Preparation of Lemongrass Essential Oil Microcapsules by Synergistic Encapsulation with Sodium Carboxymethyl Starch and Sodium Caseinate and Its Antibacterial Properties

-

摘要: 为了研究柠檬香茅精油在延长泡菜货架期方面的应用。本研究以柠檬香茅精油为芯材,羧甲基淀粉钠、酪蛋白酸钠为壁材制备柠檬香茅精油微胶囊,考察羧甲基淀粉钠与酪蛋白酸钠的质量比对柠檬香茅精油微胶囊的理化性能、微观形态、热稳定性等的影响,评估微胶囊化对精油中化学成分及泡菜中主要致病菌抑菌活性的影响。结果表明,羧甲基淀粉钠与酪蛋白酸钠质量比为1:5、1:9时,精油包埋率无显著性差异(P>0.05),分别为98.29%、96.90%,其外观为球状、块状,随酪蛋白酸钠含量的增加,微胶囊表面的微孔逐渐减少,空洞变小。热失重曲线中最大失重速率的温度随酪蛋白含量增加而向高温方向移动,最高达314.27 ℃,纯精油仅为106.27 ℃。气相色谱-质谱联用(GC-MS)结果表明精油微胶囊处理保留了诸如橙花醇(34.69%)、乙酸香叶酯(27.41%)、芳樟醇(5.65%)、石竹烯(6.50%)等抑菌成分。这使得柠檬香茅精油微胶囊对泡菜中枯草芽孢杆菌(主要的腐败菌)及表皮葡萄球菌(引起包装袋胀袋的细菌)有较强的抑菌性,其最小抑菌浓度分别为97.66、195.31 µg/mL,最大杀菌浓度均为1562.5 µg/mL。综上所述,羧甲基淀粉钠与酪蛋白酸钠作为包封剂制备柠檬香茅精油微胶囊具有可行性,且对泡菜中主要腐败菌有抑制效果。这为进一步探究柠檬香茅精油在延长泡菜货架期上的应用提供思路。Abstract: To investigate the application of lemongrass essential oil in extending the shelf life of pickle. This study used lemongrass essential oil as the core material, sodium carboxymethyl starch and sodium caseinate as wall materials to prepare lemongrass essential oil microcapsules, and examined the effects of the mass ratio of sodium carboxymethyl starch to sodium caseinate on physicochemical properties, microscopic morphology, thermal stability, and others of lemongrass essential oil microcapsules. Furthermore, the effects of microencapsulation on the chemical composition of the essential oil and the antibacterial activity against major pathogenic bacteria in pickle was evaluated. Results showed that when the mass ratio of sodium carboxymethyl starch to sodium caseinate was 1:5 and 1:9, there was no significant difference in the essential oil encapsulation rate (P>0.05), which was 98.29% and 96.90%, respectively. The appearance was spherical and blocky. With the increasing sodium caseinate content, the micropores on the surface of the microcapsules gradually decreased, and the cavities became smaller. The thermogravimetric curves showed that the temperature corresponding to the maximum weight loss rate of microcapsules was increased with the increasing casein content, reaching a maximum of 314.27 ℃, while that of pure essential oil was only 106.27 ℃. Gas chromatgraphy-mass spectrometry (GC-MS) results showed that essential oil microcapsulation treatment retained multiple antibacterial ingredients of essential oils such as nerol (34.69%), geranyl acetate (27.41%), linalool (5.65%) and caryophyllene (6.50%). This conferred lemongrass essential oil microcapsules strong antibacterial properties against the main spoilage bacteria Bacillus subtilis in pickle and Staphylococcus epidermidis, the bacteria that cause packaging bags to bulge, with the minimum inhibitory concentration of 97.66 µg/mL for Bacillus subtilis and 195.31 µg/mL for Staphylococcus epidermidis, and the maximum bactericidal concentration of 1562.5 µg/mL for both bacteria. In summary, it is feasible to use sodium carboxymethyl starch and sodium caseinate as encapsulating agents to prepare lemongrass essential oil microcapsules, with a desirable inhibitory effect on the main spoilage bacteria in pickle. This research would provide a new perspective for further exploring the application of lemongrass essential oil in extending the shelf life of pickle.

-

香茅[Cymbopogon citrate (DC.) Starf]是香茅属多年生草本,从香茅中提取的油状物即为香茅草精油,带有强烈的柠檬气味,抑菌作用显著,但其热稳定性不佳,难以直接用作抑菌剂[1−2]。精油微胶囊化既能实现对营养物质的保护,亦具备更高的稳定性、还可作为载体,掩盖植物精油的不良气味,可开发食品防腐保鲜剂[3]。目前已有研究以β-环糊精为壁材,以饱和水溶液法[4]及溶液流延法[5]制备香茅精油微胶囊;以胆固醇、大豆卵磷脂及氯仿为壁材,采用薄膜-超声分散法制备柠檬草精油纳米脂质体[6];以明胶、阿拉伯胶或羧甲基纤维素为壁材,采用复合凝聚法制备微胶囊[7];以三聚氰胺-甲醛预聚物与聚丙烯酸改性剂的原位聚合法制备[8];以海藻酸盐、吐温80制备柠檬香茅纳米乳液制剂[9];利用聚乳酸羟基乙酸共聚物(PLGA),通过乳化/溶剂扩散技术制备香茅草精油供药纳米颗粒[10];以麦芽糖糊精、明胶为壁材,通过冷冻干燥法制备微胶囊[11];以壳聚糖和三聚磷酸钠为壁材,利用离子交联法制备香茅精油微胶囊[12]。但目前为止,柠檬香茅精油微胶囊的包埋率最高仅为92.24%,通过改变微胶囊壁材及包埋方法以提高精油包埋率成为研究热点。羧甲基淀粉钠(Carboxymethyl starch,简称CMS)是一种阴离子淀粉醚,具有电负性、冷水可溶胀等特点,可通过聚合作用及形成氢键来提高包埋物的稳定性,从而提供缓释功能[13]。早期研究者用水解后的玉米淀粉在羧甲基化的变性淀粉部分取代阿拉伯胶作微胶囊化壁材,发现CMS部分取代阿拉伯胶对提高固形物浓度有利,但对乳状液的乳化稳定性不利[14]。羧甲基淀粉钠与亲水性胶体复配可以增加乳液体系的稳定性,比如羧甲基淀粉钠-黄原胶复配体系可用于蓝莓花青素及紫檀芪包埋。但是包埋物、亲水性胶体种类不同,其复配效果亦存在差异。前人已将酪蛋白酸钠与果胶、壳聚糖、醇溶蛋白和海藻酸钠等进行复配[15−16],目前研究中缺乏对羧甲基淀粉钠与酪蛋白酸钠复配体系的特性研究,相互之间的作用机制也不明确,且尚未见到此复配体系在柠檬香茅精油微胶囊包埋中的应用。

根据前期对亲水性胶体的筛选,选择了亲水性胶体中带有正电荷的酪蛋白酸钠与羧甲基淀粉钠复配。基于此,本研究以柠檬香茅精油为芯材,以羧甲基淀粉钠、酪蛋白酸钠为壁材,采用冷冻干燥法制备柠檬香茅精油微胶囊,分析其理化性能及微观形态,进一步探究此微胶囊对泡菜中主要腐败微生物的抑菌活性,以期为延长泡菜货架期提供参考。

1. 材料与方法

1.1 材料与仪器

柠檬香茅精油 法国Florihana公司;酪蛋白酸钠 上海麦克林生化科技有限公司;羧甲基淀粉钠 食用级,河南久化生物科技有限公司;石油醚 国药集团化学试剂;氨水 广东光华科技股份有限公司;乙醚 重庆川东化工有限公司;LB肉汤培养基、营养肉汤培养基、琼脂粉 生工生物工程股份有限公司。

DLK-2060D真空冻干机 宁波新芝生物科技股份有限公司;IKA T18数显型高速分散机 德国IKA公司;HVE-50高温高压蒸汽灭菌锅 日本Hirayama公司;SPARK 10M多功能酶标仪 瑞士TECAN;SW-CJ-2FD洁净工作台 苏净安泰公司;7890A-5975C型气质联用仪(GC-MS) 美国安捷伦科技有限公司;SDT600同步热分析仪 美国TA仪器公司;Tensor27傅里叶红外光谱 德国Bruker公司;Sigma300扫描电子显微镜 德国ZEISS公司。

1.2 实验方法

1.2.1 微胶囊的制作

参考臧芳波等[12]的方法,并稍作修改。将酪蛋白酸钠(BR,来源于牛奶)溶于蒸馏水中,高速搅拌溶解,加入羧甲基淀粉钠充分混合,之后放入4 ℃冰箱中,充分水合24 h。根据前期一系列实验的比例探索,将羧甲基淀粉钠与酪蛋白酸钠的质量比例设置为9:1、5:1、1:1、1:5、1:9,所有壁材均为食品级。将过夜水合后的溶液放入高速均质机,以10000 r/min均质15 min,在上述混合液中用注射器以每秒一滴的速度滴入精油,混合液置于冰水浴中。之后将均质好的混合液置于-80 ℃冷肼中降温,真空冷冻干燥箱中冻干得到微胶囊粉末。

1.2.2 包埋率测定

参照赵国瑜等[17]的方法,准确称取1.000~2.000 g已制备的微胶囊粉末用30 mL石油醚振荡3 min后过滤,再用10 mL石油醚清洗滤纸上固体残渣,这样重复操作3次后合并滤液。将洗涤液转移到预先恒重的烧杯中,置于70 ℃水浴锅上蒸发石油醚。当已无明显石油醚液体存在时,将烧杯于70 ℃烘箱中干燥1 h,每隔0.5 h称量1次,至称量前后干燥烧瓶的质量不超过0.1 mg。准确称量,按照式(1)计算表面油含量。

(1) 式中,M1为干燥后烧杯的重量,g;m0为空烧杯的质量,g;M为样品的质量,g。

参照范方宇等[18]的方法,准确称取1.000~2.000 g微胶囊粉末,加入10 mL 60 ℃蒸馏水中充分溶解,倒入分液漏斗中并加入1 mL氨水摇匀,加入10 mL无水乙醇,充分摇匀,然后加入25 mL乙醚,摇匀后放出气体并加入25 mL石油醚,静置分层,取上层液,在70 ℃水浴中蒸发石油醚和乙醚,再置于70 ℃烘箱中烘干,准确称量,按照式(2)计算总的精油含量。

(2) 式中,M2为干燥后烧杯的重量,g;m0为空烧杯的质量,g;M为样品的质量,g。

(3) 式中,m1为表面油含量,g;m2为微胶囊总的精油含量,g。

1.2.3 微胶囊粉末的色泽评价及微观形态观察

参照刘双双等[19]的方法,对微胶囊粉末进行色泽观察。参考张丽红等[20]的方法采用扫描电子显微镜观察香茅精油微胶囊的表面形貌,将10 mg左右精油微胶囊分散在贴有导电胶的样品台上,并将多余的粉末吹去,喷金后,采用扫描电子显微镜观察其结构。电子枪加速电压为15 kv。

1.2.4 微胶囊的傅里叶红外光谱(FTIR)表征

参照李丹等[21]的方法并做修改,取1~2 mg微胶囊粉末和150 mg溴化钾(提前在烘箱中干燥)充分研磨,通过压片机制成完整、均匀、半透明的薄片样品然后用红外光谱仪测量。光谱扫描范围为400~4000 cm−1。

1.2.5 热稳定性分析

参考臧芳波等[12]的方法,称取样品3~10 mg置于坩埚中,在同步热分析仪上开始测定,测试温度范围是30~600 ℃,升温速率是10 ℃/min,载气为氮气。

1.2.6 GC-MS分析

参考Lü等[22]的方法并做改进,称取100 mg微胶囊和精油样品经乙酸乙酯预处理,0.22 μm微孔滤膜过滤后GC-MS进样分析。色谱柱为HP-5MS(30.0 m×250 μm,0.25 μm);起始温度35 ℃保持1 min,以5 ℃/min的速度升至220 ℃保持25 min,以20 ℃/min的速度升至280 ℃保持2 min;气化室温度280 ℃;传输线温度300 ℃;载气He;载气流量1.0 mL/min;精油样品分流比50:1,微胶囊样品不分流测试;进样量1 μL。

质谱条件:EI源;电子能量70 eV;离子源温度230 ℃;四极杆150 ℃;扫描模式为Scan;扫描质量范围为35~500 u。

1.2.7 抑菌性测定

培养基配制:在250 mL试剂瓶中加入100 mL蒸馏水,混合2.5 g LB肉汤培养基后进行121 ℃、15 min的高压灭菌得到LB液体培养基。在相同的步骤下,再加入1.5 g琼脂粉,高压灭菌后冷却并倒入15 mL一次性无菌平皿中得到LB固体培养基。另外,在250 mL试剂瓶中加入100 mL蒸馏水,溶解1.8 g营养肉汤培养基后于115 ℃、30 min高压灭菌得到营养肉汤(NB)。

细菌悬液制备:在细菌培养管中加入LB液体培养基,分别从金黄色葡萄球菌、枯草芽孢杆菌、产气肠杆菌、铜绿假单胞菌和表皮葡萄球菌固体培养基上挑取单菌落加入液体培养基中,振荡培养过夜(15 h)。将待测样本于紫外灯下照射30 min灭菌,备用。

实验分精油组和微胶囊组,每组设置3个平行,另设置对照组1(5%乙醇加菌液)、对照组2(5%乙醇加LB液体培养基)。用营养肉汤将产气肠杆菌稀释至105 CFU/mL,用LB液体培养基分别将其他菌液稀释至105 CFU/mL,备用。设置样品精油的初始浓度为30 mg/mL,样品微胶囊的初始浓度为50 mg/mL,在96孔板中依次二倍稀释样品溶液。将96孔板置于恒温培养箱中37 ℃培养24 h,拍照并记录浑浊孔附近第一个清澈孔的样品浓度即为最小抑菌浓度(MIC)。培养结束后,各取第一个浑浊孔及其前两个孔进行涂板,放于恒温培养箱37 ℃培养18 h,取出拍照并记录菌落数,当涂布平板长出的菌落数≤5 CFU,则此涂布的样品浓度为最大杀菌浓度(MBC)。

1.3 数据处理

采用Origin 2021软件处理数据并绘图,SPSS 20.0软件进行标准差及差异显著性分析(当P<0.05时,差异显著),采用LSD、Duncan多重比较的统计方法。

2. 结果与分析

2.1 微胶囊包埋率分析

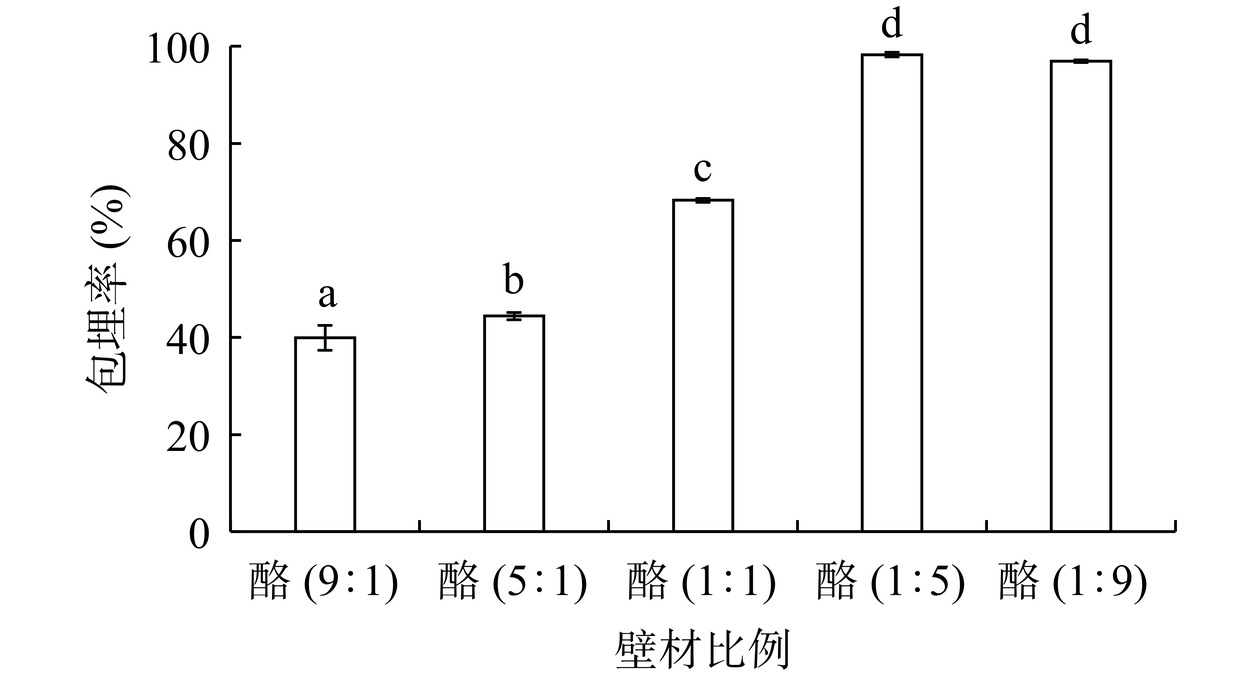

羧甲基淀粉钠与酪蛋白酸钠复配具有很好的协效性,两者复配可以增加乳液体系的稳定性,但两者的混合比例会影响其相互之间的作用方式[13]。当羧甲基淀粉钠与酪蛋白酸钠质量比依次为9:1、5:1、1:1、1:5、1:9时,其包埋率分别为39.93%、44.43%、68.29%、98.29%、96.90%(图1)。微胶囊中随酪蛋白酸钠含量增加,羧甲基淀粉钠含量减少,柠檬香茅精油包埋率增加,壁材质量比为1:5、1:9时精油包埋率无显著性差异(P>0.05),但是当壁材质量比为1:9时,精油包埋率开始降低,可能是由于此时亲水性胶体酪蛋白酸钠含量过高,干扰了其与羧甲基淀粉钠之间的相互作用从而导致包埋率降低。

2.2 微胶囊的表观颜色及微观形态观察

同时随酪蛋白酸钠含量增加,微胶囊色泽由乳白色转为浅黄色至橘皮色(图2)。

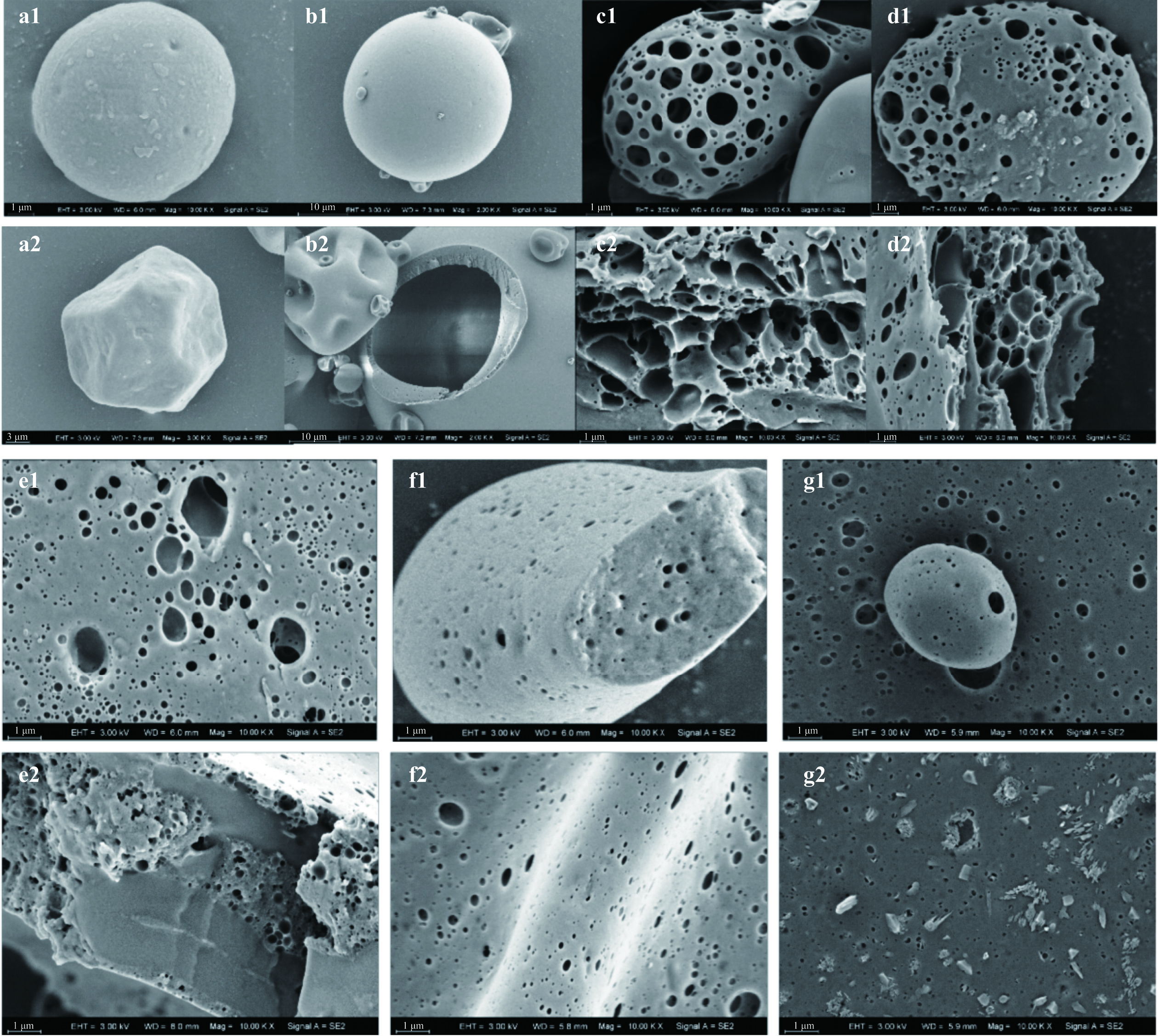

羧甲基淀粉钠与酪蛋白酸钠质量比不同制得的柠檬香茅精油微胶囊的SEM图,见图3。结果显示,羧甲基淀粉钠与酪蛋白酸钠颗粒的外观为球形(图3a、图3b),但酪蛋白酸钠壁材易破裂,两者作为壁材制得微胶囊后外观为球形、块状,球形数量少于块状,可能是由于冷冻干燥过程中微胶囊内部水分挥发,壁材凹陷皱缩成为片状。随酪蛋白酸钠含量的增加,球形、块状表面的微孔逐渐减少,空洞变小,柠檬香茅精油不易从空洞中扩散,包埋率增加,但当壁材质量比为(羧甲基淀粉钠:酪蛋白酸钠=1:9)时,SEM图显示微胶囊表面虽然空隙变小但是有团聚物粘附(图3g),可能是由于壁材比例不恰当,酪蛋白酸钠含量太高,这与精油微胶囊的包埋率正好对应。

2.3 微胶囊红外吸收图谱

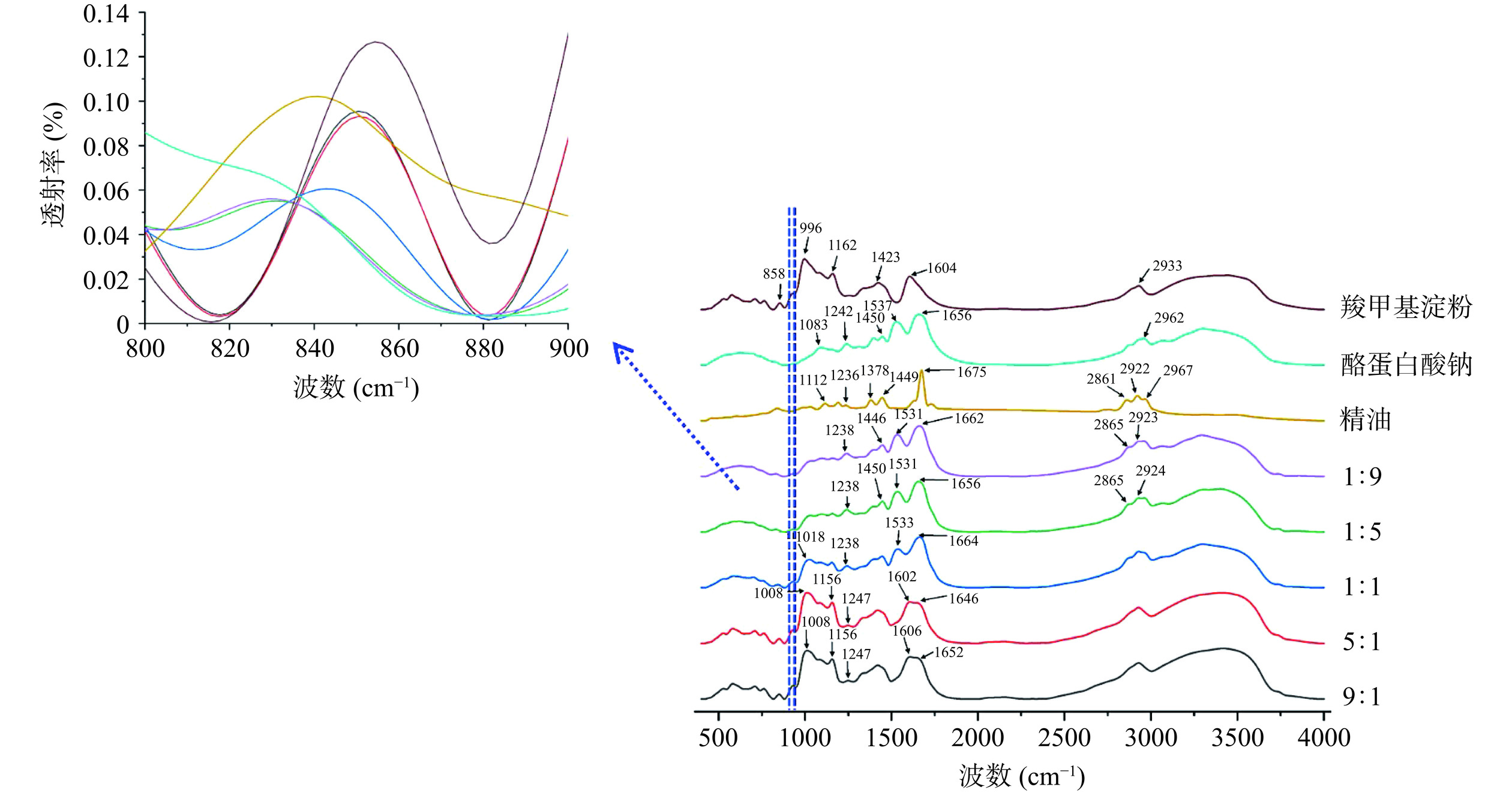

如图4所示,羧甲基淀粉的特征吸收峰有羧酸盐-COO-(1604、1423 cm−1),其中1604 cm−1处为C-O的对称和不对称伸缩振动[23−24],烷烃C-H反对称伸缩振动(2933 cm−1),取代苯上的C-H弯曲振动(858 cm−1),烯烃C-H弯曲振动(996 cm−1),酯类C-O-C的振动吸收峰(1162 cm−1)[25]。酪蛋白酸钠的特征吸收峰有烷烃类C-H伸缩振动(2962 cm−1),酰胺I带-C=O的伸缩振动(1656 cm−1),酰胺I带C-N的伸缩振动和N-H弯曲振动(1537 cm−1),烷烃类C-H弯曲变形振动(1450 cm−1),C-O伸缩振动(1242、1083 cm−1)[26]。精油的特征吸收峰有饱和碳原子上的C-H伸缩振动(2861、2922、2967 cm−1),酰胺I带C=O伸缩振动峰(1675 cm−1),烯烃类C=C伸缩振动(1449 cm−1),烷烃类-CH3对称弯曲振动吸收峰(1378 cm−1),C-O伸缩振动吸收峰(1112、1236 cm−1)[12]。精油微胶囊的特征吸收峰包含酰胺I带C=O伸缩振动峰(1652、1646、1664、1656、1662 cm−1),饱和碳原子上的C-H伸缩振动(2865、2923 cm−1)(壁材比:1:5、1:9),且C=O吸收峰位置整体左移变宽,说明制备的微胶囊中含有柠檬香茅精油,精油的烯烃类C=C伸缩振动(1449 cm−1)减弱,烷烃类-CH3对称弯曲振动吸收峰(1378 cm−1)消失,可能是由于精油被包埋的缘故。比较其他特征峰,代表性特征峰大多重叠,但是在波长800~900 cm−1范围内,精油在839 cm−1处有明显的C-H弯曲振动,精油微胶囊(9:1、5:1)在850 cm−1处有吸收峰,与羧甲基淀粉的854 cm−1很相近,这是由于此壁材比例处羧甲基淀粉含量较高,因此两者的吸收峰波长很接近,但此比例下微胶囊中精油的包埋率也较低。当羧甲基淀粉与酪蛋白酸钠的比例为1:1时,此吸收峰左移,波长为843 cm−1,当壁材比例变为1:5、1:9时,吸收峰继续左移,波长为831 cm−1,这与微胶囊中随酪蛋白含量增加,包埋率不断增加的趋势一致。

2.4 微胶囊热稳定性

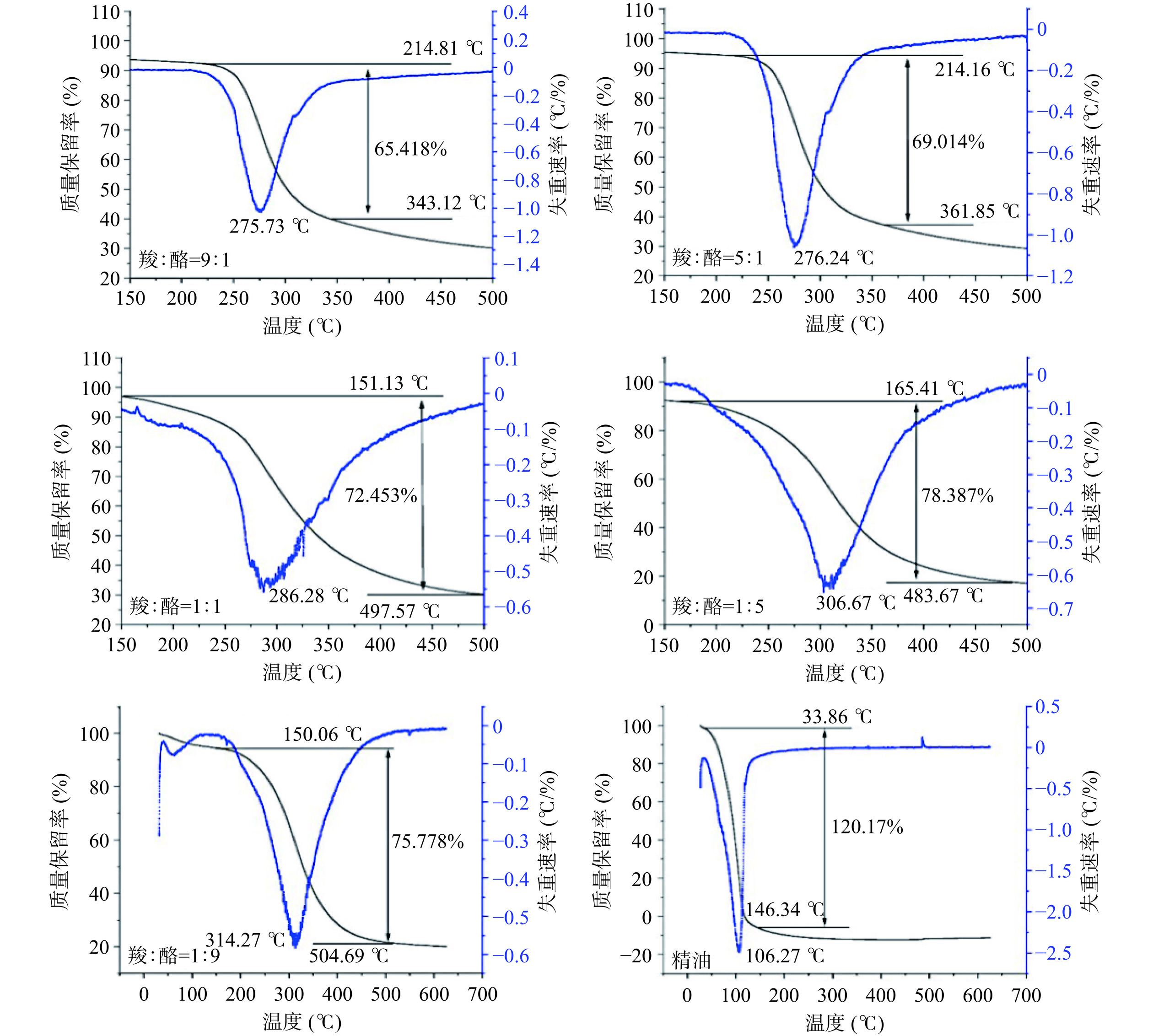

由热重分析(TG)曲线及微商热重分析(DTG)曲线图可知(图5),热失重为1个阶段,柠檬香茅精油挥发的温度在33.86~146.34 ℃,峰值在106.27 ℃,此阶段质量损失为120.17%,主要是精油中杂质、水分及挥发性成分的散失。随着羧甲基淀粉钠与酪蛋白酸钠的质量比由9:1至1:9,微胶囊的质量损失率由65.418%至78.387%再降低到75.778%,热失重曲线中最大失重速率的温度在向高温方向移动,最高达314.27 ℃,可能是随着酪蛋白酸钠含量增加,其与羧甲基淀粉钠结合得更紧密,大分子链间的相互作用增强,对精油的阻隔作用增加,微胶囊内部的柠檬香茅精油降解速率减缓,微胶囊稳定性增加,这与前人研究结果一致[13]。与精油的热失重曲线中温度相比,柠檬香茅精油微胶囊处理后其最大失重速率的温度增加,均高于146.34 ℃,柠檬香茅精油微胶囊在150 ℃之前质量较稳定,说明微胶囊处理起到保护精油的作用,升高其分解温度。

2.5 包埋后精油的成分变化

由表1可知,精油中主要的挥发性化学成分包括橙花醇(0.86%)、芳樟醇(4.50%)、γ-衣兰油烯(5.73%)、香叶醇(29.75%)、乙酸香叶酯(27.66%)、莰烯(4.91%)、橙花醛(4.05%)、柠檬醛(4.66%)、石竹烯(8.39%),许智萍等[27]在香茅草精油中也分析出香叶醇、橙花醛、乙酸香叶酯等主要成分。与精油相比,微胶囊中主要的挥发性化学成分橙花醇(34.69%)、芳樟醇(5.65%)、γ-衣兰油烯(6.12%)相对含量增加,可能是由于精油中挥发掉的成分镶嵌在了微胶囊中[22]。香叶醇(0.08%)、乙酸香叶酯(27.41%)、莰烯(4.69%)、橙花醛(3.58%)、石竹烯(6.50%)等相对含量降低,可能是被壁材选择性包封[28],也可能是微胶囊过程中由于其低沸点而挥发。

表 1 柠檬香茅精油及精油微胶囊的化学成分Table 1. Chemical composition of lemongrass essential oil and essential oil microcapsules类型 名称 CAS 相对保留时间 相对含量(%) 精油 微胶囊 萜烯类 莰烯 79-92-5 8.475 4.91 4.69 烯烃 反式,1,2-二(1-甲基乙烯基)环丁烷 19465-02-2 10.935 1.31 1.42 萜烯类 罗勒烯 13877-91-3 11.657 0.61 0.15 酮类 4-壬酮 4485-09-0 12.399 2.95 2.21 呋喃类 3-甲基-2-(3-甲基-2-丁烯基)呋喃 15186-51-3 13.145 0.16 2.58 醇类 芳樟醇 78-70-6 13.226 4.50 5.65 呋喃类 2-3,3-环氧-2-甲基丁烷-3-甲基呋喃 92356-06-4 15.378 1.06 0.63 醇类 橙花醇 106-25-2 17.109 0.86 34.69 醛类 橙花醛 141-27-5 17.519 4.05 3.58 单萜醇类 香叶醇 106-24-1 17.88 29.75 0.08 萜烯醛类 柠檬醛 5392-40-5 18.46 4.66 − 萜烯类 α-衣兰烯 14912-44-8 20.683 0.53 0.31 酯类 乙酸香叶酯 105-87-3 21.074 27.66 27.41 萜烯类 石竹烯 87-44-5 21.946 8.39 6.50 萜烯类 α-石竹烯 6753-98-6 22.801 0.86 0.70 萜烯类 γ-衣兰油烯 30021-74-0 24.298 5.73 6.12 萜烯醚类 (-)-氧化石竹烯 1139-30-6 25.963 2.00 3.28 2.6 柠檬香茅精油微胶囊对泡菜中腐败菌的抑菌活性

泡菜是我国一种历史悠久的蔬菜加工制品,在常温流通过程中,其内部的微生物会持续生长,使得泡菜发粘、长白花甚至胀袋,因此泡菜的保存问题亟待解决[29]。枯草芽孢杆菌是导致泡菜腐败的主要微生物之一[30],其可导致泡菜生花。金黄色葡萄球菌是常见的食源性致病菌[31],产气肠杆菌是泡菜中具有产组胺特性的微生物之一[32]。铜绿假单胞菌、表皮葡萄球菌是主要的产气菌,易引起包装涨袋的问题[33],同时枯草芽孢杆菌、假单胞菌也会导致泡菜质地变软[34]。由表2可知,柠檬香茅精油对金黄色葡萄球菌、枯草芽孢杆菌、产气肠杆菌、铜绿假单胞菌、表皮葡萄球菌均有抑菌作用,其最小抑菌浓度分别为15、3.75、15、15、1.875 mg/mL,最大杀菌浓度分别为15、7.5、15、15、7.5 mg/mL(表3)。精油微胶囊对金黄色葡萄球菌、枯草芽孢杆菌、表皮葡萄球菌的最小抑菌浓度分别为97.66、97.66、195.31 µg/mL,对产气肠杆菌、铜绿假单胞菌的最小抑菌浓度未测出。精油微胶囊对枯草芽孢杆菌、表皮葡萄球菌的最大杀菌浓度分别为1562.5、1562.5 µg/mL。研究结果显示,柠檬香茅精油的主要成分为香叶醇(29.75%)、乙酸香叶酯(27.66%)、石竹烯(8.39%)及莰烯(4.91%)等,对霉菌、细菌有很强的杀菌力[35−37],可作为食品添加剂加入到食品中起到抑菌防腐的作用。但是精油中的这些挥发性成分易挥发,精油包埋制成微胶囊能保留精油中的主要抑菌成分。

表 2 柠檬香茅精油及精油微胶囊对泡菜中主要腐败菌的最小抑菌浓度Table 2. Minimum inhibitory concentration (MIC) of lemongrass essential oil and essential oil microcapsules against the main spoilage bacteria in pickles样品 最小抑菌浓度(MIC) 金黄色葡萄球菌 枯草芽孢杆菌 产气肠杆菌 铜绿假单胞菌 表皮葡萄球菌 精油 15 mg/mL 3.75 mg/mL 15 mg/mL 15 mg/mL 1.875 mg/mL 微胶囊 97.66 µg/mL 97.66 µg/mL − − 195.31 µg/mL 表 3 柠檬香茅精油及精油微胶囊对泡菜中主要腐败菌的最大杀菌浓度Table 3. Maximum bactericidal concentration (MBC) of lemongrass essential oil and essential oil microcapsules against the main spoilage bacteria in pickles样品 最大杀菌浓度(MBC) 金黄色葡萄球菌 枯草芽孢杆菌 产气肠杆菌 铜绿假单胞菌 表皮葡萄球菌 精油 15 mg/mL 7.5 mg/mL 15 mg/mL 15 mg/mL 7.5 mg/mL 微胶囊 − 1562.5 µg/mL − − 1562.5 µg/mL 3. 结论

本文围绕羧甲基淀粉钠与酪蛋白酸钠复配制备柠檬香茅精油微胶囊的理化性质、热稳定性和抑菌效果展开讨论。研究结果显示,羧甲基淀粉钠与酪蛋白酸钠协同包埋柠檬香茅精油的包埋率可达95%以上。微观形态观察发现,随酪蛋白酸钠含量的增加,微胶囊表面的微孔逐渐减少,空洞变小。同时微胶囊的热稳定性呈现随酪蛋白含量增加而增强的趋势,精油微胶囊处理保留了精油中诸如橙花醇(34.69%)、乙酸香叶酯(27.41%)、石竹烯(6.50%)、γ-衣兰油烯(6.12%)、橙花醛(3.58%)、芳樟醇(5.65%)等抑菌成分,降低了精油中有效成分的挥发。柠檬香茅精油微胶囊对泡菜中金黄色葡萄球菌、枯草芽孢杆菌、产气肠杆菌、铜绿假单胞菌、表皮葡萄球菌有较强的抑菌性,其中对金黄色葡萄球菌、枯草芽孢杆菌、表皮葡萄球菌的最小抑菌浓度分别为97.66、97.66、195.31 µg/mL,对枯草芽孢杆菌、表皮葡萄球菌的最大杀菌浓度分别为1562.5、1562.5 µg/mL。这为进一步探究柠檬香茅精油在延长泡菜货架期上的应用提供思路。

-

表 1 柠檬香茅精油及精油微胶囊的化学成分

Table 1 Chemical composition of lemongrass essential oil and essential oil microcapsules

类型 名称 CAS 相对保留时间 相对含量(%) 精油 微胶囊 萜烯类 莰烯 79-92-5 8.475 4.91 4.69 烯烃 反式,1,2-二(1-甲基乙烯基)环丁烷 19465-02-2 10.935 1.31 1.42 萜烯类 罗勒烯 13877-91-3 11.657 0.61 0.15 酮类 4-壬酮 4485-09-0 12.399 2.95 2.21 呋喃类 3-甲基-2-(3-甲基-2-丁烯基)呋喃 15186-51-3 13.145 0.16 2.58 醇类 芳樟醇 78-70-6 13.226 4.50 5.65 呋喃类 2-3,3-环氧-2-甲基丁烷-3-甲基呋喃 92356-06-4 15.378 1.06 0.63 醇类 橙花醇 106-25-2 17.109 0.86 34.69 醛类 橙花醛 141-27-5 17.519 4.05 3.58 单萜醇类 香叶醇 106-24-1 17.88 29.75 0.08 萜烯醛类 柠檬醛 5392-40-5 18.46 4.66 − 萜烯类 α-衣兰烯 14912-44-8 20.683 0.53 0.31 酯类 乙酸香叶酯 105-87-3 21.074 27.66 27.41 萜烯类 石竹烯 87-44-5 21.946 8.39 6.50 萜烯类 α-石竹烯 6753-98-6 22.801 0.86 0.70 萜烯类 γ-衣兰油烯 30021-74-0 24.298 5.73 6.12 萜烯醚类 (-)-氧化石竹烯 1139-30-6 25.963 2.00 3.28 表 2 柠檬香茅精油及精油微胶囊对泡菜中主要腐败菌的最小抑菌浓度

Table 2 Minimum inhibitory concentration (MIC) of lemongrass essential oil and essential oil microcapsules against the main spoilage bacteria in pickles

样品 最小抑菌浓度(MIC) 金黄色葡萄球菌 枯草芽孢杆菌 产气肠杆菌 铜绿假单胞菌 表皮葡萄球菌 精油 15 mg/mL 3.75 mg/mL 15 mg/mL 15 mg/mL 1.875 mg/mL 微胶囊 97.66 µg/mL 97.66 µg/mL − − 195.31 µg/mL 表 3 柠檬香茅精油及精油微胶囊对泡菜中主要腐败菌的最大杀菌浓度

Table 3 Maximum bactericidal concentration (MBC) of lemongrass essential oil and essential oil microcapsules against the main spoilage bacteria in pickles

样品 最大杀菌浓度(MBC) 金黄色葡萄球菌 枯草芽孢杆菌 产气肠杆菌 铜绿假单胞菌 表皮葡萄球菌 精油 15 mg/mL 7.5 mg/mL 15 mg/mL 15 mg/mL 7.5 mg/mL 微胶囊 − 1562.5 µg/mL − − 1562.5 µg/mL -

[1] 李佳敏, 孙飞龙, 史宇, 等. 植物精油微胶囊在食品保鲜中的应用研究进展[J]. 现代食品科技,2024,40(1):332−339. [LI J M, SUN F L, SHI Y, et al. Research progress in the application of essential oil microcapsules in food preservation[J]. Modern Food Science and Technology,2024,40(1):332−339.] LI J M, SUN F L, SHI Y, et al. Research progress in the application of essential oil microcapsules in food preservation[J]. Modern Food Science and Technology, 2024, 40(1): 332−339.

[2] VERMA R S, SINGH S, PADALIA R C, et al. Essential oil composition of the sub-aerial parts of eight species of Cymbopogon (Poaceae)[J]. Industrial Crops and Products,2019,142:111830−111839. doi: 10.1016/j.indcrop.2019.111830

[3] 王慧, 杨子明, 周闯, 等. 纳米微胶囊技术及其在植物精油中的应用[J]. 高分子通报,2018(9):41−46. [WANG H, YANG Z M, ZHOU C, et al. Nanometer microcapsule technology and its application in plant essential oils[J]. Polymer Bulletin,2018(9):41−46.] WANG H, YANG Z M, ZHOU C, et al. Nanometer microcapsule technology and its application in plant essential oils[J]. Polymer Bulletin, 2018(9): 41−46.

[4] 杨欣, 姜子涛, 李荣. 柠檬草精油与β-环糊精及其衍生物包结行为的研究[J]. 食品科学,2009,30(23):96−100. [YANG X, JIANG Z T, LI R. Inclusion reactions of β-cyclodextrin and its derivatives with Cymbopogon citratus volatile oil[J]. Food Science,2009,30(23):96−100.] YANG X, JIANG Z T, LI R. Inclusion reactions of β-cyclodextrin and its derivatives with Cymbopogon citratus volatile oil[J]. Food Science, 2009, 30(23): 96−100.

[5] 陈智杰. 包埋柠檬草精油的聚乙烯醇/淀粉活性抑菌抗氧化薄膜的制备及其在大黄鱼保鲜中的应用研究[D]. 上海:上海海洋大学, 2021. [CHENG Z J. Preparation of poly (vinyl) alcohol/starch antimicrobial and antioxidant active film embedded with lemongrass oil and its application on preservation of large yellow[D]. Shanghai:Shanghai Ocean University, 2021.] CHENG Z J. Preparation of poly (vinyl) alcohol/starch antimicrobial and antioxidant active film embedded with lemongrass oil and its application on preservation of large yellow[D]. Shanghai: Shanghai Ocean University, 2021.

[6] 崔海英, 戴锦铭, 柏梅, 等. 柠檬草精油纳米脂质体抗不同材质表面金黄色葡萄球菌生物膜的研究[J]. 中国食品添加剂,2017(3):55−60. [CUN H Y, DAI J M, BAI M, et al. Lemongrass oil nanoliposomes against S. aureus biofilm formed on different materials[J]. China Food Additives,2017(3):55−60.] CUN H Y, DAI J M, BAI M, et al. Lemongrass oil nanoliposomes against S. aureus biofilm formed on different materials[J]. China Food Additives, 2017(3): 55−60.

[7] LIU C H, ZHOU H J, LIU J Y, et al. Preparation of antibacterial lemongrass oil microcapsules and their application in cotton fabrics[J]. Advanced Materials Research,2013,627:271−274.

[8] UMIGA B, UMIGA B, RAVNJAK D, et al. Antimicrobial paper coatings containing microencapsulated Cymbopogon citratus oil[J]. Multidisciplinary Digital Publishing Institute,2019,9(8):470.

[9] MARTINA C, GIUSEPPE C, FRANCESCO L, et al. Alginate-assisted lemongrass (Cymbopogon nardus) essential oil dispersions for antifungal activity[J]. Foods,2021,10(7):1528. doi: 10.3390/foods10071528

[10] ALMEIDA K B, RAMOS A S, NUNES J B, et al. PLGA nanoparticles optimized by box-behnken for efficient encapsulation of therapeutic Cymbopogon citratus essential oil[J]. Colloids and Surfaces, B. Biointerfaces,2019,181:935−942. doi: 10.1016/j.colsurfb.2019.06.010

[11] MARTINS W, JSFD A, FEITOSA B F, et al. Lemongrass (Cymbopogon citratus DC. Stapf) essential oil microparticles:development, characterization, and antioxidant potential[J]. Food Chemistry,2021,355(2):129644.

[12] 臧芳波, 李冲, 韩雪, 等. 香茅精油微胶囊的制备及表征分析[J]. 中国调味品,2023,48(1):191−195. [ZANG F B, LI C, HAN X, et al. Preparation and characterization analysis of citronella essential oil microcapsules[J]. China Condiment,2023,48(1):191−195.] ZANG F B, LI C, HAN X, et al. Preparation and characterization analysis of citronella essential oil microcapsules[J]. China Condiment, 2023, 48(1): 191−195.

[13] 蔡旭冉. 羧甲基淀粉钠与黄原胶复配体系特性及其应用研究[D]. 合肥:安徽农业大学, 2020. [CAI X R. Study on properties and application of carboxymethyl starch and xanthan gum combinations[D]. Hefei:Anhui Agricultural University, 2020.] CAI X R. Study on properties and application of carboxymethyl starch and xanthan gum combinations[D]. Hefei: Anhui Agricultural University, 2020.

[14] 张燕萍, 刘秋育. 变性淀粉作微胶囊壁材研究初探[J]. 食品工业科技,1998(1):20−21,19. [ZHANG Y P, LIU Q Y. Study on modified starch as wall material of microcapsules[J]. Science and Technology of Food Industry,1998(1):20−21,19.] ZHANG Y P, LIU Q Y. Study on modified starch as wall material of microcapsules[J]. Science and Technology of Food Industry, 1998(1): 20−21,19.

[15] 白雪, 田忠华, 赵悦琳, 等. 以高粱醇溶蛋白和酪蛋白酸钠为壁材制备粉末油脂的工艺优化[J]. 粮食与油脂,2021,34(2):33−37. [BAI X, TIAN Z H, ZHAO Y L, et al. Process optimization of oil powder using kafirin and sodium casinate as wall materials[J]. Journal of Cereals & Oils,2021,34(2):33−37.] BAI X, TIAN Z H, ZHAO Y L, et al. Process optimization of oil powder using kafirin and sodium casinate as wall materials[J]. Journal of Cereals & Oils, 2021, 34(2): 33−37.

[16] 孙妍. 米糠蛋白-阿拉伯胶-酪蛋白酸钠复合纳米颗粒的制备及性质研究[D]. 沈阳:辽宁大学, 2022. [SUN Y. Preparation and properties of rice bran protein-gum arabic-sodium caseinate composite nanoparticle[D]. Shenyang:Liaoning University, 2022.] SUN Y. Preparation and properties of rice bran protein-gum arabic-sodium caseinate composite nanoparticle[D]. Shenyang: Liaoning University, 2022.

[17] 赵国瑜, 范方宇, 槐晋东. 纳米SiO2/明胶茶油微胶囊的制备及性能[J]. 精细化工,2022,39(2):367−374,402. [ZHAO G Y, FAN F Y, HUAI J D. Preparation and properties of nano-SiO2/gelatin camellia oil microcapsules[J]. Fine Chemical,2022,39(2):367−374,402.] ZHAO G Y, FAN F Y, HUAI J D. Preparation and properties of nano-SiO2/gelatin camellia oil microcapsules[J]. Fine Chemical, 2022, 39(2): 367−374,402.

[18] 范方宇, 董选刚, 常艳琼, 等. 喷雾干燥法制备茶油微胶囊的研究[J]. 河南工业大学学报,2013,34(6):73−76. [FAN F Y, DONG X G, CHANG Y Q, et al. Study on preparation of camellia seed oil microcapsule by spray drying[J]. Journal of Henan University of Technology,2013,34(6):73−76.] FAN F Y, DONG X G, CHANG Y Q, et al. Study on preparation of camellia seed oil microcapsule by spray drying[J]. Journal of Henan University of Technology, 2013, 34(6): 73−76.

[19] 刘双双, 那治国, 徐飞, 等. 壁材对香草兰精油微胶囊物性与释放特性的影响[J]. 食品科学,2019,40(3):129−134. [LIU S S, NA Z G, XU F, et al. Effects of wall materials on properties and release characteristics of vanilla essential oil microcapsules[J]. Food Science,2019,40(3):129−134.] LIU S S, NA Z G, XU F, et al. Effects of wall materials on properties and release characteristics of vanilla essential oil microcapsules[J]. Food Science, 2019, 40(3): 129−134.

[20] 张丽红, 黄梦, 王桂瑛, 等. 木姜子精油微胶囊制备工艺优化及其品质分析[J]. 食品工业科技,2022,43(2):157−165. [ZHANG L H, HUANG M, WANG G Y, et al. Preparation process optimization and quality analysis of Litsea pungens hemsl essential oil microcapsules[J]. Science and Technology of Food Industry,2022,43(2):157−165.] ZHANG L H, HUANG M, WANG G Y, et al. Preparation process optimization and quality analysis of Litsea pungens hemsl essential oil microcapsules[J]. Science and Technology of Food Industry, 2022, 43(2): 157−165.

[21] 李丹, 汪秀妹, 梁杰, 等. 复合凝聚法制备槲皮素微胶囊及其表征[J]. 食品研究与开发,2023,44(15):127−135. [LI D, WANG X M, LIANG J, et al. Quercetin microcapsules:preparation by complex coacervation and characterization[J]. Food Research and Development,2023,44(15):127−135.] LI D, WANG X M, LIANG J, et al. Quercetin microcapsules: preparation by complex coacervation and characterization[J]. Food Research and Development, 2023, 44(15): 127−135.

[22] LÜ H X, HUO S S, ZHAO L L, et al. Preparation and application of cinnamon-Litsea cubeba compound essential oil microcapsules for peanut kernel postharvest storage[J]. Food Chemistry,2023,415:135734. doi: 10.1016/j.foodchem.2023.135734

[23] 刘钟栋, 孙有宁, 陈建慧. 糯小麦羧甲基淀粉钠的微波合成及性质研究[J]. 中国食品添加剂,2010(3):103−107. [LIU Z D, SUN Y N, CHEN J H. Studies on the properties and microwave synthesis of waxy wheat carboxy methyl starch[J]. China Food Additives,2010(3):103−107.] LIU Z D, SUN Y N, CHEN J H. Studies on the properties and microwave synthesis of waxy wheat carboxy methyl starch[J]. China Food Additives, 2010(3): 103−107.

[24] 吕伟, 刘祥, 李谦定. 高粘度羧甲基淀粉钠的研究进展[J]. 材料导报,2006,20(6):22−27. [LÜ W, LIU X, LI Q D. Advances in research of carboxymethyl starch sodium with high viscosity[J]. Material Reviews,2006,20(6):22−27.] LÜ W, LIU X, LI Q D. Advances in research of carboxymethyl starch sodium with high viscosity[J]. Material Reviews, 2006, 20(6): 22−27.

[25] 钟振声, 钟艳萍, 孙昂. 马铃薯交联-羧甲基淀粉钠的结构与性能[J]. 华南理工大学学报,2011,39(3):22−27. [ZHONG Z S, ZHONG Y P, SUN A. Structure and properties of potato cross-linked carboxymethyl starch[J]. Journal of South China University of Technology,2011,39(3):22−27.] ZHONG Z S, ZHONG Y P, SUN A. Structure and properties of potato cross-linked carboxymethyl starch[J]. Journal of South China University of Technology, 2011, 39(3): 22−27.

[26] 王擎宇, 王梦遥, 黄慧敏, 等. 果胶/酪蛋白酸钠复合运载体系的构建及对番茄红素的控释机理[J]. 食品科学,2020,41(11):83−89. [WANG Q Y, WANG M Y, HUANG H M, et al. Construction of pectin/sodium caseinate composite delivery system and controlled release mechanism of incorporated lycopene from it[J]. Food Science,2020,41(11):83−89.] WANG Q Y, WANG M Y, HUANG H M, et al. Construction of pectin/sodium caseinate composite delivery system and controlled release mechanism of incorporated lycopene from it[J]. Food Science, 2020, 41(11): 83−89.

[27] 许智萍, 范源洪, 何璐, 等. 云南香茅草精油含量及主要化学成分分析[J]. 热带农业科学,2020,40(11):115−120. [XU Z P, FAN Y H, HE L, et al. Essential oil content and chemical composition of citronella in Yunnan[J]. Chinese Journal of Tropical Agriculture,2020,40(11):115−120.] XU Z P, FAN Y H, HE L, et al. Essential oil content and chemical composition of citronella in Yunnan[J]. Chinese Journal of Tropical Agriculture, 2020, 40(11): 115−120.

[28] YUAN C, WANG Y L, LIU Y W, et al. Physicochemical characterization and antibacterial activity assessment of lavender essential oil encapsulated in hydroxypropyl-beta-cyclodextrin[J]. Industrial Crops and Products,2019,130:104−110. doi: 10.1016/j.indcrop.2018.12.067

[29] 李佳, 赵旭, 李欣蔚, 等. 一种复合防腐剂对不同泡菜防腐效果的研究[J]. 粮食与食品工业,2022,29(2):25−27. [LI J, ZHAO X, LI X W, et al. Study on the preservative effect of a compound preservative on different pickles[J]. Cereal and Food Industry,2022,29(2):25−27.] LI J, ZHAO X, LI X W, et al. Study on the preservative effect of a compound preservative on different pickles[J]. Cereal and Food Industry, 2022, 29(2): 25−27.

[30] 王猛. 四川泡菜腐败过程中腐败细菌的分离鉴定及其腐败特性分析[D]. 成都:西华大学, 2016. [WANG M. Isolation, identification and characteristics analysis of spoilage bacteria in Sichuan pickle during the deteriorating process[D]. Chengdu:Xihua University, 2016.] WANG M. Isolation, identification and characteristics analysis of spoilage bacteria in Sichuan pickle during the deteriorating process[D]. Chengdu: Xihua University, 2016.

[31] 燕平梅, 宋敏丽, 赵文婧. 东北泡菜中抑菌微生物的分离筛选及鉴定[J]. 中国调味品,2020,45(3):53−56. [YAN P M, SONG M L, ZHAO W J. Isolation, screening and identification of bacteriostatic microorganisms in pickles of northeast China[J]. China Condiment,2020,45(3):53−56.] YAN P M, SONG M L, ZHAO W J. Isolation, screening and identification of bacteriostatic microorganisms in pickles of northeast China[J]. China Condiment, 2020, 45(3): 53−56.

[32] 徐赛男. 浙东传统腌冬瓜危害性成分形成规律及控制研究[D]. 宁波:宁波大学, 2015. [XU S N. Study on the formation and control of harmful components of traditional pickled winter melon in eastern Zhejiang Province[D]. Ningbo:Ningbo University, 2015.] XU S N. Study on the formation and control of harmful components of traditional pickled winter melon in eastern Zhejiang Province[D]. Ningbo: Ningbo University, 2015.

[33] 朱翔, 李恒, 邓奥宇, 等. 泡辣椒中产气微生物的分离及鉴定[J]. 食品与发酵科技,2017,53(4):97−101. [ZHU X, LI H, DENG A Y, et al. Isolation and identification of gas-spoilage in Bubble Pepper[J]. Food and Fermentation Sciences and Technology,2017,53(4):97−101.] ZHU X, LI H, DENG A Y, et al. Isolation and identification of gas-spoilage in Bubble Pepper[J]. Food and Fermentation Sciences and Technology, 2017, 53(4): 97−101.

[34] 马国涵. 应用乳酸菌制剂控制传统东北酸菜腐败的研究[D]. 锦州:渤海大学, 2019. [MA G H. Research on control of spoilage of Traditional Northeast Suancai by using lactic acid bacteria preparation[D]. Jinzhou:Bohai University, 2019.] MA G H. Research on control of spoilage of Traditional Northeast Suancai by using lactic acid bacteria preparation[D]. Jinzhou: Bohai University, 2019.

[35] KAUR H, BHARDWAJ U, KAUR R. Cymbopogon nardus essential oil:A comprehensive review on its chemistry and bioactivity[J]. Journal of Essential Oil Research,2021,33(3):205−220. doi: 10.1080/10412905.2021.1871976

[36] THIELMANN J, THEOBALD M, WUTZ A, et al. Litsea cubeba fruit essential oil and its major constituent citral as volatile agents in an antimicrobial packaging material[J]. Food Microbiology,2021,96:103725. doi: 10.1016/j.fm.2020.103725

[37] SEIBERT J B, VIEGAS J, ALMEIDA T C, et al. Nanostructured systems improve the antimicrobial potential of the essential oil from Cymbopogon densiflorus leaves[J]. Journal of Natural Products,2019,82(12):3208−3220. doi: 10.1021/acs.jnatprod.8b00870

下载:

下载:

下载:

下载: