Developments in Research into Mechanisms Underlying and Regulating Flavor Generation in Processed Freshwater Fish Products

-

摘要: 淡水鱼制品因其高蛋白低脂肪,味道鲜美、香气醇厚而备受消费者们喜爱。其良好风味物质是鱼肉中可溶性物质间发生的一系列复杂的生化反应形成的,主要有蛋白质降解、脂质氧化、美拉德反应及美拉德与脂质氧化相互作用。淡水鱼预制过程中良好风味的形成是其品质评价和消费者购买导向的重要指标,也是淡水鱼预制产品的工业化生产和推广的重要影响因素。基于此,本文系统综述了预制淡水鱼产品的风味特征、风味形成机理、影响因素及调控方法。此外,在充分了解风味形成的基础上,还讨论了预制淡水鱼产品未来发展过程中的重要研究方向。未来研究中,需不断革新技术,应关注风味化合物浓度与其风味特性之间的量效关系,确定淡水鱼及其制品中关键风味物质呈现可接受鲜味的浓度范围和产生腥味的浓度范围,从而实现淡水鱼及其制品不良风味的精确调控。Abstract: Freshwater fish products are popular among consumers for their high protein and low fat contents and favorable flavors and aromas. Substances that contribute to favorable flavors are generated through various complex biochemical reactions acting on soluble substances in fish. These complex reactions include protein degradation, lipid oxidation, the Maillard reaction, and the interaction between the Maillard reaction and lipid oxidation. Favorable flavors in processed freshwater fish products are major indicators of quality and predictors of consumer preference and exert an important influence on the industrial production and promotion of processed freshwater fish products. This paper systematically reviews the flavor characteristics, flavor formation mechanism, influencing factors and regulation methods of prepared freshwater fish products. In addition, on the basis of a full understanding of flavor formation, important research directions in the future development of prefabricated freshwater fish products are also discussed. In future research, it's necessary to continuously innovate the technology, pay attention to the dose-response relationship between the concentration of flavor compounds and their flavor characteristics, and determine the concentration range of key flavor compounds in freshwater fish and their products that can present acceptable umami and produce fishy odor, so as to realize the precise regulation of the undesirable flavor of freshwater fish and their products.

-

Keywords:

- freshwater fish /

- processed products /

- flavor generation mechanisms /

- regulation

-

淡水鱼制品因其高蛋白低脂肪并含有多种维生素及矿物质,味道鲜美、香气诱人而备受消费者们欢迎,且2022年4月26日发布的最新版《中国居民膳食指南(2022)》中,首次提出“东方健康膳食模式”,特强调常吃鱼虾等水产品。淡水鱼从大江小河到餐桌其加工工序极其复杂,为使人们更加便捷的享受淡水鱼系列美食,淡水鱼预制产品便得到快速开发与发展。目前,按照复热方式的难易程度,市场上的淡水鱼预制菜可分为即烹类(鱼糜、鱼丸、免浆鱼片、炒鱼片)、即热类(酸汤鱼、剁椒鱼头、红烧鲈鱼、烤鱼)与即食类(熏鱼、鱼干、酥鱼、鱼罐头)3种类型。

因鲜活的淡水鱼具有很浓的泥腥味和鱼腥味,需经过不同加工方式处理后方可赋予淡水鱼制品诱人的风味。淡水鱼预制过程中良好的风味形成是其品质评价和消费者购买导向的重要指标,也是淡水鱼预制产品的工业化生产和推广的重要影响因素。因此,深入探讨淡水鱼预制产品风味形成机理、影响因素及调控方式,对淡水鱼预制产业发展具有重要意义。鉴于此,本文对预制淡水鱼风味形成机制包括蛋白质降解、脂质氧化、美拉德反应及美拉德与脂质氧化相互作用进行了详细的综述,对影响淡水鱼预制产品风味因素及调控方式进行了归纳总结,并分析了淡水鱼预制产品未来研究的重要方向,以期为淡水鱼预制产品良好风味的保持、好吃健康的双向调控及我国淡水鱼预制产业的健康可持续发展提供理论思路。

1. 淡水鱼预制产品的风味特征及形成机理

1.1 淡水鱼预制产品的风味特征

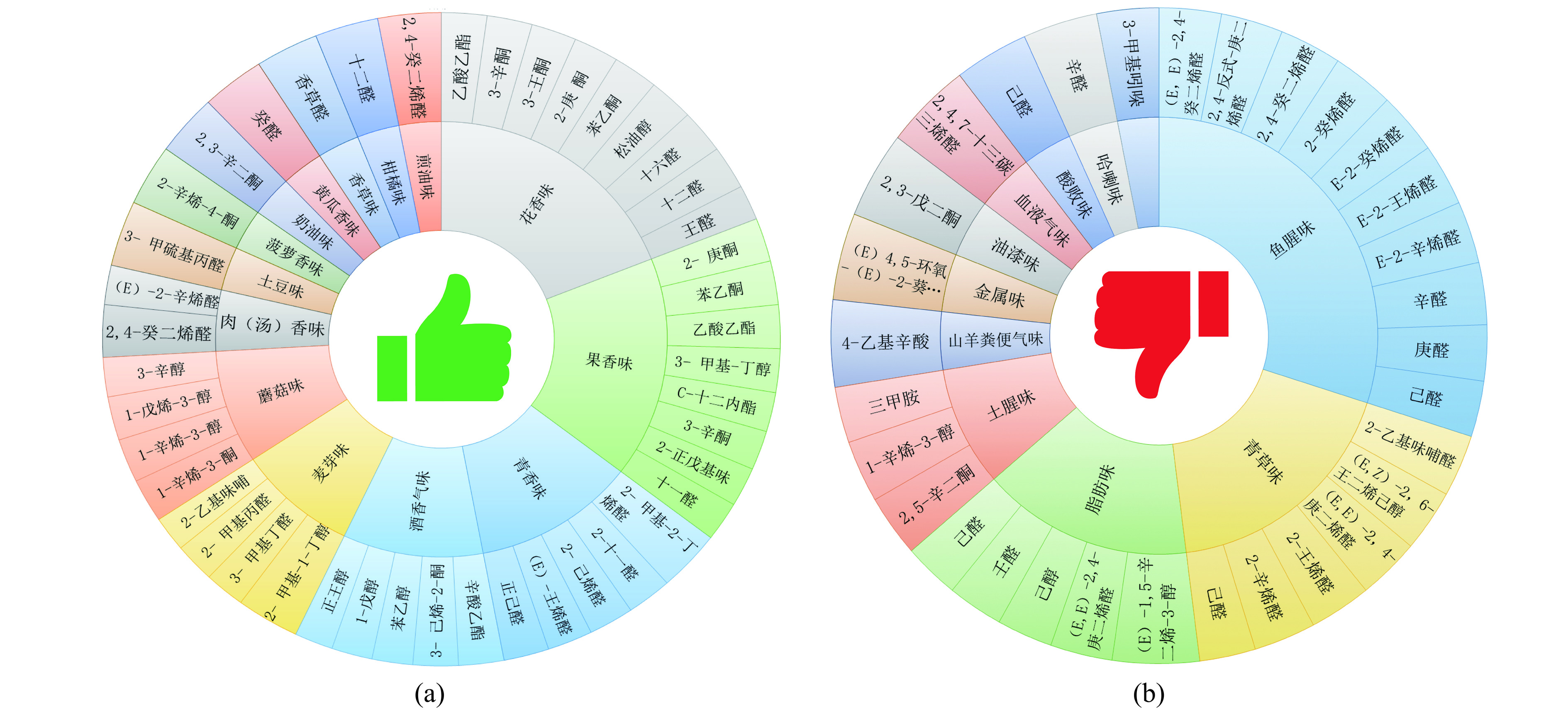

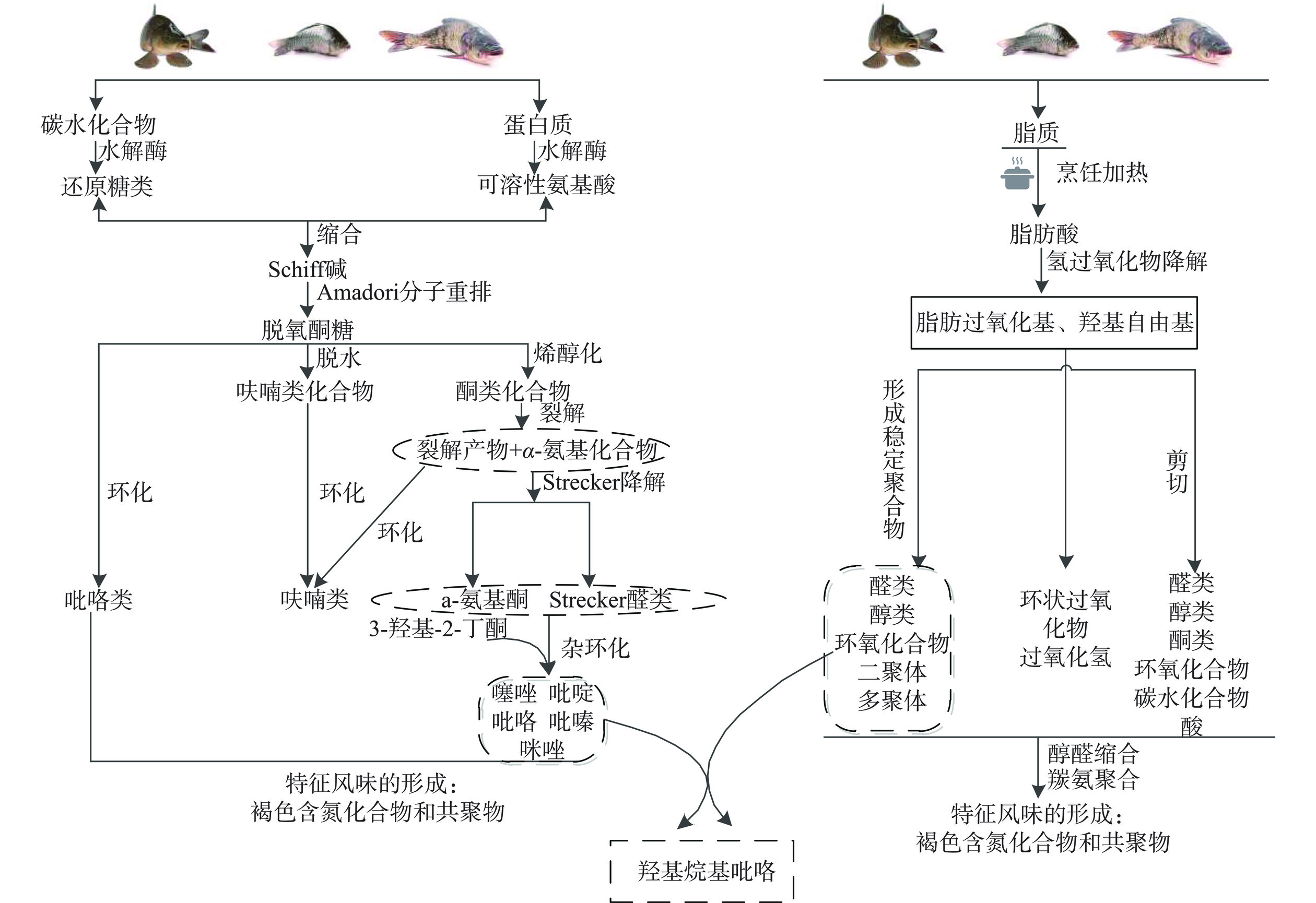

淡水鱼预制产品的风味主要由挥发性气味物质和非挥发性滋味物质两部分组成,挥发性气味物质由羰基化合物、酸类、醇类、酚类、含硫化合物、芳香族化合物、呋喃类及其他含氮化合物等一些挥发性化学成分构成[1−2];非挥发性滋味物质主要包括非含氮化合物(有机酸、糖类)和含氮化合物(多肽、核苷酸及游离氨基酸),其中挥发性气味物质对淡水鱼预制产品整体风味的影响较大,也是消费者对淡水鱼预制产品可接受度的重要衡量标准之一。淡水鱼预制产品风味是由风味前体物质、中间物质及降解产物在预处理及加工过程中通过一系列复杂的化学反应产生,包括令人愉悦(果香味、清香味、油煎味)和厌恶的风味,如图1(a)、(b)所示。

1.2 淡水鱼预制产品的风味形成机理

淡水鱼预制产品的特征性风味形成机理是其可溶性物质之间发生的复杂化学反应而形成的,主要包括:脂质氧化、美拉德反应、蛋白质降解、美拉德反应与脂质氧化相互作用等。

1.2.1 脂质氧化

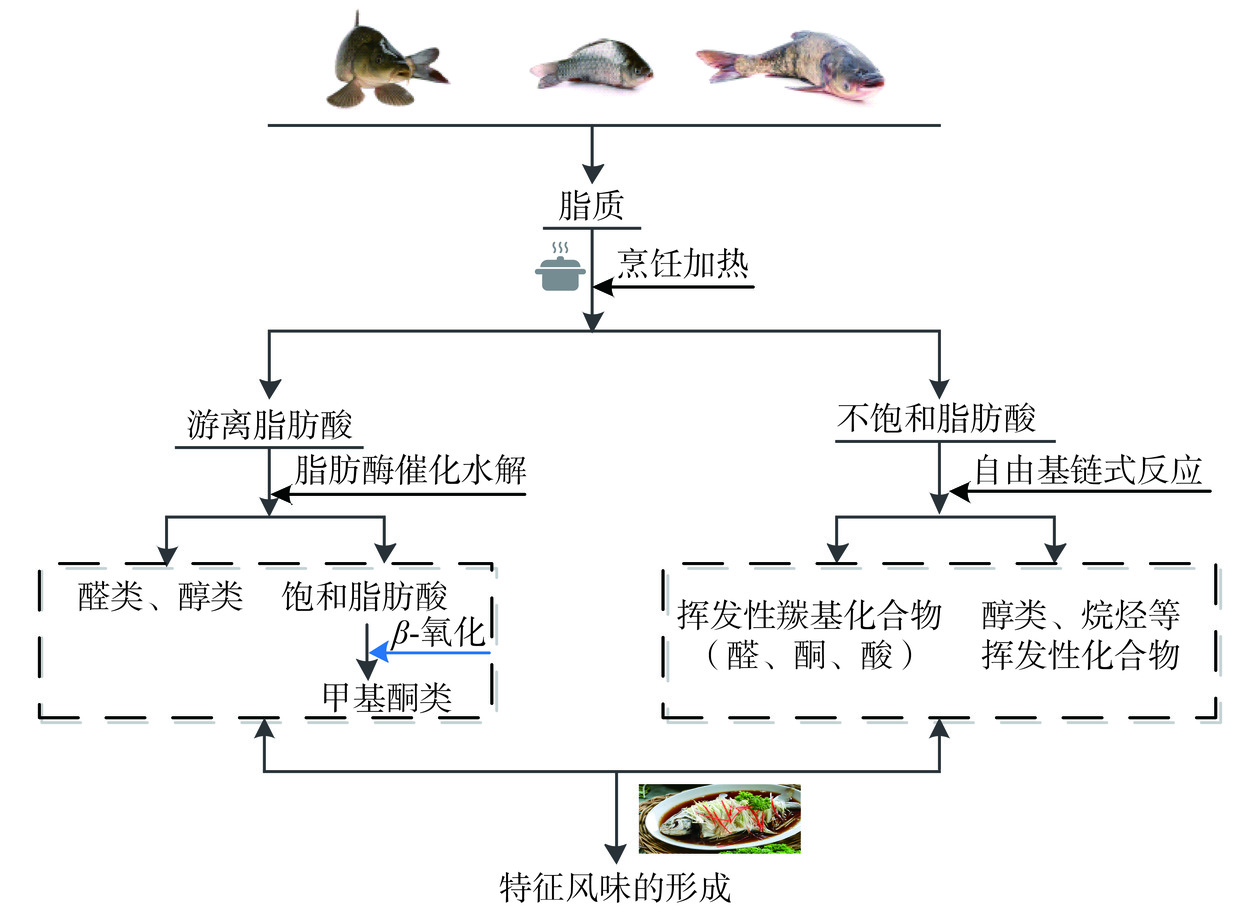

淡水鱼虽然属于低脂肪食物原料,但其中含有丰富的多不饱和脂肪酸(PUFAs),经加工预制后形成的预制淡水鱼,呈现不同风味,而挥发性醇类及挥发性羰基化合物是鱼肉新鲜美味的主要风味成分。风味来源机理为鱼肉中脂质在加热(最高温度不超过100 ℃)条件下,通过自由基链式反应(起始、增殖、终止)自发地生成一系列氧化代谢物,继而进一步分解生成酮、醛、醇等挥发性化合物,如图2所示。在起始阶段,不饱和脂肪酸(UFA)在受热(最高温度不超过100 ℃)条件下发生脱氢反应,生成烷基自由基;在增殖期阶段,碳双键断裂,发生加成反应,生成烷基过氧自由基(ROO•);在终止阶段,氢过氧化物,发生还原反应生成烷氧基基团(RO•)。随后游离脂肪酸在脂肪酶催化作用下水解生成醛、醇、饱和及不饱和脂肪酸。不饱和脂肪酸氧化生成氢过氧化物需要过氧化自由基的催化,饱和脂肪酸经过β-氧化生成乙酰辅酶A,β-酮酸脱羧生成甲基酮[3],进而赋予鱼类特征的风味物质。煮熟的鲑鱼中含量最大的风味物质是庚醛和4-庚烯醛,赋予鱼肉煮熟土豆和类土豆气味[4]。基于此原理,有研究表明,鱼肉中的脂质在95~100 ℃加热8~10 min的条件下,会产生良好的风味物质并且在30~95 ℃温度范围内,温度越高,草鱼肉中挥发性风味物质含量越高,其种类从23种逐渐增加至74种[5]。此外,合理的加热烹饪方法使鲢鱼醛、醇、酮和碳氢类物质的含量增加,肌苷酸(IMP)含量降低,将鱼块放入微波炉专用碗中,功率设定为800 W,加热3 min后取出,翻面,再放入微波炉继续加热3 min,使得熟鲢鱼肉中醛、醇、酮和碳氢含量降低,IMP对鲜味的贡献下降[6]。

1.2.2 美拉德反应

美拉德反应是食品加热产生风味最重要的一类反应,因其特有的焦香味和色泽,可以掩盖淡水鱼类产品的异味、消除鱼腥味,并增强鱼类的鲜味及焦香味。

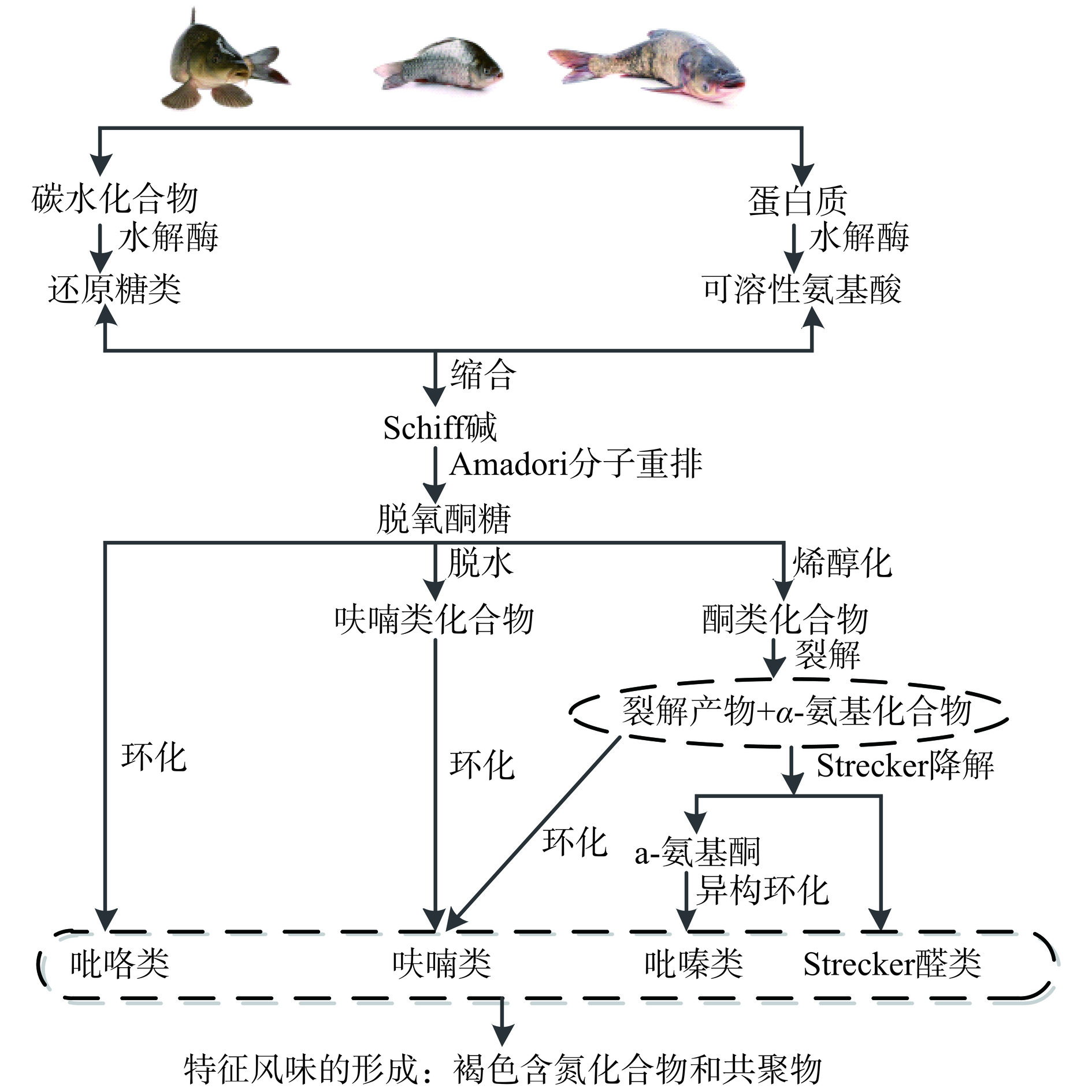

美拉德反应本质上是羰基化合物和氨基化合物的反应,故又被称为羰氨反应。淡水鱼鱼肉中含有丰富的可溶性氨基酸、多肽及还原糖,这些物质经缩合、聚合、脱水等赋予淡水鱼预制产品特有的色泽和风味[7]。淡水鱼加工过程中的美拉德反应机理(图3)所示[8],初期:还原糖与氨基酸经缩合反应,生成席夫碱,再通过分子重排生成Amadori或中间体He-ynes,然后形成羰基中间体。中期:脱氧还原酮糖脱水、烯醇化、环化生成呋喃类化合物、酮类化合物、吡咯类,裂解产物氨基酸经Strecker降解、二羰基化合物与氨基酸发生反应,进一步生成醛类、吡嗪、吡啶和吡咯等。末期:一系列反应所形成的中间产物再发生聚合反应生成褐色含氮化合物和共聚物,进而赋予鱼类特殊的焦香味及诱人的色泽。在复杂的淡水鱼食品体系中,美拉德反应极其复杂,各阶段反应产物可两两相互反应,且受到多种因素包括温度、反应时间、水活度、pH等影响,也是淡水鱼加热获得特殊风味的重要途径,有研究表明,Gao等[9]将木糖和半胱氨酸复配,进行羰氨反应,并添加至罗非鱼副产物水解液中得到具有浓烈肉香味的产品。

1.2.3 蛋白质降解

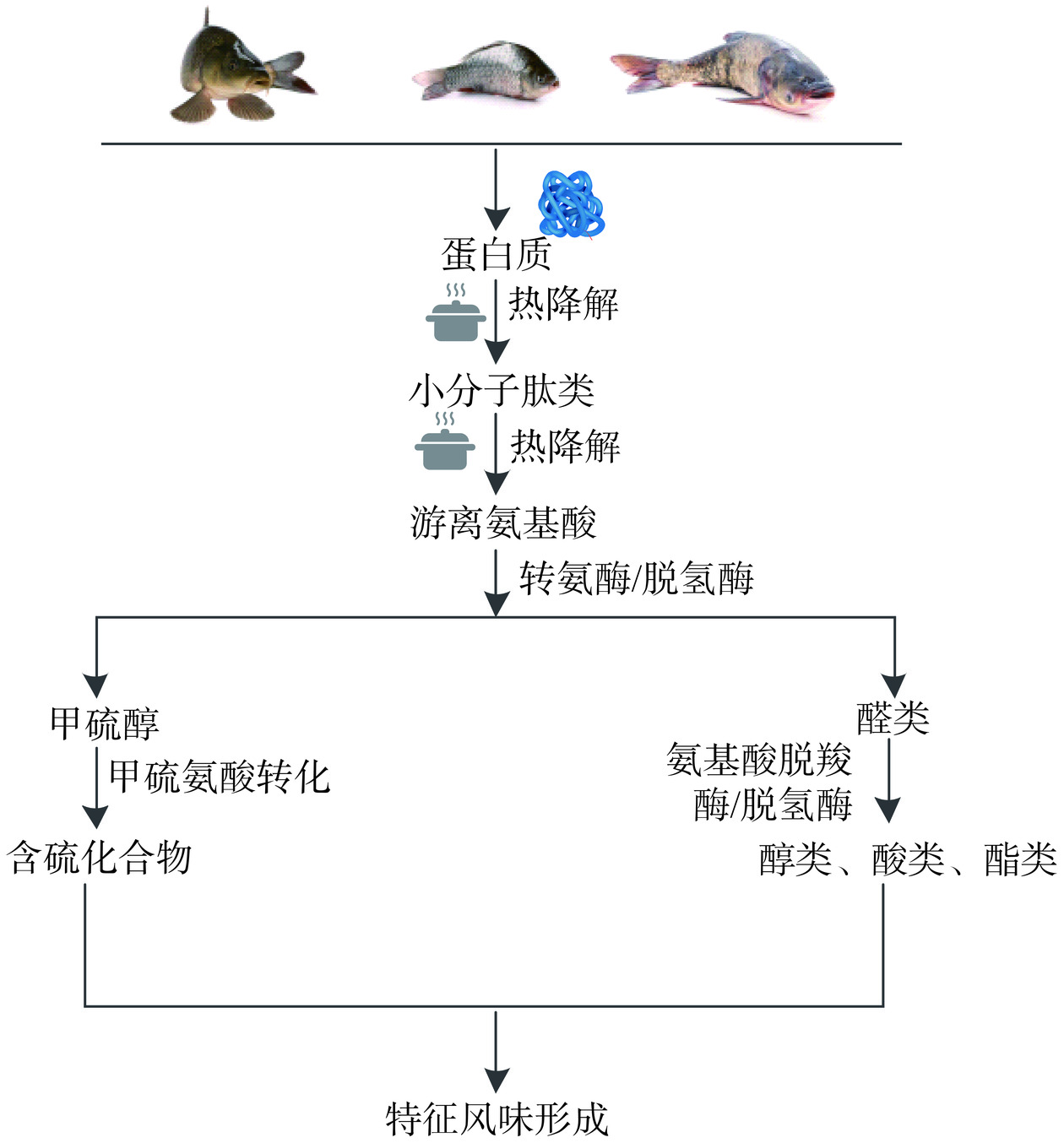

淡水鱼中高蛋白通过不同的烹饪方式会发生热降解使鱼肌肉蛋白质和多肽发生变性,改变其固有的结构,导致多肽链降解形成游离氨基酸。这些游离氨基酸赋予淡水鱼鱼肉呈现不同风味,如有呈甜味的甘氨酸、丝氨酸和丙氨酸,呈甜苦味的赖氨酸,呈鲜味的谷氨酸和天冬氨酸,以及呈苦味的亮氨酸和异亮氨酸等。反复加热会使游离氨基酸代谢转化为各种醇类、醛类、酸类、酯类和含硫化合物,是产生特征风味的重要途径。其机理如图4游离氨基酸在转氨基的作用下形成α−酮酸,α−酮酸又可以转化为醛或甲硫醇,醛类化合物在各种氨基酸脱羧酶的作用下进一步还原为相应的醇类化合物,而在脱氢酶的作用下,醛类又可生成酸类化合物;由甲硫氨酸转氨作用生成的甲硫醇则被分解为各种含硫化合物[10]。许多研究证明蛋氨酸和半胱氨酸是形成肉香味的重要组成成分,其加热产生的H2S会与脂肪氧化的产生的醛酮化合物发生脱水,缩合,形成噻唑、噻吩等[8]。

1.2.4 美拉德反应与脂质氧化相互作用

不同烹饪条件下,鱼肉受热过程中,多种反应类型和途径对提升鱼肉口感、风味增香具有协同作用。美拉德反应和脂质氧化所产生的众多具有高反应活性的中间体可再次发生相互作用,产生新的风味物质,从而促进肉香味醇厚化。脂质通过作用于美拉德反应抑制挥发性含硫化合物和杂环化合物的形成,并得出脂质对美拉德反应的影响机制是先抑制后参与美拉德反应,最终生成较多的脂质-美拉德化合物。如图5所示,这一途径主要是通过氨基酸与醛类之间发生Str-eker降解,所生成α-氨基酮、一氧化碳、硫化氢等活性中间体与脂肪氧化产生的不饱和醛酮发生反应,进而形成羟基烷基吡咯、呋喃等[11]。二次反应产物相较于单一美拉德反应,其主要特征是含有一个或多个氮或硫原子的杂环化合物及含有四个或更多碳原子的长链烷基。

2. 淡水鱼预制产品风味影响因素及其调控方式

2.1 养殖环境的影响及其调控

淡水鱼预制产品的风味受养殖环境影响较大,不同养殖模式下淡水鱼鱼肉制得的产品,风味都存在一定差异。我国淡水鱼常见的养殖模式有水库养殖、湖泊养殖、池塘养殖、稻田养殖及人工水泥池塘养殖等。黄爱霞等[12]研究了池塘内循环跑道对青鱼形体指数和肌肉营养价值的影响,结果显示循环水养殖能提高青鱼肌肉营养价值。温利等[13]比较普通池塘养殖和池塘循环水养殖对草鱼品质的影响,发现池塘循环水养殖的草鱼腥异味物质含量更低,鲜味核苷酸含量更高,风味品质更好。Zhang等[14]研究草鱼在池塘循环养殖模式下,其鲜味物质含量较高,鱼腥味、泥腥味物质含量很低。

淡水鱼预制产品鱼腥味、泥腥味较重,是因为水环境中的泥沙淤泥、藻类放线菌、真菌等的存在,极易导致鱼体吸附或摄食土臭素(GSM)、二甲基异莰醇(MIB)等土腥味物质[15]。改善养殖环境,降低养殖环境中藻类、真菌的含量是调控淡水鱼预制产品风味的重要手段。目前,已有大量的研究证实采用循环流水养殖模式及通过改变鱼饲料的组成可以减少养殖环境中水体异味的形成[16−17]。Green等[18]研究了各种因素对介导淡水鱼异味化合物产生的微生物丰度的影响,结果表明,水体蓝藻和硅藻与鱼类GSM和MIB浓度均显著相关,蓝藻中束丝藻、颤藻和鱼腥藻3个属与GSM和MIB浓度呈正相关(P<0.05),且向水体中加入硫酸铜或含有铁、钙等阳离子化合物,可以降低水的富营养化程度和产生异味的微生物(如蓝藻和放线菌)的负荷。通过改善淡水鱼养殖环境来降低腥味的研究已取得较好的成果[19−20]。此外,流水暂养过程中,醛类醇类和烯类随暂养天数逐渐减少,有利于不良气味的脱除[21−22]。

2.2 屠宰方式的影响及其调控

淡水鱼预制产品整体质量和风味品质均会受到屠宰方式的影响,新鲜活鱼在屠宰过程中会受到外部应激反应,导致蛋白质降解、厌氧糖酵解、脂肪氧合代谢的形成发生显著变化,进而影响其产品的风味品质[23−24]。目前,常用的鱼类屠宰方式主要有:敲击头部(急杀)、鳃部放血(去鳃)、冰颤、二氧化碳法、氮气法、电击法、窒息法等[25]。新鲜活鱼屠宰过程中,受到的应激反应越小,鱼肉在后期加工贮藏时的风味品质越好[26−27]。吴永俊等[28]研究了四种屠宰方式(急杀法、去鳃放血法、低温屠宰法、窒息法)对虹鳟鱼背肉和尾肉中的挥发性成分的影响,结果发现低温屠宰的虹鳟鱼肉挥发性成分含量最高,鱼肉风味最佳,其中窒息法屠宰的虹鳟鱼肉风味品质最差。这主要是因为低温屠宰引起的应激反应最小,且随着虹鳟鱼死亡时间的延长,其他三种屠宰方式应激反应的增强,导致鱼体糖原降解速度加快,蛋白质降解严重,脂肪酸酶促氧化加快等。草鱼在加工前采用去鳃屠宰、急杀屠宰和自然死亡三种屠宰方式进行预处理,结果发现,不同宰杀方式对草鱼背肉呈味水溶性成分影响较大,自然死亡的草鱼肉滋味最差,急杀致死和去鳃致死组滋味差别不明显。因此,在加工过程中,要避免鱼血渗入肌肉[29]。方静等[30]和陈盎弘等[31]分别对罗非鱼和冷冻斑点叉尾鮰鱼进行不同屠宰方式处理,得出敲击头部和冰颤放血屠宰能得到更好的风味品质。苏欣等[1]指出,鱼血中含有较高含量的苦味氨基酸,如果鱼类在屠宰过程中肌肉中渗入鱼血,鱼肉风味会降低。因此,在淡水鱼屠宰过程中应选取低温屠宰、冰颤放血等应激反应较小的屠宰方式,且在屠宰处理过程中谨防鱼血渗入到鱼肉中,可以显著提高新鲜淡水鱼预制产品的风味。

2.3 腌制工艺的影响及其调控

腌制是淡水鱼预制产品加工过程的重要环节,其目的是为了使香辛料和腌制液更好地进入鱼肉内部,达到去腥、调味、增香等,对产品风味进行调控。传统腌制方法包括干腌、湿腌、混合腌制和注射腌制等,其机理是利用腌制液的高渗透压,实现腌制液中盐分向物料内部的迁移。但是传统腌制方式存在许多局限性,如:腌制原料单一、腌制不均匀、效率低、产品风味品质差等问题[32]。因此,为提升淡水鱼预制产品风味,需采用联合滚揉、超声辅助、高压辅助、电磁波辅助腌制等新型腌制工艺。孙付万[33]在研究鲢鱼预制菜开发过程中,比较了传统湿腌与超声辅助湿腌对鲢鱼预制菜风味的影响,通过GC-MS对风味物质进行检测,鉴定出超声辅助湿腌后醛类物质减少,烃类和醇类物质含量上升,腥味物质含量降低,总体风味物质上升,产品风味品质良好。方媛璐等[34]以鮰鱼为原料,采用传统浸泡腌制、传统盐水注射腌制、真空滚揉腌制以及高压腌制4种腌制工艺对鮰鱼都进行腌制得到调理鮰鱼产品,结果表明,将鱼肉与腌制液按照0.5 g/mL的料液比均匀混合﹐在高压(200 MPa)条件下腌制15 min后所得调理鮰鱼的综合评价最高,具有浓郁的风味特色,整体可接受度高。

除了采用新型腌制工艺调控淡水鱼预制产品风味外,还可以选用天然植物新原料如草药、香料、藻类等为淡水鱼的腌制原料,赋予鱼类预制产品良好的风味[35]。天然植物活性提取物亦可有效调控淡水鱼风味,延缓淡水鱼预制产品异味的形成[36]。例如,使用海藻提取物可以减缓鲶鱼鱼片冷藏过程中脂质氧化产生的挥发性香气化合物的发展[37];迷迭香提取物可使鲢鱼的腥味值降低约58%[38]。此外,植物乳杆菌[39]、风味蛋白酶[40]、酵母提取物[41]等新型外源添加物被广泛运用于淡水鱼预制产品的风味调控。

2.4 烹饪处理的影响及其调控

烹饪处理是鱼类预制菜变成食物过程的重要环节,在烹饪处理过程中,鱼肉会在高温下发生一系列的化学反应,使得鱼肉的风味、质地及外观形态发生显著变化[42]。鱼肉的常见烹饪处理有清蒸、水煮、油炸、炖焖、红烧等。不同的烹饪处理方式,由于其传热介质不同,对产品风味品质的影响不同[43−44]。传统油炸虽然会赋予产品诱人的风味、色泽,但也会导致产品的脂肪含量显著增加,且高温下化学反应会产生丙烯酰胺、丙二醛、5-羟甲基糠醛和反式脂肪酸等危害因子[45]。传统水煮烹饪能促进营养物质的释放,使肉质易于消化,但此法会降低产品的风味和滋味[46]。

因此,为使淡水鱼预制产品获得良好的风味,应采用新型烹饪处理方法对预制产品风味进行调控。常见的淡水鱼预制菜新型烹饪处理方法有真空低温慢煮、微波加热、空气炸制、汽蒸等。Hu等[47]采用不同烹饪处理方法(低温慢煮、蒸、微波、烘烤和油炸)对预制生鱼片进行烹饪,结果表明烘烤和煎炸,使得羰基和席夫碱的含量显著增加,游离硫醇的含量降低,而低温慢煮和清蒸的鱼片芳香族氨基酸和赖氨酸均发生氧化,使得鱼片获得最佳风味品质。卢琳等[48]等深入探究油炸、空气炸制、预油炸+空气炸制对鱼饼风味的影响,结果表明,空气炸制不仅可以降低鱼饼脂肪和丙二醛含量,还可以赋予鱼饼油炸风味和口感,是代替传统油炸方式较好的选择。邱文兴等[42]以预制好的鲜鲈鱼为原料,分别利用水煮、真空低温慢煮、空气炸3种烹饪处理后制成样品,利用气相色谱-质谱法(GC-MS)、电子鼻等技术,对其风味进行了分析。结果表明空气炸制的鲈鱼挥发性风味物质含量较高,真空低温慢煮的鱼肉挥发性成分含量较低。此外,研究表明烤鱼预制菜的最佳烹饪处理为微波复热,与蒸汽复热和烘烤复热相比,挥发性风味物质含量高尤其是醇类、醛类含量高,这是因为微波复热的加热温度高时间短,加速了脂质氧化及美拉德反应[49]。

2.5 包装方式的影响及其调控

淡水鱼预制产品在贮藏流通环境中,由于化学反应、脂质氧化、内源性酶和微生物的共同作用,很容易导致鱼肉不良风味的形成,甚至发生腐败粘稠。近年来,在预制产品包装领域,真空包装、改性气调包装及可食用膜包装或可食用涂层得到广泛的研究。Li等[50]海藻酸钠-没食子酸(ALG-GAL)涂层对鲭鱼风味化合物和品质特性的影响,在4 ℃冷藏期间保存12 d,结果表明,ALG涂层与GAL相结合,通过减少异味化合物和TVC数量,提高了冷藏鲭鱼片的质量。一种基于PLA/ZnO纳米颗粒/精油的新型活性纳米复合膜,应用于保存冷藏鱼片,鱼片的保质期从8 d显著增加到16 d[51]。Du等[52]开发的FMP/CS/RE复合薄膜在食品包装行业和食品冷链运输中具有很好的保鲜作用,可以有效抑制鱼类脂质氧化。除此之外,壳聚糖、明胶、海藻酸钠、真菌壳聚糖等均用于开发可食用薄膜,运用于鱼类产品在流通过程中进行保鲜[53−55]。在真空气调包装领域,通常是采用抽真空或者改变气体成分来调节微生物生长,延缓蛋白质分解、脂质氧化、厌氧糖酵解等一系列生化反应,从而有效抑制鱼腥味的发展,提高产品的风味品质和储存稳定性[56]。白晓州等[57]研究表明柠檬草精油与普鲁兰多糖复合涂膜对冷藏鲈鱼具有良好的保鲜效果,不仅能延长冷藏鲈鱼货架期,还使得冷藏鲈鱼在运输流通过程中保持优良的风味品质。

因此,为有效进行风味调控,淡水鱼预制产品在流通前必须采取科学的包装及储藏措施,以保持淡水鱼固有的风味品质。

3. 结论与展望

淡水鱼预制产品的风味特征形成机理包括蛋白质降解、脂肪氧化、美拉德反应及脂肪氧化与美拉德反应等,其风味品质受到淡水鱼的养殖环境、屠宰方式、腌制工艺、包装储藏及烹饪处理的影响。在明确风味形成机理及风味影响因素的基础上,通过相应的调控措施来实现淡水鱼预制产品风味的有效调控。

淡水鱼预制产品风味品质研究仍需解决以下几个方面的难题:a.现有的研究中重点侧重关注与鱼腥味有关的挥发性化合物的组成和含量,忽略了风味物质的浓度和阈值对淡水鱼及其制品风味特性的影响。因此,b.天然植物及其提取物(紫苏、八角、姜蒜、酵母提取物等)作为调味料被广泛运用于淡水鱼及其制品的加工过程中,便于去腥增香,提升风味品质,但风味改善机理有待深入研究,明确天然植物或提取物对鱼类及其制品风味改善机理,可为淡水鱼预制产品风味控制技术的建立提供理论依据。

淡水鱼预制菜作为预制菜中的重要类型,近年来发展迅速,市场需求量越来越大。为使淡水鱼预制菜更好地满足人们日益增长的市场需求,在今后的研究中,需要不断进行技术革新,应关注风味化合物浓度与其风味特性之间的量效关系,确定淡水鱼及其制品中关键风味物质呈现可接受鲜味的浓度范围和产生腥味的浓度范围,从而实现淡水鱼及其制品不良风味的精确调控。

-

-

[1] 苏欣, 黄春红, 曹菊花. 淡水鱼鱼肉风味物质及其影响因素研究进展[J]. 肉类研究,2018,32(8):78−82. [SU Xin, HUANG Chunhong, CAO Juhua. Review of flavor substances in freshwater fish and factors influencing them[J]. Meat Research,2018,32(8):78−82.] SU Xin, HUANG Chunhong, CAO Juhua. Review of flavor substances in freshwater fish and factors influencing them[J]. Meat Research, 2018, 32(8): 78−82.

[2] 陈剑岚, 陈舜胜, 施文正, 等. 大小草鱼肉呈味水溶性成分的比较[J]. 食品与发酵工业,2017,43(1):213−217. [CHEN Jianlan, CHEN Shunsheng, SHI Wenzheng, et al. Study of water-soluble flavor components in fish meat of different size of grass carp[J]. Food and Fermentation Industries,2017,43(1):213−217.] CHEN Jianlan, CHEN Shunsheng, SHI Wenzheng, et al. Study of water-soluble flavor components in fish meat of different size of grass carp[J]. Food and Fermentation Industries, 2017, 43(1): 213−217.

[3] CHANG C, WU G, ZHANG H, et al. Deep-fried flavor:Characteristics, formation mechanisms, and influencing factors[J]. Critical Reviews in Food Science and Nutrition,2020,60:1496−1514. doi: 10.1080/10408398.2019.1575792

[4] YANG W, SHI W, ZHOU S, et al. Research on the changes of water-soluble flavor substances in grass carp during steaming[J]. Journal of Food Biochemistry,2019,43(11):e12993.

[5] 施文正, 陈青云, 尤其嘉, 等. 不同温度条件下草鱼肉挥发性成分的检测[J]. 食品科学,2014,35(4):66−70. [SHI Wenzheng, CHEN Qingyun, YOU Qijia, et al. Effect of solid-phase microextraction temperature on the determination of volatile compounds of grass carp meat[J]. Food Science,2014,35(4):66−70.] doi: 10.7506/spkx1002-6630-201404014 SHI Wenzheng, CHEN Qingyun, YOU Qijia, et al. Effect of solid-phase microextraction temperature on the determination of volatile compounds of grass carp meat[J]. Food Science, 2014, 35(4): 66−70. doi: 10.7506/spkx1002-6630-201404014

[6] 刘敬科. 鲢鱼风味特征及热历史对鲢鱼风味的影响[D]. 武汉:华中农业大学, 2009. [LIU Jingke. Flavor character of silver carp and the influence of heating history on the silver carp flavor[D]. Wuhan:Huazhong Agricultural University, 2019.] LIU Jingke. Flavor character of silver carp and the influence of heating history on the silver carp flavor[D]. Wuhan: Huazhong Agricultural University, 2019.

[7] RUFIAN-HENARES J A, DELGADO-ANDRADE C, MORALES F J. Assessing the maillard reaction development during the toasting process of common flours employed by the cereal products industry[J]. Food Chemistry,2009,114(1):93−99. doi: 10.1016/j.foodchem.2008.09.021

[8] 胡祥飞. 草鱼油煎加工风味形成机理初探及1000吨鱼制品生产工厂设计[D]. 南昌:南昌大学, 2022. [HU Xiangfei. Preliminary study on flavor formation mechanism of pan-frying grass carp and design of 1000 tons fish products production plant [D]. Nanchang:Nanchang University, 2022.] HU Xiangfei. Preliminary study on flavor formation mechanism of pan-frying grass carp and design of 1000 tons fish products production plant [D]. Nanchang: Nanchang University, 2022.

[9] GAO P, XIA W S, LI X Z, et al. Optimization of the Maillard reaction of xylose with cysteine for modulating aroma compound formation in fermented tilapia fish head hydrolysate using response surface methodology[J]. Food Chemistry,2020,331:127353. doi: 10.1016/j.foodchem.2020.127353

[10] FENG L, TANG N C, LIU R J, et al. The relationship between flavor formation, lipid metabolism, and microorganisms in fermented fish products[J]. Food and Function,2021,12(13):5685−5702. doi: 10.1039/D1FO00692D

[11] HENNING C, GLOMB M A. Pathways of the Maillard reaction under physiological conditions[J]. Glycoconjugate Journal,2016,33:499−512. doi: 10.1007/s10719-016-9694-y

[12] 黄爱霞, 陈建明, 姜建湖, 等. 池塘内循环跑道养殖青鱼形体指数和肌肉营养价值分析[J]. 科学养鱼,2021(5):73−74. [HUANG Aixia, CHEN Jianming, JIANG Jianhu, et al. Analysis on body morphological indexes and muscle nutritive value of black carp in the pond recirculating aquaculture[J]. Scientific Fish Farming,2021(5):73−74.] doi: 10.3969/j.issn.1004-843X.2021.05.039 HUANG Aixia, CHEN Jianming, JIANG Jianhu, et al. Analysis on body morphological indexes and muscle nutritive value of black carp in the pond recirculating aquaculture[J]. Scientific Fish Farming, 2021(5): 73−74. doi: 10.3969/j.issn.1004-843X.2021.05.039

[13] 温利, 李温蓉, 陶玲, 等. 池塘循环水养殖对混养草鱼食用品质的影响[J]. 水生生物学报,2023,47(8):1353−1362. [WEN Li, LI Wenrong, TAO Ling, et al. Effect of recirculating water aquaculture in pond on the eating quality of polyculture grass carp[J]. Chinese Journal of Hydrobiology,2023,47(8):1353−1362.] doi: 10.7541/2023.2022.0177 WEN Li, LI Wenrong, TAO Ling, et al. Effect of recirculating water aquaculture in pond on the eating quality of polyculture grass carp[J]. Chinese Journal of Hydrobiology, 2023, 47(8): 1353−1362. doi: 10.7541/2023.2022.0177

[14] ZHANG T G, ZHANG L Z, YIN T, et al. Recent understanding of stress response on muscle quality of fish:From the perspective of industrial chain[J]. Trends in Food Science & Technology,2023,140:104145.

[15] 付朝松. 淡水池塘养殖环境的生态调控技术研究[D]. 上海:上海海洋大学, 2023. [FU Chaosong. Regulation techniques of freshwater pond aquaculture environment[D]. Shanghai:Shanghai Ocean University, 2023.] FU Chaosong. Regulation techniques of freshwater pond aquaculture environment[D]. Shanghai: Shanghai Ocean University, 2023.

[16] RAJU P, SULTAN M, MIZANUR R M, et al. Potential contribution of fish feed and phytoplankton to the content of volatile terpenes in cultured pangasius (Pangasianodon hypophthalmus) and Tilapia (Oreochromis niloticus)[J]. J Agric Food Chem,2017,65(18):3730−3736. doi: 10.1021/acs.jafc.7b00497

[17] PODDUTURI R, PETERSEN M A, VESTERGAARD M, et al. Case study on depuration of RAS-produced pikeperch (Sander lucioperca) for removal of geosmin and other volatile organic compounds (VOCs) and its impact on sensory quality[J]. Aquaculture,2021,530:735754. doi: 10.1016/j.aquaculture.2020.735754

[18] GREEN B W, RAWLES S D, SCHRADER K K, et al. Impact of dietary phytase on tilapia performance and biofloc water quality[J]. Aquaculture,2021,541:736845. doi: 10.1016/j.aquaculture.2021.736845

[19] LINDHOLM-LEHTO P C, KIURU T, HANNELIN P. Control of off-flavor compounds in a full-scale recirculating aquaculture system rearing rainbow trout Oncorhynchus mykiss[J]. Journal of Applied Aquaculture,2022,34(2):469−488. doi: 10.1080/10454438.2020.1866733

[20] PETTERSSON S J, LINDHOLM-LEHTO P C, PULKKINEN J T, et al. Effect of ozone and hydrogen peroxide on off-flavor compounds and water quality in a recirculating aquaculture system[J]. Aquacultural Engineering,2022,98:102277. doi: 10.1016/j.aquaeng.2022.102277

[21] AZARIA S, VAN-RIJN J. Off-flavor compounds in recirculating aquaculture systems (RAS):Production and removal processes[J]. Aquacultural Engineering,2018,83:57−64. doi: 10.1016/j.aquaeng.2018.09.004

[22] 周敏, 陈丽丽, 袁美兰, 等. 短期暂养对草鱼肉质和挥发性风味的影响[J]. 食品工业,2016,37(11):139−143. [ZHOU Min, CHEN Lili, YUAN Meilan, et al. Research on the effects of short term starvation to the grass carp meat quality and volatile flavor[J]. Food Industry,2016,37(11):139−143.] ZHOU Min, CHEN Lili, YUAN Meilan, et al. Research on the effects of short term starvation to the grass carp meat quality and volatile flavor[J]. Food Industry, 2016, 37(11): 139−143.

[23] ZHANG L, LI Q, LYU J, et al. The impact of stunning methods on stress conditions and quality of silver carp (Hypophthalmichthys molitrix) fillets stored at 4 ℃ during 72 h postmortem[J]. Food Chemistry,2017,216:130−137. doi: 10.1016/j.foodchem.2016.08.004

[24] ZHANG J, LI Y, YANG X, et al. Effects of oregano essential oil and nisin on the shelf life of modified atmosphere packed grass carp (Ctenopharyngodon idellus)[J]. LWT,2021,147:111609. doi: 10.1016/j.lwt.2021.111609

[25] 张荣层. 屠宰应激对团头鲂肌肉冷冻保存鲜度和质构特性的影响[D]. 武汉:华中农业大学, 2022. [ZHANG Rongceng. Effects of stress during slaughtering on muscle freshness and textural properties of blunt snout bream (Megalobrama amblycephala) during cryopreservation[J]. Wuhan:Huazhong Agricultural University, 2022.] ZHANG Rongceng. Effects of stress during slaughtering on muscle freshness and textural properties of blunt snout bream (Megalobrama amblycephala) during cryopreservation[J]. Wuhan: Huazhong Agricultural University, 2022.

[26] 周娇娇, 郭丹婧, 尤娟, 等. 不同致死方式对鳝鱼肌肉鲜度及生物胺含量的影响[J]. 华中农业大学学报,2016,35(6):129−135. [ZHOU Jiaojiao, GUO Danjing, Youjuan, et al. Effects of different slaughter methods on freshness and biogenic amines of Monopterus albus muscle[J]. Journal of Huazhong Agricultural University,2016,35(6):129−135.] ZHOU Jiaojiao, GUO Danjing, Youjuan, et al. Effects of different slaughter methods on freshness and biogenic amines of Monopterus albus muscle[J]. Journal of Huazhong Agricultural University, 2016, 35(6): 129−135.

[27] 刁玉段, 张晶晶, 史珊珊, 等. 致死方式对草鱼肉挥发性成分和脂肪氧合酶活性的影响[J]. 食品科学,2016,37(18):64−70. [DIAO Yuduan, ZHANG Jingjing, SHI Shanshan, et al. Effect of different slaughter methods on volatile compounds and lipoxygenase activity of grass carp meat[J]. Food Science,2016,37(18):64−70.] doi: 10.7506/spkx1002-6630-201618011 DIAO Yuduan, ZHANG Jingjing, SHI Shanshan, et al. Effect of different slaughter methods on volatile compounds and lipoxygenase activity of grass carp meat[J]. Food Science, 2016, 37(18): 64−70. doi: 10.7506/spkx1002-6630-201618011

[28] 吴永俊, 王莉, 康翠翠, 等. 不同致死方式对虹鳟鱼肉挥发性成分的影响[J]. 甘肃农业大学学报,2019,54(3):152−162. [WU Yongjun, WANG Li, KANG Cuicui, et al. Effects of different slaughter methods on the volatile components of rainbow trout meat[J]. Journal of Gansu Agricultural University,2019,54(3):152−162.] WU Yongjun, WANG Li, KANG Cuicui, et al. Effects of different slaughter methods on the volatile components of rainbow trout meat[J]. Journal of Gansu Agricultural University, 2019, 54(3): 152−162.

[29] 陈剑岚, 邵琳雅, 施文正, 等. 不同宰杀方式对草鱼肉呈味水溶性成分的影响[J]. 食品科学,2016,37(17):27−31. [CHEN Jianlan, SHAO Linya, SHI Wenzheng, et al. Effect of different slaughter methods on water-soluble flavor components in grass carp meat[J]. Food Science,2016,37(17):27−31.] doi: 10.7506/spkx1002-6630-201617005 CHEN Jianlan, SHAO Linya, SHI Wenzheng, et al. Effect of different slaughter methods on water-soluble flavor components in grass carp meat[J]. Food Science, 2016, 37(17): 27−31. doi: 10.7506/spkx1002-6630-201617005

[30] 方静, 黄卉, 李来好, 等. 不同致死方式对罗非鱼鱼片品质的影响[J]. 南方水产科学,2013,9(5):13−18. [FANG Jing, HUANG Hui, LI Laihao, et al. Effect of different slaughter methods on quality of Oreochromis sp. fillets[J]. Southern Aquatic Sciences,2013,9(5):13−18.] doi: 10.3969/j.issn.2095-0780.2013.05.003 FANG Jing, HUANG Hui, LI Laihao, et al. Effect of different slaughter methods on quality of Oreochromis sp. fillets[J]. Southern Aquatic Sciences, 2013, 9(5): 13−18. doi: 10.3969/j.issn.2095-0780.2013.05.003

[31] 陈盎弘, 许艳顺, 姜启兴, 等. 宰杀方式对冷冻斑点叉尾鮰品质的影响[J]. 现代食品科技,2015,31(9):218−222,131. [CHEN Anghong, XU Yanshun, JIANG Qixing, et al. Effect of slaughter methods on quality of frozen channel catfish fillets[J]. Modern Food Technology,2015,31(9):218−222,131.] CHEN Anghong, XU Yanshun, JIANG Qixing, et al. Effect of slaughter methods on quality of frozen channel catfish fillets[J]. Modern Food Technology, 2015, 31(9): 218−222,131.

[32] 吴晓蒙, 饶雷, 张洪超, 等. 新型食品加工技术提升预制菜肴质量与安全[J]. 食品科学技术学报,2022,40(5):1−13. [WU Xiaomeng, RAO Lei, ZHANG Hongchao, et al. Quality and safety improvement of premade cuisine by novel food processing technologies[J]. Journal of Food Science and Technology,2022,40(5):1−13.] doi: 10.12301/spxb202200904 WU Xiaomeng, RAO Lei, ZHANG Hongchao, et al. Quality and safety improvement of premade cuisine by novel food processing technologies[J]. Journal of Food Science and Technology, 2022, 40(5): 1−13. doi: 10.12301/spxb202200904

[33] 孙付万. 鲢鱼预制菜研制及贮藏期品质特性研究[D]. 天津:天津科技大学, 2022. [SUN Fuwan. Research on the development and quality characteristics of prepared silver carp food during storage[D]. Tianjin:Tianjin University of Science and Technology, 2022.] SUN Fuwan. Research on the development and quality characteristics of prepared silver carp food during storage[D]. Tianjin: Tianjin University of Science and Technology, 2022.

[34] 方媛璐, 商梓敬, 邬祥忠, 等. 基于模糊数学感官评价法的调味鱼腌制工艺优化[J]. 中国调味品,2022,47(5):155−157,162. [FANG Yuanlu, SHANG Zijing, WU Xiangzhong, et al. Optimization of salting process of seasoned fish based on fuzzy mathematics sensory evaluation method[J]. Chinese Condiments,2022,47(5):155−157,162.] FANG Yuanlu, SHANG Zijing, WU Xiangzhong, et al. Optimization of salting process of seasoned fish based on fuzzy mathematics sensory evaluation method[J]. Chinese Condiments, 2022, 47(5): 155−157,162.

[35] INANLI A G, TÜMERKAN E T A, ELABED N, et al. The impact of chitosan on seafood quality and human health:A review[J]. Trends in Food Science & Technology,2020,97:404−416.

[36] PRESENZA L, TEIXEIRA B F, GALVÄO J A, et al. Technological strategies for the use of plant-derived compounds in the preservation of fish products[J]. Food Chemistry, 2023:136069.

[37] DEEPITHA R P, XAVIER K A M, LAYANA P, et al. Quality improvement of Pangasius fillets using aqueous seaweed (Padina tetrastromatica) extract[J]. Lwt,2021,137:110418. doi: 10.1016/j.lwt.2020.110418

[38] HUANG P, WANG Z, SHI Y, et al. Deodorizing effects of rosemary extract on silver carp (Hypophthalmichthys molitrix) and determination of its deodorizing components[J]. Journal of Food Science,2022,87(2):636−650. doi: 10.1111/1750-3841.16023

[39] 梁进欣, 陈晓红, 李珊, 等. 植物乳杆菌对干腌马鲛鱼降盐增鲜效果的影响[J]. 食品科学,2022,43(6):174−180. [LIANG Jinxin, CHEN Xiaohong, LI Shan, et al. Salt-Reducing and umami-enhancing effect of Lactobacillus plantarum on dry cured mackere[J]. Food Science,2022,43(6):174−180].] doi: 10.7506/spkx1002-6630-20210203-065 LIANG Jinxin, CHEN Xiaohong, LI Shan, et al. Salt-Reducing and umami-enhancing effect of Lactobacillus plantarum on dry cured mackere[J]. Food Science, 2022, 43(6): 174−180]. doi: 10.7506/spkx1002-6630-20210203-065

[40] 徐鸣, 万金庆, 侯博玉, 等. 风味蛋白酶对冰温腌制鳜鱼肉品质的影响[J]. 大连海洋大学学报,2022,37(3):513−523. [XU Ming, WAN Jinqing, HOU Boyu, et al. Effects of flavor protease on quality of marinated mandarin fish at ice temperature[J]. Journal of Dalian Ocean University,2022,37(3):513−523.] XU Ming, WAN Jinqing, HOU Boyu, et al. Effects of flavor protease on quality of marinated mandarin fish at ice temperature[J]. Journal of Dalian Ocean University, 2022, 37(3): 513−523.

[41] ZANG J, YU D, ZHANG P, et al. The key enzymes and flavor precursors involved in formation of characteristic flavor compounds of low-salt fermented common carp (Cyprinus carpio L.)[J]. LWT Food Science and Technology,2022,154:112806. doi: 10.1016/j.lwt.2021.112806

[42] 邱文兴, 杜柳, 易弛, 等. 不同加热方式结合迷迭香对大口黑鲈脂质氧化及其风味的影响[J]. 食品安全质量检测学报,2023,14(11):43−51. [QIU Wenxing, DU Liu, YI Chi, et al. Effects of different heating methods combined with Rosmarinus on lipid oxidation and its flavour in Micropterus salmoides[J]. Journal of Food Safety and Quality Inspection,2023,14(11):43−51.] QIU Wenxing, DU Liu, YI Chi, et al. Effects of different heating methods combined with Rosmarinus on lipid oxidation and its flavour in Micropterus salmoides[J]. Journal of Food Safety and Quality Inspection, 2023, 14(11): 43−51.

[43] 张璇, 莫皓然, 赵会, 等. 不同烹饪方式对草鱼肉挥发性风味成分的影响[J]. 食品工业科技,2024,45(10):263−272. [ZHANG Xuan, MO Haoran, ZHAO Hui, et al. Effects of different cooking methods on volatile components of Ctenopharyngodon idella meat[J]. Science and Technology of Food Industry,2024,45(10):263−272.] ZHANG Xuan, MO Haoran, ZHAO Hui, et al. Effects of different cooking methods on volatile components of Ctenopharyngodon idella meat[J]. Science and Technology of Food Industry, 2024, 45(10): 263−272.

[44] 曾萍, 张业辉, 张友胜, 等. 不同烹饪方式对盐渍鱼干风味和微观结构的影响[J]. 现代食品科技,2019,35(6):207−215,138. [ZENG Ping, ZHANG Yehui, ZHANG Yousheng, et al. Effect of cooking methods on the flavor and microstructure of salted-dried fish[J]. Modern Food Technology,2019,35(6):207−215,138.] ZENG Ping, ZHANG Yehui, ZHANG Yousheng, et al. Effect of cooking methods on the flavor and microstructure of salted-dried fish[J]. Modern Food Technology, 2019, 35(6): 207−215,138.

[45] TORNBERG E V A. Effects of heat on meat proteins implications on structure and quality of meat products[J]. Meat Science,2005,70(3):493−508. doi: 10.1016/j.meatsci.2004.11.021

[46] 步营, 李月, 朱文慧, 等. 不同烹饪方式对海鲈鱼品质和风味的影响[J]. 中国调味品,2020,45(1):26−30. [BU Ying, LI Yue, ZHU Wenhui, et al. Effects of different cooking methods on quality and flavor of sea bass[J]. Chinese Condiments,2020,45(1):26−30.] doi: 10.3969/j.issn.1000-9973.2020.01.006 BU Ying, LI Yue, ZHU Wenhui, et al. Effects of different cooking methods on quality and flavor of sea bass[J]. Chinese Condiments, 2020, 45(1): 26−30. doi: 10.3969/j.issn.1000-9973.2020.01.006

[47] HU L, REN S, SHEN Q, et al. Proteomic study of the effect of different cooking methods on protein oxidation in fish fillets[J]. Rsc Advances,2017,7(44):27496−27505. doi: 10.1039/C7RA03408C

[48] 卢琳, 路索, 武润琳, 等. 第二段加热方式对鱼饼食用品质及脂肪含量的影响[J]. 华中农业大学学报,2022,41(6):255−261. [LU Lin, LU Suo, WU Runlin, et al. Effects of second-step heating on edible quality and content of fat in fish cakes[J]. Journal of Huazhong Agricultural University,2022,41(6):255−261.] doi: 10.3969/j.issn.1000-2421.2022.6.hznydx202206030 LU Lin, LU Suo, WU Runlin, et al. Effects of second-step heating on edible quality and content of fat in fish cakes[J]. Journal of Huazhong Agricultural University, 2022, 41(6): 255−261. doi: 10.3969/j.issn.1000-2421.2022.6.hznydx202206030

[49] 王源渊, 尚珊, 丁若松, 等. 不同复热方式对预制烤鱼品质的影响[J]. 食品与发酵工业,2024,50(1):248−255. [WANG Yuanyuan, SHANG Shan, DING Ruosong, et al. Effects of different reheating methods on quality of pre-roasted fish[J]. Food and Fermentation Industry,2024,50(1):248−255.] WANG Yuanyuan, SHANG Shan, DING Ruosong, et al. Effects of different reheating methods on quality of pre-roasted fish[J]. Food and Fermentation Industry, 2024, 50(1): 248−255.

[50] LI X, TU Z, SHA X, et al. Effect of coating on flavor metabolism of fish under different storage temperatures[J]. Food Chemistry:X,2022,13:100256.

[51] HEYDARI-MAJD M, GHANBARZADEH B, SHAHIDI-NOGHABI M, et al. A new active nanocomposite film based on PLA/ZnO nanoparticle/essential oils for the preservation of refrigerated Otolithes ruber fillets[J]. Food Packaging and Shelf Life,2019,19:94−103. doi: 10.1016/j.fpsl.2018.12.002

[52] DU H, LIU C, UNSALAN O, et al. Development and characterization of fish myofibrillar protein/chitosan/rosemary extract composite edible films and the improvement of lipid oxidation stability during the grass carp fillets storage[J]. International Journal of Biological Macromolecules,2021,184:463−475. doi: 10.1016/j.ijbiomac.2021.06.121

[53] LIU Y, HUANG Y, WANG Z, et al. Recent advances in fishy odour in aquatic fish products, from formation to control[J]. International Journal of Food Science & Technology,2021,56(10):4959−4969.

[54] LIU J, SHEN S, AO N, et al. Effect of glycation on physicochemical properties and volatile flavor characteristics of silver carp mince[J]. Food Chemistry,2022,386:132−741.

[55] DAI W, WANG W, GU S, et al. Effect of chitosan-epigallocatechin gallate coating on volatile flavor compounds retention in bighead carp (Aristichthys nobilis) fillets during chilled storage[J]. LWT,2022,169:114027. doi: 10.1016/j.lwt.2022.114027

[56] ZHU Y, MA L, YANG H, et al. Super-chilling (0.7 ℃) with high-CO2 packaging inhibits biochemical changes of microbial origin in catfish (Clarias gariepinus) muscle during storage[J]. Food Chemistry,2016,206:182−190. doi: 10.1016/j.foodchem.2016.03.053

[57] 白晓州, 王田林. 柠檬草精油-普鲁兰多糖复合涂膜对冷藏鲈鱼的保鲜效果[J]. 中国食品添加剂,2023,34(7):213−220. [BAI Xiaozhou, WANG Tianlin. Fresh-keeping effect of lemongrass essential oil pullulan polysaccharide compound coating on refrigerated bass[J]. Chinese Food Additives,2023,34(7):213−220.] BAI Xiaozhou, WANG Tianlin. Fresh-keeping effect of lemongrass essential oil pullulan polysaccharide compound coating on refrigerated bass[J]. Chinese Food Additives, 2023, 34(7): 213−220.

-

期刊类型引用(1)

1. 姜获足,朱芳芳,彭金山. 消费者对预制菜认知及影响因素的统计调查. 中国食品工业. 2024(24): 41-43 .  百度学术

百度学术

其他类型引用(0)

下载:

下载:

下载:

下载: