Preparation, Properties and Applications of Pre-gelatinized Starch on Starch Based Foods

-

摘要: 随着改性淀粉的不断发展,人们对改性淀粉的功能特性、安全性和便捷性需求显著提高。预糊化淀粉(pre-gelatinized starch,PGS)是一种由物理方法改性的淀粉,是在淀粉糊化后经快速脱水干燥,而得到的一种无明显结晶的变性淀粉颗粒。PGS具有多孔、氢键断裂结构,具备冷水溶解性好、保水能力强、黏弹性高等优点,应用时冷水即可调成糊,免除了加热糊化的步骤。因此,PGS作为一种性能优良的可降解生物改性原料,在面制品、低温肉制品、调味品及其他休闲淀粉基食品等领域都具有重要的应用价值。本文简要介绍了PGS的定义、制备方法、特性及PGS性能的影响因素,阐述了PGS在淀粉基食品中的应用,并指出了PGS在食品领域未来的研究方向,旨在为推进PGS在食品行业中的应用提供参考。Abstract: With the continuous development of modified starch, people's demand for the functional characteristics, safety, and convenience of modified starch has increased significantly. Pre-gelatinized starch (PGS) is a type of starch modified by physical methods, which is a modified starch particle without obvious crystallization obtained by rapid dehydration and drying after starch gelatinization. PGS has a porous and hydrogen-bonded fracture structure, which has the advantages of good cold water solubility, strong water retention ability and high viscoelasticity. Cold water can be mixed into paste during application, eliminating the step of heating and gelatinization. Therefore, as a biodegradable raw material with excellent performance, PGS has important application value in the fields of flour products, low-temperature meat products, condiments and other leisure starch-based foods. This paper briefly introduces the definition, preparation methods, properties, and influencing factors of PGS performance, focuses on the current application status of PGS in starch-based foods, and points out the future research direction of PGS in the field of food, aiming to provide some references for promoting the application of PGS in the food industry.

-

Keywords:

- pre-gelatinization /

- starch /

- preparation /

- starch-based food /

- application

-

淀粉是由葡萄糖分子聚合而成的一类多糖,是一种最常见的大分子碳水化合物,它作为人类能量的主要来源[1−3]。淀粉主要由支链淀粉和直链淀粉组成,这两种淀粉通过特定的方式排列,形成了部分结晶区,使天然淀粉具有微晶束结构,但这也使得它在冷水中无法溶解,限制了其在食品中的应用[4]。因此,需要通过物理、化学、酶促或多重淀粉修饰改性等方法对淀粉进行改性,从而扩展淀粉在食品领域中的应用[5]。在淀粉的改性方法中,物理方法因其不使用化学试剂、环保、安全及操作简单等优点而备受关注[6]。而预糊化是一种常用的绿色、安全的物理改性方法,可以改善淀粉的特殊性质,尤其是可以提高淀粉在冷水中的溶解度和溶胀能力[7]。目前,预糊化淀粉的研究多集中在淀粉预糊化的方法、预糊化淀粉的结构和淀粉预糊化后性质的改善和其在食品中的应用等方面。例如,Ma等[1]综述了三种常用方法制备的预糊化淀粉的颗粒形貌、晶体结构、水化和糊化性能及其在面粉制品中的应用。Mohammed等[8]综述了天然淀粉的改性形式及其理化性质和结构特征,阐述了天然淀粉经过化学、物理和酶改性后在面条制品中的应用。然而,尚未见预糊化淀粉在淀粉基食品中应用的详细综述报道。因此,本文综述了PGS的形成过程、总结了PGS的制备方法及不同方法的优缺点、归纳了影响PGS的因素、阐述了PGS性质及其在淀粉基食品中的应用,为适合不同淀粉基食品的预糊化淀粉的开发和应用提供参考。

1. 预糊化淀粉

1.1 定义及形成过程

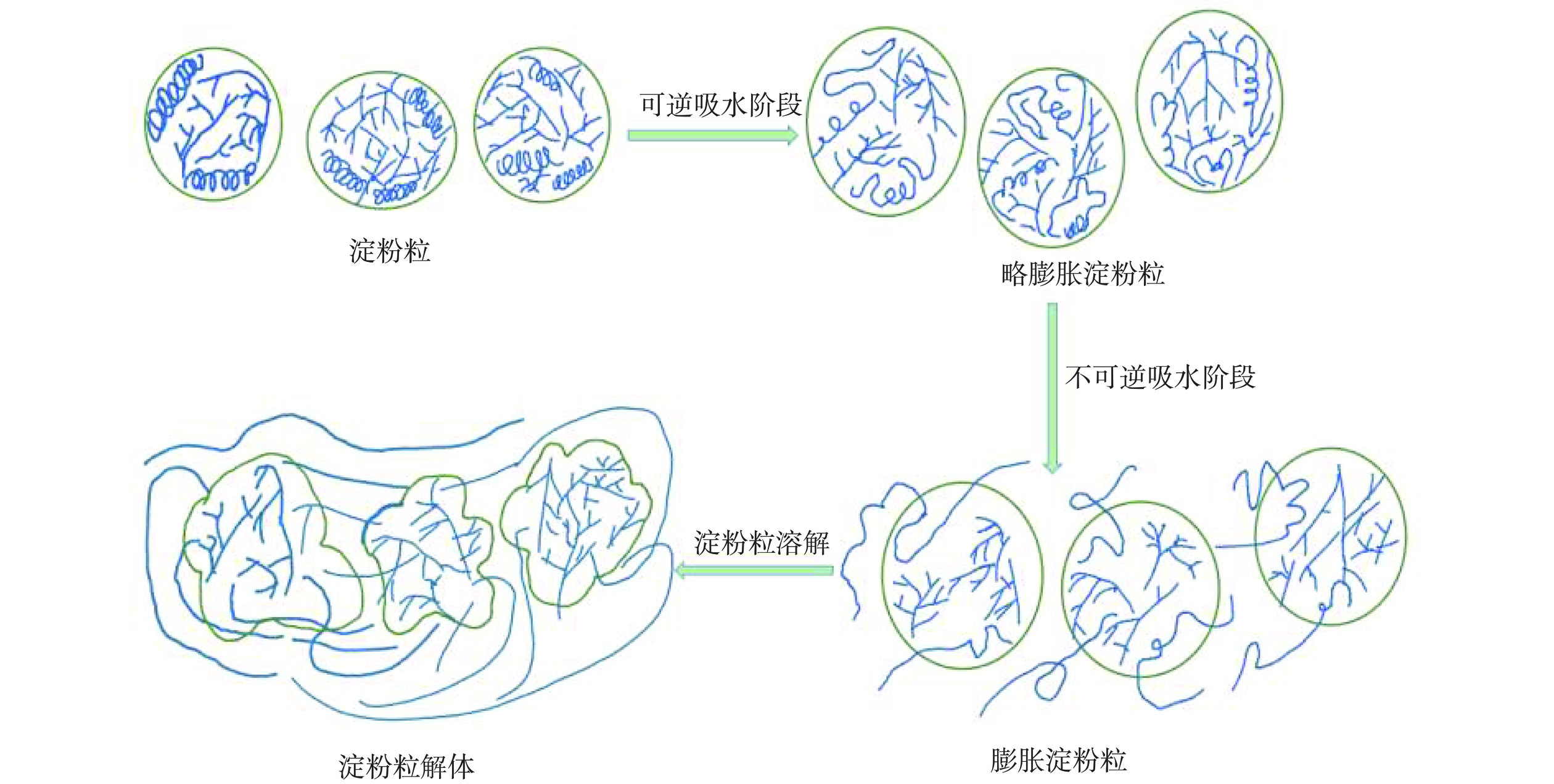

近年来,随着淀粉改性技术的发展,人们对于安全、营养丰富、方便快捷、对环境友好的淀粉改性技术的需求越来越大。天然淀粉的微晶束结构,在冷水中无法溶解,具有较差的吸水性和溶胀性,导致其在食品中的应用范围严重受限[4]。为改善天然淀粉的性质,拓宽其在食品工业中的应用,可对天然淀粉进行预糊化处理。预糊化淀粉是通过加热和机械剪切形成的一种改性淀粉,通过产生的热量达到干燥和研磨的目的,生成具有可冷水溶解、增稠或具有胶凝能力的淀粉[7]。在实际应用过程中,只需用冷水将淀粉调成糊状,因而避免了加热糊化过程中产生的不良影响。而淀粉糊化,就是在一定的温度条件下,淀粉颗粒与水发生溶胀、裂解,最终形成均匀的糊状溶液。在此过程中淀粉颗粒中有序和无序状态的淀粉分子之间发生氢键断裂后逐渐形成胶体[8]。淀粉糊化过程如图1所示,包括可逆吸水、不可逆吸水和淀粉粒溶解三个阶段。在可逆吸水期,水分进入淀粉粒的非晶质部分,使其体积稍微增大,但双折射率未发生改变;在不可逆的吸水期,当温度上升时,水分渗入到淀粉的微晶间隙中,使其不可逆地吸收大量的水分,双折射现象变得模糊不清,直至完全消失,即晶体“溶解”现象,该过程会使淀粉颗粒膨胀到原来的50~100倍[9];淀粉粒解体,淀粉分子全部进入溶液[10]。最后将制备的糊化淀粉浆快速脱水干燥,得到易分散于冷水的预糊化淀粉。

1.2 预糊化淀粉制备方法

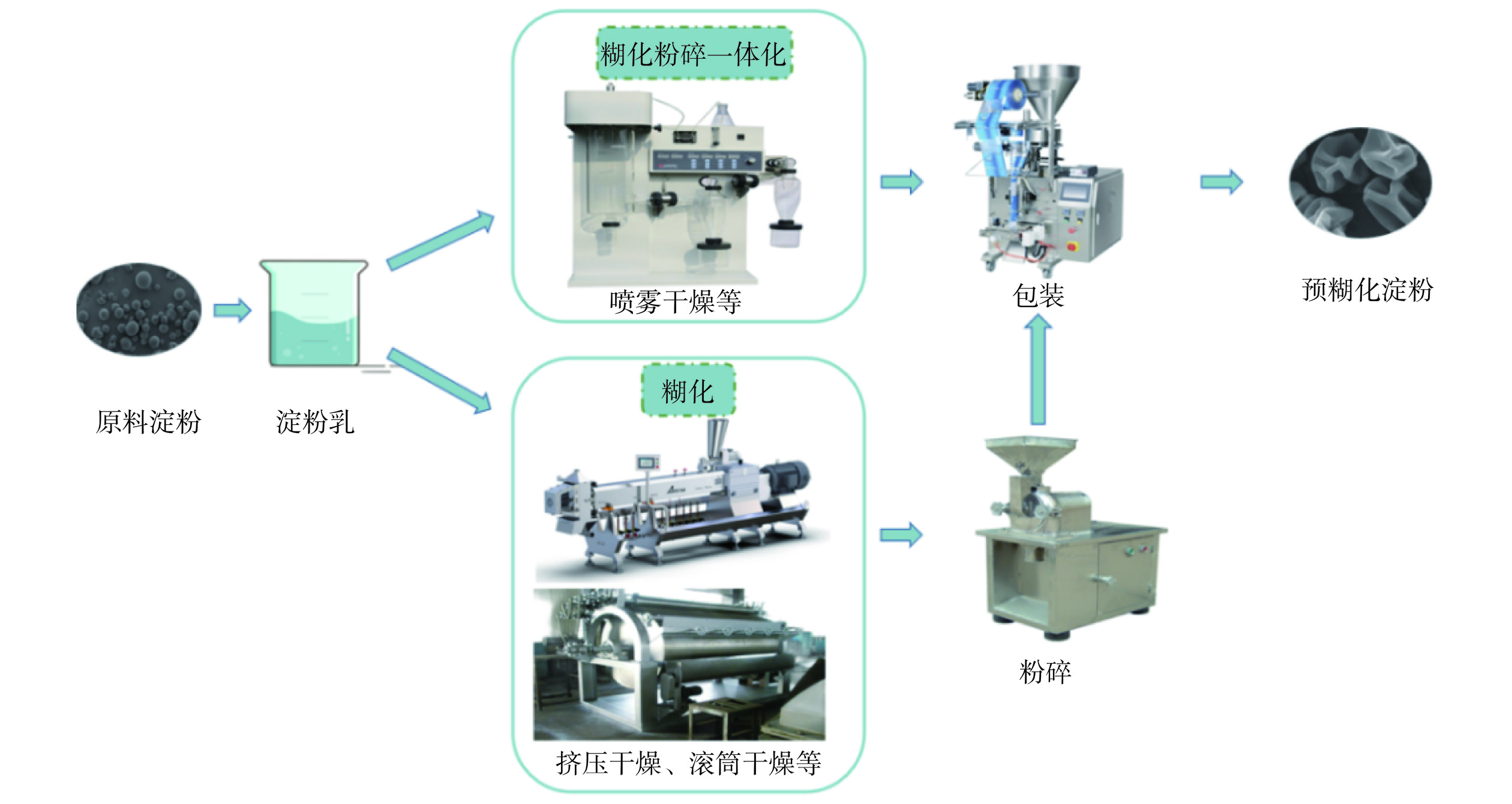

PGS的常用制备方法[8−12]包括喷雾干燥法、挤压干燥法、滚筒干燥法、真空冷冻干燥法等(表1)。预糊化淀粉制备的大致工艺流程如图2所示。

表 1 预糊化淀粉常用方法优缺点Table 1. Advantages and disadvantages of common methods of pre-gelatinized starch方法 优点 缺点 参考文献 喷雾干燥法 干燥过程迅速,可直接干燥成粉末 设备较复杂,占地面积大,投资大 [11,13−16] 易改变干燥条件,调节方便;控制产品的质量指标 雾化器、粉末回收装置价格较高 干燥室有一定负压,保证卫生条件,提高产品纯度 需要空气量多,增加鼓风机的电能消耗与回收装置的容量 生产效率高,操作人员少;生产能力大,产品质量高 热效率不高,热消耗大 滚筒干燥法 生产连续,节约时间 淀粉粒会迅速膨胀到原来体积数百倍 [17−20] 仪器设备操作简单,使用方便 具有强烈的剪切作用,使淀粉颗粒破裂,产品有很大的缺陷 产品质量稳定,不易变质 非完整性颗粒,不能承受使用过程中的剪切力及酸和碱的影响 适应范围广,应用广泛 弹性、流动性较差 挤压干燥法 设备简单,投资少 受高强度剪切力作用,黏度低 [11,17−18,21−22] 动力消耗小 产品几乎没有弹性 生产连续性强 产品质量较差 真空冷冻干燥法 产品呈现疏松多孔,黏度特性接近于原淀粉 价格昂贵,操作复杂 [12,23−24] 具有冷冻稳定,剪切糊化等优势 喷雾干燥法[11]指的是在连续式喷射蒸煮器中,利用高压蒸汽与淀粉乳进行混合,使淀粉糊化,再进行喷雾快速干燥,从而获得预糊化淀粉。Santos等[13]通过喷雾干燥法制备预糊化甘薯淀粉,发现喷雾干燥的淀粉颗粒初始时随着预热温度的升高而膨胀,表现出较大的直径,但在凝结时颗粒收缩,且糊化温度高于天然淀粉,焓变化减小。研究发现,喷雾干燥对淀粉结构、糊化及热特性也有一定的影响。Shang等[14]发现玉米淀粉经喷雾干燥处理后,表观直链淀粉含量和膨胀能力显著增加,粒度明显减小。候丽冉等[15]通过研究发现喷雾干燥降低了紫米粉的结晶度和粒径,进而使样品的峰值黏度及糊化温度均略有升高。综上所述,喷雾干燥法无需进行单独的粉碎工序,即可获得空心球状的淀粉颗粒成品,具有能耗低,进料含水量较少,同时不受剪切和热能的破坏,可以较好地保持淀粉颗粒完整性和产品黏度,产品质量稳定等优点,但成本较高[16]。

滚筒干燥法[17]是将淀粉乳液注入到两个滚筒之间(约150 ℃),乳液迅速糊化形成一层薄膜,用刮刀将其刮下,再将其粉碎后,得到预糊化淀粉。有研究发现[18],滚筒干燥法制备的荞麦淀粉,呈不规则的片状,没有完整的淀粉颗粒,这是因为制备过程的高温导致淀粉降解、分子间氢键断裂和淀粉部分或完全凝胶。同时,高明谦等[19]通过考察滚筒干燥设备的滚筒转速等相关参数对淀粉糊化度和溶解时间的影响,发现由滚筒干燥法制备的淀粉黏度、冻融稳定性、黏结力、耐热及耐剪切性均显著增强。但是生产预糊化淀粉时的生产成本高,能耗大[20]。

挤压干燥法是根据挤压膨化原理制备预糊化淀粉的方法[11,21]。由于在制备过程中不需要加水,能够用内磨擦热维持120~160 ℃的温度,因而在进行干燥时不需要使用其他热源。Han等[18]通过挤压干燥法制备挤压苦荞淀粉,发现低分子量、高黏度的苦荞淀粉可在无谷蛋白苦荞面内形成凝胶网络,对无谷苦荞面的拉伸性能有积极影响。刘云飞[22]通过调节大米淀粉原料的不同水分含量,用挤压干燥技术制备预糊化淀粉,发现可以提高淀粉糊的稳定性,降低短期老化程度,并发现挤压干燥技术可以加快淀粉凝胶网络结构形成的速率,提升了淀粉凝胶的剪切回复能力。因此,挤压干燥法生产预糊化淀粉具有连续性、能耗低、投入低和设备较简单的优点,但最终产品黏度较滚筒干燥法产品低,这可能是因为在挤压过程中机械剪切力造成分子内部糖苷键及其它部分键型断裂所致[17]。

真空冷冻干燥[12]处理后的淀粉疏松多孔,黏度接近于原淀粉,结构稳定,体积变化小,具有良好的冻融稳定性及剪切糊化等优点。薛海等[23]通过该技术制备马铃薯雪花全粉,发现其成品颗粒均一、热稳定性较好,糊化度低,复水性较好。张本山等[24]也发现真空冷冻干燥后的预糊化淀粉疏松多孔,冻融稳定性优异。真空冷冻干燥技术不仅丰富了预糊化淀粉的干燥途径,也为淀粉冻干产品的应用提供了理论基础。此外,除上述4种常见预糊化淀粉制备方法外,还包括微波法[25]、脉冲喷气法[17]、机械活化法[26]、蒸汽升温法[27]、超声辅助法[28]、酶解辅助法[28]等制备方法。

2. 预糊化淀粉的特性

2.1 糊化特性

淀粉在高温下溶胀、分裂形成均匀糊状溶液的特性,称为淀粉的糊化[29]。糊化特性指标包括糊化温度、峰值黏度、崩解值、回生值等,主要用于评价淀粉特性[30]。糊化性能受支链淀粉长度、直链淀粉含量和淀粉粒径的分布的影响[31]。支链淀粉主要负责颗粒膨胀,而直链淀粉和脂质则限制颗粒膨胀。Shen等[32]在研究中,将燕麦淀粉在70 ℃下进行喷雾干燥处理后,暴露于电子束照射下,获得新型预糊化淀粉。研究结果表明喷雾干燥导致淀粉长B3链与分子量的比例降低,显著提高了淀粉的糊化特性。有研究发现,挤压处理对淀粉糊化性能的影响更为显著。这可能是因为挤压干燥处理导致淀粉部分或完全凝胶化,而淀粉易吸收水,在冷水中膨胀得更快[33]。同时,李祉贤等[34]发现预糊化处理能够显著改善葛根淀粉的糊化黏度、凝胶化温度及凝胶化热焓值。研究表明,预糊化甘薯淀粉和木薯淀粉在冷水中黏度略有增加,这可能与预糊化引起不同淀粉晶体结构的不同破坏程度有关[35]。预糊化甘薯淀粉的最终黏度增加,表明处理过程会导致甘薯淀粉结构发生轻微变化,回生黏度代表谷值黏度与最终黏度之差,反映了冷却阶段黏度的二次增加,这归因于直链与支链淀粉的重排[13]。预糊化淀粉的回生黏度增加,表明更多的直链淀粉分子在加热过程中从膨胀颗粒中浸出,并在冷却过程中重新组合形成网络[35]。

2.2 水合特性

水合特性是淀粉水化性能的一个重要参数[36−37]。研究发现,无定形淀粉链与结晶态淀粉之间的分子间作用力对其有较大影响,这是因为淀粉在预糊化过程中,分子间和分子内氢键的断裂,导致淀粉的晶体结构被破坏,预糊化淀粉与水的结合能力显著增加[38]。有研究者发现,预糊化甘薯淀粉的峰值黏度显著高于天然甘薯淀粉,且在水溶液中的最大溶胀点为最高值,说明预糊化淀粉具有较强的水化性能,这表明经过预糊化处理后,甘薯淀粉分子重新排列,增加了颗粒的保水能力[39]。溶胀能力和溶解度是考察预糊化淀粉水合特性的重要指标。研究发现,预糊化淀粉在冷水中的溶胀能力和溶解度明显高于天然淀粉[39−40]。这可能是因为预糊化过程导致分子内氢键减弱,直链淀粉和支链淀粉分子之间以及支链淀粉链之间的相互作用减少。而键的减弱伴随着次要稳定结构的形成和直链淀粉分子浸出的增加,从而导致淀粉颗粒表面积的增加和水的渗透[41]。因此,预糊化小麦淀粉的溶胀能力和溶解性显著高于原始淀粉,这可能是由于预糊化过程中淀粉颗粒的破坏、结晶度的降低和淀粉分子的降解[6,42]。

2.3 热稳定性

淀粉热稳定性是食品加工的一个重要方面[43]。淀粉是大分子物质,其分散在水介质中属悬浮液水溶胶,是一种典型的热力学不稳定体系,易发生沉降分层。因此,通过预糊化处理淀粉,可以有效提升淀粉的热稳定性,从而使其更好地应用在各类淀粉基食品中。林倩等[44]研究发现糊化处理后淀粉的焓值显著低于未处理的淀粉,这是因为焓能反映糊化过程中双螺旋的解离量和双螺旋的有序性,焓越小,热稳定性越好,表明经过预糊化处理后的淀粉热稳定性得到提升。大米淀粉经预糊化处理后,淀粉颗粒棱角逐渐熔化至融合,说明其热稳定性显著提高[45]。此外,Goel等[46]通过考察预糊化淀粉的烘烤特性,发现其在连续加热和剪切过程中能够保持良好的稳定性,可以更好地应用于荞麦面条等一系类荞麦食品中。Ye等[47]的研究表明,预糊化淀粉在制备过程中,原料水分越高,热稳定性越好。Hu等[48]也发现预糊化处理后的淀粉具有良好的热稳定性,可用于提高面条产品的耐煮性和咀嚼性。

2.4 酸碱稳定性

淀粉的酸碱稳定性是影响淀粉性质的重要因素,淀粉在不同pH下的水相互作用的差异与碱和酸对淀粉分子行为的不同影响有关[4]。酸碱稳定性弱,不利于预糊化淀粉的在食品加工方面的应用。由于碱性条件会影响淀粉分子在溶液中的结构和物理行为,破坏淀粉的分子间氢键,增强水溶性,从而有利于淀粉的溶解。而酸性条件则可以水解糖苷键,裂解直链淀粉分子,增加低分子量链的数量,从而增加水溶性,降低吸水性。这是因为酸性pH引起淀粉链降解,而碱性pH解离淀粉-淀粉相互作用,增加了它们与水分子的相互作用,这些变化导致了样品的物理性质的进一步变化[38,49]。Li等[50]通过研究pH变化对预糊化玉米淀粉物理性能的影响,发现在低pH条件下,预糊化玉米淀粉的吸水性、黏度、凝胶硬度有所改善,在碱性pH条件下连续冻融循环的渗透降低,而酸性pH对这些性能具有相反的影响,说明淀粉在碱性pH下比酸性pH下更稳定。有研究表明不同pH下预糊化的淀粉溶液和凝胶性质,当调整溶液的pH时,发现当pH在5.0~9.0之间时,凝胶性无明显变化;当pH在3.0~5.0时凝胶性显著下降,但当pH大于9.0时,凝胶性显著增加[49,51]。因此,预糊化淀粉在碱性条件下的稳定性高于酸性条件。

2.5 凝胶特性

凝胶性作为淀粉在放置过程中稳定性重要的指标,是限制其应用的关键因素。一定浓度的淀粉在糊化后冷却即可形成具有一定硬度的凝胶,即淀粉乳受热,颗粒溶胀吸收水分破裂,淀粉分子溶解于水而糊化,成糊后具有独特的流变特性,且冷却一定的时间后会失去原本的流动状态形成凝胶,这被称为淀粉的凝胶特性[52]。预糊化淀粉的凝胶特性受很多因素影响,如直链淀粉的含量和长短、温度、浓度等因素[53]。Onyango等[54]发现不同浓度预糊化淀粉在冷水中能迅速膨胀,黏度大,可以使食物具有理想的质地特性。通常情况下,存放过程中用上清液的体积百分数来衡量淀粉的凝胶性大小,上清液越多凝胶性就越强。王宏伟等[55]通过研究预糊化处理对糯米粉糊化、流变及微观结构的影响发现,预糊化淀粉的添加有助于糯米粉颗粒表面结构的致密化,有助于复合体系链结构重组形成有序化程度较高的结晶结构,表明预糊化淀粉的添加能够显著提高糯米粉糊的凝胶特性。

3. 预糊化淀粉性能的影响因素

3.1 原料

原淀粉材料不同,淀粉中直链淀粉与支链淀粉的比例就不同,对预糊化淀粉性能有较大的影响[56−57]。原料的生长的气候、土壤、储存条件等都会使淀粉的结构和性质发生变化,从而导致预糊化淀粉的性能也发生变化[58]。在昼夜温差大的环境中生长的植物淀粉颗粒尺寸大,相对分子量高,制备出来的预糊化淀粉黏弹性高;原料越新鲜、储藏时间越短,得到的预糊化淀粉品质越好。Jiranuntakul等[59]对不同晶型的淀粉进行热处理,以大米淀粉、马铃薯淀粉和玉米淀粉为原料,发现其结构和性质会发生不一样的变化。Nakorn等[60]研究直链淀粉含量不同的预糊化米淀粉的结晶度和流变性能,发现直链淀粉含量高的原料,预糊化淀粉的黏弹性越好。因此,原料是影响预糊化淀粉性能的重要因素。

3.2 加工方法

不同加工方法中,滚筒转速、浆液浓度、进料量、干燥温度和添加剂等因素都影响预糊化淀粉的性能[19−28]。提高浆液浓度,产品糊化度会下降;浆膜过厚,糊化较难且不均匀,易出现夹心现象。当产量一定时,干燥温度越高,产品的糊化度就越高[29]。Alamilla等[61]通过研究三个温度下喷雾干燥过程中颗粒形态变化,发现颗粒的大小和形状随着干燥过程而变化,这些变化与原料的含水量和干燥温度有关。在低温下,最终产物的尺寸最小(12 μm),而在中温和高温干燥中,颗粒的平均直径分别为32 μm和37 μm。在较低温度下时,会有较大程度的收缩率,且平均粒径通常比在较高温度下的低。这是由于在低温干燥下水的扩散较高温干燥慢,淀粉结构有更多的时间收缩。低温干燥下形成塌陷的颗粒,而高温干燥时形成刚性颗粒,这与高温快速蒸发和颗粒的高压有关。

3.3 颗粒形状大小

预糊化淀粉颗粒形状和大小对预糊化的性能也存在一定的影响,颗粒大则易于糊化[62]。随着预糊化的进行,最外层的水分迅速蒸发,使颗粒表面出现轻微凹陷和褶皱现象,淀粉颗粒的形状逐渐趋于椭圆形,部分淀粉大颗粒的体积缩小,颗粒表面变得越来越凹陷,并发生萎缩现象[63]。这是因为预糊化过程中,随着加热温度的升高,淀粉颗粒吸收了大量的水,导致淀粉颗粒更显著的膨胀,内部结构的分解,致使预糊化后淀粉颗粒的体积显著收缩[58]。若产品是中空球状或片状结构,则具有较高的冷糊黏度和较低的热糊黏度,感官色泽好,复水速度快,但容易聚集成团状,分散不均;若产品是类球状或立方体,性质则和中空球状或片状的淀粉性质相反,其平均粒径小于天然淀粉,而其球形颗粒可以提高流动性[63]。

3.4 其他

为了满足不同的生产需求,淀粉在糊化时可以加一些添加剂来改变预糊化淀粉的性能[56,64]。如加入盐溶离子可以明显提高淀粉的溶解度,有利于淀粉分子糊化,促进体积膨胀,减少反应需要的能量。加入一些添加剂有助于进一步提高预糊化淀粉性能,NaHCO3、NaOH能降低淀粉聚合度从而使淀粉易于糊化,单硬脂酸甘油酯等能与直链淀粉的螺旋环嵌合而抑制淀粉老化,也有利于淀粉糊化[56]。此外,蛋白质、糖、脂肪等其他物质存在时也会对预糊化淀粉的性能产生影响。

4. 预糊化淀粉在淀粉基食品中的应用

4.1 预糊化淀粉在面制品中的应用

面制品指的是以小麦面粉为主要原料,以糖类、油脂等为辅料所制作出来的食品,碳水化合物是其中含量最高的化学成分,约占总质量的75%[65]。由于传统面制品存在口感、凝胶性、流变性和保水性较差等问题,而预糊化淀粉具有良好的冷水黏度和吸水指数,可以增加组分间的黏附性,促进了面筋网络的扩展,从而提高了面团的抗拉强度和成形性[66]。马宁等[67]探究猴头菇-青稞预糊化粉的不同添加比例对桃酥品质的影响时发现预糊化淀粉的糊化温度降低,具有更低的回生值与衰减值,还具有更好的稳定性。因此,将面制品中的淀粉进行预糊化处理,可以有效改善面制品的品质。冷冻面团温度波动引起的冰晶重结晶在冷冻储存过程中破坏酵母细胞,导致面制品解冻后发酵能力降低,而预糊化淀粉可吸水,在冷水中膨胀形成凝胶,可在酵母细胞表面形成保护层,为酵母细胞提供提高发酵能力的碳源[68]。Li等[69]研究了预糊化淀粉对冷冻馒头面团品质的影响,研究结果表明,预糊化淀粉可以显著提高馒头的比容积,降低馒头的硬度。此外,由于预糊化淀粉具有较好的保水能力,非常适用于生产老年人和儿童的高水分面粉产品[70],同时,其高效的吸水性可以改善体系的产气能力。因此,将其应用在烘焙食品中可获得更加酥软的食品。研究发现,在面条制作过程中添加预糊化玉米淀粉可高达15%,使其具有高质量和可接受的感官性能[70]。使用预糊化淀粉制备的面包比天然淀粉制备的面包外观更光滑,面包屑结构更均匀。随着温度的升高,淀粉的损伤越大,面包的表面积越大,这有利于促进其在面制品中的应用[66]。

4.2 预糊化淀粉在低温肉制品中的应用

肉制品是人类膳食中不可或缺的优质蛋白质来源,它拥有良好的组织状态,又以营养丰富、风味独特以及使用方便而受到人们的青睐[39]。低温肉制品[71]指的是在常压下,通过蒸、煮、熏、烤等热杀菌工艺,使肉制品的中心温度达到68~72 ℃,并维持一定的时间,从而得到的产品。随着肉类产业结构的调整,大中城市冷链系统的不断完善,人民生活水平的不断提高,低温肉制品逐渐得到了迅速发展[72]。

低温肉制品的加工品质如蒸煮损失率、持水性、持油性、质构特性、感官品质等,受机械处理的影响,此外,低温肉制品也受原辅料种类及品质特性的影响,主要包括肌肉蛋白种类、原料肉僵直状态、亲水胶体、非肉蛋白和淀粉类等[71]。Tindy等[73]研究发现,预糊化淀粉的加入可以提高低温肉制品的风味、颜色、质地等特性,还可以降低热量和蒸煮损失,使颜色稳定,改善感官、流变学和纹理相关参数。有研究者指出,预糊化淀粉可以提高低温肉制品的质量和可接受性,增强冻融稳定性,结合水含量升高,增加体积、提高切片能力以及延长保质期等,而且还可以降低生产成本[74]。因此,预糊化淀粉的使用可以有效延长低温肉制品的保质期和提高感官特性[75],为淀粉在肉类产品中的应用创造了新的可能性。

4.3 预糊化淀粉在调味品中的应用

调味品是指能调节食品风味的物质,具有使用方便、改善食品状态的特点[76]。目前,常见的调味品有色拉酱、酱油和卡仕达酱等,它们的组分更为复杂,往往在加工过程中经过长时间剪切或高温处理,导致黏度显著下降,严重影响产品品质,降低消费者的感官和使用体验[77−78]。预糊化淀粉由于具备抗剪切能力好、不易老化、透明度高等优点可以很好地解决上述问题。有研究发现[79]在色拉酱中加入羟丙基二淀粉磷酸酯使淀粉预糊化,对其黏度、烘焙性能、低温稳定性和感官等的研究,结果发现,当预糊化淀粉添加量较少的时候,它的状态偏稀,容易分散,保型性不好,随着添加量的增加,色拉酱的烘焙性能和低温稳定性会显著提高,效果也会更显著。在添加量为4.5%的时候,可以达到较好的保型性和稳定性,并且感官评分最高。张洪微等[80]以多孔玉米淀粉为原料,采用喷雾干燥技术制备粉末酱油,经对照分析可知,通过喷雾干燥制备的预糊化淀粉,应用在酱油中较好地保存了原酱油的风味。张淑芬等[81]以蜡质玉米淀粉为原料,通过滚筒干燥法制备预糊化淀粉应用于卡仕达酱中,结果表明,预糊化淀粉可提高卡仕达酱的耐焙烤能力,特别适合应用于冷加工卡仕达酱制品中。综上所述,在调味品中添加预糊化淀粉,不仅可提高其质地、感官质量,降低其制作成本,且可以改善调味品的质量及储藏性能。

4.4 预糊化淀粉在休闲淀粉基食品中的应用

预糊化淀粉不仅应用在面制品、低温肉制品和调味品中,在裹衣花生、米发糕、冲调米粉等其他淀粉基休闲食品中均有应用。黄亚明等[82]采用预糊化淀粉制备裹衣花生,研究结果表明,使用预糊化淀粉可使花生的香味浓郁醇厚,更加酥脆可口,预糊化淀粉的吸水性较强,因此在裹衣中作为黏合剂,减少糖分的摄入。高水分损失被认为是微波烘焙食品快速老化的一个重要原因[83]。添加预糊化的木薯淀粉可以减少微波烘焙蛋糕在烘烤和储存过程中的失水量,并有效延缓微波烘焙蛋糕的老化。吴宗帅等[84]研究了预糊化淀粉对米发糕质量的影响,实验结果显示,预糊化淀粉可以明显改善米发糕的比容、弹性和组织结构,并对其老化有很好的抑制作用。王宏伟等[55]将预糊化淀粉以不同的比例(0%~8%)分别加入到糯米粉中,对预糊化淀粉-糯米粉复合体系的糊化、流变特性进行了测试,并对其微观结构进行了分析。实验结果显示:在糯米粉复合体系中,加入预糊化淀粉可以使其峰值黏度、回生值及弹性得到明显提升。并且,随着添加量的增加,其凝胶结构特性变化更加明显。Fernanda等[85]研究水分和挤压温度对含木薯淀粉食品膨胀和颜色的影响,发现预糊化木薯淀粉具有高吸收率、在水中的溶解度和吸油性较好。邵子晗等[86]对碎米淀粉进行预糊化处理后通过滚筒干燥法制备成即食冲调米粉,结果表明,预糊化处理后的米粉冲调特性和消化性质得到显著改善。Bortnowska等[87]研究了预糊化蜡质玉米淀粉浓度对以干鸡蛋黄和酪蛋白酸钠制备的低脂水包油乳状液的理化性质和稳定性的影响,得到该预糊化淀粉可用于低脂健康食品乳液的开发的结论。

预糊化淀粉对淀粉基食品具有改善口感、保鲜品质等作用,而且预糊化淀粉具有可再生特性,价格低廉,拥有很好的市场前景。

5. 结论与展望

预糊化淀粉具有多孔、无明显结晶的结构,其制备方法多样,具有绿色环保和使用便捷等优点。预糊化对改善淀粉的结构和功能特性方面效果显著,这对淀粉自身和最终淀粉产品的质量均有显著的影响。与天然淀粉分子相比,预糊化淀粉具有改善的糊化特性、水合特性、热稳定性、酸碱稳定性、凝胶特性等理化特性,在淀粉基食品中具有良好的应用前景。针对各种食品对淀粉性质的需求,制备具有不同特性的预糊化淀粉并应用具有重要意义。

目前对预糊化淀粉的研究多针对其制备工艺及理化性质研究,对预糊化后理化性质变化的机理研究较少。为了更好地发挥预糊化淀粉在淀粉基食品方面的作用,除了需要合理的选用改性淀粉、加强改性淀粉的应用研究之外,还需要探索预糊化淀粉制备方法对理化性质和产品品质影响的机理,以获得预糊化淀粉对产品品质影响的机制。期望在未来的食品行业中,预糊化淀粉的研究可以更加深入,应用更加广泛。

-

表 1 预糊化淀粉常用方法优缺点

Table 1 Advantages and disadvantages of common methods of pre-gelatinized starch

方法 优点 缺点 参考文献 喷雾干燥法 干燥过程迅速,可直接干燥成粉末 设备较复杂,占地面积大,投资大 [11,13−16] 易改变干燥条件,调节方便;控制产品的质量指标 雾化器、粉末回收装置价格较高 干燥室有一定负压,保证卫生条件,提高产品纯度 需要空气量多,增加鼓风机的电能消耗与回收装置的容量 生产效率高,操作人员少;生产能力大,产品质量高 热效率不高,热消耗大 滚筒干燥法 生产连续,节约时间 淀粉粒会迅速膨胀到原来体积数百倍 [17−20] 仪器设备操作简单,使用方便 具有强烈的剪切作用,使淀粉颗粒破裂,产品有很大的缺陷 产品质量稳定,不易变质 非完整性颗粒,不能承受使用过程中的剪切力及酸和碱的影响 适应范围广,应用广泛 弹性、流动性较差 挤压干燥法 设备简单,投资少 受高强度剪切力作用,黏度低 [11,17−18,21−22] 动力消耗小 产品几乎没有弹性 生产连续性强 产品质量较差 真空冷冻干燥法 产品呈现疏松多孔,黏度特性接近于原淀粉 价格昂贵,操作复杂 [12,23−24] 具有冷冻稳定,剪切糊化等优势 -

[1] MA H, LIU M, LIANG Y, et al. Research progress on properties of pre-gelatinized starch and its application in wheat flour products[J]. Grain Oil Science and Technology,2022,5(2):87−97. doi: 10.1016/j.gaost.2022.01.001

[2] LI Y, WANG R, LIANG R, et al. Dynamic high-pressure microfluidization assisting octenyl succinic anhydride modification of rice starch[J]. Carbohydrate Polymers,2018,193:336−342. doi: 10.1016/j.carbpol.2018.03.103

[3] HE H X, XIA W, CHEN R Y, et al. A new pre-gelatinized starch preparing by gelatinization and spray drying of rice starch with hydrocolloids[J]. Carbohydrate Polymers,2020,229:115485. doi: 10.1016/j.carbpol.2019.115485

[4] OGRODOWSKA D, DAMERAU A, BANASZCZYK P, et al. Native and pregelatinized potato and rice starches and maltodextrin as encapsulating agents for linseed oil ethyl esters-Comparison of emulsion and powder properties[J]. Journal of Food Engineering,2024,364:111799. doi: 10.1016/j.jfoodeng.2023.111799

[5] HADIS R, DAGMARA B, ILKEM D, et al. Starch modification through its combination with other molecules:Gums, mucilages, polyphenols and salts[J]. Carbohydrate Polymers,2023,314:120905−120905. doi: 10.1016/j.carbpol.2023.120905

[6] WANG Q F, LI L M, ZHENG X L. A review of milling damaged starch:Generation, measurement, functionality and its effect on starch-based food systems[J]. Food Chemistry,2020,315:126267. doi: 10.1016/j.foodchem.2020.126267

[7] SUI Z Q, KONG X L. Physical modifications of starch[M]. Springer Singapore:Citation Details, 2018.

[8] MOHAMMED O, BIN X. Review on the physicochemical properties, modifications, and applications of starches and its common modified forms used in noodle products[J]. Food Hydrocolloids,2021,112:106286. doi: 10.1016/j.foodhyd.2020.106286

[9] 朱晓康. 预糊化淀粉[J]. 粮食与油脂,1993(2):17−22. [ZHU X K. Pre-gelatinized starch[J]. Cereals & Oils,1993(2):17−22.] ZHU X K. Pre-gelatinized starch[J]. Cereals & Oils, 1993(2): 17−22.

[10] LI Q Q, LIU S Y, OBADI M, et al. The impact of starch degradation induced by pre-gelatinization treatment on the quality of noodles[J]. Food Chemistry,2020,302:125267. doi: 10.1016/j.foodchem.2019.125267

[11] ERICH B M, MONICA R, MIGUEL A, et al. Addition of galactomannans and citric acid in corn starch processed by extrusion:Retrogradation and resistant starch studies[J]. Food Hydrocolloids,2018,83:485−496. doi: 10.1016/j.foodhyd.2018.03.009

[12] 任广跃, 李晖, 段续, 等. 常压冷冻干燥技术在食品中的应用研究[J]. 食品研究与开发,2013,34(18):119−122. [REN G Y, LI H, DUAN X, et al. Study on the application of atmospheric freeze-drying technology in food[J]. Food Research and Development,2013,34(18):119−122.] doi: 10.3969/j.issn.1005-6521.2013.18.030 REN G Y, LI H, DUAN X, et al. Study on the application of atmospheric freeze-drying technology in food[J]. Food Research and Development, 2013, 34(18): 119−122. doi: 10.3969/j.issn.1005-6521.2013.18.030

[13] SANTOS D R P T, FRANCO L M C, LEONEL M. Gelatinized sweet potato starches obtained at different preheating temperatures in a spray dryer[J]. International Journal of Biological Macromolecules,2020,149:1339−1346. doi: 10.1016/j.ijbiomac.2019.11.105

[14] SHANG J Q, HU Z Q, WANG P Z, et al. Effect of operating conditions on structure and digestibility of spray-dried corn starch[J]. Food Research International,2023,174:113511. doi: 10.1016/j.foodres.2023.113511

[15] 侯丽冉, 何萌, 罗芳会, 等. 烘焙和喷雾干燥对紫米粉特性和结构的影响[J]. 食品科技,2020,45(2):177−184. [HOU L R, HE M, LUO F H, et al. Effects of baking and spray drying on the characteristics and structure of purple rice flour[J]. Food Research International,2020,45(2):177−184.] HOU L R, HE M, LUO F H, et al. Effects of baking and spray drying on the characteristics and structure of purple rice flour[J]. Food Research International, 2020, 45(2): 177−184.

[16] 关英伟. 一种预糊化淀粉及其制备方法[P]. 中国:CN103739721B, 2015-02-25. [GUAN Y W. Pregelatinized starch and its preparation method[P]. China:CN103739721B, 2015-02-25.] GUAN Y W. Pregelatinized starch and its preparation method[P]. China: CN103739721B, 2015-02-25.

[17] 曹志强, 曹咏梅, 曹志刚, 等. 预糊化淀粉的研究进展[J]. 大众科技,2016,18(1):31−34. [CAO Z Q, CAO Y M, CAO Z G, et al. The research progress of pre-gelatinized starch[J]. Popular Science Technology,2016,18(1):31−34.] doi: 10.3969/j.issn.1008-1151.2016.01.011 CAO Z Q, CAO Y M, CAO Z G, et al. The research progress of pre-gelatinized starch[J]. Popular Science Technology, 2016, 18(1): 31−34. doi: 10.3969/j.issn.1008-1151.2016.01.011

[18] HAN X M, XING J J, HAN C, et al. The effects of extruded endogenous starch on the processing properties of gluten-free tartary buckwheat noodles[J]. Carbohydrate Polymers,2021,267:118−170.

[19] 高明谦, 吴宗帅, 张永, 等. 改性淀粉在滚筒干燥设备生产中的应用研究[J]. 河南化工,2020,37(6):19−22. [GAO M Q, WU Z S, ZHANG Y, et al. Study on the application of modified starch in the production of drum drying equipment[J]. Henan Chemical Industry,2020,37(6):19−22.] GAO M Q, WU Z S, ZHANG Y, et al. Study on the application of modified starch in the production of drum drying equipment[J]. Henan Chemical Industry, 2020, 37(6): 19−22.

[20] MAJZOOBI1 M, RADI M, FARAHNAKY A, et al. Physicochemical properties of pre-gelatinized wheat starch produced by a twin drum drier[J]. Journal of Animal Science and Technology,2011,13(2):193−202.

[21] SANTOS T, FRANCO C, DEMIATE I M, et al. Spray-drying and extrusion processes:Effects on morphology and physicochemical characteristics of starches isolated from Peruvian carrot and cassava[J]. International Journal of Biological Macromolecules,2018,118:1346−1353. doi: 10.1016/j.ijbiomac.2018.06.070

[22] 刘云飞. 改良挤压技术对大米淀粉结构和性质的影响及其在淀粉基食品中的应用[D]. 南昌:南昌大学, 2020. [LIU Y F. Effect of improved extrusion technology on the structure and properties of rice starch and its application in starch-based food[D]. Nanchang:Nanchang University, 2020.] LIU Y F. Effect of improved extrusion technology on the structure and properties of rice starch and its application in starch-based food[D]. Nanchang: Nanchang University, 2020.

[23] 薛海, 贺阳, 孟祥敏, 等. 马铃薯雪花全粉真空冷冻干燥制备工艺及其性质[J]. 食品工业,2020,41(2):113−117. [XUE H, HE Y, MENG X M, et al. Preparation technology and properties of potato snowflake powder by vacuum freeze-drying[J]. Food Industry,2020,41(2):113−117.] XUE H, HE Y, MENG X M, et al. Preparation technology and properties of potato snowflake powder by vacuum freeze-drying[J]. Food Industry, 2020, 41(2): 113−117.

[24] 张本山, 高凌云, 陈福泉. 冷冻干燥处理后糊化玉米淀粉的性质[J]. 华南理工大学学报(自然科学版),2010,38(8):105−110. [ZHANG B S, GAO L Y, CHEN F Q. Properties of gelatinized corn starch after freeze-drying treatment[J]. J Cent South Univ T (Natural Science Edition),2010,38(8):105−110.] doi: 10.3969/j.issn.1000-565X.2010.08.020 ZHANG B S, GAO L Y, CHEN F Q. Properties of gelatinized corn starch after freeze-drying treatment[J]. J Cent South Univ T (Natural Science Edition), 2010, 38(8): 105−110. doi: 10.3969/j.issn.1000-565X.2010.08.020

[25] JIANG X F, WANG J Y, LI L X, et al. Effect of chlorogenic acid on lotus seed starch gelatinization behavior and complexation mode during microwave treatment[J]. Food Hydrocolloids,2023,144:108925. doi: 10.1016/j.foodhyd.2023.108925

[26] 昝学梅, 刘明, 刘艳香, 等. 酶解辅助预糊化技术工艺优化及风味物质差异分析[J]. 食品工业科技,2021,42(8):19−28. [ZAN X M, LIU M, LIU Y X, et al. Process optimization of enzyme-assisted pregelatinization technology and analysis of flavor substance difference[J]. Science and Technology of Food Industry,2021,42(8):19−28.] ZAN X M, LIU M, LIU Y X, et al. Process optimization of enzyme-assisted pregelatinization technology and analysis of flavor substance difference[J]. Science and Technology of Food Industry, 2021, 42(8): 19−28.

[27] 王记伟, 宁雨奇, 胡华宇, 等. 乙酰化柠檬酸酯化交联机械活化淀粉的制备及性质分析[J]. 现代食品科技,2021,37(4):199−206. [WANG J W, NING Y Q, HU H Y, et al. Preparation of acetylated citric acid esterified and cross-linked mechanically activated starch and the analysis of their properties[J]. Modern Food Science and Technology,2021,37(4):199−206.] WANG J W, NING Y Q, HU H Y, et al. Preparation of acetylated citric acid esterified and cross-linked mechanically activated starch and the analysis of their properties[J]. Modern Food Science and Technology, 2021, 37(4): 199−206.

[28] ABEDI E, MOUSAVIFARD M, POURMOHAMMADI K, et al. Horn ultrasonic-assisted pregelatinized starch with various streamline patterns as a green process:Computational fluid dynamics and microbubble formation of process[J]. Journal of Food Process Engineering,2021,44(3):e13625. doi: 10.1111/jfpe.13625

[29] 黄立兰, 黄广明, 劳晔. 淀粉糊化度测定方法的研究进展[J]. 饲料工业,2014,35(13):53−57. [HUANG L L, HUANG G M, LAO Y. Research progress on determination methods of starch gelatinization degree[J]. Feed Industry,2014,35(13):53−57.] HUANG L L, HUANG G M, LAO Y. Research progress on determination methods of starch gelatinization degree[J]. Feed Industry, 2014, 35(13): 53−57.

[30] 高德荣, 郭文善, 封超年, 等. 小麦淀粉峰值粘度的选择指标[J]. 江苏农业学报,2007(4):371−373. [GAO D R, GUO W S, FENG C N, et al. Selection index of peak viscosity of wheat starch[J]. Jiangsu Journal of Agricultural Sciences,2007(4):371−373.] doi: 10.3969/j.issn.1000-4440.2007.04.022 GAO D R, GUO W S, FENG C N, et al. Selection index of peak viscosity of wheat starch[J]. Jiangsu Journal of Agricultural Sciences, 2007(4): 371−373. doi: 10.3969/j.issn.1000-4440.2007.04.022

[31] SINGH N, KAUR A, SHEVKANI K, et al. Structural, morphological, thermal, and pasting properties of starches from diverse Indian potato cultivars[J]. Starch-Stärke,2018,70:1700130.

[32] SHEN H S, YU J T, BAI J Q, et al. A new pre-gelatinized starch preparing by spray drying and electron beam irradiation of oat starch[J]. Food Chem,2023,398:133938−133938. doi: 10.1016/j.foodchem.2022.133938

[33] XU M, XU Y, JI S, et al. Investigation of the 3D printability of modified starch-based inks and their formation mechanism:Application in ice cream[J]. Food Hydrocolloids,2024,154:110038. doi: 10.1016/j.foodhyd.2024.110038

[34] 李祉贤, 奉思思, 孙佳颖, 等. 高温烘烤对葛根淀粉物化、结构及消化特性的影响[J]. 中国粮油学报,2023,38(10):104−111. [LI Z X, FENG S S, SUN J Y, et al. Effect of high temperature baking on physicochemical, structural and digestive characteristics of Pueraria starch[J]. Journal of the Chinese Cereals and Oils Association,2023,38(10):104−111.] doi: 10.3969/j.issn.1003-0174.2023.10.017 LI Z X, FENG S S, SUN J Y, et al. Effect of high temperature baking on physicochemical, structural and digestive characteristics of Pueraria starch[J]. Journal of the Chinese Cereals and Oils Association, 2023, 38(10): 104−111. doi: 10.3969/j.issn.1003-0174.2023.10.017

[35] DOS SANTOS T P R, FRANCO C M L, DO CARMO E L, et al. Effect of spray-drying and extrusion on physicochemical characteristics of sweet potato starch[J]. International Journal of Food Science and Technology,2019,56:376−383. doi: 10.1007/s13197-018-3498-y

[36] 苏键, 李振玉. 几种不同来源淀粉的水合特性和糊化特性研究[J]. 粮食与油脂,2022,35(8):43−46,56. [SU J, LI Z Y. Study on hydration characteristics and gelatinization characteristics of several starches from different sources[J]. Grain and Oil,2022,35(8):43−46,56.] doi: 10.3969/j.issn.1008-9578.2022.08.011 SU J, LI Z Y. Study on hydration characteristics and gelatinization characteristics of several starches from different sources[J]. Grain and Oil, 2022, 35(8): 43−46,56. doi: 10.3969/j.issn.1008-9578.2022.08.011

[37] 杨世雄, 高飞虎, 张玲, 等. 预糊化淀粉在食品中应用的研究进展[J]. 中国粮油学报,2022,37(8):314−320. [YANG S X, GAO F H, ZHANG L, et al. Research progress on the application of pregelatinized starch in food[J]. Journal of the Chinese Cereals and Oils Association,2022,37(8):314−320.] doi: 10.3969/j.issn.1003-0174.2022.08.043 YANG S X, GAO F H, ZHANG L, et al. Research progress on the application of pregelatinized starch in food[J]. Journal of the Chinese Cereals and Oils Association, 2022, 37(8): 314−320. doi: 10.3969/j.issn.1003-0174.2022.08.043

[38] DANG Y, IMAIZUMI T, NISHIZU T, et al. Effect of the addition of pregelatinized rice starch paste on the retrogradation of rice starch gel[J]. Food Hydrocolloids,2023,145:109159. doi: 10.1016/j.foodhyd.2023.109159

[39] XU F, LIU W, ZHANG L, et al. Thermal, structural, rheological and morphological properties of potato starch-gluten model dough systems:Effect of degree of starch pre-gelatinization[J]. Food Chemistry,2022,396:133628−133628. doi: 10.1016/j.foodchem.2022.133628

[40] IZIDORO R D, SIERAKOWSKI M R, HAMINIUK C W I, et al. Physical and chemical properties of ultrasonically, spray-dried green banana (Musa cavendish) starch[J]. Journal of Food Engineering,2011,104(4):639−648. doi: 10.1016/j.jfoodeng.2011.02.002

[41] LI E P, LÜ J Q, HUO D A, et al. Importance of amylose chain-length distribution in determining starch gelatinization and retrogradation property of wheat flour in the presence of different salts[J]. Carbohydrate Polymers,2023,308:120648−120648. doi: 10.1016/j.carbpol.2023.120648

[42] 刘成梅, 杨晓会, 钟业俊, 等. 韧化及湿热处理对大米淀粉理化特性和微观结构的影响[J]. 食品工业科技, 2016, 37(5):49−53. [LIU C M, YANG X H, ZHONG Y J, et al. Effects of annealing and heat-moisture treatment on the rice starch physicochemical properties and microstructure[J]. Science and Technology of Food Industry, 2016, 37(5):49−53.] LIU C M, YANG X H, ZHONG Y J, et al. Effects of annealing and heat-moisture treatment on the rice starch physicochemical properties and microstructure[J]. Science and Technology of Food Industry, 2016, 37(5): 49−53.

[43] LIU G D, GU Z B, HONG Y, et al. Structure, functionality and applications of debranched starch:A review[J]. Trends in Food Science & Technology,2017,63:70−79.

[44] 林倩, 夏天雨, 江昊. 马铃薯淀粉的微波和射频韧化处理特性研究[J]. 食品与发酵工业,2023,49(10):32−38. [LIN Q, XIA T Y, JIANG H. Study on toughening characteristics of potato starch by microwave and radio frequency[J]. Food and Fermentation Industries,2023,49(10):32−38.] LIN Q, XIA T Y, JIANG H. Study on toughening characteristics of potato starch by microwave and radio frequency[J]. Food and Fermentation Industries, 2023, 49(10): 32−38.

[45] ZHEN W, SEN M, BINGHUA S, et al. Effects of thermal properties and behavior of wheat starch and gluten on their interaction:A review[J]. International Journal of Biological Macromolecules,2021,177:474−484. doi: 10.1016/j.ijbiomac.2021.02.175

[46] GOEL C, SEMWAL A D, KHAN A, et al. Physical modification of starch:Changes in glycemic index, starch fractions, physicochemical and functional properties of heat-moisture treated buckwheat starch[J]. Journal of Food Science and Technology-Mysore,2020,57(8):2941−2948. doi: 10.1007/s13197-020-04326-4

[47] YE J, HU X, ZHANG F, et al. Freeze-thaw stability of rice starch modified by improved extrusion cooking technology[J]. Carbohydrate Polymers,2016,151:113−118. doi: 10.1016/j.carbpol.2016.05.026

[48] HU A, WANG X, LI L, et al. Effects of annealing time on structure and properties of sweet potato starch[J]. Cereal Chemistry,2020,97(3):573−580. doi: 10.1002/cche.10272

[49] JIN J, CHENG L, CHEN C, et al. Synthesis, characterization, and application of starch-based adhesives modified with itaconic acid and N-hydroxyethyl acrylamide[J]. Industrial Crops and Products,2023,196:116524. doi: 10.1016/j.indcrop.2023.116524

[50] LI J, WANG Q, MENG F, et al. Analysis of instability of starch-based Pickering emulsion under acidic condition of pH<4 and improvement of emulsion stability[J]. International Journal of Biological Macromolecules,2024,261:129886. doi: 10.1016/j.ijbiomac.2024.129886

[51] BEMILLER J N. Physical modification of starch[M]. Chapter 5-Physical Modification of Starch, 2018:223−253.

[52] MARTINS L F, EL M L S H, GUERRA R A D, et al. Physical modification of starch by heat-moisture treatment and annealing and their applications:A review[J]. Carbohydrate Polymers,2021,274:118665−118665. doi: 10.1016/j.carbpol.2021.118665

[53] SUGIURA F, ITO S, ARAI E. Effect of pregelatinized starch paste on the ease of swallowing high-moisture content bread[J]. Journal of Food Engineering,2017,214:209−217. doi: 10.1016/j.jfoodeng.2017.06.021

[54] ONYANGO C, MUTUNGI C, UNBEHEND G, et al. Rheological and textural properties of sorghum-based formulations modified with variable amounts of native or pregelatinized cassava starch[J]. LWT-Food Science and Technology,2011,44(3):687−693. doi: 10.1016/j.lwt.2010.08.019

[55] 王宏伟, 王新天, 肖乃勇, 等. 预糊化淀粉对糯米粉糊化、流变性能及微观结构的影响[J]. 中国粮油学报,2019,34(4):57−62. [WANG H W, WANG X T, XIAO N Y, et al. Effect of pre-gelatinized starch on pasting, rheological properites and microstructures of glutinous rice flour[J]. Journal of the Chinese Cereals and Oils Association,2019,34(4):57−62.] doi: 10.3969/j.issn.1003-0174.2019.04.011 WANG H W, WANG X T, XIAO N Y, et al. Effect of pre-gelatinized starch on pasting, rheological properites and microstructures of glutinous rice flour[J]. Journal of the Chinese Cereals and Oils Association, 2019, 34(4): 57−62. doi: 10.3969/j.issn.1003-0174.2019.04.011

[56] 周建芹, 罗发兴. 预糊化淀粉在食品中的应用[J]. 食品工业,2000(3):7−8. [ZHOU J Q, LUO F X. Application of pregelatinized starch in food[J]. Food Industry,2000(3):7−8.] ZHOU J Q, LUO F X. Application of pregelatinized starch in food[J]. Food Industry, 2000(3): 7−8.

[57] RU J, TOYOHIKO K, YASUSHI Y, et al. Sweet potato starch with low pasting temperature to improve the gelling quality of surimi gels after freezing[J]. Food Hydrocolloids,2018,81:467−473. doi: 10.1016/j.foodhyd.2018.03.024

[58] 赵雪莹. 不同水分含量制备所得预糊化大米淀粉性质的比较及在米糕中的应用[D]. 无锡:江南大学, 2022. [ZHAO X Y. Comparison of properties of pregelatinized rice starch prepared with different moisture content and its application in rice cake[D]. Wuxi:Jiangnan University, 2022.] ZHAO X Y. Comparison of properties of pregelatinized rice starch prepared with different moisture content and its application in rice cake[D]. Wuxi: Jiangnan University, 2022.

[59] JIRANUNTAKUL W, PUTTANLEK C, RUNGSARDTHONG V, et al. Microstructural and physicochemical properties of heat-moisture treated waxy and normal starches[J]. Journal of Food Engineering,2011,104(2):246−258. doi: 10.1016/j.jfoodeng.2010.12.016

[60] NAKORN K N, TONGDANG T, SIRIVONGPAISAL P. Crystallinity and rheological properties of pregelatinized rice starches differing in amylose content[J]. Starch-Stärke,2009,61:101−108.

[61] ALAMILLA B L, CHANONA P J J, JIMÉNEZ A A R, et al. Description of morphological changes of particles along spray drying[J]. Journal of Food Engineering,2005,67(1−2):179−184. doi: 10.1016/j.jfoodeng.2004.05.063

[62] YE J P, HU X T, LUO S J, et al. Properties of starch after extrusion:A review[J]. Starch-Stärke,2018,70:11−12.

[63] SANTOS T P R, FRANCO C M L, DOCRAMO E L, et al. Effect of spray drying and extrusion on physicochemical characteristics of sweet potato starch[J]. Food Science and Technology,2019,56:376−383.

[64] 黄来发. 食品增稠剂[M]. 北京:中国轻工业出版社, 2009:342. [HUANG L F. Food thickeners[M]. Beijing:China Light Industry Press, 2009:342.] HUANG L F. Food thickeners[M]. Beijing: China Light Industry Press, 2009: 342.

[65] 马德敏, 孙春芳, 丁四海, 等. 一种应用于重油蛋糕中变性淀粉的研究[J]. 农产品加工,2021(11):13−15. [MA D M, SUN C F, DING S H, et al. Study on modified starch used in heavy oil cake[J]. Farm Product Processing,2021(11):13−15.] MA D M, SUN C F, DING S H, et al. Study on modified starch used in heavy oil cake[J]. Farm Product Processing, 2021(11): 13−15.

[66] MANIGLIA B C, POLACHINI T C, NORWOOD E A, et al. Thermal technologies to enhance starch performance and starchy products[J]. Current Opinion in Food Science,2021,40:72−80. doi: 10.1016/j.cofs.2021.01.005

[67] 马宁, 陈雨婷, 方东路, 等. 猴头菇-青稞预糊化粉的添加对桃酥品质的影响[J]. 食品科学,2020,41(20):46−53. [MA N, CHEN Y T, FANG D L, et al. Effect of adding different amounts of pre-gelatinized highland barley flour supplemented with Hericium erinaceus powder on the quality characteristics of crisp cakes[J]. Food Science,2020,41(20):46−53.] doi: 10.7506/spkx1002-6630-20200507-068 MA N, CHEN Y T, FANG D L, et al. Effect of adding different amounts of pre-gelatinized highland barley flour supplemented with Hericium erinaceus powder on the quality characteristics of crisp cakes[J]. Food Science, 2020, 41(20): 46−53. doi: 10.7506/spkx1002-6630-20200507-068

[68] CARRILLO H N, GUADARRAMA A Y, VERNON E J, et al. Effect of gelatinized flour fraction on thermal and rheological properties of wheat-based dough and bread[J]. International Journal of Food Science and Technology,2016,53:3996−4006. doi: 10.1007/s13197-016-2399-1

[69] LI Y, LI C, BAN X F, et al. New insights into the alleviating role of starch derivatives on dough quality deterioration caused by freeze[J]. Food Chemistry,2021,362:130240−130240. doi: 10.1016/j.foodchem.2021.130240

[70] YOUISF E I, GADALLAH M G E, SOROUR A M. Physico-chemical and rheological properties of modified corn starches and its effect on noodle quality[J]. Annals of Agricultural Science,2012,57:19−27. doi: 10.1016/j.aoas.2012.03.008

[71] 刘欣睿, 孔保华, 夏秀芳, 等. 低温慢煮对肉制品食用品质及货架期影响的研究进展[J]. 肉类研究,2022,36(12):49−56. [LIU X R, KONG B H, XIA X F, et al. Progress in research on the effect of sous-vide on the eating quality and shelf-life of meat products[J]. Meat Res,2022,36(12):49−56.] LIU X R, KONG B H, XIA X F, et al. Progress in research on the effect of sous-vide on the eating quality and shelf-life of meat products[J]. Meat Res, 2022, 36(12): 49−56.

[72] AZAD M A K, DEY M, KHANAM F, et al. Authentication of meat and meat products using molecular assays:A review[J]. Journal of the Science of Food and Agriculture,2023,12:100586.

[73] TINDY R P, ALFIANA A, VITA P, et al. Effect of different starch on the characteristics of edible film as functional packaging in fresh meat or meat products:A review[J]. Mater Today Proc,2023,396(2):192−199.

[74] PATRICK O A, ESTHER K B, ERNEST B, et al. Non-meat ingredients in meat products:A scoping review[J]. Journal of Applied Botany and Food Quality,2022,2(1):100044.

[75] RAMANDEEP K, MINAXI S. Cereal polysaccharides as sources of functional ingredient for reformulation of meat products:A review[J]. Journal of Functional Foods,2019,62(C):103527−103527.

[76] 刘瑞钦, 郑立红. 复合调味料中食品增稠剂——变性淀粉的使用[J]. 中国酿造,2004(2):37−38. [LIU R Q, ZHENG L H. Compound seasoning Chinese food thickener:Use of modified starch[J]. China Brewing,2004(2):37−38.] doi: 10.3969/j.issn.0254-5071.2004.02.014 LIU R Q, ZHENG L H. Compound seasoning Chinese food thickener: Use of modified starch[J]. China Brewing, 2004(2): 37−38. doi: 10.3969/j.issn.0254-5071.2004.02.014

[77] BORTNOWSKA G, BALEJKO J, SCHUBE V, et al. Stability and physicochemical properties of model salad dressings prepared with pregelatinized potato starch[J]. Carbohydrate Polymers,2014,111:624−632. doi: 10.1016/j.carbpol.2014.05.015

[78] 别平平, 陈燕芳, 张子倩, 等. 变性淀粉在调味品中的功用分析[J]. 现代食品,2022,28(15):28−32. [BIE P P, CHEN Y F, ZHANG Z Q, et al. Function analysis of modified starch in condiment[J]. Modern Food,2022,28(15):28−32.] BIE P P, CHEN Y F, ZHANG Z Q, et al. Function analysis of modified starch in condiment[J]. Modern Food, 2022, 28(15): 28−32.

[79] 陈颖娴, 杨菁, 李妙莲. 黄原胶和变性淀粉在焙烤型沙拉酱中的应用研究[J]. 中国食品添加剂,2019,30(6):93−98. [CHEN Y X, YANG J, LI M L. The application of xanthan gum and modified starch on bakery salad dressing[J]. China Food Additives,2019,30(6):93−98.] doi: 10.3969/j.issn.1006-2513.2019.06.012 CHEN Y X, YANG J, LI M L. The application of xanthan gum and modified starch on bakery salad dressing[J]. China Food Additives, 2019, 30(6): 93−98. doi: 10.3969/j.issn.1006-2513.2019.06.012

[80] 张洪微, 崔素萍, 魏文毅, 等. 多孔玉米淀粉制备粉末酱油的研究[J]. 粮油食品科技,2009,17(2):54−56. [ZHANG H W, CUI S P, WEI W Y, et al. Study on preparation of powdered soy sauce from porous corn starch[J]. Science and Technology of Cereals, Oils and Foods,2009,17(2):54−56.] doi: 10.3969/j.issn.1007-7561.2009.02.019 ZHANG H W, CUI S P, WEI W Y, et al. Study on preparation of powdered soy sauce from porous corn starch[J]. Science and Technology of Cereals, Oils and Foods, 2009, 17(2): 54−56. doi: 10.3969/j.issn.1007-7561.2009.02.019

[81] 张淑芬, 吴宗帅, 吴磊, 等. 预糊化变性淀粉的制备及其在卡仕达酱中的应用研究[J]. 食品科技,2017,42(8):278−282. [ZHANG S F, WU Z S, WU L, et al. Preparation of pregelatinized modified starch and application in Custard cream[J]. Food Science and Technology,2017,42(8):278−282.] ZHANG S F, WU Z S, WU L, et al. Preparation of pregelatinized modified starch and application in Custard cream[J]. Food Science and Technology, 2017, 42(8): 278−282.

[82] 黄亚明, 张淑芬, 吴宗帅, 等. 预糊化淀粉在裹衣花生中的应用[J]. 现代食品,2020(7):81−82,86. [HUANG Y M, ZHANG S F, WU Z S, et al. Application of pre-gelatinized starches in coated peanuts[J]. Modern Food,2020(7):81−82,86.] HUANG Y M, ZHANG S F, WU Z S, et al. Application of pre-gelatinized starches in coated peanuts[J]. Modern Food, 2020(7): 81−82,86.

[83] 袁璐, 胡婕伦, 殷军艺. 微波辐射对淀粉结构特性的影响及其在淀粉类食品加工中应用的研究进展[J]. 食品工业科技,2020,41(18):330−337,347. [YUAN L, HU J L, YIN J Y. Progress on the effect of microwave irradiation on structural characteristics of starch and its application in starch derived food processing[J]. Science and Technology of Food Industry,2020,41(18):330−337,347.] YUAN L, HU J L, YIN J Y. Progress on the effect of microwave irradiation on structural characteristics of starch and its application in starch derived food processing[J]. Science and Technology of Food Industry, 2020, 41(18): 330−337,347.

[84] 吴宗帅, 张淑芬, 吴磊, 等. 预糊化改性淀粉对米发糕品质的影响[J]. 中国食品添加剂,2021,32(3):33−39. [WU Z S, ZHANG S F, WU L, et al. Effect of pre-gelatinized modified starch on properties of steamed rice bread[J]. China Food Additives,2021,32(3):33−39.] WU Z S, ZHANG S F, WU L, et al. Effect of pre-gelatinized modified starch on properties of steamed rice bread[J]. China Food Additives, 2021, 32(3): 33−39.

[85] FERNANDA A F, MANOEL S S, FLAVIO A D S, et al. Physical quality of snacks and technological properties of pre-gelatinized flours formulated with cassava starch and dehydrated cassava bagasse as a function of extrusion variables[J]. LWT-Food Science and Technology,2015,62(2):1112−1119. doi: 10.1016/j.lwt.2015.02.030

[86] 邵子晗, 洪莹, 曹磊, 等. 预糊化时间对即食冲调米粉品质的影响[J]. 食品科学,2022,43(4):1−9. [SHAO Z H, HONG Y, CAO L, et al. Effects of pregelatinization time on the quality of instant rice powder[J]. Food Science,2022,43(4):1−9.] SHAO Z H, HONG Y, CAO L, et al. Effects of pregelatinization time on the quality of instant rice powder[J]. Food Science, 2022, 43(4): 1−9.

[87] BORTNOWSKA G, BALEJKO J, TOKARCZYK G, et al. Effects of pregelatinized waxy maize starch on the physicochemical properties and stability of model low-fat oil-in-water food emulsions[J]. Food Hydrocolloids,2014,36:229−237. doi: 10.1016/j.foodhyd.2013.09.012

-

期刊类型引用(2)

1. 程晓,文辉. 淀粉改性及在造纸工业中的应用与研究进展. 造纸科学与技术. 2024(10): 61-66+137 .  百度学术

百度学术

2. 胡方洋,邓健,张得祥,刘彩华,麦馨允,朱正杰. 凯特芒果淀粉的提取及其性质研究. 食品与生物技术学报. 2024(10): 163-172 .  百度学术

百度学术

其他类型引用(4)

下载:

下载:

下载:

下载: