Research Advanced on Processing and Quality Safety Control Technology of Pre-made Pork Dishes

-

摘要: 随着食品工业化进程及生产技术的提升,同时现代快节奏的生活方式以及中央厨房市场的增长,预制菜成为餐饮行业及家庭的重要选择。以猪肉为主要原料的预制菜制品成为预制菜市场的重要组成部分,且市场份额持续稳定增长。猪肉预制菜的品质与加工技术、贮藏技术以及质量控制技术密切相关。本文综述了猪肉类预制菜的原料特性、加工以及质量控制技术,以期为猪肉预制菜的高质量发展提供指导。Abstract: With the industrialization of the food industry and the advancement of production technology, along with the simultaneous modern fast-paced lifestyle and the growth of the central kitchen market, pre-made dishes have become an important choice for both the catering industry and households. Pre-made dishes made primarily with pork as the main ingredient have become an important component of the pre-made dishes market and the market share continues to grow steadily. The quality of pre-made pork dishes is closely linked to processing technology, storage techniques and quality control measures. This paper reviews the material characteristics, processing and quality control technologies of pre-made pork dishes and aims to guide for their high-quality development.

-

随着生活节奏的加快、居民收入的提高和消费观念的转变,可以快速食用的“预制菜”受到人们的欢迎,市场需求激增[1]。同时,随着预制菜市场规模的扩大,预制菜品质和供销渠道不断提升和改善,进一步激发消费者的购买欲望和预制菜市场的发展[2−3]。2022年,中国预制菜市场规模约为4151.5亿元,涉及预制菜加工的企业约6.4万家,且未来还将继续增加,预制菜产业发展潜力巨大[4]。预制菜根据原料来源可分为畜禽类、水产类、果蔬类、粮食类以及药膳类等,以猪肉为主要原料加工制成的预制菜品类在畜禽类预制菜中占主要部分[5]。

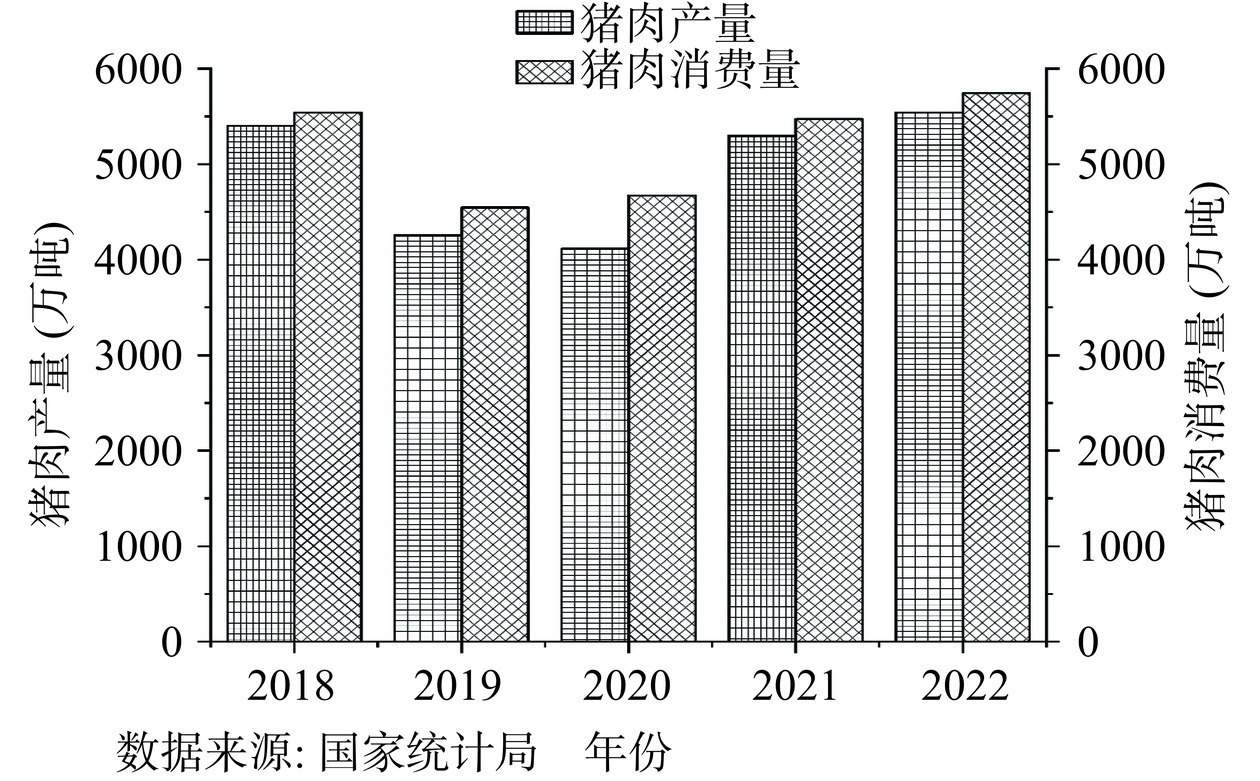

我国猪肉产量和消费量巨大(图1),2021年猪肉产量达5295.9万吨,较2020年增加了1182.60万吨,同比增长28.75%。同时,我国虽然猪肉消费总量大,2021年中国猪肉消费量为5472.60万吨,但人均消费量仍较低[6]。猪肉预制菜是以猪肉或其制品作为主要原料,使用或不使用调味料等辅料,不添加防腐剂,采用现代标准化中央厨房集中生产方式,在生产过程中经过预处理、预加工或加工及包装制成的半成品或成品,以便于消费者购买后快速烹饪。该类产品的制作过程通常包括清洗、切割、腌制或调味、熟制等处理步骤[7−8]。猪肉预制菜不仅提供了便捷和快速的烹饪选择,而且可以通过多种精深加工技术,开发出多元化产品,以满足消费者对种类和品质的需求。本文综述了猪肉预制菜的原料特性、加工工艺及质量控制技术,以猪肉原料的营养特点和加工适应性为基础,总结了猪肉预制菜预处理、加工、贮藏过程中的关键技术和质量控制技术,同时分析了猪肉预制菜的未来发展趋势,旨在为推进我国猪肉预制菜产业健康高质量发展提供参考。

1. 猪肉预制菜的原料特性

1.1 猪肉原料的营养特点与功能特性

现代研究表明猪肉中主要含有蛋白质、脂肪、维生素和矿物质等营养成分,营养丰富且易于加工[9]。程志斌等[10]发现猪肉必需氨基酸组成和酪蛋白组成相似,消化率高,适合人体的生长需求;富含磷、钾、铁和镁等人体营养中的重要矿物质元素;含有多种维生素,以维生素B1和维生素B2为主。此外,脂肪是人类饮食中脂肪酸的重要来源,其含量是影响感官品质的重要因素,某些类型的脂肪酸,尤其是n-3脂肪酸,对血管疾病、癌症和类风湿性关节炎具有积极影响[11]。除了脂肪酸外,许多脂质对人类健康具有积极作用,例如甘油酯、鞘脂类和甘油磷脂等[12]。

1.2 猪肉原料的加工适应性

在猪肉预制菜的生产中,部位的选择直接影响产品的类型与加工方式。猪肉中脂肪含量较低、肌纤维细腻的部位,可以制作小酥肉、调理猪排和回锅肉等预制菜;脂肪含量中等、具有肥瘦相间的部位,可以加工制作烧白、梅菜扣肉和红烧肉等预制菜;猪小排部位则可用于制作糖醋排骨等预制菜[13]。同时,根据肉质特性的差异用于不同的加工产品,例如嫩肉适合制作火锅片,瘦肉可以用于制作腌制肉制品,猪肉皮则适合用于烟熏食品的生产[14]。

2. 猪肉预制菜加工技术

2.1 腌制技术

腌制处理是猪肉预制菜加工过程中的重要处理方式,可以改善制品风味、嫩度和保水性[15]。目前,常用的腌制技术包括湿腌法、干腌法、滚揉腌制以及通过超声或改变压力进行辅助腌制等。湿法腌制是将肉加入一定浓度食盐溶液进行腌制,腌制产品肉质柔软但会造成营养物质流失;干法腌制是在肉表面涂上腌制剂,依靠肉本身渗出的汁液与盐混合形成腌制液进行腌制,腌制过程会造成表面脱水,影响品质[16]。真空滚揉腌制是依靠机械“摔打作用”和“真空作用”相结合,提高肌肉蛋白质溶出速率而加速腌制过程[17]。超声辅助腌制借助空化效应和机械效应,通过改变腌制环境的温度和压力,从而提高腌制液的转移速率及穿透能力,加速传质过程,提高腌制效率和肉的嫩度[18]。此外,真空度可以改善腌制效果和腌制猪肉品质,对比传统腌制、高压腌制和真空腌制对猪肉品质的影响,发现真空腌制肉具有较高的保水性和盐溶性蛋白含量,同时色泽、嫩度和质地优于其他两种方式的腌制肉[19−20]。静态变压腌制通过交替进行真空、加压和常压过程,使肉处于压力规则不断变化的环境中,腌制液通过周期性的吸入和挤出交替而完成腌制过程,相较滚揉腌制,此法不会导致肉块软化变形[17]。常见的腌制技术见表1。

表 1 猪肉预制菜腌制技术Table 1. Salting technology of pre-made pork dishes腌制技术 工艺参数 机理及效果 参考文献 湿腌 腌制7 h和12 h 腌制液在传质过程中引起了肌肉功能特性的变化,改变猪肉蛋白质的热稳定性,改善了质地及保藏性能 [21] 滚揉腌制 滚揉时间8 h、滚揉机转速11 r/min和腌制液添加量35% 调理猪排剪切应力最低为12.46 N,嫩度最好 [22] 超声波辅助腌制 超声功率260 W、超声时间60 min 汁液流失和水分流失较传统腌制分别减少48.34%和58.21%,且乳化稳定性最好 [23] 静态变压腌制 -70 kpa-常压-160 kPa-常压循环交替;真空时间20 min,常压时间10 min,加压时间20 min,常压时间10 min下

循环进行腌制效率和保水性提高,剪切力、硬度、弹性和胶黏性较低,且改善了嫩度和色泽 [17] 2.2 嫩化技术

肉制品嫩度是消费者的主观感受,一般借助感官评价或剪切力的大小进行衡量[24]。猪肉预制菜的加工方法和烹饪参数包括时间、温度和压力等会影响猪肉的结构,从而影响嫩度[25]。目前,常用腌制、酶处理、超声等方式破坏肌肉结构,增加蛋白质水解以提高猪肉预制菜的嫩度。腌制通过改变蛋白质的溶解度或通过蛋白酶的作用介导蛋白质来影响肌肉结构,从而改善肉的嫩度[26]。木瓜蛋白酶或菠萝蛋白酶等外源酶可通过破坏肌肉微观结构和降解肌原纤维蛋白而达到嫩化的目的,但由于蛋白酶广泛的特异性和高效性,会导致肉过度嫩化和微观结构广泛降解,对风味和品质产生不良影响[27−28]。超声波嫩化肉类通过快速压缩和膨胀作用使肉制品肌原纤维蛋白结构断裂,破坏溶酶体结构,释放蛋白酶,加速蛋白水解或变性,达到嫩化效果[29−30]。常见猪肉预制菜嫩化技术见表2。

表 2 猪肉预制菜嫩化技术Table 2. Tenderization technology of pre-made pork dishes嫩化技术 工艺参数 机理及效果 参考文献 腌制 滚揉时间8 h、滚揉机转速11 r/min和腌制液添加量35% 剪切应力最低为12.46 N,嫩度最好 [22] 木瓜蛋白酶 300 U/g 适当降解调理猪排的蛋白质,改善其嫩度和提高

其保水性[31] 木瓜蛋白酶 酶添加量为340.0 U/g、嫩化时间15 min和嫩化

温度49 ℃调理猪排嫩度适宜,剪切应力2.48 kg,感官评价为90.14(总分100) [32] 超声波 超声时间99.9 min、功率为147 W、频率为35.3 kHz 降低小酥肉的剪切力、硬度和咀嚼性,增加了

小酥肉的嫩度[33] 超声辅助无花果叶蛋白酶 超声功率240 W、超声时间5 min、无花果叶蛋白酶

复合嫩化剂用量4.0 g/100 g肉样、嫩化温度50 ℃、

嫩化时间60 min、pH7.5猪脯肉的剪切应力为29.8 N,感官分析其硬度、嫩度和咀嚼性较好,感官得分为39.2(总分40) [34] 低温预热和传统烹饪结合 传统高温加热结合在50 ℃预热35 min或者在

60 ℃预热5/20 min降低了猪肉块的剪切应力,提高了其持水力,

改善了其嫩度[35] 2.3 热加工工艺

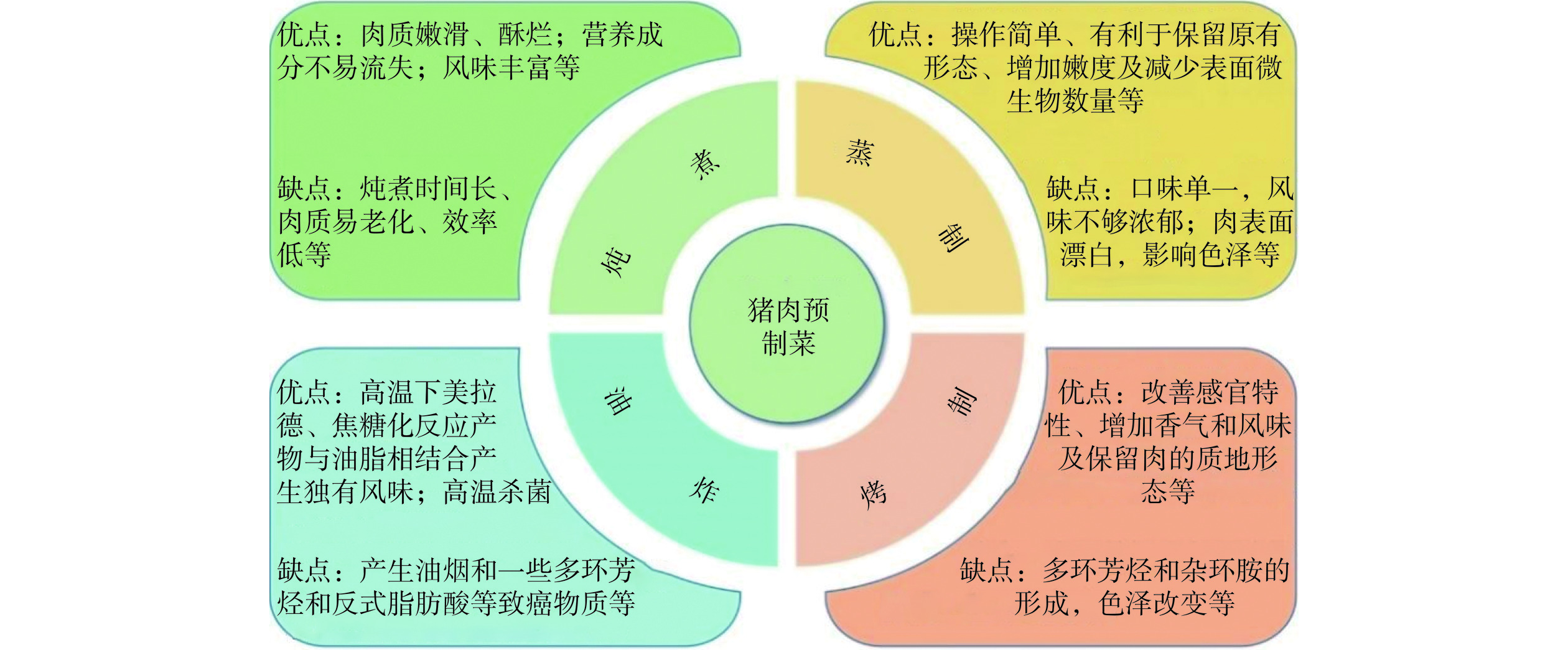

猪肉预制菜的热加工可以赋予制品特殊口感和风味,同时杀灭微生物、灭活抗营养酶和提高消化率等[36−37]。常见的热加工工艺包括炖煮、蒸制、油炸和烤制,不同热加工工艺及其特点存在显著差异(图2)[38]。许雪萍等[39]研究蒸制、煮制、微波和烤制等方式对猪肉的影响,热加工处理后脂质氧化程度均提高,以烤制提高最明显,同时挥发性成分也存在差异,蒸制总醇含量最高,微波和烤制产生的吡嗪类物质及烃类高于其他两种方式。昝博文等[40]发现煮、蒸、炸和炒4种热加工方式均使调理里脊肉的失重率和质构特性升高,但蒸制在湿热加工中失重率较低,咀嚼性高,炒制的失重率为炸制的50%左右,硬度和咀嚼性低。在新型食品加工技术的基础上,结合真空和超高压用于制作猪肉预制菜可降低产品热处理的温度,低温热处理具有降低食品营养损失、抑制异味生成、保留原始风味和降低好氧菌生长等优点[41]。昝博文[38]对比4种蒸煮方式对猪肉预制菜特性的影响,相比于其他3种蒸煮方式,低温真空长时蒸煮使烹饪损失率降低3.56%~8.23%,检测到挥发性风味物质最多为30种。

2.4 复热技术

猪肉预制菜在食用前需要进行复热,常见的复热方式包括:水煮复热、蒸汽复热、油炸复热、烘烤复热及微波复热等,常见的猪肉预制菜复热技术见表3。不同复热方式和工艺的选择,会影响猪肉预制菜的口感和风味,复热不均匀使某些部位未熟化,降低食用品质的同时增加安全风险[42−43]。复热过度则会导致预制菜得率降低、持水力下降、影响色泽及嫩度等。某些冷冻肉类预制菜在复热过程中会产生一种过熟味,这种特殊的异味是由细胞膜磷脂所产生的[44]。因此,不同类型的猪肉预制菜应采用合适的复热方式,适度的复热功率和时间是保证在不过度加热的前提下,使其达到合适的温度,同时保持预制菜的质地和口感。相同复热工艺对不同热加工得到猪肉预制菜品质的影响也有差异,煮制、微波和煎炸等方式得到的猪肉预制菜通过微波复热,提高了煮制猪肉和微波猪肉的色泽,而对煎炸猪肉影响较小[45]。

表 3 猪肉预制菜复热技术Table 3. Reheating technology of pre-made pork dishes产品 复热工艺 效果 参考文献 猪肉串 煎炸复热 随着温度升高和油炸处理量增加,产品的过氧化值和苯并芘含量显著增加 [46] 佛跳墙 水浴复热、微波复热、蒸汽复热 降低了汤汁中的游离氨基酸和5’-核苷酸含量,蒸汽复热后产品的感官评分最高 [47] 回锅肉 微波复热 确定最佳复热工艺,感官品质提高 [48] 猪肉饼 微波复热 适度微波复热可以降低预制猪肉饼的过熟味关键风味因子含量,改善产品的风味品质 [49] 鱼浆猪肉复合凝胶 油炸复热、蒸汽复热 提高鱼浆猪肉复合凝胶的破断强度、凹陷深度和持水性,降低鱼浆猪肉复合凝胶的含水量 [50] 黑豆豆腐肉丸 微波复热及油炸复热 微波复热的黑豆豆腐肉丸感官评分、硬度、胶黏性、咀嚼性、水分含量及出品率均比油炸复热高 [51] 烧白 水煮、微波及蒸汽 复热后挥发性物质相对含量增加,与复热前相比,微波复热后特征风味物质含量增加18种,

蒸汽复热后增加5种,且微波复热后烧白感官评价最高为81.10(总分100)[52] 糖醋排骨 水煮、微波及蒸汽 复热均会使糖醋排骨色泽变暗、保水性降低和嫩度下降,同时使特征性风味物质种类和含量损失,其中水煮复热对品质和风味物质影响较小 [53] 冷冻猪肉丸 水煮、微波及蒸汽 在3种复热方式中,蒸汽复热后其硬度最小、弹性最高和肌肉品质最好 [54] 红烧肉 微波复热 最佳复热参数为微波功率为720 W,加热60 s,此时红烧肉的出品率、水分含量、

嫩度和感官品质最佳[55] 滑肉 水煮、蒸汽及微波 复热后,鲜味氨基酸含量升高、苦味和甜味氨基酸含量降低;除蒸汽复热外,

其余复热方式使风味物质相对含量降低[56] 3. 猪肉预制菜质量控制技术

3.1 贮藏保鲜技术

猪肉预制菜在加工贮藏过程发生的品质劣变主要是由于微生物生长及蛋白和脂质氧化,相关变化会影响其品质[57]。为延长保质期并保持良好的品质,目前常采用低温贮藏、特殊包装及添加保鲜剂等方式进行贮藏保鲜。不同贮藏方式对猪肉预制菜的品质和货架期影响较大,因此需根据其特点选择合适的贮藏方式[34]。微冻处理预制猪肉后,其保质期可达28 d,且在7~21 d内可较好地保证其品质,优于冷藏和冷冻[38]。风冷冷冻和浸渍冷冻后的调理猪肉分别贮藏在−5 ℃和−18 ℃,除保水性外,浸渍冷冻后的调理猪肉品质较佳,但要根据贮藏期长短选择合适的贮藏温度[58]。低温气调包装是将产品密封在含有特殊气体环境中,控制温度在0 ℃以下、冰点以上的贮藏技术,合适的气体比例是延长保质期的关键[59]。50% CO2+50% N2组合对乳酸菌和肠杆菌等腐败菌抑制效果最强,有利于预调理荠菜猪肉馅贮藏[60]。此外,在预制菜制品中添加具有抗菌性和抗氧化性的保鲜剂,可以抑制微生物生长,延长货架期[61]。在猪肉肠中添加食用菌粉不仅可以丰富猪肉肠风味而且可以延长保质期[62]。向预调理白肉中添加复合保鲜剂可以将其保质期由3 d延长至8 d[63]。罗薇[64]优化了复合保鲜配方,当乳酸链球菌素为0.045%、茶多酚为0.015%和葡萄籽油为0.5%时,预调理烧烤五花肉在0~4 ℃条件下的货架期由6 d延长至12 d。在调理猪肉饼中添加柠檬精油纳米乳液,可改善产品质构特性,抑制大肠杆菌等腐败菌的繁殖[65]。综合低温贮藏,添加保鲜剂并结合真空包装的贮藏保鲜技术,可以使预调理猪肉馅保质期达18 d以上[66]。预制菜对新鲜度的要求促进贮藏保鲜技术的发展与应用,但目前大部分猪肉预制菜仍采用冷冻贮藏。近年来,超声波辅助冷冻和电场辅助低温贮藏等新型低温贮藏技术逐步应用于预制菜贮藏中并改善了其品质。

3.2 保水技术

在冻结、冷藏、解冻和加工等过程中,猪肉预制菜的持水能力会发生变化,表现为保水性能的高低。保水性与预制菜制品的色泽、嫩度和出品率紧密相关,常通过添加磷酸盐、外源蛋白质、山梨醇、膳食纤维等辅料提高肉制品的保水性[67−68]。多聚磷酸盐添加到肉糜中,通过限制水分流动提高保水性,当与食盐共同作用时,蒸煮损失率低于2%[69]。向预调理猪肉丸中添加山梨醇,添加量为10%时,滴液损失、解冻损失和蒸煮损失分别降低2.48%、1.36%和7.49%,且对猪肉丸风味影响不显著[70]。腌制猪肉中添加肌原纤维蛋白,水分含量增加了1.9%~2.04%[71]。法兰克福香肠中海藻膳食纤维添加量从0.25%增加到1.25%,香肠的蒸煮损失降低19.56%~37.18%[72]。此外,不同类型保水剂复合使用后可发挥协同作用,由1.8%海藻糖、3.3%山梨醇和0.5%柠檬酸钠组成的复合保水剂,使腌制后冷冻调理猪里脊解冻后质量增加率为7.78%[73]。因此,保水剂的应用可以减少某些猪肉预制菜在复热过程中品质的损失,但也要注意保水剂种类及添加浓度,避免产生不利影响。

3.3 亚硝酸盐含量控制技术

亚硝酸钠作为防腐剂和着色剂赋予制品特殊的色泽和风味,同时有利于延长产品保质期[74−75]。GB 2760-2014规定肉制品生产中使用亚硝酸盐最高限量为150 mg/kg,成品残留量低于30 mg/kg[76−78]。猪肉类预制菜中亚硝酸盐的研究主要集中于亚硝酸盐代替技术或阻断亚硝酸盐的形成,相关技术涉及亚硝酸盐代替技术,包括添加植物提取物和/或抗氧化剂、乳酸菌发酵和添加天然腌制剂等技术;辐照技术和非热等离子体技术等[74],未来研究重点将偏向于亚硝酸盐降解技术,主要包括生物降解、亚硝酸盐还原和催化氧化等方法。常见的亚硝酸盐含量控制技术实例见表4。

表 4 猪肉预制菜亚硝酸盐控制技术Table 4. Nitrite control technology of pre-made pork dishes方法 产品 效果 参考文献 添加植物复合物粉和沙克乳杆菌、弯曲乳杆菌、肉葡萄球菌和木糖葡萄球菌 萨拉米香肠 添加植物复合物粉末后,香肠的pH下降;具有抗氧化能力,抑制脂质和

蛋白质氧化[79] 添加萝卜提取物和肉葡萄球菌 火腿 萝卜提取物具有高硝酸盐含量和大量抗氧化剂,添加萝卜提取物的火腿

具有与腌制火腿类似的色泽,表明其具有作为亚硝酸钠的天然替代品的

可行性[80] 添加白萝卜粉和木糖葡萄球菌、肉糖葡萄球菌、戊糖片球菌、乳酸片球菌 猪肉发酵干香肠 添加白萝卜粉可以抑制蛋白质分解和乳酸菌繁殖,白萝卜粉为0.5%时对香肠感官质量影响最佳,但抗氧化能力低于添加亚硝酸盐组,所以白萝卜粉可作为代替亚硝酸盐的一种策略 [81] 添加复合果蔬浆和木糖葡萄球菌、

肉葡萄球菌及清酒乳杆菌发酵香肠 果蔬发酵香肠成品的亚硝酸盐残留量低于国家标准(30 mg/kg),同时生物胺和N-亚硝胺含量均低于对照组,表明果蔬浆可部分代替亚硝酸盐 [82] 添加竹叶、迷迭香、留兰香和甘草的

提取物及茶多酚调理乳化肠 竹叶提取物的护色作用和抗氧化效果最佳,显著优于0.010%亚硝酸钠;0.012%~0.030%茶多酚与0.030%~0.040%竹叶提取物的抗氧化活性均显著优于0.020%异抗坏血酸钠 [83] 添加异抗坏血酸钠、红曲色素及乳酸链球菌素 腊肠 亚硝酸盐替代物的最佳复配组合为0.065%异抗坏血酸钠,0.15%红曲色素,0.06%乳酸链球菌素和0.004%亚硝酸钠,与添加0.009%亚硝酸钠制作的

腊肠感官品质相近,可以降低亚硝酸钠使用量[84] 橄榄叶提取物 猪肉香肠 橄榄叶提取物的添加可以降低亚硝酸盐的残留量 [85] 茶黄素和茶多酚 腌制香肠 添加茶黄素和茶多酚可使亚硝酸盐残留量从89.14 mg/kg分别降低至

76.77 mg/kg和80.35 mg/kg,其机制是通过抑制亚铁肌红蛋白氧化为

铁肌红蛋白来减少亚硝酸盐残留量[86] 甜菜根提取物 香肠 含有500 ppm ε-聚赖氨酸和1%的甜菜根提取物的香肠在贮藏期间亚硝酸盐残留量最低 [87] 黑加仑叶提取物 猪肉罐头 添加150 mg/kg黑加仑叶提取物可有效降低脂肪氧化,亚硝酸盐的添加量

减少50 mg/kg[88] 芹菜粉 腌制猪肉 芹菜粉代替亚硝酸盐添加腌肉中,可降低亚硝酸盐残留量,添加0.3%芹菜粉腌肉30 d时亚硝酸盐残留量为7.46 mg/kg,比对照组降低53.58% [80] γ射线照射 如皋火腿 5 kGy γ辐照降低了如皋火腿中的亚硝酸盐残留,辐照后第55 d亚硝酸盐含量比对照低25.92%,第135 d后比对照低69.67% [89] γ射线照射 冷藏香肠 5 kGy γ辐照使香肠中亚硝酸盐残留量降低8.5%~16.65%,添加乳酸钠结合γ辐照更有利于降低亚硝酸盐残留量 [90] 常压非热等离子体处理 腌制火腿 非热等离子体固化的火腿残余亚硝酸盐含量较高,贮藏过程中残余亚硝酸盐含量下降较快 [91] 冷等离子体处理磷酸盐溶液 烟熏香肠 冷等离子体处理的磷酸盐溶液,结合30%~70%的亚硝酸钠,使烟熏香肠中亚硝酸盐残留量显著低于亚硝酸盐处理组 [92] 常压冷等离子体处理植物蛋白制剂溶液 猪肉香肠 常压冷等离子体活化大豆或豌豆蛋白制剂溶液可延长猪肉香肠的货架期,可作为亚硝酸钠的合适替代品 [93] 冷等离子体水用于腌制 腌制火腿 冷等离子体水处理的腌制火腿具有与传统火腿相同的感官质量,但是亚硝酸盐残留量降低了39.38%~49.17% [94] 低温等离子体处理磷酸盐 烟熏中式香肠 低温等离子体处理磷酸盐溶液添加到香肠中可以抑制脂肪氧化,与亚硝酸盐处理香肠相比,亚硝酸盐残留量降低61.47% [95] 高静水压技术 伊比利亚干腌猪肉 高静水压处理可以将亚硝酸盐的添加量从75 mg/kg减少到37.5 mg/kg,同时对制品色泽、蛋白质和脂质氧化没有影响 [96] 高压和添加醋处理 乳化型香肠 高压(500 MPa,12 min)和添加醋(1%)联合处理对产气荚膜梭菌的抑制

作用与单独使用亚硝酸钠相似[97] 4. 小结与展望

我国预制菜产业发展迅猛,猪肉预制菜作为占比最大的畜禽类预制菜中主要组成部分,未来具有很大的发展空间及潜力。但是也存在一些亟需解决的问题:一是原料来源差异,猪肉预制菜品质和风味存在不稳定状态;二是加工技术以传统加工为主,容易造成营养损失和产生异味物质;三是相关标准不完善,原料采集、生产和流通过程缺少监管。预制菜市场的发展促使产品的营养、品质和质量安全的提升以及相关标准的制定,需要从原料品质控制、加工技术提升和质量控制等方面进行研究与开发,创新猪肉预制菜系列产品。

营养保持及控制技术的发展使猪肉预制菜在保证品质和风味的基础上,降低加工过程油脂和食用盐的用量,增加蔬菜和谷类含量,提高产品营养价值。计算机技术、3D打印技术、人工智能技术和工业4.0等新技术的发展,有利于提高预制菜产品的口感,延长产品保质期,提高生产效率,推动产业实现提质增效。

-

表 1 猪肉预制菜腌制技术

Table 1 Salting technology of pre-made pork dishes

腌制技术 工艺参数 机理及效果 参考文献 湿腌 腌制7 h和12 h 腌制液在传质过程中引起了肌肉功能特性的变化,改变猪肉蛋白质的热稳定性,改善了质地及保藏性能 [21] 滚揉腌制 滚揉时间8 h、滚揉机转速11 r/min和腌制液添加量35% 调理猪排剪切应力最低为12.46 N,嫩度最好 [22] 超声波辅助腌制 超声功率260 W、超声时间60 min 汁液流失和水分流失较传统腌制分别减少48.34%和58.21%,且乳化稳定性最好 [23] 静态变压腌制 -70 kpa-常压-160 kPa-常压循环交替;真空时间20 min,常压时间10 min,加压时间20 min,常压时间10 min下

循环进行腌制效率和保水性提高,剪切力、硬度、弹性和胶黏性较低,且改善了嫩度和色泽 [17] 表 2 猪肉预制菜嫩化技术

Table 2 Tenderization technology of pre-made pork dishes

嫩化技术 工艺参数 机理及效果 参考文献 腌制 滚揉时间8 h、滚揉机转速11 r/min和腌制液添加量35% 剪切应力最低为12.46 N,嫩度最好 [22] 木瓜蛋白酶 300 U/g 适当降解调理猪排的蛋白质,改善其嫩度和提高

其保水性[31] 木瓜蛋白酶 酶添加量为340.0 U/g、嫩化时间15 min和嫩化

温度49 ℃调理猪排嫩度适宜,剪切应力2.48 kg,感官评价为90.14(总分100) [32] 超声波 超声时间99.9 min、功率为147 W、频率为35.3 kHz 降低小酥肉的剪切力、硬度和咀嚼性,增加了

小酥肉的嫩度[33] 超声辅助无花果叶蛋白酶 超声功率240 W、超声时间5 min、无花果叶蛋白酶

复合嫩化剂用量4.0 g/100 g肉样、嫩化温度50 ℃、

嫩化时间60 min、pH7.5猪脯肉的剪切应力为29.8 N,感官分析其硬度、嫩度和咀嚼性较好,感官得分为39.2(总分40) [34] 低温预热和传统烹饪结合 传统高温加热结合在50 ℃预热35 min或者在

60 ℃预热5/20 min降低了猪肉块的剪切应力,提高了其持水力,

改善了其嫩度[35] 表 3 猪肉预制菜复热技术

Table 3 Reheating technology of pre-made pork dishes

产品 复热工艺 效果 参考文献 猪肉串 煎炸复热 随着温度升高和油炸处理量增加,产品的过氧化值和苯并芘含量显著增加 [46] 佛跳墙 水浴复热、微波复热、蒸汽复热 降低了汤汁中的游离氨基酸和5’-核苷酸含量,蒸汽复热后产品的感官评分最高 [47] 回锅肉 微波复热 确定最佳复热工艺,感官品质提高 [48] 猪肉饼 微波复热 适度微波复热可以降低预制猪肉饼的过熟味关键风味因子含量,改善产品的风味品质 [49] 鱼浆猪肉复合凝胶 油炸复热、蒸汽复热 提高鱼浆猪肉复合凝胶的破断强度、凹陷深度和持水性,降低鱼浆猪肉复合凝胶的含水量 [50] 黑豆豆腐肉丸 微波复热及油炸复热 微波复热的黑豆豆腐肉丸感官评分、硬度、胶黏性、咀嚼性、水分含量及出品率均比油炸复热高 [51] 烧白 水煮、微波及蒸汽 复热后挥发性物质相对含量增加,与复热前相比,微波复热后特征风味物质含量增加18种,

蒸汽复热后增加5种,且微波复热后烧白感官评价最高为81.10(总分100)[52] 糖醋排骨 水煮、微波及蒸汽 复热均会使糖醋排骨色泽变暗、保水性降低和嫩度下降,同时使特征性风味物质种类和含量损失,其中水煮复热对品质和风味物质影响较小 [53] 冷冻猪肉丸 水煮、微波及蒸汽 在3种复热方式中,蒸汽复热后其硬度最小、弹性最高和肌肉品质最好 [54] 红烧肉 微波复热 最佳复热参数为微波功率为720 W,加热60 s,此时红烧肉的出品率、水分含量、

嫩度和感官品质最佳[55] 滑肉 水煮、蒸汽及微波 复热后,鲜味氨基酸含量升高、苦味和甜味氨基酸含量降低;除蒸汽复热外,

其余复热方式使风味物质相对含量降低[56] 表 4 猪肉预制菜亚硝酸盐控制技术

Table 4 Nitrite control technology of pre-made pork dishes

方法 产品 效果 参考文献 添加植物复合物粉和沙克乳杆菌、弯曲乳杆菌、肉葡萄球菌和木糖葡萄球菌 萨拉米香肠 添加植物复合物粉末后,香肠的pH下降;具有抗氧化能力,抑制脂质和

蛋白质氧化[79] 添加萝卜提取物和肉葡萄球菌 火腿 萝卜提取物具有高硝酸盐含量和大量抗氧化剂,添加萝卜提取物的火腿

具有与腌制火腿类似的色泽,表明其具有作为亚硝酸钠的天然替代品的

可行性[80] 添加白萝卜粉和木糖葡萄球菌、肉糖葡萄球菌、戊糖片球菌、乳酸片球菌 猪肉发酵干香肠 添加白萝卜粉可以抑制蛋白质分解和乳酸菌繁殖,白萝卜粉为0.5%时对香肠感官质量影响最佳,但抗氧化能力低于添加亚硝酸盐组,所以白萝卜粉可作为代替亚硝酸盐的一种策略 [81] 添加复合果蔬浆和木糖葡萄球菌、

肉葡萄球菌及清酒乳杆菌发酵香肠 果蔬发酵香肠成品的亚硝酸盐残留量低于国家标准(30 mg/kg),同时生物胺和N-亚硝胺含量均低于对照组,表明果蔬浆可部分代替亚硝酸盐 [82] 添加竹叶、迷迭香、留兰香和甘草的

提取物及茶多酚调理乳化肠 竹叶提取物的护色作用和抗氧化效果最佳,显著优于0.010%亚硝酸钠;0.012%~0.030%茶多酚与0.030%~0.040%竹叶提取物的抗氧化活性均显著优于0.020%异抗坏血酸钠 [83] 添加异抗坏血酸钠、红曲色素及乳酸链球菌素 腊肠 亚硝酸盐替代物的最佳复配组合为0.065%异抗坏血酸钠,0.15%红曲色素,0.06%乳酸链球菌素和0.004%亚硝酸钠,与添加0.009%亚硝酸钠制作的

腊肠感官品质相近,可以降低亚硝酸钠使用量[84] 橄榄叶提取物 猪肉香肠 橄榄叶提取物的添加可以降低亚硝酸盐的残留量 [85] 茶黄素和茶多酚 腌制香肠 添加茶黄素和茶多酚可使亚硝酸盐残留量从89.14 mg/kg分别降低至

76.77 mg/kg和80.35 mg/kg,其机制是通过抑制亚铁肌红蛋白氧化为

铁肌红蛋白来减少亚硝酸盐残留量[86] 甜菜根提取物 香肠 含有500 ppm ε-聚赖氨酸和1%的甜菜根提取物的香肠在贮藏期间亚硝酸盐残留量最低 [87] 黑加仑叶提取物 猪肉罐头 添加150 mg/kg黑加仑叶提取物可有效降低脂肪氧化,亚硝酸盐的添加量

减少50 mg/kg[88] 芹菜粉 腌制猪肉 芹菜粉代替亚硝酸盐添加腌肉中,可降低亚硝酸盐残留量,添加0.3%芹菜粉腌肉30 d时亚硝酸盐残留量为7.46 mg/kg,比对照组降低53.58% [80] γ射线照射 如皋火腿 5 kGy γ辐照降低了如皋火腿中的亚硝酸盐残留,辐照后第55 d亚硝酸盐含量比对照低25.92%,第135 d后比对照低69.67% [89] γ射线照射 冷藏香肠 5 kGy γ辐照使香肠中亚硝酸盐残留量降低8.5%~16.65%,添加乳酸钠结合γ辐照更有利于降低亚硝酸盐残留量 [90] 常压非热等离子体处理 腌制火腿 非热等离子体固化的火腿残余亚硝酸盐含量较高,贮藏过程中残余亚硝酸盐含量下降较快 [91] 冷等离子体处理磷酸盐溶液 烟熏香肠 冷等离子体处理的磷酸盐溶液,结合30%~70%的亚硝酸钠,使烟熏香肠中亚硝酸盐残留量显著低于亚硝酸盐处理组 [92] 常压冷等离子体处理植物蛋白制剂溶液 猪肉香肠 常压冷等离子体活化大豆或豌豆蛋白制剂溶液可延长猪肉香肠的货架期,可作为亚硝酸钠的合适替代品 [93] 冷等离子体水用于腌制 腌制火腿 冷等离子体水处理的腌制火腿具有与传统火腿相同的感官质量,但是亚硝酸盐残留量降低了39.38%~49.17% [94] 低温等离子体处理磷酸盐 烟熏中式香肠 低温等离子体处理磷酸盐溶液添加到香肠中可以抑制脂肪氧化,与亚硝酸盐处理香肠相比,亚硝酸盐残留量降低61.47% [95] 高静水压技术 伊比利亚干腌猪肉 高静水压处理可以将亚硝酸盐的添加量从75 mg/kg减少到37.5 mg/kg,同时对制品色泽、蛋白质和脂质氧化没有影响 [96] 高压和添加醋处理 乳化型香肠 高压(500 MPa,12 min)和添加醋(1%)联合处理对产气荚膜梭菌的抑制

作用与单独使用亚硝酸钠相似[97] -

[1] YI B, XU H Y. Research and development status of prepared foods in China:A review[J]. Applied Sciences,2023,13(14):7998. doi: 10.3390/app13147998

[2] XIONG Y L, LIN X X, WEN X W, et al. The analysis of residents' intention to consume pre-made dishes in China:A grounded theory[J]. Foods,2023,12(20):3798. doi: 10.3390/foods12203798

[3] 王静香, 张忠明, 李纪岳, 等. 我国预制菜产业发展特点与趋势预判[J]. 粮油食品科技,2024,32(1):193−200. [WANG J X, ZHANG Z M, LI J Y, et al. Development characteristics and trend prediction of prefabricated dishes industry in China[J]. Science and Technology of Cereals, Oils and Foods,2024,32(1):193−200.] WANG J X, ZHANG Z M, LI J Y, et al. Development characteristics and trend prediction of prefabricated dishes industry in China[J]. Science and Technology of Cereals, Oils and Foods, 2024, 32(1): 193−200.

[4] 赵超凡, 陈树俊, 李文兵, 等. 预制菜产业发展问题分析[J]. 现代食品科技,2023,39(2):104−109. [ZHAO C F, CHEN S J, LI W B, et al. Analysis of issues in the development of the prepared dishes sector[J]. Modern Food Science and Technology,2023,39(2):104−109.] ZHAO C F, CHEN S J, LI W B, et al. Analysis of issues in the development of the prepared dishes sector[J]. Modern Food Science and Technology, 2023, 39(2): 104−109.

[5] 郭双霜, 朱春, 刘海璐, 等. 肉类预制菜全产业链质量安全控制技术研究进展[J]. 肉类研究,2023,37(12):61−68. [GUO S S, ZHU C, LIU H L, et al. Research progress on quality and safety control technologies for the whole industry chain of precooked meat dishes[J]. Meat Research,2023,37(12):61−68.] GUO S S, ZHU C, LIU H L, et al. Research progress on quality and safety control technologies for the whole industry chain of precooked meat dishes[J]. Meat Research, 2023, 37(12): 61−68.

[6] 刘小红, 陈瑶生. 2022年生猪产业发展状况、未来发展趋势与建议[J]. 中国畜牧杂志,2023,59(3):264−268. [LIU X H, CHEN Y S. Development status, future trends, and recommendations for the swine industry in 2022[J]. Chinese Journal of Animal Science,2023,59(3):264−268.] LIU X H, CHEN Y S. Development status, future trends, and recommendations for the swine industry in 2022[J]. Chinese Journal of Animal Science, 2023, 59(3): 264−268.

[7] 曾璐瑶, 王海滨, 廖鄂, 等. 畜禽类预制菜加工技术研究进展[J]. 食品工业科技,2023,44(7):490−499. [ZENG L Y, WANG H B, LIAO E, et al. Processing technology progress on prepared dishes of livestock and poultry[J]. Science and Technology of Food Industry,2023,44(7):490−499.] ZENG L Y, WANG H B, LIAO E, et al. Processing technology progress on prepared dishes of livestock and poultry[J]. Science and Technology of Food Industry, 2023, 44(7): 490−499.

[8] 杨铭铎, 张瑛, 崔莹莹, 等. 调理食品内涵及其研究进展[J]. 中国调味品,2022,47(3):211−216. [YANG M D, ZHANG Y, CUI Y Y, et al. The connotation and research progress of prepared food[J]. China Condiment,2022,47(3):211−216.] doi: 10.3969/j.issn.1000-9973.2022.03.042 YANG M D, ZHANG Y, CUI Y Y, et al. The connotation and research progress of prepared food[J]. China Condiment, 2022, 47(3): 211−216. doi: 10.3969/j.issn.1000-9973.2022.03.042

[9] 张晨, 严鹏伟, 杨诗奇. 猪肉的营养价值及加工利用的研究进展[J]. 食品安全导刊,2019(12):130. [ZHANG C, YAN P W, YANG S Q. Research progress on the nutritional value and processing utilization of pork[J]. China Food Safety Magazine,2019(12):130.] ZHANG C, YAN P W, YANG S Q. Research progress on the nutritional value and processing utilization of pork[J]. China Food Safety Magazine, 2019(12): 130.

[10] 程志斌, 葛长荣, 李德发. 浅谈猪肉的营养价值[J]. 肉类工业,2005(5):34−40. [CHEN Z B, GE C R, LI D F. A brief discussion on the nutritional value of pork[J]. Meat Industry,2005(5):34−40.] doi: 10.3969/j.issn.1008-5467.2005.05.016 CHEN Z B, GE C R, LI D F. A brief discussion on the nutritional value of pork[J]. Meat Industry, 2005(5): 34−40. doi: 10.3969/j.issn.1008-5467.2005.05.016

[11] YI W, HUANG Q, WANG Y, et al. Lipo-nutritional quality of pork:The lipid composition, regulation, and molecular mechanisms of fatty acid deposition[J]. Animal Nutrition,2023,13:373−385. doi: 10.1016/j.aninu.2023.03.001

[12] SUN T T, WANG X C, CONG P X, et al. Mass spectrometry-based lipidomics in food science and nutritional health:A comprehensive review[J]. Comprehensive Reviews in Food Science and Food Safety,2020,19(5):2530−2558. doi: 10.1111/1541-4337.12603

[13] 李诚. 猪肉的分级、分割及分割肉加工[J]. 肉类工业,2003(3):5−7. [LI C. The grading, cutting and processing of pork[J]. Meat Industry,2003(3):5−7.] doi: 10.3969/j.issn.1008-5467.2003.03.003 LI C. The grading, cutting and processing of pork[J]. Meat Industry, 2003(3): 5−7. doi: 10.3969/j.issn.1008-5467.2003.03.003

[14] 猪肉不同部位的吃法[J]. 北京农业, 2011(31):49. [Different ways of eating different parts of pork[J]. Beijing Agriculture, 2011(31):49.] Different ways of eating different parts of pork[J]. Beijing Agriculture, 2011(31): 49.

[15] 田慧颖, 张国华, 贾如. 不同猪肉的营养成分与食用品质分析[J]. 山西农业科学,2022,50(11):1583−1590. [TIAN H Y, ZHANG G H, JIA R. Analysis of nutritional composition and edible quality of different pork[J]. Journal of Shanxi Agricultural Sciences,2022,50(11):1583−1590.] TIAN H Y, ZHANG G H, JIA R. Analysis of nutritional composition and edible quality of different pork[J]. Journal of Shanxi Agricultural Sciences, 2022, 50(11): 1583−1590.

[16] 宋玉, 郑健, 黄峰, 等. 不同腌制方式对煮制猪肉品质、组织形态和蛋白结构的影响[J]. 食品工业科技,2022,43(23):103−111. [SONG Y, ZHENG J, HUANG F, et al. Effects of different salting methods on the quality traits, histomorphology and protein structure of cooked pork steaks[J]. Science and Technology of Food Industry,2022,43(23):103−111.] SONG Y, ZHENG J, HUANG F, et al. Effects of different salting methods on the quality traits, histomorphology and protein structure of cooked pork steaks[J]. Science and Technology of Food Industry, 2022, 43(23): 103−111.

[17] 郭昕, 黄峰, 张春江, 等. 静态变压腌制技术对猪肉品质的影响[J]. 中国农业科学,2015,48(11):2229−2240. [GUO X, HUANG F, ZHANG C J, et al. Effects of pressure varied static brining on pork quality[J]. Scientia Agricultura Sinica,2015,48(11):2229−2240.] doi: 10.3864/j.issn.0578-1752.2015.11.014 GUO X, HUANG F, ZHANG C J, et al. Effects of pressure varied static brining on pork quality[J]. Scientia Agricultura Sinica, 2015, 48(11): 2229−2240. doi: 10.3864/j.issn.0578-1752.2015.11.014

[18] CONTRERAS-LOPEZ G, CARNERO-HERNANDEZ A, HUERTAJIMENEZ M, et al. High-intensity ultrasound applied on cured pork:Sensory and physicochemical characteristics[J]. Food Science and Nutrition,2020,8(2):786−795. doi: 10.1002/fsn3.1321

[19] 张立彦, 熊玲. 真空腌制条件对猪肉食盐渗透规律及品质变化的影响[J]. 现代食品科技,2013,29(11):2595−2600. [ZHANG L Y, XIONG L. Effect of vacuum pickling on salt osmotic dehydration and quality changes of pork[J]. Modern Food Science and Technology,2013,29(11):2595−2600.] ZHANG L Y, XIONG L. Effect of vacuum pickling on salt osmotic dehydration and quality changes of pork[J]. Modern Food Science and Technology, 2013, 29(11): 2595−2600.

[20] 唐雪燕, 任丽影, 王丽莎, 等. 不同腌制方式对猪肉品质的影响[J]. 食品研究与开发,2016,37(23):114−119. [TANG X Y, REN L Y, WANG L S, et al. Effect of different curing processing on quality of pork[J]. Food Research and Development,2016,37(23):114−119.] doi: 10.3969/j.issn.1005-6521.2016.23.027 TANG X Y, REN L Y, WANG L S, et al. Effect of different curing processing on quality of pork[J]. Food Research and Development, 2016, 37(23): 114−119. doi: 10.3969/j.issn.1005-6521.2016.23.027

[21] 王引兰, 王恒鹏, 饶胜其. 不同腌制时间对调理猪肉干品质特性的影响[J]. 食品与发酵工业,2021,47(16):219−225. [WANG Y L, WANG H P, RAO S Q. Effects of different pickling time on the quality of conditioned pork jerky[J]. Food and Fermentation Industries,2021,47(16):219−225.] WANG Y L, WANG H P, RAO S Q. Effects of different pickling time on the quality of conditioned pork jerky[J]. Food and Fermentation Industries, 2021, 47(16): 219−225.

[22] 高天, 李蛟龙, 张林, 等. 调理猪排制品滚揉腌制工艺的优化[J]. 食品工业科技,2015,36(12):211−215. [GAO T, LI J L, ZHANG L, et al. Optimization of tumbling marinade conditions for prepared pork chops[J]. Science and Technology of Food Industry,2015,36(12):211−215.] GAO T, LI J L, ZHANG L, et al. Optimization of tumbling marinade conditions for prepared pork chops[J]. Science and Technology of Food Industry, 2015, 36(12): 211−215.

[23] 李心悦, 曹涓泉, 徐静, 等. 超声波辅助腌制对猪肉糜食用品质及凝胶性能的影响[J]. 肉类研究,2022,36(8):21−28. [LI X Y, CAO J Q, XU J, et al. Effects of ultrasonic-assisted curing on eating quality and gel properties of minced pork[J]. Meat Research,2022,36(8):21−28.] LI X Y, CAO J Q, XU J, et al. Effects of ultrasonic-assisted curing on eating quality and gel properties of minced pork[J]. Meat Research, 2022, 36(8): 21−28.

[24] WARNER R, MILLER R, HA M, et al. Meat tenderness:Underlying mechanisms, instrumental measurement, and sensory assessment[J]. Meat and Muscle Biology,2021,4(2):17−25.

[25] BANACH J K, MODZELEWSKA-KAPITULA M, WICHMAN K, et al. Effects of electrical stimulation applied in combination with shock chilling method on selected quality attributes of beef from young bulls, heifers, and cows carcasses[J]. Journal of Food Processing and Preservation,2018,42(4):e13571. doi: 10.1111/jfpp.13571

[26] 包玉龙, 徐万军, 贾世亮, 等. 肉类嫩度形成机理及嫩化调控研究进展[J]. 肉类研究,2023,37(4):34−40. [BAO Y L, XU W J, JIA S L, et al. Theoretical aspects of meat tenderness and research progress on meat tenderization[J]. Meat Research,2023,37(4):34−40.] BAO Y L, XU W J, JIA S L, et al. Theoretical aspects of meat tenderness and research progress on meat tenderization[J]. Meat Research, 2023, 37(4): 34−40.

[27] RAWDKUEN S, JAIMAKREU M, BENJAKUL S. Physicochemical properties and tenderness of meat samples using proteolytic extract from Calotropis procera latex[J]. Food Chemistry,2013,136(2):909−916. doi: 10.1016/j.foodchem.2012.08.077

[28] BHAT Z F, MORTON J D, MASON S L, et al. Applied and emerging methods for meat tenderization:A comparative perspective[J]. Comprehensive Reviews in Food Science and Food Safety,2018,17(4):841−859. doi: 10.1111/1541-4337.12356

[29] ALARCON-ROJO A D, CARRILLO-LOPEZ L M, REYES-VILLAGRANA R, et al. Ultrasound and meat quality:A review[J]. Ultrasonics Sonochemistry,2019,55:369−382. doi: 10.1016/j.ultsonch.2018.09.016

[30] 邵建航, 昝林森. 超声波联合处理改善牛肉嫩度的研究进展[J]. 中国牛业科学,2019,45(6):59−61,90. [SHAO J H, ZAN L S. Advances in research on improving beef tenderness by ultrasonic combined treatment[J]. China Cattle Science,2019,45(6):59−61,90.] doi: 10.3969/j.issn.1001-9111.2019.06.017 SHAO J H, ZAN L S. Advances in research on improving beef tenderness by ultrasonic combined treatment[J]. China Cattle Science, 2019, 45(6): 59−61,90. doi: 10.3969/j.issn.1001-9111.2019.06.017

[31] 张豪, 高贞. 木瓜蛋白酶对调理猪排品质的影响[J]. 中国食品添加剂,2023,34(7):228−233. [ZHANG H, GAO Z. Effects of papain on the quality of pork chops[J]. China Food Additives,2023,34(7):228−233.] ZHANG H, GAO Z. Effects of papain on the quality of pork chops[J]. China Food Additives, 2023, 34(7): 228−233.

[32] 柳艳霞, 张豪, 赵莉君, 等. 木瓜蛋白酶嫩化调理猪排工艺条件的优化[J]. 现代食品科技,2018,34(8):172−179,23. [LIU Y X, ZHANG H, ZHAO L J, et al. Optimization for tenderization process of conditioning pork chop by papain[J]. Modern Food Science and Technology,2018,34(8):172−179,23.] LIU Y X, ZHANG H, ZHAO L J, et al. Optimization for tenderization process of conditioning pork chop by papain[J]. Modern Food Science and Technology, 2018, 34(8): 172−179,23.

[33] 龙锦鹏, 黄静, 邓楷, 等. 超声波嫩化对小酥肉品质的影响[J]. 食品与发酵科技,2019,55(5):29−34. [LONG J P, HUANG J, DENG K, et al. Effect of ultrasonic tenderization on the quality of braised pork cubes[J]. Food and Fermentation Technology,2019,55(5):29−34.] LONG J P, HUANG J, DENG K, et al. Effect of ultrasonic tenderization on the quality of braised pork cubes[J]. Food and Fermentation Technology, 2019, 55(5): 29−34.

[34] 唐福元, 刘晓庚, 毛匡奇, 等. 超声辅助无花果叶蛋白酶复合嫩化剂对猪脯肉嫩度的影响[J]. 食品科学,2017,38(12):204−210. [TANG F Y, LIU X G, MAO K Q, et al. Optimization of pork tenderization using ultrasound treatment combined with tenderizer combination[J]. Food Science,2017,38(12):204−210.] doi: 10.7506/spkx1002-6630-201712031 TANG F Y, LIU X G, MAO K Q, et al. Optimization of pork tenderization using ultrasound treatment combined with tenderizer combination[J]. Food Science, 2017, 38(12): 204−210. doi: 10.7506/spkx1002-6630-201712031

[35] YAO Y, WANG X, CUI H, et al. Improved tenderness and water retention of pork pieces and its underlying molecular mechanism through the combination of low-temperature preheating and traditional cooking[J]. Food Chemistry,2023,421:136137. doi: 10.1016/j.foodchem.2023.136137

[36] 杨天意, 周晓燕, 罗飞, 等. 烹饪加工对肉类品质和营养特性影响的研究进展[J]. 美食研究,2022,39(1):44−52. [YANG T Y, ZHOU X Y, LUO F, et al. Research advances in effect of cooking on meat quality and nutrition properties[J]. Journal of Researches on Dietetic Science and Culture,2022,39(1):44−52.] YANG T Y, ZHOU X Y, LUO F, et al. Research advances in effect of cooking on meat quality and nutrition properties[J]. Journal of Researches on Dietetic Science and Culture, 2022, 39(1): 44−52.

[37] MEADE S J, REID E A, GERRARD J A, et al. The impact of processing on the nutritional quality of food proteins[J]. Journal of AOAC International,2005,88(3):904−922. doi: 10.1093/jaoac/88.3.904

[38] 昝博文. 预制调理工艺对猪肉品质特性的影响研究[D]. 成都:成都大学, 2023. [ZAN B W. Study on the effects of prepared technology on pork quality[D]. Chengdu:Chengdu University, 2023.] ZAN B W. Study on the effects of prepared technology on pork quality[D]. Chengdu: Chengdu University, 2023.

[39] 许雪萍, 李静, 范亚苇, 等. 不同烹调方式对猪肉脂质氧化和挥发性风味物质的影响[J]. 食品工业,2019,40(1):151−155. [XU X P, LI J, FAN Y W, et al. Effects of different cooking methods on lipid oxidation and volatile flavor compounds in pork[J]. The Food Industry,2019,40(1):151−155.] XU X P, LI J, FAN Y W, et al. Effects of different cooking methods on lipid oxidation and volatile flavor compounds in pork[J]. The Food Industry, 2019, 40(1): 151−155.

[40] 昝博文, 白婷, 唐丽, 等. 热加工工艺对调理里脊肉色泽和质构特性的影响[J]. 中国调味品,2022,47(12):53−60. [ZAN B W, BAI T, TANG L, et al. Effect of thermal processing on color and texture properties of prepared tenderloin[J]. China Condiment,2022,47(12):53−60.] doi: 10.3969/j.issn.1000-9973.2022.12.010 ZAN B W, BAI T, TANG L, et al. Effect of thermal processing on color and texture properties of prepared tenderloin[J]. China Condiment, 2022, 47(12): 53−60. doi: 10.3969/j.issn.1000-9973.2022.12.010

[41] DOMINGUEZ-HERNANDEZ E, SALASEVICIENE A, ERTBJERG P. Low-temperature long-time cooking of meat:Eating quality and underlying mechanisms[J]. Meat Science,2018,143:104−113. doi: 10.1016/j.meatsci.2018.04.032

[42] 唐丽, 白婷, 王卫, 等. 复热方式对番茄里脊预制菜品质的影响[J]. 中国调味品,2024,49(2):69−78. [TANG L, BAI T, WANG W, et al. Effects of reheating methods on quality of prepared dishes with tomato and tenderloin[J]. China Condiment,2024,49(2):69−78.] doi: 10.3969/j.issn.1000-9973.2024.02.010 TANG L, BAI T, WANG W, et al. Effects of reheating methods on quality of prepared dishes with tomato and tenderloin[J]. China Condiment, 2024, 49(2): 69−78. doi: 10.3969/j.issn.1000-9973.2024.02.010

[43] 黎梓杭, 黄凯雯, 江伟烽, 等. 冷冻家禽类预制菜加工及复热技术研究进展[J]. 食品安全质量检测学报,2023,14(16):213−223. [LI Z H, HUANG K W, JIANG W F, et al. Advances in processing and reheating technologies for frozen prepared poultry foods[J]. Journal of Food Safety & Quality,2023,14(16):213−223.] LI Z H, HUANG K W, JIANG W F, et al. Advances in processing and reheating technologies for frozen prepared poultry foods[J]. Journal of Food Safety & Quality, 2023, 14(16): 213−223.

[44] LIU T T, YANG T S, WU C M. Changes of volatiles in soy sauce-stewed pork during cold storage and reheating[J]. Journal of the Science of Food and Agriculture,2001,81(15):1547−1552. doi: 10.1002/jsfa.978

[45] 王波, 谢安国, 康怀彬, 等. 微波复热对不同预制调理肉品的品质影响研究[J]. 食品研究与开发,2018,39(8):78−83. [WANG B, XIE A G, KANG H B, et al. Study on the effect of microwave reheating on the quality of meat prefabricated by different methods[J]. Food Research and Development,2018,39(8):78−83.] doi: 10.3969/j.issn.1005-6521.2018.08.014 WANG B, XIE A G, KANG H B, et al. Study on the effect of microwave reheating on the quality of meat prefabricated by different methods[J]. Food Research and Development, 2018, 39(8): 78−83. doi: 10.3969/j.issn.1005-6521.2018.08.014

[46] 叶韬, 王昆, 陈志娜, 等. 油炸调理肉串过程煎炸条件对大豆油苯并芘含量及理化指标的影响[J]. 中国粮油学报,2018,33(5):49−54. [YE T, WANG K, CHEN Z N, et al. The effect of frying conditions on the b (a) p content and physico-chemical properties of soybean oil during frying frozen kebabs[J]. Journal of the Chinese Cereals and Oils Association,2018,33(5):49−54.] doi: 10.3969/j.issn.1003-0174.2018.05.008 YE T, WANG K, CHEN Z N, et al. The effect of frying conditions on the b (a) p content and physico-chemical properties of soybean oil during frying frozen kebabs[J]. Journal of the Chinese Cereals and Oils Association, 2018, 33(5): 49−54. doi: 10.3969/j.issn.1003-0174.2018.05.008

[47] 胡琴, 黄旭辉, 祁立波, 等. 佛跳墙冷冻调理食品在不同复热方式下的品质变化[J]. 现代食品科技,2021,37(4):163−171. [HU Q, HUANG X H, QI L B, et al. Quality changes of frozen prepared Fotiaoqiang product reheated by different methods[J]. Modern Food Science and Technology,2021,37(4):163−171.] HU Q, HUANG X H, QI L B, et al. Quality changes of frozen prepared Fotiaoqiang product reheated by different methods[J]. Modern Food Science and Technology, 2021, 37(4): 163−171.

[48] 贾丽娜. 速冻调理回锅肉加工工艺及冻藏期间品质变化研究[D]. 无锡:江南大学, 2015. [JIA L N. Process technology of quick-frozen prepared double fired pork and quality change during frozen storage[D]. Wuxi:Jiangnan University, 2015.] JIA L N. Process technology of quick-frozen prepared double fired pork and quality change during frozen storage[D]. Wuxi: Jiangnan University, 2015.

[49] 张凯华, 臧明伍, 张哲奇, 等. 微波复热时间对预制猪肉饼过熟味、脂肪氧化和水分分布特性的影响[J]. 食品科学,2020,41(9):50−56. [ZHANG K H, ZANG M W, ZHANG Z Q, et al. Effect of microwave reheating time on warmed-over flavor, lipid oxidation and water distribution in precooked pork patties[J]. Food Science,2020,41(9):50−56.] doi: 10.7506/spkx1002-6630-20190816-173 ZHANG K H, ZANG M W, ZHANG Z Q, et al. Effect of microwave reheating time on warmed-over flavor, lipid oxidation and water distribution in precooked pork patties[J]. Food Science, 2020, 41(9): 50−56. doi: 10.7506/spkx1002-6630-20190816-173

[50] 路索, 刘曼曼, 秦瑞珂, 等. 油炸风味鱼浆猪肉复合凝胶制品复热方式的研究[J]. 华中农业大学学报,2020,39(6):82−87. [LU S, LIU M M, QIN R K, et al. Reheating methods of fried-flavor fish paste/pork composite gel[J]. Journal of Huazhong Agriculture University,2020,39(6):82−87.] LU S, LIU M M, QIN R K, et al. Reheating methods of fried-flavor fish paste/pork composite gel[J]. Journal of Huazhong Agriculture University, 2020, 39(6): 82−87.

[51] 冯爽, 张佳美, 陆家慧, 等. 复热方式对黑豆豆腐肉丸品质的影响[J]. 食品研究与开发,2023,44(7):53−59. [FENG S, ZHANG J M, LU J H, et al. Effect of reheating method on the quality of black bean curd meatballs[J]. Food Research and Development,2023,44(7):53−59.] doi: 10.12161/j.issn.1005-6521.2023.07.008 FENG S, ZHANG J M, LU J H, et al. Effect of reheating method on the quality of black bean curd meatballs[J]. Food Research and Development, 2023, 44(7): 53−59. doi: 10.12161/j.issn.1005-6521.2023.07.008

[52] 董平, 范文教, 朱开宪, 等. 不同复热方式对咸烧白风味的影响[J]. 食品科技,2023,48(2):122−129. [DONG P, FAN W J, ZHU K X, et al. Effect of different reheating methods on the flavor of salty streaky pork[J]. Food Science and Technology,2023,48(2):122−129.] DONG P, FAN W J, ZHU K X, et al. Effect of different reheating methods on the flavor of salty streaky pork[J]. Food Science and Technology, 2023, 48(2): 122−129.

[53] 赵颖颖, 李三影, 闫路辉, 等. 不同复热方式对糖醋排骨品质的影响[J]. 中国调味品,2021,46(7):52−59. [ZHAO Y Y, LI S Y, YAN L H, et al. Effects of different reheating methods on the quality of sweet and sour pork ribs[J]. China Condiment,2021,46(7):52−59.] doi: 10.3969/j.issn.1000-9973.2021.07.011 ZHAO Y Y, LI S Y, YAN L H, et al. Effects of different reheating methods on the quality of sweet and sour pork ribs[J]. China Condiment, 2021, 46(7): 52−59. doi: 10.3969/j.issn.1000-9973.2021.07.011

[54] 董芝杰. 不同复热方式对猪肉丸品质的影响[J]. 美食研究,2022,39(4):66−70. [DONG Z J. Effects of different reheating methods on the quality characteristics of pork meatballs[J]. Journal of Researches on Dietetic Science and Culture,2022,39(4):66−70.] DONG Z J. Effects of different reheating methods on the quality characteristics of pork meatballs[J]. Journal of Researches on Dietetic Science and Culture, 2022, 39(4): 66−70.

[55] 赵钜阳, 石长波, 张琪. 微波复热功率及时间对速冻红烧肉品质的影响[J]. 食品安全质量检测学报,2017,8(9):3519−3525. [ZHAO J Y, SHI C B, ZHANG Q. Effects of different microwave re-heating powers and time on quality of quick-frozen pork braised in brown sauce[J]. Journal of Food Safety & Quality,2017,8(9):3519−3525.] doi: 10.3969/j.issn.2095-0381.2017.09.040 ZHAO J Y, SHI C B, ZHANG Q. Effects of different microwave re-heating powers and time on quality of quick-frozen pork braised in brown sauce[J]. Journal of Food Safety & Quality, 2017, 8(9): 3519−3525. doi: 10.3969/j.issn.2095-0381.2017.09.040

[56] 胡茂芩. 川南特色菜肴滑肉的加工工艺优化及品质特性研究[D]. 成都:成都大学, 2021. [HU M C. Study on processing technology optimization and quality characteristics of slippery pork in southern Sichuan[D]. Chengdu:Chengdu University, 2021.] HU M C. Study on processing technology optimization and quality characteristics of slippery pork in southern Sichuan[D]. Chengdu: Chengdu University, 2021.

[57] 张根生, 丁一丹, 郑野, 等. 预调理肉制品防腐保鲜技术的研究进展[J]. 中国调味品,2020,45(6):185−190. [ZHANG G S, DING Y D, ZHENG Y, et al. Research progress on antisepsis and preservation technology of pre-prepared meat products[J]. China Condiment,2020,45(6):185−190.] doi: 10.3969/j.issn.1000-9973.2020.06.041 ZHANG G S, DING Y D, ZHENG Y, et al. Research progress on antisepsis and preservation technology of pre-prepared meat products[J]. China Condiment, 2020, 45(6): 185−190. doi: 10.3969/j.issn.1000-9973.2020.06.041

[58] 程伟伟, 夏列, 蒋爱民, 等. 不同冷冻方式对调理猪肉贮藏期品质影响的对比研究[J]. 食品工业科技,2015,36(8):333−339. [CHENG W W, XIA L, JIANG A M, et al. A comparative study of quality of different freezing methods prepared pork during the storage period[J]. Science and Technology of Food Industry,2015,36(8):333−339.] CHENG W W, XIA L, JIANG A M, et al. A comparative study of quality of different freezing methods prepared pork during the storage period[J]. Science and Technology of Food Industry, 2015, 36(8): 333−339.

[59] 黄卉, 陈胜军, 赵永强, 等. 水产品预制菜加工与质量安全控制技术研究进展[J]. 南方水产科学,2022,18(6):152−160. [HUNAG H, CHEN S J, ZHAO Y Q, et al. Research advances on processing and quality safety control technology of aquatic pre-made products[J]. South China Fisheries Science,2022,18(6):152−160.] doi: 10.12131/20220190 HUNAG H, CHEN S J, ZHAO Y Q, et al. Research advances on processing and quality safety control technology of aquatic pre-made products[J]. South China Fisheries Science, 2022, 18(6): 152−160. doi: 10.12131/20220190

[60] 王俊姣, 高倩妮, 叶可萍, 等. 气调包装处理对生鲜荠菜猪肉馅中微生物的影响[J]. 南京农业大学学报,2021,44(1):176−183. [WANG J J, GAO Q N, YE K P, et al. Effect of modified atmosphere packaging on microorganisms of fresh shepherd's purse pork stuffing[J]. Journal of Nanjing Agriculture University,2021,44(1):176−183.] doi: 10.7685/jnau.202004054 WANG J J, GAO Q N, YE K P, et al. Effect of modified atmosphere packaging on microorganisms of fresh shepherd's purse pork stuffing[J]. Journal of Nanjing Agriculture University, 2021, 44(1): 176−183. doi: 10.7685/jnau.202004054

[61] ZHAO S M, LI N N, LI Z, et al. Shelf life of fresh chilled pork as affected by antimicrobial intervention with nisin, tea polyphenols, chitosan, and their combination[J]. International Journal of Food Properties,2019,22(1):1047−1063. doi: 10.1080/10942912.2019.1625918

[62] 冷坪蔚, 梅议文, 芦慧勤, 等. 食用菌粉对猪肉肠冷藏过程中品质及挥发性风味物质的影响[J]. 食品工业科技,2023,44(13):356−366. [LENG P W, MEI Y W, LU H Q, et al. Effects of edible fungi on pork intestine quality and volatile flavor compounds during cold storage[J]. Science and Technology of Food Industry,2023,44(13):356−366.] LENG P W, MEI Y W, LU H Q, et al. Effects of edible fungi on pork intestine quality and volatile flavor compounds during cold storage[J]. Science and Technology of Food Industry, 2023, 44(13): 356−366.

[63] 牛欣欣, 梁宗余, 李明元, 等. 预调理李庄白肉标准化加工及保鲜工艺[J]. 食品工业,2023,44(4):67−72. [NIU X X, LIANG Z Y, LI M Y, et al. The standardized processing and preservation technology of prepared food of Lizhuang boiled pork[J]. The Food Industry,2023,44(4):67−72.] NIU X X, LIANG Z Y, LI M Y, et al. The standardized processing and preservation technology of prepared food of Lizhuang boiled pork[J]. The Food Industry, 2023, 44(4): 67−72.

[64] 罗薇. 预调理烧烤猪五花肉的工艺优化及其在保鲜过程中的品质研究[D]. 成都:四川农业大学, 2022. [LUO W. Process optimization of pre-conditioned barbecued pork belly and research on its quality during preservation[D]. Chengdu:Sichuan Agriculture University, 2022.] LUO W. Process optimization of pre-conditioned barbecued pork belly and research on its quality during preservation[D]. Chengdu: Sichuan Agriculture University, 2022.

[65] 邵楚瑶, 戴瑞彤. 柠檬精油纳米乳液对调理猪肉饼保鲜效果研究[J]. 食品安全质量检测学报,2022,13(8):2550−2557. [SHAO C Y, DAI R T. Study on the effects of nano-emulsion of lemon essential oil on fresh-keeping of marinated pork patty[J]. Journal of Food Safety & Quality,2022,13(8):2550−2557.] doi: 10.3969/j.issn.2095-0381.2022.8.spaqzljcjs202208023 SHAO C Y, DAI R T. Study on the effects of nano-emulsion of lemon essential oil on fresh-keeping of marinated pork patty[J]. Journal of Food Safety & Quality, 2022, 13(8): 2550−2557. doi: 10.3969/j.issn.2095-0381.2022.8.spaqzljcjs202208023

[66] 黄桂龙. 预调理猪肉馅配方及其保鲜技术的研究[D]. 成都:四川农业大学, 2012. [HUANG G L. Study on the fresh-keeping technology and the recipe of preprocessed of pig meat[D]. Chengdu:Sichuan Agriculture University, 2012.] HUANG G L. Study on the fresh-keeping technology and the recipe of preprocessed of pig meat[D]. Chengdu: Sichuan Agriculture University, 2012.

[67] TRIYANNANTO E, FEBRISIANTOSA A, KUSUMANINGRUM A, et al. The quality characteristics of ready-to-eat Empal Gentong affected by neat pre-cooking[J]. Food Science of Animal Resources,2022,42(4):557. doi: 10.5851/kosfa.2021.e70

[68] 吕玉, 臧明伍, 史智佳, 等. 解冻和加工过程中冷冻猪肉保水性的研究[J]. 中国食品学报,2012,12(1):148−152. [LÜ Y, ZANG M W, SHI Z J, et al. Study on water-holding capacity of frozen pork in thawing and processing[J]. Journal of Chinese Institute of Food Science and Technology,2012,12(1):148−152.] doi: 10.3969/j.issn.1009-7848.2012.01.023 LÜ Y, ZANG M W, SHI Z J, et al. Study on water-holding capacity of frozen pork in thawing and processing[J]. Journal of Chinese Institute of Food Science and Technology, 2012, 12(1): 148−152. doi: 10.3969/j.issn.1009-7848.2012.01.023

[69] 邓亚敏, 孙晓娜, 邵俊花, 等. 食盐和多聚磷酸盐影响肉糜持水性的低场核磁共振研究[C]//. 中国食品科学技术学会第十二届年会暨第八届中美食品业高层论坛论文摘要集. 大连:中国食品科学技术学会 2015:2. [DENG Y M, SUN X N, SHAO J H, et al. Low field NMR determination of water distribution in meat batters subjected to NaCl and polyphosphates[C]//. Proceedings Abstracts of the 12th Annual Meeting of the China Society of Food Science and Technology and the 8th China-US Food Industry Senior Forum. Dalian:Chinese Institute of Food Science and Technology, 2015:2.] DENG Y M, SUN X N, SHAO J H, et al. Low field NMR determination of water distribution in meat batters subjected to NaCl and polyphosphates[C]//. Proceedings Abstracts of the 12th Annual Meeting of the China Society of Food Science and Technology and the 8th China-US Food Industry Senior Forum. Dalian: Chinese Institute of Food Science and Technology, 2015: 2.

[70] 朱圣刚, 钟玉虎, 郇延军. 山梨醇对预调理猪肉糜制品品质的影响[J]. 肉类研究,2012,26(10):9−12. [ZHU S G, ZHONG Y H, HUAN Y J. Effect of sorbic alcohol on the quality of prepared minced meat products[J]. Meat Research,2012,26(10):9−12.] ZHU S G, ZHONG Y H, HUAN Y J. Effect of sorbic alcohol on the quality of prepared minced meat products[J]. Meat Research, 2012, 26(10): 9−12.

[71] KIM Y J, KIM T K, YUN H J, et al. Effects of grafted myofibrillar protein as a phosphate replacer in brined pork loin[J]. Meat Science,2023,199:109142. doi: 10.1016/j.meatsci.2023.109142

[72] YUAN D, XU Y, KONG B, et al. Application of seaweed dietary fiber as a potential alternative to phosphates in frankfurters with healthier profiles[J]. Meat Science,2023,196:109044. doi: 10.1016/j.meatsci.2022.109044

[73] 高可蒙, 梅林, 薛秀恒, 等. 无磷保水剂对冷冻调理猪肉的影响[J]. 食品科学,2015,36(6):257−261. [GAO K M, MEI L, XUE X H, et al. Influence of non-phosphate additive on water-holding capacity of frozen prepared pork[J]. Food Science,2015,36(6):257−261.] doi: 10.7506/spkx1002-6630-201506049 GAO K M, MEI L, XUE X H, et al. Influence of non-phosphate additive on water-holding capacity of frozen prepared pork[J]. Food Science, 2015, 36(6): 257−261. doi: 10.7506/spkx1002-6630-201506049

[74] TANG T T, ZHANG M, LAW C L, et al. Novel strategies for controlling nitrite content in prepared dishes:Current status, potential benefits, limitations and future challenges[J]. Food Research International,2023,170:112984. doi: 10.1016/j.foodres.2023.112984

[75] KALAYCIOĞLU Z, ERIM F B. Nitrate and nitrites in foods:Worldwide regional distribution in view of their risks and benefits[J]. Journal of Agricultural and Food Chemistry,2019,67(26):7205−7222. doi: 10.1021/acs.jafc.9b01194

[76] 国家卫生健康委员会, 国家市场监督管理总局. GB 2760-2014食品安全国家标准 食品添加剂使用标准[S]. 北京:中国标准出版社, 2014. [National Health and Family Planning Commission, State Market Regulatory Administration. GB 2760-2014 National standards for food safety Standard for use of food additives[S]. Beijing:Standards Press of China, 2014.] National Health and Family Planning Commission, State Market Regulatory Administration. GB 2760-2014 National standards for food safety Standard for use of food additives[S]. Beijing: Standards Press of China, 2014.

[77] SAID A K, ESSIEN E E, ABBAS M, et al. Association between dietary nitrate, nitrite intake, and site-specific cancer risk:A systematic review and meta-analysis[J]. Nutrients,2022,14(3):666. doi: 10.3390/nu14030666

[78] ZHANG W C B, JIANG J, HE Y Q, et al. Association between dietary nitrite intake and glioma risk:A systematic review and dose-response meta-analysis of observational studies[J]. Frontiers in Oncology,2022,12:910476. doi: 10.3389/fonc.2022.910476

[79] SACCANI G, BERGAMASCHI M, SCHIVAZAPPA C, et al. Evaluation of the antioxidant effect of a phytocomplex addition in clean label pork salami enriched in n-3 PUFA[J]. Food Chemistry,2023,399:133963. doi: 10.1016/j.foodchem.2022.133963

[80] GUIMARÃES A S, GUIMARÃES J S, ARAÚJO A B S, et al. Characterization of natural curing agents from Japanese radish (Raphanus sativus L.) for their use in clean label restructured cooked meat products[J]. LWT-Food Science and Technology,2021,150:111970. doi: 10.1016/j.lwt.2021.111970

[81] 闫瑞, 唐敏, 陈东方, 等. 白萝卜粉作为亚硝酸盐来源制备猪肉发酵干香肠[J]. 食品科学,2023,44(8):101−108. [YAN R, TANG M, CHEN D F, et al. Preparation of dry fermented pork sausage using radish powder as a source of nitrite[J]. Food Science,2023,44(8):101−108.] doi: 10.7506/spkx1002-6630-20220713-138 YAN R, TANG M, CHEN D F, et al. Preparation of dry fermented pork sausage using radish powder as a source of nitrite[J]. Food Science, 2023, 44(8): 101−108. doi: 10.7506/spkx1002-6630-20220713-138

[82] 王凯丽, 李秀明, 王洋, 等. 复合果蔬取代部分硝酸盐对降低发酵香肠中亚硝胺的作用[J]. 食品科学,2018,39(12):60−66. [WANG K L, LI X M, WANG Y, et al. Effects of partial substitution of nitrate with mixed fruit and vegetable slurries on reducing nitrosamines in fermented sausage[J]. Food Science,2018,39(12):60−66.] doi: 10.7506/spkx1002-6630-201812010 WANG K L, LI X M, WANG Y, et al. Effects of partial substitution of nitrate with mixed fruit and vegetable slurries on reducing nitrosamines in fermented sausage[J]. Food Science, 2018, 39(12): 60−66. doi: 10.7506/spkx1002-6630-201812010

[83] 任双, 叶浪, 乔晓玲, 等. 天然抗氧化剂替代部分亚硝酸钠对乳化肠护色及抗氧化效果的影响[J]. 肉类研究,2018,32(1):9−15. [[REN S, YE L, QIAO X L, et al. Effect of partial substitution of natural antioxidants for sodium nitrite on color and oxidative stability of emulsion-type sausage[J]. Meat Research,2018,32(1):9−15.] [REN S, YE L, QIAO X L, et al. Effect of partial substitution of natural antioxidants for sodium nitrite on color and oxidative stability of emulsion-type sausage[J]. Meat Research, 2018, 32(1): 9−15.

[84] 徐海祥, 谢淑娟, 施帅, 等. 异VC钠、红曲色素及Nisin替代部分亚硝酸钠对腊肠品质的影响[J]. 现代食品科技,2012,28(12):1677−1681. [XU H X, XIE S J, SHI S, et al. Effect of sodium isoascorbic acid, monascus colour and nisin instead of sodium nitrite sausage quality[J]. Modern Food Science and Technology,2012,28(12):1677−1681.] XU H X, XIE S J, SHI S, et al. Effect of sodium isoascorbic acid, monascus colour and nisin instead of sodium nitrite sausage quality[J]. Modern Food Science and Technology, 2012, 28(12): 1677−1681.

[85] DIFONZO G, TOTARO M P, CAPONIO F, et al. Olive leaf extract (OLE) addition as tool to reduce nitrate and nitrite in ripened sausages[J]. Foods,2022,11(3):451. doi: 10.3390/foods11030451

[86] GAO X Q, XIA L Y, FAN Y Q, et al. Evaluation of coloration, nitrite residue and antioxidant capacity of theaflavins, tea polyphenols in cured sausage[J]. Meat Science,2022,192:108877. doi: 10.1016/j.meatsci.2022.108877

[87] AYASEH A, ALIREZALU K, YAGHOUBI M, et al. Production of nitrite-free frankfurter-type sausages by combining ε-polylysine with beetroot extracts:An assessment of microbial, physicochemical, and sensory properties[J]. Food Bioscience,2022,49:101936. doi: 10.1016/j.fbio.2022.101936

[88] WÓJCIAK K M, FERYSIUK K, KĘSKA P, et al. Reduction of nitrite in canned pork through the application of black currant (Ribes nigrum L. ) leaves extract[J]. Molecules,2023,28(4):1749. doi: 10.3390/molecules28041749

[89] WEI F, XU X, ZHOU G, et al. Irradiated Chinese Rugao ham:Changes in volatile N-nitrosamine, biogenic amine and residual nitrite during ripening and post-ripening[J]. Meat Science,2009,81(3):451−455. doi: 10.1016/j.meatsci.2008.09.005

[90] KUO J C, CHEN H L. Combination effect of sodium lactate and irradiation on color, lactic acid bacteria, lipid oxidation and residual nitrite in Chinese sausages during storage at 25 ℃[J]. Journal of the Science of Food and Agriculture,2004,84(8):903−908. doi: 10.1002/jsfa.1722

[91] JO K, LEE J, LEE S, et al. Curing of ground ham by remote infusion of atmospheric non-thermal plasma[J]. Food Chemistry,2020,309:125643. doi: 10.1016/j.foodchem.2019.125643

[92] MENG D J, YANG X Y, LIU H, et al. Effect of cold-plasma-treated phosphate solution to substitute partial nitrite on the color, texture, and flavor of smoked sausage[J]. Bioengineering,2022,9(12):794. doi: 10.3390/bioengineering9120794

[93] MARCINKOWSKA-LESIAK M, WOJTASIK-KALINOWSKA I, ONOPIUK A, et al. Application of atmospheric pressure cold plasma activated plant protein preparations solutions as an alternative curing method for pork sausages[J]. Meat Science,2022,187:108751. doi: 10.1016/j.meatsci.2022.108751

[94] YONG H I, PARK J, KIM H J, et al. An innovative curing process with plasma‐treated water for production of loin ham and for its quality and safety[J]. Plasma Processes and Polymers,2018,15(2):1700050. doi: 10.1002/ppap.201700050

[95] 孟德娟, 孙祥祥, 刘欢, 等. 低温等离子体处理磷酸盐溶液替代亚硝酸盐对烟熏中式香肠品质的影响[J]. 食品科技,2022,47(11):106−113. [MENG D J, SUN X X, LIU H, et al. Effect of cold plasma treated of phosphate solution on the quality of smoked Chinese sausage instead of nitrite[J]. Food Science and Technology,2022,47(11):106−113.] MENG D J, SUN X X, LIU H, et al. Effect of cold plasma treated of phosphate solution on the quality of smoked Chinese sausage instead of nitrite[J]. Food Science and Technology, 2022, 47(11): 106−113.

[96] HIGUERO N, RAMÍREZ M R, Del CARMEN VIDAL-ARAGÓN M, et al. Influence of high-pressure processing and varying concentrations of curing salts on the color, heme pigments and oxidation of lipids and proteins of Iberian dry-cured loins during refrigerated storage[J]. LWT-Food Science and Technology,2022,160:113251. doi: 10.1016/j.lwt.2022.113251

[97] LEE S H, CHOE J, SHIN D J, et al. Combined effect of high pressure and vinegar addition on the control of Clostridium perfringens and quality in nitrite-free emulsion-type sausage[J]. Innovative Food Science & Emerging Technologies,2019,52:429−437.

-

期刊类型引用(3)

1. 谢春洋,刘欢,张秋玲. 猪肉预制菜供应链质量追溯体系研究——基于区块链背景下. 北方经贸. 2025(01): 79-83 .  百度学术

百度学术

2. 姜获足,朱芳芳,彭金山. 消费者对预制菜认知及影响因素的统计调查. 中国食品工业. 2024(24): 41-43 .  百度学术

百度学术

3. 郑先哲,刘慧然,刘成海,柏才宇,蒋镇泽,赵兴隆,沈柳杨,刘钗. 连续式工业化微波复热盒装米饭的加热均匀性. 农业工程学报. 2024(22): 252-263 .  百度学术

百度学术

其他类型引用(0)

下载:

下载:

下载:

下载: