Research on the Influence of Moisture State, Microscopic Morphology and Physical Properties of the Resting Dough

-

摘要: 为研究醒面对冷冻面团品质的影响,本文研究了醒面过程中(0、30、60、90、120 min),面团水分分布的变化规律以及面团冷冻后冰晶分布、微观结构和蠕变恢复特性的变化。结果表明:随着醒面时间的延长,面团中可冻结水含量降低了0.96%;微观结构的结果表明,面团在冻结过程中形成的冰晶空隙和数量逐渐减小,冰晶分布越来越均匀;随着醒面时间从0 min延长至120 min,冷冻面团的平均空隙面积从22.65减小到11.80,空隙数目从10627.00减少到3346.00;随着醒面时间的延长,在蠕变阶段,冷冻面团的最大蠕变柔量Jmax显著增加(P<0.05),零剪切粘度η0显著降低(P<0.05);面团醒发120 min后,冷冻面团最大蠕变柔量Jmax降低了0.50×10−4 Pa−1,零剪切粘度η0降低了0.43×105 Pa−1,这说明冷冻面团的硬度降低,面团的形状更容易保持;在恢复阶段,瞬时柔量J0与黏弹性柔量Jm分别增加了1.26×10−4和2.88×10−4 Pa−1,冷冻面团的恢复力增加。综上,醒面降低了面团中可冻结水的含量,提高了面团的持水力,减小了冷冻过程中冰晶对面团网络结构的破坏,从而提高了冷冻面团的品质。Abstract: To study the effect of resting on the quality of frozen dough, the changes in the moisture state of the dough during the resting process (0, 30, 60, 90, 120 min), the moisture distribution of dough and their effects on ice crystal distribution, microstructure, and creep recovery characteristics after dough freezing were investigated. The results showed that the freezable water content in the dough was decreased by 0.96% with the extension of the resting time. The pores and number of ice crystals formed in the dough during the freezing process gradually decreased and the distribution of ice crystals became more and more uniform. The average pore area decreased from 22.65 to 11.80 with the extension of the resting time from 0 min to 120 min, and the number of pores decreased from 22.65 to 11.80 with the extension of the resting time. The maximum creep flexibility Jmax increased significantly (P<0.05) and the zero shear viscosity η0 decreased significantly (P<0.05) during the creep phase as the resting time was extended. After resting for 120 mins, the maximum creep flexibility Jmax of frozen dough decreased by 0.50×10−4 Pa−1, and the zero shear viscosity η0 decreased by 0.43×105 Pa−1. This indicated that the hardness of frozen dough decreases and the shape of the dough was easier to maintain. During the recovery process, the instantaneous flexibility J0 and viscoelastic flexibility Jm increased by 1.26×10−4 and 2.88×10−4 Pa−1, respectively, and the recovery force of the frozen dough increased. In summary, resting process of dough would reduce the content of freezeable water, improve the water holding capacity, and reduce the damage of ice crystals to the dough network structure in the freezing process to improve the quality of the frozen dough.

-

Keywords:

- resting /

- moisture state /

- microstructure /

- freeze dough

-

水是面团制作的主要原料之一,对面团的形成具有重要的作用。水作为面团内部网络结构形成的内在驱动部分,其分布情况对于面团的品质有着重要的影响[1]。面团形成初期,水分在面团中分布并不均匀,面筋蛋白水合不足,面筋网络结构无法充分扩展,不利于加工[2],和面之后的醒面是面团加工过程中的重要工序之一。在醒面过程中,面团在和面过程中受到的残余应力被消除,水分动态变化导致水分趋于均匀分布,使蛋白质更好的吸水胀润,促进蛋白质之间相互交联聚合,改变面团组分的相互作用[3−5]。陈洁等[6]发现面团醒面过程中部分弱结合水转化为自由水和强结合水,麦谷蛋白大聚体(Glutenin Macropolymer,GMP)含量增加,改善了面团的拉伸特性。Liu等[7]发现面团静息30 min以上,面筋网络分布更加均匀、紧密,蛋白总长度和蛋白网络线的纵横方向均有所增加。

冷冻保藏能够很好的保持面团的新鲜度,提升面团的储藏性能[8]。但是在冷冻的过程中,面团中水分发生相变形成冰晶,进而破坏面团面筋网络结构,影响面团最终的品质[9]。而面团在冷冻之前的水分状态及分布对冷冻面团中的冰晶具有重要的影响[10]。因此在冷冻之前通过控制醒面时间影响面团中水分的分布,可以降低冷冻过程中冰晶对面团的破坏,改善冷冻面团的最终品质。目前关于醒面时间对于面团的研究主要集中于水分分布、面筋蛋白的组分变化及流变学特性等上[11−12],而关于其对非发酵面团冷冻品质影响的研究鲜有报道。

本文使用差示扫描量热仪(DSC)、多路温度测定仪、扫描电子显微镜以及旋转流变仪以不同醒面时间下的面团为样品,首先研究面团中水分状态的变化,然后将样品在−20和−40 ℃下冻结,研究在醒面之后冷冻面团的冰晶分布、微观结构和蠕变恢复特性,揭示醒面过程对面团水分状态以及冷冻后面团的冰晶分布、微观结构和蠕变恢复特性的影响。

1. 材料与方法

1.1 材料与仪器

金苑精制小麦粉(蛋白质含量11.0%,脂肪含量2.1%,含水量11.0%) 由河南金苑粮油有限公司生产。

JA20002电子分析天平 上海良平仪器仪表有限公司;AL204分析天平 上海梅特勒-托利多仪器有限公司;HA-3480A全自动搅拌揉面机 深圳克莱美斯机电科技有限公司;DZM-140台式电动压面机 永康市海鸥电器有限公司;AT4508多路温度探测仪 常州安柏精密仪器公司;HWS-080恒温恒湿箱 上海精宏实验设备有限公司;DSC Q20差示扫描量热仪 美国TA公司;TA.XT plus物性测定仪 英国TA公司;860704拉伸仪 德国Brabender公司;JSM76490LV扫描电子显微镜 日本JEOL公司;Discovery HR-1旋转流变仪 美国TA公司。

1.2 实验方法

1.2.1 面团的制备

面团的制备参考李银丽[13]的方法,称取300 g小麦粉,加入小麦粉质量45%的去离子水,将小麦粉和去离子水混合,置于和和面机中以150 r/min的转速搅拌10 min,使小麦粉和水分充分混合,制成表面光滑的面团,将制好的面团放入自封袋中密封。将样品面团放置于30 ℃的恒温箱中进行醒面,在醒面时间0、30、60、90、120 min时分别取样分析,进行后续的测定。

1.2.2 面团可冻结水含量测定

利用DSC分析醒面过程面团中的水分状态,参考He等[14]方法略有修改。精确称取不同醒面时间下面团20 mg(±1 mg)左右,将样品置于DSC坩埚中使样品能够紧贴底部,以空锅为对照。首先,DSC仪器预设温度25 ℃,将样品在25 ℃条件下平衡1 min,以5 ℃/min降至−30 ℃,在−30 ℃持续1 min,然后,以5 ℃/min升温至25 ℃,结束测试,每个样品重复测定3次,得到DSC分析曲线,用通用分析软件(TA Instruments)测定熔融峰的焓(ΔH),可冻结水的的百分比(Wfro)可用(1)计算公式得到:

(1) 式中,Wfro指可冻结水的百分比;ΔH0指纯水的热焓值(334 J/g)。

1.2.3 面团微观结构观察

将醒面后的面团碾压排除气泡干扰,用自封袋密封,分别在−20和−40 ℃的环境中进行冷冻,超低温冷冻储存箱提前调整好温度,并平衡24 h。使用多路温度测定仪记录面团中心温度的变化,每隔1 s记录一次面团中心温度,直至面团中心温度达到−18 ℃,停止记录过程。

将冷冻后的面团使用真空冷冻干燥机进行干燥。敲击干燥后的样品使样品自然断裂。选择大小合适、表面平整均匀的面块,将样品固定在导电胶上,喷金,然后在5.0 kV下,使用扫描电子显微镜在200倍的放大倍数下观察面团的微观结构[15]。

1.2.4 面团冰晶孔隙测定

将面团微观结构的图像加载到MATLAB 2016a中,程序方程参考Pan等[16]的方法计算面团中空隙的平均面积、空隙数目和空隙率。

1.2.5 面团蠕变-恢复特性测定

参考陈前等[17]的方法对面团的蠕变恢复特性进行测定,并略有修改。使用旋转流变仪对样品进行测定,将冻结温度达到−18 ℃的面团置于30 ℃的恒温箱中解冻60 min,在应变模式下进行测定,温度25 ℃,分为两个阶段:蠕变阶段,应力设置为50 Pa,时间为180 s;恢复阶段,撤去外力保持300 s,测得面团的形变恢复,每个样品测试3次。

柔量与应力及应变之间的数量关系可通过公式(2)得到:

(2) 式中:J(t)表示柔量,Pa−1;γ(t)表示应变,%;σ表示应力,Pa。

柔量曲线采用Burgers模型进行拟合。模型公式分为蠕变和恢复阶段两部分,分别为式(3)和式(4)[18]:

(3) (4) 式中:J(t)表示柔量,Pa−1;J0表示瞬时柔量,Pa−1;Jm表示黏弹性柔量,Pa−1;Jmax表示蠕变最大柔量,Pa−1;λ表示平均迟滞时间,s;η0表示零剪切粘度,Pa−1。

1.3 数据处理

每个实验均重复三次,数据平均值±标准差表示。使用Microsoft Excel 2010对数据进行整理汇总,用IBM SPSS Statistics 23软件进行显著性分析(P<0.05),通过Duncan多重比较法进行单因素方差分析检验数据的显著性。

2. 结果与分析

2.1 醒面对面团水分状态的影响

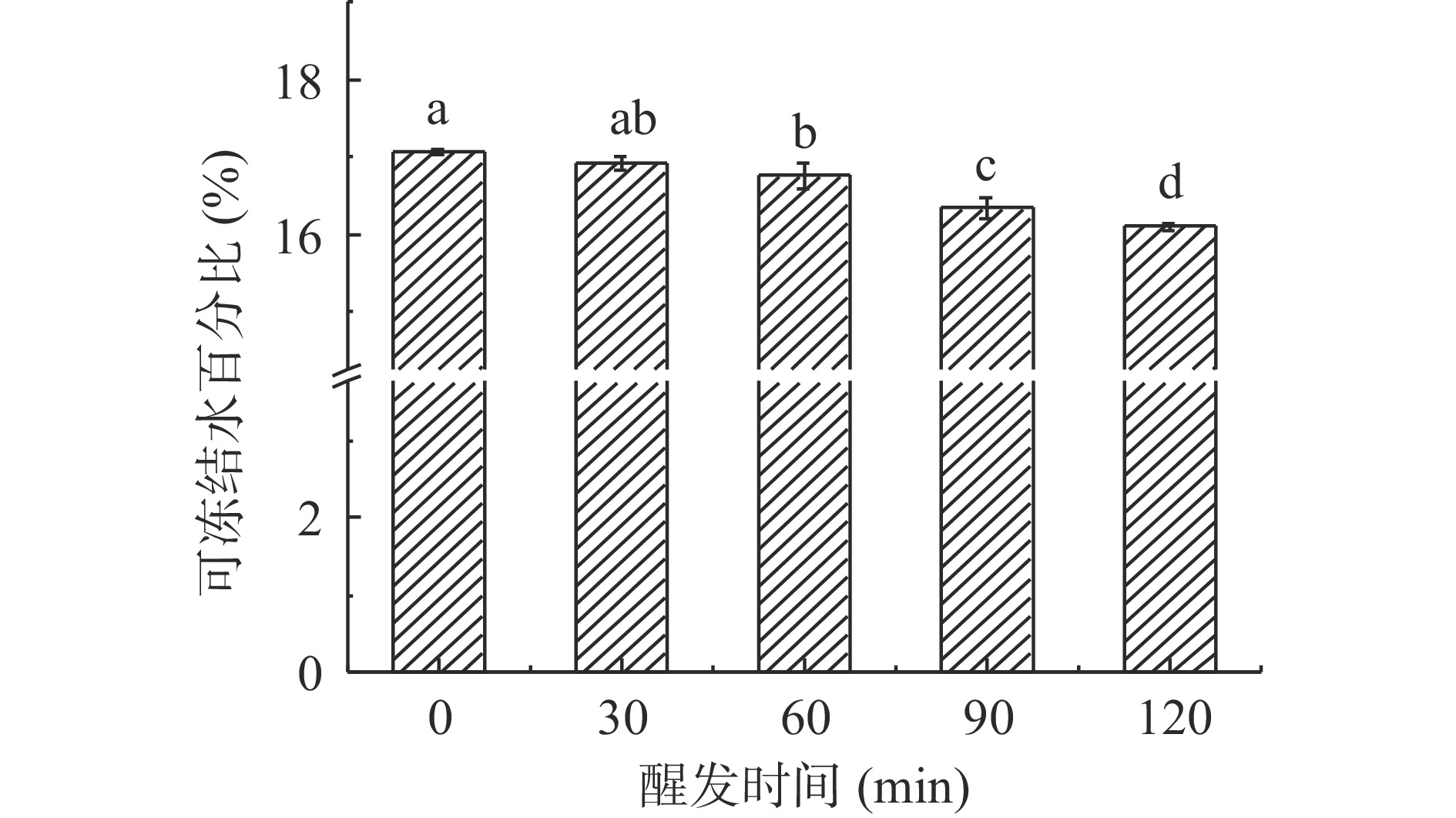

面团中可冻结水(包含自由水和弱结合水的一部分[19])含量是影响冰晶形成、冰晶的大小和分布的关键因素[20],是衡量冷冻面团品质的重要指标[21]。从图1中可知,随着醒面时间的延长,面团中可冻结水含量逐渐降低。产生这种现象的原因是在醒面过程中水分与面团组分之间的结合更加充分,降低了可冻结水的含量,面团中蛋白质与水发生水合作用时,会促进蛋白质网络结构的形成和展开,而展开的网络结构会束缚更多的水,从而减少水分子的流动性[22],减少可冻结水的含量。在醒面初期(0~30 min)面团中的水分分布不均匀,水分与面团中的组分结合不充分,导致水分流动性较高,会使面团在冻结过程中形成更多的冰晶,对冷冻面团的品质产生消极影响,而面团中可冻结水含量的降低可以降低面团在冻结时的冰晶数量和分布,削弱对冷冻面团的破坏。

为了研究醒面过程对冷冻面团微观结构及品质的影响,本文分别采用−20 和−40 ℃对面团进行冷冻,研究醒面时间对两种冷冻过程下面团微观结构、冰晶形态分布、蠕变和恢复特性的影响。

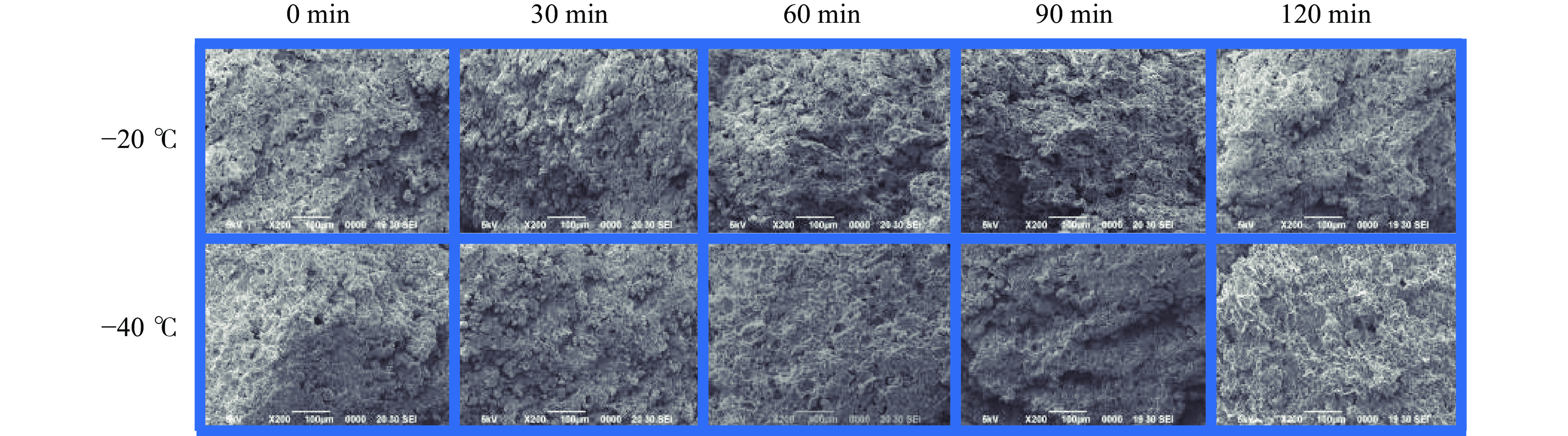

2.2 面团微观结构的变化

根据电镜图2可以发现,随着醒面时间的延长,面团在冻结过程中形成的冰晶空隙逐渐减小。面团在醒面过程中水分均匀分布,使水分与面团中的组分更好的结合,强结合水的含量增加,使面团在冷冻过程中形成的冰晶少、更均匀,保护了面团的组织结构[7,23]。随着冻结温度的降低,面筋网络结构更为紧密,连续性更好,淀粉颗粒能够镶嵌在面筋网络结构中,保护面团网络结构,提高冷冻面团的品质[24]。

当面团在−20 ℃冻结时,面团中形成的冰晶空隙明显大于−40 ℃,这是因为面团在−20 ℃条件下,面团内部生成的冰晶体积大、不规则和分布不均匀,造成面团中的空隙较大,对面团内部的蛋白质网络结构和品质造成不可逆的破坏。当面团在−40 ℃冻结时,面团中的水分快速冻结,形成的冰晶尺寸更小,对蛋白质网络结构的破坏越小,提高冷冻面团的品质[7]。

2.3 面团冰晶形态分布变化

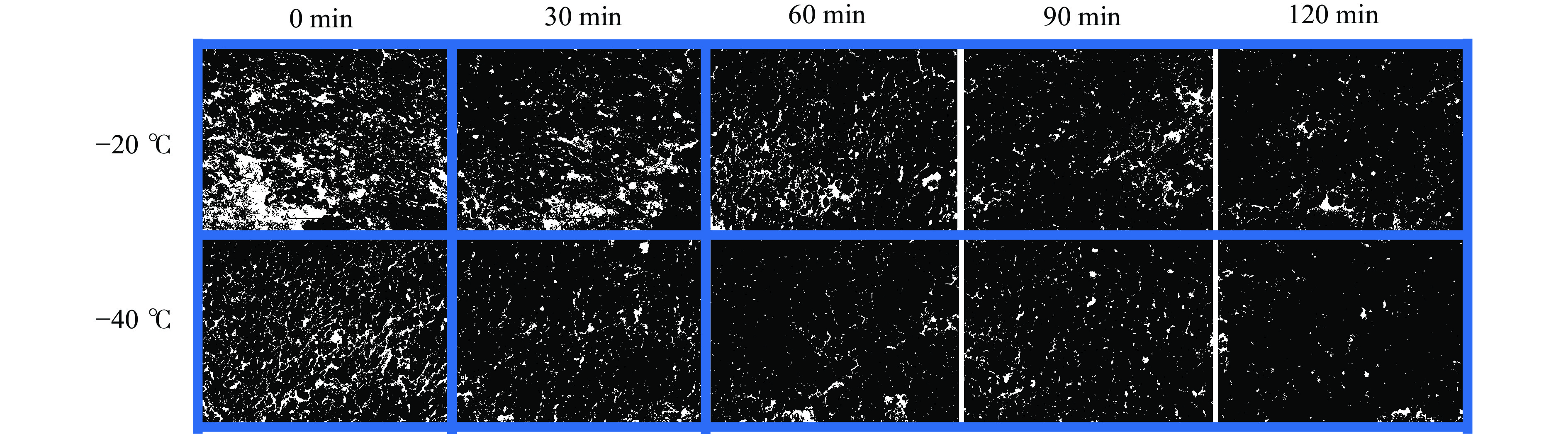

使用MATLAB软件对样品的SEM图进行冰晶空隙分布的处理,进一步观察和量化面团中冰晶空隙的分布和大小。在图像中白色区域是面团内部的冰晶,黑色区域为面团的背景。

面团的冰晶分布图如图3所示,从图3中可以直观的观察到,随着醒面时间的延长,在−20和−40 ℃条件下,面团冰晶空隙分布逐渐均匀,冰晶空隙大小和数量有明显的减少,这是因为面团在醒面过程中水分分布的均匀性增加,面团中大分子物质与水的结合更充分,可冻结水含量降低,使面团在冻结过程中形成的冰晶分布更均匀、空隙更少,减少对冷冻面团的破坏。随着冻结温度的降低,面团的冰晶空隙数量和尺寸也逐渐降低,这是因为更低的温度使面团内部的水分相变更快,使面团中的空隙分布更均匀,减低面团中冰晶空隙尺寸[25]。

由表1中冰晶孔隙参数的变化可知,面团在−20或在−40 ℃下冻结时,随着醒面时间的延长,面团中平均空隙面积、冰晶空隙数目和孔隙率都逐渐减小,说明面团在醒面过程中水分逐渐渗透,面团组分和水充分水合,可冻结水的含量降低,降低面团在冻结时的冰晶尺寸和数量。面团在相同醒面时间下,−40 ℃冷冻条件,面团中的平均空隙面积、冰晶空隙数目和孔隙率均小于−20 ℃条件下,更低的冻结温度,降低了面团在冻结过程中冰晶的尺寸和数量,保护冷冻面团的品质。

表 1 冷冻面团的冰晶孔隙参数Table 1. Ice crystal pore parameters of frozen dough冻结温度(℃) 醒面时间(min) 平均空隙面积 冰晶数目 孔隙率(%) -20 0 22.65 10627.00 19.59 30 16.89 7618.00 10.47 60 17.64 5336.00 7.66 90 12.63 4689.00 4.82 120 11.80 3346.00 3.21 -40 0 23.15 5155.00 9.71 30 12.21 7339.00 7.29 60 13.38 5086.00 5.54 90 11.49 3197.00 2.99 120 10.13 2047.00 1.69 2.4 面团的蠕变和恢复特性

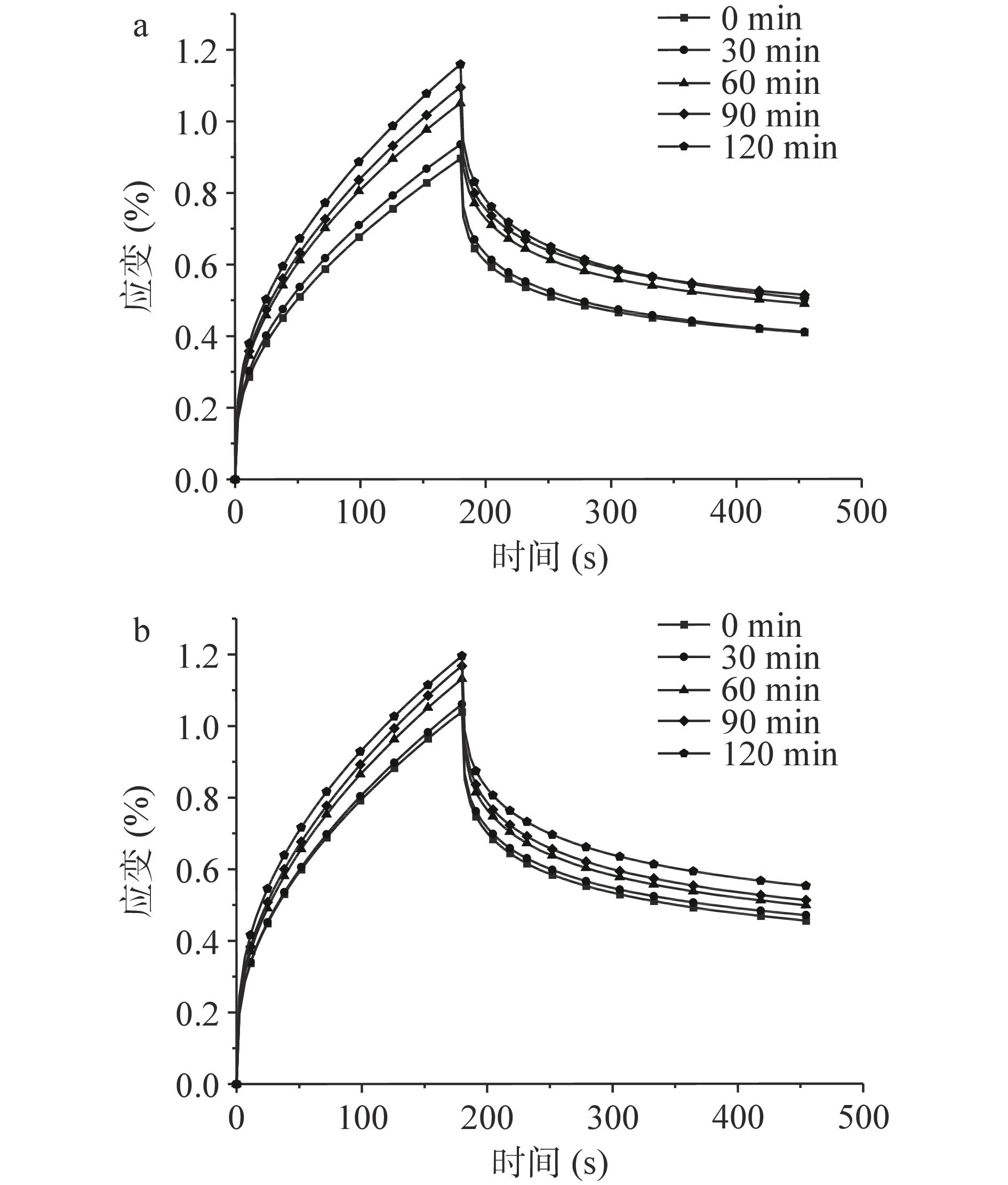

从图4中可知,在前180 s的蠕变阶段,面团持续受到外力的作用,面团的应变逐渐增加,蠕变结束以后,面团本身的弹性使形变逐渐恢复,应变逐渐降低。从图4中可知,即使完全撤出外力,面团的应变也不能完全恢复,这是因为面团在受到外力作用时导致面团内部结构发生不可逆变化,面团发生永久形变,此时面团保持一定形变不在变化,逐渐趋于平衡。

从图4中可知,在蠕变阶段相同时间下,随着醒面时间的延长,面团的应变逐渐增加。在恢复阶段,应变的变化和蠕变阶段的趋势相同。这一结果的产生与面团中蛋白质网络结构的形成度和完整度成正相关,蛋白质网络结构越紧密,抵抗变形和变形后恢复的能力越强[26]。随着醒面时间的延长,冷冻之后面团的品质得到改善,说明面团在冷冻之后,冰晶对面团的组织结构破坏减小,保留面团中更多的蛋白质网络结构,提高了冷冻面团的品质。产生这种现象的原因是:一方面,面团在醒面过程中水分得到均匀分布,强结合水含量增加,降低了可冻结水的含量,使得面团在冻结过程中形成更小和分布均匀的冰晶,对面团中蛋白质网络结构的破坏减小[27];另一方面,在醒面过程中蛋白质结构的有序性和稳定性增加,蛋白质网络结构得到充分扩展,GMP含量的增加[6],增加了面筋网络的强度,面团的结构得到改善,使得面团具有更好的蠕变和恢复特性[28]。在不同冻结温度下,面团的蠕变和恢复特性也存在差异性。在−20 ℃条件下冻结时,因为冻结速度较慢,面团中的水分在冻结过程中更容易形成大尺寸的冰晶,破坏面团中的蛋白质网络结构。因此,在−20 ℃冻结条件下,面团的恢复特性明显低于−40 ℃的条件。

用Burgers模型对面团的蠕变恢复曲线数据进行拟合,拟合度均在0.97以上,得到不同冻结温度下面团的蠕变恢复特性参数。根据表2可知,随着醒面时间的延长,在蠕变阶段,最大蠕变柔量Jmax显著增加(P<0.05),零剪切粘度η0显著降低(P<0.05),Jmax值越大,代表面团越柔软,η0值越大,表明面团在外力撤去时的流动性越高,越难以保持形状。随着醒面时间的延长,面团的Jmax增大,零剪切粘度η0减小,说明随着醒面时间的延长面团的硬度降低,面团的形状更容易保持。在恢复阶段,瞬时柔量J0与黏弹性柔量Jm均显著增大(P<0.05),J0和Jm分别代表面团在恢复阶段的弹性、黏性性能[29]。随着醒面时间的延长,J0与Jm逐渐增加,说明随着醒面时间的延长,冷冻面团的恢复力增加。醒面处理后的面团在冷冻过程中形成的冰晶尺寸更小,面团具有更完整的蛋白质网络结构,使冷冻面团得到保护,品质得到提升,具有更好的蠕变恢复特性。

表 2 面团蠕变-恢复参数的变化Table 2. Changes in creep-recovery parameters of dough冻结温度

(℃)醒面时间

(min)蠕变阶段 恢复阶段 Jmax

(×10−4 Pa−1)η0

(×105 Pa−1)J0

(×10−4 Pa−1)Jm

(×10−4 Pa−1)-20 0 1.78±0.20c 1.60±0.04a 2.39±0.00c 6.64±0.10d 30 1.91±0.50bc 1.50±0.01b 2.62±0.10c 7.35±0.20cd 60 2.10±0.10ab 1.30±0.03c 2.79±0.10bc 7.86±0.10bc 90 2.26±0.90a 1.27±0.05c 3.03±0.30b 8.49±0.70b 120 2.28±0.25a 1.17±0.01d 3.65±0.10a 9.52±0.00a -40 0 2.04±0.04b 1.41±0.03a 2.87±0.02b 7.91±0.01b 30 2.07±0.04b 1.39±0.03ab 3.00±0.01b 8.13±0.02b 60 2.34±0.01a 1.26±0.01b 3.27±0.07a 9.00±0.01a 90 2.35±0.01a 1.24±0.07b 3.32±0.01a 9.91±0.05a 120 2.36±0.02a 1.26±0.02b 3.37±0.01a 9.15±0.00a 注:各个指标的结果表示方式均为平均值±标准差;同一列中不同的上标字母表示差异显著(P<0.05)。 在相同醒面时间下,−20 ℃冻结条件下,面团的最大蠕变柔量、瞬时柔量J0和黏弹性柔量Jm均大于−40 ℃条件,而−20 ℃下的面团的零剪切粘度大于−40 ℃。说明随着面团冻结温度的降低,对面团中蛋白质网络结构的破坏和面团品质的劣变减小。有研究表明,面团的最大蠕变柔量和面团的硬度呈负相关的关系[30],随着冻结温度的升高,面团在冻结时会形成更大的冰晶,更容易破坏面筋蛋白和淀粉结构,减弱大分子物质与水的结合能力,使面团在冻结时更容易失水,面团的硬度升高[31],降低面团的最大蠕变柔量,引起冷冻面团品质的降低。然而,当面团通过醒面方式处理后,面团的蠕变最大柔量增加,面团内部的大分子物质与水得到充分的结合,面团内强结合水的含量增加,有利于形成更加连续完善的面筋蛋白网络结构[32],减少面团在冻结过程中冰晶对网络结构的破坏和面团的失水率,提高面团的最大蠕变柔量,改善冷冻面团的品质。

3. 结论

本文研究了醒面时间对面团的水分分布的影响以及对其冷冻面团冰晶分布、微观结构以及蠕变恢复特性的影响,研究发现:随着醒面时间的延长,面团的水分分布更加均匀,面团中结合水含量增加,可冻结水的含量降低,面团的持水性能提高。对面团的微观结构研究发现,随着醒面时间的延长,面团后续在冻结过程中形成的冰晶空隙和数量逐渐减小,冰晶分布越来越均匀,冷冻对面团网络结构的破坏力减弱,冷冻前醒面对面团的微观结构得到保护,提高了冷冻面团的品质。同时,随着醒面时间的延长,后续冷冻面团的蠕变恢复特性也均得到提升,−40 ℃下冻结的面团蠕变恢复特性比−20 ℃下更好,冷冻面团的品质得到更好的改善。醒面后的面团持水性提高,在冻结过程中受到的破坏减小,提高了冷冻面团的品质,研究结果为面团冻藏品质控制提供了理论基础。

-

表 1 冷冻面团的冰晶孔隙参数

Table 1 Ice crystal pore parameters of frozen dough

冻结温度(℃) 醒面时间(min) 平均空隙面积 冰晶数目 孔隙率(%) -20 0 22.65 10627.00 19.59 30 16.89 7618.00 10.47 60 17.64 5336.00 7.66 90 12.63 4689.00 4.82 120 11.80 3346.00 3.21 -40 0 23.15 5155.00 9.71 30 12.21 7339.00 7.29 60 13.38 5086.00 5.54 90 11.49 3197.00 2.99 120 10.13 2047.00 1.69 表 2 面团蠕变-恢复参数的变化

Table 2 Changes in creep-recovery parameters of dough

冻结温度

(℃)醒面时间

(min)蠕变阶段 恢复阶段 Jmax

(×10−4 Pa−1)η0

(×105 Pa−1)J0

(×10−4 Pa−1)Jm

(×10−4 Pa−1)-20 0 1.78±0.20c 1.60±0.04a 2.39±0.00c 6.64±0.10d 30 1.91±0.50bc 1.50±0.01b 2.62±0.10c 7.35±0.20cd 60 2.10±0.10ab 1.30±0.03c 2.79±0.10bc 7.86±0.10bc 90 2.26±0.90a 1.27±0.05c 3.03±0.30b 8.49±0.70b 120 2.28±0.25a 1.17±0.01d 3.65±0.10a 9.52±0.00a -40 0 2.04±0.04b 1.41±0.03a 2.87±0.02b 7.91±0.01b 30 2.07±0.04b 1.39±0.03ab 3.00±0.01b 8.13±0.02b 60 2.34±0.01a 1.26±0.01b 3.27±0.07a 9.00±0.01a 90 2.35±0.01a 1.24±0.07b 3.32±0.01a 9.91±0.05a 120 2.36±0.02a 1.26±0.02b 3.37±0.01a 9.15±0.00a 注:各个指标的结果表示方式均为平均值±标准差;同一列中不同的上标字母表示差异显著(P<0.05)。 -

[1] 张影全, 师振强, 赵博, 等. 小麦粉面团形成过程水分状态及其比例变化[J]. 农业工程学报,2020,36(15):299−306. [ZHANG Y Q, SHI Z Q, ZHAO B, et al. Changes of water status and proportion during wheat flour mixing[J]. Transactions of the Chinese Society of Agricultural Engineering,2020,36(15):299−306.] ZHANG Y Q, SHI Z Q, ZHAO B, et al . Changes of water status and proportion during wheat flour mixing[J]. Transactions of the Chinese Society of Agricultural Engineering,2020 ,36 (15 ):299 −306 .[2] 石吉勇, 刘传鹏, 吴胜斌, 等. 挂面面片水分分布均匀度的快速定量表征[J]. 食品科学,2020,41(16):138−144. [SHI J Y, LIU C P, WU S B, et al. Rapid quantitative characterization of water distribution uniformity of noodle dough sheet[J]. Food Science,2020,41(16):138−144.] doi: 10.7506/spkx1002-6630-20190701-016 SHI J Y, LIU C P, WU S B, et al . Rapid quantitative characterization of water distribution uniformity of noodle dough sheet[J]. Food Science,2020 ,41 (16 ):138 −144 . doi: 10.7506/spkx1002-6630-20190701-016[3] 张慧娟, 冯钰琳, 王静. 面团形成过程中麦谷蛋白大聚体(GMP)的动态变化规律[C]//西安:中国食品科学技术学会第十七届年会会议摘要集. 中国食品科学技术学会, 2020:253−254. [ZHANG H J, FENG Y L, WANG J. Changes to glutenin macropolymer(GMP) during dough mixing and restin[C]// Xi'an:Chinese Society of Food Science and Technology 17th Annual Meeting abstract collection. Chinese Society of Food Science and Technology, 202:253−354.] ZHANG H J, FENG Y L, WANG J. Changes to glutenin macropolymer(GMP) during dough mixing and restin[C]// Xi'an: Chinese Society of Food Science and Technology 17th Annual Meeting abstract collection. Chinese Society of Food Science and Technology, 202: 253−354.

[4] XING J J, QIAO J Y, YANG Z, et al. Effects of ultrasound-assisted resting on the qualities of whole wheat dough sheets and noodles[J]. International Journal of Food Science and Technology,2021,56(11):5609−5618. doi: 10.1111/ijfs.15078

[5] PATEL M J, CHAKRABARTI-BELL S. On the use of conventional dough extension tests in characterising flours for dough sheetability. I. simulations[J]. International Journal of Food Engineering,2016,12(3):221−230. doi: 10.1515/ijfe-2015-0087

[6] 陈洁, 汪磊, 吕莹果, 等. 醒面时间对烩面面团水分分布及麦谷蛋白大聚体的影响[J]. 中国食品学报,2018,18(6):167−173. [CHEN J, WAMG L, LÜ Y G, et al. Effect of resting time on moisture distribution and glutenin macropolymer of stewed noodles dough[J]. Journal of Chinese Institute of Food Science and Technology,2018,18(6):167−173.] CHEN J, WAMG L, LÜ Y G, et al . Effect of resting time on moisture distribution and glutenin macropolymer of stewed noodles dough[J]. Journal of Chinese Institute of Food Science and Technology,2018 ,18 (6 ):167 −173 .[7] LIU S Y, LIU Q, LI X, et al. Effects of dough resting time on the development of gluten network in different sheeting directions and the textural properties of noodle dough[J]. LWT-Food Science and Technology,2021,141:110920. doi: 10.1016/j.lwt.2021.110920

[8] WANG P, JIN Z Y, XU X M. Physicochemical alterations of wheat gluten proteins upon dough formation and frozen storage-A review from gluten, glutenin and gliadin perspectives[J]. Trends in Food Science & Technology,2015,46(2):189−198.

[9] KIANI H, SUN D W. Water crystallization and its importance to freezing of foods:A review[J]. Trends in Food Science & Technology,2011,22(8):407−426.

[10] 孙乐, 刘玫, 马豪, 等. 油的种类和添加量对冻藏后速冻非发酵饼品质的影响[J]. 食品研究与开发,2023,44(3):38−46,144. [SUN L, LIU M, MA H, et al. Effect of oli types and additions on the quality of quick-frozen non-fermented pancakes after frozen storage[J]. Food Research and Development,2023,44(3):38−46,144.] SUN L, LIU M, MA H, et al . Effect of oli types and additions on the quality of quick-frozen non-fermented pancakes after frozen storage[J]. Food Research and Development,2023 ,44 (3 ):38 −46,144 .[11] FENG Y L, ZHANG H J, WANG J, et al. Dynamic changes in glutenin macropolymer during different dough mixing and resting processes[J]. Molecules,2021,26(3):541. doi: 10.3390/molecules26030541

[12] WANG J R, GUO X N, YANG Z, et al. Combined effect of NaCl and resting on dough rheology of Chinese traditional hand-stretched dried noodles and the underlying mechanism[J]. Cereal Chemistry,2021,98(3):774−783. doi: 10.1002/cche.10420

[13] 李银丽. 超声辅助冷冻对面团加工品质的影响及其作用机制研究[D]. 郑州:郑州轻工业大学, 2019. [LI Y L. Effect of ultrasonic-assisted freezing on processing quality of dough and its mechanism[D]. Zhengzhou:Zhengzhou University of Light Industry, 2019.] LI Y L. Effect of ultrasonic-assisted freezing on processing quality of dough and its mechanism[D]. Zhengzhou: Zhengzhou University of Light Industry, 2019.

[14] HE Y J, GUO J Y, REN G Y, et al. Effects of konjac glucomannan on the water distribution of frozen dough and corresponding steamed bread quality[J]. Food Chemistry,2020,330:127243. doi: 10.1016/j.foodchem.2020.127243

[15] LIU M, LIANG Y, ZHANG H, et al. Production of a recombinant carrot antifreeze protein by Pichia pastoris GS115 and its cryoprotective effects on frozen dough properties and bread quality[J]. LWT-Food Science and Technology,2018,96:543−550. doi: 10.1016/j.lwt.2018.05.074

[16] PAN Z L, HUANG Z M, MA J Y, et al. Effects of freezing treatments on the quality of frozen cooked noodles[J]. Journal of Food Science and Technology-Mysore,2020,57(5):1926−1935. doi: 10.1007/s13197-019-04228-0

[17] 陈前, 李娜, 贺晓光, 等. 瓜尔豆胶对马铃薯-小麦混合粉面团质构和流变特性的影响[J]. 食品工业科技,2020,41(6):198−203. [CHEN Q, LI N, HE X G, et al. Effects of guar gum on texture and rheology property of potato-wheat dough[J]. Science and Technology of Food Industry,2020,41(6):198−203.] CHEN Q, LI N, HE X G, et al . Effects of guar gum on texture and rheology property of potato-wheat dough[J]. Science and Technology of Food Industry,2020 ,41 (6 ):198 −203 .[18] MIRONEASA S, IUGA M, ZAHARIA D, et al. Rheological analysis of wheat flour dough as influenced by grape peels of different particle sizes and addition levels[J]. Food and Bioprocess Technology,2019,12(2):228−245. doi: 10.1007/s11947-018-2202-6

[19] 王凯旭, 丁江涛, 刘兴丽, 等. 静电场辅助冻藏对水饺皮品质的影响[J]. 食品科技,2020,45(9):148−154. [WANG K X, DING J T, LIU X L, et al. Effect of electrostatic storage assisted freezing on the quality of dumpling wrappers[J]. Food Science,2020,45(9):148−154.] WANG K X, DING J T, LIU X L, et al . Effect of electrostatic storage assisted freezing on the quality of dumpling wrappers[J]. Food Science,2020 ,45 (9 ):148 −154 .[20] RIBOTTA P D, LEON A E, ANON M C. Effect of freezing and frozen storage on the gelatinization and retrogradation of amylopectin in dough baked in a differential scanning calorimeter[J]. Food Research International,2003,36(4):357−363. doi: 10.1016/S0963-9969(02)00227-2

[21] 刘科文, 关二旗, 李萌萌, 等. 秋葵多糖对冷冻面团贮藏稳定性的影响[J]. 食品与发酵工业,2023,49(6):92−97. [LIU K W, GUAN E Q, LI M M, et al. Effects of okra polysaccharide on storage stability of frozen dough[J]. Food and Fermentation Industries,2023,49(6):92−97.] LIU K W, GUAN E Q, LI M M, et al . Effects of okra polysaccharide on storage stability of frozen dough[J]. Food and Fermentation Industries,2023 ,49 (6 ):92 −97 .[22] 刘亚楠. 面粉组分对冷冻面团及其蒸制品品质影响的研究[D]. 郑州:河南工业大学, 2012. [LIU Y N. Effect of wheat flour on the quality of frozen dough and steamed food[D]. Zhengzhou:Henan University of Technology, 2012.] LIU Y N. Effect of wheat flour on the quality of frozen dough and steamed food[D]. Zhengzhou: Henan University of Technology, 2012.

[23] 赵双丽, 肖乃勇, 刘兴丽, 等. 竹笋膳食纤维对反复冻融面团加工特性和水分分布的影响[J]. 轻工学报,2019,34(5):20−26. [ZHAO S L, XIAO N Y, LIU X L, at al. Effects of bamboo shoot dietary fiber on the processing characteristics and moisture distribution of repeated freeze-thaw dough[J]. Journal of Light Industry,2019,34(5):20−26.] ZHAO S L, XIAO N Y, LIU X L, at al . Effects of bamboo shoot dietary fiber on the processing characteristics and moisture distribution of repeated freeze-thaw dough[J]. Journal of Light Industry,2019 ,34 (5 ):20 −26 .[24] GONG S, YANG D, WU Q, et al. Evaluation of the antifreeze effects and its related mechanism of sericin peptides on the frozen dough of steamed potato bread[J]. Journal of Food Processing and Preservation,2019,43(1):e14053.

[25] AKBARIAN M, KOOCHEKI A, MOHEBBI M, et al. Rheological properties and bread quality of frozen sweet dough with added xanthan and different freezing rate[J]. Journal of Food Science and Technology-Mysore,2016,53(10):3761−3769. doi: 10.1007/s13197-016-2361-2

[26] 陈丽. 冷冻对非发酵面团水分状态和冰晶形态的影响[D]. 北京:中国农业科学院, 2021. [CHEN L. The effect of freezing on the water state and ice crystal morphology of non-fermented dough[D]. Beijing:Chinese Academy of Agricultural Sciences, 2021.] CHEN L. The effect of freezing on the water state and ice crystal morphology of non-fermented dough[D]. Beijing: Chinese Academy of Agricultural Sciences, 2021.

[27] 刘艺. 脱皮程度与制粉方式对小麦粉及面条品质的影响[D]. 泰安:山东农业大学, 2021. [LIU Y. Effect of peeling degree and milling merhods on the quality wheat flour and noodle[D]. Taian:Shandong Agricultural University, 2021.] LIU Y. Effect of peeling degree and milling merhods on the quality wheat flour and noodle[D]. Taian: Shandong Agricultural University, 2021.

[28] 王沛. 冷冻面团中小麦面筋蛋白品质劣变机理及改良研究[D]. 无锡:江南大学, 2016. [WANG P. Gluten deterioration in frozen dough:Mechanism and improvement study[D]. Wuxi:Jiangnan University, 2016.] WANG P. Gluten deterioration in frozen dough: Mechanism and improvement study[D]. Wuxi: Jiangnan University, 2016.

[29] YU W J, XU D, ZHANG H, et al. Effect of pigskin gelatin on baking, structural and thermal properties of frozen dough:Comprehensive studies on alteration of gluten network[J]. Food Hydrocolloids,2020,102:105591. doi: 10.1016/j.foodhyd.2019.105591

[30] 杨静洁, 张波, 张影全, 等. 冻藏时间对非发酵面团流变特性及蛋白结构的影响[J]. 中国粮油学报,2020,35(8):15−21. [YANG J J, ZHANG B, ZHANG Y Q, et al. Effects of frozen storage period on the rheological properties and protein structure of non-fermented dough[J]. Journal of the Chinese Cereals and Oils Association,2020,35(8):15−21.] YANG J J, ZHANG B, ZHANG Y Q, et al . Effects of frozen storage period on the rheological properties and protein structure of non-fermented dough[J]. Journal of the Chinese Cereals and Oils Association,2020 ,35 (8 ):15 −21 .[31] LAZARIDOU A, DUTA D, PAPAGEORGIOU M, et al. Effects of hydrocolloids on dough rheology and bread quality parameters in gluten-free formulations[J]. Journal of Food Engineering,2007,79(3):1033−1047. doi: 10.1016/j.jfoodeng.2006.03.032

[32] 杨勇, 郑帅帅, 艾志录, 等. 不同冻结方式对非发酵面团的水分状态及品质特性的影响[J]. 食品科学,2022,43(5):11−16. [YANG Y, ZHENG S S, AI Z L, et al. Effects of different freezing methods on water status and quality characteristics of non-fermented dough[J]. Food Science,2022,43(5):11−16.] doi: 10.7506/spkx1002-6630-20210915-182 YANG Y, ZHENG S S, AI Z L, et al . Effects of different freezing methods on water status and quality characteristics of non-fermented dough[J]. Food Science,2022 ,43 (5 ):11 −16 . doi: 10.7506/spkx1002-6630-20210915-182 -

期刊类型引用(3)

1. 王海利,陈安琪,郭旭,黄俊杰,林艳翎,张文森. 桂圆红枣复合发酵果酱的工艺优化. 福建轻纺. 2024(03): 17-20+30 .  百度学术

百度学术

2. 曹永华,李祥睿. 金银花精油对葵花籽油氧化稳定性及煎炸品质的影响. 中国食品添加剂. 2024(06): 137-144 .  百度学术

百度学术

3. 蔡荣,徐春芳,李珊,夏伯候,李亚梅,刘武,谢菁琛,张智敏,林丽美. 山银花茎叶与花化学成分和抗炎活性比较研究. 湖南中医药大学学报. 2023(09): 1598-1608 .  百度学术

百度学术

其他类型引用(2)

下载:

下载:

下载:

下载: