Effects of Vacuum Processing Treatment on the Structure and Physical and Chemical Properties of Fresh Waxy Corn Starch

-

摘要: 为探究真空加工处理对鲜食糯玉米淀粉结构和理化性质的影响,以黄糯619和黑宝两个鲜食糯玉米品种为原料,通过扫描电子显微镜、X-射线衍射仪、傅里叶红外光谱仪、差示扫描量热仪和快速黏度分析仪等研究真空加工处理对鲜食糯玉米淀粉微观结构和理化性质的影响。结果表明:真空加工处理使黄糯619和黑宝2种鲜食糯玉米的直链淀粉含量显著升高(P<0.05),分别由5.39%和6.26%升高至8.52%和9.71%,支链淀粉含量显著降低(P<0.05),分别由94.61%和93.74%降低至91.48%和90.29%,淀粉颗粒破坏严重,淀粉的晶体类型和官能团结构没有改变,但相对结晶度分别降低了9.62%和9.41%;真空加工处理后,2种鲜食糯玉米淀粉的起始温度、峰值温度、终止温度和糊化焓值显著下降(P<0.05),淀粉的糊化温度、峰值黏度、最终黏度、衰减值、回生值显著下降(P<0.05),表明淀粉更容易发生糊化,抗老化能力增强。此外,真空加工处理使鲜食糯玉米淀粉的抗性淀粉(RS)转变为快消化淀粉(RDS)和慢消化淀粉(SDS),说明真空加工处理能够提高鲜食糯玉米淀粉的消化速率。本实验结果可以为鲜食糯玉米真空加工与利用提供理论依据。Abstract: In order to explore the effect of vacuum processing treatment on the starch structure and physical and chemical properties of fresh waxy corn, Huangnuo 619 and Heibao were used as raw materials. The microstructure and physicochemical properties of fresh waxy corn starch after vacuum processing treatment were investigated by scanning electron microscope, X-ray diffractometer, Fourier infrared spectrometer, differential scanning calorimeter and rapid viscosity analyzer. The results showed that vacuum processing treatment of Huangnuo 619 and Heibao fresh waxy corn significantly increased the amylope content (P<0.05), from 5.39% and 6.26% to 8.52% and 9.71% respectively, and significantly decreased the amylopectin content (P<0.05), from 94.61% and 93.74% to 91.48% and 90.29% respectively. Starch particles were damaged severely, the crystal type and functional group structure of starch had not been changed, but the relative crystallinity decreased by 9.62% and 9.41% respectively. After vacuum processing treatment, the initial temperature, peak temperature, final temperature and gelatinization enthalpy of the two kinds of fresh waxy corn starch decreased significantly (P<0.05), and the gelatinization temperature, peak viscosity, final viscosity, decay value and recovery value decreased significantly (P<0.05), which showed that starch was more prone to gelatinization and its anti-aging ability was enhanced. In addition, the resistant starch (RS) of fresh waxy corn starch was transformed into rapid digestible starch (RDS) and slow digestible starch (SDS) by vacuum processing treatment, indicated that the digestion rate of fresh waxy corn starch could be improved by vacuum processing treatment. The experimental results can provide theoretical basis for vacuum processing and utilization of fresh waxy corn.

-

糯玉米(Zea mays L. certaina Kulesh)又名粘玉米或蜡质型玉米,最初起源于中国云南,它是由于第9号染色体上的隐性糯质基团wx控制而产生的新品种,因其基因活性被抑制,导致籽粒内部不能直接合成直链淀粉,所以糯玉米籽粒中支链淀粉含量较高[1−3]。由于鲜食糯玉米属于季节性食品,在采后容易发生品质下降、籽粒失水皱缩等问题。因此,常采用加工处理来保证鲜食糯玉米原有的营养价值、风味和口感,并延长贮藏期[4]。其中,真空加工处理是目前鲜食玉米最常用的3种加工方式之一,因其加工设备简单,对贮藏环境要求低而备受生产企业青睐。

淀粉是食品生产中的重要原料,而玉米淀粉因资源丰富、价格低廉,被广泛应用于食品等行业[5−6],同时,淀粉对食品加工和最终产品的质量也非常重要。在粮谷原料加工中,不同的加工处理对其淀粉的结构及其理化特性有不同程度的影响。例如,真空加工处理会导致大米淀粉颗粒严重收缩和损伤,并且降低了大米淀粉的平均粒径、相对结晶度和层状结构的有序度,从而改变了大米淀粉的热性能和糊化特性[7];Li等[8]研究表明,不同的处理压力对大米淀粉的结构和性质影响不同,在高静水压压力小于480 MPa时,大米淀粉的颗粒形态、大小和晶体结构不受影响,当压力达到600 MPa时,大米淀粉颗粒形态、大小和晶体结构明显受损,导致A型晶型转变为B型晶型;但是,大米淀粉经脉冲电场处理后,其短程有序化结构重新排列,结晶结构被破坏,导致大米淀粉糊化焓值和回生值显著降低[9]。此外,Bahrani等[10]研究真空处理压力对玉米淀粉蒸汽加工前后的作用时发现,随着真空处理压力的升高,玉米淀粉颗粒被破坏,形成大小不一的聚集体,并且淀粉粒径分布向大粒径方向移动,糊化焓值显著降低,同时,在压力为0.3 MPa时,淀粉悬浮液完全流化,倾向于牛顿流体。截止目前,尚未见到真空加工处理对鲜食糯玉米淀粉的结构及其理化性质影响的报道。

为深入探究真空加工处理对鲜食糯玉米淀粉的影响,利用扫描电子显微镜、X-射线衍射仪、傅里叶红外光谱仪、快速黏度分析仪和差示扫描量热仪等设备,研究真空加工处理前后鲜食糯玉米淀粉的微观结构及其热力学特性、糊化特性和消化特性的变化,以期提高真空加工的鲜食糯玉米品质,为其开发利用提供理论依据。

1. 材料与方法

1.1 材料与仪器

黄糯619、黑宝鲜食糯玉米 黑龙江大董黑土地农业有限公司;猪胰-α-淀粉酶(≥5 U/mg)、糖化酶(100000 U/mL) 上海源叶生物科技有限公司;葡萄糖含量检测试剂盒(GOPOD) 北京盒子生工科技有限公司;氢氧化钠、氢氧化钾、碘化钾、碘、浓盐酸、亚硫酸氢钠、溴化钾 分析纯,上海阿拉丁生化试剂有限公司;食品级真空包装袋 膜厚100 μm,表面积12 cm×28 cm,材质为尼龙/耐高温蒸煮膜(PA+RCPP),透水率3.23 mg/(m2·d),透氧率56.32 mL/(m2·d) 石家庄喜龙包装有限公司。

LD-ZZ漂烫干蒸两用机 诸城市利德机械有限责任公司;TS2237204-2019反压高温灭菌锅 诸城市良工机械有限公司;RZ8150ZKJC真空包装机 瑞志机械有限公司;TG16-WS离心机 湖南湘仪实验室仪器开发有限公司;101-2AB电热鼓风干燥箱 天津市泰斯特仪器有限公司;UV-1100紫外可见分光光度计 上海凌析达仪器公司;SHZ-82B水浴恒温振荡器 常州金南仪器制造有限公司;EX324电子分析天平 奥豪斯仪器(上海)有限公司;Nicolet 6700傅里叶红外光谱仪 美国尼高力仪器公司;JSM-6390LV扫描电子显微镜 日本HITACHI公司;X-射线衍射仪 德国Bruker AXS有限公司;RVA4500快速黏度分析仪 瑞典Perten公司;DSC Q2000差示扫描量热仪 美国TA Instruments公司。

1.2 实验方法

1.2.1 鲜食糯玉米真空处理工艺

1.2.1.1 鲜食糯玉米真空处理工艺流程

原料采收→预处理→漂烫→冷却→真空包装→杀菌→水冷→包装→成品。

1.2.1.2 操作要点

鲜食糯玉米(黄糯619、黑宝)采收后先脱皮去须、切头去尾,随后进行清洗,清洗结束后在漂烫干蒸两用机中漂烫(80 ℃,5 min),漂烫结束后立即进行喷淋冷却,冷却后采用食品级真空包装袋进行抽真空包装,抽真空时间30 s,真空度−0.09 MPa[11],包装后在反压高温灭菌锅中杀菌(121 ℃,20 min),杀菌结束后进行冷却,冷却后得到鲜食糯玉米真空加工处理产品,于20 ℃下避光贮藏,并在贮藏180 d后提取其淀粉进行测定。

1.2.2 淀粉的提取

真空加工处理组样品按照1.2.1.2方法处理,对照组(未处理)样品为同批次采收的同品种鲜食糯玉米,采后未经任何处理,直接用来提取其淀粉。将随机抽取的真空加工处理组和对照组样品进行剥粒,用浓度为1 g/L的亚硫酸氢钠浸泡12 h(质量比1:5),随后用流动水清洗并加水打浆(质量比1:2),打浆后过100目筛,获得淀粉乳。将淀粉乳于4000 r/min离心10 min,弃去上清液,将沉淀移至烧杯中并用0.3%的氢氧化钠溶液搅拌30 min,重复上述离心步骤3次。最后在40 ℃干燥箱中烘干,粉碎过100目筛,得到鲜食糯玉米淀粉,封存备用。

1.2.3 指标测定

1.2.3.1 直/支链淀粉含量的测定

参照张瑜等[12]的方法,采用双波长分光光度法测定鲜食糯玉米淀粉中直链淀粉和支链淀粉含量。准确称取干燥至恒重的糯玉米淀粉0.1 g于烧杯中,加10 mL 1 mol/L的氢氧化钾溶液,于85 ℃水浴中充分搅拌溶解,冷却后用蒸馏水定容至50 mL备用。吸取该样液5 mL,加25 mL蒸馏水,用0.1 mol/L的盐酸溶液将pH调至3.0,加0.5 mL碘试剂,用蒸馏水定容至50 mL后进行测定。根据公式分别计算出样品中直链淀粉(W直)和支链淀粉(W支)的含量。

式中:W直为直链淀粉含量,%;W支为支链淀粉含量,%;Y直为直链淀粉浓度,mg/mL;Y支为支链淀粉浓度,mg/mL;M为干燥后糯玉米淀粉质量,mg。

1.2.3.2 糯玉米淀粉颗粒形貌的测定

准确称取10 mg糯玉米淀粉均匀涂抹在样品台上,进行喷金处理,通过扫描电子显微镜观察颗粒形貌。扫描条件:加速电压2.0 kV,放大1000倍[13]。

1.2.3.3 糯玉米淀粉结晶结构的测定

取一定量的糯玉米淀粉在25 ℃和相对湿度100%的条件下平衡24 h,然后进行X-射线衍射仪检测。条件为:电压40 kV,电流44 mA,扫描范围5°~45°,扫描速率4°/min。使用MDI jade 6软件计算糯玉米的相对结晶度[14]。

1.2.3.4 淀粉短程有序化结构的测定

准确称取2 mg糯玉米淀粉(干基),按m(糯玉米淀粉样品):m(KBr)=1:100添加KBr粉末,并用研钵研磨均匀,通过压片机压制成厚度约0.5 mm的薄片。利用傅里叶红外光谱仪测定淀粉的短程有序化结构,设置分辨率为4 cm−1,扫描次数64次,空气测定为背景,在波数为4000~400 cm−1范围内扫描。于1200~800 cm−1区域自去卷积处理,设定半带宽为26 cm−1,增强因子为2.4[15],测定1047和1022 cm−1处吸光度值,并按照公式计算二者比值,其比值可以表征鲜食糯玉米淀粉的短程有序结构[16]。

式中:A1047为在1047 cm−1处测定的吸光度值;A1022为在1022 cm−1处测定的吸光度值。

1.2.3.5 淀粉热力学特性的测定

参照Xiao等[17]的方法,利用差示扫描量热仪测定糯玉米淀粉热力学特性。准确称取2.0 mg糯玉米淀粉于坩埚中,加入4 μL蒸馏水混合,密封坩埚,室温下平衡48 h。以10 ℃/min的加热速率从20 ℃升温至120 ℃,同时采用空盘做对照实验。测定其起始温度(T0)、峰值温度(TP)、终止温度(TC)和糊化焓值(ΔH)。

1.2.3.6 淀粉糊化特性的测定

参照林江涛等[18]的方法,利用快速黏度分析仪测定糯玉米淀粉的糊化特性。准确称取3.0 g糯玉米淀粉于铝盒中,加25 mL蒸馏水。前10 s浆速960 r/min分散样品,之后维持160 r/min。浆液50 ℃平衡1 min,之后以12 ℃/min的速度加热至95 ℃,保持5 min,再以12 ℃/min的速度冷却至50 ℃保持2 min。记录糊化温度(℃)、峰值黏度(cP)、峰值时间(min)、最低黏度(cP)、最终黏度(cP)、衰减值(cP)和回生值(cP)。

1.2.3.7 淀粉消化特性的测定

参照郭宏伟等[19]的方法,准确称取0.2 g淀粉,加10 mL水在95 ℃水浴锅中糊化30 min,冷却后加15 mL 0.2 mol/L醋酸钠缓冲液(pH5.2),混合均匀后加入10 mL酶混合液(290 U/mL的猪胰-α-淀粉酶和15 U/mL的糖化酶),放入37 ℃恒温水浴中振荡120 min,分别在20和120 min时各取0.5 mL酶解液,加入4 mL无水乙醇,于4000 r/min离心5 min。取上清液,采用葡萄糖含量检测试剂盒测定葡萄糖含量。根据公式分别计算鲜食糯玉米淀粉的快消化淀粉(RDS)、慢消化淀粉(SDS)和抗性淀粉(RS)的质量分数。

式中:RDS为快消化淀粉相对含量,%;SDS为慢消化淀粉相对含量,%;RS为抗性淀粉相对含量,%;FG为酶水解前样品中葡萄糖含量,mg;G20为酶水解20 min后葡萄糖的含量,mg;G120为酶水解120 min葡萄糖的含量,mg;m为淀粉质量,mg;A为稀释倍数。

1.3 数据处理

本实验采用SPSS 24.0中方差分析(ANOVA)比较不同组别之间的差异显著性(P<0.05),并利用Excel 2010软件和Origin 2018进行绘图。

2. 结果与分析

2.1 真空加工处理对糯玉米直链淀粉和支链淀粉含量的影响

直链淀粉标准曲线回归方程为y=14.853x−0.0693,R2=0.9940;支链淀粉标准曲线回归方程为y=2.429x+0.0716,R2=0.9964。鲜食糯玉米直链淀粉和支链淀粉含量如表1所示,2种鲜食糯玉米支链淀粉含量明显高于直链淀粉含量,并且未经真空加工处理的2种鲜食糯玉米直链淀粉含量在蜡质玉米直链淀粉含量的范围内[20]。鲜食糯玉米经过真空加工处理后,2种鲜食糯玉米的直链淀粉含量显著上升,支链淀粉含量显著下降(P<0.05),这可能是由于鲜食糯玉米在真空加工过程中受到高温杀菌和减压的影响,导致部分支链淀粉发生降解,转化为直链淀粉[21]。

表 1 真空加工处理对糯玉米直链淀粉和支链淀粉含量的影响Table 1. Effect of vacuum processing treatment on amylose and amylopectin content of waxy corn2.2 真空加工处理对糯玉米淀粉颗粒形貌的影响

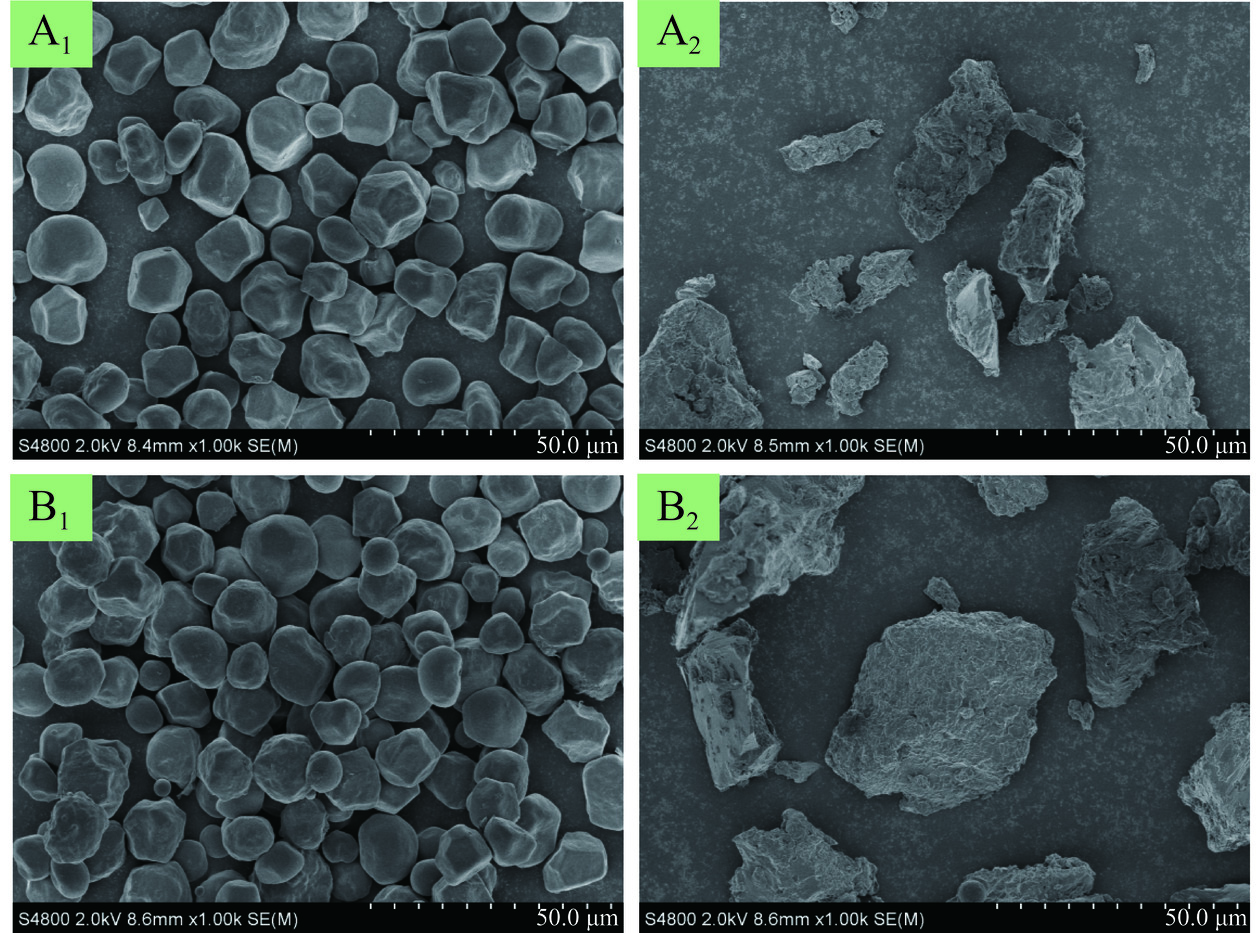

如图1A1、B1所示,未处理的黄糯619鲜食糯玉米淀粉颗粒分布较分散,呈不规则多边形和球形,表面有轻微褶皱,而未处理的黑宝糯玉米淀粉颗粒分布聚集,表面光滑、完整,少部分颗粒呈褶皱形态。由图1A2、B2可知,两种鲜食糯玉米经真空加工处理后,淀粉颗粒结构被严重破坏,完整性丧失,黄糯619糯玉米淀粉颗粒出现孔隙结构,颗粒大小不均匀,而黑宝糯玉米淀粉颗粒呈团块状分布,这可能是由于鲜食糯玉米在湿热杀菌过程中,淀粉颗粒发生糊化,导致支链淀粉被破坏,在其贮藏期间发生老化,重组为直链淀粉,表面形成孔状且形状不规则[22],从而改变了淀粉的颗粒结构。这与Bahrani等[10]在玉米淀粉减压热湿处理中的实验结果一致。

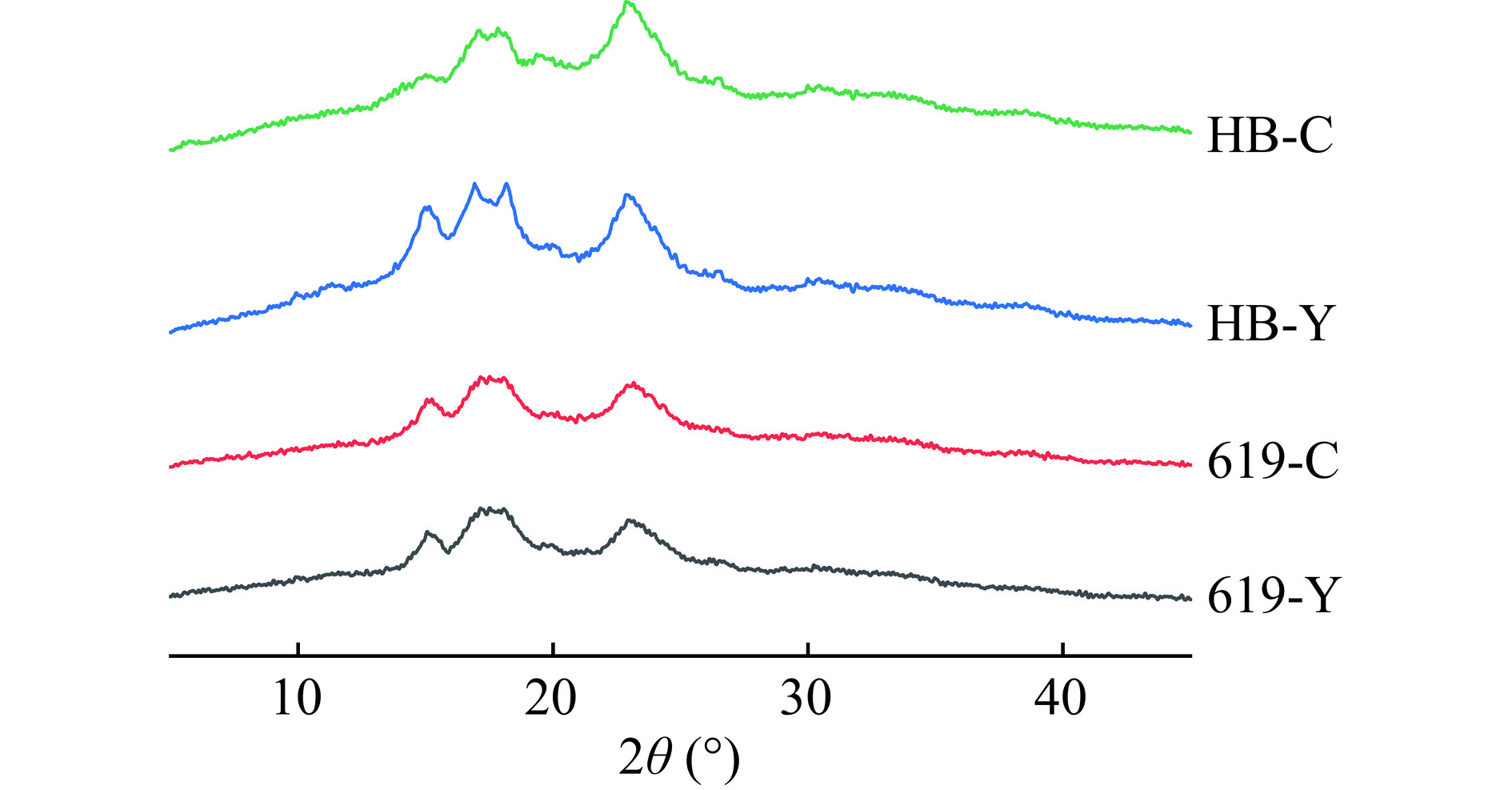

2.3 真空加工处理对糯玉米淀粉结晶结构的影响

根据淀粉的X-射线衍射图谱,可以将淀粉晶体结构分为A型、B型和C型三种,A型淀粉主要在15°、17°、18°、23°左右出现明显的衍射峰,B型淀粉在5°、17°、22°、24°左右有衍射峰,C型淀粉是A型与B型的组合类型[23]。由图2可知,不同品种的糯玉米淀粉均在2θ为15°、17°、18°和23°附近出现明显的衍射峰,因此,黄糯619和黑宝的淀粉结晶结构为A型淀粉结构,并且其淀粉经真空加工后出峰位置没有发生改变,说明真空加工处理并没有改变这2种糯玉米淀粉的晶体类型。由表2可知,2种糯玉米经真空加工处理后淀粉的相对结晶度显著降低(P<0.05),这可能是鲜食糯玉米经过真空加工处理时,由于高温杀菌和减压的作用破坏了淀粉颗粒间原有的氢键,使淀粉分子的双螺旋结构和有序排列发生变化,导致其结晶结构遭到破坏,从而导致结晶度降低[24−25]。

表 2 真空加工处理对糯玉米淀粉相对结晶度的影响Table 2. Effect of vacuum processing treatment on relative crystallinity of waxy corn starch样品 相对结晶度(%) 对照组(未处理) 真空加工处理组 黄糯619 35.73±0.44a 26.11±0.18b 黑宝 37.37±0.26a 27.96±0.22b 注:同行不同小写字母表示差异显著(P<0.05)。 2.4 真空加工处理对糯玉米淀粉短程有序化结构的影响

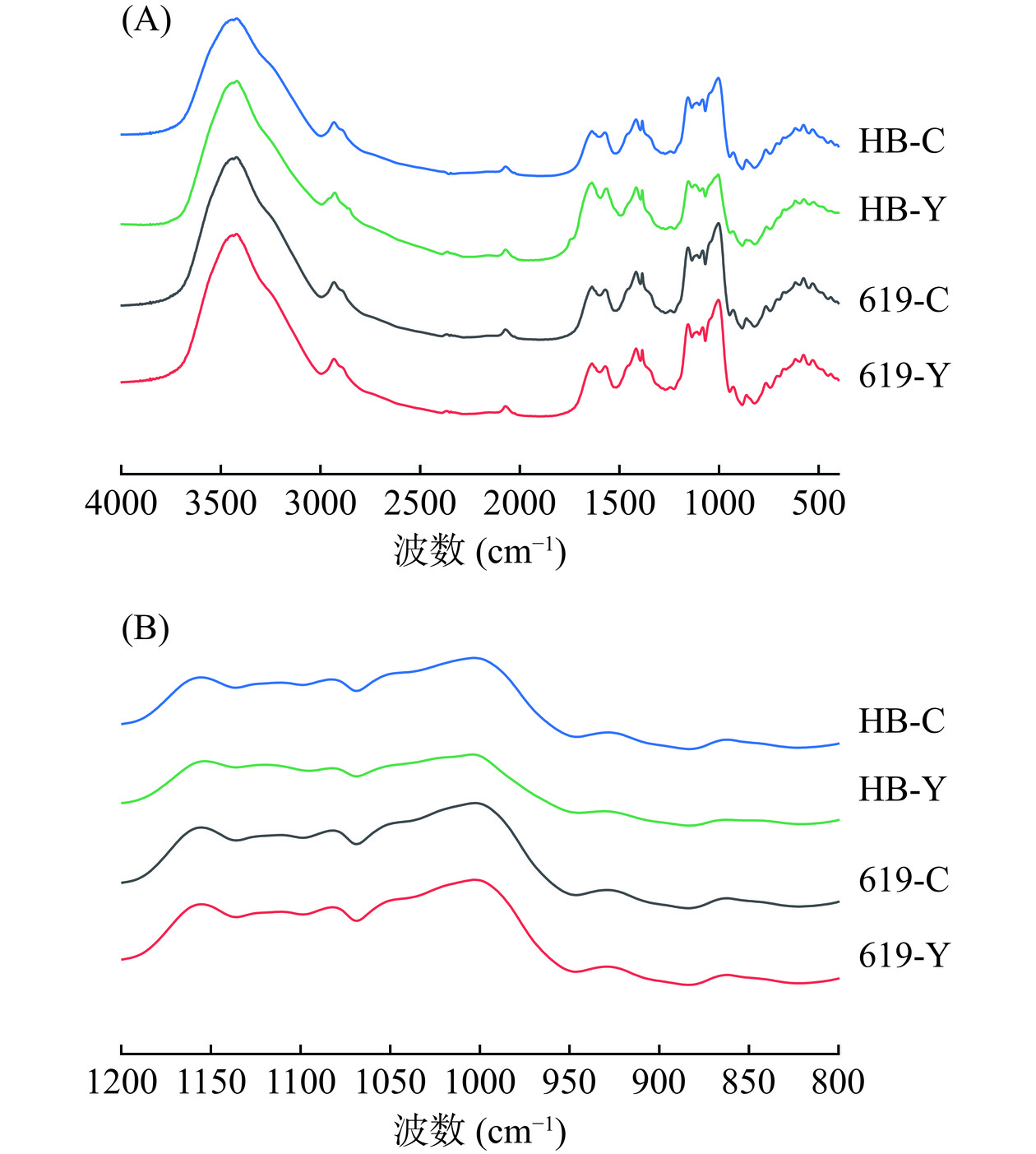

采用红外色谱法(FTIR)测定糯玉米淀粉的短程有序性,图3(A)为不同品种的糯玉米淀粉红外曲线图,可以看出各个品种的糯玉米淀粉经加工后特征峰的位置无明显变化,说明真空加工处理没有引起糯玉米淀粉相关基团的变化[26]。图3(B)为不同糯玉米淀粉在区间1200~800 cm−1的去卷积图谱,主要观测1022 cm−1和1047 cm−1两处的红外吸收峰,它代表淀粉的有序化和无定型区域,其比值(R1047/1022)可以反映糯玉米淀粉的短程有序性[27]。如表3所示,2种鲜食糯玉米经真空加工处理后,R1047/1022比值均呈下降趋势,这可能是由于在真空加工过程中受到高温杀菌和减压的影响,破坏了淀粉分子链之间或内部已有的氢键,导致淀粉分子的双螺旋结构排列不规则,无定型区域内螺旋结构被破坏,从而导致其短程有序化结构呈下降趋势[28]。

表 3 真空加工处理对糯玉米淀粉短程有序化结构的影响Table 3. Effect of vacuum processing treatment on short-range ordered structure of waxy corn starch波数(cm−1) 吸光度 619-Y 619-C HB-Y HB-C 1047 1.511±0.011 1.332±0.010 0.710±0.008 0.703±0.012 1022 1.573±0.012 1.469±0.013 0.742±0.010 0.778±0.014 1047/1022 0.961±0.012 0.907±0.011 0.957±0.009 0.904±0.013 2.5 真空加工处理对糯玉米淀粉热力学特性的影响

淀粉的起始温度、峰值温度、终止温度等相变温度和糊化焓值能够反映淀粉的结晶结构和组成的变化。表4为真空加工处理对糯玉米淀粉热力学特性的影响,2个品种的糯玉米淀粉经真空加工后起始温度、峰值温度、终止温度和糊化焓值均显著降低(P<0.05),这与Wang等[29]研究结果一致。而糊化焓值代表淀粉糊化过程中结晶结构或螺旋结构崩解所需的能量,鲜食糯玉米经真空加工处理后淀粉的糊化焓值降低,说明鲜食糯玉米在加工过程中受到高温杀菌和减压的双重作用,使淀粉的颗粒结晶区域和非晶区域内双螺旋结构被破坏,导致熔解淀粉所需能量降低[30−31]。这与本研究中结晶结构和短程有序化结构测定结果一致。

表 4 真空加工处理对糯玉米淀粉热力学特性的影响Table 4. Effect of vacuum processing treatment on the thermodynamic characteristics of waxy corn starch样品 起始温度(℃) 峰值温度(℃) 终止温度(℃) 糊化焓值(J/g) 619-Y 70.28±0.23a 75.13±0.28a 87.19±0.33c 5.11±0.04c 619-C 52.79±0.15c 61.44±0.15c 71.25±0.21d 2.26±0.02d HB-Y 65.78±0.28b 71.89±0.17b 90.20±0.27a 9.71±0.05a HB-C 50.75±0.13d 60.74±0.12d 88.40±0.29b 6.98±0.04b 2.6 真空加工处理对糯玉米淀粉糊化特性的影响

真空加工处理对糯玉米淀粉糊化特性的影响如表5所示。2个品种的鲜食糯玉米淀粉经真空加工后其糊化温度、峰值黏度、最低黏度、最终黏度、衰减值和回生值均显著降低(P<0.05)。其中,糊化温度降低说明真空加工过程中高温杀菌使糯玉米淀粉更易发生糊化;峰值黏度反映糊化过程中淀粉颗粒膨胀的最大程度[32],峰值黏度降低可能是因为淀粉的有序化结构降低、淀粉颗粒破碎所导致;衰减值为峰值黏度与最低黏度的差值,它的值越大稳定性越差,2种鲜食糯玉米真空加工后淀粉的衰减值均呈现下降趋势,表明鲜食糯玉米经真空加工后稳定性升高,这可能是淀粉颗粒聚集态结构的无序化程度增加,促进淀粉分子链在冷却过程中的重排和重结晶;回生值为最终黏度与最低黏度的差值,它能反映淀粉的老化趋势[33],黄糯619和黑宝2个品种的鲜食糯玉米经真空加工后淀粉的回生值呈下降趋势,说明抗老化能力增强,可能是受到高温杀菌和减压的影响,导致糯玉米中直链淀粉和支链淀粉的比例发生变化,长链切短,改变了淀粉链结构,破坏了某些胶束的重新聚合力,保持了淀粉的稳定性,从而使得抗老化能力增强[34−35]。

表 5 真空加工处理对糯玉米淀粉糊化特性的影响Table 5. Effect of vacuum processing treatment on gelatinization characteristics of waxy corn starch样品 糊化温度

(℃)峰值黏度

(cP)峰值时间(min) 最低黏度

(cP)最终黏度

(cP)衰减值

(cP)回生值

(cP)619-Y 86.14±0.24b 4834.68±24.37a 4.60±0.01c 1878.24±21.56a 2739.72±20.21b 2956.44±10.12b 861.48±2.12b 619-C 68.02±0.18d 2795.16±16.52c 3.40±0.00d 625.92±4.31d 999.84±9.74c 2169.24±8.73c 373.92±0.55c HB-Y 91.30±0.37a 4654.68±21.89b 5.10±0.00b 1537.44±8.64b 3433.44±14.63a 3117.24±13.65a 1896.00±7.32a HB-C 72.86±0.11c 748.92±12.73d 9.60±0.02a 655.56±7.52c 834.12±7.11d 93.36±2.11d 178.56±0.71d 2.7 真空加工处理对糯玉米淀粉消化特性的影响

淀粉的体外消化包括酶在底物中的扩散以及吸附和水解,这个过程受到分子有序化结构、晶体结构、颗粒大小及完整性、颗粒孔隙度等因素影响。根据淀粉消化速度可分为快消化淀粉(RDS,0~20 min水解)、慢消化淀粉(SDS,20~120 min水解)和抗性淀粉(RS,120 min内未水解)三种[36]。表6为真空加工处理对糯玉米淀粉消化特性的影响,可以看出2种鲜食糯玉米经真空加工后RDS和SDS含量显著上升(P<0.05),RS含量显著下降(P<0.05),这可能是鲜食糯玉米在真空加工过程中受高温杀菌和减压的影响,淀粉颗粒结构被破坏,颗粒表面出现凹痕,内部出现裂缝,使酶分子更容易进入淀粉分子内部与之结合,从而提高了淀粉消化速率,导致部分RS转化为RDS和SDS[37]。此外,淀粉内部短程有序化结构和结晶结构的破坏也可以导致淀粉酶易与淀粉分子结合、变构和定位催化,从而提高RDS和SDS的含量。

表 6 真空加工处理对糯玉米淀粉消化特性的影响Table 6. Effect of vacuum processing treatment on digestive characteristics of waxy corn starch样品 RDS含量(%) SDS含量(%) RS含量(%) 619-Y 54.74±0.85c 13.22±0.33b 32.04±1.52b 619-C 78.52±1.03a 17.21±0.78a 4.27±0.21d HB-Y 49.64±1.37d 13.86±1.03b 36.50±2.77a HB-C 72.46±0.56b 17.59±0.84a 9.95±1.63c 3. 结论

本文研究了真空加工处理对黄糯619和黑宝2个品种鲜食糯玉米淀粉的形态、微观结构和理化特性的影响。结果显示真空加工处理可使黄糯619和黑宝2种鲜食糯玉米的直链淀粉含量显著升高,支链淀粉含量显著降低(P<0.05),淀粉颗粒破坏,颗粒表面出现孔隙和团块,淀粉的相对结晶度和短程有序性降低,但晶体形状和官能团结构没有变化。这些结构变化使鲜食糯玉米真空加工处理后淀粉的糊化温度、峰值黏度、最终黏度和回生值显著降低(P<0.05),淀粉抗老化能力增强。此外,真空加工处理还可显著提高鲜食糯玉米淀粉的消化速率(P<0.05)。本研究结果为鲜食糯玉米的真空加工处理提供了基础数据,为真空加工技术在鲜食糯玉米加工中的应用提供了理论依据。

-

表 1 真空加工处理对糯玉米直链淀粉和支链淀粉含量的影响

Table 1 Effect of vacuum processing treatment on amylose and amylopectin content of waxy corn

表 2 真空加工处理对糯玉米淀粉相对结晶度的影响

Table 2 Effect of vacuum processing treatment on relative crystallinity of waxy corn starch

样品 相对结晶度(%) 对照组(未处理) 真空加工处理组 黄糯619 35.73±0.44a 26.11±0.18b 黑宝 37.37±0.26a 27.96±0.22b 注:同行不同小写字母表示差异显著(P<0.05)。 表 3 真空加工处理对糯玉米淀粉短程有序化结构的影响

Table 3 Effect of vacuum processing treatment on short-range ordered structure of waxy corn starch

波数(cm−1) 吸光度 619-Y 619-C HB-Y HB-C 1047 1.511±0.011 1.332±0.010 0.710±0.008 0.703±0.012 1022 1.573±0.012 1.469±0.013 0.742±0.010 0.778±0.014 1047/1022 0.961±0.012 0.907±0.011 0.957±0.009 0.904±0.013 表 4 真空加工处理对糯玉米淀粉热力学特性的影响

Table 4 Effect of vacuum processing treatment on the thermodynamic characteristics of waxy corn starch

样品 起始温度(℃) 峰值温度(℃) 终止温度(℃) 糊化焓值(J/g) 619-Y 70.28±0.23a 75.13±0.28a 87.19±0.33c 5.11±0.04c 619-C 52.79±0.15c 61.44±0.15c 71.25±0.21d 2.26±0.02d HB-Y 65.78±0.28b 71.89±0.17b 90.20±0.27a 9.71±0.05a HB-C 50.75±0.13d 60.74±0.12d 88.40±0.29b 6.98±0.04b 表 5 真空加工处理对糯玉米淀粉糊化特性的影响

Table 5 Effect of vacuum processing treatment on gelatinization characteristics of waxy corn starch

样品 糊化温度

(℃)峰值黏度

(cP)峰值时间(min) 最低黏度

(cP)最终黏度

(cP)衰减值

(cP)回生值

(cP)619-Y 86.14±0.24b 4834.68±24.37a 4.60±0.01c 1878.24±21.56a 2739.72±20.21b 2956.44±10.12b 861.48±2.12b 619-C 68.02±0.18d 2795.16±16.52c 3.40±0.00d 625.92±4.31d 999.84±9.74c 2169.24±8.73c 373.92±0.55c HB-Y 91.30±0.37a 4654.68±21.89b 5.10±0.00b 1537.44±8.64b 3433.44±14.63a 3117.24±13.65a 1896.00±7.32a HB-C 72.86±0.11c 748.92±12.73d 9.60±0.02a 655.56±7.52c 834.12±7.11d 93.36±2.11d 178.56±0.71d 表 6 真空加工处理对糯玉米淀粉消化特性的影响

Table 6 Effect of vacuum processing treatment on digestive characteristics of waxy corn starch

样品 RDS含量(%) SDS含量(%) RS含量(%) 619-Y 54.74±0.85c 13.22±0.33b 32.04±1.52b 619-C 78.52±1.03a 17.21±0.78a 4.27±0.21d HB-Y 49.64±1.37d 13.86±1.03b 36.50±2.77a HB-C 72.46±0.56b 17.59±0.84a 9.95±1.63c -

[1] 王娟紫, 王春芳, 乔勇进, 等. 近冰温贮藏对鲜糯玉米采后品质的影响[J]. 食品工业科技,2023,44(14):336−345. [WANG Juanzi, WANG Chunfang, QIAO Yongjin, et al. Effect of near-freezing temperature storage on the quality of postharvest fresh waxy corn[J]. Science and Technology of Food Industry,2023,44(14):336−345.] WANG Juanzi, WANG Chunfang, QIAO Yongjin, et al. Effect of near-freezing temperature storage on the quality of postharvest fresh waxy corn[J]. Science and Technology of Food Industry, 2023, 44(14): 336−345.

[2] 孙琳琳, 李克文, 孙桂莲, 等. 响应面法优化糯玉米淀粉酶解工艺制备抗消化淀粉[J]. 农产品加工,2022(18):37−40,46. [SUN Linlin, LI Kewen, SUN Guilian, et al. Optimization of hydrolysis technology for preparation of anti-digestible starch from waxy corn starch using response surface methodology[J]. Agricultural Processing,2022(18):37−40,46.] SUN Linlin, LI Kewen, SUN Guilian, et al. Optimization of hydrolysis technology for preparation of anti-digestible starch from waxy corn starch using response surface methodology[J]. Agricultural Processing, 2022(18): 37−40,46.

[3] ZHU M, LI K, LI F, et al. Correlation between the lignin content and mechanical properties of waxy corn pericarp[J]. Scientia Horticulturae,2014,179:266−270. doi: 10.1016/j.scienta.2014.09.040

[4] 李国琰, 张雁, 廖娜, 等. 过热蒸汽烫漂对甜玉米主要营养成分及感官品质的影响[J]. 中国粮油学报,2022,37(9):85−93. [LI Guoyan, ZHANG Yan, LIAO Na, et al. Effect of superheated steam blanching on main nutrients and sensory quality of sweet corn[J]. Journal of Cereals and Oils,2022,37(9):85−93.] LI Guoyan, ZHANG Yan, LIAO Na, et al. Effect of superheated steam blanching on main nutrients and sensory quality of sweet corn[J]. Journal of Cereals and Oils, 2022, 37(9): 85−93.

[5] MARTA H, CAHYANA Y, BINTANG S, et al. Physicochemical and pasting properties of corn starch as affected by hydrothermal modification by various methods[J]. International Journal of Food Properties,2022,25(1):792−812. doi: 10.1080/10942912.2022.2064490

[6] 林国荣, 郭梦雄, 蔡佳蓉. 不同胶体对玉米淀粉糊化及流变学特性的影响[J]. 食品科技,2023,48(2):268−272. [LIN Guorong, GUO Mengxiong, CAI Jiarong. Effect of different colloids on gelatinization and rheological properties of corn starch[J]. Food Science and Technology,2023,48(2):268−272.] LIN Guorong, GUO Mengxiong, CAI Jiarong. Effect of different colloids on gelatinization and rheological properties of corn starch[J]. Food Science and Technology, 2023, 48(2): 268−272.

[7] SEN L, QIN L, FENG Z, et al. Effect of vacuum combined ultrasound treatment on the fine structure and physiochemical properties of rice starch[J]. Food Hydrocolloids,2022,124:107198. doi: 10.1016/j.foodhyd.2021.107198

[8] LI W, BAI Y, MOUSAA S, et al. Effect of high hydrostatic pressure on physicochemical and structural properties of rice starch[J]. Food and Bioprocess Technology,2012,5(6):2233−2241. doi: 10.1007/s11947-011-0542-6

[9] WU C, WU Q Y, WU M, et al. Effect of pulsed electric field on properties and multi-scale structure of japonica rice starch[J]. LWT,2019,116:108515. doi: 10.1016/j.lwt.2019.108515

[10] BAHRANI S A, LOISEL C, REZZOUG S A, et al. Role of vacuum steps added before and after steaming treatment of maize starch. Impact on pasting, morphological and rheological properties[J]. Carbohydrate Polymers,2012,89(3):810−820. doi: 10.1016/j.carbpol.2012.04.015

[11] 轩瑞瑞. 鲜食糯玉米品质评价及即食加工适宜性研究[D]. 南京:南京农业大学, 2021. [XUAN Ruirui. Study on quality evaluation and ready-to-eat processing suitability of waxy maize[D]. Nanjing:Nanjing Agricultural University, 2021.] XUAN Ruirui. Study on quality evaluation and ready-to-eat processing suitability of waxy maize[D]. Nanjing: Nanjing Agricultural University, 2021.

[12] 张瑜, 舒文, 郑小变, 等. 蜡质玉米淀粉中直链淀粉和支链淀粉的含量测定对比研究[J]. 山东化工,2018,47(11):84−86. [ZHANG Yu, SHU Wen, ZHENG Xiaobian, et al. Comparative study on the determination of amylose and amylopectin content in the waxy maize starch[J]. Shandong Chemical Industry,2018,47(11):84−86.] doi: 10.3969/j.issn.1008-021X.2018.11.036 ZHANG Yu, SHU Wen, ZHENG Xiaobian, et al. Comparative study on the determination of amylose and amylopectin content in the waxy maize starch[J]. Shandong Chemical Industry, 2018, 47(11): 84−86. doi: 10.3969/j.issn.1008-021X.2018.11.036

[13] 王嘉俊, 郑瑜雪, 柴子淇, 等. 湿热和韧化处理对莜麦淀粉结构及消化特性的影响[J]. 食品安全质量检测学报,2022,13(20):6659−6666. [WANG Jiajun, ZHENG Yuxue, CHAI Ziqi, et al. Impact of heat-moisture and annealing on structure and digestive characteristics of buckwheat starch[J]. Journal of Food Safety and Quality Inspection,2022,13(20):6659−6666.] WANG Jiajun, ZHENG Yuxue, CHAI Ziqi, et al. Impact of heat-moisture and annealing on structure and digestive characteristics of buckwheat starch[J]. Journal of Food Safety and Quality Inspection, 2022, 13(20): 6659−6666.

[14] DOME K, PODGORBUNSKIKH E, BYCHKOV A, et al. Changes in the crystallinity degree of starch having different types of crystal structure after mechanical pretreatment[J]. Polymers,2020,12(3):1−12.

[15] ZHANG Y, LIU W, LIU C, et al. Retrogradation behaviour of high-amylose rice starch prepared by improved extrusion cooking technology[J]. Food Chemistry,2014,158:255−261. doi: 10.1016/j.foodchem.2014.02.072

[16] 胡荣, 汪楠, 张甫生, 等. 高压均质处理对豌豆淀粉流变特性及多尺度结构的影响[J]. 食品科学,2023,44(5):53−61. [HU Rong, WANG Nan, ZHANG Fusheng, et al. Effect of high-pressure homogenization on rheological properties and multiscale structure of pea starch[J]. Food Science,2023,44(5):53−61.] doi: 10.7506/spkx1002-6630-20220513-164 HU Rong, WANG Nan, ZHANG Fusheng, et al. Effect of high-pressure homogenization on rheological properties and multiscale structure of pea starch[J]. Food Science, 2023, 44(5): 53−61. doi: 10.7506/spkx1002-6630-20220513-164

[17] XIAO Y, WU X, ZHANG B, et al. Understanding the aggregation structure, digestive and rheological properties of corn, potato, and pea starches modified by ultrasonic frequency[J]. International Journal of Biological Macromolecules,2021,189:1008−1019. doi: 10.1016/j.ijbiomac.2021.08.163

[18] 林江涛, 孙灵灵, 岳清华. 不同粒度小麦粉淀粉的理化特性分析[J]. 现代食品科技,2022,38(8):193−198, 192. [LIN Jiangtao, SUN Lingling, YUE Qinghua. Analysis of physicochemical properties of wheat flour starch with different particle sizes[J]. Modern Food Science and Technology,2022,38(8):193−198, 192.] LIN Jiangtao, SUN Lingling, YUE Qinghua. Analysis of physicochemical properties of wheat flour starch with different particle sizes[J]. Modern Food Science and Technology, 2022, 38(8): 193−198, 192.

[19] 郭宏伟, 赵城彬, 吴玉柱, 等. 红豆淀粉-脂质复合物结构及体外消化性质[J]. 食品科学,2019,40(21):21−27. [GUO Hongwei, ZHAO Chengbin, WU Yuzhu, et al. Structure and in vitro digestibility of adzuki bean (Vigna angularis) starch-lipid complexes[J]. Food Science,2019,40(21):21−27.] doi: 10.7506/spkx1002-6630-20181112-125 GUO Hongwei, ZHAO Chengbin, WU Yuzhu, et al. Structure and in vitro digestibility of adzuki bean (Vigna angularis) starch-lipid complexes[J]. Food Science, 2019, 40(21): 21−27. doi: 10.7506/spkx1002-6630-20181112-125

[20] WAN S, LIU Q, YANG D, et al. Characterization of high amylose corn starch-cinnamaldehyde inclusion films for food packaging[J]. Food Chemistry,2023,403:134219. doi: 10.1016/j.foodchem.2022.134219

[21] 徐晓茹, 周坚, 吕庆云, 等. 挤压前、后大米淀粉理化性质的变化[J]. 中国食品学报,2019,19(12):187−194. [XU Xiaoru, ZHOU Jian, LÜ Qingyun, et al. Changes in physicochemical properties of rice starch before and after extrusion[J]. Acta Food Sinica,2019,19(12):187−194.] XU Xiaoru, ZHOU Jian, LÜ Qingyun, et al. Changes in physicochemical properties of rice starch before and after extrusion[J]. Acta Food Sinica, 2019, 19(12): 187−194.

[22] NAGULESWARAN S, VASANTHAN T, HOOVER R, et al. Molecular characterisation of waxy corn and barley starches in different solvent systems as revealed by MALLS[J]. Food Chemistry,2014,152:297−299. doi: 10.1016/j.foodchem.2013.11.108

[23] 林国荣, 张丽芬, 黄晓玲. 微波处理对枇杷核淀粉理化性质和消化性能的影响[J]. 食品工业科技,2023,44(15):55−61. [LIN Guorong, ZHANG Lifen, HUANG Xiaoling. Effect of microwave treatment on physicochemical and digestive properties of loquat kernel starch[J]. Science and Technology of Food Industry,2023,44(15):55−61.] LIN Guorong, ZHANG Lifen, HUANG Xiaoling. Effect of microwave treatment on physicochemical and digestive properties of loquat kernel starch[J]. Science and Technology of Food Industry, 2023, 44(15): 55−61.

[24] 王丽爽, 王可心, 岳喜庆, 等. 挤压处理对淀粉-米谷蛋白复合体系回生特性及流变特性的影响[J]. 食品科学,2023,44(19):35−42. [WANG Lishuang, WANG Kexin, YUE Xiqing, et al. Effect of extrusion treatment on retrogradation and rheological properties of rice starch/glutelin composite system[J]. Food Science,2023,44(19):35−42.] doi: 10.7506/spkx1002-6630-20221031-318 WANG Lishuang, WANG Kexin, YUE Xiqing, et al. Effect of extrusion treatment on retrogradation and rheological properties of rice starch/glutelin composite system[J]. Food Science, 2023, 44(19): 35−42. doi: 10.7506/spkx1002-6630-20221031-318

[25] ZHANG J, WANG Z W, SHI X M. Effect of microwave heat/moisture treatment on physicochemical properties of Canna edulis Ker starch[J]. Journal of the Science of Food and Agriculture,2009,89(4):653−664. doi: 10.1002/jsfa.3497

[26] 曹旭, 辛明航, 刘婷婷, 等. 湿热处理对油莎豆淀粉理化性质、结构及体外消化特性的影响[J]. 中国粮油学报,2022,37(10):131−137. [CAO Xu, XIN Minghang, LIU Tingting, et al. Impact of moisture treatment on physicochemical properties, structure and digestive properties of Cyperus esculentus L. starch[J]. China Journal of Cereals and Oils,2022,37(10):131−137.] CAO Xu, XIN Minghang, LIU Tingting, et al. Impact of moisture treatment on physicochemical properties, structure and digestive properties of Cyperus esculentus L. starch[J]. China Journal of Cereals and Oils, 2022, 37(10): 131−137.

[27] ZHANG Y, LI B, ZHANG Y, et al. Effect of degree of polymerization of amylopectin on the gelatinization properties of jackfruit seed starch[J]. Food Chemistry,2019,289:152−159. doi: 10.1016/j.foodchem.2019.03.033

[28] SUN Y, QIN R, ZENG J, et al. Effect of heat-moisture treatment on the structure and digestibility of sweet potato starch[J]. Foods,2023,12(16):3076. doi: 10.3390/foods12163076

[29] WANG N, LI C, MIAO D, et al. Effect of improved extrusion cooking technology (IECT) on structure, physical properties and in vitro digestibility of starch[J]. International Journal of Biological Macromolecules,2023,252:126436. doi: 10.1016/j.ijbiomac.2023.126436

[30] ZHANG Q, ZHANG S, DENG L, et al. Effect of vacuum treatment on the characteristics of oxidized starches prepared using a green method[J]. Starch-Stärke,2018,70(3-4):1700216.

[31] LEI N, CHAI S, XU M, et al. Effect of dry heating treatment on multi-levels of structure and physicochemical properties of maize starch:A thermodynamic study[J]. International Journal of Biological Macromolecules,2020,147:109−116. doi: 10.1016/j.ijbiomac.2020.01.060

[32] 白芸. 不同种类及脱支处理对淀粉与脂质相互作用的影响研究[D]. 西安:陕西科技大学, 2019. [BAI Yun. Study on the effect of different species and debranching treatment on the interaction between starch and lipid[D]. Xi’an:Shaanxi University of Science and Technology, 2019.] BAI Yun. Study on the effect of different species and debranching treatment on the interaction between starch and lipid[D]. Xi’an: Shaanxi University of Science and Technology, 2019.

[33] ZHENG M, CHAO C, YU J, et al. Effects of chain length and degree of unsaturation of fatty acids on structure and in vitro digestibility of starch-protein-fatty acid complexes[J]. Journal of Agricultural and Food Chemistry,2018,66(8):1872−1880. doi: 10.1021/acs.jafc.7b04779

[34] SU H, TU J, ZHENG M, et al. Effects of oligosaccharides on particle structure, pasting and thermal properties of wheat starch granules under different freezing temperatures[J]. Food Chemistry,2020,315:126209. doi: 10.1016/j.foodchem.2020.126209

[35] YANG Z, CHAIB S, GU Q F, et al. Impact of pressure on physicochemical properties of starch dispersions[J]. Food Hydrocolloids,2017,68:164−177. doi: 10.1016/j.foodhyd.2016.08.032

[36] 李驰, 姚佳, 韩乔, 等. 马铃薯淀粉消化特性及多酚对其影响研究进展[J]. 食品科技,2022,47(12):221−227. [LI Chi, YAO Jia, HAN Qiao, et al. Research progress on the digestion characteristics of potato starch and the effects of plant polyphenols on it[J]. Food Science and Technology,2022,47(12):221−227.] LI Chi, YAO Jia, HAN Qiao, et al. Research progress on the digestion characteristics of potato starch and the effects of plant polyphenols on it[J]. Food Science and Technology, 2022, 47(12): 221−227.

[37] WANG J, JIANG X, GUO Z, et al. Insights into the multi-scale structural properties and digestibility of lotus seed starch-chlorogenic acid complexes prepared by microwave irradiation[J]. Food Chemistry,2021,361:130171. doi: 10.1016/j.foodchem.2021.130171

下载:

下载:

下载:

下载: