Preparation and Characterization of OSA-modified Tapioca Starch-based Pickering Emulsion

-

摘要: 为探究不同制备条件对淀粉基Pickering乳液的影响,以辛烯基琥珀酸木薯淀粉酯(Octenyl Succinic Tapioca Starch,OSTS)为固体颗粒乳化剂制备Pickering乳液。以乳液粒径、流变特性、微观结构、贮藏稳定性为指标,探究了OSTS添加量(3.0%、3.5%、4.0%、4.5%、5.0%)及油相体积分数(40%、45%、50%、55%、60%)对乳液特性的影响,并对不同离子强度(100、200、300、400、500 mmol/L)及pH(2、4、6、8、10)下乳液的粒径及稳定性进行研究。结果表明,OSTS添加量5%,油相体积分数50%时,乳液粒径最小,为3.59 μm,乳液贮藏60 d后仍未出现分层。乳液内部形成了弹性凝胶网络结构,随OSTS添加量及油相体积分数的增加,乳液黏度及凝胶强度增大,抵抗变形能力增强。高浓度盐离子(NaCl浓度≥500 mmol/L)及强碱(pH≥10)会显著增大乳液粒径(P<0.05),降低乳液稳定性。OSTS添加量5%,油相体积60%,NaCl浓度100 mmol/L及pH为6条件下形成的乳液具有良好稳定性。

-

关键词:

- 辛烯基琥珀酸木薯淀粉酯 /

- Pickering乳液 /

- 流变特性 /

- 稳定性

Abstract: To investigate the effects of different preparation conditions on starch-based Pickering emulsions, Pickering emulsions were prepared using octenyl succinic tapioca starch (OSTS) as a solid particle emulsifier. The effects of OSTS additions (3.0%, 3.5%, 4.0%, 4.5%, 5.0%) and oil phase volume fractions (40%, 45%, 50%, 55%, 60%) on the properties of the emulsions were investigated by using the emulsion particle sizes, rheological properties, microstructures, and storage stabilities as the indexes. The effects of different ionic strengths (100, 200, 300, 400, 500 mmol/L) and pH levels (2, 4, 6, 8, 10) on the particle size and stability of the emulsion were also examined. Results showed that the particle size of the emulsion was the smallest, 3.59 μm, at 5% OSTS addition and a 50% volume fraction of the oil phase, and the emulsion did not show delamination after 60 d of storage. It also showed that an elastic gel network structure was formed inside the emulsion, and that its viscosity and gel strength increased with increasing OSTS addition and oil phase volume fraction, leading to an enhanced deformation resistance. Furthermore, high concentrations of salt ions (NaCl concentration ≥500 mmol/L) and strong alkalis (pH≥10) significantly increased the emulsion particle size (P<0.05) and decreased its stability. However, under the conditions of 5% OSTS addition, 60% oil phase volume, 100 mmol/L NaCl concentration, and a pH of 6, the emulsion exhibited good stability. -

乳液是由两种互不相溶的液体组成,内相以液滴形式分散到外相中形成的非均相体系。传统乳液需要表面活性剂作用于油水界面保持稳定,但由于其毒性强、成本高、稳定性低,限制了乳液的加工及应用[1]。Pickering乳液是一种由固体颗粒作为乳化剂制备的乳液,20世纪初Pickering和Ramsden发现一些不溶于水的细小颗粒,它们可以代替传统乳化剂吸附在油水界面,形成一道物理屏障,防止乳滴聚集[2−3]。这种固体颗粒的吸附是不可逆的,因此,相较于传统乳液,Pickering乳液具有更优异的性能。因其具有稳定性高、环保性强、成本低、生物相容性好等优点,在化妆品、医药、食品、材料等多个领域得到了广泛应用[4−5]。

淀粉是一种天然可再生、来源广泛、成本低廉的公认安全(GRAS)物质[6],被广泛用作稳定Pickering乳液的固体颗粒。但天然淀粉含较多羟基结构,导致其亲水性强,疏水性较差[7],稳定Pickering乳液效果不太理想。因此,需要对天然淀粉进行疏水改性,使其拥有较好的稳定油水界面的性能。辛烯基琥珀酸酐(Octenyl Succinic Anhudride,OSA)淀粉是通过酯化反应由OSA中的疏水基团取代淀粉中的部分亲水基团的一种疏水改性淀粉[8],具有油水两亲性,在稳定Pickering乳液方面显现出优异的效果。LI等[9]研究3种不同辛烯基琥珀酸酐淀粉作为固体颗粒乳化剂,稳定Pickering乳液,发现在取代度相似情况下,OSA淀粉颗粒的粒径是影响Pickering乳液液滴尺寸、乳化能力、贮藏稳定性的关键因素。姜晓丽[10]通过辛烯基琥珀酸藜麦淀粉酯稳定Pickering乳液,发现在一定范围内,OSA淀粉添加量越高,乳液液滴越小,乳化稳定性越好;油水比越高,乳液液滴大小越均匀,乳液稳定性越好。目前,国内外对于淀粉基Pickering乳液的研究主要选用蜡质玉米、小米、马铃薯、大米等高直链含量淀粉[11−14]。因直链淀粉含量对淀粉疏水改性有着直接影响,而木薯淀粉中直链淀粉含量较少,因此,关于OSA酯化木薯淀粉作为固体颗粒稳定Pickering乳液的相关报道并不多见。

基于此,本试验以自制木薯酯化淀粉为固体颗粒稳定剂制备Pickering乳液,探究不同制备条件对Pickering乳液粒径、流变学特性、微观结构以及贮藏稳定性的影响,并对不同环境下乳液的粒径及贮藏稳定性进行了研究,为拓展木薯酯化淀粉在Pickering乳液中的应用提供了理论基础。

1. 材料与方法

1.1 材料与仪器

木薯酯化淀粉 DS=0.0151,自制;玉米油 益海嘉里金龙鱼粮油食品股份有限公司;氢氧化钠 分析纯,天津市风船化学试剂科技有限公司;盐酸 分析纯,云南杨林工业开发区汕滇药业。

FJ200-SH数显高速分散均质机 上海泸析实业有限公司;LA-960V2激光粒度仪 日本HORIBA有限公司;HR 20 Discovery混合型流变仪 美国TA公司;SK2009光学显微镜 深圳赛克电子科技有限公司。

1.2 实验方法

1.2.1 Pickering乳液制备

取适量酯化淀粉加入去离子水,60 ℃水浴2 min,加入适量玉米油,14000 r/min均质3 min后制得Pickering乳液[12]。10 mL透明玻璃瓶(直径:22 mm,高度:51 mm)中常温密封保存,待进行后续测试。

1.2.1.1 不同OSTS添加量制备Pickering乳液

以OSTS为颗粒乳化剂,分别配制为3%、3.5%、4%、4.5%、5%的水相,固定油相体积分数为50%,其余实验方法同1.2.1。

1.2.1.2 不同油相体积分数制备Pickering乳液

以玉米油为油相,分别配制油相体积分数为40%、45%、50%、55%、60%,固定OSTS添加量为5%,其余实验方法同1.2.1。

1.2.2 乳液粒径测定

采用激光粒度分析仪测定乳液粒径与分布,分散介质:去离子水,折射率:1.33,搅拌速率:300 r/min,循环泵速率:500 r/min,温度:25 ℃。

1.2.3 乳液流变学特性的测定

静态流变测定:测量温度25 ℃,剪切速率0.01~1000 s−1,考察乳液表观黏度的变化趋势。

动态流变测定:0.1~100 Pa振幅应力扫描确定乳液线性黏弹区域[15]。振幅频率测试条件为温度25 ℃,振幅频率0.01~100 Hz。考察乳液储能模量(G')与损耗模量(G'')的变化趋势。

1.2.4 乳液微观结构

将新鲜制备的Pickering乳液,用胶头滴管分别取一滴,两倍蒸馏水稀释,置于载玻片上,盖上盖玻片,电子显微镜进行观察和拍照,放大倍数400。

1.2.5 乳液贮藏稳定性

将乳液装入玻璃瓶中,室温(25 ℃)下贮藏,分别于第1、30、60 d拍照记录并测量乳析指数(CI),利用公式(1)计算:

CI(\%) = H/H0×100 (1) 式中:H为乳析层高度,cm;H0为乳液总高度,cm。

1.2.6 不同环境对Pickering乳液的影响

1.2.6.1 离子强度

水相中加入适量NaCl使其浓度分别为100、200、300、400、500 mmol/L,固定OSTS添加量5%、油相体积分数50%,其余试验方法同1.2.1,测定乳液粒径并观察贮藏稳定性。

1.2.6.2 pH

0.1 mol/L的氢氧化钠水溶液或盐酸水溶液将水相pH分别调节为2、4、6、8、10,固定OSTS添加量5%、油相体积分数50%,其它试验方法同1.2.1,测定乳液粒径并观察贮藏稳定性。

1.3 数据处理

所有实验均重复3次,采用SPSS 26.0数据处理,P<0.05时表示结果存在显著性差异,Origin 2017绘图。

2. 结果与分析

2.1 不同制备条件对乳液性质的影响

2.1.1 不同制备条件对乳液粒径的影响

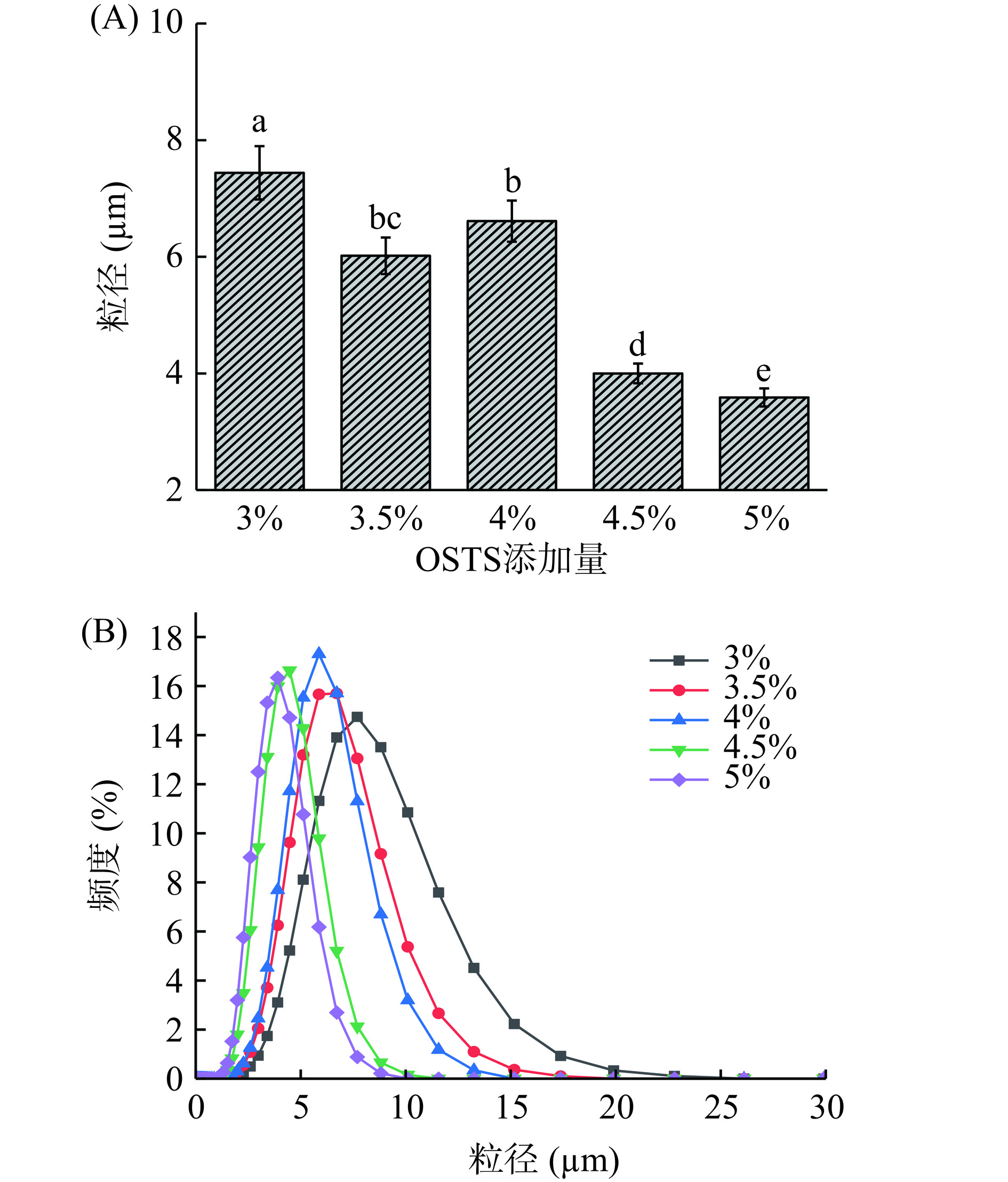

Pickering乳液的液滴粒径越细小均匀,液滴的分散稳定性越好;乳液粒径分布范围越窄,表明乳液均一性越高,乳液的稳定性越高。图1(A)可见,OSTS添加量3%~5%时,Pickering乳液粒径随淀粉添加量的增加而先增大后减小,乳液体系的物理稳定性先减弱后增强,当淀粉颗粒达到5%时乳液粒径最小,为3.59 μm,相较3%添加量的乳液显著减小107.24%(P<0.05)。原因为OSTS添加量较低时,不足以满足在油滴表面的覆盖率,乳液液滴间易发生碰撞聚结[16];随添加量的增加,更多的淀粉颗粒能够进入到油水界面,形成紧密堆积的单层屏障,防止液滴的聚结,形成的乳液粒径较小[17]。邱天昊[18]以OSA糯米淀粉纳米晶为乳化剂稳定Pickering乳液也发现同样规律。图1(B)可见,OSTS添加量3%~5%时,Pickering乳液粒径分布均呈现单峰,曲线向小粒径方向平移,5%时粒径分布范围最窄,表明此时乳液均一性最高。

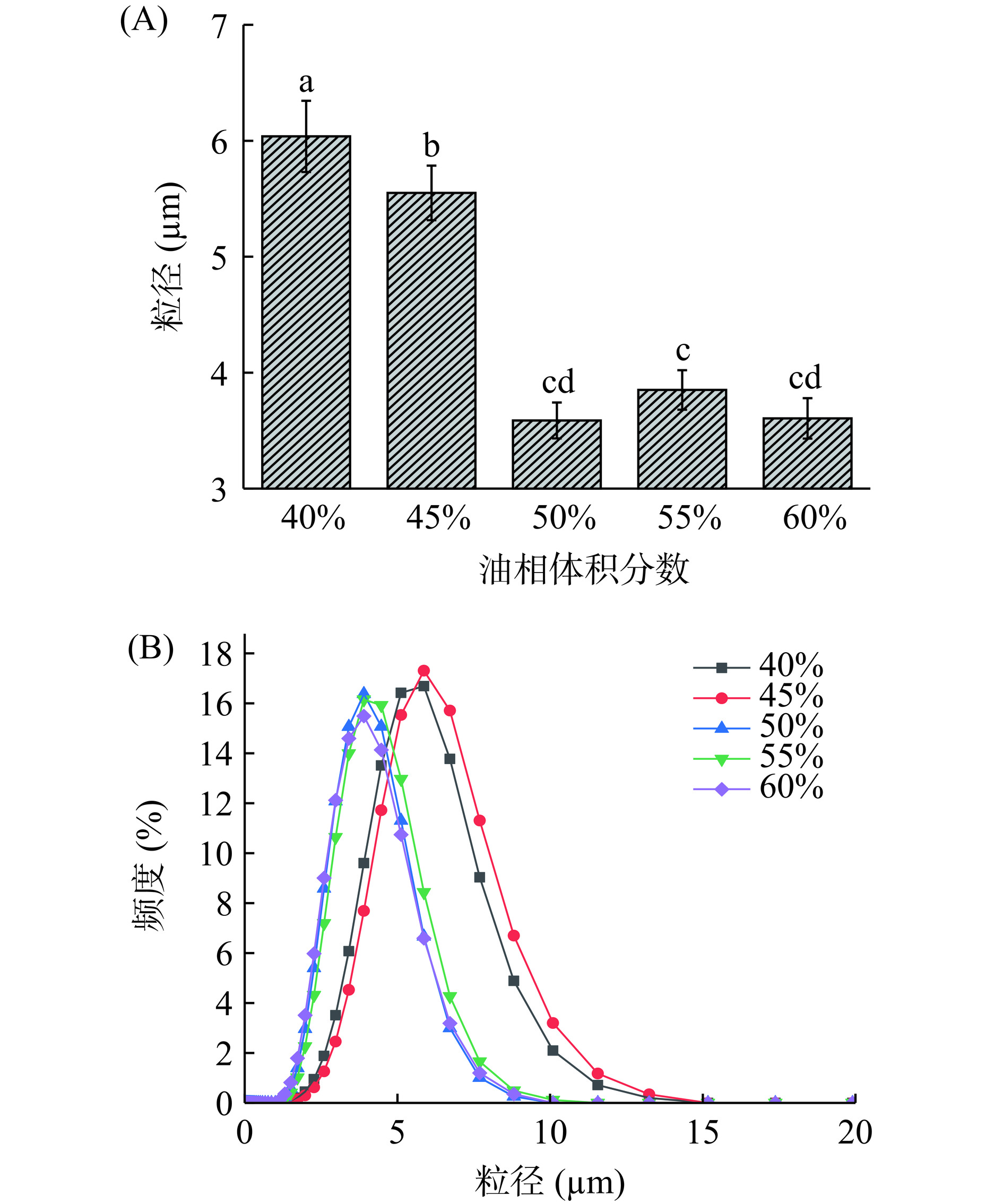

图2(A)可见,油相体积分数40%~60%时,Pickering乳液粒径随油相体积增大而减小,后趋于平稳。油相体积40%~50%时,乳液粒径由6.04 μm减小至3.59 μm,显著(P<0.05)减小了40.56%,因为当油相体积分数过低时,OSTS颗粒相对油相体积比例过多,处于过饱和状态,未被完全利用,导致乳液粒径较大,稳定性较差[19];油相体积50%~60%时,OSTS颗粒被完全利用到油水界面并形成一层屏障,液滴之间空隙变小,粒径大小基本保持稳定,分布均匀,此时Pickering乳液的分散稳定性较好[10]。图2(B)可见,油相体积40%~60%时,Pickering乳液粒径分布均呈现单峰,曲线向小粒径方向平移,油相体积超过50%后,粒径分布范围变化甚微,此时乳液均一性较高。

2.1.2 不同制备条件对乳液流变特性的影响

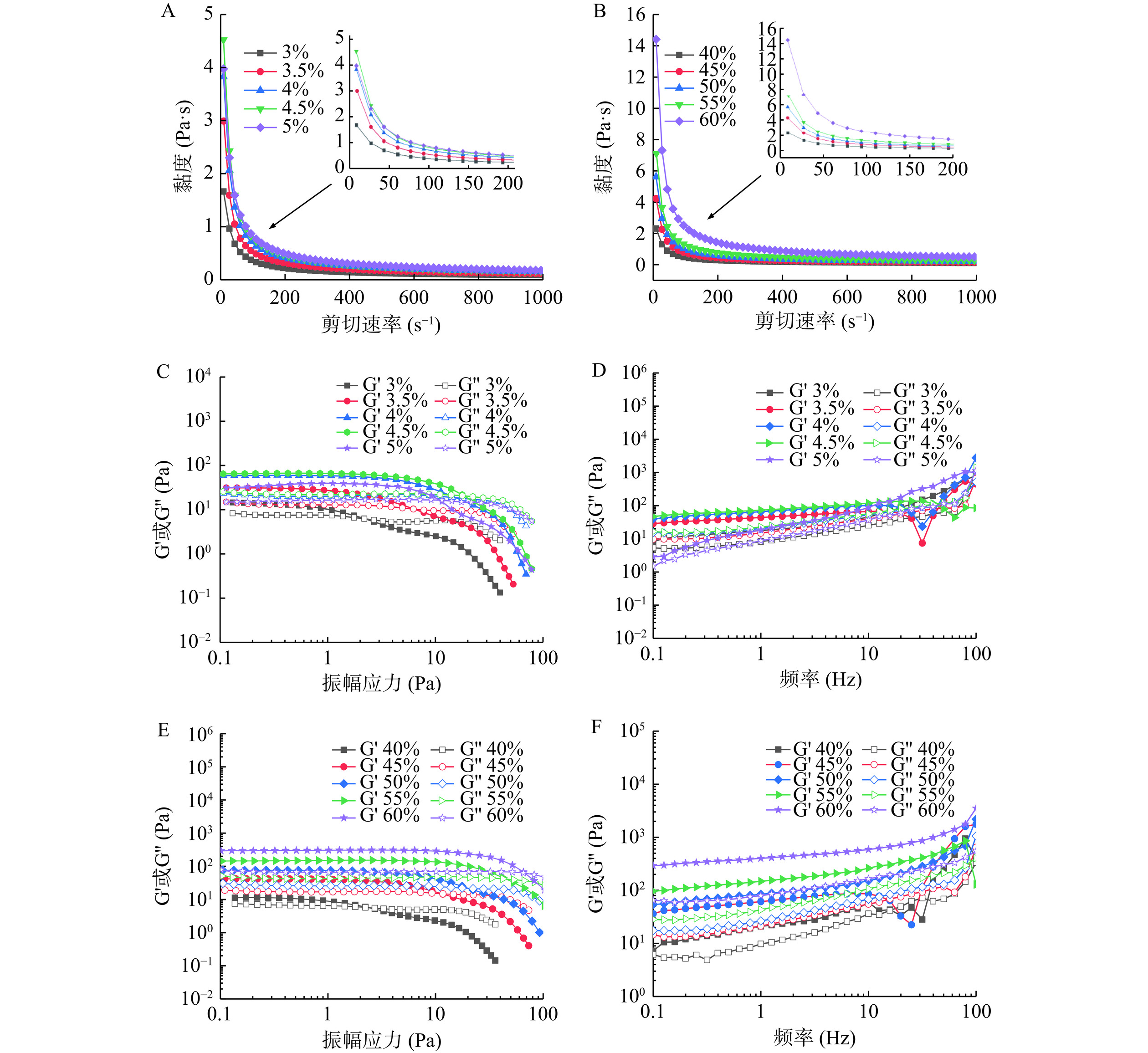

图3A可见,随OSTS添加量的增加,对应乳液体系表观粘度增大,原因为随OSTS添加量的增加,水相中淀粉分子相互交错缠绕形成网络结构,导致乳液表观粘度增加[20]。所有乳液表观粘度在剪切速率0~200 s−1时,随剪切速率的增加而急剧下降。在剪切速率200~400 s−1时乳液表观粘度变为缓慢下降,表现出剪切稀化现象,为非牛顿流体的典型特征。原因为在外力剪切作用下,OSTS乳液体系的内相液滴发生破裂形变及位置重排,重新排列或形变的淀粉颗粒更容易互相滑过,导致内相液滴的有效浓度降低,同时伴随液滴之间的相互作用力减弱,摩擦力减小,粘度下降[21−22]。剪切速率大于400 s−1后,乳液液滴被完全破坏,表观粘度趋于平衡,达到稳定,表现为近牛顿流体。可能是因为乳液絮凝速率与瓦解速率达到平衡,乳液内部保持相对稳定的状态[23]。

图3B为不同油相体积分数的OSTS颗粒稳定的Pickering乳液的静态剪切流变图。在剪切速率0~1000 s−1范围内,所有乳液都表现出剪切稀化的特性,说明剪切过程中淀粉分子互相缠绕结构被破坏的速度大于形成的速度,随油相体积分数的增加,对应乳液体系表观粘度增大。原因为随油相体积分数的增加,乳液中油滴堆积程度提高,TANG等[24]利用大豆冷凝胶蛋白作为乳化剂稳定Pickering乳液,发现随油相体积分数的增加,乳液表观粘度增大,与本文结果一致。

以振幅应力扫描测量乳液的线性黏弹区,以保证振幅频率扫描在乳液的线性黏弹区内进行图3C。储能模量G'代表储存弹性形变能量的能力和原子间的结合强度;耗能模量G''代表形变产生的能耗,反应体系的黏性。由图3D可见,低OSTS添加量乳液的G'明显低于高OSTS添加量乳液,G'越低,表示乳液液滴间相互作用力越弱,越容易受到外力影响,发生形变[25]。随OSTS添加量的增加,乳液G'及G''随振荡频率的增加呈现增大趋势,初始频率阶段OSTS添加量为4.5%时乳液G'为最大,随频率增加,G'呈现先增大后减小的趋势。当G'>G''时,表明乳液呈弹性为主的凝胶结构状态,主要表现为固体特性,随频率继续增大,G'<G''时,表明乳液凝胶结构被破坏,形成了黏性为主的液体性质[26]。当OSTS添加量为5%时,虽然在初始阶段乳液的G'略低,但在振荡频率0.1~100 s−1整个过程中始终保持G'>G'',表明乳液全程呈现以弹性为主导的弱凝胶特性,即高OSTS添加量乳液液滴因彼此之间的相互作用形成了一定机械强度的凝胶网络结构[21]。SONG等[27]在以OSA改性大米淀粉、玉米淀粉制备Pickering乳液中也报道了随淀粉添加量的增加,Pickering乳液的凝胶强度逐渐增强。

图3E~图3F可见,油相体积分数明显影响Pickering乳液的黏弹性,高油相体积乳液的G'明显高于低油相体积乳液,且高油相体积乳液在振荡频率0.1~100 s−1范围内,G'明显大于G'',表明乳液中形成了弹性凝胶网络结构。原因为当油相体积较高时,水相中的OSTS颗粒含量相对较少,油滴间的相互作用会促进凝胶网络结构的重新编排,增大液滴的絮凝程度,形成更强的凝胶网络结构;相反,当油相体积较低时,水相中的OSTS颗粒含量相对较多,更多的颗粒吸附在油滴表面形成界面分子膜,使液滴不能为凝胶网络结构提供整合动力[20]。

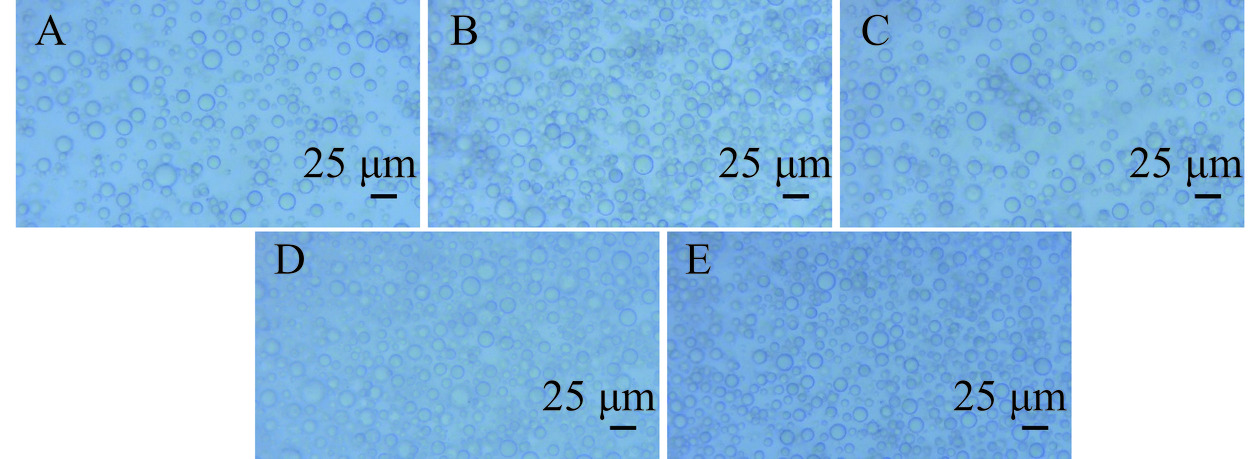

2.1.3 不同制备条件对乳液微观结构的影响

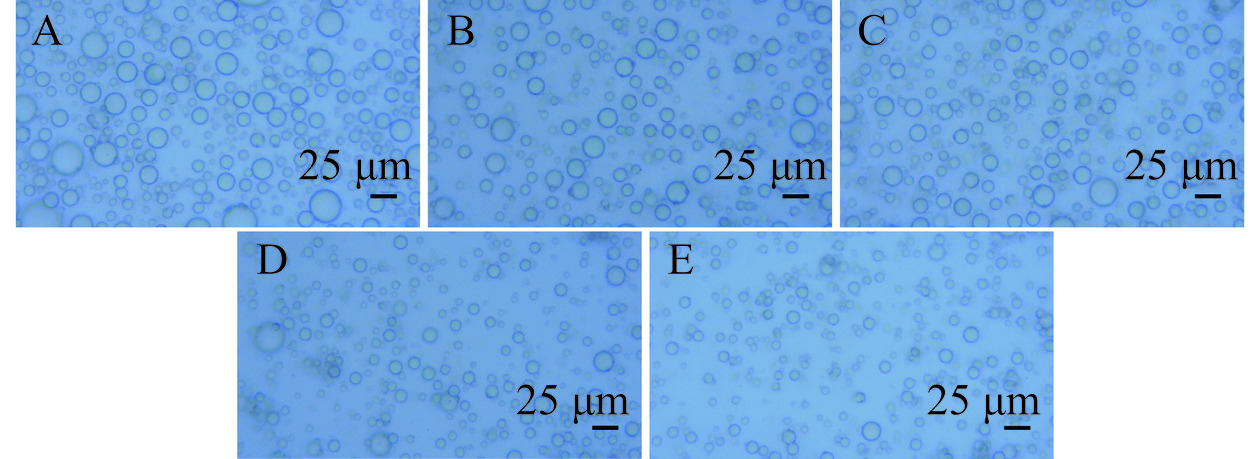

图4为不同OSTS添加量(3%~5%)所制备的Pickering乳液微观结构图。在低OSTS添加量时,乳液液滴粒径尺寸较大,且均一性较低,随OSTS添加量的增加,乳液液滴粒径逐渐变小,分布均匀、均一性高,与粒径检测结果一致。当OSTS添加量为3%时,Pickering乳液液滴呈现边缘清晰、形状规则的圆形液滴,但液滴尺寸不一,差异较大,这是由于添加量低时,OSTS在油滴表面的覆盖率不足,液滴相互碰撞过程中,油滴未被颗粒覆盖的部分相互靠拢发生聚结[28]。当OSTS添加量达到5%时,液滴变得细小均匀,此时OSTS颗粒在油滴表面的覆盖率增加,以稳定更大的界面面积,防止液滴间的聚结,形成了紧密稳定的界面膜[29]。

图5为不同油相体积分数(40%~60%)所制备的Pickering乳液微观结构图。在低油相体积分数时,乳液液滴粒径尺寸较大,且均一性较低,随油相体积分数的增加,乳液液滴粒径逐渐变小,分布均匀,均一性高,与粒径检测结果一致。当油相体积分数40%~50%时,Pickering乳液呈现边缘清晰、形状规则的圆形液滴,但液滴尺寸不一,差异较大;当油相体积分数50%~60%时,乳液液滴尺寸均匀,分布致密。

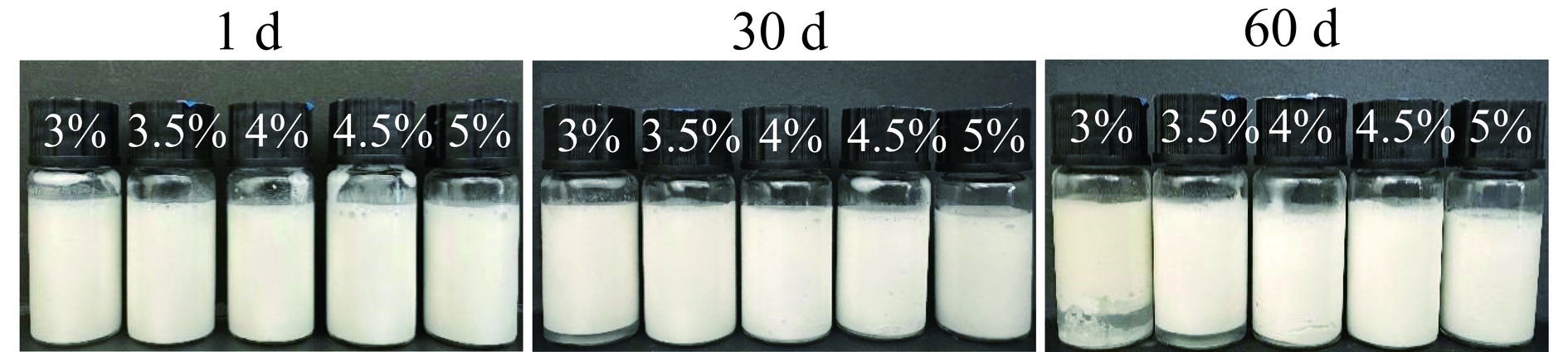

2.1.4 不同制备条件对乳液贮藏稳定性的影响

图6可见,油相体积为50%,OSTS添加量为3%~5%时,Pickering乳液呈白色乳状液。OSTS添加量为3%、贮藏30 d时,乳液下层部分形成乳析水层,表1可见,此时乳析指数为5.26%,60 d时乳析指数为26.67%;OSTS添加量为3.5%、贮藏60 d时,乳析指数为9.09%;高添加量的Pickering乳液放置60 d后仍未出现分层。原因为乳液体系中相邻液滴与OSTS颗粒间相互作用,形成了一定强度的三维网络结构防止油滴自由移动。乳液随OSTS添加量的增加从流体状态转变为凝胶状态,水相黏度增大,淀粉颗粒与油滴之间的引力增大,形成较为稳定的Pickering乳液[30]。

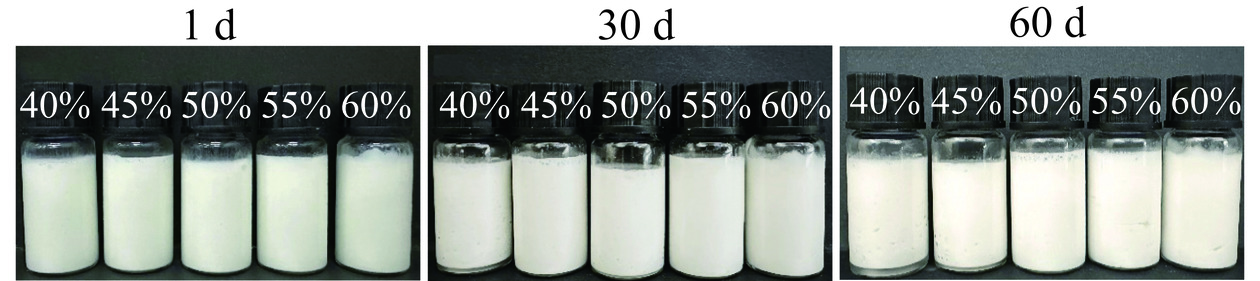

表 1 OSTS添加量对Pickering乳液CI值的影响Table 1. Effects of OSTS addition on CI value of Pickering emulsionOSTS添加量(%) 贮藏时间(d) 1 30 60 3 0 5.26±0.43 26.67±0.81 3.5 0 0 9.09±0.53 4 0 0 0 4.5 0 0 0 5 0 0 0 图7可见,OSTS添加量为5%,油相体积为40%~60%时,Pickering乳液呈白色乳状液。油相体积为40%、贮藏30 d时,乳液下层部分形成乳析水层,表2可见,此时乳析指数为4.67%,60 d时乳析指数为10.87%;油相体积为45%、贮藏60 d时,乳析指数为3.66%。油相体积为50%~60%时,Pickering乳液放置60 d后仍未出现分层,DAI等[31]也发现了类似的结果。原因为油相体积的增加,使过饱和的OSTS颗粒得到充分利用,附着更多的油相稳定乳液;乳液黏度随油相体积增大而增加,根据斯托克斯定律,提高乳液黏度或减小乳液液滴尺寸可抑制重力分离,提高乳液稳定性[32]。

表 2 油相体积分数对Pickering乳液CI值的影响Table 2. Effects of oil phase volume fraction on CI value of Pickering emulsion油相体积分数(%) 贮藏时间(d) 1 30 60 40 0 4.67±0.22 10.87±0.30 45 0 0 3.66±0.16 50 0 0 0 55 0 0 0 60 0 0 0 2.2 不同环境对乳液性质的影响

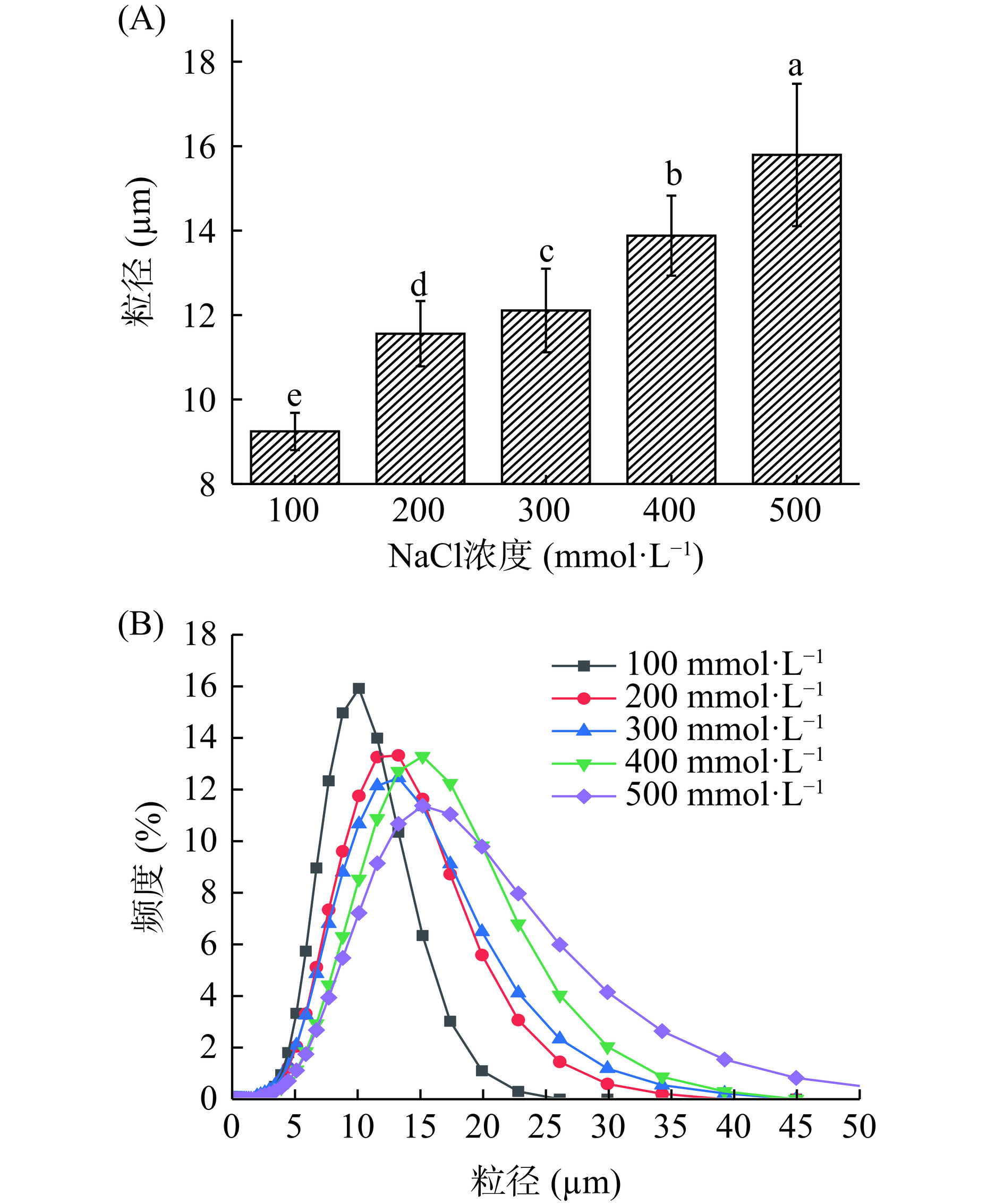

2.2.1 不同环境对乳液粒径的影响

图8A可见,固定OSTS添加量5%,油相体积分数50%,NaCl浓度100~500 mmol/L时,Pickering乳液粒径随NaCl浓度的增加而增大,当NaCl浓度达到500 mmol/L时,乳液粒径最大,为15.79 μm,相较100 mmol/L的乳液显著增大70.89%(P<0.05)。与SHAO等[33]的研究结果类似,原因为NaCl对OSTS颗粒的静电屏蔽作用,Na+通过静电斥力屏蔽了OSTS颗粒表面的电荷,减弱了颗粒之间和颗粒与水界面的相互作用,促进了颗粒与油滴间的相互作用,导致液滴聚集,粒径增大。FRENCH等[34]研究发现,可能是NaCl改变了淀粉颗粒接触角,降低了颗粒成功吸附在油水界面的概率,吸附成功的颗粒因在油水界面的相互作用力减弱,也会在液滴聚集过程中从界面脱落。图8B可见,NaCl浓度100~500 mmol/L时,Pickering乳液粒径分布均呈现单峰,曲线向大粒径方向平移,粒径分布范围逐步增大,与平粒径结果一致。

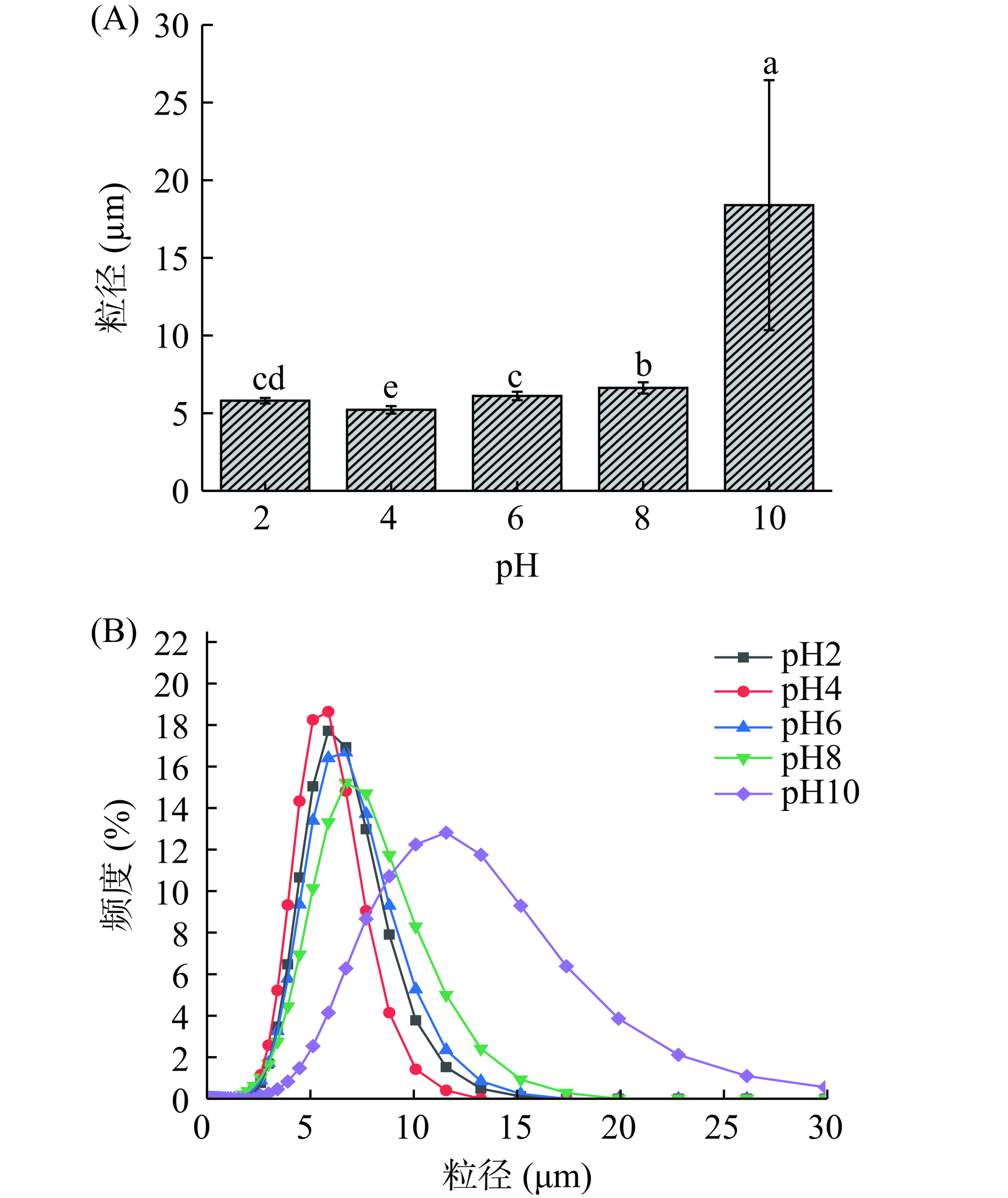

图9(A)可见,固定OSTS添加量5%,油相体积分数50%,水相pH为2~8时,Pickering乳液粒径大小变化并不明显,粒径分布在5.80~6.62 μm之间,可见在水相pH为2~8范围内,Pickering乳液受pH影响不显著。原因为低pH时OSTS静电斥力增强,颗粒分散性增强,聚集作用被抑制[35]。在水相pH为10的碱性条件下乳液粒径达到最大,为18.39 μm,相较pH为8的乳液显著增大177.79%(P<0.05)。凡莎莎[36]制备的Pickering乳液在pH为3~9时,乳液粒径大小均匀,分布稳定,pH为11时,粒径显著增大,此时乳液出现破乳及分层现象。由此可见,在较高pH下Pickering乳液的粒径受影响较大,稳定性降低。这也与KO等[37]的研究结论一致。图9(B)可见,水相pH为2~10时,Pickering乳液粒径分布均呈现单峰,曲线向大粒径方向平移,粒径分布范围逐步增大,与平粒径结果一致。

2.2.2 不同环境对乳液贮藏稳定性的影响

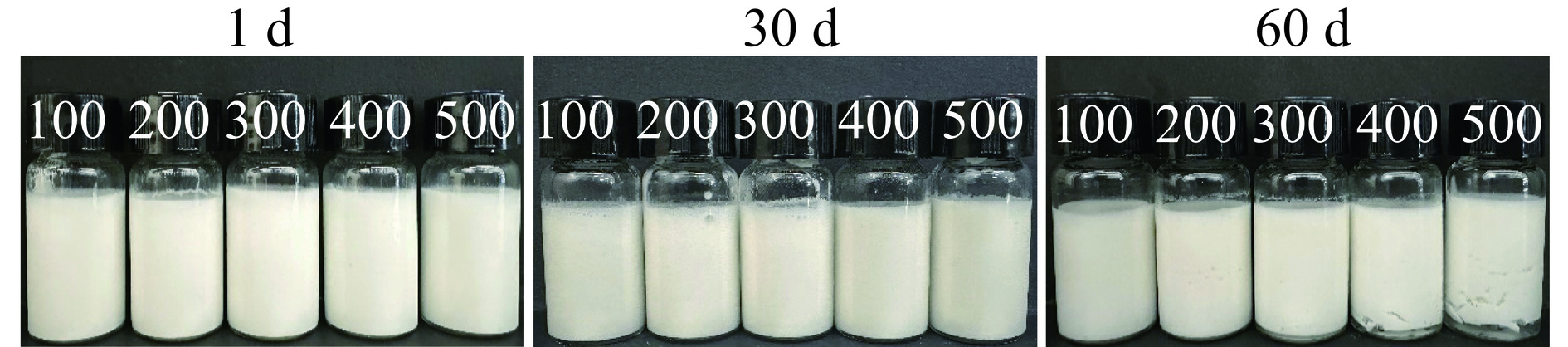

图10可见,固定OSTS添加量为5%,油相体积为50%,NaCl浓度为100~500 mmol/L时,Pickering乳液呈白色乳状液。NaCl浓度为400 mmol/L、贮藏60 d时,乳液下层部分形成乳析水层,表3可见,此时乳析指数为22.86%;NaCl浓度为500 mmol/L、贮藏60 d时,乳析指数为53.49%。低浓度(100~300 mmol/L)时,Pickering乳液放置60 d后仍未出现分层情况。原因为盐离子会降低或屏蔽淀粉颗粒表面电荷,淀粉颗粒之间及颗粒与液滴之间的静电斥力减弱,导致淀粉颗粒发生聚凝或絮沉现象,从而影响其在油水两相界面分散行为[38]。沈小倩等[39]以甘蔗渣纳米纤维稳定Pickering乳液时也发现高浓度NaCl会导致乳液出现分层现象。

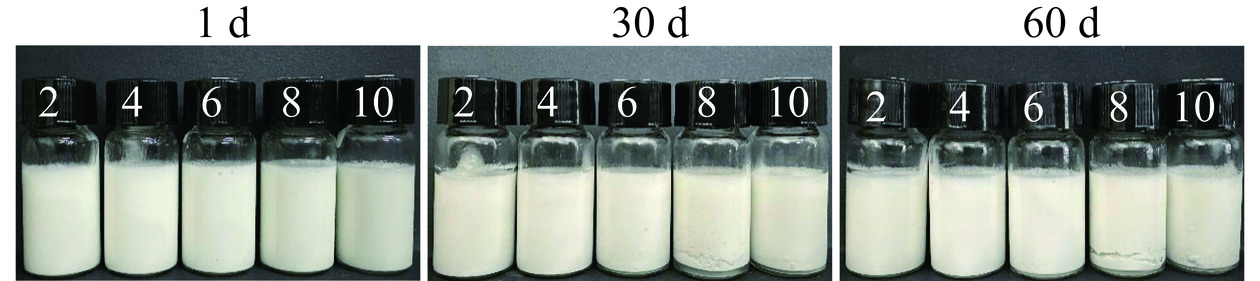

表 3 离子强度对Pickering乳液CI值的影响Table 3. Effects of NaCl concentration on CI value of Pickering emulsionNaCl浓度(mmol/L) 贮藏时间(d) 1 30 60 100 0 0 0 200 0 0 0 300 0 0 0 400 0 0 22.86±0.49 500 0 0 53.49±0.74 图11可见,固定OSTS添加量为5%,油相体积为50%,水相pH为2~10时,Pickering乳液呈白色乳状液。pH为8、贮藏30 d时,乳液下层部分形成乳析水层,表4可见,此时乳析指数为22.42%,60 d时,乳析指数为24.24%;pH为10、贮藏30 d时,乳析指数为10.91%,60 d时,乳析指数为30.29%。pH为8和pH为10乳液同为稳定性较差乳液,随贮藏天数增加,pH对乳液的影响逐渐明显。pH为2~6时,Pickering乳液贮藏60 d仍保持良好的稳定性。原因为体系pH的改变导致淀粉颗粒的表面润湿性和带电量发生了变化,从而影响了颗粒之间及颗粒与液滴之间的静电排斥作用,最终影响乳液稳定性[40]。

表 4 pH对Pickering乳液CI值的影响Table 4. Effects of aqueous pH on CI value of Pickering emulsionpH 贮藏时间(d) 1 30 60 2 0 0 0 4 0 0 0 6 0 0 0 8 0 22.42±0.87 24.24±0.66 10 0 10.91±0.39 30.29±0.71 3. 结论

木薯淀粉资源丰富,尺寸均一,且粒度较小,但由于较好的亲水性,导致其乳化稳定性差。经过辛烯基琥珀酸酐改性使其具有油水两亲性,将得到的OSTS颗粒作为稳定剂制备Pickering乳液,乳化效果得到了很大程度提升。随OSTS添加量增加,乳液粒径逐渐减小,最小为3.59 μm;随油相体积分数增加,乳液粒径先减小后趋于稳定,由6.04 μm减小至3.59 μm。流变特性结果显示,乳液形成了内部凝胶网络结构,随OSTS添加量及油相体积分数的增加,增加了乳液黏度及凝胶强度。OSTS添加量达到4%、油相体积分数达到50%后,乳液贮藏60 d后仍表现出良好的稳定性。分析两种环境下的乳液发现,随NaCl浓度增加,乳液粒径逐渐增大,浓度超过400 mmol/L时,乳液出现分层现象;水相pH2~8时,对乳液粒径影响不大,pH达到10后,粒径急剧增大,此时乳液出现明显分层。OSTS添加量5%,油相体积60%,NaCl浓度100 mmol/L及pH为6条件下形成的乳液具有良好稳定性。此结果为木薯酯化淀粉的利用途径和食品级Pickering乳液稳定剂的开发提供一定的参考。

-

表 1 OSTS添加量对Pickering乳液CI值的影响

Table 1 Effects of OSTS addition on CI value of Pickering emulsion

OSTS添加量(%) 贮藏时间(d) 1 30 60 3 0 5.26±0.43 26.67±0.81 3.5 0 0 9.09±0.53 4 0 0 0 4.5 0 0 0 5 0 0 0 表 2 油相体积分数对Pickering乳液CI值的影响

Table 2 Effects of oil phase volume fraction on CI value of Pickering emulsion

油相体积分数(%) 贮藏时间(d) 1 30 60 40 0 4.67±0.22 10.87±0.30 45 0 0 3.66±0.16 50 0 0 0 55 0 0 0 60 0 0 0 表 3 离子强度对Pickering乳液CI值的影响

Table 3 Effects of NaCl concentration on CI value of Pickering emulsion

NaCl浓度(mmol/L) 贮藏时间(d) 1 30 60 100 0 0 0 200 0 0 0 300 0 0 0 400 0 0 22.86±0.49 500 0 0 53.49±0.74 表 4 pH对Pickering乳液CI值的影响

Table 4 Effects of aqueous pH on CI value of Pickering emulsion

pH 贮藏时间(d) 1 30 60 2 0 0 0 4 0 0 0 6 0 0 0 8 0 22.42±0.87 24.24±0.66 10 0 10.91±0.39 30.29±0.71 -

[1] 马永强, 牛绩超, 尤婷婷, 等. Pickering乳液的稳定性研究及其在食品领域的应用进展[J]. 食品工业科技,2023,44(23):376−386. [MA Y Q, NIU J C, YOU T T, et al. Research on the stability of Pickering emulsion and its application in the field of food[J]. Science and Technology of Food Industry,2023,44(23):376−386.] MA Y Q, NIU J C, YOU T T, et al. Research on the stability of Pickering emulsion and its application in the field of food[J]. Science and Technology of Food Industry, 2023, 44(23): 376−386.

[2] PICKERING S U. Pickering:Emulsions[J]. Journal of the Chemical Society, Transactions,1907,91:2001−2021. doi: 10.1039/CT9079102001

[3] RAMSDEN W. Separation of solids in the surface-layers of solutions and 'suspensions' (observations on surface-membranes, bubbles, emulsions, and mechanical coagulation). Preliminary account[J]. Proceedings of the royal Society of London,1904,72(477−486):156−164. doi: 10.1098/rspl.1903.0034

[4] ORTIZ D G, POCHAT-BOHATIER C, CAMBEDOUZOU J, et al. Current trends in Pickering emulsions:Particle morphology and applications[J]. Engineering,2020,6(4):468−482. doi: 10.1016/j.eng.2019.08.017

[5] HARMAN C L G, PATEL M A, GULDIN S, et al. Recent developments in Pickering emulsions for biomedical applications[J]. Current Opinion in Colloid & Interface Science,2019,39:173−189.

[6] 王小凤, 马畅, 关家乐, 等. 淀粉稳定的Pickering乳液制备及其应用研究进展[J]. 农业科技与装备,2021(1):66−68. [WANG X F, MA C, GUAN J L, et al. Research progress on preparation and application of starch-stabilized Pickering emulsion[J]. Agricultural Science and Technology and Equipment,2021(1):66−68.] WANG X F, MA C, GUAN J L, et al. Research progress on preparation and application of starch-stabilized Pickering emulsion[J]. Agricultural Science and Technology and Equipment, 2021(1): 66−68.

[7] ZHENG W X, REN L, HAO W Z, et al. Encapsulation of indole-3-carbinol in Pickering emulsions stabilized by OSA-modified high amylose corn starch:Preparation, characterization and storage stability properties[J]. Food Chemistry,2022,386:132846. doi: 10.1016/j.foodchem.2022.132846

[8] 王淳玉, 季慧, 刘云国, 等. 辛烯基琥珀酸改性淀粉的制备与表征研究进展[J]. 食品研究与开发,2021,42(9):191−197. [WANG C Y, JI H, LIU Y G, et al. Research progress on preparation and characterization of octenylsuccinic acid modified starch[J]. Food Research and Development,2021,42(9):191−197.] doi: 10.12161/j.issn.1005-6521.2021.09.028 WANG C Y, JI H, LIU Y G, et al. Research progress on preparation and characterization of octenylsuccinic acid modified starch[J]. Food Research and Development, 2021, 42(9): 191−197. doi: 10.12161/j.issn.1005-6521.2021.09.028

[9] LI Songnan, LI Chao, YANG Yinzhou, et al. Starch granules as Pickering emulsifiers:Role of octenylsuccinylation and particle size[J]. Food Chemistry,2019,283:437−444. doi: 10.1016/j.foodchem.2019.01.020

[10] 姜晓丽. 辛烯基琥珀酸藜麦淀粉酯的制备及其在稳定Pickering乳液中的性能研究[D]. 沈阳:沈阳师范大学, 2021. [JIANG X L. Preparation of quinoa starch ester Octenylsuccinate and its performance in stabilized Pickering emulsion[D]. Shenyang:Shenyang Normal University, 2021.] JIANG X L. Preparation of quinoa starch ester Octenylsuccinate and its performance in stabilized Pickering emulsion[D]. Shenyang: Shenyang Normal University, 2021.

[11] CHENG F, AI Y F, GHOSH S. Utilization of octenyl succinic anhydride-modified pea and corn starches for stabilizing oil-in-water emulsions[J]. Food Hydrocolloids,2021,118:106773. doi: 10.1016/j.foodhyd.2021.106773

[12] 陆兰芳, 晏杰, 黄世林, 等. 复合改性小米淀粉Pickering乳液负载β-胡萝卜素性能研究[J]. 食品与发酵工业,2022,48(10):149−155,163. [LU L F, YAN J, HUANG S L, et al. Study on the performance of β-carotene loaded with Pickering emulsion of composite modified millet starch[J]. Food and Fermentation Industry,2022,48(10):149−155,163.] LU L F, YAN J, HUANG S L, et al. Study on the performance of β-carotene loaded with Pickering emulsion of composite modified millet starch[J]. Food and Fermentation Industry, 2022, 48(10): 149−155,163.

[13] LÓPEZ-PEDROUSO M, LORENZO J M, MOREIRA R, et al. Potential applications of Pickering emulsions and high internal-phase emulsions (HIPEs) stabilized by starch particles[J]. Current Opinion in Food Science,2022,46:100866. doi: 10.1016/j.cofs.2022.100866

[14] NO J, SHIN M. Preparation and characteristics of Octenyl Succinic Anhydride-modified partial waxy rice starches and encapsulated paprika pigment powder[J]. Food Chemistry,2019,295:466−474. doi: 10.1016/j.foodchem.2019.05.064

[15] 刘炯娜, 张丹, 蒋雨心, 等. 核桃蛋白-低聚半乳糖复合纳米颗粒的制备及其Pickering乳液性质[J]. 精细化工,2024,41(7):1590−1598,1614. [LIU J N, ZHANG D, JIANG Y X, et al. Preparation of walnut protein-oligogalactan composite nanoparticles and their Pickering emulsion properties[J]. Fine Chemicals,2024,41(7):1590−1598,1614.] LIU J N, ZHANG D, JIANG Y X, et al. Preparation of walnut protein-oligogalactan composite nanoparticles and their Pickering emulsion properties[J]. Fine Chemicals, 2024, 41(7): 1590−1598,1614.

[16] 刘灿灿, 孙潇鹏, 李坚斌, 等. 球磨-酯化复合改性槟榔芋淀粉对Pickering乳液形成的影响[J]. 食品科学技术学报,2021,39(3):101−110. [LIU C C, SUN X P, LI J B, et al. Effect of ball milling-esterification composite modified areca nut taro starch on the formation of Pickering emulsion[J]. Journal of Food Science and Technology,2021,39(3):101−110.] doi: 10.12301/j.issn.2095-6002.2021.03.011 LIU C C, SUN X P, LI J B, et al. Effect of ball milling-esterification composite modified areca nut taro starch on the formation of Pickering emulsion[J]. Journal of Food Science and Technology, 2021, 39(3): 101−110. doi: 10.12301/j.issn.2095-6002.2021.03.011

[17] XU T, YANG J, HUA S X, et al. Characteristics of starch-based Pickering emulsions from the interface perspective[J]. Trends in Food Science & Technology,2020,105:334−346.

[18] 邱天昊. OSA淀粉纳米晶的制备及其稳定Pickering乳液的研究[D]. 沈阳:沈阳师范大学, 2022. [QIU T H. Preparation of OSA starch nanocrystals and their stabilisation of Pickering emulsion[D]. Shenyang:Shenyang Normal University, 2022.] QIU T H. Preparation of OSA starch nanocrystals and their stabilisation of Pickering emulsion[D]. Shenyang: Shenyang Normal University, 2022.

[19] 陆兰芳, 杨鹏, 王展, 等. 辛烯基琥珀酸小米淀粉酯稳定Pickering乳液[J]. 食品科学,2020,41(22):42−48. [LU L F, YANG P, WANG Z, et al. Octenylsuccinate millet starch ester stabilized Pickering emulsion[J]. Food Science,2020,41(22):42−48.] doi: 10.7506/spkx1002-6630-20190925-312 LU L F, YANG P, WANG Z, et al. Octenylsuccinate millet starch ester stabilized Pickering emulsion[J]. Food Science, 2020, 41(22): 42−48. doi: 10.7506/spkx1002-6630-20190925-312

[20] 项宽宽. 辛烯基琥珀酸淀粉酯微粒的制备及在Pickering乳液中的应用[D]. 郑州:河南工业大学, 2022. [XIANG K K. Preparation of Octenylsuccinate amyl ester microparticles and their application in Pickering emulsions[D]. Zhengzhou:Henan University of Technology, 2022.] XIANG K K. Preparation of Octenylsuccinate amyl ester microparticles and their application in Pickering emulsions[D]. Zhengzhou: Henan University of Technology, 2022.

[21] 余振宇. OSA改性芋头淀粉基Pickering乳液运载体系稳定机制及其特性研究[D]. 合肥:合肥工业大学, 2020. [YU Z Y. Study on the stability mechanism and characteristics of OSA-modified taro starch-based pickering emulsion carrying system[D]. Hefei:Hefei University of Technology, 2020.] YU Z Y. Study on the stability mechanism and characteristics of OSA-modified taro starch-based pickering emulsion carrying system[D]. Hefei: Hefei University of Technology, 2020.

[22] DIAO X Q, GUAN H, ZHAO X, et al. Properties and oxidative stability of emulsions prepared with myofibrillar protein and lard diacylglycerols[J]. Meat Science,2016,115:16−23. doi: 10.1016/j.meatsci.2016.01.001

[23] 王中江, 常宗明, 张翠, 等. 超声波及高压均质制备大豆蛋白-磷脂酰胆碱纳米乳液的特性比较[J]. 中国食品学报,2019,19(8):157−165. [WANG Z J, CHANG Z M, ZHANG C, et al. Comparison of characteristics of soybean protein-phosphatidylcholine nanoemulsion prepared by ultrasonic and high-pressure homogenization[J]. Chinese Journal of Food Science,2019,19(8):157−165.] WANG Z J, CHANG Z M, ZHANG C, et al. Comparison of characteristics of soybean protein-phosphatidylcholine nanoemulsion prepared by ultrasonic and high-pressure homogenization[J]. Chinese Journal of Food Science, 2019, 19(8): 157−165.

[24] TANG C H, LIU F. Cold, gel-like soy protein emulsions by microfluidization:emulsion characteristics, rheological and microstructural properties, and gelling mechanism[J]. Food Hydrocolloids,2013,30(1):61−72. doi: 10.1016/j.foodhyd.2012.05.008

[25] 裴亚琼. 疏水化大米淀粉微粒稳定的Pickering乳状液的制备与稳定性研究[D]. 郑州:河南农业大学, 2014. [PEI Y Q. Preparation and stability of hydrophobic rice starch particle-stabilized Pickering emulsion[D]. Zhengzhou:Henan Agricultural University, 2014.] PEI Y Q. Preparation and stability of hydrophobic rice starch particle-stabilized Pickering emulsion[D]. Zhengzhou: Henan Agricultural University, 2014.

[26] 赵国瑜, 范方宇, 黄瑾, 等. 纳米SiO2改性4种大分子材料的乳液制备及性质[J]. 食品科学,2022,43(8):22−28. [ZHAO G Y, FAN F Y, HUANG J, et al. Preparation and properties of emulsion of four nano-SiO2 modified macromolecular materials[J]. Food Science,2022,43(8):22−28.] ZHAO G Y, FAN F Y, HUANG J, et al. Preparation and properties of emulsion of four nano-SiO2 modified macromolecular materials[J]. Food Science, 2022, 43(8): 22−28.

[27] SONG X Y, PEI Y Q, QIAO M W, et al. Preparation and characterizations of Pickering emulsions stabilized by hydrophobic starch particles[J]. Food Hydrocolloids,2015,45:256−263. doi: 10.1016/j.foodhyd.2014.12.007

[28] HEDJAZI S, RAZAVI S H. A comparison of canthaxanthine Pickering emulsions, stabilized with cellulose nanocrystals of different origins[J]. International Journal of Biological Macromolecules,2018,106:489−497. doi: 10.1016/j.ijbiomac.2017.08.030

[29] MWANGI W W, HO K W, TEY B T, et al. Effects of environmental factors on the physical stability of pickering-emulsions stabilized by chitosan particles[J]. Food Hydrocolloids,2016,60:543−550. doi: 10.1016/j.foodhyd.2016.04.023

[30] 韩墨, 于化鹏, 彭羽, 等. 辛烯基琥珀酸淀粉酯纳米颗粒稳定Pickering乳液及其乳化性分析[J]. 食品研究与开发,2022,43(5):28−34. [HAN M, YU H P, PENG Y, et al. Octenyl Succinate starch nanoparticle stabilized Pickering emulsion and its emulsification analysis[J]. Food Research Development,2022,43(5):28−34.] doi: 10.12161/j.issn.1005-6521.2022.05.005 HAN M, YU H P, PENG Y, et al. Octenyl Succinate starch nanoparticle stabilized Pickering emulsion and its emulsification analysis[J]. Food Research Development, 2022, 43(5): 28−34. doi: 10.12161/j.issn.1005-6521.2022.05.005

[31] DAI L, SUN C X, WEI Y, et al. Characterization of Pickering emulsion gels stabilized by zein/gum arabic complex colloidal nanoparticles[J]. Food Hydrocolloids,2018,74:239−248. doi: 10.1016/j.foodhyd.2017.07.040

[32] WANG Z G, ZHANG N, CHEN C, et al. Rapeseed protein nanogels as novel Pickering stabilizers for oil-in-water emulsions[J]. Journal of Agricultural and Food Chemistry,2020,68(11):3607−3614. doi: 10.1021/acs.jafc.0c00128

[33] SHAO P, ZHANG H Y, NIU B, et al. Physical stabilities of taro starch nanoparticles stabilized Pickering emulsions and the potential application of encapsulated tea polyphenols[J]. International Journal of Biological Macromolecules,2018,118:2032−2039. doi: 10.1016/j.ijbiomac.2018.07.076

[34] FRENCH D J, FOWLER J, TAYLOR P, et al. Influence of salt concentration on the formation of Pickering emulsions[J]. Soft Matter,2020,16(31):7342−7349. doi: 10.1039/D0SM00321B

[35] 戴清源, 傅锡鹏, 朱秀灵, 等. 乳清分离蛋白-葡聚糖接枝物Pickering乳液的稳定性研究[J/OL]. 中国油脂:1−12[2023-09-19]. doi:10.19902/j.cnki.zgyz.1003-7969.220251. [DAI Q Y, FU X P, ZHU X L, et al. Stability study on Pickering emulsion of whey protein isolate-dextran graft[J/OL]. China Fats and Oils:1−12[2023-09-19]. doi:10.19902/j.cnki.zgyz.1003-7969.220251.] DAI Q Y, FU X P, ZHU X L, et al. Stability study on Pickering emulsion of whey protein isolate-dextran graft[J/OL]. China Fats and Oils: 1−12[2023-09-19]. doi: 10.19902/j.cnki.zgyz.1003-7969.220251.

[36] 凡莎莎. OSA改性苦荞淀粉基Pickering乳液的构建及其运载芦丁的应用研究[D]. 成都:成都大学, 2023. [FAN S S. Construction of OSA-modified tartary buckwheat starch-based Pickering emulsion and its application of rutin[D]. Chengdu:Chengdu University, 2023.] FAN S S. Construction of OSA-modified tartary buckwheat starch-based Pickering emulsion and its application of rutin[D]. Chengdu: Chengdu University, 2023.

[37] KO E B, KIM J Y. Application of starch nanoparticles as astabilizer for Pickering emulsions. Effect of environmentafactors and approach for enhancing its storage stabilityl[J]. Food Hydrocolloids, 2021, 120:106984.

[38] 张琳琳, 朱宇竹, 江杨, 等. 热改性莱阳芋头淀粉对乳液形成及稳定性的影响[J]. 食品科学,2020,41(6):51−57. [ZHANG L L, ZHU Y Z, JIANG Y, et al. Effect of heat-modified Laiyang taro starch on emulsion formation and stability[J]. Food Science,2020,41(6):51−57.] doi: 10.7506/spkx1002-6630-20190425-325 ZHANG L L, ZHU Y Z, JIANG Y, et al. Effect of heat-modified Laiyang taro starch on emulsion formation and stability[J]. Food Science, 2020, 41(6): 51−57. doi: 10.7506/spkx1002-6630-20190425-325

[39] 沈小倩, 张梦, 周伟, 等. pH和离子强度对甘蔗渣纳米纤维Pickering乳液稳定性的影响[J]. 食品工业科技,2022,43(6):102−108. [SHEN X Q, ZHANG M, ZHOU W, et al. Effects of pH and ionic strength on the stability of Pickering emulsion with bagasse nanofibres[J]. Food Industry Science and Technology,2022,43(6):102−108.] SHEN X Q, ZHANG M, ZHOU W, et al. Effects of pH and ionic strength on the stability of Pickering emulsion with bagasse nanofibres[J]. Food Industry Science and Technology, 2022, 43(6): 102−108.

[40] 李琛. 淀粉基微纳颗粒乳化剂的构筑与性能[D]. 无锡:江南大学, 2015. [LI C. Construction and performance of starch-based micro-nano granular emulsifier[D]. Wuxi:Jiangnan University, 2015.] LI C. Construction and performance of starch-based micro-nano granular emulsifier[D]. Wuxi: Jiangnan University, 2015.

-

期刊类型引用(0)

其他类型引用(1)

下载:

下载:

下载:

下载: