Process Optimization and Quality Research of Oil Extraction from Tiger Nut (Cyperus esculentus L.) Using Ultrasonic-assisted Extraction

-

摘要: 为提高油莎豆油的得率且保证成品品质,本研究采用超声辅助正己烷法对油莎豆油的提取工艺进行响应面试验优化,确定最优提取条件后对油莎豆油品质进行分析。在油的品质研究中,采用25 ℃(常温)、47 ℃(超声辅助提取最佳温度)、60 ℃(高温)三个温度对比超声作用对油样中总酚含量、总黄酮含量、1, 1-二苯基-2-三硝基苯肼(1,1-diphenyl-2-picrylhydrazyl,DPPH)自由基清除率、脂肪酸组成及含量的影响。结果表明:脱皮油莎豆研磨后在料液比1:15 (g/mL)、超声时间20 min、超声温度47 ℃、粉碎粒度70目时,油莎豆油的得率为25.01%±0.03%,油样为黄橙色微浊状态,具有豆类特有的香气。油莎豆油对DPPH自由基有一定的清除作用,超声可更好地溶出油莎豆中的营养物质,但对油莎豆中黄酮类物质的破坏效应相对较大,酚酸类物质在高温时含量显著(P<0.05)下降。在25~60 ℃间超声作用和温度的变化对脂肪酸的种类和含量的影响不大,油酸(C18:1)含量最高,约为73.81%~74.00%。本试验结果可以为油莎豆油脂的开发利用提供一定基础和理论依据。Abstract: In order to improve the yield and quality of tiger nut oil, the strategy of ultrasonic-assisted n-hexane was studied by response surface methodology. In this study, the total phenolic content, total flavonoid content, free radical scavenging rate, fatty acid composition, and 1,1-diphenyl-2-trinitrophenylhydrazine (DPPH) clearance rate in oil samples were investigated at three temperatures including 25 ℃ (room temperature), 47 ℃ (optimal temperature for ultrasound assisted extraction), and 60 ℃ (high temperature). The results showed that a high tiger nut oil extraction yield of 25.01%±0.03% was obtained at a solid-liquid ratio of 1:15 (g/mL), ultrasonic time of 20 min, ultrasonic temperature of 47 ℃, and particle size of 70 mesh. The obtained oil sample was yellow-orange and slightly turbid with a unique aroma of beans. Besides, tiger nut oil had a certain scavenging effect on DPPH free radicals. Ultrasound could better dissolve the nutrients in tiger nut, but it had a large destruction effect on tiger nut flavonoids, while the content of phenolic acids significantly (P<0.05) decreased at high temperatures. Ultrasonic treatment and temperature showed slight effect on the types and contents of fatty acids between 25 ℃ and 60 ℃, and the highest content of oleic acid (C18:1) was about 73.81%~74.00%. These results provide a theoretical basis for the development and utilization of oil from tiger nut.

-

油莎豆(Cyperus esculentus L.),又名铁荸荠或虎坚果,是莎草科植物的块茎,在欧洲的西班牙和非洲东北部被广泛种植,中科院植物所在1952年时将油莎豆从苏联引进中国[1]。由于油莎豆适应性及抗逆性强,能够在干旱、沙化或酸性土壤中生长[2],因此在中国北方种植较多[3]。油莎豆富含多种营养物质,其中油脂含量很高。油莎豆油以油酸(67.71%~74.60%)为主,因此不饱和脂肪酸含量高,与橄榄油的脂肪酸组成相似,营养价值也与其相当[4]。此外,油莎豆中的营养物质还具有一定的抗菌、抗氧化功效[5],Shantrell等[6]的研究结果表明,油莎豆的水提取物和甲醇提取物中含有酚类和黄酮等抗氧化活性成分,具有出色的铁还原能力,能够有效清除1,1-二苯基-2-三硝基苯肼(1,1-diphenyl-2-picrylhydrazyl,DPPH)自由基和2,2'-联氮-双(3-乙基苯并噻唑啉-6-磺酸)(2,2'-azino-bis(3-ethylbenzothiazoline-6-sulfonic acid),ABTS+)自由基,Jing等[7]通过油莎豆油的体外和体内抗氧化活性试验也表明了油莎豆油具有良好的抗氧化性能。

油脂的常见提取方法可分为机械法和浸提法两种,机械法快速省时,但出油率低;近些年在普通浸提的基础之上衍生出超临界法(supercritical fluid extraction,SFE)、水酶法(aqueous enzymatic extraction,AEE)、微波(microwave assisted extraction,MAE)及超声波辅助法(ultrasonic assisted extraction,UAE)等快速方便、得油率高的方法。段蕾[3]采用SFE提取油莎豆油,得率达到24.90%,且不饱和脂肪酸含量很高,但是实验成本较高。刘蕾等[8]利用AEE水解植物细胞壁来获取油脂,但AEE的瓶颈在于低采收率和长加工时间,且灭酶过程会使营养物质大量损失。Hu等[2]使用MAE提取油莎豆油,以石油醚和丙酮(2:1,v/v)的混合物作为溶剂,提取率为24.12%,与索式提取法(soxhlet extraction,SE)相比,油中营养成分含量更高,但是微波作用的缺点是加热不均匀。而UAE利用超声波的空化效应、机械效应以及热效应破坏细胞,可以有效补偿微波加热不均匀的缺点[9],且其成本低廉,对营养物质的损害较小。

前人的研究对油莎豆油的营养成分(总酚含量和总黄酮含量)报道较少,并且这些营养物质容易被提取方式、温度等因素影响。所以本试验利用超声辅助正己烷提取油莎豆油,并利用响应面法优化提取条件,从提取工艺和温度两个角度讨论其对油莎豆油中的总酚含量和总黄酮含量的影响,并测定了油脂的DPPH自由基清除能力和脂肪酸组成,以期为油莎豆油脂的开发利用提供一定基础和理论依据。

1. 材料与方法

1.1 材料与仪器

油莎豆 河北省衡水市;正己烷、无水乙醇、亚硝酸钠、碳酸钠、硝酸铝、氢氧化钠 分析纯,天津欧博凯化工有限公司;没食子酸标准品(HPLC≥98%)、1,1-二苯基-2-三硝基苯肼(DPPH) 上海麦克林生化科技有限公司;福林酚试剂 生物试剂,上海蓝季科技发展有限公司;芦丁标准品(HPLC≥98%) 生物试剂,北京索莱宝科技有限公司。

Blue pard生化培养箱、HWS-24电热恒温水浴锅 上海一恒科学仪器有限公司;SpectraMax M2酶标仪 美国Molecular Devices公司;HC-3018高速离心机 安徽中科中佳科学仪器有限公司;JJ-666磨粉机 绿建家居用品有限公司;RE-5205旋转蒸发仪 上海亚荣生化仪器厂;CP114电子天平 奥豪斯仪器(上海)有限公司;XM-P222H无极调功超声波清洗机 小美超声仪器(昆山)有限公司;Agilent 7890B气相色谱仪 美国Agilent公司。

1.2 实验方法

1.2.1 油莎豆油超声辅助提取工艺

油莎豆脱皮→干燥→粉碎过筛→超声辅助正己烷提取→9000 r/min,常温下离心10 min→蒸发溶剂→干燥恒重→油莎豆毛油。

操作要点:对油莎豆使用5% NaOH在70 ℃下碱烫6 min脱皮,清水洗净,自然风干4 h;粉碎过筛:使用研磨机将油莎豆研磨成细粉,超声辅助正己烷提取,并常温离心,保留上清液;蒸发溶剂:使用旋转蒸发仪于40 ℃下蒸发正己烷;干燥恒重:油莎豆粕的前后两次称量所得质量之差小于0.2 mg。制得的油莎豆油于4 ℃冰箱保存备用。

1.2.2 油莎豆油得率计算

将超声辅助提取得到的油莎豆毛油称重,与试验所需豆粉质量相比得到油莎豆油得率[8−10]。

得率(%)=毛油质量(g)豆粉质量(g)×100 1.2.3 单因素实验

称取1.00 g油莎豆粉末,按照1.2.1的流程进行超声辅助提取。控制料液比为1:14 g/mL,超声时间为20 min,超声功率210 W,粉碎粒度40目,考察不同超声温度(20、30、40、50、60 ℃)对油莎豆油得率的影响;控制料液比为1:14 g/mL,超声温度为40 ℃,超声功率210 W,粉碎粒度40目,考察不同超声时间(10、15、20、25、30、35 min)对油莎豆油得率的影响;控制料液比为1:14 g/mL,超声时间为20 min,超声温度40 ℃,粉碎粒度40目,考察不同超声功率(210、245、280、315、350、385 W)对油莎豆油得率的影响;控制超声时间为20 min,超声温度40 ℃,超声功率315 W,粉碎粒度40目,考察不同料液比(1:8、1:10、1:12、1:14、1:16、1:18 g/mL)对油莎豆油得率的影响;控制料液比为1:14 g/mL,超声时间为20 min,超声功率315 W,超声温度40 ℃,考察不同粉碎粒度(20、40、60、80、100、120目)对油莎豆油得率的影响。

1.2.4 响应面优化试验设计

根据单因素实验结果,使用Design-Expert 13的Box-Behnken模型进行响应面优化试验(BBD),选择超声温度、超声时间、料液比和粉碎粒度4个因素,进行四因素三水平的响应面设计,以油莎豆油得率为响应值,四个因素的水平设计见表1。

表 1 响应面试验因素水平设计Table 1. Levels of independent variables in the response surface design水平 因素 A超声温度

(℃)B超声时间

(min)C料液比

(g/mL)D粉碎粒度

(目)−1 30 15 1:12 40 0 40 20 1:14 60 1 50 25 1:16 80 1.2.5 油莎豆油品质分析

1.2.5.1 基本感官指标

油脂透明度、气味、滋味依据GB/T 5525-2008《植物油脂 透明度、气味、滋味鉴定法》[11]中方法测定。

1.2.5.2 总酚含量测定

采用Folin-Ciocalteu比色法。将0.2 mL油莎豆油的80%乙醇提取物与1 mL 0.1mol/L的福林酚试剂混合,静置3 min后添加3 mL 10% Na2CO3,定容至10 mL。避光反应1 h,于765 nm处测定吸光度。标准曲线的绘制:精密称量没食子酸对照品1 mg,用去离子水溶解并制成0.1 mg/mL的没食子酸标准品母液。精密量取标准品母液0、0.5、1、1.5、2、2.5 mL,按照样品的测定流程测定并绘制标准曲线,结果以每毫升溶液中没食子酸质量表示测定样品中总酚含量[12−13]。标准曲线回归方程为:y=0.4060x+0.1845,R2=0.9961。

1.2.5.3 总黄酮含量测定

取0.2 mL油莎豆油的80%乙醇提取物,与0.5 mL 5% NaNO2溶液混合,静置7 min后加入0.5 mL 10% Al(NO3)3溶液,反应7 min后加入5 mL 1mol/L的NaOH溶液,60%乙醇定容至10 mL,在510 nm处测定样品吸光度值。标准曲线的绘制:精密称量芦丁标准品10 mg,用60%乙醇溶解并定容至100 mL,制成0.1 mg/mL的芦丁标准品母液。精密量取标准品母液0、0.5、1、1.5、2、2.5 mL,按照样品的测定流程测定并绘制标准曲线,结果以每mL溶液中芦丁质量表示[12−14]。标准曲线回归方程为:y=0.6811x−0.0021,R2=0.9973。

1.2.5.4 DPPH自由基清除率测定

用无水乙醇准确配制浓度为4、8、12、16、20 mg/mL的油莎豆油样品,分别取1 mL样品,加入1 mL 0.2 mmol/L的DPPH-无水乙醇溶液,摇匀并避光静置30 min,于517 nm处测定吸光度A1;用无水乙醇代替DPPH溶液作为空白对照,测定吸光度A2;按照下式计算DPPH自由基清除率[15−16]。

DPPH自由基清除率(%)=1−A1−A2A0×100 式中:A0:无水乙醇+DPPH溶液的吸光度;A1:样品+DPPH溶液的吸光度;A2:样品+无水乙醇的吸光度。

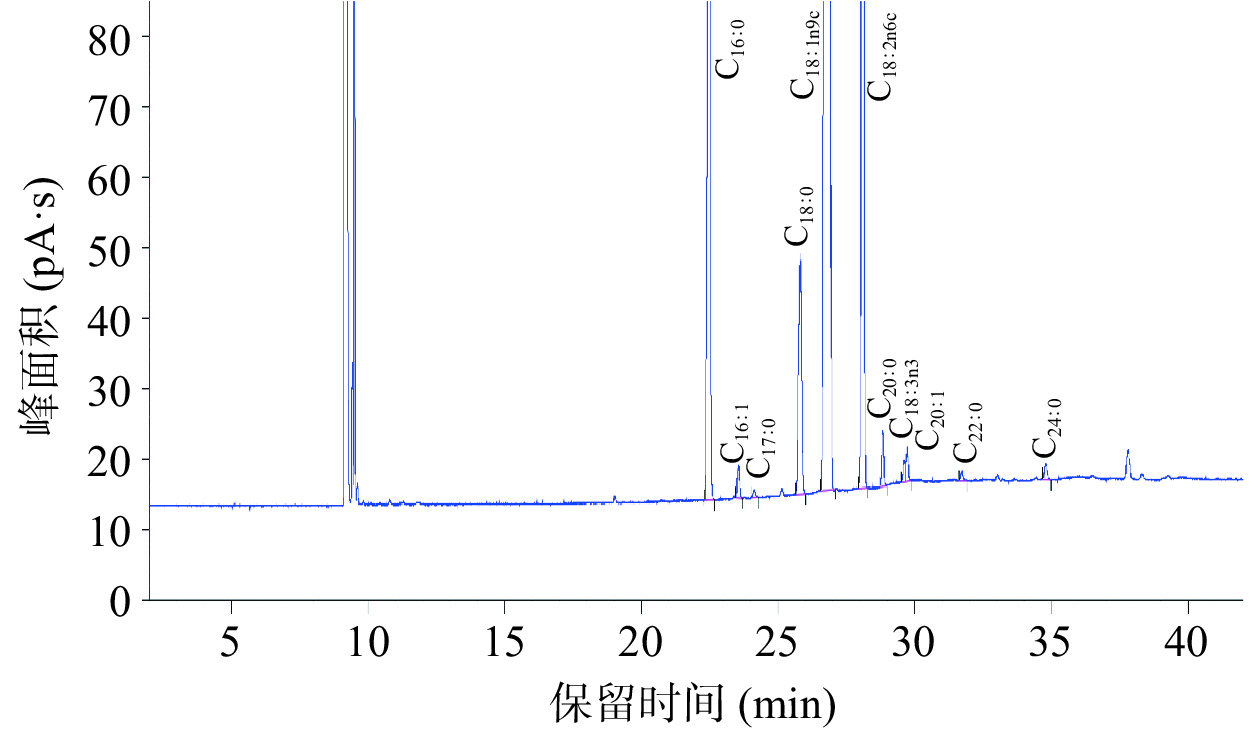

1.2.5.5 脂肪酸组成测定

脂肪酸组成测定方法参照GB 5009.168-2016[17]。气相色谱条件:色谱柱,HP-88(100 m×0.25 mm×0.25 μm);检测器,氢火焰离子化检测器(FID);载气,氮气(纯度≥99.999%);柱温:100 ℃保持13 min,10 ℃/min升温至180 ℃,保持6 min,1 ℃/min升温至200 ℃,保持20 min,4 ℃/min升温至230 ℃,保持10.5 min;进样口温度,270 ℃;检测器温度,280 ℃;分流比,30:1;进样量,1 μL。

1.3 数据处理

每组实验重复3次,数据以平均值±标准差表示。使用SPSS 26软件对数据进行Duncan多重比较,响应面数据使用Design-Expert 13和Origin 2021软件进行分析与作图。显著性水平确定为P<0.05。

2. 结果与分析

2.1 单因素实验结果

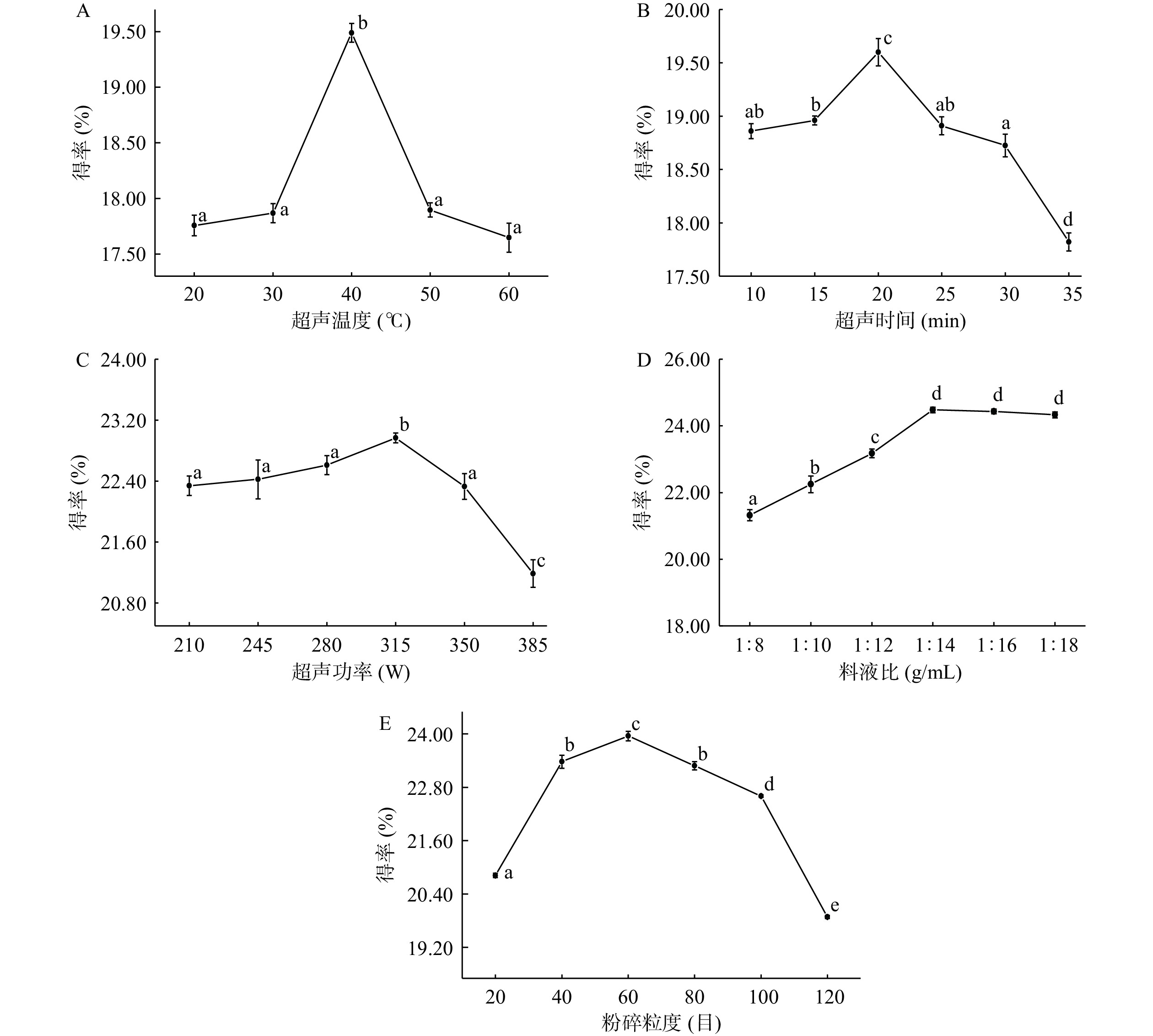

超声温度对油莎豆油得率的影响由图1A所示,油莎豆油的得率随提取温度升高先增大后减小,在40 ℃时达到最高,为19.49%。温度的升高使油脂在溶剂中溶解度增大,溶剂密度和粘度降低,油脂扩散加快,得率增加[18−19];但过高的温度增加了溶剂的饱和蒸气压,导致气泡闭合时缓冲作用增强,空化破坏作用减弱[20],正己烷的沸点较低,约为69 ℃,所以温度升高对其作为提取溶剂的提取效率有较大影响,高温也会使溶剂蒸发,减少了豆粉与溶剂之间的有效接触面积,导致得率的大幅下降。Tian等[10]提取石榴籽油与刘蕾等[8]提取油莎豆油时都在40 ℃之后得率显著(P<0.05)下降。因此选择30~50 ℃为后续试验温度。

超声时间对油莎豆油得率的影响由图1B所示,随着提取时间的延长,油莎豆油的得率先升高后下降,在15~20 min之间得率增加较快,在20 min时达到最大值19.55%。超过20 min时开始快速下降。这是因为在提取过程开始时,由于固液主体之间的浓度梯度和超声空化效应,扩散驱动力大,溶剂良好地渗透到细胞中[21];随着时间的延长,油莎豆中不溶性物质等杂质悬浮在提取物中,或重新吸附到破裂的组织颗粒上,降低了溶剂对细胞结构的渗透性[22],Joven等[23]在提取雨伞树种子油脂时也有类似的趋势。因此选择15~25 min为后续试验时间。

超声功率对油莎豆油得率的影响由图1C所示,超声功率从210 W增加到315 W时,油的得率有所增加,在315 W时达到最大值22.97%,之后随着超声功率的增大得率大幅下降,这与胡炜东等[24]和高芳芳等[25]提取油莎豆油的研究结果趋势一致。这是由于超声功率的增大使空化和机械作用强烈,油脂渗出量随之增大[26];当超声功率过大时,油脂可能分解或挥发,使提取率略有减少[22,27],故选取超声功率为315 W较适宜。

料液比对油莎豆油得率的影响由图1D所示。随着溶剂用量的增加,油莎豆油的得率逐渐增大。当液料比达到1:14(g/mL)时,油的得率达到最高值24.48%。进一步提高液料比例并未对得率产生显著增益,继续增大液料比则会导致油得率略微下降,这与Tian等[10]和Senrayan等[9]提取木棉籽油的研究结果趋势一致。由于有机溶剂的介电常数大约等于甘油三酯的介电常数,因此使用正己烷等有机溶剂容易浸入细胞内部,从而有效溶解脂质[28]。在1:8~1:14(g/mL)间逐渐上升主要是由于固液主体之间的浓度梯度给予了传质过程中的驱动力[10,29],但当溶剂过大时,对于在底部沉积的豆粉颗粒,超声产生的空化和机械等效应强度减弱,导致溶剂的浪费并增加后续工作的困难[30],故选择液料比为1:14(g/mL)左右较适宜。

粉碎粒度对油莎豆油得率的影响由图1E所示。在粉碎粒度为20~60目时,随着粉碎粒度的增加,油的得率明显提高,在60目时达到最大值23.96%,而当粉碎粒度大于60目时,得率显著(P<0.05)下降。唐琳琳[31]研究超声辅助提取红树莓籽油时发现,籽粒的粉碎粒度是影响油脂得率的关键因素,这是因为油莎豆粉质变细,使溶剂与豆粕接触面积增大,传质阻力减少,油脂更易溶出也更容易提取完全;但油莎豆粉碎过细时豆粕易沉底被压实,不易被溶剂接触完全,增加了传质阻力,不利于豆油的提取,因此导致得率下降[32]。刘花花等[32]提取石榴籽油时也发现粉碎粒度超过60目后得率也显著下降。因此粉碎粒度选择40~80目为后续试验粉碎粒度。

2.2 单因素方差分析

由表2可知,五个因素均对油的得率有极显著影响(P<0.01),超声功率相对于料液比、超声时间、超声温度和粉碎粒度对油莎豆油的得率影响较小。考虑实验条件和效率,在响应面优化试验中选择料液比、超声时间、超声温度和粉碎粒度四个因素进行考察。

表 2 单因素实验方差分析结果Table 2. Analysis of variance results of single factor experiments水平 因素 料液比 超声功率 超声时间 超声温度 粉碎粒度 F 501.531 40.013 205.802 239.037 2022.246 P 1.701×10−13 4.468×10−7 3.389×10−11 7.066×10−10 4.062×10−17 2.3 响应面优化试验结果分析

2.3.1 试验结果与方差分析

根据从单因素实验得出的最佳条件,对其进行了包括五组中心点实验在内的共29组实验,以进行四因素三水平的响应面分析,具体结果见表3。

表 3 响应面试验设计及结果Table 3. Design and results of response surface methodology experimental实验号 A超声温度 B超声时间 C料液比 D粉碎粒度 Y得率(%) 1 1 1 0 0 22.71±0.04 2 1 −1 0 0 21.43±0.10 3 1 0 1 0 23.89±0.18 4 1 0 −1 0 19.00±0.05 5 1 0 0 1 23.8±0.08 6 1 0 0 −1 19.59±0.01 7 −1 −1 0 0 20.49±0.14 8 −1 1 0 0 19.47±0.10 9 −1 0 −1 0 19.11±0.09 10 −1 0 1 0 20.42±0.06 11 −1 0 0 1 21.36±0.15 12 −1 0 0 −1 18.27±0.13 13 0 1 1 0 22.27±0.09 14 0 1 −1 0 18.56±0.09 15 0 1 0 1 21.63±0.11 16 0 1 0 −1 18.52±0.10 17 0 −1 0 1 22.08±0.16 18 0 −1 1 0 21.71±0.13 19 0 −1 −1 0 18.27±0.14 20 0 −1 0 −1 17.67±0.04 21 0 0 1 1 24.09±0.22 22 0 0 1 −1 18.52±0.15 23 0 0 −1 −1 16.81±0.06 24 0 0 −1 1 18.77±0.04 25 0 0 0 0 24.06±0.11 26 0 0 0 0 24.06±0.13 27 0 0 0 0 24.11±0.21 28 0 0 0 0 24.00±0.19 29 0 0 0 0 23.95±0.10 将上述实验数据通过Design-Expert软件进行多元回归拟合,得到拟合二次多项回归方程。以超声温度A、超声时间B、料液比C和粉碎粒度D为自变量,以油莎豆油得率为响应值,回归方程为:Y=24.24+0.9417A+0.1258B+1.70C+1.86D+0.5750AB+0.8950AC+0.2800AD+0.0675BC−0.3250BD+0.9025CD−1.28A2−1.87B2−2.29C2−2.33D2。

回归模型进一步应用方差分析及显著性检验进行评估,结果见表4。F值和P值用于显著性评估。从表可知,模型F=147.44,P<0.0001,表明回归模型极显著,具有统计学意义;失拟项F=0.2908,P>0.05,说明了模型失拟相对于纯误差造成的油莎豆油得率变异之间差异不显著,拟合度好。四个因素对油莎豆油得率的影响程度大小为:粉碎粒度>料液比>超声温度>超声时间。R2=0.9931,说明因变量与自变量间有一定的线性关系[33];校正决定系数R2Adj=0.9865,预测决定系数R2Pred=0.9776,说明该回归模型选择合适,具有良好的拟合优度和预测能力[34];变异系数C.V.%=1.34,说明结果准确性和可靠性较高。Adeq Precision值大于4表明模型抗干扰能力良好[34−35],该模型Adeq Precision=35.9394,说明其在自变量范围内是准确可靠的。

表 4 方差分析结果Table 4. Analysis of variance来源 平方和 自由度 均方 F值 P值 显著性 模型 163.81 14 11.70 147.44 <0.0001 *** A超声

温度10.64 1 10.64 134.08 <0.0001 *** B超声

时间0.1900 1 0.1900 2.39 0.1441 C料液比 34.61 1 34.61 436.14 <0.0001 *** D粉碎

粒度41.63 1 41.63 524.54 <0.0001 *** AB 1.32 1 1.32 16.66 0.0011 ** AC 3.20 1 3.20 40.37 <0.0001 *** AD 0.3136 1 0.3136 3.95 0.0667 BC 0.0182 1 0.0182 0.2297 0.6392 BD 0.4225 1 0.4225 5.32 0.0368 * CD 3.26 1 3.26 41.05 <0.0001 *** A² 10.58 1 10.58 133.32 <0.0001 *** B² 22.64 1 22.64 285.34 <0.0001 *** C² 34.08 1 34.08 429.44 <0.0001 *** D² 35.24 1 35.24 444.08 <0.0001 *** 残差 1.11 14 0.0794 失拟项 0.4677 10 0.0468 0.2908 0.9485 纯误差 0.6433 4 0.1608 总差 164.92 28 R2=0.9933,R2Adj=0.9865,R2Pred=0.9776,C.V.%=1.34,Adeq Precision=35.9394 注:***表示差异非常显著(P<0.0001),**表示差异极显著(P<0.01),*表示差异极显著(P<0.05)。 2.3.2 响应面交互作用分析

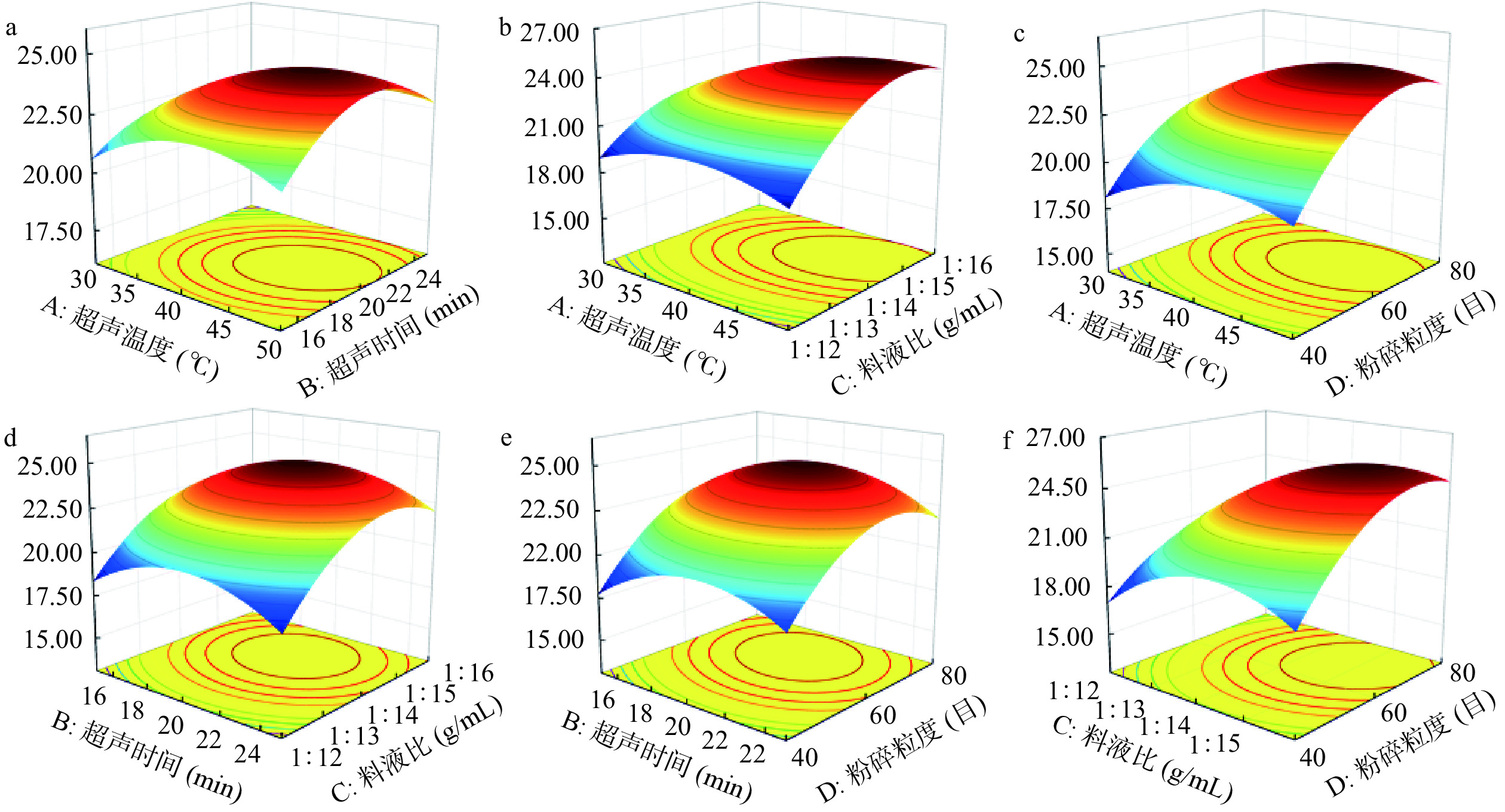

根据回归方程绘制对应的响应面图,两因素间的交互作用强弱可以从图像的等高线中体现,椭圆形代表交互作用对响应值的影响强;响应曲面的陡峭程度反映了各项因素得影响程度,陡峭代表因素对响应值的影响大。如图2所示,所有3D图像均表现出一定的“钟罩型”,说明中心条件选择恰当,得率在四因素的三个水平间都存在先升高再降低的趋势[32]。结合表4,AB、AC、BD、CD的交互作用对响应值的影响显著(P<0.05),CD的交互作用对响应值的影响最强,AC次之;AD、BC的交互作用对响应值的影响不显著。此外,单因素对得率的影响是否显著会影响响应面的形状,由于B对得率的影响不显著,所以图2a、图2d、图2e图形的超声时间面相对平缓,整体呈现较标准的伞状。粉碎粒度的显著性最大,在图2c、图2e、图2f中有所体现,得率显著提高,图形陡峭走高,图形呈现非对称性。

2.3.3 响应面优化结果及验证

通过软件分析,得到油莎豆油理论提取工艺为:料液比1:15.22(g/mL)、超声时间20.50 min、超声温度46.64 ℃、粉碎粒度71.02目,油莎豆油的最大得率为25.59%;但考虑到实际操作的可行性,将工艺调整为:料液比1:15(g/mL)、超声时间20 min、超声温度47 ℃、粉碎粒度70目,在该条件下重复提取3次油莎豆油,实际得率为24.98%、25.03%、25.02%,相对标准偏差RSD=2.00%,与回归模型预测的得率最大值相比无显著差异,说明应用响应面模型优化油莎豆油超声辅助提取工艺条件的结果可靠。

2.4 不同工艺与温度对油品质的影响

2.4.1 不同温度及超声作用对油中活性成分和抗氧化性的影响

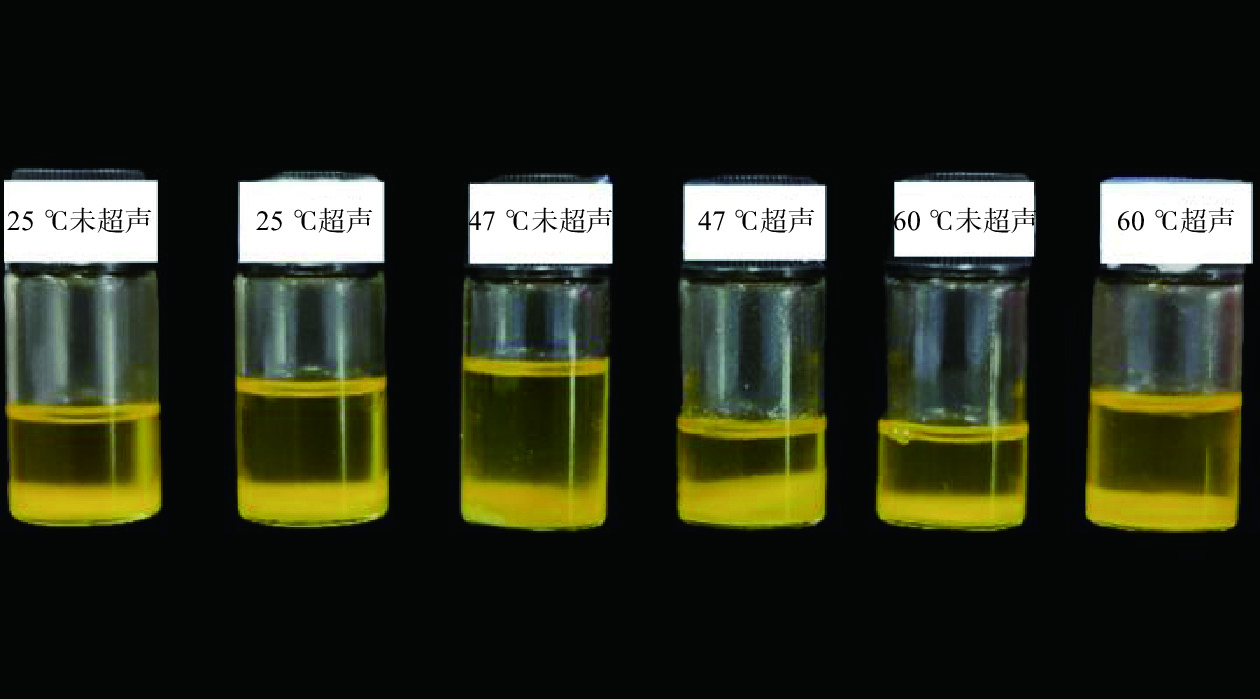

选择25 ℃(常温)、47 ℃(超声辅助提取最佳温度)、60 ℃(高温)三个温度,分别在超声与不超声的条件下进行油莎豆油的提取,并对这6组油莎豆油进行基本感官和总酚、总黄酮、DPPH清除率的测定,结果如图3~图4所示。由图3可知,6组油样因未进行精炼,在20 ℃放置24 h后均呈现微浊状态,液体为黄橙色,无明显异味,具有豆类特有的香气。

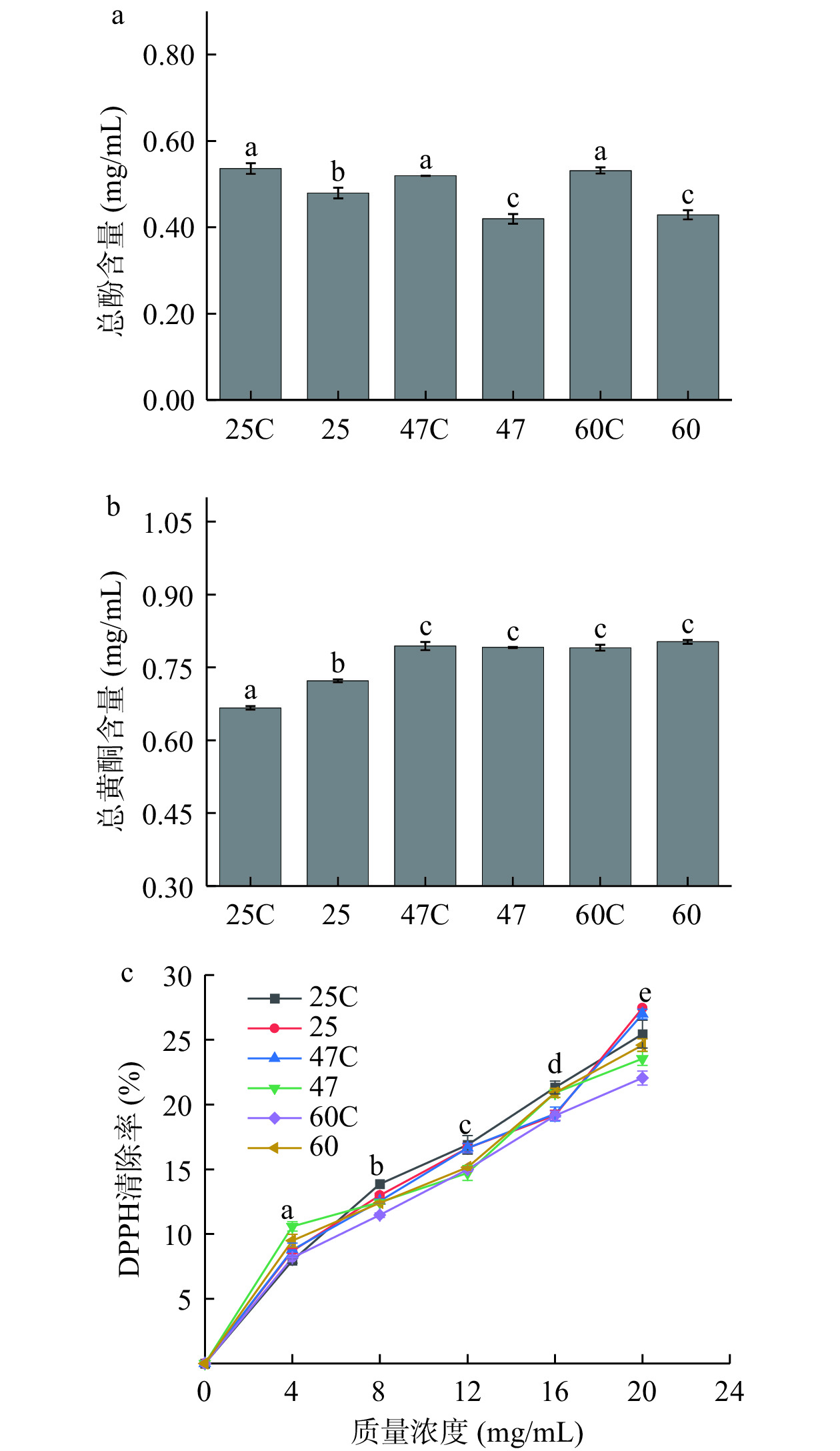

图4a表示出不同温度及超声作用下的6份油品中总酚含量的变化。在超声与未超声组中,25 ℃时的总酚含量在三个温度中最大,分别为0.54、0.48 mg/mL。从图4a中可以看出,超声组总酚含量均显著(P<0.05)高于未超声组。说明在超声作用下,油莎豆油中的酚酸类物质能更好的溶出,且在25~60 ℃间超声作用对酚酸类物质的结构破坏效应小。但随着温度的上升,油中总酚含量有些许下降,这种现象尤其体现在未超声组,说明体系温度对酚酸类物质的结构破坏效应相对较大,超声组的下降趋势不明显可能是因为超声作用下溶出的总酚比被高温破坏结构的总酚含量高,所以呈现出了这种结果。

图4b表示了不同温度及超声作用下的6份油品中总黄酮含量的变化,在提取油莎豆油的过程中,随着温度的增加,总黄酮的含量也有所增加,在60 ℃时油中总黄酮含量与47 ℃时的总黄酮含量无显著差异,但在之前的单因素实验中,油莎豆油的得率在60 ℃时相对于40 ℃显著(P<0.05)下降,这说明油莎豆油的得率与油中的总黄酮含量可能无相互影响作用。另外,根据文献[36−37]的实验结果,黄酮类物质的提取最佳温度大致在50~60 ℃之间,本实验的趋势与其相符。在超声与未超声组的对比中,在25 ℃时超声作用对总黄酮的含量有显著(P<0.05)的降低作用,这说明油莎豆油中的黄酮类物质容易被超声作用破坏,这种作用随着温度的升高而逐渐不明显,这可能是因为体系温度升高,加强了超声的空化作用,使油莎豆中的黄酮类物质更好地溶出,从而拉近了与未超声组的差距。

图4c表示了不同温度及超声作用下的6份油品的DPPH自由基清除率,油莎豆油浓度在0~20 mg/mL时对DPPH自由基的清除率随着质量浓度的升高而增大,呈现一定的线性关系,说明油莎豆油中含有抗氧化性成分,超声与否对DPPH自由基的清除率影响不显著,从整体趋势上看,温度升高会降低油脂的抗氧化活性。

2.4.2 油莎豆油脂肪酸组成分析

将油莎豆油经甲酯化后通过气相色谱仪进行分析,得到6组脂肪酸气相色谱图如图5所示,油莎豆油的脂肪酸有较好地分离且经过样品前处理后没有杂质干扰。

对6组油样进行脂肪酸组成含量检测分析,共检测出11种脂肪酸,结果见表5。

表 5 油莎豆油脂肪酸组成(%)Table 5. Fatty acid compositions of tiger nut oil (%)名称 25 25C 47 47C 60 60C 棕榈酸(C16:0) 12.82±0.00a 12.77±0.07a 12.75±0.00a 12.74±0.08a 12.74±0.09a 12.73±0.08a 棕榈一烯酸(C16:1) 0.27±0.00a 0.26±0.00a 0.27±0.00a 0.26±0.02a 0.27±0.00a 0.27±0.00a 十七烷酸(C17:0) 0.06±0.00a 0.06±0.01a 0.06±0.00a 0.06±0.00a 0.06±0.00a 0.06±0.00a 硬脂酸(C18:0) 2.53±0.00a 2.53±0.01a 2.56±0.00a 2.54±0.16a 2.49±0.11b 2.54±0.14a 油酸(C18:1n9c) 73.81±0.00a 73.92±0.15a 73.96±0.13a 73.91±0.16a 73.97±0.18a 73.91±0.17a 亚油酸(C18:2n6c) 9.48±0.00a 9.44±0.06a 9.37±0.00a 9.46±0.06a 9.45±0.06a 9.48±0.06a 花生酸(C20:0) 0.40±0.00a 0.40±0.00a 0.40±0.00a 0.40±0.00a 0.40±0.00a 0.40±0.00a 亚麻酸(C18:3n3) 0.13±0.00ab 0.13±0.00ab 0.13±0.00a 0.14±0.00b 0.13±0.00ab 0.13±0.00ab 顺-11-二十烯酸(C20:1) 0.26±0.00a 0.27±0.00a 0.27±0.00a 0.26±0.00a 0.27±0.00a 0.27±0.00a 山嵛酸(C22:0) 0.08±0.00a 0.08±0.00a 0.08±0.00a 0.08±0.00a 0.08±0.00a 0.08±0.00a 二十四酸(C24:0) 0.15±0.00a 0.14±0.00a 0.15±0.00a 0.15±0.00a 0.14±0.00a 0.15±0.00a 饱和脂肪酸(SFA) 16.04±0.00a 15.98±0.10a 16.00±0.12a 15.96±0.09a 16.24±0.58a 15.95±0.11a 单不饱和脂肪酸(MUFA) 74.35±0.00a 74.45±0.16a 74.50±0.02a 74.44±0.15a 74.52±0.17a 74.44±0.16a 多不饱和脂肪酸(PUFA) 9.62±0.00a 9.57±0.06a 9.50±0.00a 9.66±0.14a 9.58±0.06a 9.61±0.05a 不饱和脂肪酸(UFA) 83.96±0.00a 84.02±0.10a 84.00±0.01a 84.10±0.00a 84.10±0.11a 84.05±0.11a 由表5可以看出,6组油莎豆样品可检出的脂肪酸组成相同,因提取工艺和温度有微小的不同。油莎豆油脂中含量最高的脂肪酸是油酸(C18:1),含量在73.81%~74.00%左右,其次是棕榈酸(C16:0),含量大约为12.80%,与前人的研究结果类似[38−40],再次证实了油莎豆油是一种富含油酸的植物油。并且本试验采用超声辅助正己烷所提取的油莎豆油中棕榈酸(C16:0)、硬脂酸(C18:0)、油酸(C18:1n9c)和亚油酸(C18:2n6c)的含量均符合LS/T 3259-2018《油莎豆油》标准。

对6组油样的每种脂肪酸及饱和脂肪酸(SFA)、单不饱和脂肪酸(MUFA)、多不饱和脂肪酸(PUFA)、不饱和脂肪酸(UFA)的含量进行显著性分析,结果显示除硬脂酸(C18:0)和亚麻酸(C18:3n3)的含量在6组油样中有显著性(P<0.05)差异,其他脂肪酸含量的变化均不显著,这证明了在25~60 ℃超声作用和温度的变化对脂肪酸的种类和含量的影响不大。其中60 ℃未超声组的硬脂酸含量显著(P<0.05)低于其他组,这可能是由于高温所导致的,也可能是试验误差导致;超声作用对亚麻酸的含量有一定影响,超声组的含量比未超声组的含量相对较高,温度对其含量的影响还需进一步研究。

3. 结论

经超声温度、超声时间、料液比及粉碎粒度四个因素的响应面优化试验,确定油莎豆油的最优提取条件为:料液比1:15(g/mL)、超声时间20 min、超声温度47 ℃、粉碎粒度70目,在此条件下,油莎豆油的得率为25.01%±0.03%,RSD=2.00%,油样为黄橙色微浊状态,具有豆类特有的香气。油莎豆油浓度在0~20 mg/mL时对DPPH自由基有一定的清除作用;在总酚含量测定中,超声在三组不同温度下均有显著性(P<0.05)作用,未超声组的总酚含量随温度的上升而显著下降;在总黄酮含量测定中,超声与未超声组的总黄酮含量都随温度的上升而上升。研究证明超声作用使油莎豆中的营养物质能更好的溶出,但对油莎豆中黄酮类物质的破坏效应相对较大,而酚酸类物质在高温时含量显著(P<0.05)下降。在25~60 ℃超声作用和温度的变化对脂肪酸的种类和含量的影响不大,油酸(C18:1)含量最高,约为73.81%~74.00%。

油莎豆作为一种新型油料作物,本研究为油莎豆油的开发利用及新标准的制定提供了客观依据,油莎豆油作为新型能源具有重要研究意义和应用价值。

-

表 1 响应面试验因素水平设计

Table 1 Levels of independent variables in the response surface design

水平 因素 A超声温度

(℃)B超声时间

(min)C料液比

(g/mL)D粉碎粒度

(目)−1 30 15 1:12 40 0 40 20 1:14 60 1 50 25 1:16 80 表 2 单因素实验方差分析结果

Table 2 Analysis of variance results of single factor experiments

水平 因素 料液比 超声功率 超声时间 超声温度 粉碎粒度 F 501.531 40.013 205.802 239.037 2022.246 P 1.701×10−13 4.468×10−7 3.389×10−11 7.066×10−10 4.062×10−17 表 3 响应面试验设计及结果

Table 3 Design and results of response surface methodology experimental

实验号 A超声温度 B超声时间 C料液比 D粉碎粒度 Y得率(%) 1 1 1 0 0 22.71±0.04 2 1 −1 0 0 21.43±0.10 3 1 0 1 0 23.89±0.18 4 1 0 −1 0 19.00±0.05 5 1 0 0 1 23.8±0.08 6 1 0 0 −1 19.59±0.01 7 −1 −1 0 0 20.49±0.14 8 −1 1 0 0 19.47±0.10 9 −1 0 −1 0 19.11±0.09 10 −1 0 1 0 20.42±0.06 11 −1 0 0 1 21.36±0.15 12 −1 0 0 −1 18.27±0.13 13 0 1 1 0 22.27±0.09 14 0 1 −1 0 18.56±0.09 15 0 1 0 1 21.63±0.11 16 0 1 0 −1 18.52±0.10 17 0 −1 0 1 22.08±0.16 18 0 −1 1 0 21.71±0.13 19 0 −1 −1 0 18.27±0.14 20 0 −1 0 −1 17.67±0.04 21 0 0 1 1 24.09±0.22 22 0 0 1 −1 18.52±0.15 23 0 0 −1 −1 16.81±0.06 24 0 0 −1 1 18.77±0.04 25 0 0 0 0 24.06±0.11 26 0 0 0 0 24.06±0.13 27 0 0 0 0 24.11±0.21 28 0 0 0 0 24.00±0.19 29 0 0 0 0 23.95±0.10 表 4 方差分析结果

Table 4 Analysis of variance

来源 平方和 自由度 均方 F值 P值 显著性 模型 163.81 14 11.70 147.44 <0.0001 *** A超声

温度10.64 1 10.64 134.08 <0.0001 *** B超声

时间0.1900 1 0.1900 2.39 0.1441 C料液比 34.61 1 34.61 436.14 <0.0001 *** D粉碎

粒度41.63 1 41.63 524.54 <0.0001 *** AB 1.32 1 1.32 16.66 0.0011 ** AC 3.20 1 3.20 40.37 <0.0001 *** AD 0.3136 1 0.3136 3.95 0.0667 BC 0.0182 1 0.0182 0.2297 0.6392 BD 0.4225 1 0.4225 5.32 0.0368 * CD 3.26 1 3.26 41.05 <0.0001 *** A² 10.58 1 10.58 133.32 <0.0001 *** B² 22.64 1 22.64 285.34 <0.0001 *** C² 34.08 1 34.08 429.44 <0.0001 *** D² 35.24 1 35.24 444.08 <0.0001 *** 残差 1.11 14 0.0794 失拟项 0.4677 10 0.0468 0.2908 0.9485 纯误差 0.6433 4 0.1608 总差 164.92 28 R2=0.9933,R2Adj=0.9865,R2Pred=0.9776,C.V.%=1.34,Adeq Precision=35.9394 注:***表示差异非常显著(P<0.0001),**表示差异极显著(P<0.01),*表示差异极显著(P<0.05)。 表 5 油莎豆油脂肪酸组成(%)

Table 5 Fatty acid compositions of tiger nut oil (%)

名称 25 25C 47 47C 60 60C 棕榈酸(C16:0) 12.82±0.00a 12.77±0.07a 12.75±0.00a 12.74±0.08a 12.74±0.09a 12.73±0.08a 棕榈一烯酸(C16:1) 0.27±0.00a 0.26±0.00a 0.27±0.00a 0.26±0.02a 0.27±0.00a 0.27±0.00a 十七烷酸(C17:0) 0.06±0.00a 0.06±0.01a 0.06±0.00a 0.06±0.00a 0.06±0.00a 0.06±0.00a 硬脂酸(C18:0) 2.53±0.00a 2.53±0.01a 2.56±0.00a 2.54±0.16a 2.49±0.11b 2.54±0.14a 油酸(C18:1n9c) 73.81±0.00a 73.92±0.15a 73.96±0.13a 73.91±0.16a 73.97±0.18a 73.91±0.17a 亚油酸(C18:2n6c) 9.48±0.00a 9.44±0.06a 9.37±0.00a 9.46±0.06a 9.45±0.06a 9.48±0.06a 花生酸(C20:0) 0.40±0.00a 0.40±0.00a 0.40±0.00a 0.40±0.00a 0.40±0.00a 0.40±0.00a 亚麻酸(C18:3n3) 0.13±0.00ab 0.13±0.00ab 0.13±0.00a 0.14±0.00b 0.13±0.00ab 0.13±0.00ab 顺-11-二十烯酸(C20:1) 0.26±0.00a 0.27±0.00a 0.27±0.00a 0.26±0.00a 0.27±0.00a 0.27±0.00a 山嵛酸(C22:0) 0.08±0.00a 0.08±0.00a 0.08±0.00a 0.08±0.00a 0.08±0.00a 0.08±0.00a 二十四酸(C24:0) 0.15±0.00a 0.14±0.00a 0.15±0.00a 0.15±0.00a 0.14±0.00a 0.15±0.00a 饱和脂肪酸(SFA) 16.04±0.00a 15.98±0.10a 16.00±0.12a 15.96±0.09a 16.24±0.58a 15.95±0.11a 单不饱和脂肪酸(MUFA) 74.35±0.00a 74.45±0.16a 74.50±0.02a 74.44±0.15a 74.52±0.17a 74.44±0.16a 多不饱和脂肪酸(PUFA) 9.62±0.00a 9.57±0.06a 9.50±0.00a 9.66±0.14a 9.58±0.06a 9.61±0.05a 不饱和脂肪酸(UFA) 83.96±0.00a 84.02±0.10a 84.00±0.01a 84.10±0.00a 84.10±0.11a 84.05±0.11a -

[1] 王志成, 李双寿, 梁雄, 等. 中国油莎豆产业发展现状与前景展望[J]. 科技和产业,2022,22(1):62−67. [WANG Zhicheng, LI Shuangshou, LIANG Xiong, et al. Development status and prospects of chinese tiger nut industry[J]. Science and Technology and Industry,2022,22(1):62−67.] doi: 10.3969/j.issn.1671-1807.2022.01.009 WANG Zhicheng, LI Shuangshou, LIANG Xiong, et al. Development status and prospects of chinese tiger nut industry[J]. Science and Technology and Industry, 2022, 22(1): 62−67. doi: 10.3969/j.issn.1671-1807.2022.01.009

[2] HU Bin, LI Yi, SONG Jiaxing, et al. Oil extraction from tiger nut (Cyperus esculentus L.) using the combination of microwave-ultrasonic assisted aqueous enzymatic method-design, optimization and quality evaluation[J]. Journal of Chromatography A,2020,1627:461380. doi: 10.1016/j.chroma.2020.461380

[3] 段蕾. 油莎豆油提取及其氧化稳定性研究[D]. 长春:长春大学, 2020. [DUAN Lei. Extraction and oxidative stability of tiger nut oil[D]. Changchun:Changchun University, 2020.] DUAN Lei. Extraction and oxidative stability of tiger nut oil[D]. Changchun: Changchun University, 2020.

[4] 师茜, 田丽萍, 薛琳, 等. 油莎豆油与其他植物油主要脂肪酸的分析比较[J]. 食品工业,2016,37(1):52−54. [SHI Qian, TIAN Liping, XUE Lin, et al. Analysis and comparison of main fatty acids of tiger nut oil and other vegetable oils[J]. Food Industry,2016,37(1):52−54.] SHI Qian, TIAN Liping, XUE Lin, et al. Analysis and comparison of main fatty acids of tiger nut oil and other vegetable oils[J]. Food Industry, 2016, 37(1): 52−54.

[5] YU Yali, LU Xiaoyu, ZHANG Tiehua, et al. Tiger nut (Cyperus esculentus L.):Nutrition, processing, function and applications[J]. Foods,2022,11(4):601. doi: 10.3390/foods11040601

[6] SHANTRELL W, CYDNEY J, MARTHA V. Effects of processing on antioxidant capacity and metabolizing enzyme inhibition of tiger nut tubers[J]. Food and Nutrition Sciences,2019,10(9):1132−1142. doi: 10.4236/fns.2019.109082

[7] JING Siqun, OUYANG Weiqi, REN Zhiyan, et al. The in vitro and in vivo antioxidant properties of Cyperus esculentus oil from Xinjiang[J]. Journal of the Science of Food and Agriculture,2013,96(3):1505−1509.

[8] 刘蕾, 陈丽娜, 陈星. 超声波辅助提取油莎豆油脂工艺研究[J]. 粮油加工,2009,377(11):40−42. [LIU Lei, CHEN Lina, CHEN Xing. Ultrasonic assisted extraction technology of tiger nut oil[J]. Grain and Oil Processing,2009,377(11):40−42.] LIU Lei, CHEN Lina, CHEN Xing. Ultrasonic assisted extraction technology of tiger nut oil[J]. Grain and Oil Processing, 2009, 377(11): 40−42.

[9] SENRAYAN J, VENKATACHALAM S. Ultrasonic acoustic-cavitation as a novel and emerging energy efficient technique for oil extraction from kapok seeds[J]. Innovative Food Science & Emerging Technologies,2020,62:102347.

[10] TIAN Yuting, XU Zhenbo, ZHENG Baodong, et al. Optimization of ultrasonic-assisted extraction of pomegranate (Punica granatum L.) seed oil[J]. Ultrasonics sonochemistry,2013,20(1):202−208. doi: 10.1016/j.ultsonch.2012.07.010

[11] 国家质量监督检验检疫总局. GB/T 5525-2008 植物油脂 透明度、气味、滋味鉴定法[S]. 北京:中国标准出版社, 2008:1−3. [General administration of quality supervision, inspection and quarantine of the People's Republic of China. GB/T 5525-2008 method for determining the transparency, odor, and taste of vegetable oils[S] Beijing:China Standards Publishing House, 2008:1−3.] General administration of quality supervision, inspection and quarantine of the People's Republic of China. GB/T 5525-2008 method for determining the transparency, odor, and taste of vegetable oils[S] Beijing: China Standards Publishing House, 2008: 1−3.

[12] 安珈怡. 烘烤作用对红松籽油品质影响及其变化规律研究[D]. 哈尔滨:东北林业大学, 2022. [AN Jiayi. Effects of roasting on the quality of Korean pine nut oil and its variation[D]. Harbin:Northeast Forestry University, 2022.] AN Jiayi. Effects of roasting on the quality of Korean pine nut oil and its variation[D]. Harbin: Northeast Forestry University, 2022.

[13] 谭晓舒, 吴建文, 梨贵卿, 等. 火麻仁油总酚含量福林酚测定法的优化[J]. 食品研究与开发,2021,42(2):166−173. [TAN Xiaoshu, WU Jianwen, LI Guiqing, et al. Optimization of folinol determination method for total phenol content in hemp seed oil[J]. Food Research and Development,2021,42(2):166−173.] TAN Xiaoshu, WU Jianwen, LI Guiqing, et al. Optimization of folinol determination method for total phenol content in hemp seed oil[J]. Food Research and Development, 2021, 42(2): 166−173.

[14] 高妮娜, 刘鸿铖, 邹岩, 等. 提取方法对奇亚籽油品质特性的影响[J]. 食品工业科技,2020,41(6):284−291. [GAO Nina, LIU Hongcheng, ZOU Yan, et al. Effects of extraction methods on the quality characteristics of chia seed oil[J]. Food Industry Science and Technology,2020,41(6):284−291.] GAO Nina, LIU Hongcheng, ZOU Yan, et al. Effects of extraction methods on the quality characteristics of chia seed oil[J]. Food Industry Science and Technology, 2020, 41(6): 284−291.

[15] 吴修利, 徐雷, 谢英, 等. 超声波辅助提取油莎豆粕水溶性多糖及其抗氧化性[J]. 食品研究与开发,2022,43(16):81−87. [WU Xiuli, XU Lei, XIE Ying, et al. Ultrasonic assisted extraction of water-soluble polysaccharides from tiger nut meal and its antioxidative activity[J]. Food Research and Development,2022,43(16):81−87.] WU Xiuli, XU Lei, XIE Ying, et al. Ultrasonic assisted extraction of water-soluble polysaccharides from tiger nut meal and its antioxidative activity[J]. Food Research and Development, 2022, 43(16): 81−87.

[16] 张方洁, 高文婕, 查云盛, 等. 不同制油工艺对酸木瓜籽油成分及氧化稳定性的影响[J]. 食品安全质量检测学报,2023,14(4):32−40. [ZHANG Fangjie, GAO Wenjie, ZHA Yunsheng, et al. Effects of different oil production processes on the composition and oxidation stability of sour papaya seed oil[J]. Journal of Food Safety and Quality Inspection,2023,14(4):32−40.] ZHANG Fangjie, GAO Wenjie, ZHA Yunsheng, et al. Effects of different oil production processes on the composition and oxidation stability of sour papaya seed oil[J]. Journal of Food Safety and Quality Inspection, 2023, 14(4): 32−40.

[17] 国家卫生和计划生育委员会, 国家食品药品监督管理总局. GB 5009.168-2016 食物中脂肪酸的测定[S]. 北京:中国标准出版社, 2016. [National Health and Family Planning Commission, National Medical Products Administration. GB 5009.168-2016 Determination of fatty acids in food[S]. Beijing:Standards Press of China, 2016.] National Health and Family Planning Commission, National Medical Products Administration. GB 5009.168-2016 Determination of fatty acids in food[S]. Beijing: Standards Press of China, 2016.

[18] AMIRI S, SHAKERI A, SOHRABI M R, et al. Optimization of ultrasonic assisted extraction of fatty acids from Aesculus hippocastanum fruit by response surface methodology[J]. Food Chemistry,2019,271:762−766. doi: 10.1016/j.foodchem.2018.07.144

[19] DE MELLO B T F, DOS SANTOS GARCIA V A, DA SILVA C. Ultrasound-assisted extraction of oil from chia (Salvia his pânica L.) seeds:Optimization extraction and fatty acid profile[J]. Journal of Food Process Engineering,2017,40(1):12298. doi: 10.1111/jfpe.12298

[20] 袁传勋, 赵圣圣, 金日生. 响应面法优化超声辅助混合溶剂提取油茶饼残油的研究[J]. 粮食与油脂,2022,35(12):79−83. [YUAN Chuanxun, ZHAO Shengsheng, JIN Risheng. Optimizing ultrasonic-assisted mixed solvent extraction of camellia camellia cake residual oil by response surface method[J]. Food and Oils,2022,35(12):79−83.] YUAN Chuanxun, ZHAO Shengsheng, JIN Risheng. Optimizing ultrasonic-assisted mixed solvent extraction of camellia camellia cake residual oil by response surface method[J]. Food and Oils, 2022, 35(12): 79−83.

[21] HEMWIMOL S, PAVASANT P, SHOTIPRUK A. Ultrasound-assisted extraction of anthraquinones from roots of Morinda citrifolia[J]. Ultrasonics Sonochemistry,2006,13(6):543−548. doi: 10.1016/j.ultsonch.2005.09.009

[22] 麻成金, 吴竹青, 黄伟, 等. 侧柏籽油的超声辅助提取及其脂肪酸组成分析[J]. 食品科学,2010,31(24):50−55. [MA Chengjin, WU Zhuqing, HUANG Wei, et al. Ultrasonic-assisted extraction of orientalis seed oil and analysis of its fatty acid composition[J]. Food Science,2010,31(24):50−55.] MA Chengjin, WU Zhuqing, HUANG Wei, et al. Ultrasonic-assisted extraction of orientalis seed oil and analysis of its fatty acid composition[J]. Food Science, 2010, 31(24): 50−55.

[23] JOVEN J M O, GADIAN JR J T, PEREZ M A, et al. Optimized ultrasonic-assisted oil extraction and biodiesel production from the seeds of Maesopsis eminii[J]. Industrial Crops and Products,2020,155:112772. doi: 10.1016/j.indcrop.2020.112772

[24] 胡炜东, 蔡永敏, 杨俊峰. 超声波辅助提取油莎豆油工艺的研究[J]. 食品与机械,2013,29(2):109−112,129. [HU Weidong, CAI Yongmin, YANG Junfeng. Research on ultrasonic assisted extraction of tiger nut oil[J]. Food and Machinery,2013,29(2):109−112,129.] doi: 10.3969/j.issn.1003-5788.2013.02.025 HU Weidong, CAI Yongmin, YANG Junfeng. Research on ultrasonic assisted extraction of tiger nut oil[J]. Food and Machinery, 2013, 29(2): 109−112,129. doi: 10.3969/j.issn.1003-5788.2013.02.025

[25] 高芳芳, 田丽萍, 薛琳. 超声波辅助水酶法提取油莎豆油[J]. 农垦医学,2013,35(6):493−497. [GAO Fangfang, TIAN Liping, XUE Lin. Ultrasonic assisted aqueous enzymatic extraction of oil from tiger nut[J]. Journal of Nongken Medicine,2013,35(6):493−497.] GAO Fangfang, TIAN Liping, XUE Lin. Ultrasonic assisted aqueous enzymatic extraction of oil from tiger nut[J]. Journal of Nongken Medicine, 2013, 35(6): 493−497.

[26] KEMERLI-KALBARAN T OZDEMIR M. Multi-response optimization of oil extraction from pine nut (Pinus pinea L.) by response surface methodology:Extraction efficiency, physicochemical properties and antioxidant activity[J]. LWT, 2019, 103:34−43.

[27] 张峰, 仇农学. 响应面法优化超声波辅助提取辣椒籽油及脂肪酸组成分析[J]. 中国油脂, 2008, 33(11):38−43. [ZHANG Feng, QIU Nongxue. Optimization of ultrasonic-assisted extraction of capsicum seed oil and analysis of fatty acid composition by response surface method[J]. Food Science, 2008, 33(11):38−43.] ZHANG Feng, QIU Nongxue. Optimization of ultrasonic-assisted extraction of capsicum seed oil and analysis of fatty acid composition by response surface method[J]. Food Science, 2008, 33(11): 38−43.

[28] ZHANG Runyang, LIU Huamin, MA Yuxiang, et al. Characterization of fragrant oil extracted from pepper seed during subcritical propane extraction[J]. LWT,2019,110:110−116. doi: 10.1016/j.lwt.2019.04.072

[29] ZHANG Qingan, ZHANG Zhiqi, YUE Xuanfeng, et al. Response surface optimization of ultrasound-assisted oil extraction from autoclaved almond powder[J]. Food Chemistry,2009,116(2):513−518. doi: 10.1016/j.foodchem.2009.02.071

[30] 许晖, 孙兰萍, 李善菊, 等. 超声波辅助提取亚麻籽油的工艺条件优化[J]. 中国粮油学报,2009,24(7):54−58. [XU Hui, SUN Lanping, LI Shanju, et al. Optimizing the process conditions of ultrasonic assisted extraction of linseed oil[J]. Chinese Journal of Cereals and Oils,2009,24(7):54−58.] XU Hui, SUN Lanping, LI Shanju, et al. Optimizing the process conditions of ultrasonic assisted extraction of linseed oil[J]. Chinese Journal of Cereals and Oils, 2009, 24(7): 54−58.

[31] 唐琳琳. 红树莓籽油提取及体外抗氧化、降血脂活性研究[D]. 哈尔滨:东北林业大学, 2020. [TANG Linlin. Extraction of red raspberry seed oil and its in vitro antioxidant and hypolipidemic activities[D]. Harbin:Northeast Forestry University, 2020.] TANG Linlin. Extraction of red raspberry seed oil and its in vitro antioxidant and hypolipidemic activities[D]. Harbin: Northeast Forestry University, 2020.

[32] 刘花花, 康健, 欧荣, 等. 新疆石榴籽油的超声辅助提取工艺及GC-MS分析[J]. 中国油脂,2015,40(1):6−9. [LIU Huahua, KANG Jian, OU Rong, et al. Ultrasonic-assisted extraction and GC-MS analysis of pomegranate seed oil in Xinjiang[J]. China Oils and Fats,2015,40(1):6−9.] LIU Huahua, KANG Jian, OU Rong, et al. Ultrasonic-assisted extraction and GC-MS analysis of pomegranate seed oil in Xinjiang[J]. China Oils and Fats, 2015, 40(1): 6−9.

[33] 蒋汇川, 姚静阳, 张思瑶, 等. 树莓籽油的超声辅助正己烷法提取工艺优化和理化性质研究[J]. 云南大学学报(自然科学版),2021,43(5):1004−1011. [JIANG Huichuan, YAO Jingyang, ZHANG Siyao, et al. Ultrasonic-assisted n-hexane extraction process optimization and physicochemical properties of raspberry seed oil[J]. Journal of Yunnan University (Natural Science Edition),2021,43(5):1004−1011.] JIANG Huichuan, YAO Jingyang, ZHANG Siyao, et al. Ultrasonic-assisted n-hexane extraction process optimization and physicochemical properties of raspberry seed oil[J]. Journal of Yunnan University (Natural Science Edition), 2021, 43(5): 1004−1011.

[34] 郑伊琦, 张安强, 张小军, 等. 响应面优化猪苓菌核多糖超声辅助提取工艺及抗氧化活性分析[J]. 食品工业科技,2023,44(16):255−263. [ZHENG Yiqi, ZHANG Anqiang, ZHANG Xiaojun, et al. Optimizing ultrasonic-assisted extraction process and antioxidant activity analysis of sclerotinia polysaccharides from polyporus polysaccharides by response surface method[J]. Food Industry Science and Technology,2023,44(16):255−263.] doi: 10.13386/j.issn1002-0306.2022110343 ZHENG Yiqi, ZHANG Anqiang, ZHANG Xiaojun, et al. Optimizing ultrasonic-assisted extraction process and antioxidant activity analysis of sclerotinia polysaccharides from polyporus polysaccharides by response surface method[J]. Food Industry Science and Technology, 2023, 44(16): 255−263. doi: 10.13386/j.issn1002-0306.2022110343

[35] MIAO Jingnan, SHI Wang, ZHANG Junqing, et al. Response surface methodology for the fermentation of polysaccharides from Auricularia auricula using Trichoderma viride and their antioxidant activities[J]. International Journal of Biological Macromolecules,2020,155:393−402. doi: 10.1016/j.ijbiomac.2020.03.183

[36] WEN Yao, ZENG Xiang, TIAN Hongyu, et al. Optimization of extraction process of total flavonoids from Cortex lycii and its biological activities[J]. Biomass Conversion and Biorefinery, 2023:1−14.

[37] YANG Rifu, GENG Linlin, LU Haiqin, et al. Ultrasound-synergized electrostatic field extraction of total flavonoids from Hemerocallis citrina baroni[J]. Ultrasonics Sonochemistry,2017,34:571−579. doi: 10.1016/j.ultsonch.2016.06.037

[38] 宋二立, 刘玉兰, 朱文学, 等. 原料品质和制油方法对油莎豆油综合品质的影响[J]. 粮食与油脂,2022,35(3):99−103,126. [SONG Erli, LIU Yulan, ZHU Wenxue, et al. Effects of raw material quality and oil making method on the comprehensive quality of tiger nut oil[J]. Grain and Oil,2022,35(3):99−103,126.] SONG Erli, LIU Yulan, ZHU Wenxue, et al. Effects of raw material quality and oil making method on the comprehensive quality of tiger nut oil[J]. Grain and Oil, 2022, 35(3): 99−103,126.

[39] 田瑜. 油莎豆油生产工艺及产品质量研究[D]. 郑州:河南工业大学, 2016. [TIAN Yu. Research on production process and product quality of tiger nut oil[D]. Zhengzhou:Henan University of Technology, 2016.] TIAN Yu. Research on production process and product quality of tiger nut oil[D]. Zhengzhou: Henan University of Technology, 2016.

[40] 靳俊莹. 水酶法提取油莎豆油及其副产物的开发利用[D]. 郑州:河南工业大学, 2021. [JIN Junying. Development and utilization of aqueous tiger nut oil and its byproducts extracted by aqueous enzyme method[D]. Zhengzhou:Henan University of Technology, 2021.] JIN Junying. Development and utilization of aqueous tiger nut oil and its byproducts extracted by aqueous enzyme method[D]. Zhengzhou: Henan University of Technology, 2021.

-

期刊类型引用(11)

1. 刘影,庞富,陈佳鸿,陈炯葵,蔡烁仪. 本草清咽润喉糖的配方优化及抗氧化研究. 农产品加工. 2024(21): 41-46 .  百度学术

百度学术

2. 张敏君,段雪伟,王燕,杨慧文,刘冰,向文静,由天辉. 构树根皮活性成分乙醇提取工艺优化及其抗氧化活性分析. 食品工业科技. 2023(11): 196-203 .  本站查看

本站查看

3. 王蕙雯. 豫西自然发酵柿子醋抗氧化性研究. 江苏调味副食品. 2023(03): 20-23 .  百度学术

百度学术

4. 裴文清,吕泸楠,王靖宇,浦思琦,雷霜,王春丽. 木瓜皮多酚和黄酮提取工艺优化及酪氨酸酶与胰脂肪酶抑制活性研究. 食品工业科技. 2022(01): 188-195 .  本站查看

本站查看

5. 周新崇,易灿,刘进兵. 微波辅助提取崀山脐橙皮总黄酮及生物活性研究. 邵阳学院学报(自然科学版). 2022(02): 87-95 .  百度学术

百度学术

6. 张清月,董姝慧,李胤豪,赵艳丽,史彬林,闫素梅. 诺丽果不同提取物抗氧化能力的比较研究. 中国粮油学报. 2022(05): 144-150 .  百度学术

百度学术

7. 关随霞,王蕙雯,杨肖瑞,郭淑敏,张翅,张培杰,李道敏. 大青叶总黄酮提取工艺优化及抗氧化性研究. 中国食品添加剂. 2022(09): 138-144 .  百度学术

百度学术

8. 陈慧玲,刘芳,钟恒勤,王伟枫. 超声波辅助乙醇提取百香果皮黄酮的工艺优化及黄酮抗氧化性测定. 宁德师范学院学报(自然科学版). 2022(03): 280-287 .  百度学术

百度学术

9. 任海云,韩瑞,张磊. 基于Box-Behnken响应面法优化党参抗氧化活性组分提取工艺. 中医药信息. 2022(12): 5-10 .  百度学术

百度学术

10. 赵雨晴,王宝庆,徐汉,刘楠楠. 醉鱼草总黄酮的提取及抗氧化活性研究. 化学试剂. 2021(07): 979-985 .  百度学术

百度学术

11. 杨青青,龚吉军. 响应面法优化超声辅助葛根浸提工艺及浸提液抗氧化活性研究. 食品安全质量检测学报. 2021(13): 5409-5417 .  百度学术

百度学术

其他类型引用(3)

下载:

下载:

下载:

下载: