, FENG Y, et al. Changes of flavor compounds in sea bass during steaming process as analyzed by gas chromatography-ion mobility spectroscopy and chemometrics[J]. Food Science, 2021, 42(22): 270−275. doi: 10.7506/spkx1002-6630-20201219-221

[35] 平洪睿, 王亚萍, 陈佳妮, 等. 贵州苗族、水族红酸汤滋味与香气差异分析[J]. 食品工业科技科学,2024,45(8):273−283. [PING H R, WANG Y P, CHEN J N, et al. Analysis of taste and aroma differences between Miao and Shui ethnic red sour soup in Guizhou[J]. Science and Technology of Food Industry,2024,45(8):273−283.] PING H R, WANG Y P, CHEN J N, et al. Analysis of taste and aroma differences between Miao and Shui ethnic red sour soup in Guizhou[J]. Science and Technology of Food Industry, 2024, 45(8): 273−283.

[36] 王嘉楠, 刘洋, 李凯旋, 等. 炸鸡翅营养组分变化及关键香气成分分析[J]. 食品科学技术学报,2024,42(2):142−155. [WANG J N, LIU Y, LI K X, et al. Analysis of changes in nutritional compositions and key aroma compounds in fried chicken wings[J]. Journal of Food Science and Technology,2024,42(2):142−155.] WANG J N, LIU Y, LI K X, et al. Analysis of changes in nutritional compositions and key aroma compounds in fried chicken wings[J]. Journal of Food Science and Technology, 2024, 42(2): 142−155.

[37] CHEN T Y, SU W, MU Y C, et al. Study on the quality formation mechanism of Zao chili with enhanced fermentation by Lactipllantbacillus plantarum 5-1[J]. Food Chemistry,2023,17:100626.

[38] SHEN D Y, LI M K, ZHAO M, et al. Characterization of key odor-active compounds in pure chicken powder and the effect of yeast extract, using instrumental and sensory techniques[J]. Journal of Food Composition and Analysis,2023,115:104879. doi: 10.1016/j.jfca.2022.104879

-

期刊类型引用(6)

1. 焦艳娜,彭梦香,梁香,毛宪,肖中宁,曾亮,刘仲华. 茶叶中吡咯里西啶生物碱残留量检测方法及研究现状. 中国茶叶. 2024(03): 12-20 .  百度学术

百度学术

2. 佟晓波,刘广福,周政秀. 吡咯里西啶类生物碱的提取与定量分析研究. 粮食与油脂. 2024(04): 158-162 .  百度学术

百度学术

3. 张新娜,马丽艳. QuEChERS结合高效液相色谱-串联质谱法检测甘草中吡咯里西啶生物碱与风险分析. 食品安全质量检测学报. 2024(08): 314-321 .  百度学术

百度学术

4. 章豪,杨挺,吴银良,朱勇. 固相萃取-超高效液相色谱-串联质谱法测定菊花中15种吡咯里西啶生物碱毒素. 食品安全质量检测学报. 2024(21): 41-49 .  百度学术

百度学术

5. 陈言凯. 固相萃取结合超高效液相色谱-串联质谱法快速测定乳粉及液体乳中26种吡咯里西啶生物碱的含量. 食品科学. 2024(24): 266-272 .  百度学术

百度学术

6. 杨方,刘少明. 基于RASFF通报分析技术性贸易措施对商品茶出口贸易的影响. 食品安全质量检测学报. 2024(23): 192-199 .  百度学术

百度学术

其他类型引用(1)

下载:

下载:

下载:

下载: