Effect of Different Processing Techniques on the Quality of Sour Bamboo Shoots

-

摘要: 为了探究不同加工工艺对酸笋品质的影响,将麻竹笋采用切片和整根发酵两种方式处理,并分别添加盐、乳酸菌复合培养液两种不同加工辅料发酵制作酸笋,以传统添加水发酵为对照组,比较不同工艺加工酸笋的总酸、氨基态氮、亚硝酸盐、主体风味、感官评价、挥发性风味物质以及微观结构的变化。结果表明,切片酸笋氨基态氮平均含量较整根酸笋高38.2%,酸度低于整根发酵酸笋,组织结构更为疏松,挥发性物质种类比整根发酵酸笋多12种,亚硝酸盐含量差异不显著;添加盐和接种发酵酸笋中,盐发酵酸笋较接种发酵酸笋氨基态氮含量高10.6%,挥发性物质种类盐发酵比接种发酵酸笋多4种,接种发酵酸笋酸度高于盐发酵酸笋,亚硝酸盐含量显著低于盐发酵(P<0.05),所有发酵成品酸笋亚硝酸盐含量均低于3.5 mg/kg。感官评价结果显示,盐发酵的切片酸笋其色泽、口感最好,评分高达91分,综合分析得出切片盐发酵得到的酸笋酸度适宜,品质最佳。本研究为酸笋的生产工艺及工业化应用提供了理论依据和技术支撑。

-

关键词:

- 酸笋 /

- 气相色谱-质谱(GC-MS) /

- 品质分析 /

- 微观结构

Abstract: In order to investigate the effects of different processing techniques on the quality of sour bamboo shoots, bamboo shoots were treated using two methods including licing and whole fermentation, and two different processing ingredients salt and lactic acid bacteria were separately added for fermentation to produce sour bamboo shoots. A comparison was made between the sour bamboo shoots processed using different techniques in terms of total acidity, amino nitrogen value, main flavor, sensory evaluation, volatile flavor compounds, and microscopic structure changes, with traditionally water-added fermentation as the control group. The results showed that the average amino nitrogen content of sliced sour bamboo shoots was 38.2% higher than that of whole sour bamboo shoots, the acidity was lower than that of whole fermented sour bamboo shoots, the structure was more loose, the types of volatile substances were 12 more than that of whole fermented sour bamboo shoots, and the content of nitrite was not significantly different. The amino nitrogen content of salt-fermented sour shoots was 10.6% higher than that of inoculated fermented sour shoots, and the types of volatile substances were 4 more than that of inoculated fermented sour bamboo shoots. The acidity of inoculated fermented sour shoots was higher than that of the salt-fermented sour bamboo shoots, and the nitrite content was significantly lower than that of salt-fermented sour shoots (P<0.05). Notably, all fermented sour bamboo shoot products had a nitrite content lower than 3.5 mg/kg. The sensory evaluation indicated that salt-fermented sliced sour bamboo shoots had the best color and taste, with a score of 91 points. The comprehensive analysis concluded that sliced bamboo shoots fermented with salt had a suitable acidity level and the best quality. This study provides a theoretical basis and technical support for industrial application and production techniques for sour bamboo shoots.-

Keywords:

- sour bamboo shoots /

- GC-MS /

- quality analysis /

- microstructure

-

酸笋作为我国传统发酵食材,味道鲜美,营养丰富,在南方地区一直被广泛食用,具有悠久的历史[1]。酸笋不仅含有丰富的营养物质而且具有独特的风味特征,郑文迪等[2]研究发现,酸笋中的挥发性风味物质高达53种,包含了酚类、醇类、醛类和酸类等风味成分,酸笋也因独特的酸味受到人们的钟爱[2−4]。粤菜中常以酸笋调味,如酸笋鸡、酸笋焖鸭、酸汤鱼等传统菜肴,随着预制菜的盛行,这些传统菜肴逐渐走进千家万户,必然使得酸笋需求日益上升。

长期以来,传统酸笋多为家庭式自然发酵,以麻竹笋为原料,利用自然附着微生物发酵制作而成[5−6]。酸笋自然发酵的发酵周期长、容易受到杂菌污染、品质难以保证,而该问题可通过接种乳酸菌解决[7]。另外酸笋的腌制方式差异较大,常见的有将竹笋切块、切丝以及整根腌制,并且不同地区腌制添加辅料有所不同,有些直接加水进行发酵,有些加盐水发酵,但目前并未有详细研究指出何种腌制方式及添加何种辅料酸笋品质最佳[8−9]。由于以上种种原因,虽然酸笋成为一种历史悠久的发酵食品,却尚未形成规模化生产,大多以农家自产外销为主,也正因为如此酸笋市场竞争能力弱,质量和卫生安全问题存在隐患[10],极大地限制了酸笋研究及产业发展。

因此,本文采用整根和切片两种方式发酵麻竹笋,并分别添加盐、内含嗜热链球菌和保加利亚乳杆菌培养的乳酸菌复合液酸奶(乳酸菌数量不低于106 CFU/mL)两种添加不同辅料于麻竹笋中进行发酵,采用理化指标、电镜扫描、电子鼻和顶空-固相微萃取-气质联用法对不同加工方式和加工辅料酸笋在发酵过程中的理化性质、微观结构、风味和感官品质进行了研究,以期为酸笋的现代化生产提供理论支持和技术支撑。

1. 材料与方法

1.1 材料与仪器

新鲜麻竹笋 30 kg(新鲜、老嫩适宜、无病虫蛀、发霉变质),广东清远市英德市;农夫山泉水20 L、内含嗜热链球菌和保加利亚乳杆菌复合培养液(乳酸菌数量不低于106 CFU/mL)酸奶200 g、食用盐150 g 韶关学院超市。

QP2010Puls气相色谱质谱联用仪 日本岛津公司;顶空固相微萃取配套装置 美国SUPELCO公司;Smart Nose-14电子鼻 上海瑞玢智能科技有限公司;TM3030扫描电镜 上海科学仪器有限公司;HH-2水浴锅、DF-1磁力搅拌器 常州天瑞仪器有限公司;LT2001E电子天平 常熟市天量仪器有限责任公司;PHS-3C精密pH酸度计 上海雷磁仪电科学仪器股份有限公司;UV-1600紫外可见分光光度计 上海美普达仪器有限公司;发酵罐5 L 山东长盛泰玻璃制品股份有限公司。

1.2 实验方法

1.2.1 酸笋发酵工艺

酸笋制作参考郑文迪等[9]的方法:新鲜麻竹笋采用整根和切片两种方式发酵,并在两种加工方式的麻竹笋中分别添加盐、乳酸菌复合培养液两种不同加工辅料进行发酵,且以只添加农夫山泉水(记为水)发酵麻竹笋的样品为空白对照。对样品进行编号,具体为q-1切片水发酵样品,q-2切片盐发酵样品,q-3切片乳酸菌复合培养液发酵样品;z-1整根水发酵样品,z-2整根盐发酵样品,z-3整根乳酸菌复合培养液发酵样品。

发酵工艺如下:

a.采购:采购新鲜的麻竹笋,采收到加工的时间不超过12 h,长度不超过35 cm,笋体完整新鲜,笋肉呈白色,无明显粗纤维。

b.去根、去壳、切片:去除老壳,切除笋根部,剩余部分全部保留为整根麻竹笋,一部分切片麻竹笋要求垂直于纤维方向切片并且厚度均匀,大小为6 cm×1 cm×1 cm。

c.漂烫:90~100 ℃水漂洗10~15 min左右,钝化活性酶、防止酶褐变,去除部分苦涩味。

d.冷却:漂烫后捞出,平铺于纱布上至完全冷却。

e.装罐:盐水发酵笋:先调制好食盐水(农夫山泉水中含盐量为4%),把笋片放入已消毒的发酵坛中,加入食盐水至没过麻竹笋,封盖。乳酸菌复合液发酵笋:将笋片放入已消毒的发酵坛中,加入4%乳酸菌复合培养液(农夫山泉水中乳酸菌复合培养液添加量为4%)至没过麻竹笋,封盖。空白对照:农夫山泉水发酵麻竹笋,制作方法为将笋片放入已消毒的发酵坛中,加入农夫山泉水至没过麻竹笋,封盖。整根发酵麻竹笋装罐将整根麻竹笋重复以上步骤。

f.发酵:将坛子放在阳光不能照射的地方发酵。

1.2.2 酸笋发酵过程中各项理化指标的检测

酸笋发酵周期为90 d,在发酵0、10、30、60、90 d时取样。总酸含量的测定参照GB 12456-2021《食品中总酸的测定》[11]。氨基态氮的测定参照GB 5009.235-2016《食品中氨基酸态氮的测定》[12]中的方法进行。亚硝酸盐指标测定采用GB 5009.33-2016《食品安全国家标准 食品中亚硝酸盐与硝酸盐的测定》[13],每个实验组设置3个平行。

1.2.3 微观结构的测定

将待检测样品切成小块,放入干燥箱内50 ℃烘干水分,然后用专用切刀切成厚度为0.1 cm左右的薄片,把薄片固定于双面导电胶上,切面朝上,采用扫描电镜观察样品的微观结构并拍照。扫描电子显微镜电压10 kV,放大倍数选用800倍[14−15]。

1.2.4 酸笋的感官评价

对发酵90 d后的酸笋进行感官评价,由35名经常食用酸笋且经过食品专业培训的人员组成评价小组,根据NY/T 1048-2012《绿色食品笋及笋制品》及Q/ZGY 0001 S-2019《竹笋制品》中感官指标对已发酵成熟的酸笋(发酵90 d)进行感官评价,分别从酸笋的色泽、气味、滋味和质地4方面进行评分,评分标准如表1所示。

表 1 酸笋的感官评分标准Table 1. Sensory evaluation standard of sour bamboo shoots指标 感官评价标准 分值(分) 色泽

(20分)具有酸笋特有乳白色或淡黄色,有光泽 17~20 酸笋颜色偏黄或偏褐色,稍有光泽 9~16 酸笋颜色变黑,无光泽 1~8 气味

(30分)有酸笋典型的酸臭味,入口后带浓郁的

植物发酵的回香味,无异味感25~30 酸笋臭味稍重或臭味一般,入口后略带

植物发酵的回香味,稍有异味9~24 酸笋过臭或无明显臭味,入口无植物

发酵回香味,有其他异味1~8 滋味

(25分)口感清爽,咸淡适中,无异味,无不良滋味 18~25 表皮口感偏硬或偏软,切面口感干涩、

滋味一般,无不良滋味9~17 表皮口感较硬,切面口感干涩,带有

些许苦味等不良滋味1~8 质地

(25分)肉质脆嫩,切面整齐光滑,笋片内部结构紧密,

弹性好,无杂质18~25 肉质稍硬或稍软,切面稍光滑,笋片内部

结构较紧密,弹性较好,无杂质9~17 肉质过硬或过软,切面不光滑,笋片内部

结构不紧密,弹性差,带有些许杂质1~8 1.2.5 酸笋风味分析

1.2.5.1 酸笋总体风味的测定

采用电子鼻测定酸笋的总体风味情况。取发酵成熟90 d酸笋样品,捣碎后,分别准确称取4.0 g样品于洗净的顶空瓶中,迅速用专用瓶盖封口,垂直放置,静置5 min,待挥发性物质的气味充满样品瓶上空后进行电子鼻检测,每个样品平行测定3次。

电子鼻检测条件:传感器清洗时间200 s,样品准备时间15 s,样品测定时间60 s,气体流量1 L/min,每个样品重复测定3次[16]。电子鼻传感器性能描述见表2。

表 2 14个金属氧化物传感器的响应物质Table 2. Electronic nose sensors and their response to odorant compounds传感器 敏感物质类型 传感器 敏感物质类型 S1 氨气、胺类 S8 挥发性有机化合物 S2 硫化物 S9 液化气、天然气、煤气 S3 氢气 S10 液化气、可燃气体 S4 酒精、极性化合物(主要是醚类等) S11 烷烃、酒精、天然气、烟雾 S5 醇类、酮类、醛类、

芳香族化合物S12 酒精、有机溶剂(主要是醇、酯类等) S6 甲醛、甲烷 S13 烹调臭味 S7 可燃性气体 S14 甲烷、燃气 1.2.5.2 酸笋挥发性风味物质的测定

发酵酸笋中的挥发性风味物质主要来源包括竹笋本身的风味以及发酵过程中微生物作用产生的风味物质。通过SPME-GC-MS测定新鲜麻竹笋及不同加工方式的酸笋中挥发性风味成分,测定条件如下[17−20]:

SPME-GC-MS测定条件:将萃取纤维老化(270 ℃,30 min)后插入顶空瓶萃取酸笋样品中的风味物质。于60 ℃下平衡20 min,萃取40 min。然后,将已萃取的萃取纤维插入气相色谱进样口,在240 ℃下解析10 min。

GC条件:色谱柱为CD-WAX弹性石英毛细管柱(30 m×0.25 mm×0.25 μm);载气为氦气(99.999%),流速为1.0 mL/min;进样口温度为250 ℃,分流进样,分流比为20.0。升温程序为:柱温50 ℃,保持2 min,以5 ℃/min升温至180 ℃,保持15 min,以15 ℃/min升温至240 ℃。

MS条件:离子源为电子电离(EI)源,离子源温度200 ℃,电子能量70 eV,发射电流150 μA,倍增器电压1037 V,接口温度220 ℃,质量扫描范围45~500 m/z。

1.3 数据处理

总离子流色谱图经美国国家标准技术研究所NIST2014s标准谱库检索定性鉴定出成分,采用面积归一法进行相对含量分析。每个试验点重复3次,结果表示为平均值±标准差的形式,采用SPSS 22.0软件进行单因素方差分析,P<0.05表示差异显著,使用Origin 2018、Excel 2016软件作图。

2. 结果与分析

2.1 不同加工工艺酸笋发酵过程中总酸、氨基态氮和亚硝酸盐含量的变化

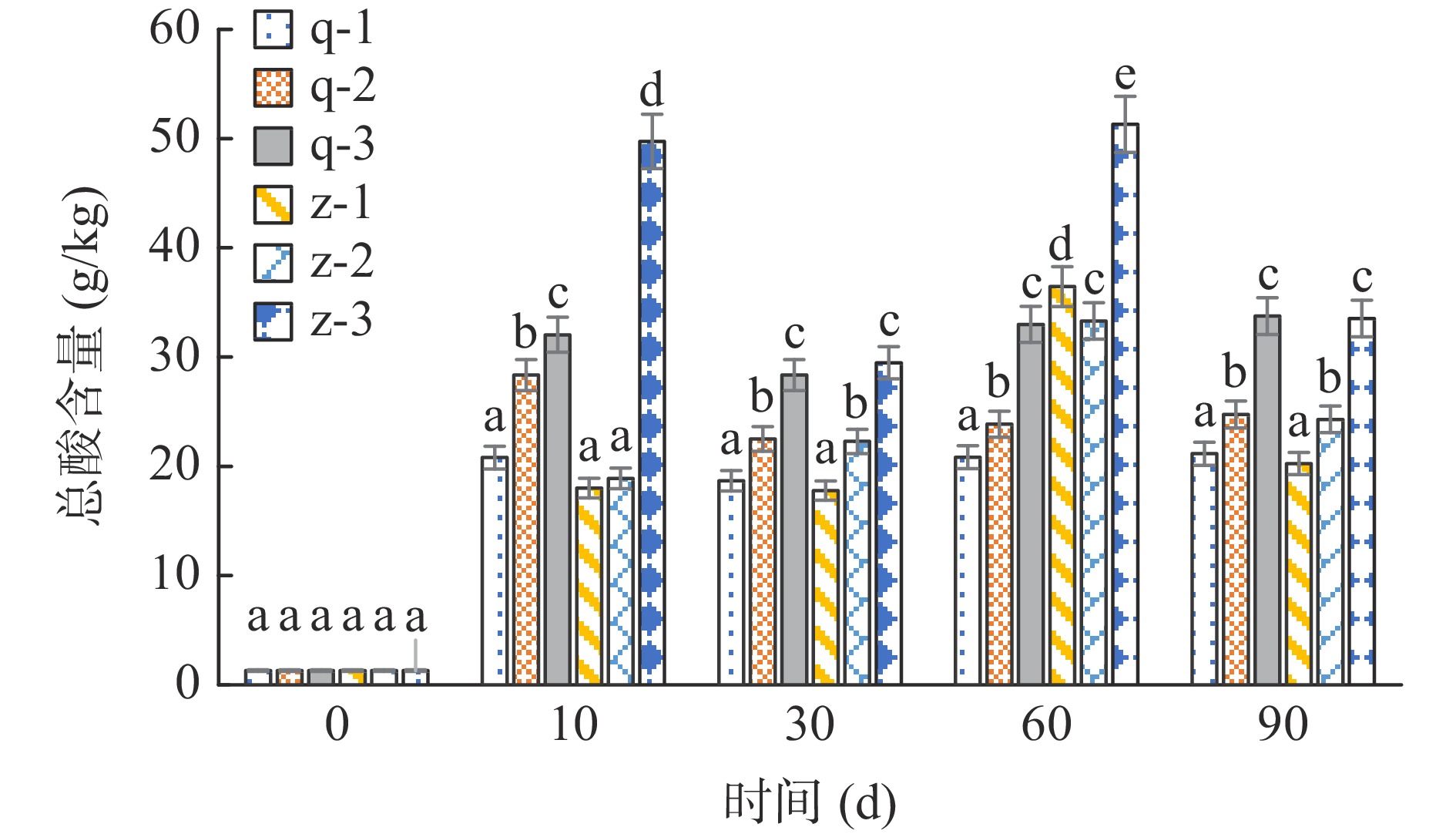

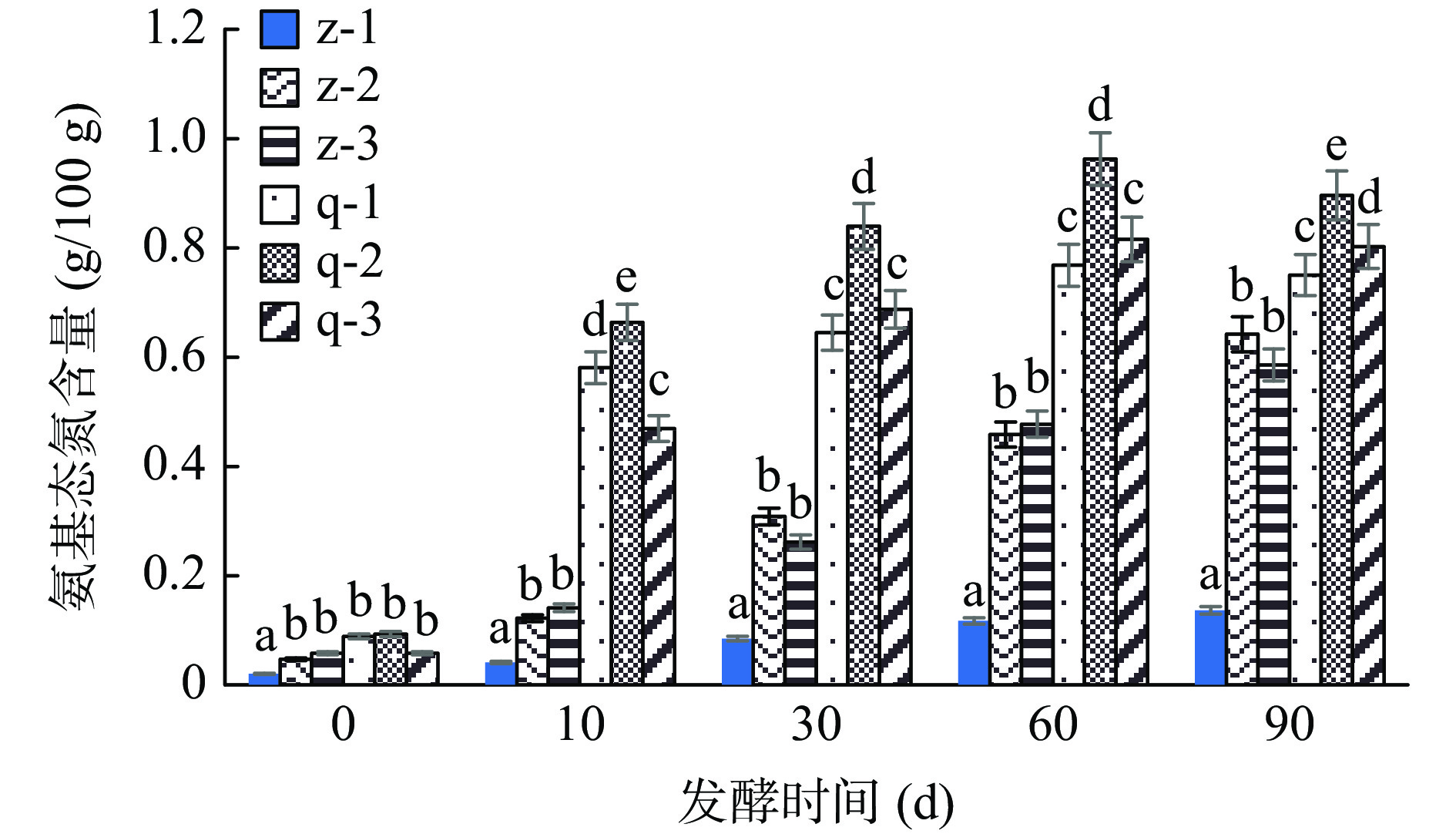

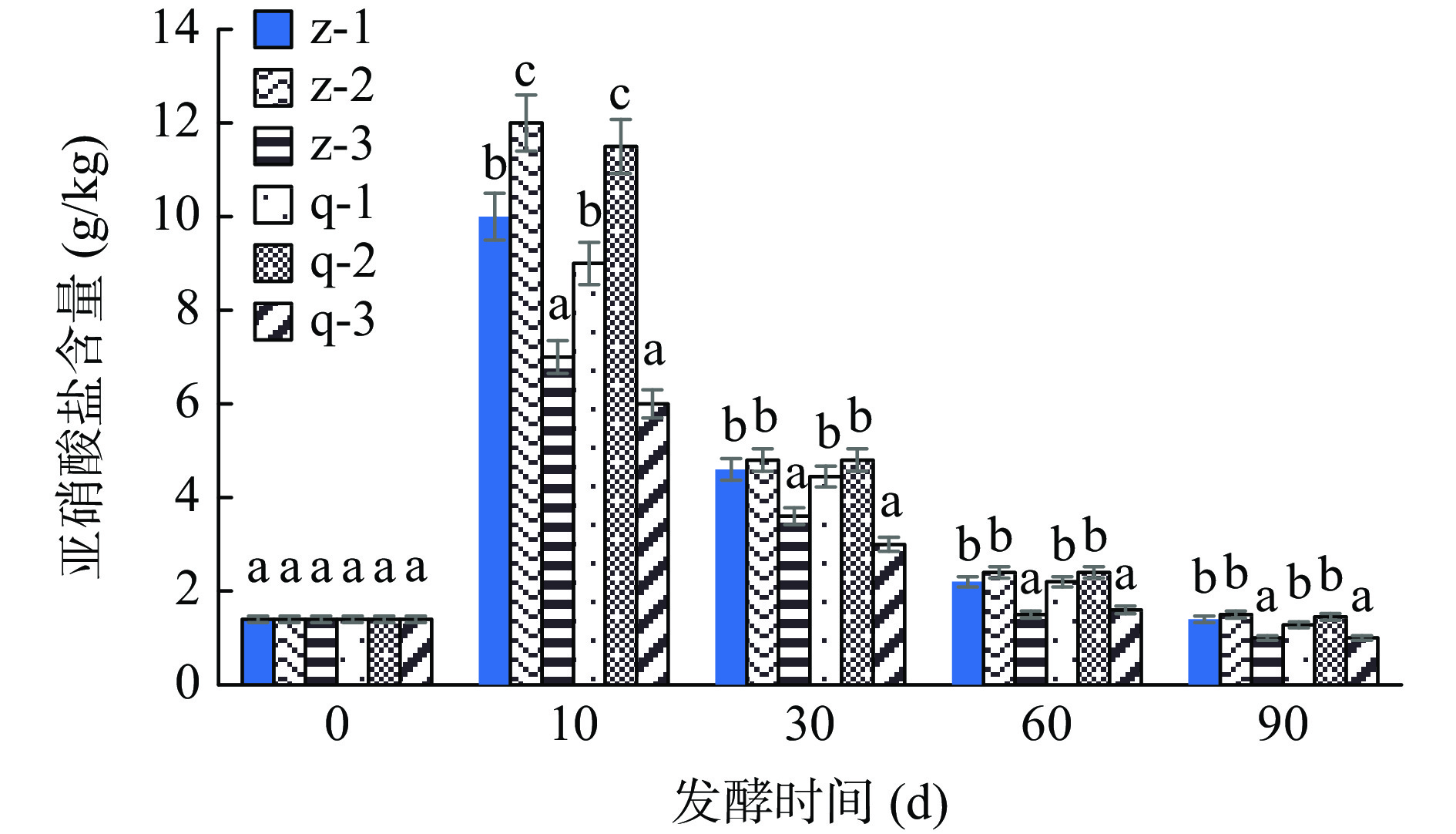

在整根和切片两种发酵方式下,分别添加不同辅料酸笋在不同发酵时间下,总酸的变化见图1。由图1所得,酸笋在发酵过程中,不同加工方式和不同辅料的酸笋总酸变化趋势较一致,在发酵前期,乳酸菌生长代谢迅速总酸含量均随时间的增长呈增加的趋势,30 d时总酸出现回落;在30~60 d阶段,总酸含量随时间的增长呈增加的趋势,乳酸菌代谢再次增加产酸量也再次达到峰值;在60~90 d阶段,乳酸菌生长代谢缓慢,相应乳酸增加缓慢。在酸笋发酵后期,由于发酵环境中营养物质的减少,大量乳酸的积累抑制了乳酸菌的生长,导致后期酸度略有降低[21−22]。发酵90 d乳酸菌复合培养液发酵酸笋酸度为33.6,盐发酵酸笋酸度为24.5,水发酵酸笋酸度21,整个发酵过程中添加乳酸菌复合培养液发酵酸笋酸度增加显著大于盐发酵及水发酵(P<0.05),这也与已报道研究结果一致[9]。这是由于乳酸菌复合培养液中含有可以产酸的嗜热链球菌、保加利亚乳杆菌,也含有大量蛋白质等营养物质,乳酸菌作为优势菌群其繁殖速度更快,产酸更多,因此可以得知纯种乳酸菌发酵酸笋能显著缩短酸笋的发酵周期。

氨基态氮含量的变化如图2所示。从图2可看出,不同加工工艺酸笋氨基态氮变化总体呈上升趋势,添加两种辅料及水发酵整根酸笋90 d氨基态氮平均含量达到0.455 g/100 g。切片发酵酸笋氨基态氮含量高于整根发酵酸笋,发酵至60 d达到高峰,平均含量达到0.849 g/100 g,然后缓慢下降。发酵相同时间,切片发酵酸笋氨基态氮含量显著高于整根发酵酸笋(P<0.05),推测原因可能是切片酸笋蛋白质能够更加快速全面的与微生物接触,微生物分泌的蛋白酶会将麻竹笋中的蛋白质降解形成氨基酸、多肽,因此氨基态氮含量显著高于整根发酵酸笋。但盐发酵酸笋氨基态氮含量显著高于接种乳酸菌复合培养液酸笋,接种酸笋乳酸菌数量增加迅速,氨基态氮被微生物作为发酵所需的氮源被利用[23]。并且酸笋中的氨基酸、多肽等不断渗透进入到酸笋水中,所以随着发酵时间延长酸笋氨基酸态氮含量也会下降。

由图3可知,不同加工方式发酵过程中亚硝酸盐含量最高为12.1 mg·kg−1(整根盐发酵第10 d),发酵30 d后亚硝酸盐含量均低于5 mg·kg−1,其中乳酸菌复合培养酸奶液发酵样品亚硝酸盐含量显著低于添加水及盐发酵酸笋,且亚硝酸盐含量最早降至3 mg/kg,这表明接种发酵剂有助于降低亚硝酸盐,这与已发表研究内容结论一致[24],这主要是因为接种发酵中,乳酸菌迅速成为主要优势菌群,抑制有害微生物的生长,进而抑制亚硝酸盐的产生。而水发酵及加盐发酵过程中乳酸菌在发酵初期没有形成优势菌群,环境中含有肠杆菌科等有害微生物所需的营养物质、氧气、适宜的pH,因此这些微生物在发酵初期会大量繁殖,亚硝酸盐含量快速上升[25]。接种发酵酸笋酸度显著高于其他两种,而亚硝酸盐含量始终低于添加水及添加盐发酵酸笋,

2.2 不同加工工艺酸笋发酵过程中的微观结构变化

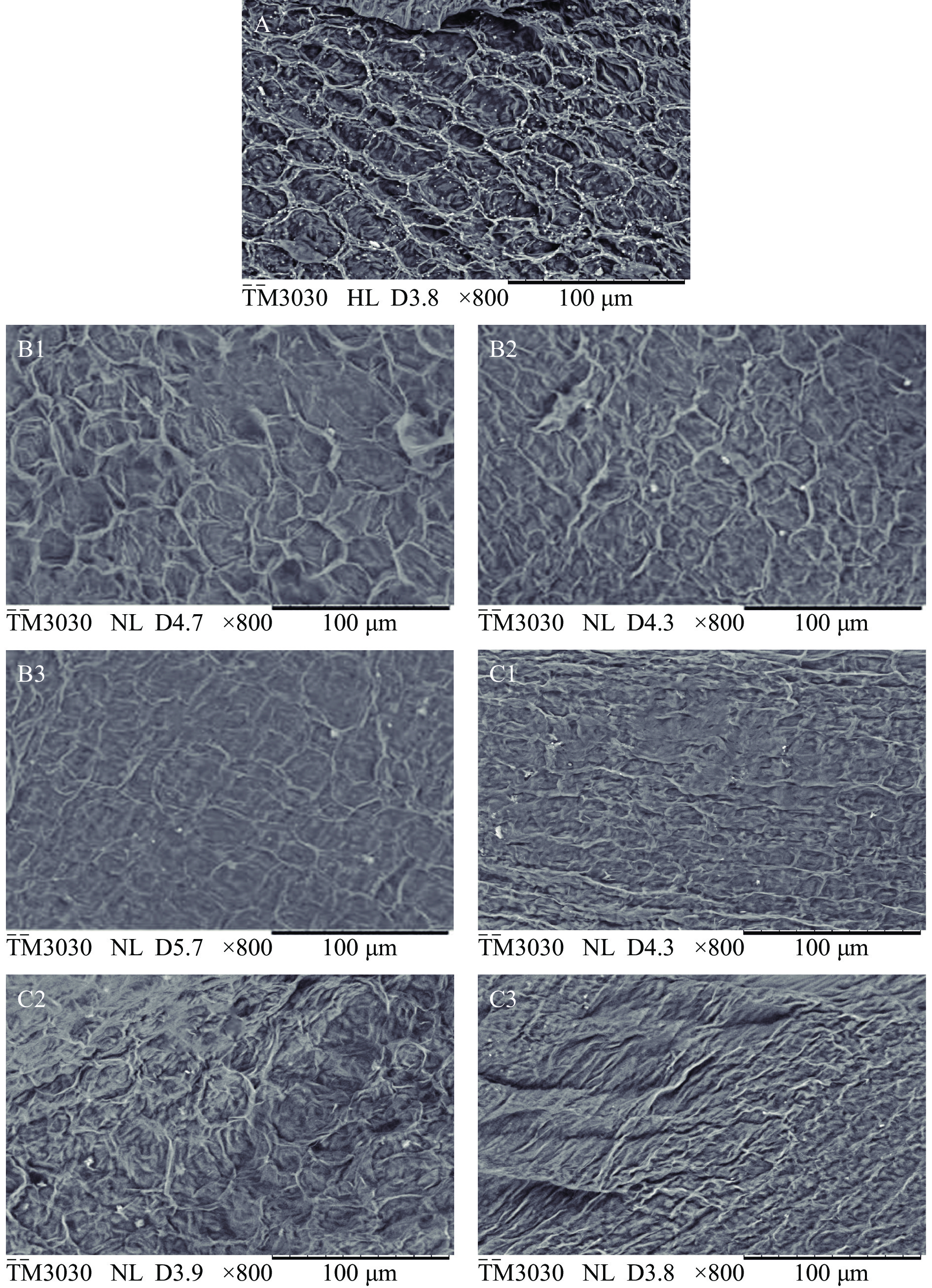

图4展示了不同加工工艺对麻竹笋组织微观结构的影响,在放大800倍下,可以看到新鲜麻竹笋组织呈蜂窝状紧密排列,细胞间隙较小,圆孔大小均一,表面光滑平整。总体上,不论是切片或整根发酵,经过发酵后,麻竹笋蜂窝状排列都变得较为疏松,圆孔大小不一,但仍保持着原来的蜂窝结构。从加工方式来看,可以看到切片酸笋的整体结构相较于整根酸笋而言组织更为疏松,这主要是切片麻竹笋与微生物接触的表面积更大,微生物作用更强导致,也是切片酸笋氨基酸态氮含量高于整根酸笋的原因。从添加不同加工辅料来看,水发酵酸笋相较于添加盐、乳酸菌复合培养液辅料酸笋的细胞完整性与紧密性较高,而添加盐、乳酸菌复合培养液辅料的酸笋结构出现明显收缩,其中盐发酵过程中酸笋结构变化相较于乳酸菌复合培养液发酵组织破坏较小,这可能是复合培养酸奶液中嗜热链球菌和保加利亚乳杆菌的作用导致的。由此可得,以酸奶为辅料发酵时酸笋的组织结构破坏较大,品质影响明显[26]。

2.3 发酵酸笋感官评价分析

在发酵90 d,对发酵酸笋进行感官评价,结果见表3。结果表明其中以盐为加工辅料发酵的酸笋品质最好,其色泽均匀,呈乳白色,口感清脆,滋味和气味方面盐发酵酸笋香味更浓郁,而乳酸菌复合培养液酸奶发酵滋味略差于自然盐发酵,蛋白质含量较高也影响发酵的进程,也可能因为酸奶中优势乳酸菌并不适宜于酸笋特征气味形成,而自然盐发酵过程中微生物种类较多,可产生酸笋特征香气[27]。

表 3 不同加工工艺酸笋和新鲜麻竹笋的感官评价Table 3. Sensory evaluation in sour bamboo shoots and bamboo shoots sample序号 酸笋 色泽(分) 气味(分) 滋味(分) 质地(分) 总分(分) 1 q-1 15 25 19 19 78 2 q-2 18 28 23 22 91 3 q-3 17 27 22 20 86 4 z-1 14 23 17 19 73

5z-2 18 27 22 19 86 6 z-3 16 25 21 20 82 7 新鲜麻竹笋 10 13 10 7 40 而同一种加工辅料不同加工方式发酵酸笋品质也有所差异,通过感官品质的分析,发现盐发酵的切片酸笋品质最佳。其主要是笋与发酵液的接触面积有关,接触面积越大,发酵效果越好,滋味越充分。综上,盐发酵的切片酸笋感官评价优于其他加工方式发酵酸笋。

2.4 不同加工工艺的成熟酸笋风味品质的研究

2.4.1 电子鼻传感器响应值结果分析

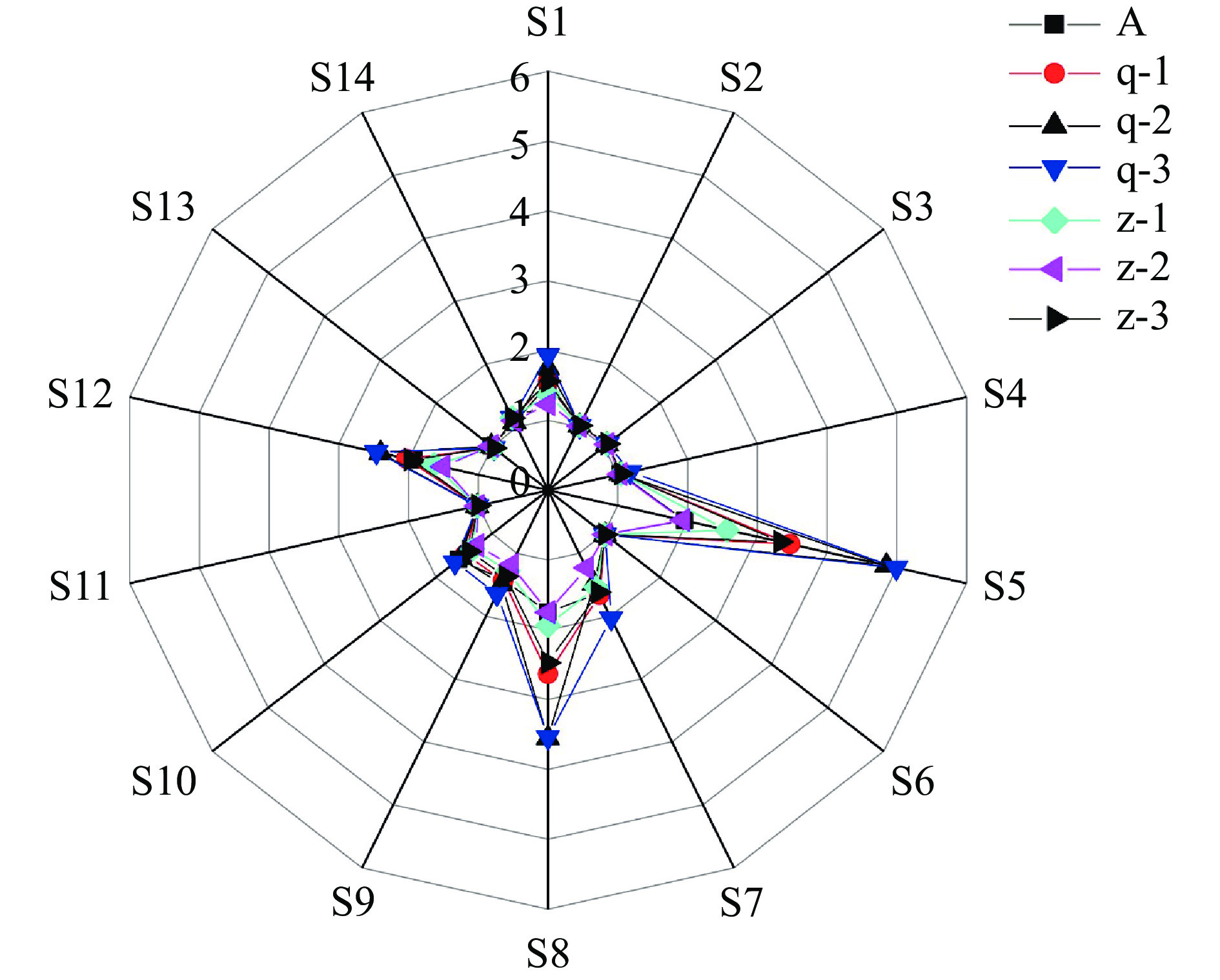

图5展示了电子鼻系统中14个传感器对不同加工工艺生产酸笋的响应雷达图。由图5可知,不同加工工艺酸笋的整体气味轮廓大致相同亦风味物质种类基本一致。但其在14个传感器处的信号强度存在一定差异,响应值大小依次为5号、8号和12号,表明样品的芳香族化合物、醇类、醛类化合物含量较多且不同样品气味物质构成不尽相同。

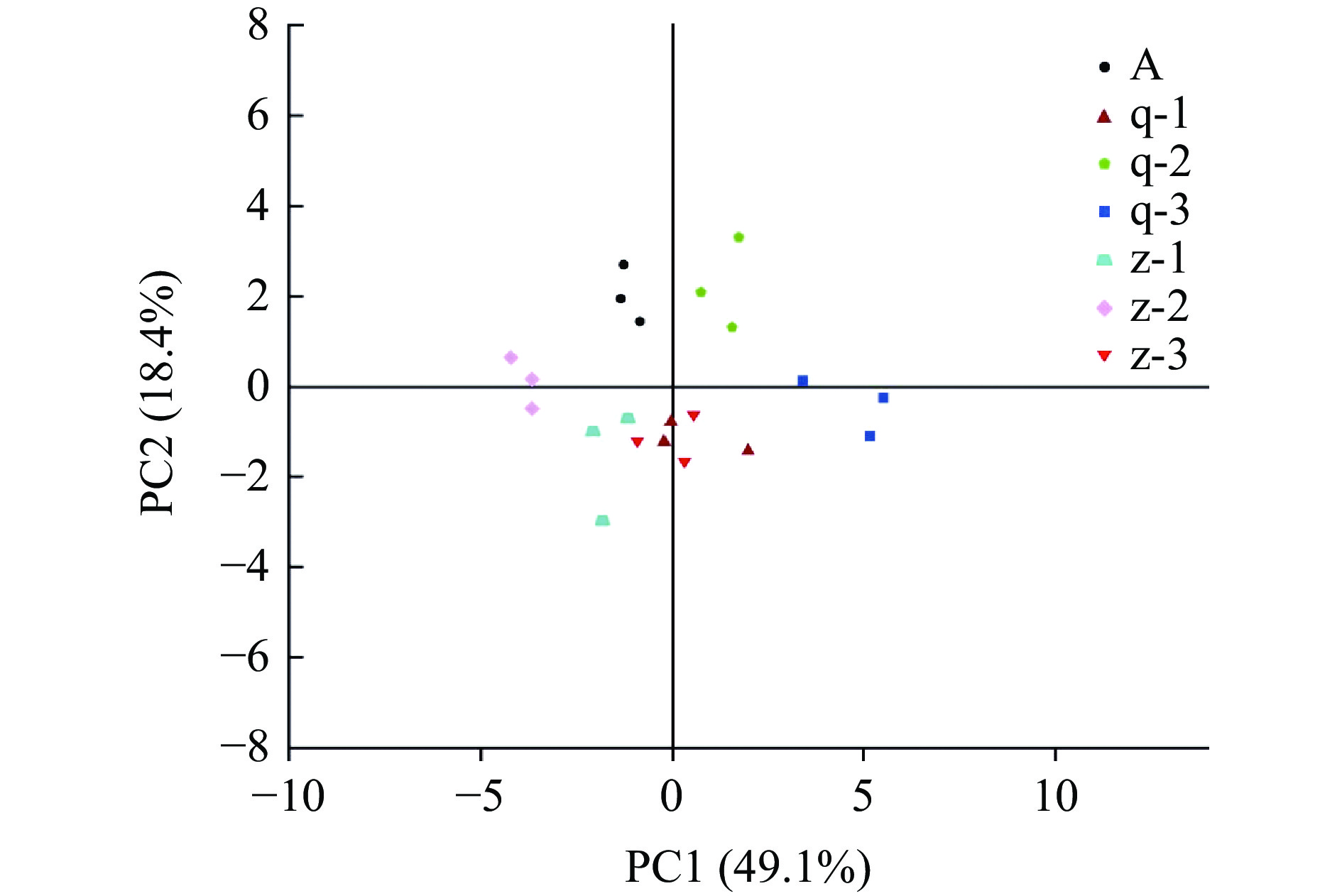

为进一步分析6个发酵90 d成熟样品与新鲜麻竹笋的差异,采用主成分分析(PCA)法对这些气味指纹数据进行数理统计。

由图6可知,不同加工工艺发酵样品中,第一主成分PC1贡献率达到49.1%,第二成分PC2贡献率达到18.4%,PC1和PC2贡献率之和达到67.2%,说明数据涵盖了卤水样品的绝大部分气味信息。由图6可以看出,不同酸笋在横坐标上的距离相对较接近,但相互间完全无重叠,表明其挥发性物质有一定的差异。PC1贡献率远大于PC2,说明样品在横坐标上距离越大,其差异性越大。其中切片发酵酸笋主要位于PCA图右侧,整根发酵酸笋主要位于PCA图左侧,说明不同加工方式对酸笋的总体风味有较大影响。另外,q-1切片水发酵样品、z-1整根水发酵样品与z-3整根酸奶发酵样品相距较近,q-3切片酸奶发酵样品与z-2-整根盐发酵样品相距较远挥发性物质差异较大,说明不同辅料的添加对酸笋的总体风味也有较大的影响。

2.4.2 酸笋中挥发性风味化合物鉴定分析

为进一步明确酸笋中挥发性风味物质,采用SPME-GC-MS技术分析新鲜麻竹笋和不同加工方式发酵90 d酸笋的挥发性风味物质,通过对8个发酵90 d的成熟样品和新鲜麻竹笋总离子流图和挥发性成分的综合分析,结果共检测到21种挥发性风味物质(表4),主要包括酚类2种、醛类11种、酮类2种、醇类2种、酯类3种和苯类1种。其中,切片水发酵、盐发酵、乳酸菌复合培养液发酵酸笋和整根水发酵、盐发酵、乳酸菌复合培养液发酵酸笋分别为15、7、5、4、3、2种。由此可知,不同加工方式中切片酸笋挥发性物质种类比整根酸笋多,这与切片笋与发酵微生物充分接触产生更多的挥发性物质有关;添加不同加工辅料发酵酸笋,挥发性物质为水发酵酸笋>盐发酵酸笋>乳酸菌复合培养液发酵酸笋,盐水发酵酸笋挥发性物质种类挥发性物质种类为9种,添加复合酸奶液发酵挥发性物质种类为5种,且盐水发酵酸笋主要风味贡献物对甲基苯酚(55.4%)含量适中[28],此结果差异进一步验证了切片盐发酵酸笋感官评分分值高这一结论。其可能是与发酵酸笋中的微生物多样性有关,由于水发酵样品自然菌群最丰富,产生挥发性物质种类最多,盐发酵样品对微生物的多样性有一定影响,但大量的乳酸菌仍能在低盐水中生长繁殖,所以盐发酵酸笋挥发性物质种类次之,乳酸菌复合培养液发酵样品中,大量嗜热链球菌、保加利亚乳杆菌生长繁殖抑制了其中微生物多样性,导致挥发性风味物质种类较低[29−30]。

表 4 酸笋和新鲜麻竹笋的挥发性成分及其含量Table 4. Volatile compounds and their content in sour bamboo shoots and bamboo shoots sample序号 CAS号 化合物 相对含量(%) 新鲜麻竹笋 切片发酵笋 整根发酵笋 q-1 q-2 q-3 z-1 z-2 z-3 1 124-19-6 壬醛 − 4.39±0.01 − − − − − 2 2548-87-0 反-2-辛烯醛 − 4.35±0.01 2.08±0.02 − − − − 3 18829-55-5 2-庚烯醛 − − 1.68±0.02 − − − − 4 3913-81-3 反式-2-葵烯醛 − 4.15±0.02 1.79±0.02 − − − − 5 2463-77-6 2-十一烯醛 1.72±0.02 5.10±0.02 − 3.82±0.01 − − − 6 53448-07-0 反-2-十一烯醛 5.21±0.02 − 2.36±0.01 − 3.12±0.02 − − 7 60784-31-8 2-壬烯醛 − − 1.43±0.01 − − − − 8 6750-03-4 反2,4-壬二烯醛 5.13±0.02 − − − − − − 9 55449-71-3 4-壬二烯醛 7.89±0.03 − − − − − − 10 112-31-2 葵醛 73.90±0.02 2.90±0.02 − − − − − 11 2363-88-4 反式-2,4-葵二烯醛 7.64±0.01 − − − − − − 12 107-88-0 1-3-丁二醇 − 2.40±0.01 − − − − − 13 112-42-5 十一醇 − 4.60±0.02 − − − − − 14 593-08-8 2-十三烷酮 − 4.30±0.02 4.3±0.02 − − − − 15 3796-70-1 香叶基丙酮 − 5.20±0.02 − 0.89±0.02 − − − 16 16326-34-4 二乙氧基乙酸甲酯 − 1.61±0.03 − − − − − 17 106-74-1 烯丙酸乙氧乙酯 1.86±0.02 2.00±0.01 − 2.33±0.02 2.08±0.02 2.25±0.02 − 18 50816-18-7 9-葵烯-1-醇乙酸酯 − − − − − 2.45±0.02 − 19 61141-66-0 3,4-二乙基联苯 5.69±0.02 1.20±0.02 − − − − − 20 106-44-5 对甲苯酚 − 52.68±0.03 55.4±0.02 65.70±0.03 53.32±0.02 54.85±0.01 65.08±0.02 21 108-95-2 苯酚 − 8.53±0.01 − 9.11±0.02 8.53±0.03 − 9.21±0.02 注:“−”表示未检测到。 以上结果可以看出,酚类是8个发酵样品挥发性成分中检测到的含量最高的一类物质,主要是对甲苯酚和苯酚,相对含量分别在52.68%~65.70%和0%~9.21%之间,新鲜麻竹笋中未检测到酚类物质。酚类物质阈值较低(苯酚为5.9 μg/mL,对甲基苯酚为0.055 μg/mL),尤其是对甲基苯酚在样品中含量较高,具有刺激性气味和焦皮臭、动物臭等特殊风味,因此可以推测其可能为酸笋的主要风味成分。郑炯等[31]对腌制的麻竹笋挥发性风味物质测定的研究结果表明,酸笋发酵过程中最主要的风味物质是对甲苯酚,发酵酸笋呈现出强烈的药味、刺激性气味,这种风味主要是对甲苯酚所导致,本文研究结果与其一致。众多研究认为,对甲基苯酚是麻竹笋中重要的游离型氨基酸—酪氨酸通过发酵后产生的副产物[31]。研究中发现,过低的对甲基苯酚会导致酸笋不够风味,但过高的苯酚和对甲基苯酚也会降低酸笋的接受程度[32−33],这可能是本试验中切片水发酵酸笋感官评价分值较低,而盐水发酵酸笋感官评价分值较高的原因。另外,在切片水发酵和盐发酵酸笋中分别检测到8种醛类物质,醛类物质气味阈值一般较低,对酸笋风味具有重要的补充作用,其中壬醛呈玫瑰香气,反-2-辛烯醛、反式-2-癸烯醛、2-十一烯醛、反-2-十一烯醛、2-壬烯醛等均呈肉类、瓜香、果香、酯香、青香、脂肪香、柑橘香味等,癸醛呈果香和花香。醇类物质中,由于其香气阈值较高,对产品风味的影响较小,所以其芬香的味道在酸笋发酵过程中体现较弱。酯类物质主要赋予特殊的水果、蔬菜等酯香味,但本试验中检测到酯类物质主要是烯丙酸乙氧乙酯、二乙氧基乙酸甲酯和9-癸烯-1-醇乙酸酯。总之,对甲苯酚是酸笋最主要的呈味物质,与其他风味物质共同作用,呈现了发酵酸笋强烈的刺激性气味。不同加工方式和不同辅料的添加影响酸笋主要风味物质对甲基苯酚的含量,也影响着酸笋风味的丰富程度。

3. 结论

通过采用切片和整根发酵方式处理麻竹笋,并分别添加盐、内含嗜热链球菌和保加利亚乳杆菌复合培养液酸奶两种不同加工辅料发酵制作酸笋。结果表明,不同加工方式中,切片酸笋发酵氨基酸态氮、酸度、组织结构、挥发性物质种类、香气成分都显著优于整根发酵。添加不同辅料酸笋中,盐发酵酸笋氨基酸态氮含量显著高于其他两种酸笋氨基酸态氮含量,接种发酵酸笋酸度、亚硝酸盐含量始终优于添加水及添加盐发酵酸笋,而盐水发酵酸笋挥发性物质种类更为丰富,且主要风味贡献物对甲基苯酚(55.4%)含量适中。由本研究可知,酸笋加工过程中选择切片盐发酵得到的酸笋酸度适宜,微观结构、口感破坏性最小,挥发性风味物质种类最为丰富,感官评分分值最高,该部分研究内容初步揭示了不同加工方式和不同辅料在麻竹笋发酵过程中品质的影响,对酸笋加工工艺和辅料添加具有一定的指导意义。后续会持续筛选研究酸笋中优势微生物并深入探究酸笋发酵优势微生物种类及影响机理,从而开发更加安全优质的酸笋产品。

-

表 1 酸笋的感官评分标准

Table 1 Sensory evaluation standard of sour bamboo shoots

指标 感官评价标准 分值(分) 色泽

(20分)具有酸笋特有乳白色或淡黄色,有光泽 17~20 酸笋颜色偏黄或偏褐色,稍有光泽 9~16 酸笋颜色变黑,无光泽 1~8 气味

(30分)有酸笋典型的酸臭味,入口后带浓郁的

植物发酵的回香味,无异味感25~30 酸笋臭味稍重或臭味一般,入口后略带

植物发酵的回香味,稍有异味9~24 酸笋过臭或无明显臭味,入口无植物

发酵回香味,有其他异味1~8 滋味

(25分)口感清爽,咸淡适中,无异味,无不良滋味 18~25 表皮口感偏硬或偏软,切面口感干涩、

滋味一般,无不良滋味9~17 表皮口感较硬,切面口感干涩,带有

些许苦味等不良滋味1~8 质地

(25分)肉质脆嫩,切面整齐光滑,笋片内部结构紧密,

弹性好,无杂质18~25 肉质稍硬或稍软,切面稍光滑,笋片内部

结构较紧密,弹性较好,无杂质9~17 肉质过硬或过软,切面不光滑,笋片内部

结构不紧密,弹性差,带有些许杂质1~8 表 2 14个金属氧化物传感器的响应物质

Table 2 Electronic nose sensors and their response to odorant compounds

传感器 敏感物质类型 传感器 敏感物质类型 S1 氨气、胺类 S8 挥发性有机化合物 S2 硫化物 S9 液化气、天然气、煤气 S3 氢气 S10 液化气、可燃气体 S4 酒精、极性化合物(主要是醚类等) S11 烷烃、酒精、天然气、烟雾 S5 醇类、酮类、醛类、

芳香族化合物S12 酒精、有机溶剂(主要是醇、酯类等) S6 甲醛、甲烷 S13 烹调臭味 S7 可燃性气体 S14 甲烷、燃气 表 3 不同加工工艺酸笋和新鲜麻竹笋的感官评价

Table 3 Sensory evaluation in sour bamboo shoots and bamboo shoots sample

序号 酸笋 色泽(分) 气味(分) 滋味(分) 质地(分) 总分(分) 1 q-1 15 25 19 19 78 2 q-2 18 28 23 22 91 3 q-3 17 27 22 20 86 4 z-1 14 23 17 19 73

5z-2 18 27 22 19 86 6 z-3 16 25 21 20 82 7 新鲜麻竹笋 10 13 10 7 40 表 4 酸笋和新鲜麻竹笋的挥发性成分及其含量

Table 4 Volatile compounds and their content in sour bamboo shoots and bamboo shoots sample

序号 CAS号 化合物 相对含量(%) 新鲜麻竹笋 切片发酵笋 整根发酵笋 q-1 q-2 q-3 z-1 z-2 z-3 1 124-19-6 壬醛 − 4.39±0.01 − − − − − 2 2548-87-0 反-2-辛烯醛 − 4.35±0.01 2.08±0.02 − − − − 3 18829-55-5 2-庚烯醛 − − 1.68±0.02 − − − − 4 3913-81-3 反式-2-葵烯醛 − 4.15±0.02 1.79±0.02 − − − − 5 2463-77-6 2-十一烯醛 1.72±0.02 5.10±0.02 − 3.82±0.01 − − − 6 53448-07-0 反-2-十一烯醛 5.21±0.02 − 2.36±0.01 − 3.12±0.02 − − 7 60784-31-8 2-壬烯醛 − − 1.43±0.01 − − − − 8 6750-03-4 反2,4-壬二烯醛 5.13±0.02 − − − − − − 9 55449-71-3 4-壬二烯醛 7.89±0.03 − − − − − − 10 112-31-2 葵醛 73.90±0.02 2.90±0.02 − − − − − 11 2363-88-4 反式-2,4-葵二烯醛 7.64±0.01 − − − − − − 12 107-88-0 1-3-丁二醇 − 2.40±0.01 − − − − − 13 112-42-5 十一醇 − 4.60±0.02 − − − − − 14 593-08-8 2-十三烷酮 − 4.30±0.02 4.3±0.02 − − − − 15 3796-70-1 香叶基丙酮 − 5.20±0.02 − 0.89±0.02 − − − 16 16326-34-4 二乙氧基乙酸甲酯 − 1.61±0.03 − − − − − 17 106-74-1 烯丙酸乙氧乙酯 1.86±0.02 2.00±0.01 − 2.33±0.02 2.08±0.02 2.25±0.02 − 18 50816-18-7 9-葵烯-1-醇乙酸酯 − − − − − 2.45±0.02 − 19 61141-66-0 3,4-二乙基联苯 5.69±0.02 1.20±0.02 − − − − − 20 106-44-5 对甲苯酚 − 52.68±0.03 55.4±0.02 65.70±0.03 53.32±0.02 54.85±0.01 65.08±0.02 21 108-95-2 苯酚 − 8.53±0.01 − 9.11±0.02 8.53±0.03 − 9.21±0.02 注:“−”表示未检测到。 -

[1] 郭荣灿, 王成华, 江虹锐, 等. 广西发酵酸笋气味物质提取方法优化及比较分析[J]. 食品工业科技,2019,40(13):202−210,220. [GUO R C, WANG C H, JIANG H R, et al. Optimization and comparison analysis of extraction methods of odorant from Guangxi fermentated bamboo shoots[J]. Science and Technology of Food Industry,2019,40(13):202−210,220.] GUO R C, WANG C H, JIANG H R, et al . Optimization and comparison analysis of extraction methods of odorant from Guangxi fermentated bamboo shoots[J]. Science and Technology of Food Industry,2019 ,40 (13 ):202 −210,220 .[2] 郑文迪, 关倩倩, 刘长根, 等. 基于GC-MS法对比广西地区酸菜和酸笋风味的差异[J]. 食品与发酵工业,2020,46(4):253−257. [ZHENG W D, GUAN Q Q, LIU Z G, et al. Comparison of flavors of Suancai and Suansun in Guangxi based on GC-MS[J]. Food and Fermentation Industries,2020,46(4):253−257.] ZHENG W D, GUAN Q Q, LIU Z G, et al . Comparison of flavors of Suancai and Suansun in Guangxi based on GC-MS[J]. Food and Fermentation Industries,2020 ,46 (4 ):253 −257 .[3] 覃慧丽, 武源, 韦维, 等. PRiME HLB固相萃取结合气相色谱-串联质谱法快速测定酸笋、酸豆角中氟虫腈及其代谢物残留量[J]. 食品安全质量检测学报,2021,12(24):9371−9376. [QIN H L, WU Y, WEI W, et al. Rapid determination of fipronil and its metabolites residues in fermented bamboo shoots and pickled cowpeas by PRiME HLB solid phase extraction combined with gas chromatography-tandem mass spectrometry[J]. Journal of Food Safety and Quality,2021,12(24):9371−9376.] QIN H L, WU Y, WEI W, et al . Rapid determination of fipronil and its metabolites residues in fermented bamboo shoots and pickled cowpeas by PRiME HLB solid phase extraction combined with gas chromatography-tandem mass spectrometry[J]. Journal of Food Safety and Quality,2021 ,12 (24 ):9371 −9376 .[4] CHEN C, LU Y Q, YU H Y, et al. Influence of 4 lactic acid bacteria on the flavor profile of fermented apple juice[J]. Food Bioscience,2019,27:30−36. doi: 10.1016/j.fbio.2018.11.006

[5] 陈正培, 蒋潮, 夏娴润, 等. 柳州酸笋中降亚硝酸盐乳酸菌的筛选及鉴定[J]. 中国酿造,2020,39(3):26−31. [CHEN Z P, JIANG C, XIA X R, et al. Screening and identification of nitrite-degrading lactic acid bacteria from Liuzhou sour bamboo shoots[J]. China Brewing,2020,39(3):26−31.] CHEN Z P, JIANG C, XIA X R, et al . Screening and identification of nitrite-degrading lactic acid bacteria from Liuzhou sour bamboo shoots[J]. China Brewing,2020 ,39 (3 ):26 −31 .[6] ZHENG J, ZHANG F S, ZHOU C H, et al. Comparison of flavor compounds in fresh and pickled bamboo shoots by GC-MS and GC-O lfactometry[J]. Japanese Society for Food Science and Technology,2014,20(1):129−138.

[7] 汤伟, 胡维, 王菁蕊, 等. 消化乳杆菌泡菜分离株W369的鉴定及其益生功能[J]. 微生物学报,2016,56(6):932−942. [TANG W, HU W, WANG J R, et al. Identification of a new probiotic Lactobacillus alimentarius W369 from Chinese traditional pickles[J]. Acta Microbiologica Sinica,2016,56(6):932−942.] TANG W, HU W, WANG J R, et al . Identification of a new probiotic Lactobacillus alimentarius W369 from Chinese traditional pickles[J]. Acta Microbiologica Sinica,2016 ,56 (6 ):932 −942 .[8] 杨晓晖, 籍保平, 李博, 等. 泡菜中优良乳酸菌的分离鉴定及其发酵性能的研究[J]. 食品科学,2005(5):130−134. [YANG X H, JI B P, LI B, et al. Isolation, identification and fermentation characteristicsstudy of lacticacid bacteria from pickles[J]. Food Science,2005(5):130−134.] YANG X H, JI B P, LI B, et al . Isolation, identification and fermentation characteristicsstudy of lacticacid bacteria from pickles[J]. Food Science,2005 (5 ):130 −134 .[9] 郑文迪. 直投式发酵酸笋生产技术研究[D]. 南昌:南昌大学, 2021. [ZHENG W D, Research of technology of direct vat set Suansun fermented[D]. Nanchang:Nanchang University, 2021.] ZHENG W D, Research of technology of direct vat set Suansun fermented[D]. Nanchang: Nanchang University, 2021.

[10] 刘永逸, 林华, 杨超, 等. 低亚硝酸盐柳州酸笋的研制及品质分析[J]. 食品与发酵工业,2022,48(19):220−224. [LIU Y Y, LIN H, YANG C, et al. Dvelopment and quality analysis of Liuzhou sour bamboo shoots with low nitrite[J]. Food and Fermentation Industries,2022,48(19):220−224.] LIU Y Y, LIN H, YANG C, et al . Dvelopment and quality analysis of Liuzhou sour bamboo shoots with low nitrite[J]. Food and Fermentation Industries,2022 ,48 (19 ):220 −224 .[11] 中华人民共和国国家卫生健康委员会国家市场监督管理总局. GB 12456-2021 食品中总酸的测定[S]. 北京:中国标准出版社, 2021. [The State Administration for Market Regulation of the State Health Commission of the People's Republic of China. GB 12456-2021 National food safety standard-Determination of total acid in foods[S]. Beijing: China Standards Publishing House, 2021.] The State Administration for Market Regulation of the State Health Commission of the People's Republic of China. GB 12456-2021 National food safety standard-Determination of total acid in foods[S]. Beijing: China Standards Publishing House, 2021.

[12] 中华人民共和国国家卫生和计划生育委员会. GB 5009.235-2016 食品中氨基酸态氮的测定[S]. 北京:中国标准出版社, 2016. [The National Health and Family Planning Commission of the People's Republic of China. GB 5009.235-2016 Determination of amino acid nitrogen in food[S]. Beijing: China Standards Publishing House, 2016.] The National Health and Family Planning Commission of the People's Republic of China. GB 5009.235-2016 Determination of amino acid nitrogen in food[S]. Beijing: China Standards Publishing House, 2016.

[13] 中华人民共和国国家卫生和计划生育委员会. GB 5009.33-2016 食品中亚硝酸盐与硝酸盐的测定[S]. 北京: 中国标准出版社, 2016. [The National Health and Family Planning Commission of the People's Republic of China. GB 5009.33-2016 Determination of nitrite and nitrate in food[S]. Beijing: China Standards Publishing House, 2016.] The National Health and Family Planning Commission of the People's Republic of China. GB 5009.33-2016 Determination of nitrite and nitrate in food[S]. Beijing: China Standards Publishing House, 2016.

[14] JIANG Q Q, NAKAZAWA N, HU Y Q, et al. Microstructural modification and its effect on the quality attributes of frozen-thawed bigeye tuna ( Thunnus obesus) meat during salting[J]. LWT,2019,100:213−219. doi: 10.1016/j.lwt.2018.10.070

[15] 李梅, 卜孟军, 崔洋, 等. 不同处理方式下毛竹笋发酵过程中质地变化分析[J]. 食品与发酵工业,2017,43(8):138−144. [LI Mei, BU Mengjun, CUI Yang, et al. Change of the texture of bamboo shoots ( Phyllostachys eduis) with different treatments during fermentation[J]. Food and Fermentation Industries,2017,43(8):138−144.] LI Mei, BU Mengjun, CUI Yang, et al . Change of the texture of bamboo shoots (Phyllostachys eduis) with different treatments during fermentation[J]. Food and Fermentation Industries,2017 ,43 (8 ):138 −144 .[16] 王储炎, 熊国远, 贾敬敏, 等. 利用电子鼻检测不同香辛料熬制的卤汤[J]. 江苏农业科学,2017,45(10):136−140. [WANG C Y, XIONG G Y, JIA J M, et al. The electronic nose is used to detect the brine soup made with different spices[J]. Jiangsu Agricultural Sciences,2017,45(10):136−140.] WANG C Y, XIONG G Y, JIA J M, et al . The electronic nose is used to detect the brine soup made with different spices[J]. Jiangsu Agricultural Sciences,2017 ,45 (10 ):136 −140 .[17] LI S B, TIAN Y F, SUN M H, et al. Characterization of key aroma compounds in fermented bamboo shoots using gas chromatography-olfactometry-mass spectrometry, odor activity values, and aroma recombination experiments[J]. Foods,2022,11(14):2106. doi: 10.3390/foods11142106

[18] GUO Y, CHEN D, DONG Y F, et al. Characteristic volatiles fingerprints and changes of volatile compounds in fresh and dried Tricholoma matsutake Singer by HS-GC-IMS and HS-SPME-GC-MS[J]. J Chromatogr B Analyt Technol Biomed Life Sci,2018,1099:46−55. doi: 10.1016/j.jchromb.2018.09.011

[19] CHEN Q, SONG J X, BI J F, et al. Characterization of volatile profile from ten different varieties of Chinese jujubes by HS-SPME/GC-MS coupled with E-nose[J]. Food Res Int,2018,105:605−615. doi: 10.1016/j.foodres.2017.11.054

[20] 党昕, 刘军, 姚凌云, 等. GC-MS结合GC-O、电子鼻评价不同预处理方式对沙枣风味的影响[J]. 食品科学,2023,44(6):327−335. [DANG X, LIU J, YAO L Y, et al. Effects of different pretreatment methods on the flavor of elaeagnus angustifolia fruit evaluated by gas chromatography-mass spectrometry, gas chromatography-olfactometry and electronic nose[J]. Food Science,2023,44(6):327−335.] DANG X, LIU J, YAO L Y, et al . Effects of different pretreatment methods on the flavor of elaeagnus angustifolia fruit evaluated by gas chromatography-mass spectrometry, gas chromatography-olfactometry and electronic nose[J]. Food Science,2023 ,44 (6 ):327 −335 .[21] RICE T, SAHIN A W, LYNCH K M, et al. Isolation, characterisation and exploitation of lactic acid bacteria capable of efficient conversion of sugars to mannitol[J]. International Journal of Food Microbiology,2020,321:108546. doi: 10.1016/j.ijfoodmicro.2020.108546

[22] CHANG J Y, CHANG H C. Improvements in the quality and shelf life of kimchi by fermentation with the induced bacteriocin-producing strain, Leuconostoc citreum GJ7 as a starter[J]. Journal of Food Science,2010,75(2):103−110.

[23] 葛燕燕, 吴祖芳, 翁佩芳. 冬瓜腌制生产工艺与品质特性变化研究[J]. 宁波大学学报(理工版),2014,27(3):1−6. [GE Y Y, WU Z F, WENG P F, et al. Processing technique of pickled wax gourd and quality analysis[J]. Journal of Ningbo University (Natural Science & Engineering Edition),2014,27(3):1−6.] GE Y Y, WU Z F, WENG P F, et al . Processing technique of pickled wax gourd and quality analysis[J]. Journal of Ningbo University (Natural Science & Engineering Edition),2014 ,27 (3 ):1 −6 .[24] 龚福明, 何彩梅, 吴桂容, 等. 乳酸菌降解发酵蔬菜中亚硝酸盐的研究现状[J]. 中国调味品,2022,47(10):201−205. [GONG F M, HE C M, WU G R, et al. Research status of nitrite degradation in fermented vegetables by lactic acid bacteria[J]. China Condiment,2022,47(10):201−205.] GONG F M, HE C M, WU G R, et al . Research status of nitrite degradation in fermented vegetables by lactic acid bacteria[J]. China Condiment,2022 ,47 (10 ):201 −205 .[25] 崔娜, 惠翔, 王宇轩, 等. 不同发酵方式对酸笋发酵过程亚硝酸盐含量变化的影响研究[J]. 食品安全导刊,2022,362(33):46−49. [CUI N, HUI X, WANG Y X, et al. Effects of different fermentation methods on the content of nitrite in sour bamboo shoots[J]. China Food Safety Magazine,2022,362(33):46−49.] CUI N, HUI X, WANG Y X, et al . Effects of different fermentation methods on the content of nitrite in sour bamboo shoots[J]. China Food Safety Magazine,2022 ,362 (33 ):46 −49 .[26] DI CAGNO, RAFFAELLA, et al. Effect of lactic acid fermentation on antioxidant, texture, color and sensory properties of red and green smoothies[J]. Food Microbiology,2011,285:1062−1071.

[27] 张雅雯, 钟源, 郭爱玲, 等. 竹笋发酵中挥发性物质及菌群多样性动态分析[J]. 中国调味品,2023,48(1):1−7,13. [ZHANG Y W, ZHONG Y, GUO A L, et al. Dynamicanalysis of volatile substances and microbial community diversity during the fermentation of bamboo shoots[J]. China Condiment,2023,48(1):1−7,13.] ZHANG Y W, ZHONG Y, GUO A L, et al . Dynamicanalysis of volatile substances and microbial community diversity during the fermentation of bamboo shoots[J]. China Condiment,2023 ,48 (1 ):1 −7,13 .[28] 关倩倩. 我国传统酸笋中微生物菌系结构及其对特征风味物质形成的影响[D]. 南昌:南昌大学, 2021. [GUAN Q Q. Microbial community flora in Chinese traditional suansun and its influence on the formation of characteristic flavors[D]. Nanchang:Nanchang University, 2021.] GUAN Q Q. Microbial community flora in Chinese traditional suansun and its influence on the formation of characteristic flavors[D]. Nanchang: Nanchang University, 2021.

[29] WANG H Y, SU W, MU Y C, et al. Correlation between microbial diversity and volatile flavor compounds of Suanzuorou, a fermented meat product from Guizhou, China[J]. Food Microbiology,2021,12:73625.

[30] SATYA S, BAL L M, SINGHAL P, et al. Bamboo shoot processing:Food quality and safety aspect (a review)[J]. Trends in Food Science & Technology,2010,21(4):181−189.

[31] 郑炯, 宋家芯, 陈光静, 等. 顶空-固相微萃取-气质联用法分析腌制麻竹笋挥发性成分[J]. 食品科学,2013,34(18):193−196. [ZHENG J, SONG J X, CHEN G J, et al. Analysis of volatile compounds in pickled ma bamboo shoots ( Dendrocalamus latifl orus) using headspace solid phase microextraction coupled with GC-MS[J]. Food Science,2013,34(18):193−196.] ZHENG J, SONG J X, CHEN G J, et al . Analysis of volatile compounds in pickled ma bamboo shoots (Dendrocalamus latifl orus) using headspace solid phase microextraction coupled with GC-MS[J]. Food Science,2013 ,34 (18 ):193 −196 .[32] LUO J, JIANG C B, ZHAO L, et al. Keto acid decarboxylase and keto acid dehydrogenase activity detected during the biosynthesis of flavor compound 3-methylbutanal by the nondairy adjunct culture Lactococcus lactis ssp. lactis F9[J]. Journal of Dairy Science,2018,101(11):9725−9735. doi: 10.3168/jds.2018-14760

[33] LU H H, HUANG C J, YU K N, et al. Effects of mixed inoculation of Leuconostoc Citreum and Lactobacillus Plantarum on Suansun (sour bamboo shoot) fermentation[J]. Social Science Electronic Publishing,2022,407:101688.

下载:

下载:

下载:

下载: