Research and Application of Smoke Flavorings in Aquatic Products Processing

-

摘要: 传统烟熏工艺是水产品常见的加工方式,但产品中多环芳烃残留问题难以解决。烟熏香料由生物质热解反应产物分离纯化制得。采用烟熏香料的液熏工艺,不仅赋予了水产品同样的烟熏风味和色泽,还有效降低了熏制品中多环芳烃的残留,同时具有工艺周期短,环境友好等优势,是传统烟熏工艺的理想替代方案。本文综述了烟熏香料的制备工艺,分析了其主要化学成分及功能活性。羰基化合物、有机酸和酚类化合物构成了烟熏香料的主要成分,赋予了其呈味、着色、抗菌及抗氧化等功能活性。总结了烟熏香料在水产品加工中的应用现状,介绍了其对水产品感官特性和贮藏品质的影响,并探讨了烟熏香料的安全性和使用管理,以期为烟熏香料在水产品加工中的应用提供参考。Abstract: The traditional smoking process is a common method of processing aquatic products, but the issue of residual polycyclic aromatic hydrocarbons (PAHs) is difficult to solve. Smoke flavorings, also known as liquid smoke, are prepared by separating and purifying the products of biomass pyrolysis reactions. The liquid smoking process using smoke flavorings not only gives the same smoked flavor and color to aquatic products, but also effectively reduces the residue of PAHs in smoked products. Besides, it has the advantages of a short process cycle and environmental friendliness, which is an ideal alternative to the traditional smoking process. This paper reviews the preparation process of smoke flavorings and analyzes their main chemical components and functional activities. Carbonyl compounds, organic acids and phenolic compounds constitute the main components of smoke flavorings, which give them functional activities such as flavor, color, antibacterial and antioxidant. The current status of the application of smoke flavorings in aquatic products processing is summarized, and their effects on the organoleptic properties and storage quality of aquatic products are introduced. The safety and use management of smoke flavorings are also discussed, with a view to providing references for the application of smoke flavorings in aquatic products processing.

-

Keywords:

- smoke flavorings /

- aquatic products /

- polycyclic aromatic hydrocarbons /

- antimicrobial /

- antioxidant

-

传统烟熏是最古老的食物保存方法之一,至今仍广泛应用于水产品、肉制品奶酪及等食品的加工与贮藏。如烟熏三文鱼(Salmo salar)在欧洲年产量约16万吨,占养殖三文鱼总量的28%[1]。天然木材熏烟是木材在缺氧或有限供氧条件下阴燃产生的蒸汽、固体颗粒及液滴的混合物,具有抗氧化和抗菌活性,有利于保持食品品质,还可赋予食品特殊的色泽和风味[2]。然而,木材熏烟不仅造成环境污染,不完全燃烧和热解木材还能生产多环芳烃(Polycyclic aromatic hydrocarbons,PAHs)和其它致癌物[3]。PAHs及其衍生物高达200多种,其中致癌性强且污染最广的是3,4-苯并芘[4](3,4-Benzo(a)pyrene,BaP)。我国食品安全国家标准GB 2762-2022规定加工污染物BaP在熏制肉类和水产品中的限量水平为5 μg/kg[5],欧盟标准为2 μg/kg[6]。因此,控制食品加工过程中PAHs的形成尤为重要,这给食品烟熏加工带来了挑战。

烟熏香料(Smoke flavouring,SF),也称为烟熏调味料或烟熏液,是生物质在无氧或缺氧条件下热解(或干馏)而产生的,然后进行冷凝,通过相分离去除灰分和焦油,仅留下酚类、有机酸和羰基化合物等对色泽和风味所必需的物质[7]。相比于传统烟熏方法,液熏技术将烟熏香料浸渍、喷洒或注射至加工食品中,不仅赋予了产品同样的烟熏风味和色泽,还有效降低了多环芳烃的残留,同时具有工艺周期短,环境友好等优势[8],目前在食品加工中得到了广泛的应用,逐渐取代了传统的烟熏方法。本文就烟熏香料在水产品加工中的研究与应用作一综述,旨在为水产品液熏加工提供参考。

1. 烟熏香料的制备及化学组分

1.1 烟熏香料的制备

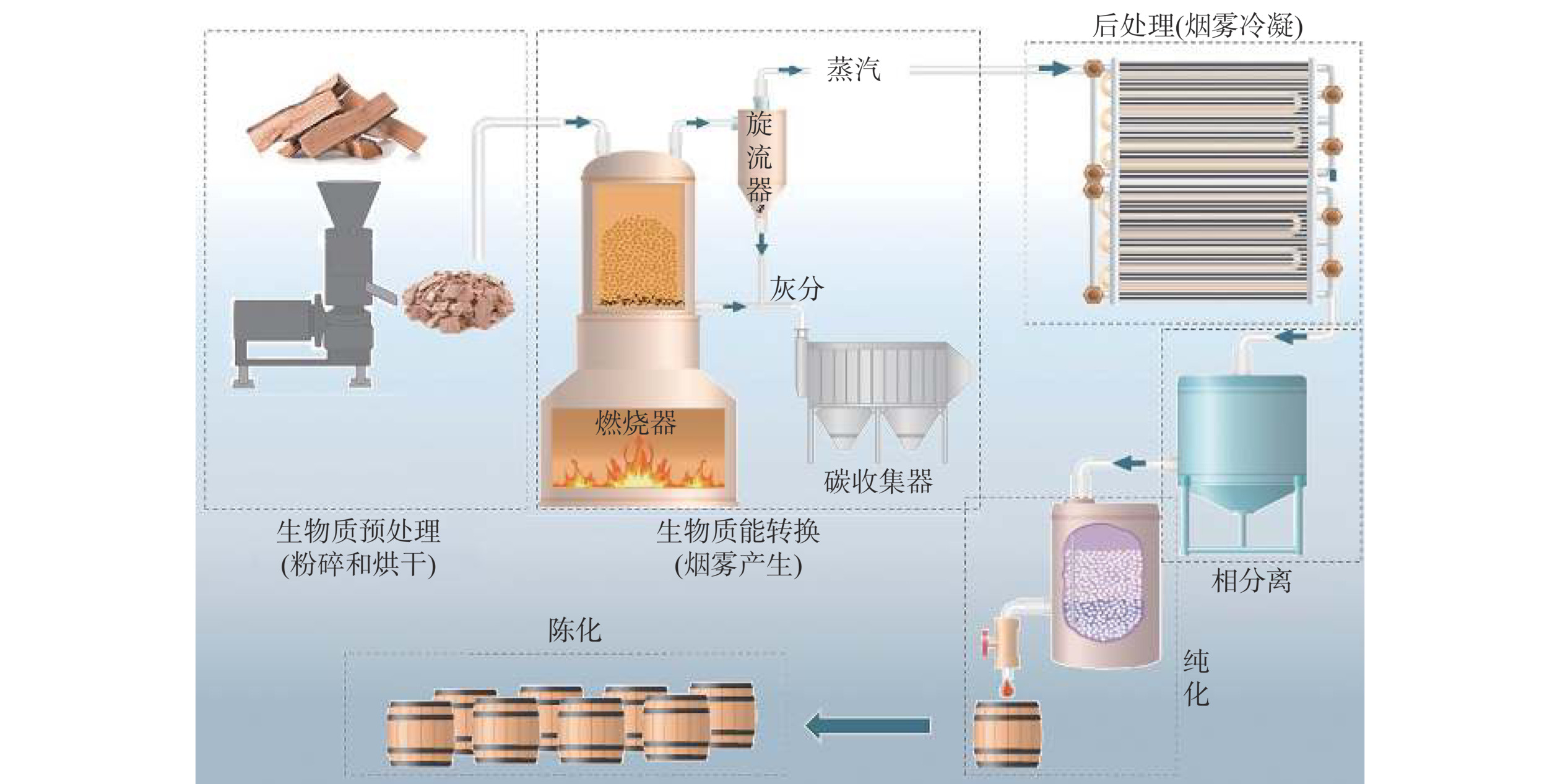

商品化烟熏香料制备的原料主要包括山毛榉(Fagus longipetiolata Seem.)、山核桃(Carya cathayensis Sarg.)及栎(Quercus acutissima)等木材[9],少量以玉米芯[10]、稻壳[11]和山核桃壳[12]等农产品副产物为原料。传统的烟熏香料生产工艺如图1所示[7],该过程可分为预处理、转化处理和后处理三个阶段。生物质原料经粉碎、烘干预处理后注入烟雾反应器进行批次或连续热能转化,产生的烟雾通过热交换器冷凝形成水相和油相,再通过相分离去除油相及其中的多环芳烃,剩余水相即为烟熏香料。得到的烟熏香料初品需要后续陈化工艺以改善感官品质,陈化一般需要数月或数年,提高储存温度可缩短陈化时间。

传统的烟熏香料生产工艺存在效率低和污染空气等问题。近年来在清洁能源领域广泛应用的生物质热解技术被尝试用于生产烟熏香料,其原理是在缺氧或惰性气体环境下,通过外部热源将生物质高温快速热解,其中的固化有机物转化为液体、固体和不可冷凝气体[13],具有生产效率高、产品质量可控且环境污染少等突出优势,但目前由此生产的商业化熏液产品尚不多见。

1.2 烟熏香料的化学组分

烟熏香料中的化学成分来源于生物质原料的热解,以木材为例,其热解可分为四个阶段,首先是木材中水分的快速蒸发,随后是半纤维素、纤维素的热解,最后是木质素的热解[7]。这三种主要组分的热解反应温度存在差异,且生成不同的热解产物。

半纤维素和纤维素的热解发生在180~350 ℃之间,主要产生羰基化合物和有机酸。羰基化合物是烟熏香料中种类最多的化合物,主要化合物有1-羟基-2-丁酮、羟基乙醛、环烯、3-甲基环戊烯、吡喃和呋喃等。羰基化合物呈焦味,易与食物中的蛋白质或氨基酸发生美拉德反应,发挥着色作用;此外,呋喃和吡喃类化合物是除酚类物质以外的第二类气味活性物质[14];有机酸主要包括丁酸、丙酸和戊酸等,既有呈味作用,又兼具抗菌活性,有助于改善产品的贮藏稳定性。

木质素在300~500 ℃之间热解,主要产生酚类物质,其中紫丁香醇(2,6-二甲氧基苯酚)是最主要的酚类化合物,其他重要酚类有丁香酚、异丁香酚、愈创木酚、苯酚和甲酚等[15],它们构成了熏制品独特的烟熏气味,同时还赋予烟熏液抗氧化活性。

由上可见,羰基化合物、有机酸和酚类化合物构成了烟熏香料的主要成分,赋予了其呈味、着色、抗菌及抗氧化等功能活性。但每种烟熏液的具体成分受木材类型和木材含水量影响较大。如奥坎木(Cylicodiscus gabunensis)烟熏香料中,2-甲氧基苯酚是主要的风味物质,呈丁香味,而樱桃木(Sacoglottis gabonensis)烟熏香料中则是糠醛,呈杏仁味[16]。

除上述活性化合物外,木材在热解时还会产生多环芳烃等有害物质,其产生量受木材类型和热解温度的影响[17]。多环芳烃具有极强毒性,但它们的水溶性很低,工业生产上采用相分离或过滤技术很容易将其从烟熏香料成品中分离出来,故在最终产品中的含量很低或检测不出,如Guillén等[18]采用气相色谱-质谱联用技术检测了5种烟熏香料中多环芳烃的含量,仅在山毛榉和白杨(Populus alba)烟熏香料检测出3,4-苯并芘,含量分别为0.04和0.06 μg/kg,低于欧盟规定的2 μg/kg标准。

2. 烟熏香料的功能活性

2.1 烟熏香料的抗菌活性

烟熏香料的抗菌活性已在单核细胞增生李斯特菌(Listeria monocytogenes)、沙门氏菌(Salmonella)、大肠杆菌(Escherichia coli)等一些食源性致病菌中得到证实[19],不同木材热解时产生不同含量的有机酸、酚类和羰基化合物,赋予了它们不同抗菌活性。如白红树(Avicennia nitida)和桃心红木(Khaya sp.)的烟熏香料,能有效抑制金黄色葡萄球菌(Staphylococcus aureus)和大肠杆菌的生长,最低抑菌浓度为20 mg/L;而红树(Rhizophora racemosa)和鸡骨常山属(Alstonia boonei)的烟熏香料在500 mg/L浓度下仅能抑制大肠杆菌生长[20]。

烟熏香料对食品腐败菌同样具有抑制活性,研究发现0.14%商用烟熏香料LS,能显著抑制磷发光杆菌(Photobacterium phosphoreum)的生长,最低抑菌浓度为0.7 mg/g[21]。同样,经烟熏香料处理的海鲷(Sparus aurata)鱼片在4 ℃冷藏7 d,致腐性假单胞菌数量比对照组降低了1.54 lg CFU/g[22]。不过,这些抗菌实验结果均基于复杂的烟熏液混合物,具体何种单体化合物发挥抗菌活性尚不清楚,有待进一步挖掘。

2.2 烟熏香料的抗氧化活性

水产品中富含不饱和脂肪酸,在加工与贮藏过程中极易发生脂质氧化,导致产品营养损失和品质劣化,甚至产生有害化合物[23]。烟熏香料中酚类物质含量较高,如苯二酚、2,6-二甲氧基苯酚等[24],其化学结构上携带一个或多个羟基,可以向自由基提供活泼氢,抑制氧化反应的发生[25]。此外,酚羟基中的未共享电子与过渡金属离子(Fe2+、Cu2+)和氧发生络合,形成较为稳定的配合物,能够减少金属离子与H2O2反应生成自由基,从而抑制自由基产生和氧化反应[26]。

研究显示,烟熏香料中的酚类物质能够有效抑制水产品加工贮藏过程中脂质氧化。如山核桃烟熏香料中儿茶酚、2-甲氧基苯酚、愈创木酚和丁香酚等酚类化合物含量较高,将其添加于鲶鱼(Pangasius hypophthalmus)肉肠中,5 ℃贮藏20 d后,烟熏香料组过氧化物值比对照组下降了0.48 meq/kg[27]。在虹鳟鱼片(Oncorhynchus mykiss)实验中同样发现了类似结果,4 ℃下贮藏110 d后,山核桃烟熏香料组的TBARS值比对照组低3.09 mg/100 g[28]。不同烟熏香料的酚类物质含量差异显著,特别是精制后的烟熏香料中酚类物质消减明显,如商品化烟熏液Code 10-Poly的酚类物质含量达到3.2 mg/mL,而精制后熏液产品仅含痕量酚类物质[29],据此推断未精制的烟熏香料抗氧化活性更强。

2.3 对内源蛋白酶的抑制活性

冷藏水产品极易由内源蛋白酶对肌原纤维和胶原蛋白的降解作用而引起质构劣化[30−31]。一些蛋白酶抑制剂,如半胱氨酸蛋白酶抑制剂[32]、钙蛋白酶抑制剂[33]等被尝试用于改善鱼片质构或冷冻鱼糜的凝胶特性,但目前可添加至食品中的可食用蛋白酶抑制剂非常有限。但烟熏香料具有潜在的内源蛋白酶抑制活性,如在液熏罗非鱼(Oreochromis niloticus)的贮藏中,在2 ℃冷藏45 d后,其肌浆蛋白和肌原纤维蛋白分子量组成与新鲜鱼片组一致,表明烟熏香料可有效抑制肌原纤维蛋白的降解[34]。不过烟熏液中成分复杂,具体何种化合物对内源性蛋白酶有抑制作用尚待进一步研究。

3. 烟熏香料在水产品加工中的应用

近来,烟熏香料已逐渐取代传统的烟熏加工技术,广泛应用于水产品加工中,相关代表性研究如表1所示。市场上的烟熏香料主要由椰壳、山核桃木和山毛榉等原料制得,一般工艺包括原料前处理、腌制、液熏和干燥等步骤。根据烟熏液处理方式的不同,可分为浸渍法、喷洒法和注射法,其中浸渍法简单易行、适用性强,应用较为广泛。不过工业上为提高熏制效率,缩短工艺时间,常通过注射机将烟熏液注入水产品中。

表 1 烟熏香料在水产品加工中的应用Table 1. Application of smoke flavourings in the processing of aquatic products水产品种类 烟熏香料 生产商 加工工艺 三文鱼[35] 商用熏液LS1和LS2 − 4 ℃干腌16 h,再浸入熏液30 s 欧洲鲈鱼[36]

(Dicentrarchus labrax)烟熏液A和B − 5 ℃下,20% NaCl溶液腌制2 h,再浸入熏液1 min 金枪鱼[37](Thunnus alalunga) 椰子壳熏液 印度尼西亚

TropicaNucifera Industry直接加入碎鱼肉中 军曹鱼[38]

(Rachycentron canadum)Smokez P-50;

SmokezEnviro 24 P美国红箭公司 25 ℃下,6% 熏液Smokez P-50中腌制2 h,再喷洒熏液SmokezEnviro 24 P 鲭鱼[39]

(Pneumatophorus japonicus)椰子壳熏液 − 浸入熏液20 min 鲍鱼[40](Abalone) 山楂核烟熏香味料 II号 济南华鲁食品有限公司 2% NaCl溶液腌制2 h,再浸入烟熏液2 h 罗氏沼虾[41]

(Macrobrachium rosenbergii )商用熏液LS − 30% NaCl溶液腌制30 min(或180 min),再将熏液进行喷洒 鳟鱼[42] 商用熏液LS 希腊Nefeloudis SA 5 ℃下,20% NaCl溶液腌制2 h,再浸入熏液60 min 鳀鱼[43](Engraulis japonicus) 商用熏液LS 美国红箭 4 ℃下,10% NaCl溶液腌制4 h,再浸入熏液3 min 虹鳟[44] SmokEz-C-10 美国红箭 4 ℃、36% NaCl溶液腌制4 h,再于15 ℃浸入烟熏液120 s 文蛤[45](Chamelea gallina) SmokEz-M-10 美国红箭 4 ℃、4% NaCl溶液+200 mL LS(终浓度3.3%)腌制2 h 黄貂鱼[46](Trygon sephen) 椰子壳熏液 − 浸入熏液2~4 h 注:“−”表示文献中未标识。 3.1 烟熏香料对水产品感官特性和贮藏品质的影响

不同烟熏香料所含风味物质不同,经处理后的水产品则呈现出不同的理化性质和感官品质,有利于满足消费者对于不同风味的需求[47]。如在风干草鱼[48](Ctenopharyngodon idella)中分别添加香梨木、红柳枝和核桃壳的烟熏香料,在4 ℃下贮藏15 d后,在色泽饱和度方面,香梨木组最佳,与传统烟熏产品最接近。在风味方面,红柳枝组的烟熏味最为浓郁,其次是核桃壳组和香梨木组,风味的差异在于烟熏香料中的呈味物质不同,红柳枝烟熏香料中主要为糖醛,核桃壳烟熏香料中为愈创木酚,香梨木烟熏香料中为苯甲醛。

此外,烟熏液还会影响水产品质构特征。如采用两种商业烟熏香料(FA和FB)处理三文鱼片后,在4 ℃下贮藏45 d,FB组的硬度始终高于FA组,且贮藏期高出13 d,其原因在于烟熏香料FB中富含羰基化合物,在熏制过程与鱼肉中的蛋白质产生美拉德反应,赋予其更高的硬度,有利于延长贮藏期[49]。由于烟熏香料成分复杂,而其应用选择目前尚缺乏相关标准,未来有必要建立烟熏香料的风味指纹图谱,阐明其与水产品感官品质形成之间的关系,为烟熏香料的应用提供理论依据。

另外,烟熏香料能够改善水产品的贮藏稳定性。挥发性盐基氮(TVB-N)通常被用作评价鱼肉鲜度的指标,其可接受范围为30~40 mg N/100 g,超过此限度,产品将失去可食性[50]。烟熏香料能显著抑制TVB-N产生,如液熏鲶鱼在4 ℃下贮藏90 d,烟熏香料组的TVB-N比对照组降低了3.49 mg N/100 g[51]。在微生物和酶的作用下,鱼肉中蛋白质或游离氨基酸分解或转化成生物胺,其中组胺是一种代表性生物胺[52]。鱼肉中组氨酸脱羧酶的存在使组胺在20~45 ℃的温度范围内快速积累,而烟熏香料能抑制脱酸酶产生菌的生长,从而减少组胺的产生。如在梭鱼[53](Liza haematocheila)的腌制过程中,室温下贮藏4 d,椰壳烟熏香料组并未检出组胺,而传统烟熏组中组胺量达到67.63 mg/kg。但烟熏香料对水产品中其他生物胺的产生是否有类似抑制作用,且具体抑制途径有待进一步研究。

3.2 烟熏香料的微囊化包埋及应用

烟熏香料具有良好的抑菌能力和抗氧化效果而被广泛使用,但其中的活性物质易与食品基质反应而丧失活性,有研究尝试将其包埋,制备成微胶囊,利于提高烟熏香料中活性物质的稳定性,并控制其释放速度[54]。如以β-环糊精为载体包埋椰壳烟熏香料,通过喷雾干燥法制得微胶囊,将其应用于罗非鱼保鲜[54],在9 d的贮存期中,1.5%椰壳熏液微胶囊组的TVB-N值和菌落总数值始终低于对照组。与此类似,以麦芽糊精和壳聚糖为载体包埋椰壳烟熏香料,通过喷雾干燥法制得纳米微胶囊,将纳米微胶囊用于金枪鱼肉的贮藏,可使金枪鱼在室温下的新鲜度保持48 h[37]。但纳米微胶囊的安全性尚需进一步评价。

3.3 含熏液抗菌包装的开发

传统的惰性食品包装是用玻璃、陶瓷、塑料等材料将食品与外界相对隔绝,仅为食品提供物理保护。而抗菌包装是一种活性包装,通过将抑菌剂掺入食品包装材料中,控制释放抑菌剂来抑制食品微生物,从而延长食品货架期[55]。Ceylan等[56]利用电纺丝法将熏液和百里香酚包埋于壳聚糖纳米纤维中,此纳米纤维可将冷藏鲈鱼片货架期延长3 d。另外,将商业液体烟雾与乳清蛋白组合,制备出可有效抑制单核细胞增生李斯特菌(Listeria monocytogenes)的可食性薄膜[57],此薄膜有望应用于食源性致病菌的防控。

4. 烟熏香料的安全性

烟熏香料已被美国食品药品监督管理局(FDA)认定为天然香料而纳入食品添加剂目录中,其中个别已进入美国食品香料和萃取物制造者协会(Flavor and extract manufacturers association,FEMA)发布的公认安全类产品(Generally regarded as safe,GRAS)列表中,如FEMA在2005年发布的GRAS 22中就含有山核桃熏液(FEMA编号为4222)。

在欧洲,烟熏香料由于其组分复杂而与其他食用香料分开管理,欧洲议会和理事会于2003年发布了第EU 2065/2003号法规,规定由欧洲食品安全局(EFSA)下设的食品接触材料、酶、香料和加工助剂(CEF)专家组负责烟熏香料的安全评估,主要依据生产商提供的熏液成分、毒理学数据、预期用途及使用水平等信息[58]。2007年EFSA发布的一份报告,认为一款代号为FF-B的熏液具有弱遗传毒性,即能损伤实验大鼠细胞DNA分子,该产品随后退出市场。2009年,CEF专家组完成了11种烟熏香料的安全审查,其中两款产品安全边际足够大,不会引起安全问题;8款产品安全边际较小,在生产商建议用途和使用水平下可能存在安全问题;一款产品AM01不排除可能的遗传毒性[59]。2013年,欧盟发布了EU 1321/2013号实施条例[60],建立了允许使用的食用烟熏香料列表,共包含了10种烟熏香料(表2),并规定了其应用范围和最大使用量,该烟熏香料列表自2014年1月1日起生效,食品生产商需要从2015年1月1日起遵守此新规。

表 2 烟熏香料在水产品中的最大使用量(g/kg)Table 2. Maximum use of smoked flavorings in aquatic products (g/kg)香料名称 生产商 来源 最大使用量(加工鱼及鱼类制品包括

贝壳类和软体动物)Scansmoke PB 1110 美国红箭 90%山毛榉,10%栎 2.00 Zesti Smoke Code 10 − 50%~60%山核桃,40%~50%栎 2.00 Smoke Concentrate 809045 − 山毛榉 0.60 Scansmoke SEF 7525 美国红箭 35%英国栎、35%白栎、10%槭树、10%山毛榉和10%山核桃 0.16 SmokEz C-10 美国红箭 25%~60%槭树,10%~40%栎,10%~25%山核桃,0~15%美国白蜡树、桦木、野黑樱桃、山毛榉 2.00 SmokEz Enviro-23 美国红箭 25%~65%槭树,20%~75%栎,0~15%山核桃、美国白蜡树、桦木、野黑樱桃、山毛榉 2.00 TradismokeTM A MAX − 山毛榉 4.00 proFagusSmoke R709 − 90%山毛榉、10%栎 2.50 Fumokomp − 85%山毛榉、15%角树 0.06 AM 01 美国红箭 山毛榉 0.08 注:“−”表示原文未提及。 与欧盟管理不同,我国食品添加剂使用标准GB 2760-2014[61]把烟熏香料归于食用香料统一管理,尚无使用限量规定,具体添加量遵循自限性原则。目录中被批准使用的有四款烟熏香料,分别为山楂核烟熏香味料Ⅰ号和Ⅱ号,硬木烟熏香味料SEF 7525以及硬木烟熏香味料SmokEz C-10。国标GB 1886.127-2016[62]又对山楂核烟熏香味料Ⅰ号和Ⅱ号的生产工艺参数、感官和理化指标进行了具体规定。

5. 结论与展望

烟熏是重要的水产品加工形式之一,液熏技术解决了传统烟熏工艺存在的多环芳烃残留、环境污染等突出问题,有助于满足人们对不同风味且安全健康水产品的消费需求。未来尚需在如下领域进一步开展研究:a. 在烟熏香料的制备方面,研究烟熏香料高温快速热解制备技术,阐明不同生物质原料的热解特性与热解机理,揭示烟熏香料中主要活性成分的生成途径,分析烟熏香料的呈味、增色、抗菌、抗氧化等活性及其化学基础;b. 针对烟熏香料味风味单一的问题,研究不同烟熏香料中的风味指纹图谱,开发复配烟熏香料等新产品,阐释代表性水产品在液熏加工过程中风味与质构形成的生化基础;c. 进一步开展烟熏香料的安全性评价,完善烟熏香料的产品标准和使用规范,为烟熏香料在食品加工中的应用提供理论和技术支撑。

-

表 1 烟熏香料在水产品加工中的应用

Table 1 Application of smoke flavourings in the processing of aquatic products

水产品种类 烟熏香料 生产商 加工工艺 三文鱼[35] 商用熏液LS1和LS2 − 4 ℃干腌16 h,再浸入熏液30 s 欧洲鲈鱼[36]

(Dicentrarchus labrax)烟熏液A和B − 5 ℃下,20% NaCl溶液腌制2 h,再浸入熏液1 min 金枪鱼[37](Thunnus alalunga) 椰子壳熏液 印度尼西亚

TropicaNucifera Industry直接加入碎鱼肉中 军曹鱼[38]

(Rachycentron canadum)Smokez P-50;

SmokezEnviro 24 P美国红箭公司 25 ℃下,6% 熏液Smokez P-50中腌制2 h,再喷洒熏液SmokezEnviro 24 P 鲭鱼[39]

(Pneumatophorus japonicus)椰子壳熏液 − 浸入熏液20 min 鲍鱼[40](Abalone) 山楂核烟熏香味料 II号 济南华鲁食品有限公司 2% NaCl溶液腌制2 h,再浸入烟熏液2 h 罗氏沼虾[41]

(Macrobrachium rosenbergii )商用熏液LS − 30% NaCl溶液腌制30 min(或180 min),再将熏液进行喷洒 鳟鱼[42] 商用熏液LS 希腊Nefeloudis SA 5 ℃下,20% NaCl溶液腌制2 h,再浸入熏液60 min 鳀鱼[43](Engraulis japonicus) 商用熏液LS 美国红箭 4 ℃下,10% NaCl溶液腌制4 h,再浸入熏液3 min 虹鳟[44] SmokEz-C-10 美国红箭 4 ℃、36% NaCl溶液腌制4 h,再于15 ℃浸入烟熏液120 s 文蛤[45](Chamelea gallina) SmokEz-M-10 美国红箭 4 ℃、4% NaCl溶液+200 mL LS(终浓度3.3%)腌制2 h 黄貂鱼[46](Trygon sephen) 椰子壳熏液 − 浸入熏液2~4 h 注:“−”表示文献中未标识。 表 2 烟熏香料在水产品中的最大使用量(g/kg)

Table 2 Maximum use of smoked flavorings in aquatic products (g/kg)

香料名称 生产商 来源 最大使用量(加工鱼及鱼类制品包括

贝壳类和软体动物)Scansmoke PB 1110 美国红箭 90%山毛榉,10%栎 2.00 Zesti Smoke Code 10 − 50%~60%山核桃,40%~50%栎 2.00 Smoke Concentrate 809045 − 山毛榉 0.60 Scansmoke SEF 7525 美国红箭 35%英国栎、35%白栎、10%槭树、10%山毛榉和10%山核桃 0.16 SmokEz C-10 美国红箭 25%~60%槭树,10%~40%栎,10%~25%山核桃,0~15%美国白蜡树、桦木、野黑樱桃、山毛榉 2.00 SmokEz Enviro-23 美国红箭 25%~65%槭树,20%~75%栎,0~15%山核桃、美国白蜡树、桦木、野黑樱桃、山毛榉 2.00 TradismokeTM A MAX − 山毛榉 4.00 proFagusSmoke R709 − 90%山毛榉、10%栎 2.50 Fumokomp − 85%山毛榉、15%角树 0.06 AM 01 美国红箭 山毛榉 0.08 注:“−”表示原文未提及。 -

[1] RIZO A, MAÑES V, FUENTES A, et al. Physicochemical and microbial changes during storage of smoke-flavoured salmon obtained by a new method[J]. Food Control,2015,56:195−201. doi: 10.1016/j.foodcont.2015.03.030

[2] RIZZO P , DEL TORO-GIPSON R S, CADWALLADER D C, et al. Identification of aroma-active compounds in cheddar cheese imparted by wood smoke[J]. Journal of Dairy Science, 2022, 105(7):5622−5640.

[3] DU H Z, LIU Q, CHEN Q, et al. Effect of woodchip types on heterocyclic aromatic amine formation and quality characteristics of smoked bacon[J]. Food Bioscience,2022,47:101709. doi: 10.1016/j.fbio.2022.101709

[4] DUTTA K, SHITYAKOV S, ZHU W, et al. High-risk meat and fish cooking methods of polycyclic aromatic hydrocarbons formation and its avoidance strategies[J]. Food Control,2022,142:109253. doi: 10.1016/j.foodcont.2022.109253

[5] 中华人民共和国国家卫生健康委员会. GB 2762-2022 食品中污染物限量[S]. 北京:中国标准出版社, 2022. [National Health Commission of the People's Republic of China. GB 2762-2022 Limits of contaminants in food[S]. Beijing:Standards Press of China, 2022.] National Health Commission of the People's Republic of China. GB 2762-2022 Limits of contaminants in food[S]. Beijing: Standards Press of China, 2022.

[6] WRETLING S, ERIKSSON A, ESKHULT G A, et al. Polycyclic aromatic hydrocarbons (PAHs) in Swedish smoked meat and fish[J]. Journal of Food Composition and Analysis,2010,23(3):264−272. doi: 10.1016/j.jfca.2009.10.003

[7] XIN X, GHOREISHI K, AN G Y, et al. The effect of liquid smoke obtained from fast pyrolysis of a hardwood on physical properties and shelf life of cheddar cheese[J]. European Food Research and Technology,2022,248:625−633. doi: 10.1007/s00217-021-03915-7

[8] HUANG Y P, ZHOU Y, LIU Y Y, et al. Effects of tea branch liquid smoke on oxidation and structure of myofibrillar protein derived from pork tenderloin during curing[J]. Food Chemistry:X,2023,17:100544.

[9] European Food Safety Authority (EFSA). Safety of smoke flavour primary product unismoke[J]. EFSA Journal,2009,7(4):983.

[10] SWASTAWATI F, BOESONO H, SUSANTO E, et al. Changes of amino acids and quality in smoked milkfish [Chanos chanos (Forskal 1775)] processed by different redestilation methods of corncob liquid smoke[J]. Aquatic Procedia,2016,7:100−105. doi: 10.1016/j.aqpro.2016.07.013

[11] MALAKA R, PURWANTI S, ALI H M, et al. Liquid smoke characteristic from coconut shell and rice husk[C]. IOP Conference Series:Earth and Environmental Science, 2021, 788(1):012078.

[12] VAN LOO E J, BABU D, CRANDALL P G, et al. Screening of commercial and pecan shell-extracted liquid smoke agents as natural antimicrobials against foodborne pathogens[J]. Journal of Food Protection,2012,75(6):1148−1152. doi: 10.4315/0362-028X.JFP-11-543

[13] PIMENTA A S, DA COSTA MONTEIRO T V, FASCIOTTI M, et al. Fast pyrolysis of trunk wood and stump wood from a Brazilian eucalyptus clone[J]. Industrial Crops and Products,2018,125:630−638. doi: 10.1016/j.indcrop.2018.08.083

[14] KOSTYRA E, BARYŁKO P N. Volatiles composition and flavour profile identity of smoke flavourings[J]. Food Quality and Preference,2006,17(1-2):85−95. doi: 10.1016/j.foodqual.2005.06.008

[15] C. T N, SEKHAR C N, C. G J, et al. Source-dependent compositional changes in coconut flavoured liquid smoke and its application in traditional Indian smoked fishery products[J]. Food Additives & Contaminants:Part A, 2020, 37(10):1610−1620.

[16] MBOUGUENG P D, SACHINDRA N M, NODEM N F D, et al. Characterization of volatile compounds of liquid smoke flavourings from some tropical hardwoods[J]. Scientific African,2020,8:e00443. doi: 10.1016/j.sciaf.2020.e00443

[17] GRECO G, VIDEGAIN M, DI STASI C, et al. Importance of pyrolysis temperature and pressure in the concentration of polycyclic aromatic hydrocarbons in wood waste-derived biochars[J]. Journal of Analytical and Applied Pyrolysis,2021,159:105337. doi: 10.1016/j.jaap.2021.105337

[18] GUILLÉN M D, SOPELANA P, PARTEARROYO M A. Polycyclic aromatic hydrocarbons in liquid smoke flavorings obtained from different types of wood. Effect of storage in polyethylene flasks on their concentrations[J]. Journal of Agricultural & Food Chemistry,2000,48(10):5083−5087.

[19] MANSUR D, SUGIWATI S, RIZAL W A, et al. Pyrolysis of cajuput (Melaleuca leucadendron) twigs and rice (Oryza sativa) husks to produce liquid smoke-containing fine chemicals for antibacterial agent application[J]. Biomass Conversion and Biorefinery,2023,13(12):10561−10574. doi: 10.1007/s13399-021-01896-x

[20] ASITA A O, CAMPBELL I A. Anti-microbial activity of smoke from different woods[J]. Letters in Applied Microbiology,2010,10(2):93−95.

[21] SAHA A, BIRKELAND S, LØVDAL T. The effect of K-lactate salt and liquid smoke on bacterial growth in a model system[J]. Journal of Aquatic Food Product Technology,2017,26(2):192−204. doi: 10.1080/10498850.2015.1110221

[22] RACIOPPO A, SPERANZA B, PILONE V, et al. Optimizing liquid smoke conditions for the production and preservation of innovative fish products[J]. Food Bioscience,2023,53:102712. doi: 10.1016/j.fbio.2023.102712

[23] BAYRAM I, DECKER E A. Underlying mechanisms of synergistic antioxidant interactions during lipid oxidation[J]. Trends in Food Science & Technology,2023,133:219−230.

[24] ZHOU B, LUO J, QUAN W, et al. Antioxidant activity and sensory quality of bacon[J]. Foods,2022,11(2):236. doi: 10.3390/foods11020236

[25] RUSINA I F, VEPRINTSEV T L, VASIL'EV R F. Antioxidant activity of diatomic phenols[J]. Russian Journal of Physical Ch-emistry B,2022,16(1):50−57. doi: 10.1134/S1990793122010274

[26] SHUL'PIN G B, KOZLOV Y N, SHUL'PINA L S. Metal complexes containing redox-active ligands in oxidation of hydrocarbons and alcohols:A review[J]. Catalysts,2019,9(12):1046. doi: 10.3390/catal9121046

[27] SHERPA K, PRIYADARSHINI M B, MEHTA N K, et al. Shelf-stability of kiln-and liquid-smoked inulin-fortified emulsion-type pangasius mince sausage at refrigerated temperature[J]. ACS Omega,2023,8(38):34431−34441. doi: 10.1021/acsomega.3c02756

[28] CAN TUNÇELLI İ, ÖZDEN Ö. Evaluation of rainbow trout and meagre fillets as novel ready-to-eat products[J]. Journal of Aquatic Food Product Technology,2023,32(4):373−383. doi: 10.1080/10498850.2023.2224317

[29] MONTAZERI N, OLIVEIRA A C M, HIMELBLOOM B H, et al. Chemical characterization of commercial liquid smoke products[J]. Food Science & Nutrition,2013,1(1):102−115.

[30] ZHUANG S, LIU Y Y, GAO S, et al. Mechanisms of fish protein degradation caused by grass carp spoilage bacteria:a bottom-up exploration from the molecular level, muscle microstructure level, to related quality changes[J]. Food Chemistry,2023,403:134309. doi: 10.1016/j.foodchem.2022.134309

[31] LI N, XIE J, CHU Y M. Degradation and evaluation of myofibril proteins induced by endogenous protease in aquatic products during storage:a review[J]. Food Science and Biotechnology,2023,32(8):1005−1018. doi: 10.1007/s10068-023-01291-4

[32] HU Y, MORIOKA K, ITOH Y. Hydrolysis of surimi paste from walleye pollock (Theragra chalcogramma) by cysteine proteinase cathepsin L and effect of the proteinase inhibitor (E-64) on gelation[J]. Food Chemistry,2007,104(2):702−708. doi: 10.1016/j.foodchem.2006.12.032

[33] HE Y F, HUANG H, LI L H, et al. The effects of modified atmosphere packaging and enzyme inhibitors on protein oxidation of tilapia muscle during iced storage[J]. LWT-Food Science and Technology,2018,87:186−193. doi: 10.1016/j.lwt.2017.08.046

[34] BOUZGARROU O, BARON R, SADOK S. Determination of the quality of liquid smoked tilapia fillets based on physicochemical analysis[J]. Journal of Food Measurement and Characterization,2020,14:978−991. doi: 10.1007/s11694-019-00347-6

[35] MARTINEZ O, SALMERÓN J, GUILLÉN M D, et al. Textural and physicochemical changes in salmon (Salmo salar) treated with commercial liquid smoke flavourings[J]. Food Chemistry,2007,100(2):498−503. doi: 10.1016/j.foodchem.2005.09.071

[36] NIEVA-ECHEVARRIA B, GOICOECHEA E, GUILLEN M D. Effect of liquid smoking on lipid hydrolysis and oxidation reactions during in vitro gastrointestinal digestion of European sea bass[J]. Food Research International,2017,97:51−61. doi: 10.1016/j.foodres.2017.03.032

[37] DARMADJI P, SETIAJI B, PRANOTO Y, et al. Antioxidative and antimicrobial activities of liquid smoke nanocapsules using chitosan and maltodextrin and its application on tuna fish preservation[J]. Food Bioscience,2014,7:71−79. doi: 10.1016/j.fbio.2014.05.008

[38] 刘法佳, 吴燕燕, 李来好, 等. 利用液熏法熏制军曹鱼片的工艺研究[J]. 食品工业科技,2011,32(11):256−259. [LIU F J, WU Y Y, LI L H, et al. Study on the processing of smoked cobia fillets by liquid smoking[J]. Science and Technology of Food Industry,2011,32(11):256−259.] LIU F J, WU Y Y, LI L H, et al. Study on the processing of smoked cobia fillets by liquid smoking[J]. Science and Technology of Food Industry, 2011, 32(11): 256−259.

[39] ALADIN A, YANI S, SYARIF T, et al. Organoleptic observations of the preservation of mackerel fish using liquid smoke from coconut shells pyrolysis[J]. World Chemical Engineering Journal,2022,6(1):29−32. doi: 10.48181/wcej.v6i1.15914

[40] 沈俊炳. 即食液熏鲍鱼生产工艺开发与优化[J]. 食品安全质量检测学报,2021,12(16):6393−6398. [SHEN J B. Development and optimization of production technology of instant liquid smoked abalone[J]. Journal of Food Safety & Quality,2021,12(16):6393−6398.] SHEN J B. Development and optimization of production technology of instant liquid smoked abalone[J]. Journal of Food Safety & Quality, 2021, 12(16): 6393−6398.

[41] PORTELLA C G, SANT'ANA L S, VALENTI W C. Sensory aspects of liquid smoking of giant river prawn:comparison with traditional smoking[J]. International Journal of Food Science & Technology,2011,46(4):834−839.

[42] ZOTOS A. Preservation time at 6±2c and 8±2c of trout (Salmo gairdnerii) fillets smoked by steaming with liquid smoke[J]. Journal of Food Processing & Preservation,2011,35(4):533−541.

[43] ÇAKIR F, AYVAZ Z. Investigation of the effect of different immersion times of anchovy fillets in liquid smoke flavoring on color by image analysis[J]. Journal of Aquatic Food Product Technology,2020,29(9):865−870. doi: 10.1080/10498850.2020.1813857

[44] ALCICEK Z, ATAR H H. The effects of salting on chemical quality of vacuum packed liquid smoked and traditional smoked rainbow trout (Oncorhyncus mykiss) fillets during chilled storage[J]. Journal of Animal & Veterinary Advances,2010,9(22):2778−2783.

[45] ALCICEK Z. Effects of different liquid smoke flavor levels on the shelf life of venus clam (Chamelea Gallina, L 1758) meat[J]. Journal of Food Processing and Preservation,2014,38(3):964−970. doi: 10.1111/jfpp.12052

[46] SUPRAPTO H, KUMALANINGSIH S, WIGNYANTO W, et al. Optimization of stingray (Trygon sephen) smoking to extend shelf life and consumer preferences using response surface methodology[C]//IOP Conference Series:Earth and Environmental Science. Bristol, IOP Publishing, 2021, 733(1):012114.

[47] HARLINA P W, YULIANA T, SHAHZAD R, et al. Study on the development and functional characteristics of salted egg with liquid smoke[J]. Food Science of Animal Resources,2023,43(3):471. doi: 10.5851/kosfa.2023.e10

[48] 阿依姑丽·吾布力. 不同烟熏液的制备及其对风干鱼品质特性的影响[D]. 乌鲁木齐:新疆农业大学, 2021. [WUBULI A. The preparation of different smoking liquids and their effects on the quality characteristics of dried fish[D]. Urumqi:Xinjiang Agricultural University, 2021.] WUBULI A. The preparation of different smoking liquids and their effects on the quality characteristics of dried fish[D]. Urumqi: Xinjiang Agricultural University, 2021.

[49] MARTINEZ O, SALMERON J, GUILLEN M D, et al. Sensorial and physicochemical characteristics of salmon (Salmo salar) treated by different smoking processes during storage[J]. Food Science & Technology International,2007,13(6):477−484.

[50] HUANG C H, HSIEH C Y, LEE Y C, et al. Inhibitory effects of high-hydrostatic-pressure processing on growth and histamine formation of histamine-forming bacteria in yellowfin tuna meat during storage[J]. Biology,2022,11(5):702. doi: 10.3390/biology11050702

[51] SOKAMTÉ T A, MBOUGUENG P D, MOUAFO T H, et al. Application of the spice afrostyrax lepidophyllus mildbr as a biopreservative and seasoning agent for hot smoked fillets of pangasius hypophthalmus[J]. Journal of Agriculture and Food Research,2022,10:100449. doi: 10.1016/j.jafr.2022.100449

[52] KOO P L, LIM G K. A review on analytical techniques for quantitative detection of histamine in fish products[J]. Microchemical Journal,2023,189:108499. doi: 10.1016/j.microc.2023.108499

[53] SWASTAWATI F, RIYADI P H, KURNIASIH R A, et al. Safety, quality, and nutritional aspect of smoked barracuda fish[J]. F1000Research,2022,11(1378):1378.

[54] ARIESTYA D I, SWASTAWATI F, SUSANTO E. Antimicrobial activity of microencapsulation liquid smoke on tilapia [Oreochromis niloticus (Linnaeus, 1758)] meat for preservatives in cold storage (±5 C°)[J]. Aquatic Procedia,2016,7:19−27. doi: 10.1016/j.aqpro.2016.07.003

[55] SHARMA R, JAFARI S M, SHARMA S. Antimicrobial bio-nanocomposites and their potential applications in food packaging[J]. Food Control,2020,112:107086. doi: 10.1016/j.foodcont.2020.107086

[56] CEYLAN Z, SENGOR G F U, YILMAZ M T. Nanoencapsulation of liquid smoke/thymol combination in chitosan nanofibers to delay microbiological spoilage of sea bass (Dicentrarchus labrax) fillets[J]. Journal of Food Engineering,2017,229:43−49.

[57] SOAZO M, PÉREZ L M, PICCIRILLI G N, et al. Antimicrobial and physicochemical characterization of whey protein concentrate edible films incorporated with liquid smoke[J]. LWT-Food Science and Technology,2016,72:285−291. doi: 10.1016/j.lwt.2016.04.027

[58] COMMISSION E. Regulation (EC) No 2065/2003 of the European Parliament and of the Council of 10 November 2003 on smoke flavourings used or intended for use in or on foods[J]. Official Journal of the European Union, 2003:1−8.

[59] THEOBALD A, ARCELLA D, CARERE A, et al. Safety assessment of smoke flavouring primary products by the European Food Safety Authority[J]. Trends in Food Science & Technology,2012,27(2):97−108.

[60] EFSA Panel on Food Additives and Flavourings (FAF), YOUNES M, AQUILINA G, et al. Scientific guidance for the preparation of applications on smoke flavouring primary products[J]. EFSA Journal,2021,19(3):e06435.

[61] 国家卫生和计划生育委员会. GB 2760-2014 食品添加剂使用标准[S]. 北京:中国标准出版社, 2014. [National Health and Family Planning Commission. GB 2760-2014 Standard for use of food additives[S]. Beijing:Standards Press of China, 2014.] National Health and Family Planning Commission. GB 2760-2014 Standard for use of food additives[S]. Beijing: Standards Press of China, 2014.

[62] 国家卫生和计划生育委员会. GB 1886.127-2016 山楂核烟熏香味料Ⅰ号、Ⅱ号[S]. 北京:中国标准出版社, 2016. [National Health and Family Planning Commission. GB 1886.127-2016 Hawthorn stone smoke aroma Ⅰ, Ⅱ[S] Beijing:Standards Press of China, 2016.] National Health and Family Planning Commission. GB 1886.127-2016 Hawthorn stone smoke aroma Ⅰ, Ⅱ[S] Beijing: Standards Press of China, 2016.

-

期刊类型引用(1)

1. 章紫英 ,周汉昌 ,黄思远 ,李婷 ,余林 ,况小宝 . 烟熏对食品风味及安全性影响研究进展. 食品工业. 2024(11): 270-276 .  百度学术

百度学术

其他类型引用(0)

下载:

下载:

下载:

下载: