Evaluation and Analysis of Key Flavor and Warmed-over Flavor of Pre-prepared Steamed Pork with Preserved Vegetable Based on HS-SPME-GC-MS Combined with Electronic Tongue

-

摘要: 为探究预制梅菜扣肉关键性风味特征以及油脂氧化程度对其过熟味(warmer-over flavor,WOF)的影响,以不同品牌预制梅菜扣肉为研究对象,采用顶空固相微萃取气相色谱质谱联用技术(headspace-solid phase microextraction-gas chromatography-mass spectrometry,HS-SPME-GC-MS)和电子舌定量检测挥发性风味化合物及味觉指标方法,通过气味活度值(odor activity value,OAV)及主成分分析对预制梅菜扣肉关键性风味因子进行筛选及分析,采用酸价、过氧化值及TBA值分析其油脂氧化程度及其过熟味。结果表明,7种预制梅菜扣肉共鉴定出85种挥发性化合物,预制梅菜扣肉关键性风味物质为:烷烃类16种、萜烯类19种、醇类7种、醛类22种、酮类3种、酯类13种、酚类3种、其他类2种;OAV共筛选出23种关键挥发性化合物,预制梅菜扣肉关键性风味物质:OAV>10的物质分别为1-辛烯-3-醇、己醛、庚醛、辛醛、壬醛、(E,E)-2,4-壬二烯醛、癸醛、(E)-2-癸烯醛、(E,E)-2,4-癸二烯醛、1-辛烯-3-酮。电子舌及过熟味感官评价结果表明,7种预制梅菜扣肉味觉以咸味、鲜味及鲜味回味为主;其过熟味主要呈现出亚麻籽油味和酸败味。7种预制梅菜扣肉油脂氧化指标较高且差异显著(P<0.05),结合相关性分析,产生过熟味的主要因子物质(E)-2-癸烯醛、2-庚酮、壬醛、1-辛烯-3-酮、(E,E)-2,4-癸二烯醛、己醛、戊醛、庚醛、(E)-2-庚烯醛及辛醛与酸价、过氧化值及TBA值呈正相关。综上所述,7种预制梅菜扣肉其关键风味因子与过熟味之间存在较大联系,且推测预制梅菜扣肉过熟味的产生与其油脂氧化程度较高有关。本研究获得的关键风味因子物质、电子舌味觉指标及过熟味感官评价指标,为预制梅菜扣肉风味质量体系的建立及过熟味控制的研究提供了依据。Abstract: In order to study the key flavor characteristics and the influence of oxidation degree of oil on warmed-over flavor of pre-prepared steamed pork with preserved vegetable. The volatile flavor compounds and taste indexes of different brands of pre-prepared steamed pork with preserved vegetable were quantitatively detected by headspace-solid phase microextraction-gas chromatography-mass spectrometry and electronic tongue. The key flavor factors of pre-prepared steamed pork with preserved vegetable were screened and analyzed by odor activity value (OAV) and principal component analysis. Acid value, peroxide value and TBA value were used to analyze the oxidation degree of oil and warmed-over flavor of different brands of pre-prepared steamed pork with preserved vegetable. Results showed that a total of 85 volatile compounds were identified from 7 kinds of pre-prepared steamed pork with preserved vegetable, including 16 alkanes, 19 terpenes, 7 alcohols, 22 aldehydes, 3 ketones, 13 esters, 3 phenols and 2 others. A total of 23 key volatile compounds were screened by OAV, and the substances with OAV>10 were 1-octene-3-ol, hexanal, heptanal, octanal, nonanal, (E,E)-2,4-nonadienal, capric aldehyde, (E)-2-decenal, (E,E)-2,4-decenal and 1-octene-3-ketone, which were the key flavor substances for pre-prepared steamed pork with preserved vegetable. The results of electronic tongue and overripe taste evaluation showed that the taste of 7 kinds of pre-prepared steamed pork with preserved vegetable were mainly salty, umami and aftertaste. Its overripe taste mainly presented linseed oil taste and rancidity taste. The oil oxidation indexes of 7 kinds of pre-prepared steamed pork with preserved vegetable were higher and the differences were significant (P<0.05). The correlation analysis showed that the main factors that produce warmed-over flavor were (E)-2-decenal, 2-heptanone, nonylaldehyde, 1-octene-3-ketone, (E,E)-2,4-decenal, hexal, pentaldehyde, heptanal, (E)-2-heptenal and octanal, which were positively correlated with acid value, peroxide value and TBA value. In summary, the key flavor factors of the 7 kinds of pre-prepared steamed pork with preserved vegetable were related to overcooked taste, and it was speculated that the overcooked taste of pre-prepared steamed pork with preserved vegetable was related to the higher oxidation degree of oil. The key flavor factors, electronic tongue and overripe taste evaluation indexes obtained in this study provide the basis for the establishment of flavor quality system and overripe taste control of pre-prepared steamed pork with preserved vegetable.

-

梅菜扣肉(steamed pork with preserved vegetable),是一道中华民族民间传统菜肴,因其肉质软烂、肥而不腻、风味独特等特点,深受广大消费者喜爱[1−2]。但由于梅菜扣肉制作工艺繁琐、耗时耗力,往往只在节日或宴席上出现。近年来,随着食品工业化进程以及生产技术的提升,同时在“后疫情时代”、“宅经济”、“懒人经济”等现象带动下,预制菜迎来井喷式发展[3],因其贮藏期长且食用便捷,极大满足且丰富了食客日常用餐需求[4−5]。但预制菜往往因风味不佳得不到消费者的青睐,其风味劣变的原因较为复杂,主要原因是预制菜在生产、贮藏和复热过程中,脂肪会氧化均裂生成己醛、庚醛、癸醛、1-辛烯-3-醇等物质,浓度高时呈现酸败味或令人恶心等气味,这些异味常被称作过熟味(warmer-over flavor,WOF),导致预制菜风味劣变[6−10]。目前国内也逐渐重视过熟味的研究,杨姣等[11]研究发现鱼糜制品在温度过高和时间过长会产生过熟味,张凯华等[12−13]研究发现猪耳朵制品和预制猪肉饼在不同复热条件和时间下产生的过熟味含量不同,适当的复热条件可降低过熟味关键因子含量。因此在预制菜加工过程中除了生产、保鲜技术的提升,还应重点关注其风味的变化,但目前国内外对于预制梅菜扣肉风味及过熟味的研究报道较为鲜见。

目前分析食品风味的技术主要有顶空固相微萃取气质联用和电子舌等,顶空固相微萃取结合气相色谱质谱联用技术(headspace-solid phase microextraction-gas chromatography-mass spectrometry,HS-SPME-GC-MS)具有样本需求量小、操作简便、灵敏度高等优点[14],可用于检测挥发性有机物,广泛应用于茶叶[15]、火腿[16]、大豆油[17]、剁辣椒[18]、食醋[19]、饼干[20]等食品领域挥发性风味成分的鉴定中;电子舌(electronic tongue)可快速、无损对食品进行检测分析,在食品行业应用广泛[21]。食品的风味是由气味和滋味相互搭配而成,GC-MS结合电子舌可以更好地评价食品的整体风味;气味活度值(odor activity value,OAV)是挥发性物质浓度与其阈值的比值,通过结合GC-MS可用于评价挥发性物质对整体风味的贡献[11],但在预制菜领域上的研究未全面应用。

本试验以市售不同品牌预制梅菜扣肉为研究对象,通过顶空固相微萃取气相色谱质谱联用仪技术检测其挥发性有机物、感官评价、电子舌作为风味检测手段,结合OAV、主成分分析及聚类分析确定预制梅菜扣肉关键性挥发性成分及过熟味物质种类。同时结合酸价、过氧化值及TBA值探究梅菜扣肉脂肪氧化程度与过熟味关键因子之间关联性,以期为预制梅菜扣肉风味质量体系的建立及过熟味控制的研究提供理论基础。

1. 材料与方法

1.1 材料与仪器

冷藏预制梅菜扣肉(生产日期均为同一天) 市售超市,冷链运输至中南林业科技大学后4 ℃保存,具体信息见表1;冰乙酸、异辛烷、碘化钾、硫代硫酸钠、重铬酸钾、异丙醇、乙醚、甲基叔丁基醚、95%乙醇、酚酞、百里香酚酞、碱性蓝6B、无水硫酸钠、无水乙醚、石油醚 湖南国伦美生物科技有限公司。

表 1 不同品牌预制梅菜扣肉信息Table 1. Information of different brands of pre-prepared steamed pork with preserved vegetable品牌 产地 配料 外观 HBS 山东 五花肉、梅干菜、食用植物油、食用盐、味精、酿造酱油(含焦糖色)、香辛料

NLE 湖南 猪肉、梅干菜、辣椒、食用盐、白砂糖、蚝油、饮用水、酿造酱油(含焦糖色)、黄豆酱、料酒、香辛料、食品添加剂(谷氨酸钠、乳酸链球菌素、红曲红)

WS 广东 带皮猪肉、梅干菜、食用盐、豆豉、味精、大豆油、酿造酱油(含焦糖色)、调味料酒、香辛料、食品添加剂(辣椒红)、食用香精香料

CZT 湖北 五花肉、梅干菜、酿造酱油(含焦糖色)、黄酒、味精、食用盐、白砂糖、香辛料

YR 安徽 猪肉、梅干菜、水、酿造酱油(含焦糖色)、黄酒(含焦糖色)、白砂糖、食用盐、食用葡萄糖、浓香型白酒、生姜、味精、香葱

CCX 湖南 五花肉、梅干菜、辣椒、蚝油、酿造酱油(含焦糖色)、豆豉、味精、食用盐、白砂糖、香辛料

CCL 湖南 五花肉、梅干菜、辣椒、蚝油、酿造酱油(含焦糖色)、味精、食用盐、白砂糖、香辛料、食用香精

08-2T恒温磁力搅拌器 上海梅颖浦仪器仪表制造有限公司;57330-U固相微萃取装置 美国Supelco公司;DH-360AB电热恒温培养箱 北京中兴伟业仪器有限公司;57348-U固相微萃取针(50/30 μm DVB/CAR/PDMS) 美国Supelco公司;7890A-5975C气相色谱质谱联用仪、HP-5MS气相色谱柱(60 m×250 μm×0.25 μm) 美国Agilent公司;SA-402B味觉分析系统(电子舌) 日本Insent公司。

1.2 实验方法

1.2.1 实验样品的制备

将预制梅菜扣肉置于25 ℃恒温箱自然解冻4 h至完全解冻,并将解冻后的预制梅菜扣肉从包装袋中取出置于容器中备用。

1.2.2 梅菜扣肉过熟味感官分析评价

参照张凯华等[12]方法稍作修改,选取20名食品专业技术人员(男:女=1:1,年龄22~30岁)组成感官评价小组,并对小组成员根据过熟味气味及相关标准进行培训,具体评定指标见表2,评价前将解冻的样品沸水浴复热30 min后在30 ℃条件下恒温放置30 min,每个样品评价时间隔3 min,且每个样品重复3次,感官评价结果取平均值并绘制过熟味感官雷达图。

表 2 过熟味感官评价标准Table 2. Sensory evaluation criteria for warmed-over flavor过熟味指标 评分参考 评分细则 0分 1~4分 5分 湿纸板味 10 g纸箱碎屑溶于100 mL

水中的气味没有

风味风味逐

渐增强风味

最强亚麻籽油味 50 g亚麻籽油在水中加热

15 min的气味硫化味 橡皮筋的气味 酸败味 植物油严重氧化的气味 金属味 0.1 g/L硫化亚铁溶液的气味 1.2.3 梅菜扣肉挥发性成分测定

1.2.3.1 萃取方法

将解冻好的样品用机器绞碎成肉糜,称取5 g梅菜扣肉肉糜置于20 mL顶空萃取瓶中,加入100 μL 2,4,6-三甲基吡啶(0.05 mg/mL)作为内标物,密封,置于85 ℃水浴中,磁力搅拌速度500 r/min,平衡20 min后,插入萃取针萃取30 min。萃取针使用前,在气质进样口活化20 min(250 ℃)。

1.2.3.2 GC-MS条件

GC条件:进样口温度250 ℃,气质接口温度280 ℃,载气(He)流速1.5 mL/min,分流比4:1。升温程序:初始50 ℃,保持1 min,以5 ℃/min升温到100 ℃保持2 min;4 ℃/min升温到180 ℃保持3 min;5 ℃/min升温到250 ℃保持5 min。

MS条件:离子源温度230 ℃,四级杆温度150 ℃,EI电离70 eV,全扫描m/z 35~550。

1.2.3.3 定性分析

使用NIST 20质谱数据库检索,与标准谱对比进行定性分析,选取相似度大于80%的挥发性风味成分定性。

1.2.3.4 定量分析

采用内标法进行定量分析,根据已知内标物2,4,6-三甲基吡啶的含量并依据挥发物峰面积与含量成正比原理来计算出未知挥发性物质的含量,按公式(1)计算:

CX=C0×V0×SXS0×m (1) 式中:CX为未知化合物的含量(μg/kg);C0为内标物的质量浓度(μg/μL);V0为内标物进样体积(μL);SX为未知化合物的峰面积(AU·min);S0为添加的内标物峰面积(AU·min);m为试样的质量(kg)。

1.2.4 电子舌检测条件

电子舌传感器特性见表3,将解冻的样品用机械绞碎成肉糜,称取10 g梅菜扣肉肉糜于烧杯中,倒入120 mL纯水,浸提20 min后冷冻离心5 min(2 ℃,9000 r/min),将上清液抽滤后倒入100 mL电子舌专用烧杯中检测。每个样品重复测定5次,单次采集时间为120 s,采取传感器信号强度在120 s的稳定数据作为输出值进行分析。

表 3 电子舌传感器Table 3. Electronic tongue sensor传感器 味觉信息 基本味 回味 鲜味传感器AEE 鲜味(氨基酸、核苷酸、有

机酸引起的鲜味)丰富度(持续的鲜味) 咸味传感器CT0 咸味(氯化钠等无机盐

引起的咸味)— 酸味传感器CA0 酸味(柠檬酸、乳酸、酒石酸、

醋酸等引起的酸味)— 苦味传感器C00 苦味(苦味物质引起的味道,在

低浓度下被感知为鲜味回味)苦味回味(含有咖啡因

等食品的苦味)涩味传感器AE1 涩味(涩味物质引起的味道,低浓度下感知为刺激性回味) 涩味回味(含有单宁、生物

碱等食品呈现的涩味)甜味传感器GL0 甜味(糖等甜味剂引起的甜味) — 1.2.5 过氧化值的测定

参照GB 5009.227-2016《食品中过氧化值的测定》中的滴定法测定过氧化值。

1.2.6 酸价的测定

参考GB 5009.229-2016《食品中酸价的测定》中的冷溶剂指示剂滴定法测定酸价。

1.2.7 硫代巴比妥酸值的测定

参考GB 5009.181-2016《食品中丙二醛的测定》中的分光光度法测定硫代巴比妥酸值。

1.2.8 OAV值的计算

通过计算气味活度值(odor activity value,OAV)来评估挥发性物质的贡献,OAV≥1的化合物通常被认为对整体风味特征具有很大贡献[22],按公式(2)计算:

OAV=CXTX (2) 式中:Cx为挥发性风味物质含量(μg/kg);Tx为该风味物质在水中的嗅味感觉阈值(μg/kg)。

1.3 数据处理

GC-MS采用工作站自带数据处理软件进行处理;电子舌及其余数据采用Microsoft Excel 2016和SPSS 22.0统计软件进行ANOVA单因素方差分析、差异显著性分析、主成分分析、聚类热图分析及相关性分析,显著性水平取P<0.05,并采用Origin 2021进行相应绘图。

2. 结果与分析

2.1 感官评价分析结果

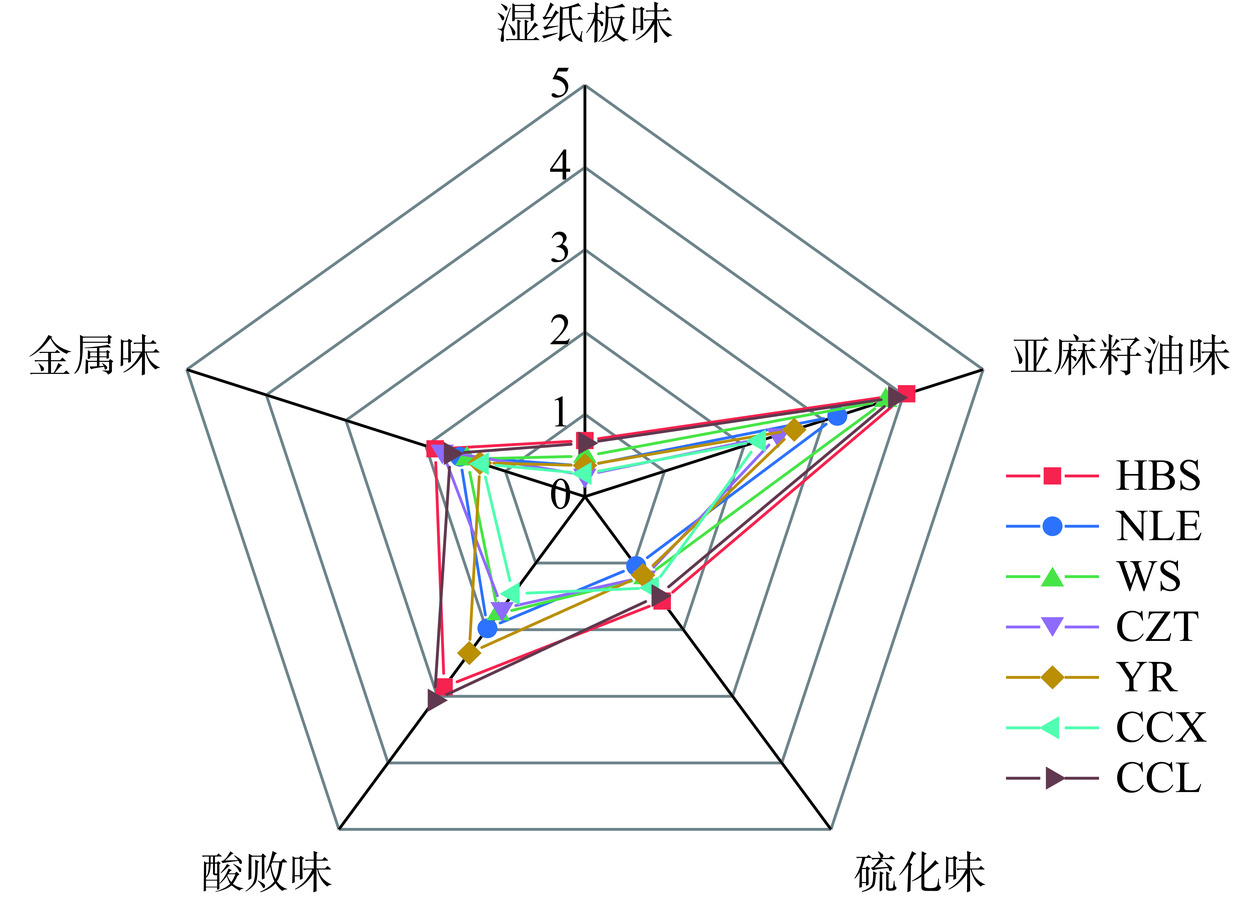

如图1所示,7种预制梅菜扣肉制品过熟味(WOF)以亚麻籽油味和酸败味为主,略带轻微金属味和硫化味,几乎无湿纸板味,而梅干菜和猪肉原有的青香味和肉香味较淡。HBS和CCL的亚麻籽油味及酸败味得分最高且分别为4.04分、2.86分和3.89分、3.06分,与其他组差异显著(P<0.05),与顶空固相微萃取气质联用仪检测出其己醛、庚醛和壬醛等低级醛类含量高有关,油脂氧化生成的低级醛是肉类产生异味的主要原因[23−24]。预制梅菜扣肉金属味和硫化味得分都在1~2分之间,各组别之间差异不大,湿纸板味得分在1分以下感知度较弱且差异不显著。

2.2 挥发性风味化合物分析结果

如表4~表5所示,基于顶空固相微萃取结合气质联用技术(HS-SPME-GC-MS)对7种市售预制梅菜扣肉的挥发性物质进行检测,7组样品(HBS、NLE、WS、CZT、YR、CCX、CCL)中共鉴定出85种挥发性物质,其中烷烃类16种、萜烯类19种、醇类7种、醛类22种、酮类3种、酯类13种、酚类3种、其他类2种,共有17种挥发性物质在7组样品中均有出现。7组预制梅菜扣肉挥发性物质总含量分别为1265.27、1189.62、1154.97、1073.13、1242.9、1128.03和1268.07 μg/kg,不同组间差异显著(P<0.05),其中醛类物质含量相对较高,HBS组和CCL组醛类物质超过总含量的50%。

表 4 不同品牌预制梅菜扣肉挥发性成分比较Table 4. Comparison of volatile compositions of different brands of pre-prepared steamed pork with preserved vegetable序号 化合物名称 分子式 含量(μg/kg) HBS NLE WS CZT YR CCX CCL 烷烃类 1 己烷(hexane) C6H14 7.24±1.94 − − − − − − 2 庚烷(heptane) C7H16 4.83±0.93a 2.45±0.33b 1.34±0.11bc 1.46±0.39bc 1.48±0.22bc 4.53±1.39a 1.04±0.17c 3 癸烷(decane) C10H22 50.65±3.36a 22.26±1.92cd 12.63±2.77d 31.29±10.26bc 34.25±7.88b 18.51±2.96b 18.03±6.27e 4 3,8-二甲基癸烷

(3,8-dimethyldecane)C12H26 12.28±4.34a − − − − 9.35±2.38a − 5 3-甲基十一烷

(3-methylundecane)C12H26 − − 4.59±1.98b 6.74±2.21a − − − 6 3-乙基-2,6,10-三甲基十一烷(3-ethyl-2,6,10-trimethylundecane) C16H34 − − 5.52±1.63 − − − − 7 正十二烷(dodecane) C12H26 28.66±6.18bcd 23.1±2.82cd 20.09±3.77d 16.96±5.21d 31.62±2.56bc 56.85±10.37a 37.91±7.41b 8 正十三烷(tridecane) C13H28 10.83±3.48a − − 6.43±2.67b − − − 9 3-甲基十三烷

(3-methyltridecane)C14H30 − − − 8.21±3.14a − − 2.76±0.27b 10 正十四烷(tetradecane) C14H30 59.01±15.34a 18.58±4.52b 11.23±1.75b 12.38±4.64b − 21.75±4.99b 23.92±3.33b 11 正十五烷(pentadecane) C15H32 25.8±5.27a 23.88±2.94ab 10.07±2.61c 8.59±0.94c 19.01±4.54b − − 12 正十六烷(hexeadecane) C16H34 12.78±1.44a 3.56±0.31d 8.34±2.67b 8.37±1.88b 5.82±1.12cd 13.76±0.67a 6.47±1.18bc 13 正十七烷(heptadecane) C17H36 8.69±3.33bc 14.07±2.12a 5.83±0.43bc − 4.04±1.23c 17.82±4.18a 9.22±3.31b 14 正十八烷(octadecane) C18H38 − 3.84±0.41b 4.69±0.97b − − 10.19±3.41a − 15 正十九烷(nonadecane) C19H40 − 6.05±0.68b − − − 9.32±1.22a − 16 正二十四烷(tetracosane) C24H50 5.61±1.04 − − − − − − 共计 226.42±4.29a 117.84±6.70c 79.72±1.30d 101.31±20.07c 102.98±7.98c 177.84±12.26b 99.35±13.72c 萜烯类 17 柠檬烯(limonene) C10H16 37.68±3.88bc 46.36±10.43b 26.54±3.18c 66.53±6.99a 34.87±5.78bc 24.62±2.72c 70.58±14.14a 18 四氢双环戊二烯(tetrahydrodicyclopentadiene) C10H16 28.88±2.98b 16.16±3.33c 19.24±2.11c 33.74±4.44b 32.99±9.27b 35.07±3.24b 47.78±3.17a 19 α-蒎烯(α-pinene) C10H16 − 6.44±2.12b − − 9.94±2.52a − 2.36±0.24c 20 莰烯(camphene) C10H16 − 12.46±2.98b 6.10±1.22c 2.72±0.42d 15.7±0.76a − − 21 β-水芹烯(β-phellandrene) C10H16 − 45.55±10.31b 35.02±3.43b − 67.51±14.54a − − 22 α-姜黄烯(α-curcumene) C15H22 8.12±1.21de 9.81±0.34cd 15.03±4.21b 4.76±0.54e 23.89±2.58a 12.38±2.99bc 6.44±1.11de 23 α-姜烯(α-zingiberene) C15H24 2.45±0.15d 10.98±2.14b 13.56±1.87a − 7.9±1.84c − − 24 β-倍半水芹烯(β-sesquiphellandrene) C15H24 − 4.16±0.33b 5.59±1.52ab − 7.31±1.67a 5.99±1.08a − 25 β-石竹烯(β-caryophyllene) C15H24 − − 24.57±2.98a 6.33±1.02c − 14.20±1.44b − 26 α-香柠檬烯(α-alpha-bergamotene) C15H24 − − 9.94±2.26 − − − − 27 γ-红没药烯(γ-bisabolene) C15H24 − 0.98±0.08bc 5.04±0.78a 0.45±0.04c 1.43±0.22b − − 28 β-红没药烯(β-bisabolene) C15H24 − 6.56±1.22b 8.91±1.54a − 6.92±1.61b 0.98±0.12c − 29 β-蒎烯(β-pinene) C15H24 2.21±0.32d − 10.76±3.11b − 15.14±2.42a 6.98±1.44c − 30 香树烯(alloaromadendrene) C15H24 − − − − 3.52±0.32 − − 31 萜品油烯(terpinolene) C10H16 − − 0.92±0.25a − − − 0.43±0.12b 32 γ-榄香烯(γ-cyclohexane) C15H24 − 0.25±0.09 − − − − − 33 α-佛手柑烯(α-bergamotene) C15H24 − − 2.34±0.08b − − 15.13±1.54a − 34 α-穆罗林烯(α-muurolene) C15H24 − − − − − 13.76±2.16 − 35 δ-杜松烯(δ-cadinene) C15H24 − 5.87±0.42b − − − 15.39±0.99a − 共计 79.35±1.12f 165.58±8.18c 183.55±3.75b 114.54±7.20e 227.13±12.91a 144.45±6.71d 127.59±17.03e 醇类 36 乙醇(ethanol) C2H6O 121.96±20.55b 203.04±60.12b 117.15±17.12b 332.61±66.53a 310.77±78.43a 170.95±20.62b 178.95±43.65b 37 芳樟醇(linalool) C10H18O − − 22.54±1.54a − − 10.55±2.89b − 38 4-萜烯醇(terpinine-4-ol) C10H18O − 7.88±1.04b 10.13±2.87a − − − − 39 1-辛烯-3-醇(1-octen-3-ol) C8H16O 14.02±2.65cd 24.96±5.34b 18.17±1.53bc 36.46±3.98a 9.21±2.11d 23.63±5.35b 33.18±6.23a 40 十五烷醇(pentadecanol) C15H32O − 3.72±0.44 − − − − − 41 桉叶油醇(cineole) C10H18O 6.44±0.78e 28.45±6.88a 13.33±2.45cd − 21.87±3.11b 10.89±2.43de 17.13±1.89bc 42 反式-2-十四烯-1-醇

(trans-2-tetradecen-1-ol)C14H28O − − 9.77±3.65 − − − − 共计 142.41±20.76d 268.05±52.74bc 191.08±14.12cd 369.07±68.35a 341.86±81.22ab 216.02±22.33cd 229.26±44.31cd 醛类 43 戊醛(pentanal) C5H10O 57.86±6.67a − − − 23.99±5.32c 5.94±0.88d 42.87±10.12b 44 己醛(hexanal) C6H12O 220.36±25.37a 88.26±7.87c 157.12±26.66b 79.83±18.87c 98.76±14.25c 75.53±13.14c 198.19±29.41a 45 庚醛(heptaldehyde) C7H14O 77.44±10.97a 55.78±5.01bc 51.59±9.84c 32.10±5.54d 44.13±4.59cd 34.25±8.16d 68.25±7.01ab 46 (E)-2-庚烯醛

(trans-2-heptenal)C7H12O 10.26±2.69b 6.66±1.34c 9.13±1.66bc − 9.19±2.44bc − 17.27±1.95a 47 辛醛(octanal) C8H16O 51.37±5.83a 45.13±10.03a 29.2±2.32c 24.31±5.21cd 32.98±3.34bc 15.67±4.29d 41.93±5.68ab 48 (E)-2-辛烯醛(trans-2-octenal) C8H14O 2.78±0.31c − 3.47±0.45b − 0.98±0.22d − 5.64±0.65a 49 壬醛(nonanal) C9H18O 143.17±14.77a 56.41±8.92cd 104.59±5.07b 68.89±3.68c 67.65±8.98c 49.76±2.43d 95.03±12.98b 50 (E,E)-2,4-壬二烯醛(trans,trans-2,4-nonadienal) C9H14O 37.44±3.03b − 27.38±3.63c 11.33±0.97e 18.63±3.99d − 47.45±7.83a 51 癸醛(decanal) C10H20O 11.60±2.92a 2.13±0.34b 11.55±0.97a − 3.81±0.93b 10.35±1.69a − 52 (E)-2-癸烯醛

(trans-2-decenal)C10H18O 20.56±1.85c 25.33±4.24bc 28.05±6.67b 13.98±0.99d − 22.56±4.46bc 44.48±2.25a 53 (E,E)-2,4-癸二烯醛(trans,trans-2,4-decadienal) C10H16O 10.71±2.85b 7.03±1.49c 3.41±0.34d − − 5.77±0.42cd 16.04±2.39a 54 2-十一烯醛(2-undecenal) C11H20O 4.33±1.32de 2.13±0.69e 8.86±1.81b − 7.34±0.84bc 11.16±1.76a 6.36±1.55cd 55 苯甲醛(benzaldehyde) C7H6O 75.27±14.03a 45.43±4.66b 44.01±4.85b 17.44±3.02d 27.12±3.69cd 38.86±7.31bc 72.90±5.16a 56 十六烷醛(hexadecanal) C16H32O − 6.46±1.41b − − − 18.89±2.64a − 57 十七烷醛(heptadecanal) C17H34O − − − − 4.76±0.35 − − 58 十八烷醛(octadecanaldehyde) C18H36O − − − 10.05±1.25 − − − 59 二十烷醛(icosanal) C20H40O − 13.58±2.26a 12.64±3.45a − − − − 60 肉桂醛(cinnamaldehyde) C9H8O − 49.25±12.41a 48.64±5.65a − 26.89±3.66b − − 61 3-糠醛(3-furaldehyde) C5H4O2 34.41±3.65b 10.56±2.12d − 18.01±5.22c 9.98±1.05d 24.68±4.43c 50.39±6.73a 62 糠醛(furfural) C5H4O2 − 6.18±2.46a 3.57±1.23b − 2.51±0.46b − − 63 香叶醛(trans-citral) C10H16O − − − − 22.07±4.26 − − 64 橙花醛(citral) C10H16O − − − − 14.11±1.47 − − 共计 757.58±32.84a 420.33±19.69d 543.29±32.19c 275.91±10.81e 414.92±19.92d 313.44±7.85e 706.82±28.36b 酮类 65 3-羟基-2-丁酮(acetoin) C4H8O2 − 0.91±0.19a − − − − 0.79±0.27a 66 2-庚酮(2-heptanone) C7H14O − 2.09±0.14b − − − − 4.78±0.71a 67 1-辛烯-3-酮(1-octen-3-one) C8H14O 6.80±2.46a 3.24±0.36b − − 2.42±0.48b 4.06±0.96b 3.77±0.88b 共计 6.80±2.47b 6.24±0.31b − − 2.42±0.48c 4.06±0.97c 9.35±1.00a 酯类 68 乙酸甲酯(methyl acetate) C3H6O2 1.7±0.31a − − − 0.89±0.19b − − 69 乙酸乙酯(ethyl acetate) C4H8O2 3.39±0.45a 2.52±0.43b − 0.63±0.13d 1.40±0.23c − 1.42±0.49c 70 棕榈酸甲酯

(methyl hexadecanoate)C17H34O2 7.61±1.21d 25.16±2.94a 8.82±0.36d 7.16±0.63d 8.42±1.38d 16.97±3.12b 12.69±1.57c 71 十六酸乙酯(ethyl palmitate) C18H36O2 − 25.80±4.98a 11.88±1.54b 6.74±1.31c − 11.59±1.74b 7.74±1.02c 72 三醋酸甘油酯(triacetin) C9H14O6 − 39.31±7.84 − − − − − 73 顺式-13-十八烯酸甲酯(methyl octadec-13-enoate) C19H36O2 − − − − − − 10.38±1.76 74 亚油酸乙酯(ethyl linoleate) C20H36O2 12.86±3.19b 23.66±2.92a − − − 14.97±2.53b − 75 油酸甲酯(methyl oleate) C19H36O2 − − 6.49±0.86b 9.28±2.47a − 8.73±1.13a − 76 油酸乙酯(ethyl oleate) C20H38O2 − 16.67±2.41a − − 12.94±1.58b − − 77 2-单棕榈酸甘油

(2-palmitoylglycerol)C19H38O4 − − 30.88±5.33 − − − − 78 二氢猕猴桃内酯(dihydroactinidiolide) C11H16O2 − − − − 6.87±1.14c 17.91±4.12a 11.69±1.27b 79 肉豆蔻酸乙酯(ethyl tetradecanoate) C16H32O2 − − − − 4.56±0.65 − − 80 顺式-13-十八烷酸甲酯(methyl 13-octadecenoate) C19H36O2 − 7.61±0.77a − 0.67±0.25b − − − 共计 25.58±3.06e 140.68±13.09a 58.09±3.57c 24.49±4.58e 35.11±2.16de 70.18±7.85b 43.93±4.04d 酚类 81 2,4-二叔丁基苯酚

(2,4-di-t-butylphenol)C14H22O − − 2.24±0.45c 4.06±1.44b − 12.13±1.97a − 82 2,6-二叔丁基-4-甲基苯酚(2,6-di-tert-butyl-4-methylphenol) C15H24O 15.54±3.41c 4.55±0.53de 1.54±0.24e 8.09±1.66d − 43.64±5.55a 32.11±8.12b 83 丁香酚(eugenol) C10H12O2 8.44±2.36d 45.45±3.55b 29.47±6.42c 59.23±12.42a 10.43±0.98d 8.72±2.67d 6.87±1.11d 共计 23.98±4.67d 50.01±3.93b 33.25±6.09cd 71.37±12.42a 10.43±0.98e 64.49±2.24a 38.98±7.02bc 其他类 84 茴香脑(cis-anethol) C10H12O 3.14±0.82c 20.89±3.12c 20.09±2.44c 116.44±23.11a 108.07±12.63a 62.84±4.45b 12.79±2.99c 85 草蒿脑(estragole) C10H12O − − 45.89±6.34b − − 74.71±12.76a − 共计 3.14±0.82d 20.89±3.12d 65.99±8.41c 116.44±23.11ab 108.07±12.63b 137.55±15.47a 12.79±2.99d 总计 1265.27±39.97a 1189.62±

49.71bc1154.97±30.4bcd 1073.13±

90.56e1242.9±58.55ab 1128.03±

22.72cd1268.07±40.49a 注:同行不同字母表示含量差异显著(P<0.05)。 表 5 不同品牌预制梅菜扣肉挥发性化合物种类Table 5. Types of volatile compounds in different brands of pre-prepared steamed pork with preserved vegetable序号 分类 数量(种) HBS NLE WS CZT YR CCX CCL 1 烷烃类 11 9 10 9 6 9 7 2 萜烯类 5 12 14 6 12 10 5 3 醇类 3 5 6 2 3 4 3 4 醛类 14 15 15 9 17 12 13 5 酮类 1 3 0 0 1 1 3 6 酯类 4 6 4 5 6 5 5 7 酚类 2 2 3 3 1 3 2 8 其他类 1 1 2 1 1 2 1 总计 85 41 53 54 35 47 46 39 烷烃类化合物主要可能来源于脂肪酸中烷氧自由基均裂而产生[25]。不同品牌预制梅菜扣肉烷烃类种类及含量分别为11种(226.42 μg/kg)、9种(117.84 μg/kg)、10种(79.72 μg/kg)、9种(101.31 μg/kg)、6种(102.98 μg/kg)、9种(177.84 μg/kg)和7种(99.35 μg/kg),烷烃类化合物嗅觉阈值往往较低[26],对预制梅菜扣肉整体风味贡献不大。

萜烯类化合物主要来源于天然植物中,分子式为异戊二烯单倍数((C5H8)n)的烃类,多以游离态或酸、酯等形式存在于生物体中[27],其阈值较低,多呈现出木质、水果和花草香味,对风味贡献相对较大[28]。NLE、WS、YR和CCX组的萜烯类化合物种类及含量较多且分别为12种(165.58 μg/kg)、14种(183.55 μg/kg)、12种(227.13 μg/kg)和10种(144.45 μg/kg),推测其可能添加的香精香料较多,丰富了预制梅菜扣肉的风味。

醇类化合物具有使人愉悦的气味,一般来源于肉类加工过程中不饱和脂肪酸氧化且阈值较低,具有植物的清香气息,对肉制品整体风味的形成及层次的丰富发挥着重要作用[29]。预制梅菜扣肉共检测出7种醇类,包括乙醇、芳樟醇、4-萜烯醇、1-辛烯-3-醇、十五烷醇、桉叶油醇和反式-2-十四烯-1-醇。芳樟醇具有柑橘、柠檬香,4-萜烯醇具有草木香,桉叶油醇具有樟脑、草药香,这三种醇类物质主要来自草果、肉桂及花椒等香辛料,可丰富预制梅菜扣肉风味层次[30−31];十五烷醇和反式-2-十四烯-1-醇可能来源于脂肪氧化的中间产物;1-辛烯-3-醇来源自脂肪氧化,在含量低时具有蘑菇味,含量高时呈现出金属味,可能是产生过熟味的主要因子[17]。

醛、酮类化合物通常由脂质的降解、氧化以及美拉德反应产生,在低浓度时呈现油脂香、青草香、花果香味,但高浓度时具有酸败、刺鼻和令人恶心的气味[32−33]。醛类物质是预制梅菜扣肉的主要挥发性香气成分,共检测出22种醛类物质如己醛、庚醛、辛醛等,其阈值较低,对预制梅菜扣肉的风味贡献较大,与其他文献研究表明醛类物质是肉类脂肪的特征风味物质的结论相类似[34−35]。7种样品醛类物质种类及含量分别为14种(757.58 μg/kg)、15种(420.33 μg/kg)、15种(543.29 μg/kg)、9种(275.91 μg/kg)、17种(414.92 μg/kg)、12种(313.44 μg/kg)和13种(706.82 μg/kg),其中HBS组含量最高,YR组种类最多,结合文献与感官评价结果表明醛类物质含量的高低与过熟味的产生关系较大。而酮类化合物性质相对稳定,其阈值一般高于同分异构体的醛类[36],7种样品中只检测出了3种酮类,相对含量较低。

酯类化合物主要源于脂肪氧化或是酯化反应生成物[37],7种预制梅菜扣肉共检测出13种酯类物质,相对含量较少。酚类、醚类化合物主要来源于香辛料或外源物质中,多呈现花果香、辛香和茴香[38−39],7种样品中共检测出3种酚类和2种醚类化合物,对预制梅菜扣肉风味有一定修饰作用。

2.3 电子舌分析结果

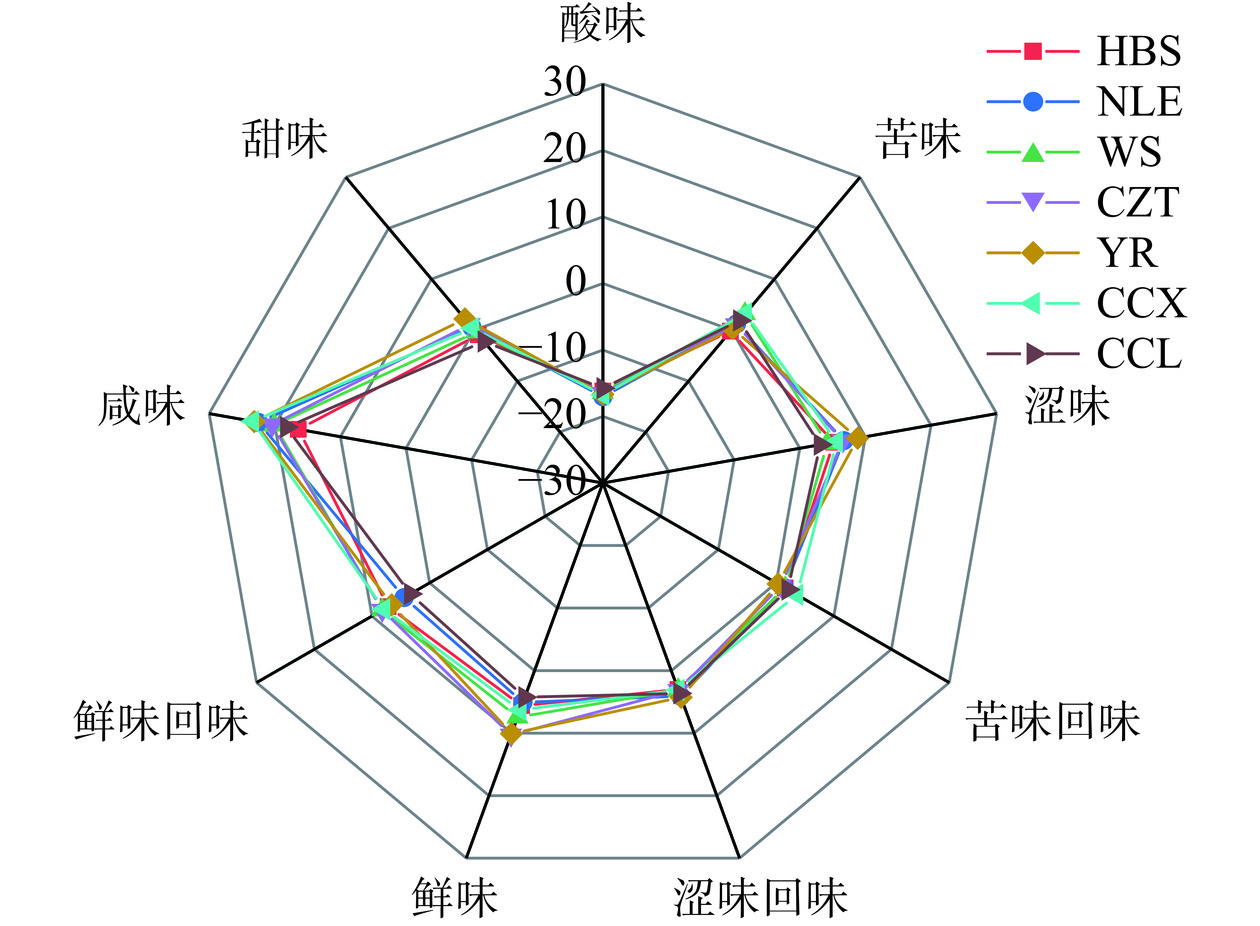

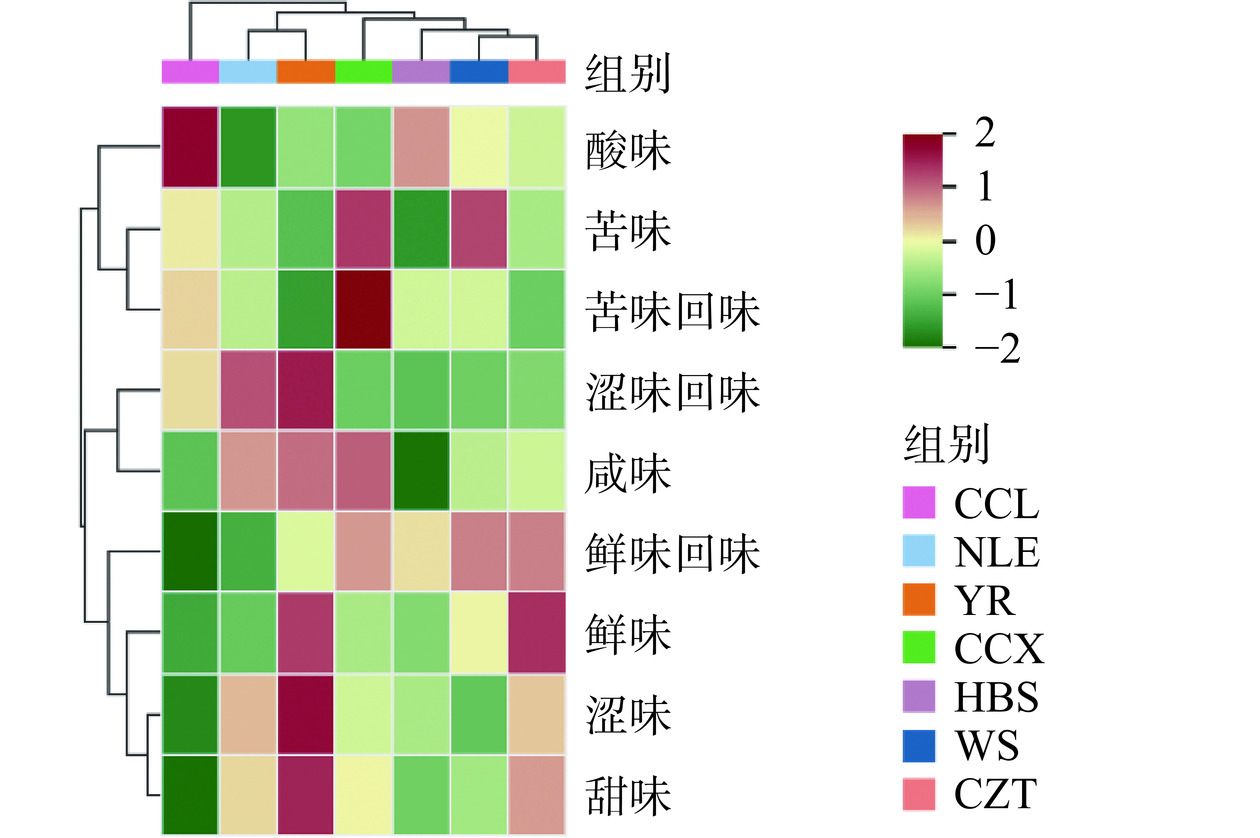

如图2~图3所示,预制梅菜扣肉通过电子舌传感器检测出的味觉主要为咸味、鲜味以及鲜味回味,符合梅菜扣肉具有咸鲜味的特点。不同品牌预制梅菜扣肉之间酸味、涩味回味的差异不显著,其余味觉差异显著(P<0.05)。其中CCX的苦味和苦味回味最突出,YR的涩味、涩味回味和甜味最突出,CZT的鲜味最突出,WS的鲜味回味最突出,以及NLE的咸味最突出。

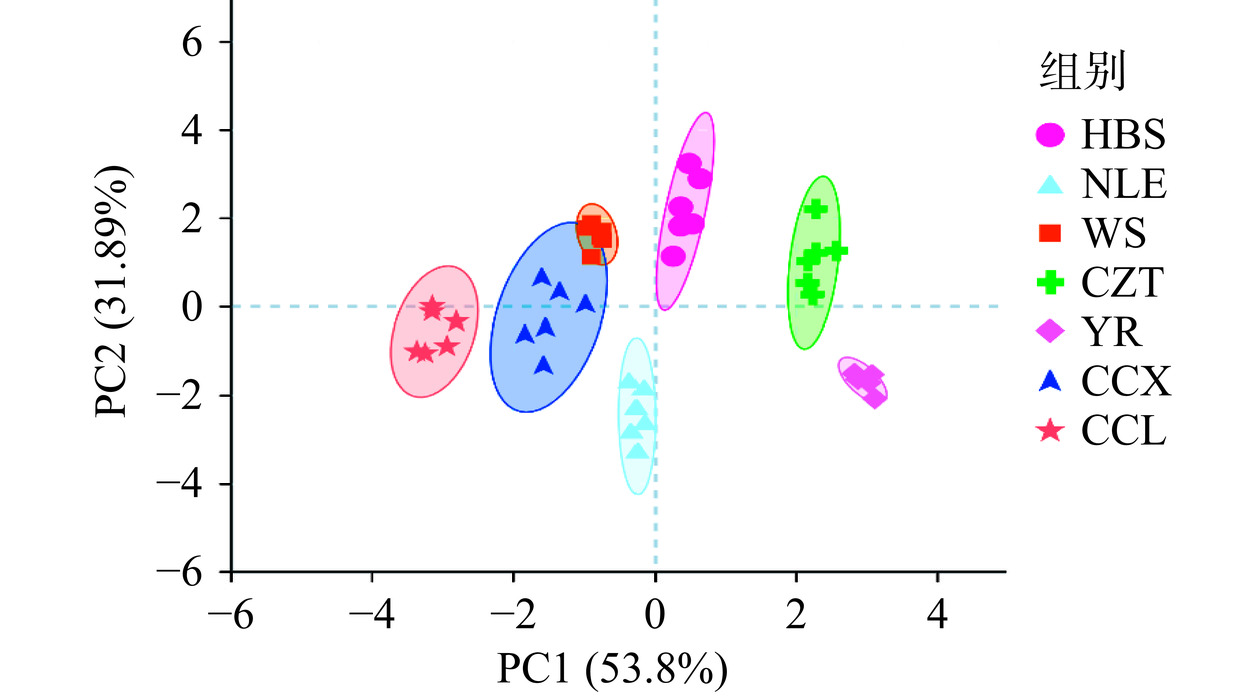

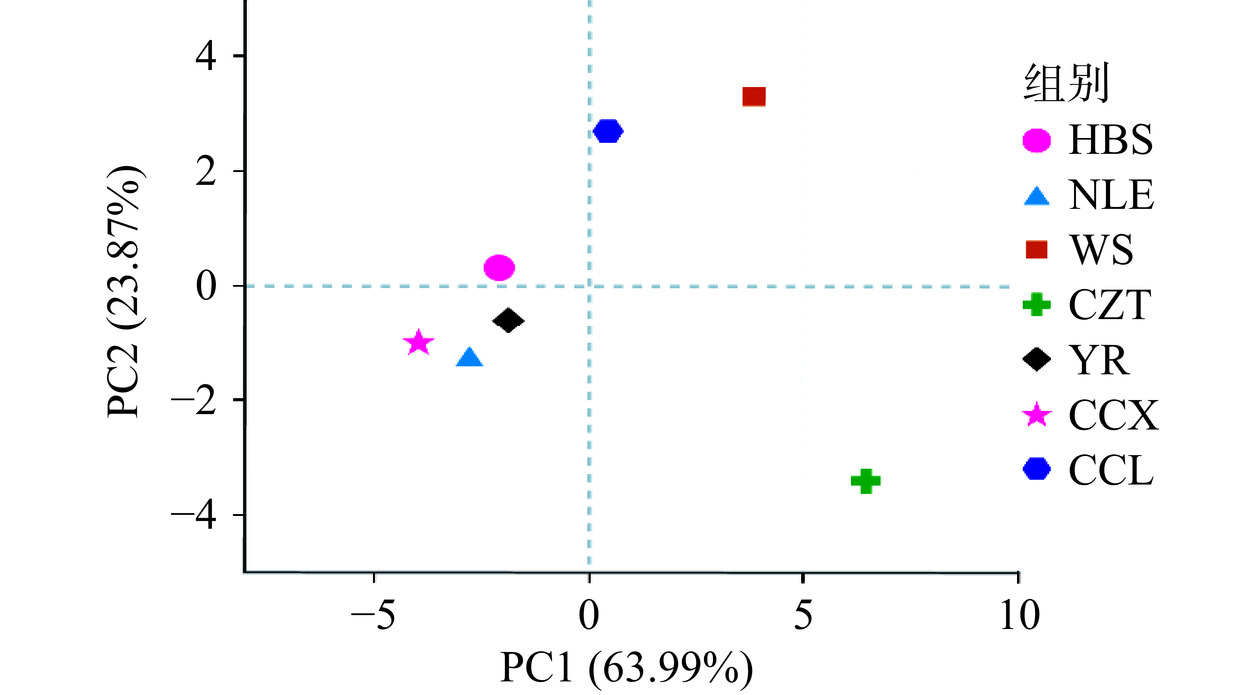

将不同品牌预制梅菜扣肉味觉通过主成分分析得到图4,主成分1和主成分2的累计贡献率为85.69%,表明主成分1和主成分2包含预制梅菜扣肉中绝大部分味觉信息,能够代表预制梅菜扣肉味觉的整体信息。主成分分析结果表明,WS和CCX之间具有部分关联性,其余品牌之间差异较为明显,使用电子舌能较好地区分不同品牌预制梅菜扣肉。

2.4 不同品牌预制梅菜扣肉挥发性风味气味活度值(OAV)分析

HS-SPME-GC-MS分析所得挥发性风味物质含量往往不能直接反映其对预制梅菜扣肉整体香气贡献的大小,而由其含量与感官阈值共同决定,故采用气味活度值(OAV)来筛选预制梅菜扣肉关键挥发性物质[40]。通常认为OAV>1时,该化合物对预制梅菜扣肉风味具有一定影响,OAV越大,则对预制梅菜扣肉风味的贡献就越大[18]。如表6所示,为部分挥发性物质OAV和嗅觉阈值,其中OAV>1的关键香气物质有23种且醛类物质最多,NLE的关键性香气物质最多,而CZT的关键性香气物质最少。

表 6 不同品牌预制梅菜扣肉挥发性风味物质OAVTable 6. OAV of volatile flavor substances in different brands of pre-prepared steamed pork with preserved vegetable风味物质 嗅觉阈值

(μg/kg)[41−43]OAV 气味描述[17,41−43] HBS NLE WS CZT YR CCX CCL 柠檬烯 10 3.77 4.64 2.65 6.65 3.49 2.46 7.06 柑橘味、橙子味、清香、甜味 α-蒎烯 6 <1 1.07 <1 <1 1.66 <1 <1 清香、木香 β-水芹烯 36 <1 1.27 <1 <1 1.88 <1 <1 薄荷香、松脂香 芳樟醇 6 <1 <1 3.76 <1 <1 1.76 <1 柑橘味、花香、木香、青草香 4-萜烯醇 3 <1 2.63 3.38 <1 <1 <1 <1 辣椒味、木香、泥土气息、霉味 1-辛烯-3-醇 1 14.02 24.96 18.17 36.46 9.21 23.63 33.18 浓厚的、甜的、金属味、蘑菇味 桉叶油醇 1.3 4.95 21.88 10.25 <1 16.82 8.38 13.18 桉树味、草药味、樟脑香 戊醛 20 2.89 <1 <1 <1 1.20 <1 2.14 焦香、清香 己醛 4.5 48.97 19.61 34.92 17.74 21.95 16.78 44.04 强烈的、酸败味、不愉快的、尖刺气息、令人作呕的气味 庚醛 3 25.81 18.59 17.20 10.70 14.71 11.42 22.75 焦香、清香、令人作呕的气味 (E)-2-庚烯醛 13 <1 <1 <1 <1 <1 <1 1.33 青香、脂肪香、奶油香、奶糖香 辛醛 0.7 73.39 64.47 41.71 34.73 47.11 22.39 59.90 青草味、柑橘味 (E)-2-辛烯醛 3 <1 <1 1.16 <1 <1 <1 1.88 清新、黄瓜、脂肪味 壬醛 1 143.17 56.41 104.59 68.89 67.65 49.76 95.03 青香、霉味 (E,E)-2,4-壬二烯醛 0.09 416.00 <1 304.22 125.89 207.00 <1 527.22 令人愉快的、煎炸肥肉样香味 癸醛 0.1 116.00 21.30 115.50 <1 38.10 103.50 <1 肥皂、橘子皮、牛脂香 (E)-2-癸烯醛 0.3 68.53 84.43 93.50 46.60 <1 75.20 148.27 油脂香 (E,E)-2,4-癸二烯醛 0.07 153.00 100.43 48.71 <1 <1 82.43 229.14 柑橘香 2-十一烯醛 0.78 5.55 2.73 11.36 <1 9.41 14.31 8.15 香橙味、树脂味 2-庚酮 1 <1 2.09 <1 <1 <1 <1 4.78 青草味、尖刺气味、令人作呕的气味 1-辛烯-3-酮 0.005 1360.00 648.00 <1 <1 484.00 812.00 754.00 草药、蘑菇、泥土味 丁香酚 6 1.41 7.58 4.91 9.87 1.74 1.45 1.15 辛辣味、丁香、木香 茴香脑 15 <1 1.39 1.34 7.76 7.20 4.19 <1 茴香 注:仅列出OAV大于1的挥发性风味物质。 由表6可知,7个品牌预制梅菜扣肉有7种共有关键性香气物质,5个品牌(HBS、NLE、YR、CCX、CCL)预制梅菜扣肉有12种共有关键性香气物质。其中1-辛烯-3-醇、己醛、庚醛、辛醛、壬醛、(E,E)-2,4-壬二烯醛、癸醛、(E)-2-癸烯醛、(E,E)-2,4-癸二烯醛、1-辛烯-3-酮的OAV都在10以上且部分因子OAV大于100,表明其对预制梅菜扣肉的整体风味贡献极大,为预制梅菜扣肉关键性风味因子,根据文献得出这类物质可能是肉制品产生过熟味关键因子[6−10]。

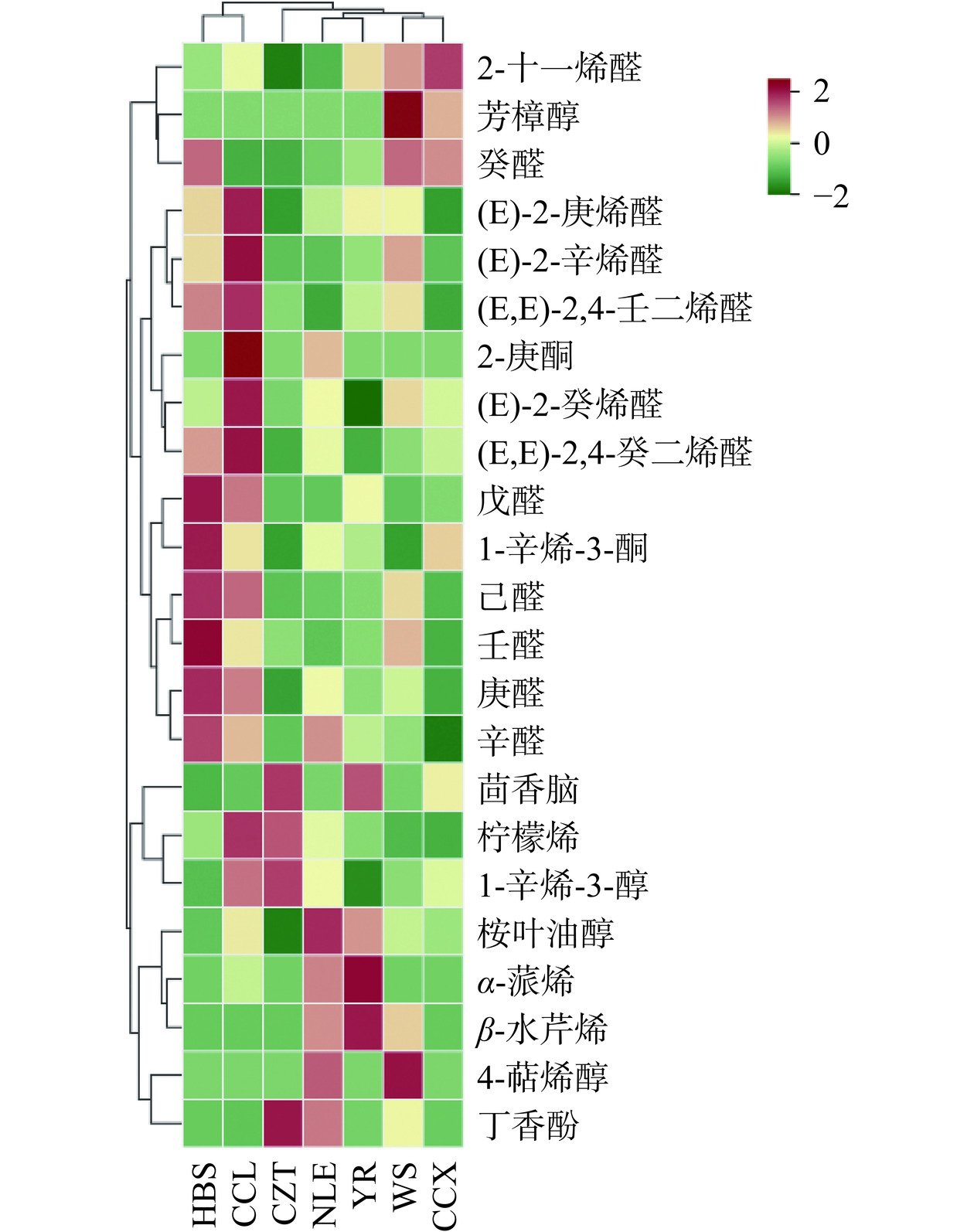

根据预制梅菜扣肉23种关键挥发性物质的OAV值绘制热图,并通过层次聚类对其进行分析,结果如图5所示,能直观表明不同品牌预制梅菜扣肉其OAV关键因子之间的差异。聚类分析能根据样本数据特征将相似度较高的样品聚为一类,7个品牌的预制梅菜扣肉共分为了4大类,其中HBS、CCL聚为一类;WS、CCX聚为一类;YR、NLE聚为一类;CZT单独为一类。将表4中不同样品关键性风味物质进行主成分分析,得到不同品牌预制梅菜扣肉风味成分载荷图,如图6所示,CCX、NLE、HBS与YR位于第一主成分负半轴且距离较近,表明其风味因子具有部分关联性;WS、CCL和CZT分别位于第一象限和第四象限,表明其存在显著差异。结合电子舌结果可知,不同品牌预制梅菜扣肉由于其配方和工艺差异,导致风味和滋味之间存在明显差异,但又在特征风味因子上存在相似性。

2.5 油脂氧化指标分析结果

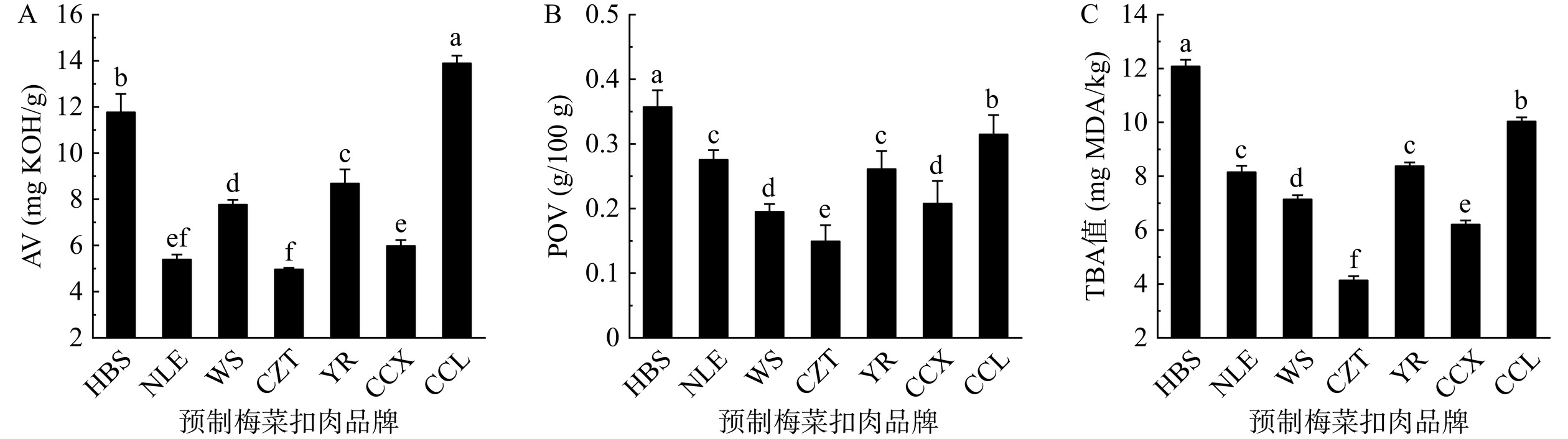

如图7A所示,CCL酸价最高,CZT最低,不同品牌预制梅菜扣肉之间酸价差异显著(P<0.05)。除CZT以外均已超过国家标准规定食用油酸价<5 mg KOH/g的最大限量,间接表明其余6种预制梅菜扣肉油脂氧化程度较高。如图7B所示,HBS过氧化值最高,CCL次之,而CZT最低,除NLE、YR及WS、CCX外,其余预制梅菜扣肉之间过氧化值差异显著(P<0.05)。最新国家标准《GB 19295-2021速冻面米与调制食品》中规定,预制菜过氧化值需小于等于0.25 g/100 g,仅WS、CZT和CCX组在限量标准以下,表明其余4组油脂氧化程度明显偏高。

TBA值是油脂中不饱和脂肪酸氧化分解所产生的衍生物如丙二醛等与TBARS反应的产物指标,可反映油脂氧化程度[44]。如图7C所示,预制梅菜扣肉TBA值与酸价、过氧化值的趋势几乎一致,不同品牌预制梅菜扣肉间TBA值差异显著(P<0.05)。结合酸价、过氧化值及TBA值结果可知,不同预制梅菜扣肉其油脂氧化程度差异显著且部分组(如HBS、CCL)的油脂氧化程度偏高。导致预制菜油脂氧化的因素很多,原材料的选择、生产过程、产品运输过程及贮藏环节都极易导致预制菜氧化。

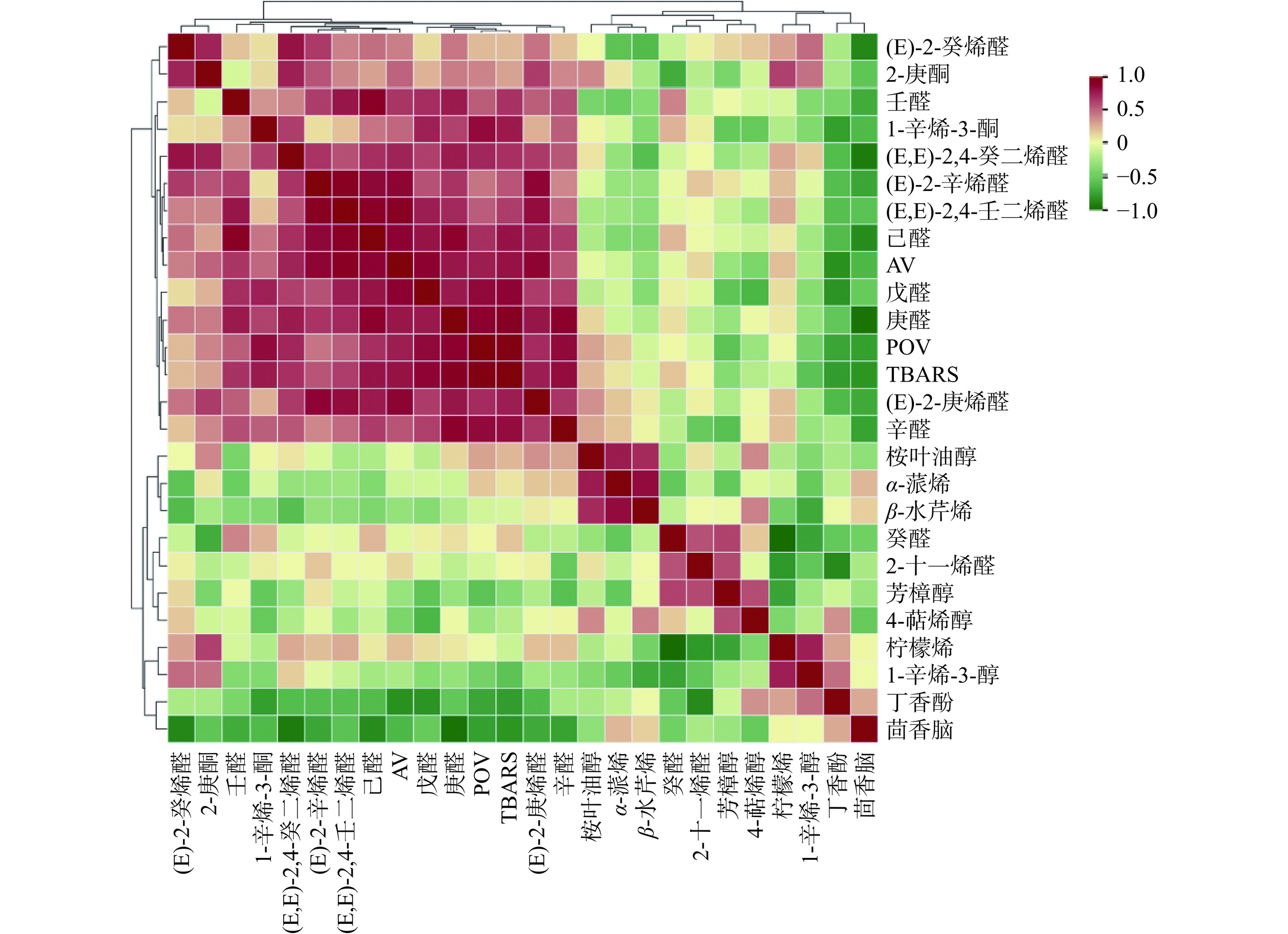

为了进一步分析油脂氧化程度与梅菜扣肉关键挥发性因子和过熟味之间的联系,将氧化指标与关键挥发性因子含量进行相关性分析,并作相关性聚类热图,如图8所示,(E)-2-癸烯醛、2-庚酮、壬醛、1-辛烯-3-酮、(E,E)-2,4-癸二烯醛、己醛、戊醛、庚醛、(E)-2-庚烯醛及辛醛与酸价、过氧化值和TBA值呈正相关,且其中1-辛烯-3-酮、(E,E)-2,4-癸二烯醛、己醛、戊醛、庚醛、(E)-2-庚烯醛及辛醛与油脂氧化指标相关性显著,与研究表明的戊醛、己醛、庚醛、壬醛、癸醛、(E,E)-2,4-癸二烯醛等物质是产生过熟味主要因子物质结果一致[6−10],同时也推测预制梅菜扣肉油脂过度氧化是其产生过熟味的重要原因之一。

3. 结论

本研究以HS-SPME-GC-MS结合电子舌、OAV、感官评价和油脂氧化指标为研究内容,分析不同品牌预制梅菜扣肉关键性挥发性风味物质及过熟味与脂肪氧化的关联性。通过感官评价结果表明预制梅菜扣肉过熟味(WOF)以亚麻籽油和酸败味为主,带有轻微的硫化味和金属味。不同品牌预制梅菜扣肉共鉴定出85种挥发性物质,其中烷烃类16种、萜烯类19种、醇类7种、醛类22种、酮类3种、酯类13种、酚类3种、其他类2种,醛类挥发性风味物质相对含量较高;预制梅菜扣肉滋味以咸味、鲜味和鲜味回味为主,且不同品牌预制梅菜扣肉之间风味、滋味差异显著(P<0.05)。OAV共筛选出预制梅菜扣肉中23种关键香气物质,1-辛烯-3-醇、己醛、庚醛、辛醛、壬醛、(E,E)-2,4-壬二烯醛、癸醛、(E)-2-癸烯醛、(E,E)-2,4-癸二烯醛、1-辛烯-3-酮是预制梅菜扣肉主要风味因子,也是其产生过熟味的主要原因之一,且与酸价、过氧化值和TBA值呈正相关,推测预制梅菜扣肉过熟味的产生可能与其油脂氧化程度较大有关。结合实验表明不同品牌预制梅菜扣肉在原料、工艺选择、生产、运输及贮藏等环节的差异会导致其品质发生不同程度油脂氧化等品质劣变问题,最终使其原有风味散失。如何控制预制菜原有风味保持、品质稳定等问题是预制菜发展的重要方向。通过对预制梅菜扣肉特征挥发性物质的检测及过熟味与油脂氧化关联性的探究,为建立预制梅菜扣肉风味质量体系及过熟味控制的研究提供了理论基础。

-

表 1 不同品牌预制梅菜扣肉信息

Table 1 Information of different brands of pre-prepared steamed pork with preserved vegetable

品牌 产地 配料 外观 HBS 山东 五花肉、梅干菜、食用植物油、食用盐、味精、酿造酱油(含焦糖色)、香辛料

NLE 湖南 猪肉、梅干菜、辣椒、食用盐、白砂糖、蚝油、饮用水、酿造酱油(含焦糖色)、黄豆酱、料酒、香辛料、食品添加剂(谷氨酸钠、乳酸链球菌素、红曲红)

WS 广东 带皮猪肉、梅干菜、食用盐、豆豉、味精、大豆油、酿造酱油(含焦糖色)、调味料酒、香辛料、食品添加剂(辣椒红)、食用香精香料

CZT 湖北 五花肉、梅干菜、酿造酱油(含焦糖色)、黄酒、味精、食用盐、白砂糖、香辛料

YR 安徽 猪肉、梅干菜、水、酿造酱油(含焦糖色)、黄酒(含焦糖色)、白砂糖、食用盐、食用葡萄糖、浓香型白酒、生姜、味精、香葱

CCX 湖南 五花肉、梅干菜、辣椒、蚝油、酿造酱油(含焦糖色)、豆豉、味精、食用盐、白砂糖、香辛料

CCL 湖南 五花肉、梅干菜、辣椒、蚝油、酿造酱油(含焦糖色)、味精、食用盐、白砂糖、香辛料、食用香精

表 2 过熟味感官评价标准

Table 2 Sensory evaluation criteria for warmed-over flavor

过熟味指标 评分参考 评分细则 0分 1~4分 5分 湿纸板味 10 g纸箱碎屑溶于100 mL

水中的气味没有

风味风味逐

渐增强风味

最强亚麻籽油味 50 g亚麻籽油在水中加热

15 min的气味硫化味 橡皮筋的气味 酸败味 植物油严重氧化的气味 金属味 0.1 g/L硫化亚铁溶液的气味 表 3 电子舌传感器

Table 3 Electronic tongue sensor

传感器 味觉信息 基本味 回味 鲜味传感器AEE 鲜味(氨基酸、核苷酸、有

机酸引起的鲜味)丰富度(持续的鲜味) 咸味传感器CT0 咸味(氯化钠等无机盐

引起的咸味)— 酸味传感器CA0 酸味(柠檬酸、乳酸、酒石酸、

醋酸等引起的酸味)— 苦味传感器C00 苦味(苦味物质引起的味道,在

低浓度下被感知为鲜味回味)苦味回味(含有咖啡因

等食品的苦味)涩味传感器AE1 涩味(涩味物质引起的味道,低浓度下感知为刺激性回味) 涩味回味(含有单宁、生物

碱等食品呈现的涩味)甜味传感器GL0 甜味(糖等甜味剂引起的甜味) — 表 4 不同品牌预制梅菜扣肉挥发性成分比较

Table 4 Comparison of volatile compositions of different brands of pre-prepared steamed pork with preserved vegetable

序号 化合物名称 分子式 含量(μg/kg) HBS NLE WS CZT YR CCX CCL 烷烃类 1 己烷(hexane) C6H14 7.24±1.94 − − − − − − 2 庚烷(heptane) C7H16 4.83±0.93a 2.45±0.33b 1.34±0.11bc 1.46±0.39bc 1.48±0.22bc 4.53±1.39a 1.04±0.17c 3 癸烷(decane) C10H22 50.65±3.36a 22.26±1.92cd 12.63±2.77d 31.29±10.26bc 34.25±7.88b 18.51±2.96b 18.03±6.27e 4 3,8-二甲基癸烷

(3,8-dimethyldecane)C12H26 12.28±4.34a − − − − 9.35±2.38a − 5 3-甲基十一烷

(3-methylundecane)C12H26 − − 4.59±1.98b 6.74±2.21a − − − 6 3-乙基-2,6,10-三甲基十一烷(3-ethyl-2,6,10-trimethylundecane) C16H34 − − 5.52±1.63 − − − − 7 正十二烷(dodecane) C12H26 28.66±6.18bcd 23.1±2.82cd 20.09±3.77d 16.96±5.21d 31.62±2.56bc 56.85±10.37a 37.91±7.41b 8 正十三烷(tridecane) C13H28 10.83±3.48a − − 6.43±2.67b − − − 9 3-甲基十三烷

(3-methyltridecane)C14H30 − − − 8.21±3.14a − − 2.76±0.27b 10 正十四烷(tetradecane) C14H30 59.01±15.34a 18.58±4.52b 11.23±1.75b 12.38±4.64b − 21.75±4.99b 23.92±3.33b 11 正十五烷(pentadecane) C15H32 25.8±5.27a 23.88±2.94ab 10.07±2.61c 8.59±0.94c 19.01±4.54b − − 12 正十六烷(hexeadecane) C16H34 12.78±1.44a 3.56±0.31d 8.34±2.67b 8.37±1.88b 5.82±1.12cd 13.76±0.67a 6.47±1.18bc 13 正十七烷(heptadecane) C17H36 8.69±3.33bc 14.07±2.12a 5.83±0.43bc − 4.04±1.23c 17.82±4.18a 9.22±3.31b 14 正十八烷(octadecane) C18H38 − 3.84±0.41b 4.69±0.97b − − 10.19±3.41a − 15 正十九烷(nonadecane) C19H40 − 6.05±0.68b − − − 9.32±1.22a − 16 正二十四烷(tetracosane) C24H50 5.61±1.04 − − − − − − 共计 226.42±4.29a 117.84±6.70c 79.72±1.30d 101.31±20.07c 102.98±7.98c 177.84±12.26b 99.35±13.72c 萜烯类 17 柠檬烯(limonene) C10H16 37.68±3.88bc 46.36±10.43b 26.54±3.18c 66.53±6.99a 34.87±5.78bc 24.62±2.72c 70.58±14.14a 18 四氢双环戊二烯(tetrahydrodicyclopentadiene) C10H16 28.88±2.98b 16.16±3.33c 19.24±2.11c 33.74±4.44b 32.99±9.27b 35.07±3.24b 47.78±3.17a 19 α-蒎烯(α-pinene) C10H16 − 6.44±2.12b − − 9.94±2.52a − 2.36±0.24c 20 莰烯(camphene) C10H16 − 12.46±2.98b 6.10±1.22c 2.72±0.42d 15.7±0.76a − − 21 β-水芹烯(β-phellandrene) C10H16 − 45.55±10.31b 35.02±3.43b − 67.51±14.54a − − 22 α-姜黄烯(α-curcumene) C15H22 8.12±1.21de 9.81±0.34cd 15.03±4.21b 4.76±0.54e 23.89±2.58a 12.38±2.99bc 6.44±1.11de 23 α-姜烯(α-zingiberene) C15H24 2.45±0.15d 10.98±2.14b 13.56±1.87a − 7.9±1.84c − − 24 β-倍半水芹烯(β-sesquiphellandrene) C15H24 − 4.16±0.33b 5.59±1.52ab − 7.31±1.67a 5.99±1.08a − 25 β-石竹烯(β-caryophyllene) C15H24 − − 24.57±2.98a 6.33±1.02c − 14.20±1.44b − 26 α-香柠檬烯(α-alpha-bergamotene) C15H24 − − 9.94±2.26 − − − − 27 γ-红没药烯(γ-bisabolene) C15H24 − 0.98±0.08bc 5.04±0.78a 0.45±0.04c 1.43±0.22b − − 28 β-红没药烯(β-bisabolene) C15H24 − 6.56±1.22b 8.91±1.54a − 6.92±1.61b 0.98±0.12c − 29 β-蒎烯(β-pinene) C15H24 2.21±0.32d − 10.76±3.11b − 15.14±2.42a 6.98±1.44c − 30 香树烯(alloaromadendrene) C15H24 − − − − 3.52±0.32 − − 31 萜品油烯(terpinolene) C10H16 − − 0.92±0.25a − − − 0.43±0.12b 32 γ-榄香烯(γ-cyclohexane) C15H24 − 0.25±0.09 − − − − − 33 α-佛手柑烯(α-bergamotene) C15H24 − − 2.34±0.08b − − 15.13±1.54a − 34 α-穆罗林烯(α-muurolene) C15H24 − − − − − 13.76±2.16 − 35 δ-杜松烯(δ-cadinene) C15H24 − 5.87±0.42b − − − 15.39±0.99a − 共计 79.35±1.12f 165.58±8.18c 183.55±3.75b 114.54±7.20e 227.13±12.91a 144.45±6.71d 127.59±17.03e 醇类 36 乙醇(ethanol) C2H6O 121.96±20.55b 203.04±60.12b 117.15±17.12b 332.61±66.53a 310.77±78.43a 170.95±20.62b 178.95±43.65b 37 芳樟醇(linalool) C10H18O − − 22.54±1.54a − − 10.55±2.89b − 38 4-萜烯醇(terpinine-4-ol) C10H18O − 7.88±1.04b 10.13±2.87a − − − − 39 1-辛烯-3-醇(1-octen-3-ol) C8H16O 14.02±2.65cd 24.96±5.34b 18.17±1.53bc 36.46±3.98a 9.21±2.11d 23.63±5.35b 33.18±6.23a 40 十五烷醇(pentadecanol) C15H32O − 3.72±0.44 − − − − − 41 桉叶油醇(cineole) C10H18O 6.44±0.78e 28.45±6.88a 13.33±2.45cd − 21.87±3.11b 10.89±2.43de 17.13±1.89bc 42 反式-2-十四烯-1-醇

(trans-2-tetradecen-1-ol)C14H28O − − 9.77±3.65 − − − − 共计 142.41±20.76d 268.05±52.74bc 191.08±14.12cd 369.07±68.35a 341.86±81.22ab 216.02±22.33cd 229.26±44.31cd 醛类 43 戊醛(pentanal) C5H10O 57.86±6.67a − − − 23.99±5.32c 5.94±0.88d 42.87±10.12b 44 己醛(hexanal) C6H12O 220.36±25.37a 88.26±7.87c 157.12±26.66b 79.83±18.87c 98.76±14.25c 75.53±13.14c 198.19±29.41a 45 庚醛(heptaldehyde) C7H14O 77.44±10.97a 55.78±5.01bc 51.59±9.84c 32.10±5.54d 44.13±4.59cd 34.25±8.16d 68.25±7.01ab 46 (E)-2-庚烯醛

(trans-2-heptenal)C7H12O 10.26±2.69b 6.66±1.34c 9.13±1.66bc − 9.19±2.44bc − 17.27±1.95a 47 辛醛(octanal) C8H16O 51.37±5.83a 45.13±10.03a 29.2±2.32c 24.31±5.21cd 32.98±3.34bc 15.67±4.29d 41.93±5.68ab 48 (E)-2-辛烯醛(trans-2-octenal) C8H14O 2.78±0.31c − 3.47±0.45b − 0.98±0.22d − 5.64±0.65a 49 壬醛(nonanal) C9H18O 143.17±14.77a 56.41±8.92cd 104.59±5.07b 68.89±3.68c 67.65±8.98c 49.76±2.43d 95.03±12.98b 50 (E,E)-2,4-壬二烯醛(trans,trans-2,4-nonadienal) C9H14O 37.44±3.03b − 27.38±3.63c 11.33±0.97e 18.63±3.99d − 47.45±7.83a 51 癸醛(decanal) C10H20O 11.60±2.92a 2.13±0.34b 11.55±0.97a − 3.81±0.93b 10.35±1.69a − 52 (E)-2-癸烯醛

(trans-2-decenal)C10H18O 20.56±1.85c 25.33±4.24bc 28.05±6.67b 13.98±0.99d − 22.56±4.46bc 44.48±2.25a 53 (E,E)-2,4-癸二烯醛(trans,trans-2,4-decadienal) C10H16O 10.71±2.85b 7.03±1.49c 3.41±0.34d − − 5.77±0.42cd 16.04±2.39a 54 2-十一烯醛(2-undecenal) C11H20O 4.33±1.32de 2.13±0.69e 8.86±1.81b − 7.34±0.84bc 11.16±1.76a 6.36±1.55cd 55 苯甲醛(benzaldehyde) C7H6O 75.27±14.03a 45.43±4.66b 44.01±4.85b 17.44±3.02d 27.12±3.69cd 38.86±7.31bc 72.90±5.16a 56 十六烷醛(hexadecanal) C16H32O − 6.46±1.41b − − − 18.89±2.64a − 57 十七烷醛(heptadecanal) C17H34O − − − − 4.76±0.35 − − 58 十八烷醛(octadecanaldehyde) C18H36O − − − 10.05±1.25 − − − 59 二十烷醛(icosanal) C20H40O − 13.58±2.26a 12.64±3.45a − − − − 60 肉桂醛(cinnamaldehyde) C9H8O − 49.25±12.41a 48.64±5.65a − 26.89±3.66b − − 61 3-糠醛(3-furaldehyde) C5H4O2 34.41±3.65b 10.56±2.12d − 18.01±5.22c 9.98±1.05d 24.68±4.43c 50.39±6.73a 62 糠醛(furfural) C5H4O2 − 6.18±2.46a 3.57±1.23b − 2.51±0.46b − − 63 香叶醛(trans-citral) C10H16O − − − − 22.07±4.26 − − 64 橙花醛(citral) C10H16O − − − − 14.11±1.47 − − 共计 757.58±32.84a 420.33±19.69d 543.29±32.19c 275.91±10.81e 414.92±19.92d 313.44±7.85e 706.82±28.36b 酮类 65 3-羟基-2-丁酮(acetoin) C4H8O2 − 0.91±0.19a − − − − 0.79±0.27a 66 2-庚酮(2-heptanone) C7H14O − 2.09±0.14b − − − − 4.78±0.71a 67 1-辛烯-3-酮(1-octen-3-one) C8H14O 6.80±2.46a 3.24±0.36b − − 2.42±0.48b 4.06±0.96b 3.77±0.88b 共计 6.80±2.47b 6.24±0.31b − − 2.42±0.48c 4.06±0.97c 9.35±1.00a 酯类 68 乙酸甲酯(methyl acetate) C3H6O2 1.7±0.31a − − − 0.89±0.19b − − 69 乙酸乙酯(ethyl acetate) C4H8O2 3.39±0.45a 2.52±0.43b − 0.63±0.13d 1.40±0.23c − 1.42±0.49c 70 棕榈酸甲酯

(methyl hexadecanoate)C17H34O2 7.61±1.21d 25.16±2.94a 8.82±0.36d 7.16±0.63d 8.42±1.38d 16.97±3.12b 12.69±1.57c 71 十六酸乙酯(ethyl palmitate) C18H36O2 − 25.80±4.98a 11.88±1.54b 6.74±1.31c − 11.59±1.74b 7.74±1.02c 72 三醋酸甘油酯(triacetin) C9H14O6 − 39.31±7.84 − − − − − 73 顺式-13-十八烯酸甲酯(methyl octadec-13-enoate) C19H36O2 − − − − − − 10.38±1.76 74 亚油酸乙酯(ethyl linoleate) C20H36O2 12.86±3.19b 23.66±2.92a − − − 14.97±2.53b − 75 油酸甲酯(methyl oleate) C19H36O2 − − 6.49±0.86b 9.28±2.47a − 8.73±1.13a − 76 油酸乙酯(ethyl oleate) C20H38O2 − 16.67±2.41a − − 12.94±1.58b − − 77 2-单棕榈酸甘油

(2-palmitoylglycerol)C19H38O4 − − 30.88±5.33 − − − − 78 二氢猕猴桃内酯(dihydroactinidiolide) C11H16O2 − − − − 6.87±1.14c 17.91±4.12a 11.69±1.27b 79 肉豆蔻酸乙酯(ethyl tetradecanoate) C16H32O2 − − − − 4.56±0.65 − − 80 顺式-13-十八烷酸甲酯(methyl 13-octadecenoate) C19H36O2 − 7.61±0.77a − 0.67±0.25b − − − 共计 25.58±3.06e 140.68±13.09a 58.09±3.57c 24.49±4.58e 35.11±2.16de 70.18±7.85b 43.93±4.04d 酚类 81 2,4-二叔丁基苯酚

(2,4-di-t-butylphenol)C14H22O − − 2.24±0.45c 4.06±1.44b − 12.13±1.97a − 82 2,6-二叔丁基-4-甲基苯酚(2,6-di-tert-butyl-4-methylphenol) C15H24O 15.54±3.41c 4.55±0.53de 1.54±0.24e 8.09±1.66d − 43.64±5.55a 32.11±8.12b 83 丁香酚(eugenol) C10H12O2 8.44±2.36d 45.45±3.55b 29.47±6.42c 59.23±12.42a 10.43±0.98d 8.72±2.67d 6.87±1.11d 共计 23.98±4.67d 50.01±3.93b 33.25±6.09cd 71.37±12.42a 10.43±0.98e 64.49±2.24a 38.98±7.02bc 其他类 84 茴香脑(cis-anethol) C10H12O 3.14±0.82c 20.89±3.12c 20.09±2.44c 116.44±23.11a 108.07±12.63a 62.84±4.45b 12.79±2.99c 85 草蒿脑(estragole) C10H12O − − 45.89±6.34b − − 74.71±12.76a − 共计 3.14±0.82d 20.89±3.12d 65.99±8.41c 116.44±23.11ab 108.07±12.63b 137.55±15.47a 12.79±2.99d 总计 1265.27±39.97a 1189.62±

49.71bc1154.97±30.4bcd 1073.13±

90.56e1242.9±58.55ab 1128.03±

22.72cd1268.07±40.49a 注:同行不同字母表示含量差异显著(P<0.05)。 表 5 不同品牌预制梅菜扣肉挥发性化合物种类

Table 5 Types of volatile compounds in different brands of pre-prepared steamed pork with preserved vegetable

序号 分类 数量(种) HBS NLE WS CZT YR CCX CCL 1 烷烃类 11 9 10 9 6 9 7 2 萜烯类 5 12 14 6 12 10 5 3 醇类 3 5 6 2 3 4 3 4 醛类 14 15 15 9 17 12 13 5 酮类 1 3 0 0 1 1 3 6 酯类 4 6 4 5 6 5 5 7 酚类 2 2 3 3 1 3 2 8 其他类 1 1 2 1 1 2 1 总计 85 41 53 54 35 47 46 39 表 6 不同品牌预制梅菜扣肉挥发性风味物质OAV

Table 6 OAV of volatile flavor substances in different brands of pre-prepared steamed pork with preserved vegetable

风味物质 嗅觉阈值

(μg/kg)[41−43]OAV 气味描述[17,41−43] HBS NLE WS CZT YR CCX CCL 柠檬烯 10 3.77 4.64 2.65 6.65 3.49 2.46 7.06 柑橘味、橙子味、清香、甜味 α-蒎烯 6 <1 1.07 <1 <1 1.66 <1 <1 清香、木香 β-水芹烯 36 <1 1.27 <1 <1 1.88 <1 <1 薄荷香、松脂香 芳樟醇 6 <1 <1 3.76 <1 <1 1.76 <1 柑橘味、花香、木香、青草香 4-萜烯醇 3 <1 2.63 3.38 <1 <1 <1 <1 辣椒味、木香、泥土气息、霉味 1-辛烯-3-醇 1 14.02 24.96 18.17 36.46 9.21 23.63 33.18 浓厚的、甜的、金属味、蘑菇味 桉叶油醇 1.3 4.95 21.88 10.25 <1 16.82 8.38 13.18 桉树味、草药味、樟脑香 戊醛 20 2.89 <1 <1 <1 1.20 <1 2.14 焦香、清香 己醛 4.5 48.97 19.61 34.92 17.74 21.95 16.78 44.04 强烈的、酸败味、不愉快的、尖刺气息、令人作呕的气味 庚醛 3 25.81 18.59 17.20 10.70 14.71 11.42 22.75 焦香、清香、令人作呕的气味 (E)-2-庚烯醛 13 <1 <1 <1 <1 <1 <1 1.33 青香、脂肪香、奶油香、奶糖香 辛醛 0.7 73.39 64.47 41.71 34.73 47.11 22.39 59.90 青草味、柑橘味 (E)-2-辛烯醛 3 <1 <1 1.16 <1 <1 <1 1.88 清新、黄瓜、脂肪味 壬醛 1 143.17 56.41 104.59 68.89 67.65 49.76 95.03 青香、霉味 (E,E)-2,4-壬二烯醛 0.09 416.00 <1 304.22 125.89 207.00 <1 527.22 令人愉快的、煎炸肥肉样香味 癸醛 0.1 116.00 21.30 115.50 <1 38.10 103.50 <1 肥皂、橘子皮、牛脂香 (E)-2-癸烯醛 0.3 68.53 84.43 93.50 46.60 <1 75.20 148.27 油脂香 (E,E)-2,4-癸二烯醛 0.07 153.00 100.43 48.71 <1 <1 82.43 229.14 柑橘香 2-十一烯醛 0.78 5.55 2.73 11.36 <1 9.41 14.31 8.15 香橙味、树脂味 2-庚酮 1 <1 2.09 <1 <1 <1 <1 4.78 青草味、尖刺气味、令人作呕的气味 1-辛烯-3-酮 0.005 1360.00 648.00 <1 <1 484.00 812.00 754.00 草药、蘑菇、泥土味 丁香酚 6 1.41 7.58 4.91 9.87 1.74 1.45 1.15 辛辣味、丁香、木香 茴香脑 15 <1 1.39 1.34 7.76 7.20 4.19 <1 茴香 注:仅列出OAV大于1的挥发性风味物质。 -

[1] 姜元娇. 梅菜扣肉[J]. 中国蜂业,2013,64(6):63−64. [JIANG Y J. Steamed pork with preserved vegetable[J]. Apiculture of China,2013,64(6):63−64.] JIANG Y J. Steamed pork with preserved vegetable[J]. Apiculture of China, 2013, 64(6): 63−64.

[2] 王翔. 梅菜扣肉的传说[J]. 肉类工业,2013(7):56. [WANG X. The legend of steamed pork with preserved vegetable[J]. Meat Industry,2013(7):56.] WANG X. The legend of steamed pork with preserved vegetable[J]. Meat Industry, 2013(7): 56.

[3] 孙晓, 杨思羽, 曾帅, 等. 后疫情时代川菜预制菜产业发展路径探索[J]. 四川旅游学院学报,2023(5):24−28. [SUN X, YANG S Y, ZENG S, et al. Exploration on the development path of Sichuan prepared dish industry in the post-pandemic era[J]. Journal of Sichuan Tourism University,2023(5):24−28.] doi: 10.3969/j.issn.1008-5432.2023.05.006 SUN X, YANG S Y, ZENG S, et al. Exploration on the development path of Sichuan prepared dish industry in the post-pandemic era[J]. Journal of Sichuan Tourism University, 2023(5): 24−28. doi: 10.3969/j.issn.1008-5432.2023.05.006

[4] 耿伟. 预制菜的安全与控制研究进展浅析[J]. 中国食品,2023(17):128−131. [GENG W. An overview of the progress of research on the safety and control of prepared vegetables[J]. China Food,2023(17):128−131.] doi: 10.3969/j.issn.1000-1085.2023.17.044 GENG W. An overview of the progress of research on the safety and control of prepared vegetables[J]. China Food, 2023(17): 128−131. doi: 10.3969/j.issn.1000-1085.2023.17.044

[5] 李冬梅, 张雪迪, 毕景然, 等. 中式预制菜肴产业的传承与创新[J]. 中国食品学报,2022,22(10):1−8. [LI D M, ZHANG X D, BI J R, et al. Inheritance and innovation of Chinese prepared dishes industry[J]. Journal of Chinese Institute of Food Science and Technology,2022,22(10):1−8.] LI D M, ZHANG X D, BI J R, et al. Inheritance and innovation of Chinese prepared dishes industry[J]. Journal of Chinese Institute of Food Science and Technology, 2022, 22(10): 1−8.

[6] O’SULLIVAN M G, BYRNE D V, JENSEN M T, et al. A comparison of warmed-over flavour in pork by sensory analysis, GC/MS and the electronic nose[J]. Meat Science,2003,65(3):1125−1138. doi: 10.1016/S0309-1740(02)00342-X

[7] TIKK K, HAUGEN J E, ANDERSEN H J, et al. Monitoring of warmed-over flavour in pork using the electronic nose-correlation to sensory attributes and secondary lipid oxidation products[J]. Meat Science,2008,80(4):1254−1263. doi: 10.1016/j.meatsci.2008.05.040

[8] KIM S Y, LI J, LIM N R, et al. Prediction of warmed-over flavour development in cooked chicken by colorimetric sensor array[J]. Food Chemistry,2016,211:440−447. doi: 10.1016/j.foodchem.2016.05.084

[9] LUNGU N S, AFOLAYAN A J, IDAMOKORO E M. Warmed-over flavour profiles, microbial changes, shelf-life and check-all-that-apply sensory analysis of cooked minced pork treated with varying levels of Moringa oleifera leaf and root powder[J]. Heliyon,2022,8(9):e10616. doi: 10.1016/j.heliyon.2022.e10616

[10] KERLER J, GROSCH W. Odorants contributing to warmed-over flavor (wof) of refrigerated cooked beef[J]. Journal of Food Science,1996,61(6):1271−1275. doi: 10.1111/j.1365-2621.1996.tb10977.x

[11] 杨姣, 安玥琦, 陈雨欣, 等. 鱼糜制品加热过程中过熟味的特征风味成分解析[J]. 现代食品科技,2020,36(8):265−280. [YANG J, AN Y Q, CHEN Y X, et al. Characterization of odorant components in surimi products with warmed-over flavor during the heating process[J]. Modern Food Science and Technology,2020,36(8):265−280.] YANG J, AN Y Q, CHEN Y X, et al. Characterization of odorant components in surimi products with warmed-over flavor during the heating process[J]. Modern Food Science and Technology, 2020, 36(8): 265−280.

[12] 张凯华, 臧明伍, 张哲奇, 等. 不同复热方式对猪耳朵制品挥发性风味和脂肪氧化的影响[J]. 食品科学,2018,39(14):242−248. [ZHANG K H, ZANG M W, ZHANG Z Q, et al. Effect of reheating methods on volatile flavor constituents and lipid oxidation in cooked pig ear[J]. Food Science,2018,39(14):242−248.] doi: 10.7506/spkx1002-6630-201814036 ZHANG K H, ZANG M W, ZHANG Z Q, et al. Effect of reheating methods on volatile flavor constituents and lipid oxidation in cooked pig ear[J]. Food Science, 2018, 39(14): 242−248. doi: 10.7506/spkx1002-6630-201814036

[13] 张凯华, 臧明伍, 张哲奇, 等. 微波复热时间对预制猪肉饼过熟味、脂肪氧化和水分分布特性的影响[J]. 食品科学,2020,41(9):50−56. [ZHANG K H, ZANG M W, ZHANG Z Q, et al. Effect of microwave reheating time on warmed-over flavor, lipid oxidation and water distribution in precooked pork patties[J]. Food Science,2020,41(9):50−56.] doi: 10.7506/spkx1002-6630-20190816-173 ZHANG K H, ZANG M W, ZHANG Z Q, et al. Effect of microwave reheating time on warmed-over flavor, lipid oxidation and water distribution in precooked pork patties[J]. Food Science, 2020, 41(9): 50−56. doi: 10.7506/spkx1002-6630-20190816-173

[14] 王洪乾, 寇亚平, 姚晨阳, 等. 基于HS-SPME-GC-MS测定5种蔷薇属植物花瓣挥发性成分[J]. 植物遗传资源学报,2023,24(6):1626−1638. [WANG H Q, KOU Y P, YAO C Y, et al. Detection of volatile organic compounds in five rose petals based on headspace solid phase microextraction-gas chromatography-mass spectrometry[J]. Journal of Plant Genetic Resources,2023,24(6):1626−1638.] WANG H Q, KOU Y P, YAO C Y, et al. Detection of volatile organic compounds in five rose petals based on headspace solid phase microextraction-gas chromatography-mass spectrometry[J]. Journal of Plant Genetic Resources, 2023, 24(6): 1626−1638.

[15] 梁子钧, 俞滢, 张磊, 等. 基于HS-SPME-GC-MS分析茶树新品系‘白云0492’白茶香气特征成分[J]. 食品科学,2023,44(22):313−321. [LIANG Z J, YU Y, ZHANG L, et al. Analysis of aroma characteristics of new strain ‘Baiyun 0492’ white tea based on HS-SPME-GC-MS[J]. Food Science,2023,44(22):313−321.] doi: 10.7506/spkx1002-6630-20230217-166 LIANG Z J, YU Y, ZHANG L, et al. Analysis of aroma characteristics of new strain ‘Baiyun 0492’ white tea based on HS-SPME-GC-MS[J]. Food Science, 2023, 44(22): 313−321. doi: 10.7506/spkx1002-6630-20230217-166

[16] CHEN C, FAN X, HU Y, et al. Effect of different salt substitutions on the decomposition of lipids and volatile flavor compounds in restructured duck ham[J]. LWT,2023,176:114541. doi: 10.1016/j.lwt.2023.114541

[17] 吴思雨, 谢萱, 刘雨雯, 等. 基于电子鼻、HS-SPME-GC-MS和HS-GC-IMS评价不同制油工艺对大豆油品质及风味的影响[J]. 食品科学,2024,45(4):183−196. [WU S Y, XIE X, LIU Y W, et al. The effects of different oil production processes on the quality and flavor of soybean oil were evaluated based on electronic nose, HS-SPME-GC-MS and HS-GC-IMS[J]. Food Science,2024,45(4):183−196.] doi: 10.7506/spkx1002-6630-20230510-090 WU S Y, XIE X, LIU Y W, et al. The effects of different oil production processes on the quality and flavor of soybean oil were evaluated based on electronic nose, HS-SPME-GC-MS and HS-GC-IMS[J]. Food Science, 2024, 45(4): 183−196. doi: 10.7506/spkx1002-6630-20230510-090

[18] 何旭峰, 易良键, 郑容, 等. 基于HS-SPME-GC-MS对传统剁椒发酵过程中挥发性成分和关键香气物质分析[J]. 食品与发酵工业,2023,49(19):296−303. [HE X F, YI L J, ZHENG R, et al. Analysis of volatile components and key aroma substances in the fermentation process of traditional chopped pepper based on HS-SPME-GC-MS[J]. Food and Fermentation Industries,2023,49(19):296−303.] HE X F, YI L J, ZHENG R, et al. Analysis of volatile components and key aroma substances in the fermentation process of traditional chopped pepper based on HS-SPME-GC-MS[J]. Food and Fermentation Industries, 2023, 49(19): 296−303.

[19] 孙鹤, 刘晓媛, 陈玉婷, 等. 基于HS-SPME-GC-MS技术分析酿造食醋中的挥发性成分[J]. 发酵科技通讯,2023,52(2):76−84. [SUN H, LIU X Y, CHEN Y T, et al. Analysis of volatile components in brewing vinegar based on HS-SPME GC-MS[J]. Bulletin of Fermentation Science and Technology,2023,52(2):76−84.] SUN H, LIU X Y, CHEN Y T, et al. Analysis of volatile components in brewing vinegar based on HS-SPME GC-MS[J]. Bulletin of Fermentation Science and Technology, 2023, 52(2): 76−84.

[20] 杨萌, 秦磊磊, 覃先武, 等. HS-SPME-GC-MS法分析苏打饼干中挥发性风味成分[J]. 食品工业,2023,44(5):304−307. [YANG M, QIN L L, QIN X W, et al. Analysis of volatile aroma compounds in soda biscuit by HS-SPME-GC-MS[J]. Food Industry,2023,44(5):304−307.] YANG M, QIN L L, QIN X W, et al. Analysis of volatile aroma compounds in soda biscuit by HS-SPME-GC-MS[J]. Food Industry, 2023, 44(5): 304−307.

[21] 张寅, 王保卫, 陈志敏. 电子舌技术在普洱茶年份鉴别中的应用[J]. 浙江农业科学,2023,64(11):2756−2759. [ZHANG Y, WANG B W, CHEN Z M. Application of electronic tongue technology in the identification of puerh tea vintages[J]. Journal of Zhejiang Agricultural Sciences,2023,64(11):2756−2759.] ZHANG Y, WANG B W, CHEN Z M. Application of electronic tongue technology in the identification of puerh tea vintages[J]. Journal of Zhejiang Agricultural Sciences, 2023, 64(11): 2756−2759.

[22] 张文玉, 李雅, 马赫, 等. 气相色谱-质谱联用结合化学计量法分析不同干燥方式对芫荽风味物质的影响[J]. 食品与发酵工业,2024,50(4):294−301. [ZHANG W Y, LI Y, MA H, et al. Analysis of effects of different drying methods on flavor substances of coriander using GC-MS combined with stoichiometric method[J]. Food and Fermentation Industries,2024,50(4):294−301.] ZHANG W Y, LI Y, MA H, et al. Analysis of effects of different drying methods on flavor substances of coriander using GC-MS combined with stoichiometric method[J]. Food and Fermentation Industries, 2024, 50(4): 294−301.

[23] SATO K, HEGARTY G R. Warmed-over flavor in cooked meats[J]. Journal of Food Science,2008,36(7):1098−1102.

[24] HIGGINS F M. Effects of alpha-tocopheryl acetate supplementation and salt addition on the oxidative stability (tbars) and warmed-over flavour (wof) of cooked turkey meat[J]. British Poultry Science,1999,40(1):59−64. doi: 10.1080/00071669987845

[25] 张宁, 陈海涛, 孙宝国, 等. 固相微萃取和同时蒸馏萃取方法比较传统腊牛肉的风味成分[J]. 中国食品学报,2016,16(6):247−258. [ZHANG N, CHEN H T, SUN B G, et al. A comparison of solid-phase microextraction with simultaneous distillation for the analysis of volatile aroma compositions in traditional preserved beef[J]. Journal of Chinese Institute of Food Science and Technology,2016,16(6):247−258.] ZHANG N, CHEN H T, SUN B G, et al. A comparison of solid-phase microextraction with simultaneous distillation for the analysis of volatile aroma compositions in traditional preserved beef[J]. Journal of Chinese Institute of Food Science and Technology, 2016, 16(6): 247−258.

[26] 曹伟峰, 张悦妍, 向情儒, 等. 基于HS-SPME-GC-MS和gc-ims结合电子鼻分析真空冷却对酱牛肉风味的影响[J]. 食品工业科技,2022,43(9):341−348. [CAO W F, ZHANG Y Y, XIANG Q R, et al. Analysis of the effect of vacuum cooling on the flavor of sauce beef based on HS-SPME-GC-MS and GC-IMS combined with electronic nose[J]. Science and Technology of Food Industry,2022,43(9):341−348.] CAO W F, ZHANG Y Y, XIANG Q R, et al. Analysis of the effect of vacuum cooling on the flavor of sauce beef based on HS-SPME-GC-MS and GC-IMS combined with electronic nose[J]. Science and Technology of Food Industry, 2022, 43(9): 341−348.

[27] 师彦平. 单萜和倍单萜化学[M]. 北京:化学工业出版社, 2008. [SHI Y P. Monoterpene and sesquiterpene chemistry[M]. Beijing:Chemical Industry Press, 2008.] SHI Y P. Monoterpene and sesquiterpene chemistry[M]. Beijing: Chemical Industry Press, 2008.

[28] 樊艳. SPME-GC-MS结合ROAV分析腐乳中的主体风味物质[J]. 食品工业科技,2021,42(8):227−234. [FAN Yan. Analysis of main flavor substances in fermented soybean curd by SPME-GC-MS and ROAV[J]. Science and Technology of Food Industry,2021,42(8):227−234.] FAN Yan. Analysis of main flavor substances in fermented soybean curd by SPME-GC-MS and ROAV[J]. Science and Technology of Food Industry, 2021, 42(8): 227−234.

[29] 周晓, 周劲松, 刘特元, 等. 基于HS-SPME-GC-MS分析循环熬制卤水对风味熟制小鱼干风味的影响[J]. 食品工业科技,2023,44(19):320−328. [ZHOU X, ZHOU J S, LIU T Y, et al. Analysis of the effects in the flavor anchovy during circulating boiling brine based on HS-SPME-GC-MS[J]. Science and Technology of Food Industry,2023,44(19):320−328.] ZHOU X, ZHOU J S, LIU T Y, et al. Analysis of the effects in the flavor anchovy during circulating boiling brine based on HS-SPME-GC-MS[J]. Science and Technology of Food Industry, 2023, 44(19): 320−328.

[30] 李丽, 蒋景龙, 胡佳乐, 等. 不同品种柑橘果皮精油关键香气物质筛选[J]. 食品工业科技,2023,44(24):259−269. [LI L, JIANG J L, HU J L, et al. Screening of key aroma components in essential oils from citrus peels of different cultivars[J]. Science and Technology of Food Industry,2023,44(24):259−269.] LI L, JIANG J L, HU J L, et al. Screening of key aroma components in essential oils from citrus peels of different cultivars[J]. Science and Technology of Food Industry, 2023, 44(24): 259−269.

[31] 吴梓仟, 周劲松, 刘特元, 等. 基于HS-SPME-GC-MS分析不同卤制条件下卤制液香气差异[J]. 食品工业科技,2023,44(24):311−318. [WU Z Q, ZHOU J S, LIU T Y, et al. Analysis of differences in marinade aroma under different brining conditions based on HS-SPME-GC-MS[J]. Science and Technology of Food Industry,2023,44(24):311−318.] WU Z Q, ZHOU J S, LIU T Y, et al. Analysis of differences in marinade aroma under different brining conditions based on HS-SPME-GC-MS[J]. Science and Technology of Food Industry, 2023, 44(24): 311−318.

[32] 尹含靓, 肖何, 邓高文, 等. 基于HS-SPME-GC-MS分析风味鱼仔加工过程中风味物质的变化[J]. 中国调味品,2022,47(3):8−13. [YIN H L, XIAO H, DENG G W, et al. Analysis of the changes in volatile flavor components of flavored fish larvae during processing by HS-SPME-GC-MS[J]. China Condiment,2022,47(3):8−13.] doi: 10.3969/j.issn.1000-9973.2022.03.002 YIN H L, XIAO H, DENG G W, et al. Analysis of the changes in volatile flavor components of flavored fish larvae during processing by HS-SPME-GC-MS[J]. China Condiment, 2022, 47(3): 8−13. doi: 10.3969/j.issn.1000-9973.2022.03.002

[33] KOHNO Y, MAKINO T, KANAKUBO M. Effect of phase behavior for ionic liquid catalysts with reactants/products on reactivity of esterification from long-chain fatty alcohols and fatty acids[J]. Fluid Phase Equilibria,2019,490:107−113. doi: 10.1016/j.fluid.2019.03.001

[34] GONG H, YANG Z, LIU M, et al. Time-dependent categorization of volatile aroma compound formation in stewed chinese spicy beef using electron nose profile coupled with thermal desorption gc-ms detection[J]. Food Science and Human Wellness,2017,6(3):137−146. doi: 10.1016/j.fshw.2017.07.001

[35] 荀文, 王桂瑛, 赵文华, 等. 基于HS-SPME-GC-MS法比较瓢鸡和盐津乌骨鸡不同部位挥发性风味成分[J]. 核农学报,2021,35(4):923−932. [XUN W, WANG G Y, ZHAO W H, et al. HS-SPME-GC-MS-based volatile flavor in breast and leg muscle of piao chicken and Yanjin silky fowl[J]. Journal of Nuclear Agricultural Sciences,2021,35(4):923−932.] doi: 10.11869/j.issn.100-8551.2021.04.0923 XUN W, WANG G Y, ZHAO W H, et al. HS-SPME-GC-MS-based volatile flavor in breast and leg muscle of piao chicken and Yanjin silky fowl[J]. Journal of Nuclear Agricultural Sciences, 2021, 35(4): 923−932. doi: 10.11869/j.issn.100-8551.2021.04.0923

[36] TOMAC A, COVA M C, NARVAIZ P, et al. Texture, color, lipid oxidation and sensory acceptability of gamma-irradiated marinated anchovy fillets[J]. Radiation Physics and Chemistry,2015,106:337−342. doi: 10.1016/j.radphyschem.2014.08.010

[37] 廖林, 刘悦, 贺稚非, 等. 基于顶空固相微萃取结合气相色谱-质谱技术的卤烤兔肉丁加工过程中挥发性风味物质变化分析[J]. 食品与发酵工业,2022,48(14):235−243. [LIAO L, LIU Y, HE Z F, et al. Analysis of volatile flavor substances during processing of halogen roast rabbit meat based on headspace solid-phase microextraction combined with gas chromatography-mass spectrometry[J]. Food and Fermentation Industries,2022,48(14):235−243.] LIAO L, LIU Y, HE Z F, et al. Analysis of volatile flavor substances during processing of halogen roast rabbit meat based on headspace solid-phase microextraction combined with gas chromatography-mass spectrometry[J]. Food and Fermentation Industries, 2022, 48(14): 235−243.

[38] ESCUDERO A, ARIAS I, LACAU B, et al. Effects of vineyard ‘potential’ and grape maturation on the aroma-volatile profile of grenache wines[J]. OENO One,2019,53(4):2381.

[39] 韦友兵, 吴香, 周辉, 等. 萨拉米发酵成熟过程中微生物菌群变化及对风味的影响[J]. 肉类研究,2018,32(12):48−54. [WEI Y B, WU X, ZHOU H, et al. Changes of microbial flora during the fermentation of Salami and their effect on flavor[J]. Meat Research,2018,32(12):48−54.] WEI Y B, WU X, ZHOU H, et al. Changes of microbial flora during the fermentation of Salami and their effect on flavor[J]. Meat Research, 2018, 32(12): 48−54.

[40] 张权, 李金林, 胡明明, 等. 基于电子鼻和 SAFE-GC-MS 分析调味小龙虾挥发性风味特征差异[J/OL]. 食品与发酵工业, 1−14. [2024-08-15]. https://doi.org/10.13995/j.cnki.11-1802/ts.036446. [ZHANG Q, LI J L, HU M M, et al. Analysis of volatile flavor characteristics of seasoned crayfish based on electronic nose and SAFE-GC-MS[J/OL]. Food and Fermentation Industries, 1−14. [2024-08-15]. https://doi.org/10.13995/j.cnki.11-1802/ts.036446.] ZHANG Q, LI J L, HU M M, et al. Analysis of volatile flavor characteristics of seasoned crayfish based on electronic nose and SAFE-GC-MS[J/OL]. Food and Fermentation Industries, 1−14. [2024-08-15]. https://doi.org/10.13995/j.cnki.11-1802/ts.036446.

[41] 韩颖, 易宇文, 何莲, 等. 基于电子鼻和气质联用分析萌芽大蒜挥发性物质差异[J]. 食品工业科技,2024,45(5):243−252. [HAN Y, YI Y W, HE L, et al. Analysis of the difference of volatile substances in sprouted garlic based on electronic nose and GC-MS[J]. Science and Technology of Food Industry,2024,45(5):243−252.] HAN Y, YI Y W, HE L, et al. Analysis of the difference of volatile substances in sprouted garlic based on electronic nose and GC-MS[J]. Science and Technology of Food Industry, 2024, 45(5): 243−252.

[42] 刘斌善, 魏晓明, 邵丹青, 等. GC-MS/O结合香气活性值表征烧麦中关键香气成分及其贮存过程中的变化情况[J]. 食品科学,2023,44(6):268−276. [LIU B S, WEI X M, SHAO D Q, et al. Characterization of the key odorants in Shaomai and their changes during storage by GC-MS/O coupled with OAV[J]. Food Science,2023,44(6):268−276.] doi: 10.7506/spkx1002-6630-20220728-315 LIU B S, WEI X M, SHAO D Q, et al. Characterization of the key odorants in Shaomai and their changes during storage by GC-MS/O coupled with OAV[J]. Food Science, 2023, 44(6): 268−276. doi: 10.7506/spkx1002-6630-20220728-315

[43] ZHU Y, CHEN J, CHEN X, et al. Use of relative odor activity value (ROAV) to link aroma profiles to volatile compounds:Application to fresh and dried eel (Muraenesox cinereus)[J]. International Journal of Food Properties,2020,23(1):2257−2270. doi: 10.1080/10942912.2020.1856133

[44] 饶伟丽. 风干肉热风干过程中水分迁移机制研究[D]. 北京:中国农业科学院, 2018. [RAO W L. Mechanis m of water migration in air-dried meat during hot air drying[D]. Beijing:Chinese Academy of Agricultural, 2018.] RAO W L. Mechanis m of water migration in air-dried meat during hot air drying[D]. Beijing: Chinese Academy of Agricultural, 2018.

下载:

下载:

下载:

下载: