Effect of Different Particle Sizes on Physical and Functional Properties of Walnut Green Husk Powder

-

摘要: 为合理利用核桃青皮资源,探究粉碎处理对核桃青皮粉体的影响,本实验对不同粒径核桃青皮粉的物理特性(粒径分布、填充性、流动性、持水力、持油力、膨胀力和微观结构)及功能特性(活性物质含量、抗氧化能力)进行了研究。结果发现,经过粉碎及过筛处理后,核桃青皮粉粒径具有显著性差异(P<0.05)。核桃青皮粉的松密度、持水力、持油力随粒径的减小不断下降,而休止角和滑动角不断增加,振实密度和膨胀力分别呈现先降低后增加和先增加后降低的趋势,傅里叶红外光谱表明,粉碎过程并未破坏粉体的分子结构;此外,粉碎度为200目的样品提取液的活性物质含量和抗氧化能力显著高于其他样品(P<0.05)。与粉碎度为100目的样品相比,200目样品提取液中总多酚、总黄酮、萜类物质和醌类物质含量分别提高了7.1%、19.5%、16.8%和16.4%。本实验为微粉碎在核桃青皮加工产业的实际应用提供了理论依据。Abstract: To optimize the resource utilization of walnut green husk and investigate the impact of grinding treatment on walnut green husk powder, this experiment was carried out to investigate the physical characteristics (particle size distribution, filling, flowability, water-holding capacity, oil-holding capacity, swelling capacity, and microstructure) and functional characteristics (active substance content, and antioxidant activity) in walnut green husk powders with varying particle sizes. The results demonstrated that the particle size of walnut green husk powder exhibited a significant difference (P<0.05) following grinding and sieving treatment. The bulk density, water-holding capacity and oil-holding capacity of walnut green husk powder exhibited a continuous decrease with decreasing particle size. Conversely, the angle of repose and sliding angle showed an increasing trend. Additionally, the tap density tended to initially decrease and then increase, while the swelling capacity displayed a pattern of first increasing and then decreasing. Fourier infrared spectroscopy analysis revealed no discernible damage to the molecular structure of the powder during the grinding process. In addition, the extract of the sample with 200 mesh showed significantly higher active substance content and antioxidant capacity than the other samples (P<0.05). Compared with the sample with 100 mesh, the contents of total polyphenols, total flavonoids, terpenoids and quinones were increased by 7.1%, 19.5%, 16.8% and 16.4%, respectively. This experiment provides a theoretical basis for the practical application of micro grinding in walnut green husk processing industry.

-

Keywords:

- walnut green husk /

- microcrush /

- particle size /

- powder properties /

- active substances /

- antioxidants

-

核桃(Juglans regia L.)是我国重要的木本油料树种之一,我国核桃的种植面积和产量均居世界首位[1]。核桃青皮又名青龙衣,是核桃未成熟果实的绿色外果皮,最早记载于《开宝本草》,因其味苦、涩,性平,具有清热解毒、止痛止泻、杀虫灭菌等功效,作为中草药应用已有千年的历史[2]。核桃青皮富含多种生物活性物质,如多酚、黄酮、萜类、醌类,这些成分赋予了核桃青皮抑菌消炎、抗氧化、抗肿瘤等多种药理学功能[3]。核桃青皮提取液还被用于食品抗氧化剂、抑菌剂和保鲜剂等[4]。但新鲜的核桃青皮水分含量高,极易腐烂变质,在产区大量的核桃青皮被随意堆放或直接丢弃,造成了极大的资源浪费和环境污染。因此,对核桃青皮进行回收和加工利用,延长其贮藏期尤为重要。

对鲜核桃青皮进行干燥制粉处理是一种切实可行的方法,所得粉体既可以用作中药生药粉、中药固体制剂和中药浸膏粉等[5],还可以用于提取醌类、酮类、萜类、多糖等功能性成分。微粉碎技术是一种近年来发展较快的新型食品加工技术,微粉碎后粉体粒径的减小会促进多糖、多酚和黄酮类化合物的释放,提高粉体颗粒的生物活性,同时还可以改变原材料的物理和化学性质,改善工业生产参数,提高有效成分提取率和应用价值等[6]。目前,微粉碎技术在核桃青皮加工方面的研究未见报道,因此本实验将干燥后的核桃青皮粉碎过筛得到不同粒径的核桃青皮粉,探讨不同粒径核桃青皮粉的物理特性和功能特性,以期为核桃青皮的加工利用提供理论参考。

1. 材料与方法

1.1 材料与仪器

核桃青皮 香玲核桃品种的成熟、绿色外果皮,购于河南省郑州市金水区农贸市场;DPPH(1,1-二苯基-2-三硝基苯肼)、ABTS(2,2-联氮-二(3-乙基-苯并噻唑-6-磺酸)二铵盐) 北京博奥拓达科技有限公司;没食子酸、芦丁、齐墩果酸、胡桃醌 标准品,纯度≥98%,上海源叶生物科技有限公司;大豆油 广东翁江化学试剂有限公司。

FW-200高速万能粉碎机 北京中兴伟业仪器有限公司;LS13320激光粒度分析仪 美国贝克曼库尔特有限公司;Vertex70傅里叶红外光谱仪 德国卡尔斯鲁厄布鲁克分析仪器公司;KQ-700DE数控超声波清洗器 上海佑科仪器有限责任公司;HC-3018R高速冷冻离心机 安徽中科中佳科学仪器有限公司;RE-52AA旋转蒸发仪 上海亚荣生化仪器厂;Tecan Austria GmbH酶标仪 帝肯奥地利有限责任公司;真空脉动干燥机 河南省农业科学院。

1.2 实验方法

1.2.1 核桃青皮粉体的制备

选择无机械损伤和腐烂变质的新鲜核桃青皮作为实验原料。将核桃青皮切块,平铺在干燥盘上,放入真空脉动干燥机中,设定连续干燥程序为75 ℃(3.5 h),65 ℃(5.0 h),55 ℃(1.5 h),将物料干燥至含水率10%以下。冷却后用高速粉碎机进行粉碎,转速为26000 r/min,功率800 W,电压220 V,单次粉碎量为200 g,每粉碎30 s暂停1 min进行粉体散热降温。粉碎后分别过40、60、80、100、200目筛网,样品依次命名为W40、W60、W80、W100和W200。将干燥粉用透明自封袋密封后置于干燥器中保存备用。

1.2.2 粒径大小及分布测定

使用LS13320激光粒度分析仪的干法模块测定核桃青皮粉的粒径,记录D10(颗粒累积分布为10%的粒径)、D50(颗粒累积分布为50%的粒径,又称中位粒径)、D90(颗粒累积分布为90%的粒径)、均值粒径和表面积平均粒径(S.D.),并根据公式(1)计算粒径分布的跨度值(Span)[7]。

Span=D90−D10D50 (1) 1.2.3 松密度和振实密度测定

参照刘文卓等[8]的方法,精确称取10 g(m)不同粒径的核桃青皮粉末,将其通过玻璃漏斗缓缓倒入20 mL量筒内,尽量减少粉体在筒壁的附着,不压实测定粉体所占量筒的体积(v),根据公式(2)计算核桃青皮粉体松密度。

松密度(g/mL)=mv (2) 分别称取不同粒径的核桃青皮粉末各5 g,缓慢倒入10 mL量筒中,小幅均匀振荡至量筒内粉体体积不再变化为止。振实密度为粉体质量除以粉体的最后体积。

1.2.4 休止角和滑动角测定

休止角和滑动角的测定参考李硕等[9]的方法进行。将漏斗固定于铁架台,下放一块水平放置的白纸板,使漏斗尾端与白纸板间的垂直距离为3 cm,将核桃青皮粉末倒入漏斗中,使其在自然状态下形成圆锥体,直到漏斗尾端与形成的圆锥体尖端接触到为止,记录此时圆锥体的高度H和半径R,并根据公式(3)计算休止角α:

α=arctan H/R (3) 称取10 g核桃青皮粉末置于光滑玻璃板中部,缓缓抬起玻璃板的一端至90%以上的粉末滑落,用量角器记录此时玻璃板与水平面的角度,即为滑动角β。

1.2.5 持水力和持油力测定

准确称取核桃青皮粉末0.2 g(m)于10 mL离心管中,加入8 mL蒸馏水,在室温下浸泡24 h后,8000 r/min离心30 min。去除上清液,称量沉淀质量(M)。持水力计算见公式(4):

持水力(g/g)=M−mm (4) 称取3 g(m)核桃青皮粉末于预先干燥的离心管中,称量干燥离心管和样品的总质量(m1),然后加入20 mL大豆油,充分混匀后7000 r/min离心20 min,去除上层油,称量离心管和沉淀的质量(m2),并根据公式(5)计算持油力[10]:

持油力(g/g)=m2−m1m (5) 1.2.6 膨胀力测定

参照赵愉涵等[11]的方法,准确称取2 g(m)核桃青皮粉末置于标有刻度的试管中,记录初始体积(V1)。加入15 mL蒸馏水,振荡混匀后于室温下静置24 h,记录粉末膨胀后的体积(V2)。按照公式(6)计算粉体膨胀力:

膨胀力(mL/g)=V2−V1m (6) 1.2.7 傅里叶红外光谱分析

分别取2 mg不同粒径的核桃青皮粉末与KBr(300 mg)混合,采用固体压片法进行制样[12]。扫描范围为4000~400 cm−1,分辨率为0.16 cm−1。

1.2.8 活性物质含量测定

分别称取1 g不同粒径的核桃青皮粉末与50 mL 75%乙醇溶液混合均匀,在超声功率为490 W、超声温度为60 ℃的条件下提取140 min(此参数条件是基于实验室前期对超声辅助提取活性物质进行优化后所得到的最优提取工艺)。然后将溶液置于离心管中,7000 r/min离心15 min。使用旋转蒸发仪对溶剂进行减压浓缩回收至近乎干燥,得到的混合物干膏加入甲醇溶解并定容至100 mL,作为核桃青皮粉末提取液[13]。采用NaNO2-Al(NO2)3法[14]、香草醛-冰醋酸法[15]、Folinol比色法[16]和分光光度法[17]测定核桃青皮粉末提取液中的总黄酮、萜类、酚类和醌类物质含量。分别以芦丁、齐墩果酸、没食子酸和胡桃醌为标准品,在510、546、760和426 nm处测量吸光度。根据标准品的校准曲线,计算出核桃青皮粉末提取液中各活性物质的含量。

1.2.9 抗氧化能力测定

核桃青皮粉末提取液的抗氧化能力通过DPPH自由基清除能力、ABTS+自由基清除能力、OH自由基清除能力和铁还原能力(FRAP)进行综合评估。抗氧化能力测定参照Shen等[18]所述方法测定,具体如下:

分别取1 mL核桃青皮粉末提取液和2 mL DPPH溶液(4×10−4 moL/L)混匀,1 mL蒸馏水和2 mL DPPH溶液混匀,1 mL核桃青皮粉末提取液和2 mL蒸馏水混匀,均静置30 min后,在517 nm处测定吸光度,分别记为A1,A0,A2,根据公式(7)计算核桃青皮粉末提取液对DPPH自由基的清除率:

DPPH自由基清除率(%)=(1−A1−A2A0)×100 (7) 分别取1 mL核桃青皮粉末提取液和5 mL ABTS溶液混匀,1 mL甲醇和5 mL ABTS溶液混匀,1 mL核桃青皮粉末提取液和5 mL甲醇混匀,均在室温下避光反应30 min后,在734 nm处测定吸光度,分别记为A样品,A空白,A对照,根据公式(8)计算核桃青皮粉末提取液对ABTS+自由基的清除率:

ABTS+自由基清除率(%)=(1−A样品−A对照A空白)×100 (8) 在试管中加入0.5 mL 10 mmol/L水杨酸-乙醇溶液、1 mL核桃青皮粉末提取液、0.5 mL 10 mmol/L FeSO4溶液、3 mL蒸馏水,最后加入5 mL 100 mmol/L H2O2启动Fenton反应,摇匀后于510 nm处测定吸光度A1;取0.5 mL蒸馏水代替10 mmol/L FeSO4溶液所测得的吸光度为A2;取1 mL蒸馏水代替样品溶液所测得的吸光度为A3,根据公式(9)计算核桃青皮粉末提取液对·OH的清除率:

⋅OH清除率(%)=(1−A1−A2A3)×100 (9) 在试管中依次加入1%铁氰化钾2.5 mL,磷酸盐缓冲液(pH6.6)2.5 mL,核桃青皮粉末提取液1 mL,混匀后50 ℃水浴反应20 min,急速冷却,加入10%三氯乙酸2.5 mL,摇匀后7000 r/min离心5 min,取上清液2.5 mL加0.1%三氯化铁0.5 mL,静置5 min,于波长700 nm处测定各样品吸光度。

1.3 数据处理

所有处理和实验测定均重复3次,结果以“平均值±标准差”表示。采用Origin 2023b、Minitab 19软件进行图形绘制和数据统计分析,以P<0.05表示数据具有统计学差异。

2. 结果与分析

2.1 核桃青皮粉体的粒径分布

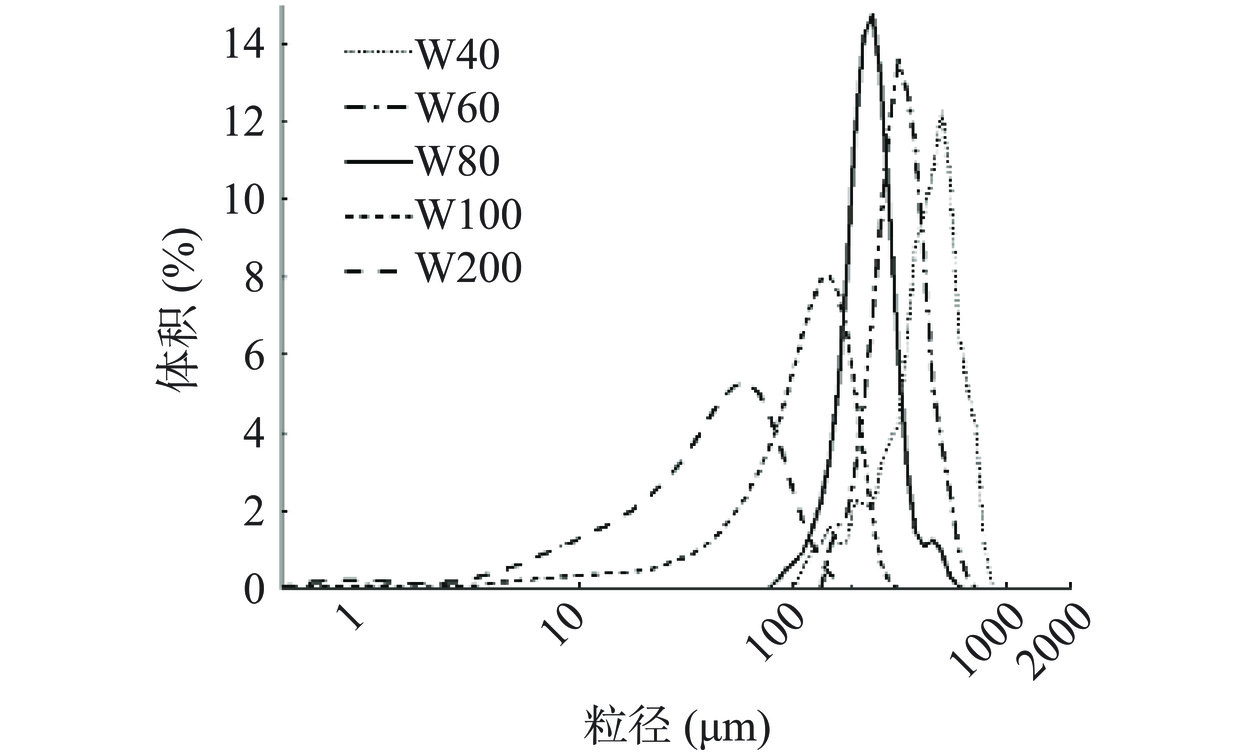

核桃青皮粉体的粒径分布结果如表1和图1所示,分别通过40、60、80、100和200目筛获得的核桃青皮粉体的粒径有显著性差异(P<0.05)。随着过筛目数的增大,核桃青皮粉的D50由446.10 μm减小到41.48 μm。随着粒径的减小,核桃青皮粉的表面积平均粒径(S.D.)显著降低(P<0.05),由184.65 μm减小到33.67 μm。跨度值(Span)表征粒径分布宽度,跨度值越小,粒径越均匀,粒径分布越窄[19]。W100和W200样品的跨度值较大,颗粒均匀性较差。粒径分布结果说明实验的粉碎处理能够有效提高粉体的粉碎程度,对核桃青皮粉具有良好的破碎作用且粒径差异显著(P<0.05)。

表 1 不同核桃青皮粉体的粒径Table 1. Particle size of different walnut green husk powder样品 D10(μm) D50(μm) D90(μm) 均值粒径(μm) S.D.(μm) Span(μm) W40 179.70±62.23a 446.10±8.34a 667.60±14.42a 438.95±12.66a 184.65±38.11a 1.10±0.19bc W60 202.70±29.98a 322.65±9.97b 458.10±21.35b 326.30±19.80b 100.85±5.44b 0.79±0.05cd W80 164.75±2.19a 236.35±0.64c 327.50±3.96c 243.90±1.56c 79.97±5.86bc 0.69±0.02d W100 32.40±0.96b 119.55±0.64d 197.95±1.06d 118.05±0.92d 60.99±0.04bc 1.38±0.01b W200 9.44±0.44b 41.48±1.29e 89.31±3.41e 45.39±2.24e 33.67±1.32c 1.92±0.06a 注:同列字母不同表示差异显著(P<0.05)。 2.2 不同粒径对核桃青皮粉松密度和振实密度的影响

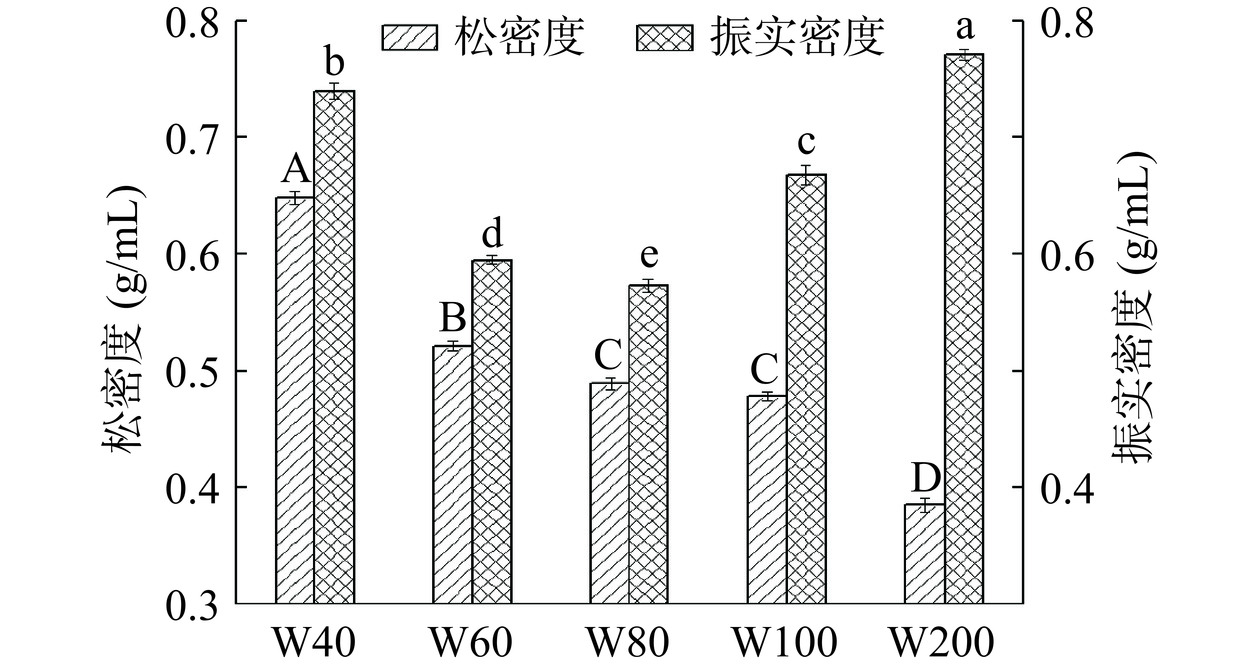

不同粒径对核桃青皮粉松密度和振实密度的影响如图2所示。松密度和振实密度是用来表征物料填充性的重要指标,密度较高的粉体更利于物料的压片成型和低成本包装及运输[20]。实验结果显示,随着粉体粒径的减小,核桃青皮粉的松密度由0.648 g/mL减少至0.385 g/mL,振实密度呈现先降低后增加的趋势,W200样品的振实密度值最大,为0.771 g/mL。这可能是由于青皮粉体颗粒分布不均匀,当粉体粒径减小时,粉末间的黏附力增大,容易出现架空、结拱、空洞等堆积效应,导致粉末间隙增大,松密度降低[21]。振实密度呈现先下降后增加的趋势可能是由于W40和W60样品的粉体颗粒较大,形状不规则,在敲击振动过程中粉体堆积效应仍有所保留,而W80~W200样品粉体颗粒较小,在受到外部敲击振动时,粉体中的架空、空洞等结构被破坏,从而粉体的振实密度有所增大。

2.3 不同粒径对核桃青皮粉休止角和滑动角的影响

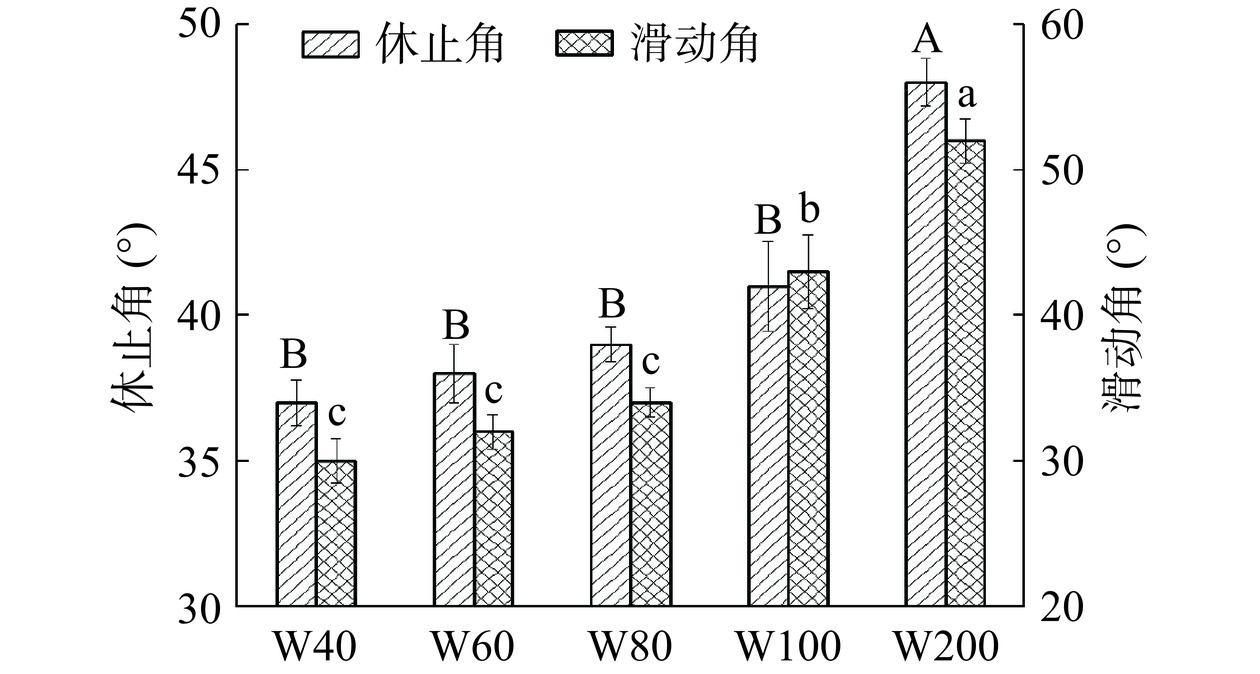

休止角和滑动角通常被用来表征粉体流动性的好坏。其数值越小,表明粉体的流动性越好[22]。不同粒径对核桃青皮粉休止角和滑动角的影响如图3所示。随着粒径的减小,核桃青皮粉的休止角和滑动角均有所增加,休止角由37°增加到48°,滑动角由30°增加到52°。W200样品的休止角和滑动角显著增加(P<0.05),表明粉体之间吸附力和凝聚性较强,相应的粉体流动性较差。刘颖等[23]的研究结果也表明微粉碎能够显著提高大豆、玉米和发芽糙米粉体的休止角和滑动角。这可能是由于随着粉体粒径的不断减小,粉体的比表面积增大,粉体颗粒间的相互作用力和静电引力增加,产生颗粒附着、聚合现象,从而增加了粉体与玻璃板之间的摩擦力,导致其流动性下降[24]。核桃青皮作为一种中药材,在制备为粉体药物时,较强的粉体黏附力即较低的粉体流动性会增加其对小肠壁细胞的吸附作用,有利于机体吸收有效成分,从而更好地发挥药效[25],对核桃青皮粉体流动性的研究结果显示,W200样品的休止角和滑动角均显著高于其他样品(P<0.05),表明200目粉碎度的样品更适合胶囊类药物的制备。

2.4 不同粒径对核桃青皮粉持水力和持油力的影响

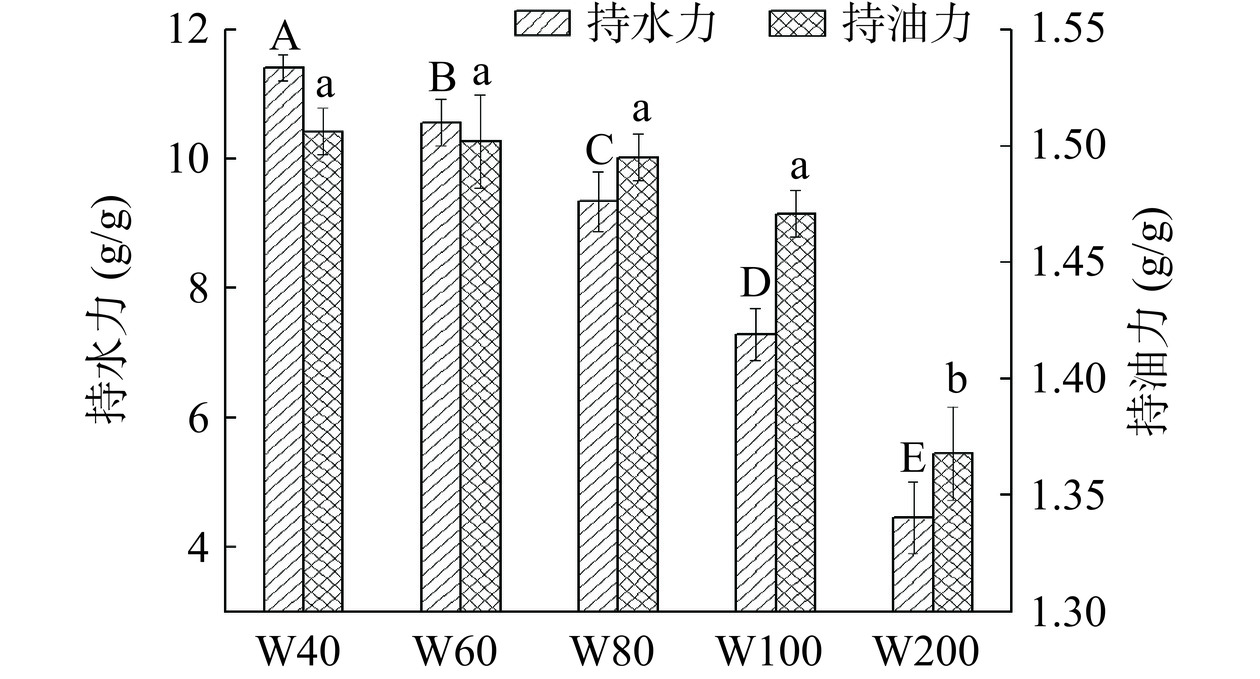

不同粒径对核桃青皮粉持水力和持油力的影响如图4所示。随着粒径的减小,核桃青皮粉的持水力和持油力均有所下降。W40样品的持水力和持油力最高,分别为11.41、1.51 g/g。这可能是由于随着粉体粒径的减小,机械作用力在一定程度上破坏了核桃青皮的纤维结构、亲水、亲油基团和细胞壁等结构,与水、油的结合能力下降。同时,当粉体粒径过小时,粉体颗粒之间产生黏附聚合作用会导致粉体与水、油接触不充分,也会造成持水力和持油力下降[26]。这与黄浩燃等[27]的研究结果一致,与冯晶晶等[28]的实验结果相反,这可能与其所采用的湿法粉碎加工方式有关,本文中所采用的干法粉碎对核桃青皮纤维结构的破坏程度更高,因此随粉体粒径的减小,核桃青皮粉体持水力和持油力越差。

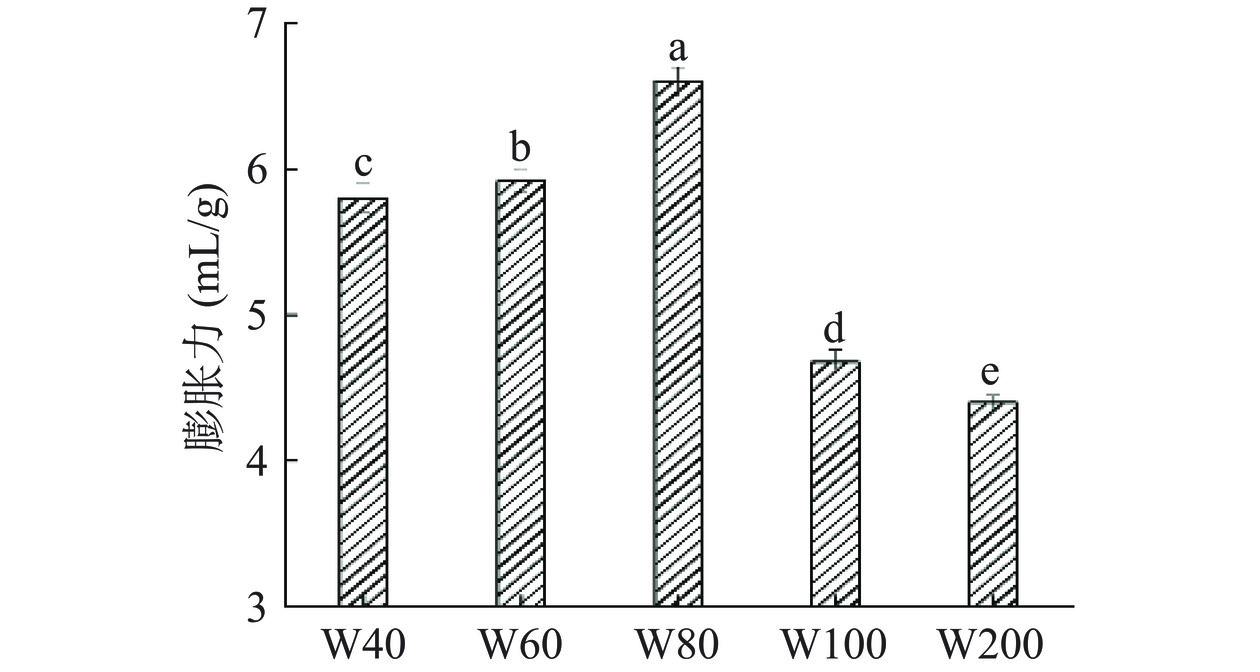

2.5 不同粒径对核桃青皮粉膨胀力的影响

膨胀力是反映样品,尤其是纤维样品水合能力的重要指标,与样品纤维结构及组成密切相关[29]。膨胀力越大,样品的表面积和吸附作用就越大[30]。图5为不同粒径对核桃青皮粉膨胀力的影响,随着粒径的减小,核桃青皮粉的膨胀力呈现先上升后下降的趋势。样品(W80)粒径为236.35 μm时,膨胀力值达到最大,为6.6 mL/g,这是因为随着粉碎程度的增加,单位体积内粉体颗粒数增加,粉体表面积增大,暴露出更多的极性部位和亲水基团,有利于粉体吸水膨胀;同时由于机械剪切力的作用,粉体的长链纤维结构断裂,短链纤维增多,导致粉体膨胀力增加[31]。当样品(W200)粒径减小至41.48 μm时,样品的膨胀力达到最低值,这是可能是由于粉碎程度的加强破坏了核桃青皮粉的纤维结构,大分子物质含量降低,减弱了粉体对水的束缚作用。曹琦琦等[32]也指出过度粉碎会破坏粉体的纤维结构,对粉体的物理特性造成负面影响。

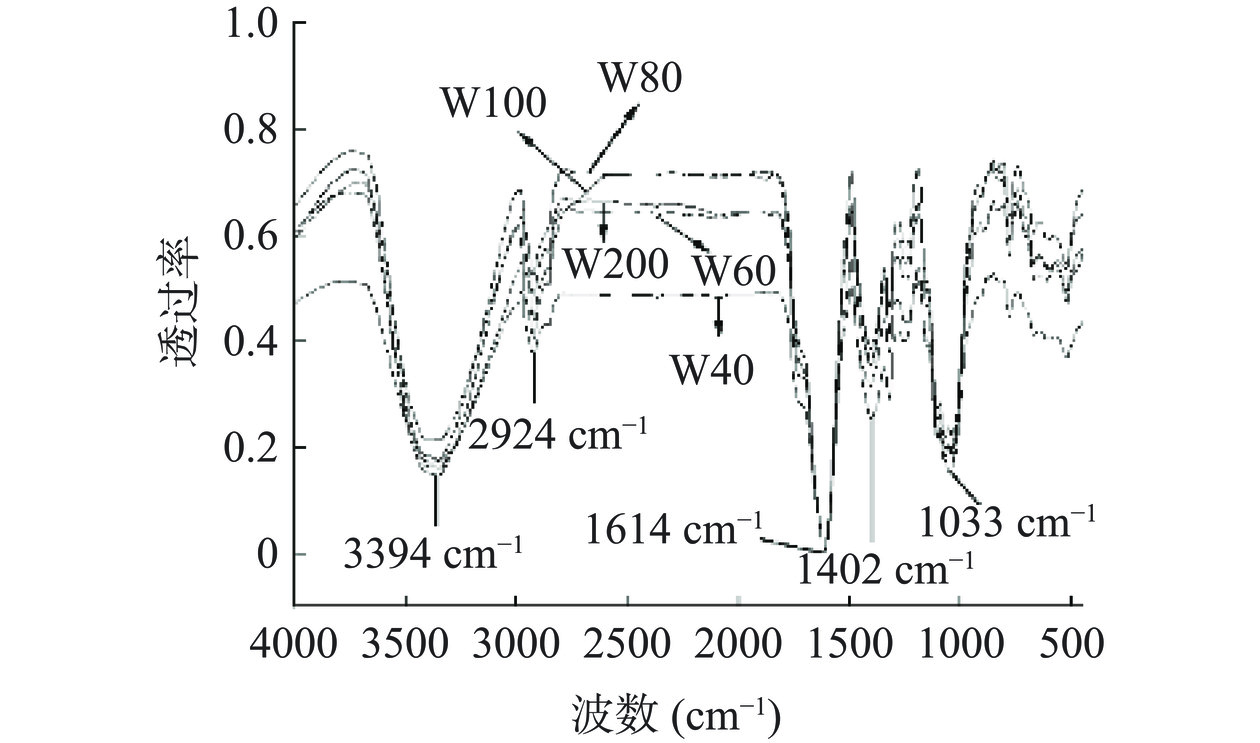

2.6 不同粒径核桃青皮粉的傅里叶红外光谱分析

不同粒径核桃青皮粉的傅里叶红外光谱如图6所示。5种不同粒径的核桃青皮粉的峰强度略有差异,但在峰形和峰位置上均显示出类似的峰条带,没有产生新的吸收峰。这与微粉碎在山楂[33]、灰枣[34]等的应用中展现出类似的研究结果,粉碎加工不会改变主要成分和基团结构。在核桃青皮粉的主要吸收峰中,3394 cm−1处的峰与核桃青皮粉中纤维素和半纤维素中-OH的伸缩振动有关,较大的峰面积表明核桃青皮粉中含有较多的纤维素[35];2924 cm−1处的吸收峰对应于糖类甲基和亚甲基上-CH的伸缩振动;在1614 cm−1处出现的强吸收峰可能是C=O的特征峰,表明核桃青皮粉中含有较多糖醛酸;1402、1033 cm−1处的特征峰分别是由-CH弯曲振动和C-O-C中的C-O伸缩振动引起的[36]。对核桃青皮粉体的傅里叶红外光谱分析表明,粉碎过程没有对核桃青皮的主要特征峰造成破坏,未改变核桃青皮的分子结构。

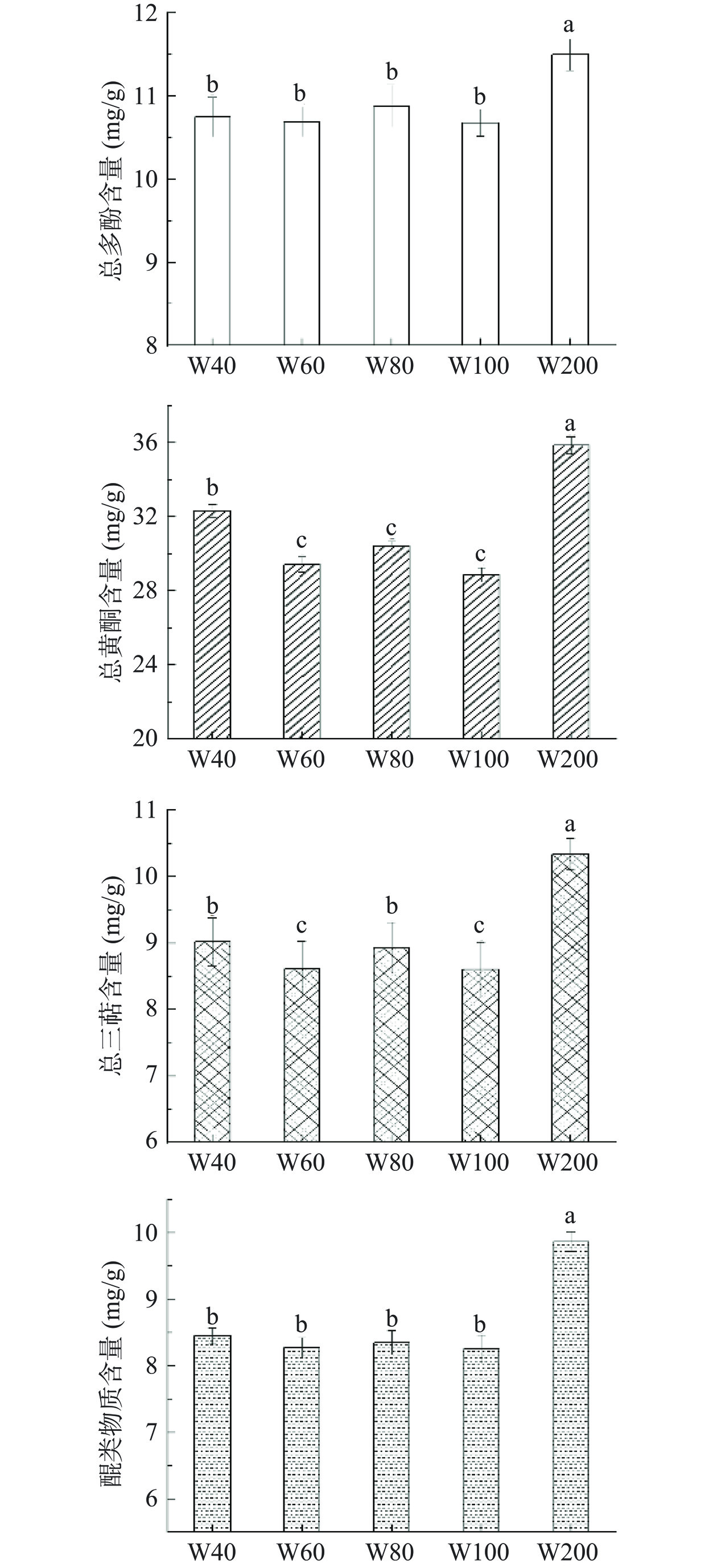

2.7 不同粒径对核桃青皮粉末提取液中活性物质含量和抗氧化能力的影响

不同粒径对核桃青皮粉末提取液中活性物质含量的影响如图7所示。实验结果显示,W40、W60、W80、W100样品提取液中总多酚和醌类物质含量差异不显著(P>0.05),W200样品提取液中其他活性物质含量均显著提高(P<0.05)。与各活性物含量最低的W100样品相比,W200样品提取液的总多酚含量提高了7.1%,总黄酮含量提高了19.5%,萜类物质含量提高了16.8%,醌类物质含量提高了16.4%。这可能是由于微粉碎大大降低了粉体的平均粒径,有助于增强细胞的破裂程度,释放出更多的生物活性物质。同时粒径减小能够增加活性物质与提取溶剂的接触面积,使活性物质的提取更加充分完全[37]。黄藩等[38]对白茶的研究结果也表明微粉碎能增大白茶粉颗粒的比表面积,提高主要生化成分的浸出量。但卫子颜等[39]的研究表明,随粉体粒径的减小,米糠中多酚含量先增加后减少,这可能是由于微粉碎时间过长,剧烈的机械作用力严重破坏细胞结构,导致多酚含量下降。而本研究微粉碎过程中采用间歇式粉碎,每粉碎30 s暂停1 min进行粉体散热降温,所以并未出现总多酚含量降低的情况。

图8为不同粒径对核桃青皮粉末提取液抗氧化能力的影响。结果表明,5种样品都具有一定的自由基清除能力和铁还原能力,其中,对DPPH自由基的清除能力均在90%以上。W200样品提取液的抗氧化活性显著高于W40~W100样品(P<0.05)。这与W200样品提取液中多酚、黄酮和萜类化合物含量较高有关,Soto等[40]的研究结果也表明酚类化合物、类黄酮、萜类化合物和单宁酸等植物活性成分具有良好的抗氧化活性。陈璁等[41]对双孢蘑菇提取液的抗氧化活性研究表明微粉碎能够增大粉体的比表面积,促进酚类等活性物质的溶出,增强样品溶液的抗氧化活性。同时微粉碎使核桃青皮粉体孔隙率增加,增强粉体在溶剂中的分散性、溶解性和化学反应活性等,从而增强粉体的抗氧化能力[42]。

3. 结论

本文对核桃青皮进行不同程度的粉碎及过筛处理,研究了不同粒径对核桃青皮物理特性、活性成分含量和抗氧化能力的影响。结果表明,经过粉碎及过筛处理后,核桃青皮粉体粒径显著下降(P<0.05),粉碎处理对核桃青皮产生了有效的破碎作用;随着粉体粒径的不断减小,核桃青皮粉的松密度、持水力、持油力不断下降,休止角和滑动角不断增加,振实密度呈现先降低后增加的趋势,膨胀力呈现先增加后降低的趋势;核桃青皮W200样品提取液中的活性物质含量和抗氧化能力显著高于W40~W100样品(P<0.05),表明微粉碎在一定程度上能够提高核桃青皮粉活性物质的溶出。研究结果可为微粉碎在核桃青皮加工产业的综合开发利用提供理论依据。

-

表 1 不同核桃青皮粉体的粒径

Table 1 Particle size of different walnut green husk powder

样品 D10(μm) D50(μm) D90(μm) 均值粒径(μm) S.D.(μm) Span(μm) W40 179.70±62.23a 446.10±8.34a 667.60±14.42a 438.95±12.66a 184.65±38.11a 1.10±0.19bc W60 202.70±29.98a 322.65±9.97b 458.10±21.35b 326.30±19.80b 100.85±5.44b 0.79±0.05cd W80 164.75±2.19a 236.35±0.64c 327.50±3.96c 243.90±1.56c 79.97±5.86bc 0.69±0.02d W100 32.40±0.96b 119.55±0.64d 197.95±1.06d 118.05±0.92d 60.99±0.04bc 1.38±0.01b W200 9.44±0.44b 41.48±1.29e 89.31±3.41e 45.39±2.24e 33.67±1.32c 1.92±0.06a 注:同列字母不同表示差异显著(P<0.05)。 -

[1] 曾宪浩, 刘永翔, 李俊, 等. 贵州核桃产业现状与发展战略分析[J]. 贵州农业科学,2022,50(12):114−121. [ZENG X H, LIU Y X, LI J, et al. Current situation and development strategy analysis of the walnut industry in Guizhou Province[J]. Guizhou Agricultural Science,2022,50(12):114−121.] ZENG X H, LIU Y X, LI J, et al. Current situation and development strategy analysis of the walnut industry in Guizhou Province[J]. Guizhou Agricultural Science, 2022, 50(12): 114−121.

[2] 付起凤, 宋红娟, 马丹娜, 等. 抗肿瘤中药青龙衣化学成分研究[J]. 中医药学报,2021,49(4):25−29. [FU Q F, SONG H J, MA D N, et al. Study on triterpenoids compounds of green walnut husks of Juglans mandshurica Maxim[J]. Acta Chinese Medicine and Pharmacology,2021,49(4):25−29.] FU Q F, SONG H J, MA D N, et al. Study on triterpenoids compounds of green walnut husks of Juglans mandshurica Maxim[J]. Acta Chinese Medicine and Pharmacology, 2021, 49(4): 25−29.

[3] 石磊岭, 马晓玲, 阿拉腾图雅, 等. 青龙衣的化学成分及应用研究进展[J]. 中医药导报,2020,26(5):122−125. [SHI L L, MA X L, ALATENGTUYA, et al. Research progress of Qinglongyi (cortex juglandies mandshuricae)[J]. Guiding Journal of Traditional Chinese Medicine and Pharmacology,2020,26(5):122−125.] SHI L L, MA X L, ALATENGTUYA, et al. Research progress of Qinglongyi (cortex juglandies mandshuricae)[J]. Guiding Journal of Traditional Chinese Medicine and Pharmacology, 2020, 26(5): 122−125.

[4] ALI J E, ALIREZA O, MAHNAZ T, et al. A comprehensive review on the chemical constituents and functional uses of walnut (Juglans spp.) husk[J]. International Journal of Molecular Sciences,2019,20:3920. doi: 10.3390/ijms20163920

[5] 杨泽锐, 彭丽华, 邓雯, 等. 中药粉体的发展历史概述[J]. 安徽农业科学,2016,44(12):141−143,145. [YANG Z R, PENG L H, DENG W, et al. Development history of ultra-fine powder of traditional Chinese medicine[J]. Journal of Anhui Agricultural Sciences,2016,44(12):141−143,145.] YANG Z R, PENG L H, DENG W, et al. Development history of ultra-fine powder of traditional Chinese medicine[J]. Journal of Anhui Agricultural Sciences, 2016, 44(12): 141−143,145.

[6] ZHANG Y, LI R, SHANG G, et al. Mechanical grinding alters physicochemical, structural, and functional properties of tobacco (Nicotiana tabacum L.) leaf powders[J]. Industrial Crops and Products,2021,173:114149. doi: 10.1016/j.indcrop.2021.114149

[7] 赵秋艳, 许淇, 郭星星, 等. 粉碎粒径对豆渣化学组成和物理特性的影响[J]. 山东化工,2022,51(7):61−64. [ZHAO Q Y, XU Q, GUO X X, et al. Effect of particle size on chemical composition and physical characteristics of okara[J]. Shandong Chemical Industry,2022,51(7):61−64.] ZHAO Q Y, XU Q, GUO X X, et al. Effect of particle size on chemical composition and physical characteristics of okara[J]. Shandong Chemical Industry, 2022, 51(7): 61−64.

[8] 刘文卓, 雷菁清, 崔明明, 等. 不同粒径黑果枸杞粉体的理化性质分析[J]. 现代食品科技,2020,36(10):108−117. [LIU W Z, LEI J Q, CUI M M, et al. Physicochemical properties of Lycium rathenicum Murr. powder with different particle sizes[J]. Modern Food Science & Technology,2020,36(10):108−117.] LIU W Z, LEI J Q, CUI M M, et al. Physicochemical properties of Lycium rathenicum Murr. powder with different particle sizes[J]. Modern Food Science & Technology, 2020, 36(10): 108−117.

[9] 李硕, 王本欢, 朱向东, 等. 干燥时间对9种常用陇药煮散颗粒粉体学特性的影响[J]. 中药材,2021,44(5):1191−1198. [LI S, WANG B H, ZHU X D, et al. Effect of drying time on the powder chemical properties of boiled and dispersed granules of nine kinds of commonly used long medicines[J]. Journal of Chinese Medicinal Materials,2021,44(5):1191−1198.] LI S, WANG B H, ZHU X D, et al. Effect of drying time on the powder chemical properties of boiled and dispersed granules of nine kinds of commonly used long medicines[J]. Journal of Chinese Medicinal Materials, 2021, 44(5): 1191−1198.

[10] 吴兴雨, 孙凯杨, 姚玥, 等. 两种方法提取的亚麻籽蛋白持水性、持油性、溶解性和氨基酸组成比较[J]. 中国油脂,2021,46(4):43−46,51. [WU X Y, SUN K Y, YAO Y, et al. Comparison of water holding capacity, oil holding capacity, solubility and amino acid composition of flaxseed protein extracted by two methods[J]. China Oils and Fats,2021,46(4):43−46,51.] WU X Y, SUN K Y, YAO Y, et al. Comparison of water holding capacity, oil holding capacity, solubility and amino acid composition of flaxseed protein extracted by two methods[J]. China Oils and Fats, 2021, 46(4): 43−46,51.

[11] 赵愉涵, 陈庆敏, 岳凤丽, 等. 超微粉碎处理对五谷杂粮粉特性的影响[J]. 中国果菜,2022,42(7):28−35. [ZHAO Y H, CHEN Q M, YUE F L, et al. Effects of superfine grinding treatment on the properties of mixed powder of grains[J]. China Fruit & Vegetable,2022,42(7):28−35.] ZHAO Y H, CHEN Q M, YUE F L, et al. Effects of superfine grinding treatment on the properties of mixed powder of grains[J]. China Fruit & Vegetable, 2022, 42(7): 28−35.

[12] SARKAR T, SAHA S K, SALAUDDIN M, et al. Drying kinetics, fouruer-transform infrared spectroscopy analysis and sensory evaluation of sun, hot-air, microwave and freeze-dried mango leather[J]. Journal of Microbiology Biotechnology and Food Sciences,2021,10:3313. doi: 10.15414/jmbfs.3313

[13] 徐亚飞, 雷宏杰, 王瑞珍, 等. 不同干燥方式对核桃青皮品质的影响[J]. 食品工业科技,2017,38(9):212−215,227. [XU Y F, LEI H J, WANG R Z, et al. Effects of different drying methods on the quality of walnut green husks[J]. Science and Technology of Food Industry,2017,38(9):212−215,227.] XU Y F, LEI H J, WANG R Z, et al. Effects of different drying methods on the quality of walnut green husks[J]. Science and Technology of Food Industry, 2017, 38(9): 212−215,227.

[14] TU J, LIU H, SUN N, et al. Optimization of the steam explosion pretreatment effect on total flavonoids content and sntioxidative activity of seabuckthom pomace by response surface methodology[J]. Molecules,2018,24:60. doi: 10.3390/molecules24010060

[15] HAO J, SI Q, WANG Z, et al. Optimization of extraction process and dynamic changes in triterpenoids of lactuca indica from different medicinal parts and growth periods[J]. Molecules,2023,28:3345. doi: 10.3390/molecules28083345

[16] XIANG J, LI W, NDOLO V U, et al. A comparative study of the phenolic compounds and in vitro antioxidant capacity of finger millets from different growing regions in Malawi[J]. Journal of Cereal Science,2019,87:143−149. doi: 10.1016/j.jcs.2019.03.016

[17] QIN D, XIANG B, ZHOU X, et al. Microemulsion as solvent for naphthoquinones extraction from walnut (Juglans mandshurica Maxim) green husk using high voltage electrical discharge[J]. Separation and Purification Technology,2022,281:119983. doi: 10.1016/j.seppur.2021.119983

[18] SHEN H Y, HOU Y J, XI M H, et al. Electron beam irradiation enhanced extraction and antioxidant activity of active compounds in green walnut husk[J]. Food Chemistry,2022,373:131520. doi: 10.1016/j.foodchem.2021.131520

[19] 唐菡颀, 朱红广, 仇菊, 等. 粒径对燕麦麸皮结构、物理特性及体外益生菌黏附力的影响[J]. 河南工业大学学报(自然科学版),2023,44(3):25−33. [TANG H X, ZHU H G, QIU J, et al. Effect of particle size on the structural and physical properties of oat bran and the adhesion of probiotic in vitro[J]. Journal of Henan University of Technology (Natural Science Edition),2023,44(3):25−33.] TANG H X, ZHU H G, QIU J, et al. Effect of particle size on the structural and physical properties of oat bran and the adhesion of probiotic in vitro[J]. Journal of Henan University of Technology (Natural Science Edition), 2023, 44(3): 25−33.

[20] 雷菁清, 刘文卓, 肖明, 等. 青海柴达木红枸杞粉体研究[J]. 农产品质量与安全,2021,109(1):89−95. [LEI J Q, LIU W Z, XIAO M, et al. Study on the powder of red medlar of Qaidam in Qinghai Province[J]. Quality and Safety of Agro-Products,2021,109(1):89−95.] LEI J Q, LIU W Z, XIAO M, et al. Study on the powder of red medlar of Qaidam in Qinghai Province[J]. Quality and Safety of Agro-Products, 2021, 109(1): 89−95.

[21] 周葵, 张雅媛, 游向荣, 等. 不同粒径青香蕉粉的粉体特性[J]. 食品工业科技,2018,39(7):6−9,14. [ZHOU K, ZHANG Y Y, YOU X R, et al. Properties of green banana powder in different particle sizes[J]. Science and Technology of Food Industry,2018,39(7):6−9,14.] ZHOU K, ZHANG Y Y, YOU X R, et al. Properties of green banana powder in different particle sizes[J]. Science and Technology of Food Industry, 2018, 39(7): 6−9,14.

[22] 冉欢, 夏晓霞, 雷小娟, 等. 双酶协同酶解处理对冬枣粉理化特性及结构特征的影响[J]. 食品与发酵工业,2023,49(11):240−246. [RAN H, XIA X X, LEI X J, et al. Dual enzyme synergetic enzymatic hydrolysis and its effect on physicochemical properties and structural characteristics of Ziziphus jujuba Mill. powder[J]. Food and Fermentation Industries,2023,49(11):240−246.] RAN H, XIA X X, LEI X J, et al. Dual enzyme synergetic enzymatic hydrolysis and its effect on physicochemical properties and structural characteristics of Ziziphus jujuba Mill. powder[J]. Food and Fermentation Industries, 2023, 49(11): 240−246.

[23] 刘颖, 高帅, 张云亮, 等. 超微粉碎对大豆、玉米、发芽糙米物化特性影响[J]. 食品科技,2020,45(9):168−173. [LIU Y, GAO S, ZHANG Y L, et al. Effect of superfine grinding on physicochemical properties of soybean, corn and germinated rice[J]. Food Science and Technology,2020,45(9):168−173.] LIU Y, GAO S, ZHANG Y L, et al. Effect of superfine grinding on physicochemical properties of soybean, corn and germinated rice[J]. Food Science and Technology, 2020, 45(9): 168−173.

[24] 张丽媛, 陈如, 田昊, 等. 超微粉碎对苹果膳食纤维理化性质及羟自由基清除能力的影响[J]. 食品科学,2018,39(15):139−144. [ZHANG L Y, CHEN R, TIAN H, et al. Effect of superfine grinding on physicochemical properties and hydroxyl radical scavenging capacity of apple dietary fiber[J]. Journal of Food Science,2018,39(15):139−144.] ZHANG L Y, CHEN R, TIAN H, et al. Effect of superfine grinding on physicochemical properties and hydroxyl radical scavenging capacity of apple dietary fiber[J]. Journal of Food Science, 2018, 39(15): 139−144.

[25] 张雪, 张东杰, 张爱武. 气流超微粉碎对苦荞粉物化特性的影响[J]. 食品与机械,2021,37(8):45−51. [ZHANG X, ZHANG D J, ZHANG A W. Effect of jet milling on the physical and chemical properties of tartary buckwheat powder[J]. Food and Machinery,2021,37(8):45−51.] ZHANG X, ZHANG D J, ZHANG A W. Effect of jet milling on the physical and chemical properties of tartary buckwheat powder[J]. Food and Machinery, 2021, 37(8): 45−51.

[26] 朱爽, 宋莉莎, 张佰清, 等. 大麦超微粉的营养品质及物理特性分析[J]. 现代食品科技,2022,38(1):289−295,93. [ZHU S, SONG L S, ZHANG B Q, et al. Analysis of nutritional quality and physical properties of barley ultrafine powder[J]. Modern Food Science and Technology,2022,38(1):289−295,93.] ZHU S, SONG L S, ZHANG B Q, et al. Analysis of nutritional quality and physical properties of barley ultrafine powder[J]. Modern Food Science and Technology, 2022, 38(1): 289−295,93.

[27] 黄浩燃, 张星启, 温辉翠, 等. 球磨处理对菠萝蜜果皮不溶性膳食纤维结构及性能的影响[J]. 食品工业科技,2023,44(11):211−218. [HUANG H R, ZHANG X Q, WEN H C, et al. Effect of ball milling on the structure and properties of insoluble dietary fiber in jackfruit peel[J]. Science and Technology of Food Industry,2023,44(11):211−218.] HUANG H R, ZHANG X Q, WEN H C, et al. Effect of ball milling on the structure and properties of insoluble dietary fiber in jackfruit peel[J]. Science and Technology of Food Industry, 2023, 44(11): 211−218.

[28] 冯晶晶, 郭建峰, 马心茹, 等. 超微粉碎对沙棘茶粉颗粒结构及理化特性的影响[J]. 食品与发酵工业,2023,49(7):198−204. [FENG J J, GUO J F, MA X R, et al. Effect of ultrafine grinding on powder structure and physicochemical properties of sea buckthorn tea[J]. Food and Fermentation Industries,2023,49(7):198−204.] FENG J J, GUO J F, MA X R, et al. Effect of ultrafine grinding on powder structure and physicochemical properties of sea buckthorn tea[J]. Food and Fermentation Industries, 2023, 49(7): 198−204.

[29] 郝竞霄, 石福磊, 惠靖茹, 等. 普通粉碎与超微粉碎对茶树菇粉体加工物理特性的影响[J]. 食品与发酵工业,2021,47(3):95−100. [HAO J X, SHI F L, HUI J R, et al. Effects of common grinding and ultrafine grinding on physical properties of Agrocybe cylindracea powder[J]. Food and Fermentation Industries,2021,47(3):95−100.] HAO J X, SHI F L, HUI J R, et al. Effects of common grinding and ultrafine grinding on physical properties of Agrocybe cylindracea powder[J]. Food and Fermentation Industries, 2021, 47(3): 95−100.

[30] 林丽静, 黄晓兵, 龚霄, 等. 超微粉碎对菠萝皮渣理化特性的影响[J]. 农产品加工,2016,420(22):19−21,24. [LIN L J, HUANG X B, GONG X, et al. Influence of micronization on the physicochemical properties of pineapple peel[J]. Farm Products Processing,2016,420(22):19−21,24.] LIN L J, HUANG X B, GONG X, et al. Influence of micronization on the physicochemical properties of pineapple peel[J]. Farm Products Processing, 2016, 420(22): 19−21,24.

[31] 唐明明, 孙汉巨, 赵金龙, 等. 超微粉碎对水芹粉末理化性质及抗氧化活性的影响[J]. 现代食品科技,2019,35(7):55−65. [TANG M M, SUN H J, ZHAO J L, et al. Effect of superfine gringing on the physicochemical properties and antioxidant activities of water dropwort powder[J]. Modern Food Science and Technology,2019,35(7):55−65.] TANG M M, SUN H J, ZHAO J L, et al. Effect of superfine gringing on the physicochemical properties and antioxidant activities of water dropwort powder[J]. Modern Food Science and Technology, 2019, 35(7): 55−65.

[32] 曹琦琦, 黄妮子, 滕建文, 等. 微粉碎对百香果皮纤维粉理化性质及功能活性的影响[J]. 食品工业科技,2021,42(16):28−36. [CAO Q Q, HUANG N Z, TENG J W, et al. Effect of grinding on physicochemical and functional properites of the passion fruit peel residue[J]. Science and Technology of Food Industry,2021,42(16):28−36.] CAO Q Q, HUANG N Z, TENG J W, et al. Effect of grinding on physicochemical and functional properites of the passion fruit peel residue[J]. Science and Technology of Food Industry, 2021, 42(16): 28−36.

[33] 方园, 崔楠, 代银银, 等. 制备方法对山楂果胶理化特性的影响[J]. 食品科学,2021,42(11):130−136. [FANG Y, CUI N, DAI Y Y, et al. Effect of preparation methods on physicochemical properties of hawthorn pectin[J]. Journal of Food Science,2021,42(11):130−136.] FANG Y, CUI N, DAI Y Y, et al. Effect of preparation methods on physicochemical properties of hawthorn pectin[J]. Journal of Food Science, 2021, 42(11): 130−136.

[34] 丁华, 魏佳, 林丽静, 等. 响应面法优化灰枣超微粉制备工艺及其粉体性能表征[J]. 现代食品科技,2023,39(1):238−246. [DING H, WEI J, LIN L J, et al. Optimization of superfine comminution technology and properties of Zizyphus jujube using response surface methodology[J]. Modern Food Science and Technology,2023,39(1):238−246.] DING H, WEI J, LIN L J, et al. Optimization of superfine comminution technology and properties of Zizyphus jujube using response surface methodology[J]. Modern Food Science and Technology, 2023, 39(1): 238−246.

[35] 夏晓霞, 寇福兵, 薛艾莲, 等. 超微粉碎对枣粉理化性质、功能特性及结构特征的影响[J]. 食品与发酵工业,2022,48(12):37−45. [XIA X X, KOU F B, XUE A L, et al. Effect of superfine grinding on physicochemical properties, functional and structure characteristics of jujube powder[J]. Food and Fermentation Industries,2022,48(12):37−45.] XIA X X, KOU F B, XUE A L, et al. Effect of superfine grinding on physicochemical properties, functional and structure characteristics of jujube powder[J]. Food and Fermentation Industries, 2022, 48(12): 37−45.

[36] 郑慧, 孙艳, 张眙曼, 等. 颗粒粒径对荷叶不溶性膳食纤维结构、理化及感官品质的影响[J]. 天然产物研究与开发,2022,34(9):1530−1538. [ZHENG H, SUN Y, ZHANG C M, et al. Effects of particle size on the structure, physicochemical and sensory qualities of insoluble dietary fiber from lotus leaf[J]. Natural Product Research and Development,2022,34(9):1530−1538.] ZHENG H, SUN Y, ZHANG C M, et al. Effects of particle size on the structure, physicochemical and sensory qualities of insoluble dietary fiber from lotus leaf[J]. Natural Product Research and Development, 2022, 34(9): 1530−1538.

[37] ZHANG J, DONG Y, NISAR T, et al. Effect of superfine-grinding on the physicochemical and antioxidant properties of Lycium ruthenicum Murray powders[J]. Powder Technology,2020,372:68−75.

[38] 黄藩, 张厅, 马伟伟, 等. 超微粉碎对白茶主要生化成分的影响[J]. 四川农业科技,2021(11):52−55. [HUANG F, ZHANG T, MA W W, et al. Effect of ultra-micro-milling on the main biochemical components of white tea[J]. Sichuan Agricultural Science and Technology,2021(11):52−55.] doi: 10.3969/j.issn.1004-1028.2021.11.018 HUANG F, ZHANG T, MA W W, et al. Effect of ultra-micro-milling on the main biochemical components of white tea[J]. Sichuan Agricultural Science and Technology, 2021(11): 52−55. doi: 10.3969/j.issn.1004-1028.2021.11.018

[39] 卫子颜, 谢勇, 王朦朦, 等. 超微粉碎对米糠多酚的组成及抗氧化活性的影响[J]. 食品与发酵工业,2022,48(14):138−144. [WEI Z Y, XIE Y, WANG M M, et al. Effect of ultrafine grinding on the composition and antioxidant activity of phenolic compounds in rice bran[J]. Food and Fermentation Industries,2022,48(14):138−144.] WEI Z Y, XIE Y, WANG M M, et al. Effect of ultrafine grinding on the composition and antioxidant activity of phenolic compounds in rice bran[J]. Food and Fermentation Industries, 2022, 48(14): 138−144.

[40] SOTO K M, PEREZ B, MENDOZA L, et al. Antioxidants in traditional mexican medicine and their applications as antitumor treatments[J]. Pharmaceuticals,2023,16:482. doi: 10.3390/ph16040482

[41] 陈璁, 叶爽, 王桂华, 等. 不同干燥方式和粉碎程度对双孢蘑菇理化、营养和功能特性的影响[J]. 食品科学,2023,44(1):88−97. [CHEN C, YE S, WANG G H, et al. Effects of different drying methods and crushing degrees on the physicochemical, nutritional and functional properties of Agaricus bisporus[J]. Journal of Food Science,2023,44(1):88−97.] doi: 10.7506/spkx1002-6630-20211215-172 CHEN C, YE S, WANG G H, et al. Effects of different drying methods and crushing degrees on the physicochemical, nutritional and functional properties of Agaricus bisporus[J]. Journal of Food Science, 2023, 44(1): 88−97. doi: 10.7506/spkx1002-6630-20211215-172

[42] 张小利, 夏春燕, 王慧清, 等. 超微粉碎对香菇多酚组成及抗氧化活性的影响[J]. 食品科学,2015,36(11):42−49. [ZHANG X L, XIA C Y, WANG H Q, et al. Effect of superfine grinding on compositions and antioxidant activity of phenolic compounds from shiitake mushrooms (Lentinus edodes)[J]. Journal of Food Science,2015,36(11):42−49.] ZHANG X L, XIA C Y, WANG H Q, et al. Effect of superfine grinding on compositions and antioxidant activity of phenolic compounds from shiitake mushrooms (Lentinus edodes)[J]. Journal of Food Science, 2015, 36(11): 42−49.

-

期刊类型引用(4)

1. 刘艳艳,张涛,王媛媛,李明婉,丁申,杨超臣,陈圆圆,赖勇,张党权. 核桃枝的抗氧化、抗菌及抗肿瘤活性研究. 河南农业大学学报. 2025(01): 57-67 .  百度学术

百度学术

2. 马珂,欧阳文枝,何雪梅,戴涛涛,陈军,高洁,孙健. 低温冲击磨处理对银耳及其多糖性质的影响. 南方农业学报. 2024(07): 2044-2057 .  百度学术

百度学术

3. 肖佳豪,张群,潘兆平,李涛,孙恬,江盛宇,李绮丽,付复华. 低温超微粉碎对茶枝柑果肉粉理化性质和功能特性的影响. 食品科学. 2024(20): 220-231 .  百度学术

百度学术

4. 赵晨晨,吕家慧,刘畅,童若楠,王梦锦,刘恒,邢丽花,于娇,耿璐娜,俞年军. 不同粒径多花黄精粉物理特性及体外模拟胃肠消化特性研究. 食品工业科技. 2024(21): 93-102 .  本站查看

本站查看

其他类型引用(0)

下载:

下载:

下载:

下载: