Preparation, Quality and Purine-lowering Activity of Functional Yak Yoghurt during Storage Period

-

摘要: 为研发一款降嘌呤的功能性牦牛酸奶,以副干酪乳杆菌259和商业发酵剂为发酵菌株,通过单因素实验优化牦牛酸奶菌株接种量,观察牦牛酸奶后熟期及贮藏期品质变化,利用气相色谱-质谱联用技术(GC-MS)解析后熟期和贮藏贮藏期的风味物质变化,高效液相色谱法(HPLC)测定牦牛酸奶的降嘌呤活性。结果表明:牦牛酸奶后熟24 h时,副干酪乳杆菌259接种量5%时感官评分最优,活菌数3.1×108 CFU/mL,酸度为96°T,对黄嘌呤氧化酶(xanthine oxidase,XOD)的抑制率为51.51%。5%接种量副干酪乳杆菌259的牦牛酸奶在贮藏期28 d内活菌数高于107 CFU/m L,酸度低于105.4°T,随贮藏时间增加,pH及持水力逐渐降低,感官品质、硬度、内聚力、黏度、稠度以及对XOD抑制活性先上升后下降;牦牛酸奶后熟期主要风味物质是醇类、酯类、酮类、芳香杂环类以及含硫化合物,贮藏期比后熟期增加了酸类物质;醇类化合物的相对含量和数量最多,赋予酸奶水果香气、花香和甜味;贮藏期牦牛酸奶对肌苷和鸟苷的降解率先上升后下降,最高可达84.6%和86.5%。由此可见,副干酪乳杆菌259发酵的牦牛酸奶品质较好,可抑制黄嘌呤氧化酶活性,有效降解肌苷鸟苷,在预防和辅助治疗高尿酸血症上有较好的应用潜力。Abstract: In order to develop a purine-reducing functional yak yoghurt, Lactobacillus paracasei 259 and commercial starter was used as the fermentation strain in this experiment. The inoculation amount of yak yoghurt strain was optimized by single factor experiment, and the quality changes of yak yoghurt during post-ripening period and storage period were observed. Gas chromatography-mass spectrometry (GC-MS) was used to analyze the changes of flavor substances during post-ripening period and storage period, and the purine-lowering activity of yak yoghurt was determined by high performance liquid chromatography (HPLC). The results showed that the post-ripening time of yak yoghurt was 24 h, the sensory score was the best when the inoculation amount of Lactobacillus paracasei 259 was 5%, the number of viable bacteria was 3.1×108 CFU/mL, the acidity was 96°T, and the inhibition rate of xanthine oxidase (XOD) was 51.51%. Yak yogurt with 5% inoculum of Lactobacillus paracasei 259 had a viable bacterial count higher than 107 CFU/mL during 28 d of storage, and the acidity was lower than 105.4°T. With the increase of storage time, the pH and water holding capacity decreased gradually, and the sensory quality, hardness, cohesion, viscosity, consistency and XOD inhibitory activity increased first and then decreased. The main flavor substances in yak yogurt after ripening were alcohols, esters, ketones, aromatic heterocycles and sulfur compounds. The acids increased at storage period compared to the post-ripening period. The relative content and quantity of alcohols were the highest, which gave the yogurt a fruity, floral and sweet flavor. The degradation of inosine and guanosine in yak yogurt during the storage period firstly increased and then decreased, up to 84.6% and 86.5%, respectively. It can be seen that yak yogurt fermented by Lactobacillus paracasei 259 is of better quality, inhibits xanthine oxidase activity, effectively degrades inosine guanosine, and has good potential for application in the prevention and adjunctive treatment of hyperuricemia.

-

Keywords:

- yak yoghurt /

- texture quality /

- flavor compounds /

- xanthine oxidase /

- inosine /

- guanosine

-

高尿酸血症(hyperuricemia,HUA)由人体内嘌呤代谢紊乱或排泄异常导致尿酸生成过多而形成[1]。HUA也会引起一些并发症,如:冠心病[2]、高血压[3]、糖尿病[4]和慢性肾脏病[5]等。目前临床用于降尿酸药物主要有别嘌醇、非布司他和苯溴马隆,但长期使用药物,患者会出现胃肠道不适、肝功能异常、血液系统损害以及潜在的心脏相关性死亡风险[6−8],严重威胁身体健康。

食疗法对于身体的伤害程度较小,但食疗法通过控制嘌呤食物的摄入降低尿酸是有限的。易康祺等[9]证明控制高血压饮食模式对降低高尿酸血症患病的风险具有积极作用。已有研究表明,益生菌可降低高尿酸血症小鼠体内的尿酸含量[10−11]。孟迎平等[12]研究发现益生菌能预防尿酸积累。用含有益生菌Lactobacillus gasseri PA-3的酸奶干预患者饮食,能够降低受试者的血清尿酸水平[13−14]。因此,可以将益生菌加入食疗中,研究一款功能性食品对降解嘌呤、缓解高尿酸血症具有重要的现实意义。

牦牛乳营养丰富,富含人体所必需的氨基酸,与普通牛乳相比维生素A、干物质、蛋白质、微量元素和矿物质含量极为丰富[15],而且牦牛酸奶更易被乳糖不耐症患者消化吸收[16]。目前牦牛奶市场销售面很窄,未能发挥其最大价值。将牦牛乳发酵成酸奶,不仅可以弱化膻味,还能优化营养价值,使维生素、氨基酸等含量更丰富[17]。

本课题组前期从传统牦牛乳中筛选出副干酪乳杆菌259,且体内外试验验证其具有强降解嘌呤核苷能力。本文以此发酵菌株研发一款降解嘌呤的牦牛酸奶,通过单因素实验确定牦牛酸奶菌株最佳接种量,分析牦牛酸奶贮藏过程中品质变化,GC-MS法检测牦牛酸奶后熟过程以及贮藏期的香味物质变化,高效液相色谱法测定牦牛酸奶对肌苷和鸟苷的降解率。以上研究对于开发具有降嘌呤功效的乳酸菌,以及缓解高尿酸血症具有一定的指导意义。

1. 材料与方法

1.1 材料与仪器

牦牛乳全脂营养奶粉(蛋白质24 g/100 g、脂肪26.2 g/100 g、碳水化合物44.5 g/100 g) 华羚乳品股份有限公司;副干酪乳杆菌259 由西南民族大学课题组提供;商业发酵剂(含保加利亚乳杆菌、嗜热链球菌、嗜热乳杆菌、植物乳杆菌和干酪乳杆菌) 川秀公司;MRS琼脂培养基、MRS肉汤培养基 青岛海博生物技术有限公司;甲醇(色谱纯)、无水乙醇、氢氧化钠、氯化钠、磷酸氢钠、磷酸二氢钾、氢氧化钠(均为分析纯) 购于阿拉丁生化科技股份有限公司;黄嘌呤、黄嘌呤氧化酶(xanthine oxidase,XOD)、肌苷、鸟苷 均为分析纯,上海源叶生物科技有限公司。

Agilent 1260高效液相色谱仪 安捷伦科技(中国)有限公司;GCMS-TQ8040气相色谱-质谱联用仪、Rtx-5MS毛细管色谱柱 日本岛津公司;TA. XT. Plus质构分析仪 英国Stable Micro System公司;V-1000紫外分光光度计 上海翱艺仪器有限公司;Centrifuge 5424R高速冷冻离心机 德国艾本德股份公司;HH-6数显恒温水浴锅 国华(常州)仪器制造有限公司;PL-303分析天平 梅特勒-托利多集团;DHP-9052恒温培养箱 上海齐欣科学仪器有限公司;PHS-3C pH计 上海仪电科学仪器股份有限公司。

1.2 实验方法

1.2.1 菌种的活化与制备

将冷冻保存的副干酪乳杆菌259室温解冻,解冻后吸取200 μL接种于5 mLMRS肉汤培养基中,37 ℃培养24 h,吸取1 mL已活化的菌种于5 mL MRS肉汤培养基中,37 ℃培养24 h,活菌数为108 CFU/mL。按一定比例(2%、3%、4%、5%、6%)加入到已杀菌复原乳中。

1.2.2 牦牛酸奶制备工艺流程

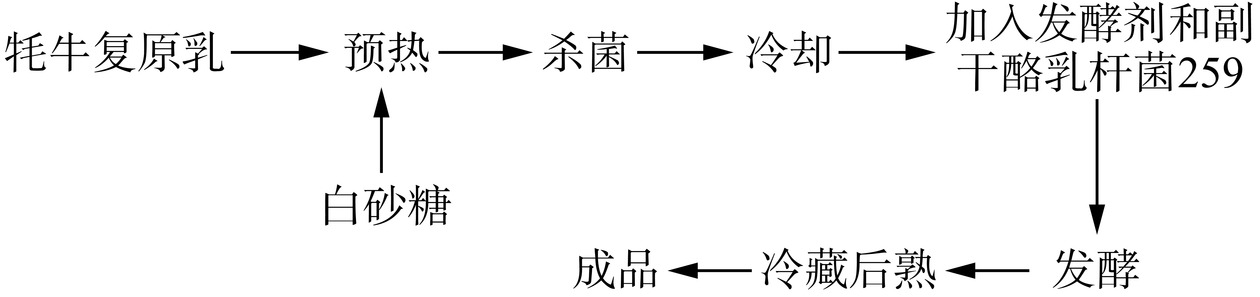

工艺流程如图1所示。

1.2.3 牦牛酸奶工艺操作要点

牦牛复原乳:将牦牛奶粉与水混合均匀,牦牛奶粉:水=1:7;预热:将牦牛复原乳水浴加热至40 ℃,同时加入6%白砂糖;杀菌:牦牛乳置于水浴锅中搅拌加热至68 ℃后持续30 min;冷却:灭菌后的牦牛乳再冷却至41 ℃;发酵:添加0.2%商业发酵剂及副干酪乳杆菌259,37 ℃恒温培养箱发酵5 h至凝乳;冷藏后熟:凝乳后的成品置于4 ℃冰箱中,冷藏24 h。

1.2.4 副干酪乳杆菌259接种量优化试验

按1.2.2工艺流程,分别以2%、3%、4%、5%、6%的菌种量接种副干酪乳杆菌259,进行滴定酸度、活菌数和XOD抑制活性的测定及感官评价,选择适宜的接种量水平。

1.2.5 感官评价

参考于素素等[18]感官评价方法,取10瓶后熟24 h的牦牛酸奶,请10名食品专业人员进行感官鉴定,小组成员由5名男性和5名女性(20~35岁)组成,从色泽、风味、口感、组织状态四方面进行评定,满分为100分,评分标准见表1。

表 1 牦牛酸奶感官评分标准Table 1. Sensory evaluation criteria of yak yoghurt指标 指标特征 评分 色泽(15分) 呈均匀乳白或微黄色 12~15 淡黄色 8~11 浅灰色或灰白色 4~7 异常颜色 0~3 风味(30分) 风味纯正,牦牛酸奶滋味气味明显 24~30 风味均一,香气略淡 16~23 香气较淡、稍有酒精发酵味 8~15 有酒精发酵味或其他不良气味 0~7 口感(20分) 稠度适宜,酸甜适度 16~20 稠度适宜,微酸或微甜 11~15 偏稠或偏稀,偏酸或偏甜 6~10 偏稠或偏稀,过酸或过甜 0~5 组织状态(35分) 爽滑可口、无颗粒感、无乳清析出 27~35 细腻度较差、无颗粒感、少量乳清析出 18~26 有颗粒感、有气泡、乳清析出 9~17 颗粒感严重、有大量气泡、乳清析出严重 0~8 1.2.6 牦牛酸奶理化指标测定方法

1.2.6.1 牦牛酸奶滴定酸度检测

参考GB 5009.239-2016中食品酸度的测定方法[19]。

1.2.6.2 牦牛酸奶活菌数检测

取搅拌均匀的样品0.5 mL于4.5 mL无菌生理盐水中,进行梯度稀释,选取适当的稀释倍数以平板涂布法接种于MRS琼脂培养基,37 ℃恒温培养24 h后计数[20]。

1.2.6.3 牦牛酸奶XOD抑制活性检测

参考苏日娜[21]的方法制备样品。底物溶液配制:精密称量黄嘌呤0.057 g,用1.5%质量浓度的氢氧化钠溶液溶解得到a液;配制2.7%质量浓度的磷酸二氢钾溶液为b液;a和b混匀加蒸馏水稀释至500 μmol/L; XOD溶液的配制:取XOD用PBS缓冲液(0.1 mol/L,pH7.4)溶解配制浓度5 U/L的酶溶液。

反应体系体积为1 mL,依次加入样品200 μL,5 U/L的XOD溶液400 μL,40 ℃孵育30 min,加入500 μmol/L黄嘌呤溶液400 μL,40 ℃孵育15 min,在295 nm处测定吸光度值。实验分别设置样品组、空白组、酶组和底物组,样品组含样品、酶和底物;空白组含底物和样品,不含酶;酶组含酶和底物,不加样品;底物组只含底物。XOD抑制率计算公式为:

抑制率(%)=(1−样品OD值−空白OD值酶OD值−底物OD值)×100 1.2.6.4 牦牛酸奶pH检测

参考于茜等[22]方法,样品恢复至室温后,取灭菌玻璃棒搅拌均匀,用PHS-3C pH计测定样品pH。

1.2.6.5 牦牛酸奶质构特性检测

使用TA-XT Plus质构仪,采用TPA模式测定牦牛酸奶硬度、稠度、内聚性和黏度,测量条件如下[18]:探头P/0.5,测前速度为1.0 mm/s,测试速度为10.0 mm/s,测后速度为5.0 mm/s,压缩距离30 mm。

1.2.6.6 牦牛酸奶持水力检测

参考罗湘蓉等[23]方法,并稍作修改。离心管中加入10 mL牦牛酸奶样品,6000 r/min,15 min,静置10 min,弃去上清液。计算公式为:

M(%)=w3−w1w2−w1×100 式中:w1为离心管质量,w2为加样后离心管质量,w3为离心后弃去上清液离心管质量;M为持水力,%。

1.2.7 牦牛酸奶贮藏期理化指标测定

取4 ℃条件下贮藏1、3、5、7、10、14、18、21、24、28 d的牦牛酸奶,测定指标同1.2.5、1.2.6。并分析上述指标贮藏期内的动态变化。

1.2.8 GC-MS技术检测牦牛酸奶中挥发性风味物质

参考李安等[24]方法稍作修改。取5 mL样品于20 mL的顶空瓶内,加入2 g氯化钠。样品预孵化30 min(60 ℃),然后用 50/30 μm DVB/CAR/PDMS萃取头吸附30 min(60 ℃),解吸20 min。

气相色谱(GC)条件:采用Rtx-5MS毛细管色谱柱(30 m×0.25 mm×0.25 μm),载气He流速为1.0 mL/min。升温程序:起始柱温45 ℃,维持1 min,以3 ℃/min的速度升到180 ℃,再以6 ℃/min速度升到220 ℃,维持10 min,进样口温度为250 ℃。

质谱(MS)条件:全扫描,采集质量范围50~500 m/z;电子电离源:70 eV,离子源温度:250 ℃。

定性定量方法:牦牛酸奶中风味物质的鉴定以其保留时间和NIST 08标准库匹配定性,最终选取匹配度大于800的结果。用各物质的峰面积归一化法计算挥发性风味物质的相对含量(%)。

1.2.9 牦牛酸奶贮藏期降解核苷能力的测定

色谱条件:液相色谱仪安捷伦1260,C18色谱柱(3.5 µm,4.6 mm×150 mm);流动相为0.01 mol/L KH2PO4溶液:甲醇=90:10(V/V),流速为1.0 mL/min,柱温为30 ℃,测定波长为260 nm。

按色谱条件每3 d进行测定,通过保留时间对牦牛酸奶中剩余肌苷和鸟苷进行定性,并以峰面积外标法定量。取2 mL肌苷-鸟苷溶液(2 mmol/L)加入到2 mL牦牛酸奶中,37 ℃,160 r/min摇动1 h。在4 ℃,10000 r/min,离心10 min后,取上清液沸水中处理5 min以结束反应,4 ℃,10000 r/min,10 min离心后,用0.22 μm针孔滤头过滤,通过HPLC分析测定肌苷和鸟苷的含量[25]。

肌苷和鸟苷降解率计算公式如下:

降解率(%)=n−Xn×100 式中:n:降解前肌苷或鸟苷的含量(mmol),X:降解后肌苷或鸟苷的含量(mmol)。

1.3 数据处理

各试验数据重复测定3次,采用SPSS 26进行数据统计方差及显著性分析(P<0.05),采用Origin 2021绘图,采用SIMCA14.1进行主成分分析及偏最小二乘法分析。

2. 结果与分析

2.1 副干酪乳杆菌259接种量优化

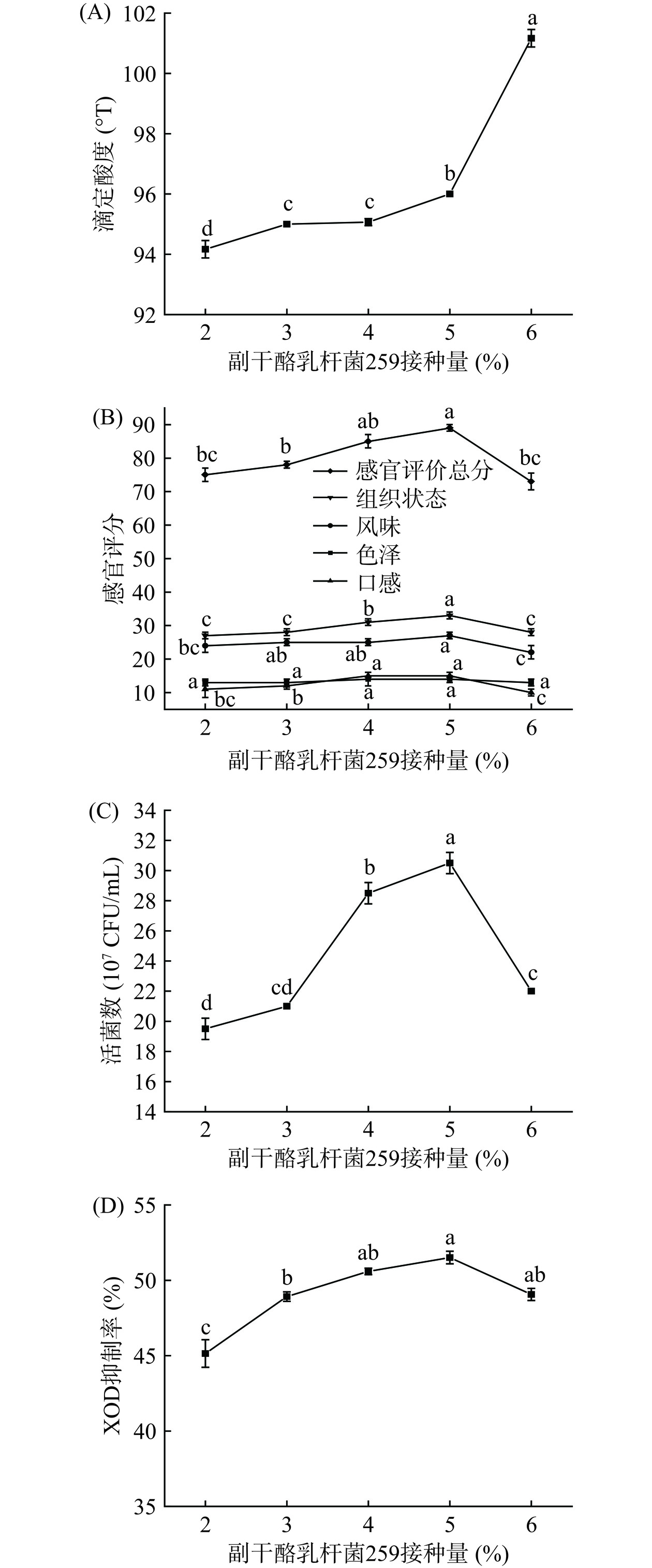

以1.2.4制备的酸奶为检测样品。由图2A可知,随着副干酪乳杆菌259接种量增加,牦牛酸奶酸度逐渐增加,接种量为5%~6%变化较大,这可能是由于接种量过大,导致发酵速度过快产酸较多[26]。感官评分(图2B)随接种量先增加后降低,说明当接种量为5%时牦牛酸奶的接受度最高。图2C可知活菌数先增多,当接种量为5%~6%时开始减少,这可能是由于乳杆菌生长随着产酸量增加而受到抑制。对XOD的抑制率先增大再减小(图2D)。

![]() 图 2 副干酪乳杆菌259接种量对牦牛酸奶品质的影响注:图中不同小写字母不同表示差异显著(P<0.05),图3同。Figure 2. Effect of Lactobacillus paracasei 259 inoculation on the quality of yak yoghurt

图 2 副干酪乳杆菌259接种量对牦牛酸奶品质的影响注:图中不同小写字母不同表示差异显著(P<0.05),图3同。Figure 2. Effect of Lactobacillus paracasei 259 inoculation on the quality of yak yoghurt综合以上指标,当接种量为5%时,活菌数达到3.1×108 CFU/mL,滴定酸度96°T,感官品质达到最优,酸奶爽滑可口、无颗粒感、口感丰富、无乳清析出,因此选取副干酪乳杆菌259接种量为5%制备的酸奶进行后续指标的测定。

2.2 牦牛酸奶在贮藏期间品质变化

以副干酪乳杆菌259接种量为5%的牦牛酸奶发酵冷藏后熟24 h为检测样品,分别贮藏不同时间。

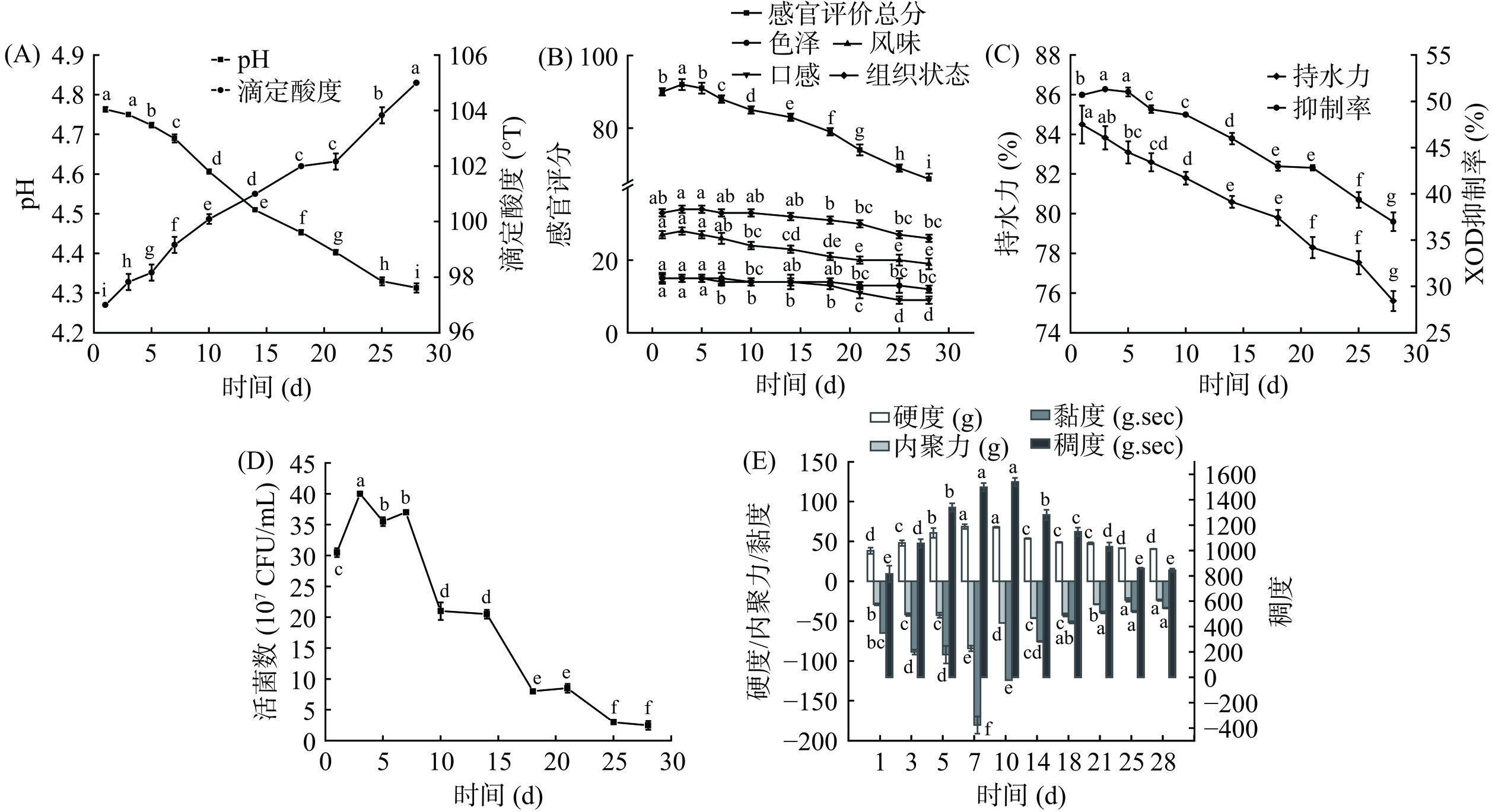

由图3A知,1~7 d牦牛酸奶的pH变化较小,贮藏10 d后出现较大幅度下降。随酸奶贮藏时间延长,乳酸菌持续发酵,pH持续降低,邱爽等[27]发现一般酸奶适口的pH为4.2~4.7。贮藏期间牦牛酸奶的酸度不断升高,21 d后酸度较大幅度上升,是由于乳酸菌还在继续产酸[28],这与pH呈下降趋势相关联,与刘文星等[29]研究结果一致。酸度范围在97~106°T,研究表明,酸奶最佳酸度为80~120°T[27]。图3B感官评价可知酸奶在前7 d的品质最好,随后感官评分开始下降,这是由于牦牛酸奶的酸度升高,导致感官下降,21 d开始其口感变差。

由图3C可知,随贮藏时间延长,牦牛酸奶的持水力逐渐下降。可能原因是随pH下降,酸奶的凝胶结构被破坏或者菌种在代谢过程中需要水的参与,导致持水力下降[28]。在贮藏期间,牦牛酸奶对XOD的抑制率先上升再下降,崔方超等[30]研究发现对XOD产生抑制作用的是乳酸菌代谢产物中的有机酸类物质,因此牦牛酸奶对XOD的抑制率上升可能是因为副干酪乳杆菌259在发酵过程中活菌数不断增加,代谢产物增加,所以对XOD的抑制活性不断增加;而随着贮藏时间增加,活菌数减少,乳酸菌代谢产物随之减少,副干酪乳杆菌259对XOD的抑制活性下降。

贮藏期间,活菌数的变化趋势为先上升后下降(图3D),第1 d,活菌数为3×108 CFU/mL,而在第3 d时,活菌数达到最多为4×108 CFU/mL,在第28 d时活菌数为3×107 CFU/mL,但是仍高于国家标准中规定的1×106 CFU/mL。活菌数变化与于素素等[18]研究结果一致,可能是因为有机酸的增加抑制了菌的增长。

牦牛酸奶的硬度、内聚力、黏度在1~7 d上升,在7~28 d 逐渐下降。稠度在1~10 d增加,在10~28 d逐渐下降(图3E)。硬度、内聚力、黏度、稠度的升高,可能是胞外多糖的含量逐渐升高,与蛋白质基质相互作用,形成稳定的三维网状结构;随后硬度、内聚力、黏度、稠度下降,可能是酸奶稳定性减弱,酪蛋白凝胶聚集结构不稳定,导致乳清析出[31]。综上,建议牦牛酸奶的货架期为21 d,在前21 d牦牛酸奶的品质较优,其功能性较佳。

2.3 GC-MS技术检测牦牛酸奶中挥发性风味物质

2.3.1 后熟期间牦牛酸奶中挥发性风味物质

2.3.1.1 后熟期间牦牛酸奶中挥发性风味物质组成分析

采用GC-MS技术对后熟期间牦牛酸奶样品中的挥发性风味物质进行测定,并用偏最小二乘法分析,结果见表2。

表 2 GC-MS 鉴定牦牛酸奶后熟期间主要挥发性风味物质Table 2. GC-MS identification of the main volatile flavor substances during post-ripening of yak yoghurt序号 化合物 保留时间(min) 相对含量(%) 8 h 12 h 16 h 20 h 24 h 醇类 异戊醇 9.28 17.92±0.10d 18.16±0.45c 21.91±0.22b 16.49±0.36d 22.23±0.40a 正己醇 14.66 7.46±0.06d 7.56±0.08b 7.44±0.09d 7.52±0.06c 10.44±0.47a 3-甲硫基丙醇 28.82 1.33±0.22c 1.34±0.06c 1.06±0.05d 1.39±0.09b 1.58±0.13a 苯甲醇 34.55 1.23±0.02b 1.24±0.02b 0.94±0.06d 1.04±0.13c 1.42±0.13a 苯乙醇 35.64 2.63±0.01c 2.67±0.14b 2.06±0.05e 4.59±0.12a 2.27±0.23d 酯类 乙酸乙酯 2.55 8.15±0.04d 8.26±0.09b 8.58±0.15a 6.40±0.08e 8.18±0.21c 硝酸异戊酯 9.78 0.57±0.01c 0.58±0.03b − 0.81±0.04a − 酮类 5-甲基-2-己酮 8.44 0.36±0.01b 0.37±0.02a − − − 环己酮 11.88 − − 2.09±0.08a 1.70±0.06b − 2-甲基环戊酮 11.88 1.87±0.04c 1.90±0.10b − − 2.39±0.12a 2-壬酮 15.77 1.89±0.03b 1.91±0.15a 1.38±0.13d 0.76±0.07e 1.83±0.04c 2-十一酮 24.04 0.95±0.02d 0.97±0.07c 1.15±0.12a 0.93±0.11e 1.02±0.04b 醛类 2-甲基十一醛 15.97 − − − 0.64±0.01a − 苯乙醛 25.89 0.71±0.05a 0.71±0.05a 0.49±0.01b 0.29±0.02d 0.43±0.04c 其他 二甲基砜 35.40 − − 1.00±0.10b 1.95±0.03a 0.84±0.05c 注:同行小写字母不同表示差异显著(P<0.05),表中“−”表示未检出;表3同。 后熟期间牦牛酸奶中共检测到15种风味物质。其中醇类物质为主要香味物质,异戊醇和正己醇的相对含量最高,且持续增加,在24 h时分别达到22.23%±0.40%和10.44%±0.47%,异戊醇具有香蕉的香甜味[32],正己醇具有青草香[33]。苯乙醇、苯甲醇有花香气味[34],相对含量为0.9%~5%。3-甲硫基丙醇在整个后熟期相对含量为1%~1.6%,低浓度的3-甲硫基丙醇有烤奶酪香气[35]。

其次相对含量较高的是酯类,乙酸乙酯相对含量在16 h时达到8.58%±0.15%,可提供苹果的香气[36]。酮类物质中2-壬酮为牦牛酸奶关键风味物质,后熟期相对含量在0.7%~2%,呈现奶油香气和果香,使得酸奶风味更醇厚[37]。16、20 h检出环己酮(薄荷味[38]);2-甲基环戊酮(干酪奶香[39])24 h相对含量达2.39%±0.12%

另外,酸奶后熟16 h时检出二甲基砜,可能是因为牛奶蛋白加热变性后引起半胱氨酸中的巯基暴露,随着后熟时间增加,暴露的巯基发生Strecker降解产生[40],二甲基砜具有抗炎[41]、抗氧化、抗癌、抗肿瘤[42]、促进生长、滋养皮肤以及提升毛发质量等作用,被广泛应用于保健食品中[43],对于本功能性酸奶可起到其他辅助功能作用。因此,后熟期间牦牛酸奶风味主要以醇类酯类为主要呈味物质,呈现出一定的水果香和奶油香气。

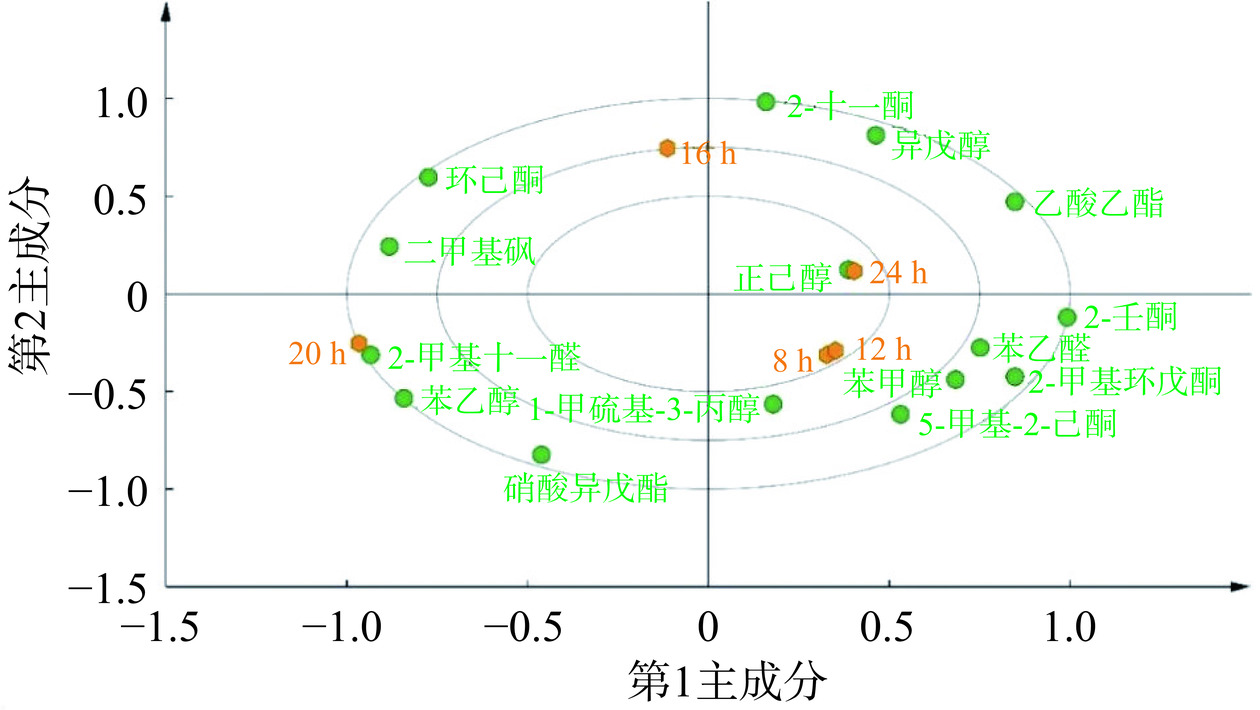

2.3.1.2 后熟期间牦牛酸奶中挥发性风味物质相关性分析

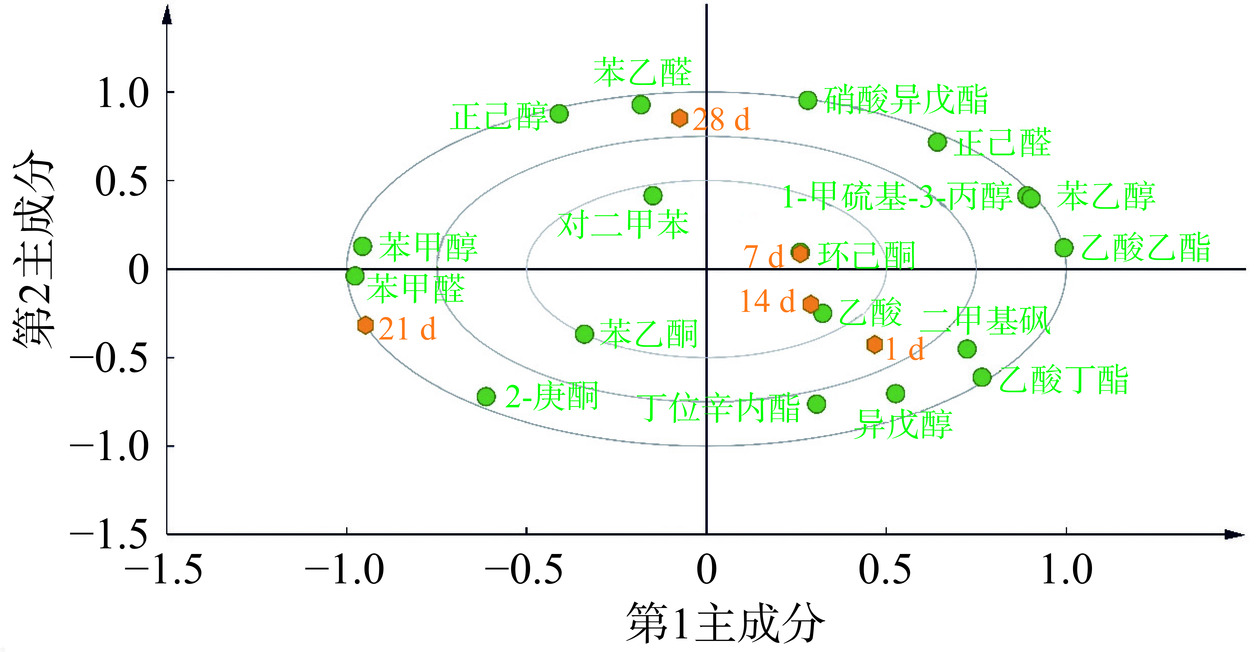

第1主成分贡献率为49%,第2主成分贡献率为30%。由图4可知,8 h与12 h的挥发性风味物质组成最为相似,与苯甲醇和苯乙醛呈相关性,主要表现为花香和水果香气;16 h的酸奶与挥发性风味物质的相关性均不显著,未呈现较高相关性;20 h与2-甲基十一醛和苯乙醇呈较高的相关性,主要表现为花香味;24 h与正己醇呈较高的相关性,主要表现为青草香。后熟12 h其挥发性风味物质呈现出较强的水果香与花香,使牦牛酸奶风味更加醇厚。

2.3.2 贮藏期牦牛酸奶中挥发性风味物质

2.3.2.1 贮藏期牦牛酸奶中挥发性风味物质组成分析

由表3可知,贮藏期牦牛酸奶中共检测到18种风味物质。醇类物质相对含量最高,其次为酯类、酮类、芳香族化合物、酸类、醛类和有机硫化物。与后熟期相比,增加了酸类物质和芳香族化合物。

表 3 GC-MS鉴定牦牛酸奶贮藏期主要挥发性风味物质Table 3. GC-MS identification of the main volatile flavor substances in yak yoghurt during the storage period种类 化合物 保留时间(min) 相对含量(%) 1 d 7 d 14 d 21 d 28 d 醇类 异戊醇 9.28 15.76±0.25a 12.76±0.09b 11.63±0.10c 11.22±0.02d 9.44±0.11e 正己醇 14.66 7.75±0.07d 8.47±0.22c 7.62±0.07e 8.95±0.07b 10.89±0.01a 3-甲硫基丙醇 28.83 1.36±0.09b 1.13±0.16d 1.20±0.04c − 1.43±0.05a 苯甲醇 34.53 1.56±0.08c 1.48±0.13d 1.57±0.02c 2.35±0.13a 1.98±0.05b 苯乙醇 35.62 2.59±0.25b 2.49±0.08c 2.56±0.08b 1.83±0.05d 2.63±0.06a 酯类 乙酸乙酯 2.55 6.02±0.25a 5.50±0.05c 5.72±0.06b − 4.48±0.01d 乙酸丁酯 5.25 4.45±0.08a 4.13±0.23c 4.19±0.07b 3.85±0.02d 3.81±0.06d 硝酸异戊酯 9.77 0.59±0.02c 0.76±0.06b 0.60±0.04c 0.43±0.02d 1.10±0.01a 丁位辛内酯 37.15 1.30±0.16a − 0.83±0.02b 0.49±0.01c − 酮类 2-庚酮 8.24 6.28±0.18b 3.00±0.09d 3.57±0.05c 9.08±0.03a 2.02±0.03e 环己酮 11.90 − 0.84±0.02a − − − 苯乙酮 26.05 − 0.78±0.01a 0.67±0.07c 0.75±0.03b − 芳香族 对二甲苯 6.89 0.50±0.04b 0.43±0.04c − 0.40±0.06c 0.58±0.06a 酸类 乙酸 32.18 1.07±0.04c 1.36±0.10b 13.26±0.14a 0.67±0.04d 0.43±0.03e 醛类 正己醛 5.47 1.01±0.02b 0.89±0.01c 1.02±0.01d − 1.69±0.07a 苯甲醛 21.24 0.83±0.04c − − 10.16±0.13a 3.73±0.18b 苯乙醛 25.89 − 0.79±0.07b 0.56±0.02c 0.49±0.06d 1.25±0.04a 其他 二甲基砜 35.40 0.91±0.05a 0.86±0.02b 0.54±0.03c 0.35±0.10d 0.32±0.03e 醇类物质中,1 d时异戊醇相对含量最高为15.76%±0.25%,后随时间增加而下降,异戊醇表现为苹果白兰地香气[44]和杂醇油气味,异戊醇相对含量减少的原因可能是由于醇类化合物通过一系列反应转化成酸类化合物[45];正己醇相对含量不断增加,28 d时可达10.89%±0.01%,表现为不良气味[46],影响酸奶的风味;苯甲醇在贮藏期相对含量逐渐增高,21 d时达2.35%±0.13%,21 d后开始减少,苯乙醇在28 d时相对含量达到最高为2.63%±0.06%。

与后熟期相比,贮藏期风味物质增加了正己醛、苯甲醛等醛类物质。苯甲醛相对含量先增加后减少,21 d相对含量最高为10.16%,高浓度苯甲醛具有水果香气[47],可为酸奶提供较好的风味;酮类物质中,2-庚酮赋予牦牛酸奶奶油香气和果香,是牦牛乳的代表性挥发性风味物质[48],在21 d相对含量最高为9.08%±0.03%,28 d相对含量最低。

21 d至28 d期间,正己醇相对含量持续增加而苯甲醛和2-庚酮含量降低使其风味品质变差。其次乙酸乙酯和乙酸丁酯的含量随时间增加而降低,含量在3%~7%。整个贮藏期间,二甲基砜相对含量不断减少,乙酸乙酯、乙酸丁酯等酯类物质在贮藏期含量降低,可能与脂肪或脂肪酸的热降解和氧化相关[49]。

贮藏期产生果香和奶香的主要物质含量增加,主要集中在21 d最高,随后其含量下降产生不良气味使牦牛酸奶风味下降,因此在21 d前牦牛酸奶风味较好。

2.3.2.2 贮藏期牦牛酸奶中挥发性风味物质相关性分析

第1主成分贡献率为41%,第2主成分贡献率为33%。由图5可知,1 d与异戊醇、乙酸丁酯和二甲基砜呈相关性,主要表现为水果香气;7 d与环己酮呈较高相关性,主要表现为薄荷味;14 d与乙酸呈较高相关性,主要表现为酸味;21 d与苯甲醛和2-庚酮有相关性,主要表现为奶油香和果香;28 d与对二甲苯和苯乙醛呈较高相关性,主要表现为微量甜味。贮藏期牦牛酸奶主要风味物质表现为奶油香和果香。

2.4 高效降解核苷能力的测定

2.4.1 肌苷和鸟苷标准曲线的建立

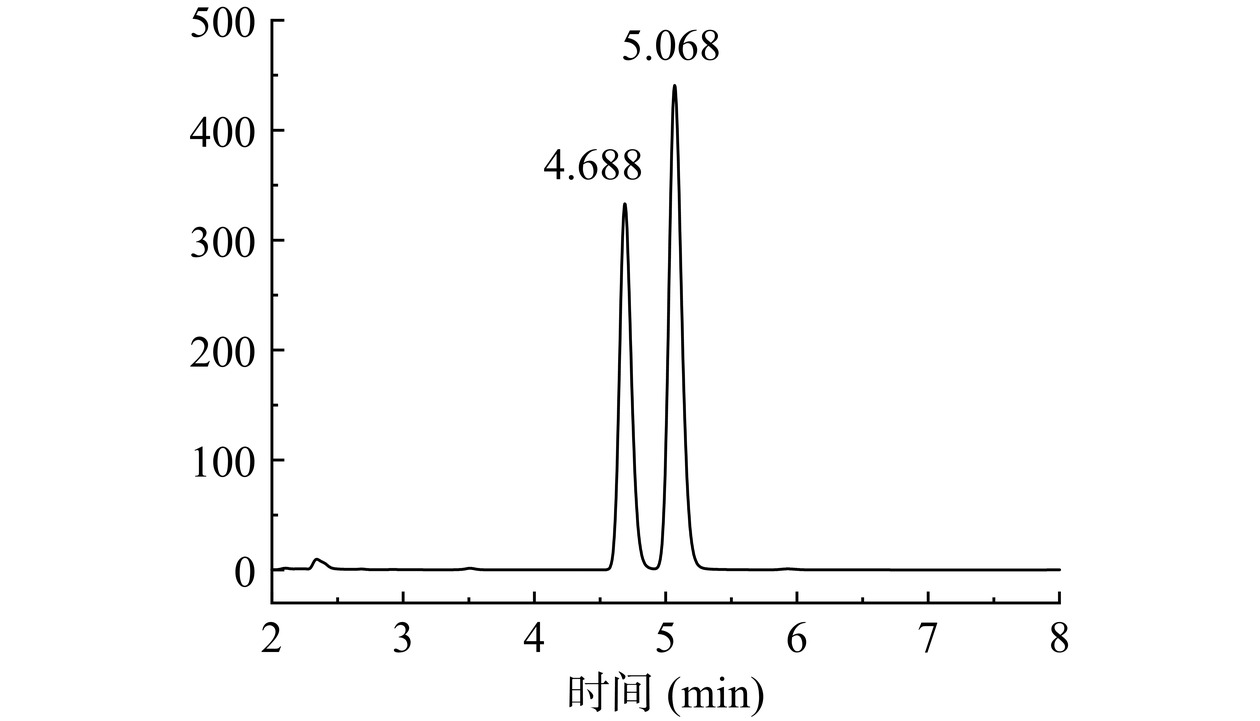

参考李杰等[50]方法,首先通过肌苷和鸟苷标准溶液的梯度稀释,采用HPLC建立标准曲线,以峰面积、相应浓度为纵坐标、横坐标绘制标准曲线,肌苷的标准曲线为y=30382x+108.87,决定系数R²为0.9998;鸟苷的标准曲线为y=41620x+129.23,决定系数R²为0.9998。由图6可知,肌苷保留时间为4.688 min,鸟苷保留时间5.068 min,色谱峰出峰完整且完全分离,故此条件可以检测肌苷和鸟苷的含量。

2.4.2 贮藏期牦牛酸奶对肌苷、鸟苷降解率的测定

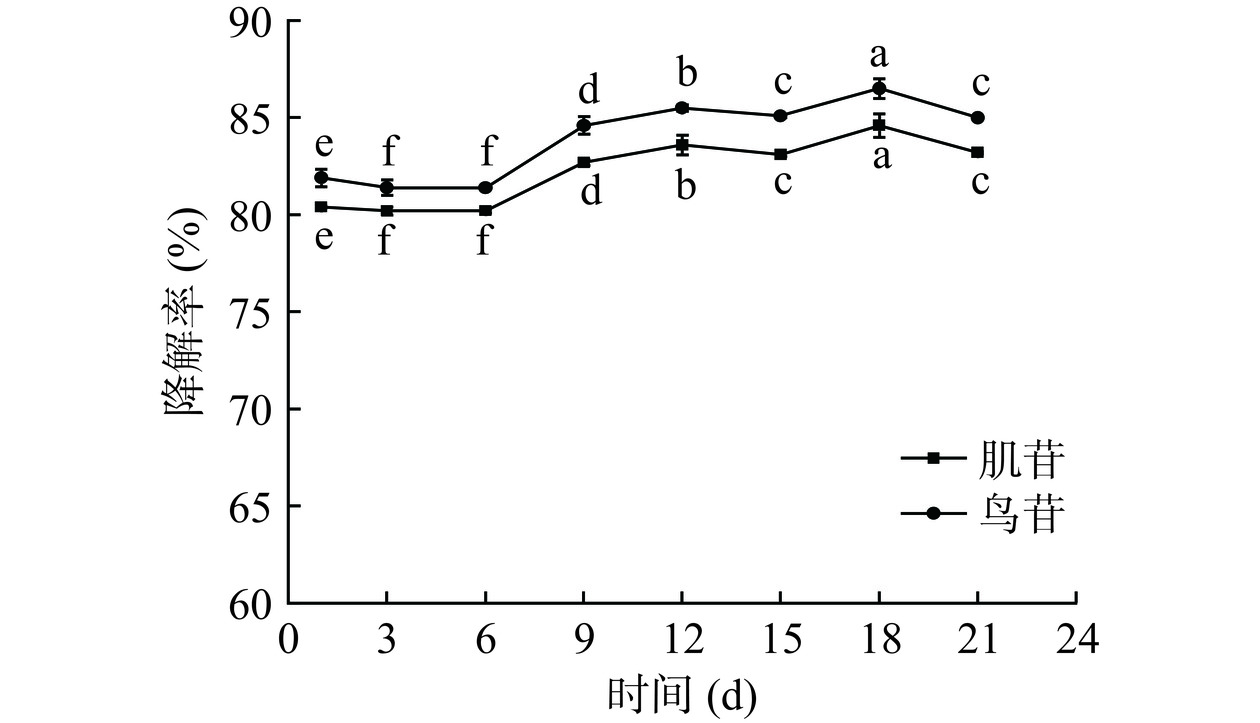

肌苷、鸟苷为尿酸底物,经转化水解为黄嘌呤,最终由XOD转化生成尿酸,因此减少肌苷和鸟苷摄入量,可以降低尿酸水平[51]。副干酪乳杆菌259牦牛酸奶可以与肌苷和鸟苷反应,由图7可知降解率在贮藏期最高可达到 84.6% 和 86.5%。与 Lu 等[25]研究结果基本一致。贮藏期酸奶对肌苷和鸟苷的降解率不稳定,1~6 d有小幅度降低可能是由于活菌数突然增多,微生物利用酸奶中小分子物质发生生物转化[52],随后抑制率升高,总体趋势在18 d达到最高,随后下降,可能原因是随时间延长酸度增加,有机酸的增加抑制乳酸菌生长[53],限制了副干酪乳杆菌259对肌苷和鸟苷的降解率。

3. 结论

本实验对功能性牦牛酸奶制备、贮藏期内品质及降嘌呤活性研究,后熟24 h的酸奶检测结果表明,副干酪乳杆菌259最佳接种量为5%,活菌数为3.1×108 CFU/mL,酸度为96°T,对黄嘌呤氧化酶的抑制率为51.51%。贮藏期内牦牛酸奶活菌数高于107 CFU/mL,酸度低于105.4°T,随贮藏时间增加,pH及持水力逐渐降低,感官品质、硬度、内聚力、黏度、稠度以及对XOD抑制活性先上升后下降,在前21 d具有良好的品质。后熟期与贮藏期的牦牛酸奶挥发性风味物质种类含量明显不同,检测出有醇类、酯类、酮类、芳香杂环类、酸类、醛类以及含硫化合物,其中醇类化合物的相对含量和数量最多,主要表现为水果香气、花香和甜味,随着贮藏时间延长,能够增加香味的挥发性物质含量降低,具有不良气味的挥发性物质增多,21 d开始品质下降。副干酪乳杆菌259牦牛酸奶对肌苷和鸟苷的降解率分别在贮藏18 d时最高达到84.6%和86.5%,所以含副干酪乳杆菌259的牦牛酸奶对降解嘌呤起到有效作用,具有预防和辅助治疗高尿酸血症的潜力。

-

图 2 副干酪乳杆菌259接种量对牦牛酸奶品质的影响

注:图中不同小写字母不同表示差异显著(P<0.05),图3同。

Figure 2. Effect of Lactobacillus paracasei 259 inoculation on the quality of yak yoghurt

表 1 牦牛酸奶感官评分标准

Table 1 Sensory evaluation criteria of yak yoghurt

指标 指标特征 评分 色泽(15分) 呈均匀乳白或微黄色 12~15 淡黄色 8~11 浅灰色或灰白色 4~7 异常颜色 0~3 风味(30分) 风味纯正,牦牛酸奶滋味气味明显 24~30 风味均一,香气略淡 16~23 香气较淡、稍有酒精发酵味 8~15 有酒精发酵味或其他不良气味 0~7 口感(20分) 稠度适宜,酸甜适度 16~20 稠度适宜,微酸或微甜 11~15 偏稠或偏稀,偏酸或偏甜 6~10 偏稠或偏稀,过酸或过甜 0~5 组织状态(35分) 爽滑可口、无颗粒感、无乳清析出 27~35 细腻度较差、无颗粒感、少量乳清析出 18~26 有颗粒感、有气泡、乳清析出 9~17 颗粒感严重、有大量气泡、乳清析出严重 0~8 表 2 GC-MS 鉴定牦牛酸奶后熟期间主要挥发性风味物质

Table 2 GC-MS identification of the main volatile flavor substances during post-ripening of yak yoghurt

序号 化合物 保留时间(min) 相对含量(%) 8 h 12 h 16 h 20 h 24 h 醇类 异戊醇 9.28 17.92±0.10d 18.16±0.45c 21.91±0.22b 16.49±0.36d 22.23±0.40a 正己醇 14.66 7.46±0.06d 7.56±0.08b 7.44±0.09d 7.52±0.06c 10.44±0.47a 3-甲硫基丙醇 28.82 1.33±0.22c 1.34±0.06c 1.06±0.05d 1.39±0.09b 1.58±0.13a 苯甲醇 34.55 1.23±0.02b 1.24±0.02b 0.94±0.06d 1.04±0.13c 1.42±0.13a 苯乙醇 35.64 2.63±0.01c 2.67±0.14b 2.06±0.05e 4.59±0.12a 2.27±0.23d 酯类 乙酸乙酯 2.55 8.15±0.04d 8.26±0.09b 8.58±0.15a 6.40±0.08e 8.18±0.21c 硝酸异戊酯 9.78 0.57±0.01c 0.58±0.03b − 0.81±0.04a − 酮类 5-甲基-2-己酮 8.44 0.36±0.01b 0.37±0.02a − − − 环己酮 11.88 − − 2.09±0.08a 1.70±0.06b − 2-甲基环戊酮 11.88 1.87±0.04c 1.90±0.10b − − 2.39±0.12a 2-壬酮 15.77 1.89±0.03b 1.91±0.15a 1.38±0.13d 0.76±0.07e 1.83±0.04c 2-十一酮 24.04 0.95±0.02d 0.97±0.07c 1.15±0.12a 0.93±0.11e 1.02±0.04b 醛类 2-甲基十一醛 15.97 − − − 0.64±0.01a − 苯乙醛 25.89 0.71±0.05a 0.71±0.05a 0.49±0.01b 0.29±0.02d 0.43±0.04c 其他 二甲基砜 35.40 − − 1.00±0.10b 1.95±0.03a 0.84±0.05c 注:同行小写字母不同表示差异显著(P<0.05),表中“−”表示未检出;表3同。 表 3 GC-MS鉴定牦牛酸奶贮藏期主要挥发性风味物质

Table 3 GC-MS identification of the main volatile flavor substances in yak yoghurt during the storage period

种类 化合物 保留时间(min) 相对含量(%) 1 d 7 d 14 d 21 d 28 d 醇类 异戊醇 9.28 15.76±0.25a 12.76±0.09b 11.63±0.10c 11.22±0.02d 9.44±0.11e 正己醇 14.66 7.75±0.07d 8.47±0.22c 7.62±0.07e 8.95±0.07b 10.89±0.01a 3-甲硫基丙醇 28.83 1.36±0.09b 1.13±0.16d 1.20±0.04c − 1.43±0.05a 苯甲醇 34.53 1.56±0.08c 1.48±0.13d 1.57±0.02c 2.35±0.13a 1.98±0.05b 苯乙醇 35.62 2.59±0.25b 2.49±0.08c 2.56±0.08b 1.83±0.05d 2.63±0.06a 酯类 乙酸乙酯 2.55 6.02±0.25a 5.50±0.05c 5.72±0.06b − 4.48±0.01d 乙酸丁酯 5.25 4.45±0.08a 4.13±0.23c 4.19±0.07b 3.85±0.02d 3.81±0.06d 硝酸异戊酯 9.77 0.59±0.02c 0.76±0.06b 0.60±0.04c 0.43±0.02d 1.10±0.01a 丁位辛内酯 37.15 1.30±0.16a − 0.83±0.02b 0.49±0.01c − 酮类 2-庚酮 8.24 6.28±0.18b 3.00±0.09d 3.57±0.05c 9.08±0.03a 2.02±0.03e 环己酮 11.90 − 0.84±0.02a − − − 苯乙酮 26.05 − 0.78±0.01a 0.67±0.07c 0.75±0.03b − 芳香族 对二甲苯 6.89 0.50±0.04b 0.43±0.04c − 0.40±0.06c 0.58±0.06a 酸类 乙酸 32.18 1.07±0.04c 1.36±0.10b 13.26±0.14a 0.67±0.04d 0.43±0.03e 醛类 正己醛 5.47 1.01±0.02b 0.89±0.01c 1.02±0.01d − 1.69±0.07a 苯甲醛 21.24 0.83±0.04c − − 10.16±0.13a 3.73±0.18b 苯乙醛 25.89 − 0.79±0.07b 0.56±0.02c 0.49±0.06d 1.25±0.04a 其他 二甲基砜 35.40 0.91±0.05a 0.86±0.02b 0.54±0.03c 0.35±0.10d 0.32±0.03e -

[1] 石慧, 梁晓珊, 黄丽文, 等. 一种高尿酸血症大鼠模型诱导方法的改良和效果评价研究[J]. 中国应用生理学杂志,2020,36(3):223−227. [SHI Hui, LIANG Xiaoshan, HUANG Liwen, et al. The optimization and assessment of the method for inducing hyperuricemia in rats[J]. Chinese Journal of Applied Physiology,2020,36(3):223−227.] doi: 10.12047/j.cjap.5933.2020.049 SHI Hui, LIANG Xiaoshan, HUANG Liwen, et al. The optimization and assessment of the method for inducing hyperuricemia in rats[J]. Chinese Journal of Applied Physiology, 2020, 36(3): 223−227. doi: 10.12047/j.cjap.5933.2020.049

[2] FREEDMAN D S, WILLIAMSON D F, GUNTER E W, et al. Relation of serum uric acid to mortality and ischemic heart disease. The NHANES I epidemiologic follow-up study[J]. Am J Epidemiol,1995,141(7):637−644. doi: 10.1093/oxfordjournals.aje.a117479

[3] WANG J, TIAN Q Q, CHEN J R, et al. Hyperuricemia and risk of incident hypertension:A systematic review and meta-analysis of observational studies[J]. PLoS One,2014,9(12):e114259. doi: 10.1371/journal.pone.0114259

[4] LÜ Q, MENG X F, HE F F, et al. High serum uric acid and increased risk of type 2 diabetes:A systemic review and meta-analysis of prospective cohort studies[J]. PLoS One,2013,8(2):e56864. doi: 10.1371/journal.pone.0056864

[5] MADERO M, SARNAK M J, WANG X, et al. Uric acid and long-term outcomes in CKD[J]. Am J Kidney Dis,2009,53(5):796−803. doi: 10.1053/j.ajkd.2008.12.021

[6] AYOUB I, ALMAANI S, BRODSKY S, et al. Revisiting medullary tophi:A link between uric acid and progressive chronic kidney disease[J]. Clinical Nephrology,2015,85(2):109−109.

[7] 朱楠, 侯杰, 李洁, 等. 降尿酸药物别嘌醇、非布司他和苯溴马隆的严重不良反应综述[J]. 中国合理用药探索,2021,18(6):6−9. [ZHU Nan, HOU Jie, LI Jie, et al. A review of serious adverse reactions of urate lowering drugs allopurinol, febuxostat and benzbromarone[J]. Chinese Journal of Rational Drug Use,2021,18(6):6−9.] ZHU Nan, HOU Jie, LI Jie, et al. A review of serious adverse reactions of urate lowering drugs allopurinol, febuxostat and benzbromarone[J]. Chinese Journal of Rational Drug Use, 2021, 18(6): 6−9.

[8] MURRELL G A, RAPEPORT W G. Clinial pharmacokinetics of allopurinol[J]. Clin Pharmacokinet,1986,11(5):343−353. doi: 10.2165/00003088-198611050-00001

[9] 易康祺, 崔淑衡, 郁雨婷, 等. 社区居民控制高血压饮食模式与高尿酸血症的关联研究[J]. 中国慢性病预防与控制,2023,31(1):26−30. [YI Kangqi, CUI Shuheng, YU Yuting, et al. Study on association between the dietary approaches to stop hypertension (DASH) diet and hyperuricemia among community residents[J]. Chinese Journal of Prevention and Control of Chronic Diseases,2023,31(1):26−30.] YI Kangqi, CUI Shuheng, YU Yuting, et al. Study on association between the dietary approaches to stop hypertension (DASH) diet and hyperuricemia among community residents[J]. Chinese Journal of Prevention and Control of Chronic Diseases, 2023, 31(1): 26−30.

[10] LI M, YANG D, MEI L, et al. Screening and characterization of purine nucleoside degrading lactic acid bacteria isolated from Chinese Sauerkraut and evaluation of the serum uric acid lowering effect in hyperuricemic rats[J]. PLoS One,2014,9(9):e105577. doi: 10.1371/journal.pone.0105577

[11] 牛春华, 肖茹雪, 赵子健, 等. 植物乳杆菌UA149的降尿酸作用[J]. 现代食品科技,2020,36(2):1−6,217. [NIU Chunhua, XIAO Ruxue, ZHAO Zijian, et al. Serum uric acid lowering effect of Lactobacillus plantarum UA149 on hyperuricemic rats[J]. Modern Food Science and Technology,2020,36(2):1−6,217.] NIU Chunhua, XIAO Ruxue, ZHAO Zijian, et al. Serum uric acid lowering effect of Lactobacillus plantarum UA149 on hyperuricemic rats[J]. Modern Food Science and Technology, 2020, 36(2): 1−6,217.

[12] 孟迎平, 冯杰, 魏华, 等. 肠道菌群对饮食诱导的高尿酸血症的调控研究进展[J]. 食品工业科技,2022,43(18):465−473. [MENG Yingping, FENG Jie, WEI Hua, et al. Research progress on the regulation of intestinal flora on diet-induced hyperuricemia[J]. Science and Technology of Food Industry,2022,43(18):465−473.] MENG Yingping, FENG Jie, WEI Hua, et al. Research progress on the regulation of intestinal flora on diet-induced hyperuricemia[J]. Science and Technology of Food Industry, 2022, 43(18): 465−473.

[13] TSUKUBA, INTERNATIONAL, CLINICAL, et al. Placebo controlled double blind parallel randomized study to test the uratelowering effect of yogurt containing Lactobacillus gasseri PA-3 in adult males with marginal hyperuricemia[J]. Gout and Nucleic Acid Metabolism,2016,40(1):21−31. doi: 10.6032/gnam.40.21

[14] YAMANAKA H, TANIGUCHI A, TSUBOI H, et al. Hypouricaemic effects of yoghurt containing Lactobacillus gasseri PA-3 inpatients with hyperuricaemia and/or gout:A randomised, double-blind, placebo-controlled study[J]. Modern Rheumatology,2019,29(1):146−150. doi: 10.1080/14397595.2018.1442183

[15] 张建华, 李文浩. 黑枸杞牦牛奶酪制品的加工工艺研究[J]. 中国奶牛,2022(12):49−53. [ZHANG Jianhua, LI Wenhao. Research on the processing technology of yak cheese products with black wolfberry[J]. China Dairy Cattle,2022(12):49−53.] ZHANG Jianhua, LI Wenhao. Research on the processing technology of yak cheese products with black wolfberry[J]. China Dairy Cattle, 2022(12): 49−53.

[16] 吴海玥, 张艳. 普洱茶牦牛酸奶加工工艺研究[J]. 青海畜牧兽医杂志,2022,52(4):23−27. [WU Haiyue, ZHANG Yan. Study on processing technology of Pu'er tea yak yogurt[J]. Qinghai Journal of Animal Husbandry and Veterinary,2022,52(4):23−27.] WU Haiyue, ZHANG Yan. Study on processing technology of Pu'er tea yak yogurt[J]. Qinghai Journal of Animal Husbandry and Veterinary, 2022, 52(4): 23−27.

[17] 杨洁, 薛建岗, 陈永福, 等. 西藏地区两种传统发酵乳的氨基酸含量分析[J]. 中国奶牛,2013(8):50−53. [YANG Jie, XUE Jiangang, CHEN Yongfu, et al. Analysis of amino acid content of two traditional fermented milk in Tibet[J]. China Dairy Cattle,2013(8):50−53.] YANG Jie, XUE Jiangang, CHEN Yongfu, et al. Analysis of amino acid content of two traditional fermented milk in Tibet[J]. China Dairy Cattle, 2013(8): 50−53.

[18] 于素素, 杨佳杰, 马向阳, 等. 含发酵乳杆菌HY01牦牛酸奶工艺优化及主体风味成分动态解析[J]. 食品科学,2021,42(2):105−113. [YU Susu, YANG Jiajie, MA Xiangyang, et al. Process optimization and dynamic analysis of main flavor components of yak yogurt containing Lactobacillus fermentum HY01[J]. Food Science,2021,42(2):105−113.] doi: 10.7506/spkx1002-6630-20191104-025 YU Susu, YANG Jiajie, MA Xiangyang, et al. Process optimization and dynamic analysis of main flavor components of yak yogurt containing Lactobacillus fermentum HY01[J]. Food Science, 2021, 42(2): 105−113. doi: 10.7506/spkx1002-6630-20191104-025

[19] 国家卫生和计划生育委员会. GB 5009.239-2016 食品酸度的测定[S]. 北京:中国标准出版社, 2016:3−8. [National Health and Family Planning Commission. GB 5009.239-2016 Determination of food acidity[S]. Beijing:China Standard Press, 2016:3−8.] National Health and Family Planning Commission. GB 5009.239-2016 Determination of food acidity[S]. Beijing: China Standard Press, 2016: 3−8.

[20] 王雪杭, 李瑞东, 蒋云龙, 等. 植物乳杆菌胞外多糖协同鱼明胶改善低脂酸奶品质特性[J]. 食品科学,2023,44(10):73−81. [WANG Xuehang, LI Ruidong, JIANG Yunlong, et al. Lactobacillus plantarum extracellular polysaccharide synergises with fish gelatin to improve the quality characteristics of low-fat yoghurt[J]. Food Science,2023,44(10):73−81.] WANG Xuehang, LI Ruidong, JIANG Yunlong, et al. Lactobacillus plantarum extracellular polysaccharide synergises with fish gelatin to improve the quality characteristics of low-fat yoghurt[J]. Food Science, 2023, 44(10): 73−81.

[21] 苏日娜. 藏药高原荨麻降尿酸、抗良性前列腺增生物质基础及作用机制研究[D]. 南昌:江西中医药大学, 2019. [SU Rina. Study on the material basis and mechanism of reducing uric acid and anti-benign prostatic hyperplasia of Tibetan medicine plateau nettle[D]. Nanchang:Jiangxi University of Traditional Chinese Medicine, 2019.] SU Rina. Study on the material basis and mechanism of reducing uric acid and anti-benign prostatic hyperplasia of Tibetan medicine plateau nettle[D]. Nanchang: Jiangxi University of Traditional Chinese Medicine, 2019.

[22] 于茜, 李理. Alcalase蛋白酶及碳源对大豆酸奶流变学特性的影响[J]. 食品与机械,2014,30(4):21−23,29. [YU Qian, LI Li. Effects of Alcalase protease and carbon source on the rheological properties of soybean yogurt[J]. Food and Machinery,2014,30(4):21−23,29.] YU Qian, LI Li. Effects of Alcalase protease and carbon source on the rheological properties of soybean yogurt[J]. Food and Machinery, 2014, 30(4): 21−23,29.

[23] 罗湘蓉, 黄宝莹, 范安妮, 等. 草莓香精对发酵乳品质的影响[J]. 现代食品,2018(2):117−120. [LUO Xiangrong, HUANG Baoying, FAN Anni, et al. The effect of strawberry flavor on the quality of fermented milk[J]. Modern Food,2018(2):117−120.] LUO Xiangrong, HUANG Baoying, FAN Anni, et al. The effect of strawberry flavor on the quality of fermented milk[J]. Modern Food, 2018(2): 117−120.

[24] 李安, 邢军, 马龙, 等. GC-MS比较三种发酵乳的挥发性化合物[J]. 中国乳品工业,2020,48(2):12−17. [LI An, XING Jun, MA Long, et al. GC-MS comparison of volatile compounds in three fermented milks[J]. China Dairy Industry,2020,48(2):12−17.] LI An, XING Jun, MA Long, et al. GC-MS comparison of volatile compounds in three fermented milks[J]. China Dairy Industry, 2020, 48(2): 12−17.

[25] LU Lianghua, LIU Tiantian, LIU Xiaoling, et al. Screening and identification of purine degrading Lactobacillus fermentum 9-4 from Chinese fermented rice-flour noodles[J]. Food Science and Human Wellness,2022,11(5):1402−1408. doi: 10.1016/j.fshw.2022.04.030

[26] WANG J, GUO Z, ZHANG Q, et al. Effect of probiotic Lactobacillus casei Zhang on fermentation characteristics of set yogurt[J]. International Journal of Dairy Technology,2010,63(1):105−112. doi: 10.1111/j.1471-0307.2009.00556.x

[27] 邱爽, 宋铮, 张璟琳, 等. 细菌素bifidocin A对凝固型发酵乳品质及贮藏性能的影响[J]. 中国食品学报,2020,20(9):156−165. [QIU Shuang, SONG Zheng, ZHANG Jinglin, et al. The effect of bifidocin A on the quality and storage performance of coagulated fermented milk[J]. Journal of Chinese Institute of Food Science and Technology,2020,20(9):156−165.] QIU Shuang, SONG Zheng, ZHANG Jinglin, et al. The effect of bifidocin A on the quality and storage performance of coagulated fermented milk[J]. Journal of Chinese Institute of Food Science and Technology, 2020, 20(9): 156−165.

[28] 崔斐. 甘蔗酸奶加工工艺及其品质研究[D]. 南宁:广西大学, 2021:48. [CUI Fei. Study on the processing technology and quality of sugarcane yogurt[D]. Nanning:Guangxi University, 2021:48.] CUI Fei. Study on the processing technology and quality of sugarcane yogurt[D]. Nanning: Guangxi University, 2021: 48.

[29] 刘文星, 刘忠义, 惠丹阳, 等. 低温贮藏时间对黄浆水酸奶稳定性的影响[J]. 西北农林科技大学学报(自然科学版),2023,51(3):132−142. [LIU Wenxing, LIU Zhongyi, HUI Danyang, et al. The effect of low temperature storage time on the stability of yellow syrup yoghurt[J]. Journal of Northwest A & F University (Natural Science Edition),2023,51(3):132−142.] LIU Wenxing, LIU Zhongyi, HUI Danyang, et al. The effect of low temperature storage time on the stability of yellow syrup yoghurt[J]. Journal of Northwest A & F University (Natural Science Edition), 2023, 51(3): 132−142.

[30] 崔方超, 韩瑜娟, 李婷婷, 等. 乳酸菌代谢物中黄嘌呤氧化酶抑制剂的筛选[J]. 中国食品学报,2022,22(8):11−21. [CUI Fangchao, HAN Yujuan, LI Tingting, et al. Screening of xanthine oxidase inhibitors in lactic acid bacteria metabolites[J]. Journal of Chinese Institute of Food Science and Technology,2022,22(8):11−21.] CUI Fangchao, HAN Yujuan, LI Tingting, et al. Screening of xanthine oxidase inhibitors in lactic acid bacteria metabolites[J]. Journal of Chinese Institute of Food Science and Technology, 2022, 22(8): 11−21.

[31] 王鑫磊, 王萌, 闫春晓, 等. 马乳酒样乳杆菌ZW3对酸奶风味及质构的影响[J]. 食品科学,2022,43(10):119−123. [WANG Xinlei, WANG Meng, YAN Chunxiao. Effects of Lactobacillus kefiranofaciens ZW3 on flavor and texture of yogurt[J]. Food Science,2022,43(10):119−123.] WANG Xinlei, WANG Meng, YAN Chunxiao. Effects of Lactobacillus kefiranofaciens ZW3 on flavor and texture of yogurt[J]. Food Science, 2022, 43(10): 119−123.

[32] XU Y, ZHAO J, LIU X, et al. Flavor mystery of Chinese traditional fermented Baijiu:The great contribution of ester compounds[J]. Food Chem,2022,369:130920. doi: 10.1016/j.foodchem.2021.130920

[33] 鲍忠定. 吹扫捕集-GC/MS法测定不同酒龄绍兴酒中挥发性化合物[D]. 杭州:浙江工业大学, 2008. [BAO Zhongding. Determination of volatile compounds in Shaoxing wine of different ages by purge and Trap-GC/MS[D]. Hangzhou:Zhejiang University of Technology, 2008.] BAO Zhongding. Determination of volatile compounds in Shaoxing wine of different ages by purge and Trap-GC/MS[D]. Hangzhou: Zhejiang University of Technology, 2008.

[34] 尤宇漫, 徐岩, 范文来, 等. 金种子馥合香白酒香气成分分析[J]. 食品与发酵工业,2023,49(9):291−297. [YU Y M, XU Y, FAN W L, et al. Analysis of the aroma composition of Jinshi Fuhixiang liquor[J]. Food and Fermentation Industries,2023,49(9):291−297.] YU Y M, XU Y, FAN W L, et al. Analysis of the aroma composition of Jinshi Fuhixiang liquor[J]. Food and Fermentation Industries, 2023, 49(9): 291−297.

[35] 方颂平, 刘飞翔, 邢爽, 等. 白酒饮后舒适度评价及其与主要风味成分相关性分析[J]. 食品科学技术学报,2024,42(3):70−80. [FANG Songping, LIU Feixiang, XING Shuang, et al. Evaluation of post-drinking comfort of white wine and its correlation analysis with main flavor components[J]. Journal of Food Science and Technology,2024,42(3):70−80.] FANG Songping, LIU Feixiang, XING Shuang, et al. Evaluation of post-drinking comfort of white wine and its correlation analysis with main flavor components[J]. Journal of Food Science and Technology, 2024, 42(3): 70−80.

[36] CHUA J Y, LIU S Q. Effect of single amino acid addition on growth kinetics and flavor modulation by Torulaspora delbrueckii in soy (tofu) whey alcoholic beverage fermentation[J]. Food Research International,2020,135:109283. doi: 10.1016/j.foodres.2020.109283

[37] TIAN H X, SHI Y H, ZHANG Y, et al. Screening of aroma-producing lactic acid bacteria and their application in improving the aromatic profile of yogurt[J]. Food Biochem, 2019, 43(10): e12837

[38] 杨镰, 王天杨, 吴宝珠, 等. 基于GC-IMS结合多元统计模型分析不同酵母菌发酵对豆汤酱挥发性化合物的影响[J]. 食品工业科技,2024,45(14):282−289. [YANG Xian, WANG Tianyang, WU Baozhu, et al. Analysis of the effect of different yeast fermentation on volatile compounds in bean soup sauce based on GC-IMS combined with multivariate statistical modeling[J]. Science and Technology of Food Industry,2024,45(14):282−289.] YANG Xian, WANG Tianyang, WU Baozhu, et al. Analysis of the effect of different yeast fermentation on volatile compounds in bean soup sauce based on GC-IMS combined with multivariate statistical modeling[J]. Science and Technology of Food Industry, 2024, 45(14): 282−289.

[39] 贺子玉, 何心, 胡楠, 等. 发酵辣椒中的微生物及其风味物质研究进展[J]. 现代食品科技,2023,39(8):334−342. [HE Ziyu, HE Xin, HU Nan, et al. Progress of research on microorganisms and their flavour substances in fermented chilli peppers[J]. Modern Food Science and Technology,2023,39(8):334−342.] HE Ziyu, HE Xin, HU Nan, et al. Progress of research on microorganisms and their flavour substances in fermented chilli peppers[J]. Modern Food Science and Technology, 2023, 39(8): 334−342.

[40] AL-ATTABI Z, D'ARCY B R, DEETH H C. Volatile sulphur compounds in UHT milk[J]. Critical Reviews in Food Science and Nutrition,2009,49(1):28−47.

[41] KIM Y H, KIM D H, LIM H, et al. The anti-inflammatory effects of methylsulfonylmethane on lipopolysaccharide-induced inflammatory responses in murine macrophages[J]. Biological and Pharmaceutical Bulletin,2009,32(4):651−656. doi: 10.1248/bpb.32.651

[42] KARABAY A Z, AKTAN F, SUNGUROGLU A, et al. Methylsulfonylmethane modulates apoptosis of LPS/IFN-gamma-activated RAW264.7 macrophage-like cells by targeting p53, Bax, Bcl-2, cytochrome c and PARP proteins[J]. Immunopharmacology and Immunotoxicology,2014,36(6):379−389.

[43] 郭丹, 张黎梦, 印遇龙, 等. 二甲基砜的生物学功能及其在宠物营养与食品中的应用[J]. 饲料工业,2023,44(11):87−92. [GUO Dan, ZHANG Limeng, YIN Yulong, et al. Biological function of dimethyl sulfone and its application in pet nutrition and food[J]. Feed Industry,2023,44(11):87−92.] GUO Dan, ZHANG Limeng, YIN Yulong, et al. Biological function of dimethyl sulfone and its application in pet nutrition and food[J]. Feed Industry, 2023, 44(11): 87−92.

[44] 罗晓凤, 李涛, 张亚楠. 顶空固相微萃取-GC/MS法分析栝楼瓤的香气成分[J]. 华西药学杂志,2022,37(6):655−657. [LUO Xiaofeng, LI Tao, ZHANG Yanan. Analysis of aroma components in Trichosanthes kirilowii pulp by headspace solid phase microextraction-GC/MS[J]. West China Journal of Pharmaceutical Sciences,2022,37(6):655−657.] LUO Xiaofeng, LI Tao, ZHANG Yanan. Analysis of aroma components in Trichosanthes kirilowii pulp by headspace solid phase microextraction-GC/MS[J]. West China Journal of Pharmaceutical Sciences, 2022, 37(6): 655−657.

[45] 贺红军, 邹慧, 孙宁, 等. 紫薯酸奶和普通酸奶挥发性风味物质差异性研究[J]. 现代食品科技,2014,30(8):225−230. [HE Hongjun, ZOU Hui, SUN Ning, et al. Study on the difference of volatile flavor substances between purple sweet potato yogurt and ordinary yogurt[J]. Modern Food Science and Technology,2014,30(8):225−230.] HE Hongjun, ZOU Hui, SUN Ning, et al. Study on the difference of volatile flavor substances between purple sweet potato yogurt and ordinary yogurt[J]. Modern Food Science and Technology, 2014, 30(8): 225−230.

[46] 齐琳, 王帅, 苏晨, 等. 乳酸菌发酵核桃酸乳不良气味的形成与分析[J]. 食品科学,2022,43(14):234−241. [QI Lin, WANG Shuai, SU Chen, et al. The formation and analysis of the bad odor of walnut yoghurt fermented by lactic acid bacteria[J]. Food Science,2022,43(14):234−241.] QI Lin, WANG Shuai, SU Chen, et al. The formation and analysis of the bad odor of walnut yoghurt fermented by lactic acid bacteria[J]. Food Science, 2022, 43(14): 234−241.

[47] 李婷, 田佳乐, 刘洋, 等. 基于固相微萃取-气相色谱-质谱与电子鼻技术分析发酵乳中的挥发性风味物质[J]. 食品与发酵工业,2020,46(10):233−241. [LI Ting, TIAN Jiale, LIU Yang, et al. Analysis of volatile flavor compounds in fermented milk based on solid phase microextraction-gas chromatography-mass spectrometry and electronic nose technology[J]. Food and Fermentation Industry,2020,46(10):233−241.] LI Ting, TIAN Jiale, LIU Yang, et al. Analysis of volatile flavor compounds in fermented milk based on solid phase microextraction-gas chromatography-mass spectrometry and electronic nose technology[J]. Food and Fermentation Industry, 2020, 46(10): 233−241.

[48] 马瑞娟, 许英瑞, 薛元泰, 等. 牦牛乳风味物质及影响因素研究进展[J]. 食品工业科技,2020,41(10):363−368. [MA Ruijuan, XU Yingrui, XUE Yuantai, et al. Progress of research on yak milk flavour substances and influencing factors[J]. Science and Technology of Food Industry,2020,41(10):363−368.] MA Ruijuan, XU Yingrui, XUE Yuantai, et al. Progress of research on yak milk flavour substances and influencing factors[J]. Science and Technology of Food Industry, 2020, 41(10): 363−368.

[49] 顾军强, 钟葵, 周素梅, 等. 不同热处理燕麦片风味物质分析[J]. 现代食品科技,2015,31(4):282−288,62. [GU Junqiang, ZHONG Kui, ZHOU Sumei, et al. Analysis of flavor substances of oatmeal with different heat treatments[J]. Modern Food Science and Technology,2015,31(4):282−288,62.] GU Junqiang, ZHONG Kui, ZHOU Sumei, et al. Analysis of flavor substances of oatmeal with different heat treatments[J]. Modern Food Science and Technology, 2015, 31(4): 282−288,62.

[50] 李杰, 张鹏霞, 周健, 等. 传统泡菜中高效降解核苷乳酸菌的筛选及其特性研究[J]. 食品与发酵工业,2024,50(12):227−233. [LI Jie, ZHANG Pengxia, ZHOU Jian, et al. Screening and characterization of efficient nucleoside-degrading lactic acid bacteria in traditional pickles[J]. Food and fermentation industry,2024,50(12):227−233.] LI Jie, ZHANG Pengxia, ZHOU Jian, et al. Screening and characterization of efficient nucleoside-degrading lactic acid bacteria in traditional pickles[J]. Food and fermentation industry, 2024, 50(12): 227−233.

[51] 任宇杰, 单成俊, 王英, 等. 降解嘌呤核苷乳酸菌的筛选及益生特性探索[J]. 微生物学通报,2023,50(2):541−552. [REN Yujie, DAN Chengjun, WANG Ying, et al. Screening of purine nucleoside-degrading lactic acid bacteria and exploration of their probiotic properties[J]. Microbiology China,2023,50(2):541−552.] REN Yujie, DAN Chengjun, WANG Ying, et al. Screening of purine nucleoside-degrading lactic acid bacteria and exploration of their probiotic properties[J]. Microbiology China, 2023, 50(2): 541−552.

[52] 李幸. 冠突散囊菌发酵绿茶莓茶潜在体外降尿酸活性的研究[D]. 长沙:湖南农业大学, 2022. [LI Xing. Study on the potential in vitro uric acid-lowering activity of green tea berry tea fermented with Aspergillus coronarius[D]. Changsha:Hunan Agricultural University, 2022.] LI Xing. Study on the potential in vitro uric acid-lowering activity of green tea berry tea fermented with Aspergillus coronarius[D]. Changsha: Hunan Agricultural University, 2022.

[53] 刘向蕾. 酸奶贮藏期间乳酸菌含量及pH值变化的测定分析[J]. 科技信息, 2009, 310(26):184,186. [LIU Xianglei. Determination and analysis of lactic acid bacteria content and pH value changes during yogurt storage[J]. Science and Technology Information, 2009, 310(26):184,186.] LIU Xianglei. Determination and analysis of lactic acid bacteria content and pH value changes during yogurt storage[J]. Science and Technology Information, 2009, 310(26): 184,186.

下载:

下载:

下载:

下载: