Effects of Cold Storage Insulation Packaging Box on the Quality of Sweet Corn in Simulated Cold Chain Transportation

-

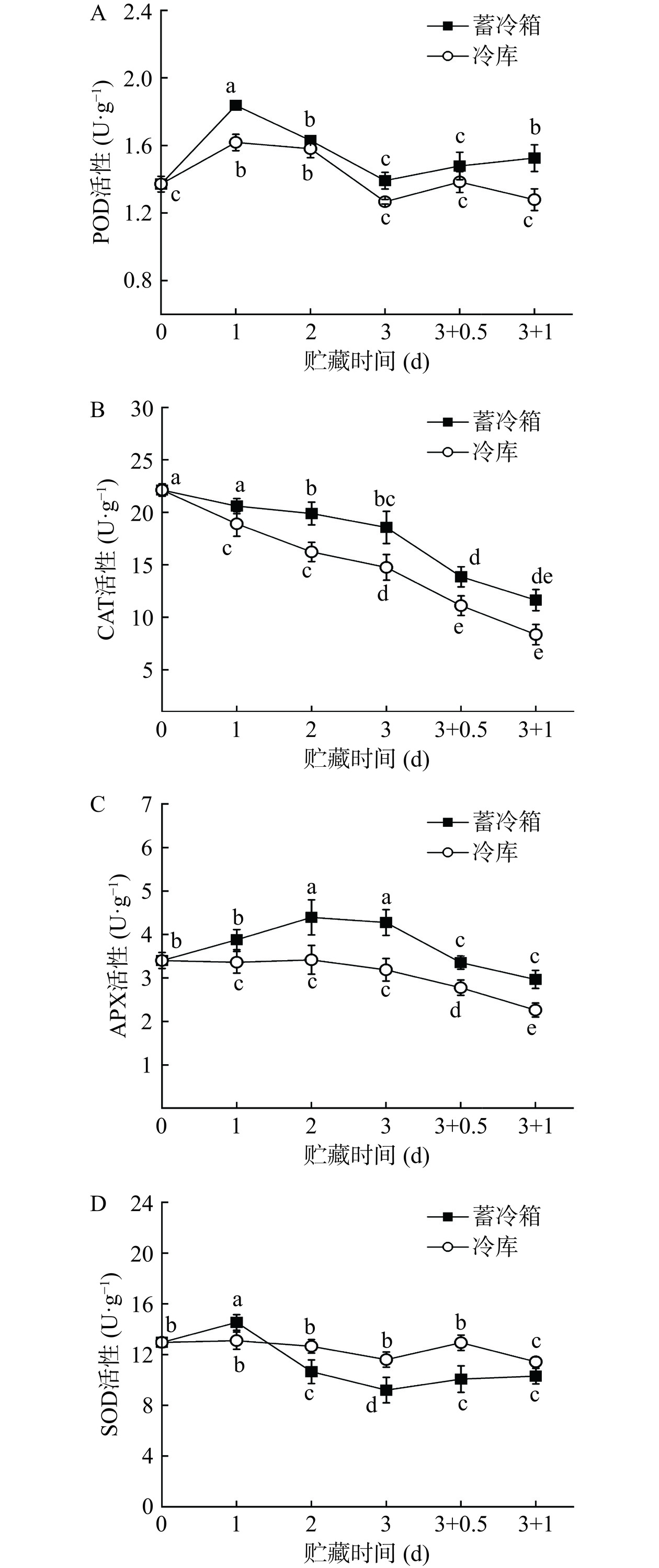

摘要: 甜玉米采后生理代谢旺盛,极易老化,严重影响食用品质。为了明确采后蓄冷包装模拟冷链运输对甜玉米品质的影响,以‘金冠218’甜玉米为实验材料,以冷库贮藏(4 ℃)模拟冷藏车运输为对照,研究了蓄冷箱包装甜玉米在模拟冷链运输3 d及随后常温货架(20 ℃)贮藏1 d过程中的品质变化。结果表明:蓄冷箱包装的甜玉米中心最高温度3 d内不超过7 ℃,蓄冷保温效果良好。与对照相比,蓄冷箱包装模拟冷链运输可以很好地维持甜玉米冷链运输和货架期间的品质,延缓甜玉米苞叶颜色的变化,其中模拟冷链运输3 d后甜玉米的质量损失率降低了72.66%,可溶性固形物含量提高了4.97%,可溶性糖含量提高了10.13%;甜玉米的抗氧化酶除超氧化物歧化酶(superoxide dismutase,SOD)活性下降外,过氧化物酶(peroxidase,POD)、过氧化氢酶(catalase,CAT)、抗坏血酸过氧化物酶(ascorbate peroxidase,APX)活性比对照组有显著提高(P<0.05)。综上所述,利用蓄冷箱包装可以保持甜玉米冷链运输过程和货架期的品质,研究结果为甜玉米采后物流运输过程的蓄冷包装保鲜提供了技术依据。Abstract: Sweet corn was highly susceptible to senescence due to its elevated physiological metabolism after harvest, resulting in a decline in its edible quality. The aim of this study was to assess the effects of a cold storage insulation packaging box on the quality attributes of postharvest sweet corn (cv. 'Jinguan 218') during a simulated cold chain transportation period of 3 d and subsequent shelf life at room temperature (20 ℃) for 1 d. The control group involved cold storage at 4 ℃ to mimic refrigerated truck transportation. The results showed that the internal temperature of sweet corn packed in the cold storage insulation packaging box remained below 7 ℃ throughout the 3 d period. In comparison to the control group, the cold storage insulation packaging box effectively maintained the quality of sweet corn during cold chain transportation and shelf life, and delayed husk discoloration. The mass loss rate of sweet corn was reduced by 72.66% after 3 d of cold chain distribution using the packaging box, the soluble solid content was increased by 4.97%, and soluble sugar content was enhanced by 10.13%. Meanwhile, the activities of peroxidase (POD), catalase (CAT) and ascorbate peroxidase (APX) in sweet corn packaged with the cold storage insulation packaging box were significantly (P<0.05) higher than those in the control group, although the activity of superoxide dismutase (SOD) was inhibited by cold storage insulation packaging box. Therefore, the cold storage insulation packaging box demonstrated its ability to maintain the quality of sweet corn throughout cold chain logistics and shelf life. This work provides a technical basis for the preservation of sweet corn through cold storage packaging during post-harvest logistics and transportation.

-

Keywords:

- sweet corn /

- cold storage /

- mass loss /

- soluble sugar /

- antioxidant activity

-

甜玉米皮薄汁多,营养物质丰富,深受消费者喜爱[1]。2021年中国甜玉米的产量达2464万吨,市场消费量579亿穗,对采后贮藏运输需求巨大。然而甜玉米往往在高温多雨的夏秋季节成熟,采后生理代谢旺盛,极易发生品质劣变[2]。其中,抗氧化系统在甜玉米采后衰老中发挥重要作用,抗氧化酶能够清除自由基,减少活性氧(reactive oxygen species,ROS)的积累,维持细胞膜的稳定性[3]。因此,维持甜玉米采后抗氧化酶的活性对于保持甜玉米采后品质至关重要。甜玉米采后需要迅速采用低温贮藏和冷链物流运输[4]的方式。但是我国冷链技术发展晚、水平低、断链现象严重,这给甜玉米采后运输过程中的品质保持带来极大的挑战[5]。目前,甜玉米采后保鲜方法有气调贮藏、冰温贮藏、冷藏等。研究发现,利用一定浓度的二氧化碳和氧气的气调保鲜,能延长甜玉米的采后寿命[6]。4 ℃低温冷藏可以维持甜玉米的良好风味品质[7]。先低温锻炼再冰温贮藏的甜玉米,色香味口感俱佳[7]。当前的研究主要集中在甜玉米采后贮藏和预冷环节,对于甜玉米采后冷链物流运输的技术研究鲜见报道。并且,现阶段冷链物流中最好的方法是冷藏车运输,但冷藏车运输成本较高。生产上仍多采用常温网袋或泡沫箱加碎冰的方式运输甜玉米穗[8]。采用的常温网袋包装甜玉米易出现发热、腐烂发霉等现象,外苞叶容易破损。泡沫箱加冰贮藏方式冰融化后会导致箱内积水,易造成甜玉米品质损害及微生物繁殖等问题[8−9]。为此,亟需不断开发新的甜玉米保鲜运输方式。

蓄冷技术是利用物质的显热或者潜热特性储存冷量,在需要的时候将冷量释放出去供需求方使用的一种技术[10],能够解决供冷量在时间和空间上不匹配的问题[11]。主要的蓄冷剂有甘露醇水溶液、KCl溶液、NaCl溶液及甘氨酸水溶液、辛酸溶液等物质[12−13],蓄冷剂与保温箱的结合可形成密封的小型冷藏环境。与冷藏车运输相比,蓄冷箱包装可以针对同一货车中的不同果蔬独立包装,减少彼此之间的干扰,加快供销点的卸货速度,提高效率。且蓄冷箱能多次重复利用,可减少外包材的使用,降低成本。研究表明,冰袋结合泡沫箱包装能使杏的温度在17 h内维持在20 ℃以下,保持较好的糖酸比风味;使蟠桃果实在24 h内温度保持在10 ℃以下,保持较高的抗氧化酶活性;蓄冷剂结合保温箱包装使胡萝卜在55 h内温度维持在10 ℃以下[14]。

为了明确蓄冷技术在甜玉米运输过程和货架期间的保鲜效果,本研究拟以冷库贮藏模拟冷藏车运输为对照,研究蓄冷箱包装模拟冷链运输3 d和常温货架贮藏1 d后对甜玉米品质的影响,揭示蓄冷箱在甜玉米冷链运输过程中的控温保鲜作用,为其在甜玉米冷链物流中的可应用性提供依据。

1. 材料与方法

1.1 材料与仪器

甜玉米 ‘金冠218’品种的甜玉米。采收后挑选成熟度一致,无病虫害,长短均一、苞叶无机械损伤的甜玉米穗,置于周转筐中,真空预冷后立即放入4 ℃、相对湿度为85%的冷库;乙酸乙酯 分析纯,现代东方(北京)科技发展有限公司;浓硫酸 优级纯,国药集团化学试剂有限公司;蔗糖 分析纯,西陇化工股份有限公司;30%过氧化氢 分析纯,天津市大茂化学试剂厂;愈创木酚 分析纯,南开大学精细化学实验厂;过氧化氢酶活性检测试剂盒(紫外吸收法)(货号:AKAO003-1U)、抗坏血酸过氧化物酶活性检测试剂盒(货号:AKVI006U)、超氧化物歧化酶活性检测试剂盒(货号:AKAO001C) 北京盒子生工科技有限公司。

WZY-1温度自记仪 北京建华仪科技发展有限公司;CR-400全自动测色色差计 日本Konica Minolta公司;A11 basic分析研磨机 德国 IKA公司;HW·SY11-K型电热恒温水浴锅 北京市长风仪器仪表公司;UV-1800紫外分光光度计 日本京都岛津公司。

SK-50蓄冷箱 广州思诚科技有限公司。内部尺寸为450 mm×450 mm×450 mm,外部尺寸为560 mm×560 mm×560 mm。箱体厚度110 mm,由100 mm聚氨酯泡沫与10 mm真空绝热板组成,导热系数为0.004 W/(m·k)。蓄冷箱为顶部开放式,有效容积为50 L。使用蓄冷箱自带的6块与箱内壁面长宽相同尺寸的蓄冷板,为箱内提供冷量。蓄冷板的规格及物理特性如表1所示。实验前蓄冷板置于−20 ℃冷冻48 h备用,蓄冷箱置于4 ℃库中冷却12 h备用。

表 1 蓄冷板的规格及物理特性Table 1. Specifications and physical characteristics of cold storage plate指标 数值范围 主要成分 1.2%超吸收性聚合物,0.1 mol/L甘露醇,

0.1%苯甲酸钠和0.8 mol/LKCl溶液相变温度 −3.7~−2.5 ℃ 导热系数 0.029~0.041 W/(m·K) 相变潜热 306.3~307.2 kJ/kg 密度 0.99 g/cm3 尺寸 450 mm×450 mm×20 mm 1.2 实验方法

1.2.1 甜玉米处理方法

带有完整苞叶的甜玉米穗,随机分成两组(每组质量10 kg)。一组整齐摆放在周转筐中,周转筐用聚乙烯薄膜袋(厚30 µm)套住并扎口密封。置于温度为4 ℃,相对湿度为85%的冷库中贮藏3 d,作为对照组,以模拟冷藏车运输。另一组整齐摆放在一个带有6块冰板的密封蓄冷箱中。置于35 ℃恒温环境中放置3 d,模拟夏季高温冷链运输的环境,之后取出甜玉米穗置于常温货架(20 ℃)环境中贮藏1 d,定期观察取样和测定各项指标,蓄冷箱取样要迅速,于1 min内取样完毕并立即密封。甜玉米包装系统如图1A所示。重复3次。

1.2.2 蓄冷箱体空载状态下内部温度的时空变化

温度测点布置如图1B所示。蓄冷箱中放入冰板后,用胶带将温度计探头固定到T1、T3两点,之后将蓄冷箱扣盖密封。置于35 ℃恒温环境中放置3 d。采用WZY-1温度自动记录仪实时测定蓄冷箱内具体温度点的温度变化,每10 min记录一次。

1.2.3 蓄冷箱体中甜玉米内部温度时空特征

甜玉米真空预冷后,保留完整苞叶,整齐摆放于蓄冷箱,直至装满。如图1A所示。置于35 ℃恒温环境中,装箱时,在箱内正上方(T1)、中心(T2)、正下方(T3)、侧上方(T4)、侧下方(T5)点各取一根玉米,将WZY-1温度自计仪插入甜玉米芯的中心位置以监测甜玉米果实内部的温升变化,每10 min记录一次。

1.2.4 色差测定

取3根甜玉米穗,采用色差仪测定甜玉米外苞叶侧面赤道区的色差值,每根甜玉米测3个侧面,重复3次。

1.2.5 质量损失率测定

取3根甜玉米穗,采用电子天平称量,记录数据后计算。按照下式进行:

1.2.6 可溶性糖含量的测定

参照曹建康等[15]的方法,略有改动。用研磨机将甜玉米冻样研磨成粉末,称取1.0 g样品置于刻度试管中。加入10 mL蒸馏水匀浆,于沸水中提取30 min,冷却后在4 ℃、8000×g条件下离心25 min,用蒸馏水定容至100 mL。于25 mL刻度试管中加0.5 mL样液、1.5 mL蒸馏水、0.5 mL蒽酮—乙酸乙酯试剂(0.02 g/mL)、5 mL 浓度为98%的浓硫酸。测定波长630 nm处的吸光度值。根据蔗糖的标准曲线计算可溶性糖含量,表示为g/kg。重复3次。

1.2.7 可溶性固形物测定

从3根甜玉米穗中部环绕部位随机取适量甜玉米完整籽粒,于研钵中挤压出汁后用滴管取澄清汁液,滴到糖度计中进行测定。重复3次。

1.2.8 过氧化物酶(peroxidase,POD)活性测定

参照曹建康等[15]的方法,略有改动。称取5.0 g甜玉米粉末,加入5.0 mL含1 mmol/L PEG、4% PVPP和1% Triton X-100的提取缓冲液。冰浴研磨至匀浆,于4 ℃、12000×g离心30 min,收集上清液低温保存备用。反应体系包括:3.0 mL 25 mmol/L愈创木酚溶液、0.5 mL上清液、200 µL 0.5 mol/L H2O2溶液。记录15 s时在波长470 nm处吸光度值,作为初始值,然后每隔1 min记录一次,连续测定6次。以每克样品每分钟吸光度变化值增加1时为1个POD活性单位(U)。POD活性单位为U/g。重复3次。

1.2.9 过氧化氢酶(catalase,CAT)活性测定

称取0.1 g甜玉米粉末,冰浴匀浆,4 ℃、8000×g离心10 min,取上清。依次加入35 µL上清液,1000 µL CAT检测工作液。混匀后测定波长240 nm处5 s时吸光值和65 s时吸光值。每克组织每分钟催化1 µmol H2O2降解定义为一个酶活性单位(U)。CAT活性单位为U/g。重复3次。

1.2.10 抗坏血酸过氧化物酶(ascorbate peroxidase,APX)活性测定

称取0.1 g甜玉米粉末,加入1 mL试剂一提取液,冰浴匀浆,4 ℃、13000×g离心20 min,取上清为粗酶液。依次加入100 µL粗酶液、700 µL试剂一、100 µL试剂二、100 µL试剂三。测定粗酶液和蒸馏水空白组10 s时波长290 nm处吸光值,准确反应120 s后,再次测定两者的吸光度值。每克样品每分钟氧化1 µmol抗坏血酸定义为一个酶活性单位(U)。APX活性单位为U/g。重复3次。

1.2.11 超氧化物歧化酶(superoxide dismutase,SOD)活性测定

称取0.1 g甜玉米粉末,加入1 mL试剂一提取液,4 ℃、8000×g离心10 min,取上清。按说明书依次加入试剂后测定波长560 nm处的吸光度值。当黄嘌呤氧化酶偶联反应体系中抑制率为50%时,反应体系中的SOD酶活性定义为一个酶活性单位(U)。SOD活性单位为U/g。重复3次。

1.3 数据处理

数据整理采用Excel 2021统计分析软件,利用Origin 2022软件进行整理绘图,利用IMB SPSS Statistics 25软件对数据进行最小差异性显著性(least significant difference,LSD)分析。

2. 结果与分析

2.1 蓄冷箱空载内部温升及放入甜玉米后果实温升变化

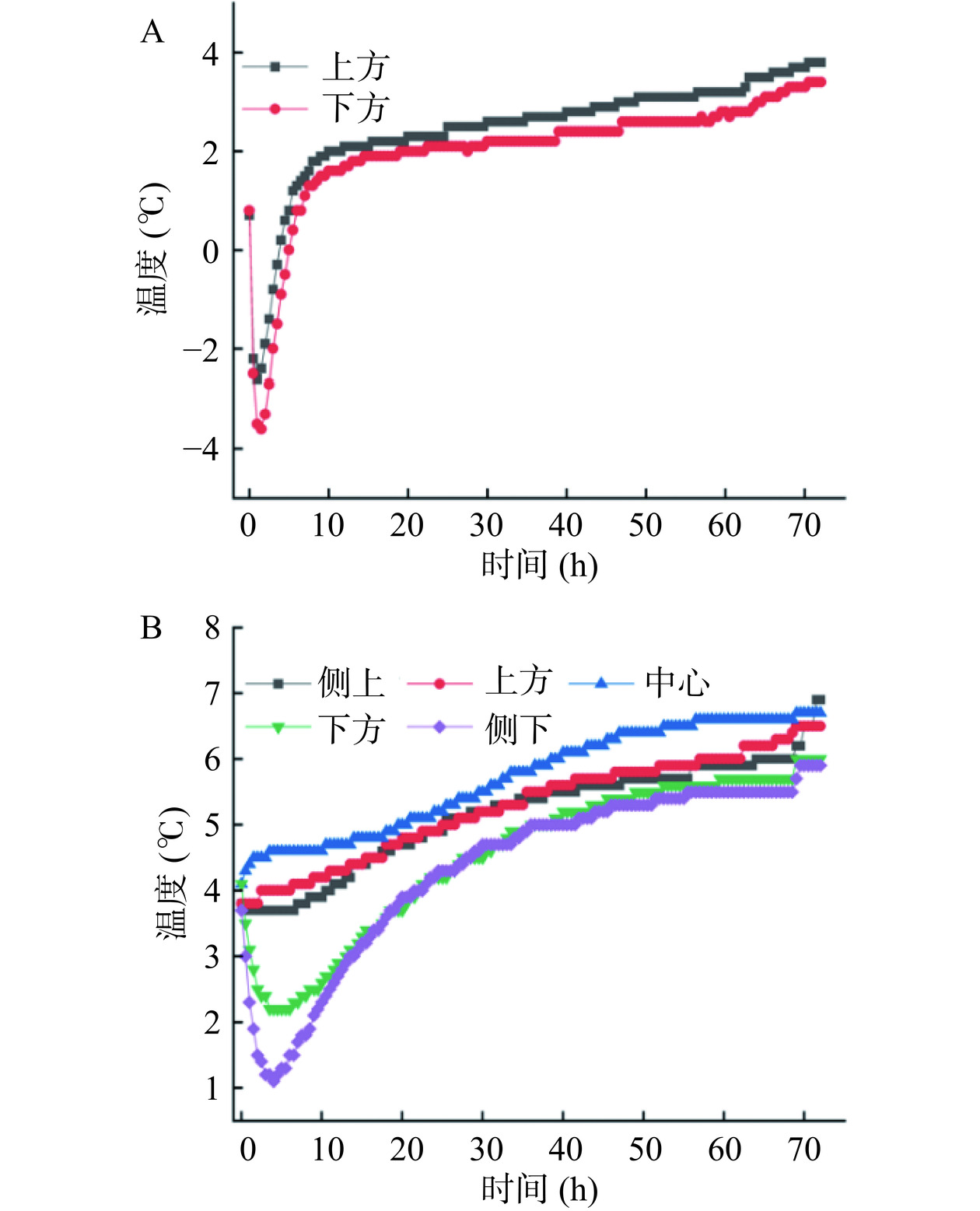

为了明确蓄冷箱在空载状态下内部温升及放入甜玉米后果实内部的温升变化,进行了蓄冷箱的蓄冷保温及维持果实低温的实验。将蓄冷板装入蓄冷箱,空载密封后,由图2A可知,温度迅速下降至−2.5 ℃,然后回温,在密封12 h时温度仅从−2.5 ℃达到2 ℃,然后到72 h时才缓慢上升至4 ℃。箱内下方温度与上方温度变化一致,但上方温度略高于下方。这可能是由于箱内较冷的空气密度大,下沉聚集在箱子下部造成的。将预冷后的甜玉米装入蓄冷箱密封后,蓄冷箱内各位置温度发生了明显上升。由图2B可知,箱内中心位置的甜玉米温度最高,但是在72 h内仅从4 ℃逐渐上升至7 ℃。上方和侧上方温度变化与中心一致,同时刻温度远低于中心温度。下方和侧下方温度先下降后上升,72 h后,最高温度不超过6 ℃。中心温度高可能是因为甜玉米呼吸作用产生的热量聚集在中心未及时散出,并且此位置的甜玉米距离冰板最远。折弯弯等[16]、朱麟等[17]研究结果表明,泡沫箱加冰的温度变化趋势为先下降后上升,与本研究结果一致。但泡沫箱加冰在48 h后温度达到25 ℃。因此,本研究的蓄冷箱包装具有良好的蓄冷保温性能,可用于甜玉米蓄冷包装模拟冷链物流运输,能使甜玉米温度在72 h内保持在7 ℃以下。

2.2 蓄冷箱包装对甜玉米色差的影响

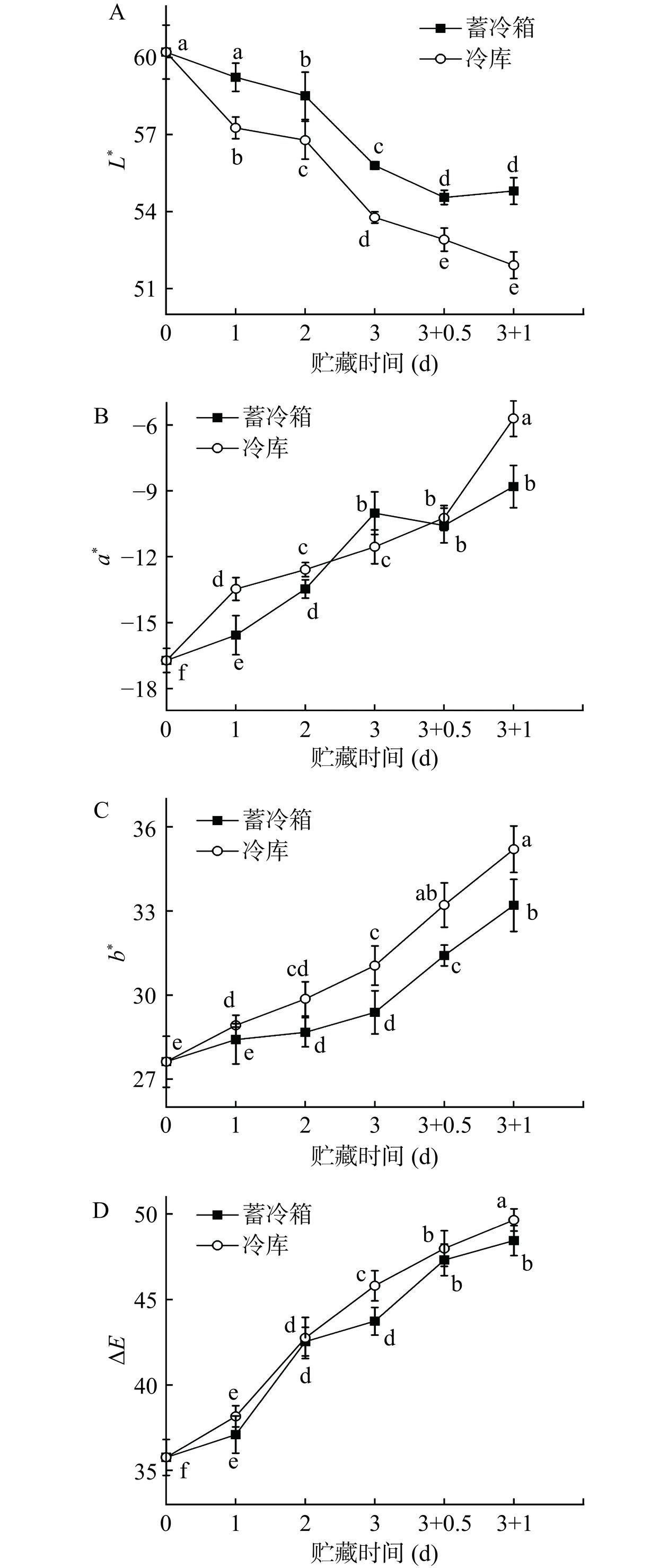

甜玉米苞叶表皮颜色代表的是衰老进程变化,L*、a*、b*和ΔE值能够反映其苞叶色泽变化,进而反映其新鲜程度[7,18]。L*值由小到大表示甜玉米苞叶颜色由暗到明。如图3A所示,在整个贮藏期间,冷库贮藏的甜玉米L*值逐渐下降,表明甜玉米苞叶的亮度逐渐变暗。蓄冷箱包装的甜玉米L*值也逐渐下降,但始终显著高于冷库贮藏的甜玉米(P<0.05)。低温冷藏期间,蓄冷箱包装的甜玉米比冷库的亮度值高3.62%,这可能与冷库贮藏甜玉米苞叶表皮失水有关。常温货架贮藏1 d后,蓄冷箱包装的甜玉米比冷库的亮度值高5.27%。a*值由小到大表示甜玉米苞叶颜色由绿到红。如图3B所示,冷库贮藏的甜玉米a*值在3 d内缓慢上升,表明甜玉米在贮藏过程中绿色逐渐褪去。蓄冷箱包装的甜玉米a*值整体也呈上升趋势。常温货架贮藏1 d后,蓄冷箱包装的甜玉米比冷库的a*值低35.19%,说明蓄冷箱包装降低了玉米苞叶的褪绿速度。

b*值由小到大表示甜玉米苞叶颜色由蓝到黄。如图3C所示,冷库贮藏的甜玉米b*值在贮藏期间逐渐上升,说明甜玉米苞叶会逐渐发生黄化现象。蓄冷箱包装的甜玉米b*值也逐渐增加,但是显著低于冷库中贮藏的甜玉米(P<0.05)。蓄冷箱包装的甜玉米在贮藏72 h后比冷库的b*值低5.38%,常温货架贮藏1 d后,蓄冷箱包装的甜玉米比冷库的b*值低5.68%,说明蓄冷箱包装延缓了甜玉米苞叶的黄化速度。ΔE可以反映甜玉米在贮运过程中的颜色变化程度。由图3D可知,冷库贮藏的甜玉米ΔE逐渐增大,表明甜玉米在贮藏过程中色差逐渐变大。蓄冷箱包装的甜玉米ΔE也逐渐增大,但始终显著低于冷库贮藏的甜玉米(P<0.05)。这可能是蓄冷箱包装的甜玉米苞叶亮度变化小、转黄、褪绿程度低的原因。蒋侬辉等[19]研究结果表明,荔枝采用冰袋结合电商物流包装的方式降低了L*值的上升和ΔE值的下降趋势。本研究中,蓄冷包装与冷库贮藏相比,抑制了甜玉米亮度的降低和褪绿、转黄的过程,与以上结论相符。综上,蓄冷箱包装在冷链物流运输过程中对甜玉米苞叶的外观品质具有显著的保护作用,并且在货架期间也能使甜玉米维持相对较好的色泽。

2.3 蓄冷箱包装对甜玉米质量损失率的影响

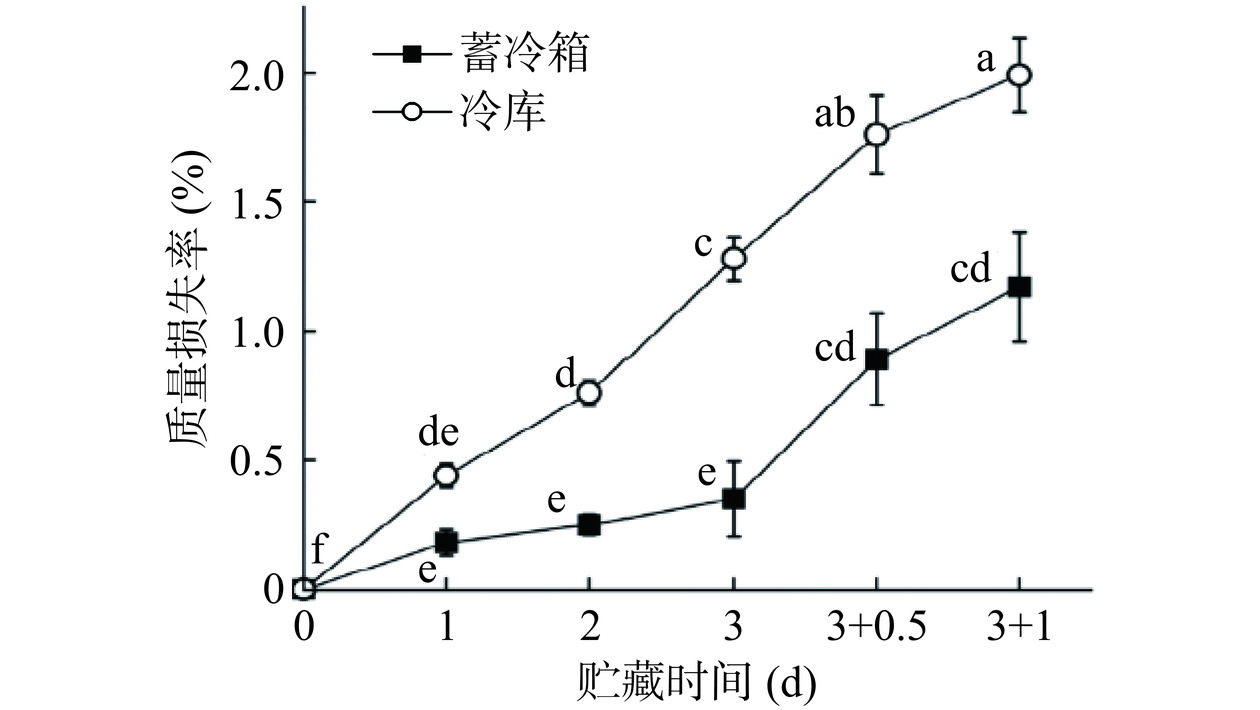

质量损失率可以表征甜玉米在贮藏过程中的水分流失情况,失水会直接影响到甜玉米的外观和口感[5]。如图4所示,在低温贮藏和常温货架贮藏期间,冷库贮藏的甜玉米质量损失率逐渐增加,蓄冷箱包装的甜玉米质量损失率也逐渐增加,但是显著低于冷库贮藏的甜玉米(P<0.05)。在低温贮藏72 h后,蓄冷箱包装的甜玉米质量损失率比冷库组低72.66%,常温货架贮藏1 d后,蓄冷箱包装的甜玉米质量损失率比冷库组低41.21%。可能是由于蓄冷箱包装的甜玉米是处于一个密封性较好的环境中,水分散失相对较少,且蓄冷箱内放置的冰板在释热过程中表面会出现少量水蒸汽,能够维持蓄冷箱内的湿度环境,进而降低甜玉米的质量损失。饶先军等[20]研究表明,与0 ℃相比,聚乙烯袋包装能维持果蔬湿度环境,降低内部水分蒸腾,减少干耗。本研究中蓄冷箱包装的甜玉米质量损失率显著降低,与以上研究结论相符。因此,蓄冷箱包装能显著降低甜玉米水分的流失,更好地保持其柔嫩多汁的口感。

2.4 蓄冷箱包装对甜玉米可溶性糖和可溶性固形物含量的影响

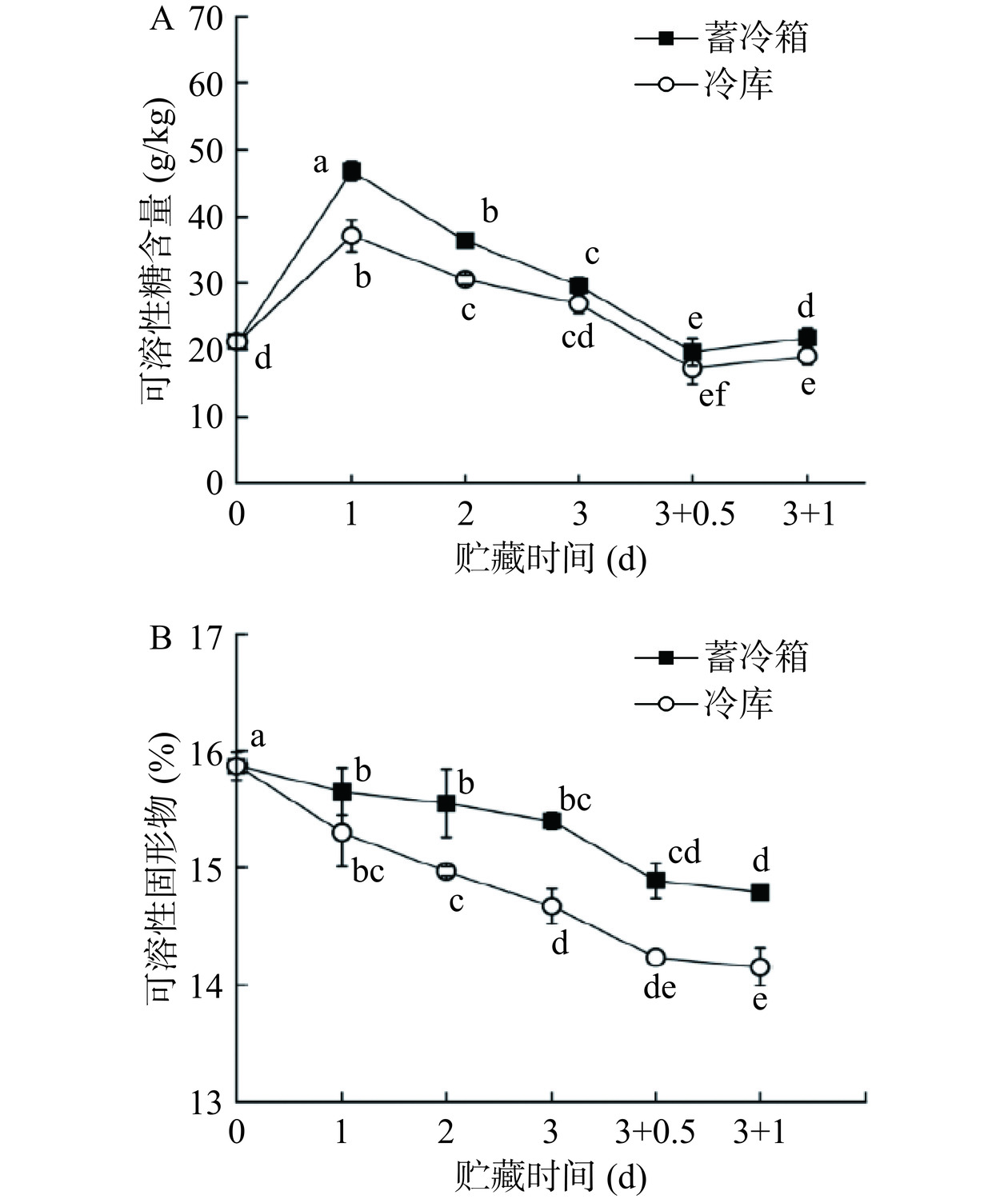

甜玉米中可溶性糖是甜味的主要来源,含量较高。贮藏期间受淀粉水解、呼吸作用等因素的影响[3],含量逐渐降低。如图5A所示,冷库贮藏的甜玉米可溶性糖含量先增加后降低,蓄冷箱包装的甜玉米可溶性糖含量也是先增加后降低,但是显著高于冷库中的甜玉米(P<0.05)。低温贮藏3 d后,蓄冷箱包装的甜玉米可溶性糖含量比冷库的高10.13%,常温货架贮藏1 d后,两组相差14.43%。这可能与蓄冷箱封闭严密导致甜玉米呼吸作用减弱、可溶性糖消耗降低有关。Zhou等[21]研究表明,哈密瓜采后低温贮藏过程中,可溶性糖含量呈现先上升后下降的趋势,与本研究结果一致。本研究中甜玉米在常温货架贮藏0.5 d以后可溶性糖含量升高,可能与失水有关。因此,蓄冷箱包装可显著延缓可溶性糖含量的降低(P<0.05),减少甜玉米冷链运输过程及货架期间自身营养物质的消耗。

可溶性固形物是影响甜玉米风味的一个重要因素,主要成分为可溶性糖,还包括能溶于水的矿物质、维生素、酸等[18]。由图5B可知,冷库贮藏的甜玉米可溶性固形物含量逐渐降低,蓄冷箱包装的甜玉米可溶性固形物含量也逐渐降低,但始终高于冷库贮藏的甜玉米(P<0.05)。低温贮藏的3 d后,蓄冷箱包装的甜玉米比冷库的可溶性固形物含量高4.97%。常温货架贮藏1 d后,两组相差4.52%,差距减小。说明蓄冷箱包装延缓了甜玉米在冷链物流及货架期间糖类物质的分解代谢,保持了较好的食用品质。Nazoori等[22]研究表明,果实贮藏过程中可溶性固形物含量下降是由于呼吸消耗,贮藏后期增加是由于水分的流失和糖的积累。本研究中可溶性固形物的变化与以上结论基本一致,并且蓄冷箱的低温密封包装导致甜玉米的呼吸代谢活动减弱,延缓了衰老进程。

2.5 蓄冷箱包装对甜玉米抗氧化酶活性的影响

植物细胞代谢过程会产生活性氧物质,随后转变成高度活泼的氧自由基及其衍生物。清除H2O2等活性氧物质有助于维持细胞正常生理功能[1]。POD、CAT、SOD、APX等酶能提高活性氧的分解速率,清除植物体内过多的自由基,防止脂质过氧化,对于维持植物体内活性氧的动态平衡发挥着关键作用[23]。

2.5.1 蓄冷箱包装对甜玉米POD活性的影响

POD能够将H2O2、O2−·、NO等强氧化物进行还原,转化成水等无毒无害的物质,从而清除甜玉米细胞中活性氧,减轻过量活性氧对细胞的损害,保护细胞的正常结构[24]。图6A表明,贮藏1 d后,冷库的甜玉米贮藏POD活性显著上升(P<0.05),蓄冷箱包装的甜玉米POD活性上升幅度更明显。之后两组的POD活性逐渐下降,蓄冷箱包装的甜玉米POD活性整体水平显著高于冷库的(P<0.05)。低温贮藏3 d后,蓄冷箱包装的甜玉米POD活性比冷库的提高了9.89%。常温货架贮藏1 d后,POD活性出现小幅度的增加,可能与低温转入常温货架后,随着温度升高,呼吸代谢加快,衰老进程加速有关。王艳颖等[25]的研究结果表明,间歇升温能够提高POD的活性,抑制了活性氧的积累。本研究蓄冷箱中温度呈缓慢上升状态,POD活性相对提高,与以上研究结论相符。由此推断POD酶可能参与了甜玉米的抗氧化防御过程,改善POD酶活性可能有利于防止过氧化物对甜玉米细胞产生损害。

2.5.2 蓄冷箱包装对甜玉米CAT活性的影响

CAT是一种抗氧化酶,能够促使植物体内的H2O2分解为分子氧和水,清除自由基[26−27]。图6B表明,冷库贮藏的甜玉米CAT活性逐渐降低,蓄冷箱包装的甜玉米CAT活性也逐渐降低,但是显著高于冷库贮藏的甜玉米(P<0.05)。低温贮藏3 d后,蓄冷箱包装的甜玉米CAT活性比冷库中的高25.80%。Jiang等[28]研究表明,低温会抑制果实的CAT活性。本研究中24 h后蓄冷箱内温度高于4 ℃,增强了CAT的活性,与以上研究结论一致。常温货架贮藏1 d后,蓄冷箱包装的甜玉米CAT活性比冷库中的高39.4%。20 ℃常温货架后,CAT活性未提升,可能是由于氧化应激加剧导致抗氧化剂的氧化消耗和酶蛋白功能障碍[28]。CAT活性的强弱能在某种程度上反映果实耐藏性与衰老的程度,因此采用蓄冷箱包装能够增强甜玉米抗氧化防御系统的能力,延缓甜玉米衰老腐败的进程。

2.5.3 蓄冷箱包装对甜玉米APX活性的影响

APX 是植物清除活性氧的重要抗氧化酶之一,能够与植物体内抗坏血酸反应,能将细胞内多种来源的H2O2转化为H2O,从而避免H2O2对植物体造成的伤害[3]。从图6C可以看出,冷库贮藏的甜玉米APX活性基本保持稳定,一直处于较低的水平。蓄冷箱包装的甜玉米在冷藏阶段APX活性持续升高,常温货架贮藏后逐渐下降,整体水平显著高于冷库的(P<0.05)。低温3 d后,蓄冷箱包装的甜玉米APX活性比冷库的高34.11%。冷藏2 d时甜玉米的APX活性达到高峰值,可能是进入低温贮藏环境后出现应激反应,适应环境后应激性消失,伴随着甜玉米细胞膜脂的氧化,APX活性逐渐降低。转入到20 ℃常温货架贮藏后,随着甜玉米的衰老加剧,APX活性下降速率加快,常温货架贮藏1 d后,蓄冷箱包装的甜玉米APX活性比冷库中的高31.1%。Wang等[29]研究结果表明,10% CO2处理能够增强鲜切梨果实贮藏期间的APX活性。本研究中蓄冷箱密封包装,由于甜玉米的呼吸作用,可以使箱内形成一个低O2高CO2的环境,从而增强了甜玉米APX的活性,与以上研究结论相符。因此与冷库相比,蓄冷箱包装能延缓APX活性的下降,维持活性氧清除系统的平衡,有利于保持甜玉米冷链运输及货架期间的品质。

2.5.4 蓄冷箱包装对甜玉米SOD活性的影响

SOD可以催化组织中超氧阴离子发生歧化反应而产生H2O2,清除活性氧自由基,从而减少自由基对甜玉米细胞膜的损伤,延缓其组织衰老[29−30]。图6D表明,甜玉米在冷库贮藏期间,SOD活性变化不大,处于较稳定的水平。蓄冷箱包装的甜玉米贮藏1 d后,体内SOD活性显著上升(P<0.05),之后不断下降,且低于对照。低温贮藏3 d后,蓄冷箱包装的甜玉米SOD活性比冷库中的低20.75%。常温货架贮藏1 d后,蓄冷箱包装的甜玉米SOD活性比冷库中的低9.7%。可能是由于冷库温度比较稳定,因此贮藏期间SOD活性波动较小,这与Habibi等[24]的研究结果一致,4 ℃低温能够维持SOD 活性。与冷库相比,蓄冷箱包装的甜玉米贮藏过程中SOD活性先升高后降低,可能是由于蓄冷箱中温度的缓慢变化,对SOD的稳定性产生影响。

3. 结论

本实验以‘金冠218’甜玉米为实验材料,以冷库(4 ℃)模拟冷藏车运输为对照,研究了蓄冷箱包装模拟冷链运输对甜玉米贮藏品质的影响。结果表明,本研究的蓄冷箱包装可使甜玉米穗内部温度在3 d内保持在7 ℃以下,蓄冷保温效果良好。与对照相比,蓄冷箱包装还延缓了甜玉米的品质变化,减少水分流失,提高可溶性固形物与可溶性糖含量,延缓甜玉米苞叶的黄化、褪绿现象。进一步分析表明,本研究蓄冷箱包装甜玉米能保持较高的POD、CAT、APX等抗氧化酶活性,可减少甜玉米体内活性氧的积累,从而减轻了细胞膜脂的氧化,延缓了甜玉米的衰老和品质劣变。此外,由于蓄冷箱维持低温、密封的特性,能够抑制甜玉米的呼吸代谢,可减少甜玉米营养物质的消耗。因此,本研究结果为甜玉米采后流通品质的保持提供了理论依据和实践参考,蓄冷箱包装在甜玉米冷链运输过程中具有明显的应用前景。

-

表 1 蓄冷板的规格及物理特性

Table 1 Specifications and physical characteristics of cold storage plate

指标 数值范围 主要成分 1.2%超吸收性聚合物,0.1 mol/L甘露醇,

0.1%苯甲酸钠和0.8 mol/LKCl溶液相变温度 −3.7~−2.5 ℃ 导热系数 0.029~0.041 W/(m·K) 相变潜热 306.3~307.2 kJ/kg 密度 0.99 g/cm3 尺寸 450 mm×450 mm×20 mm -

[1] SUN Y N, WANG K, DONG Y H, et al. Effects of radiofrequency blanching on lipoxygenase inactivation, physicochemical properties of sweet corn (Zea mays L.), and its correlation with cell morphology[J]. Food Chemistry,2022,394:133498. doi: 10.1016/j.foodchem.2022.133498

[2] YACTAYO C J P, BOEHLEIN S, BEIRIGER R L, et al. The impact of post-harvest storage on sweet corn aroma[J]. Phytochemistry Letters,2022,52:33−39. doi: 10.1016/j.phytol.2022.09.001

[3] LOTFI M, HAMDAMI N, DALVI-ISFAHAN M, et al. Effects of high voltage electric field on storage life and antioxidant capacity of whole pomegranate fruit[J]. Innovative Food Science & Emerging Technologies,2022,75:102888.

[4] ANAND S, BARUA M K. Modeling the key factors leading to post-harvest loss and waste of fruits and vegetables in the agri-fresh produce supply chain[J]. Computers and Electronics in Agriculture,2022,198:106936. doi: 10.1016/j.compag.2022.106936

[5] LIU H, LI D L, XU W C, et al. Application of passive modified atmosphere packaging in the preservation of sweet corns at ambient temperature[J]. LWT,2021,136:110295. doi: 10.1016/j.lwt.2020.110295

[6] 郑远荣, 邵小龙, 李云飞. 甜玉米冰温贮藏保鲜研究[J]. 食品工业科技,2008,29(12):203−206. [ZHENG Y R, SHAO X L, LI Y F. Study on the preservation of sweet corn during ice temperature storage[J]. Food Industry Technology,2008,29(12):203−206.] ZHENG Y R, SHAO X L, LI Y F. Study on the preservation of sweet corn during ice temperature storage[J]. Food Industry Technology, 2008, 29(12): 203−206.

[7] CALVO B P, O HARE T. Effect of freezing and cool storage on carotenoid content and quality of zeaxanthin-biofortified and standard yellow sweet-corn (Zea mays L.)[J]. Journal of Food Composition and Analysis,2020,86:103353.

[8] 王福东. 北京地区甜玉米采后品质的影响因素调查与分析[J]. 中国蔬菜,2020(7):76−82. [WANG F D. Investigation and analysis of factors influencing the postharvest quality of sweet corn in Beijing area[J]. Chinese Vegetables,2020(7):76−82.] WANG F D. Investigation and analysis of factors influencing the postharvest quality of sweet corn in Beijing area[J]. Chinese Vegetables, 2020(7): 76−82.

[9] LIU J Y, LIN Y F, LIN H T, et al. Impacts of exogenous ROS scavenger ascorbic acid on the storability and quality attributes of fresh longan fruit[J]. Food Chemistry: X,2021,12:100167. doi: 10.1016/j.fochx.2021.100167

[10] 陈剑, 陈曦, 雷贻诚, 等. 具有低温蓄冷剂的斯特林低温冰箱性能研究[J]. 制冷学报,2023,44(2):144−150. [CHEN J, CHEN X, LEI Y C, et al. Research on the performance of stirling cryogenic refrigerator with low temperature storage agent[J]. Journal of Refrigeration,2023,44(2):144−150.] CHEN J, CHEN X, LEI Y C, et al. Research on the performance of stirling cryogenic refrigerator with low temperature storage agent[J]. Journal of Refrigeration, 2023, 44(2): 144−150.

[11] ZHANG Y, XU Y Q, LU R W, et al. Form-stable cold storage phase change materials with durable cold insulation for cold chain logistics of food[J]. Postharvest Biology and Technology,2023,203:112409. doi: 10.1016/j.postharvbio.2023.112409

[12] LI C C, LI Y X, HE Y L. Optimization of super water-retention phase change gels for cold energy storage in cold chain transportation[J]. Journal of Energy Storage,2023,61:106719. doi: 10.1016/j.est.2023.106719

[13] KENISARIN M M, KENISARINA K M. Form-stable phase change materials for thermal energy storage[J]. Renewable and Sustainable Energy Reviews,2012,16(4):1999−2040. doi: 10.1016/j.rser.2012.01.015

[14] 段爱鹏, 刘斌, 王瑞星. 蓄冷箱内Al2O3-H2O蓄冷材料对冷藏胡萝卜的温度模拟研究[J]. 冷藏技术,2017,40(1):22−27. [DUAN A P, LIU B, WANG R X. Temperature simulation study of Al2O3-H2O cold storage material in a cold storage box on refrigerated carrots[J]. Refrigeration Technology,2017,40(1):22−27.] DUAN A P, LIU B, WANG R X. Temperature simulation study of Al2O3-H2O cold storage material in a cold storage box on refrigerated carrots[J]. Refrigeration Technology, 2017, 40(1): 22−27.

[15] 曹建康, 姜微波, 赵玉梅. 果蔬采后生理生化试验指导[M]. 北京:中国轻工业出版社, 2007:46−82. [CAO J K, JIANG W B, ZHAO Y M. Guidelines for postharvest physiological and biochemical testing of fruits and vegetables[M]. Beijing:China Light Industry Press, 2007:46−82.] CAO J K, JIANG W B, ZHAO Y M. Guidelines for postharvest physiological and biochemical testing of fruits and vegetables[M]. Beijing: China Light Industry Press, 2007: 46−82.

[16] 折弯弯, 程曦, 张洪翠, 等. 蓄冷剂控温泡沫箱对常温物流莴笋尖的保鲜机理[J]. 食品与发酵工业,2018,44(3):170−178. [ZHEN W W, CHENG X, ZHANG H C, et al. The fresh-keeping mechanism of cryogen temperature controlled foam box on lettuce tip under normal temperature logistics[J]. Food and Fermentation Industry,2018,44(3):170−178.] ZHEN W W, CHENG X, ZHANG H C, et al. The fresh-keeping mechanism of cryogen temperature controlled foam box on lettuce tip under normal temperature logistics[J]. Food and Fermentation Industry, 2018, 44(3): 170−178.

[17] 朱麟, 凌建刚, 尚海涛. 不同包装方式对模拟物流配送杨梅品质的影响[J]. 保鲜与加工,2016,16(1):87−90. [ZHU L, LING J G, SHANG H T. The effect of different packaging methods on the quality of red bayberry in simulated logistics delivery[J]. Preservation and Processing,2016,16(1):87−90.] ZHU L, LING J G, SHANG H T. The effect of different packaging methods on the quality of red bayberry in simulated logistics delivery[J]. Preservation and Processing, 2016, 16(1): 87−90.

[18] KUMAR N, KACHHADIVA S, NAVI P. Storage stability and characterization of biochemical, rehydration and colour characteristics of dehydrated sweet corn kernels[J]. Journal of Stored Products Research,2020,87:101619. doi: 10.1016/j.jspr.2020.101619

[19] 蒋侬辉, 黄泽鹏, 刘伟, 等. 电商物流包装贮运对‘翡翠’荔枝贮藏品质的影响[J]. 食品工业科技,2019,40(18):249−254. [JIANG N H, HUANG Z P, LIU W, et al. The impact of e-commerce logistics packaging, storage and transportation on the storage quality of 'Jade' lychee[J]. Food Industry Technology,2019,40(18):249−254.] JIANG N H, HUANG Z P, LIU W, et al. The impact of e-commerce logistics packaging, storage and transportation on the storage quality of 'Jade' lychee[J]. Food Industry Technology, 2019, 40(18): 249−254.

[20] 饶先军, 刘升, 颜丽萍. 聚乙烯袋包装和0 ℃冷藏对结球生菜品质的影响[J]. 食品与机械,2012,28(2):177−179. [RAO X J, LIU S, YAN L P. The effect of polyethylene bag packaging and 0 ℃ refrigeration on the quality of headed lettuce[J]. Food and Machinery,2012,28(2):177−179.] RAO X J, LIU S, YAN L P. The effect of polyethylene bag packaging and 0 ℃ refrigeration on the quality of headed lettuce[J]. Food and Machinery, 2012, 28(2): 177−179.

[21] ZHOU D D, ZHANG Q, WU C E, et al. Change of soluble sugars, free and glycosidically bound volatile compounds in postharvest cantaloupe fruit response to cutting procedure and storage[J]. Scientia Horticulturae,2022,295:110863. doi: 10.1016/j.scienta.2021.110863

[22] NAZOORI F, MOLLAI S, SOBHANI F, et al. Carboxymethyl cellulose and carnauba wax treatments kept the pomegranate fruit (Punica granatum L.) quality during cold storage via improving enzymatic defense system and bioactive compounds[J]. Scientia Horticulturae,2023,309:111645. doi: 10.1016/j.scienta.2022.111645

[23] SITTHITRAI K, KETTHAISONG D, LERTRAT K, et al. Bioactive, antioxidant and enzyme activity changes in frozen, cooked, mini, super-sweet corn (Zea mays L. saccharata 'Naulthong')[J]. Journal of Food Composition and Analysis,2015,44:1−9. doi: 10.1016/j.jfca.2015.06.001

[24] HABIBI F, GUILLEN F, SERRANO M, et al. Postharvest treatment with glycine betaine enhances chilling tolerance of blood orange fruit by increasing antioxidant defence systems and osmoregulation during cold storage[J]. Scientia Horticulturae,2022,305:111352. doi: 10.1016/j.scienta.2022.111352

[25] 王艳颖, 胡文忠, 刘程惠, 等. 问歇升温对采后香蕉李贮藏中酶促褐变的影响[J]. 食品科学,2010,31(2):245−249. [WANG Y Y, HU W Z, LIU C H, et al. The effect of intermittent heating on enzymatic browning of postharvest banana plum during storage[J]. Food Science,2010,31(2):245−249.] WANG Y Y, HU W Z, LIU C H, et al. The effect of intermittent heating on enzymatic browning of postharvest banana plum during storage[J]. Food Science, 2010, 31(2): 245−249.

[26] BAHCECI K S, SERPEN A, GOKMEN V, et al. Study of lipoxygenase and peroxidase as indicator enzymes in green beans:Change of enzyme activity, ascorbic acid and chlorophylls during frozen storage[J]. Journal of Food Engineering,2005,66(2):187−192. doi: 10.1016/j.jfoodeng.2004.03.004

[27] XU C, ZHANG X Y, LIANG J, et al. Cell wall and reactive oxygen metabolism responses of strawberry fruit during storage to low voltage electrostatic field treatment[J]. Postharvest Biology and Technology,2022,192:112017. doi: 10.1016/j.postharvbio.2022.112017

[28] JIANG L, HAN Z H, LIU J L, et al. Intermittent stepwise cooling and warming ameliorate chilling injury and improve quality in postharvest ‘Guifei’ mango fruit[J]. LWT,2023,181:114740. doi: 10.1016/j.lwt.2023.114740

[29] WANG D, LI W X, LI D, et al. Effect of high carbon dioxide treatment on reactive oxygen species accumulation and antioxidant capacity in fresh-cut pear fruit during storage[J]. Scientia Horticulturae,2021,281:109925. doi: 10.1016/j.scienta.2021.109925

[30] MA Y Y, ZHANG W D, CHENG S B, et al. Postharvest storage at near-freezing temperature maintained the quality and antioxidant properties of Prunus domestica L. cv. Ximei fruit[J]. Scientia Horticulturae,2022,293:110720. doi: 10.1016/j.scienta.2021.110720

-

期刊类型引用(3)

1. 陶有洁,肖益东,钟瑞,何嘉琦. 山药黏蛋白与卡拉胶对低脂发酵乳品质的影响. 中国食品添加剂. 2025(03): 157-164 .  百度学术

百度学术

2. 李阳,陈树兴. 单、双峰骆驼酸奶品质与风味的比较. 食品与机械. 2024(05): 173-179 .  百度学术

百度学术

3. 刘妍妍,陈文璐,孙志刚,郑莹莹,李亚霖,郝婷婷. 乳清蛋白酶解物对酸奶品质及抗氧化活性的影响. 中国乳业. 2024(10): 84-92 .  百度学术

百度学术

其他类型引用(0)

下载:

下载:

下载:

下载: