A Review on the Functional Properties, Extraction and Microencapsulation of Almond Oil

-

摘要: 杏仁油营养丰富,是一种功能性食用油,同时具有很高的药用价值。本文在介绍杏仁油抗氧化、降血糖和预防心血管疾病等多种功能特性的基础上,对国内外杏仁油的提取和微胶囊化制备技术进行综述和展望。通过对杏仁油机械压榨法、溶剂萃取法、水萃取法等多种不同提取方法比较,以及喷雾干燥法、复合凝聚法、挤压法和冷冻干燥法等微胶囊化制备技术进行分析,明确不同技术方法的优缺点,以期为稳定杏仁油的制备及其合理利用提供理论参考,建立一种方便、快捷、高效、安全的杏仁油产业化生产和制备技术。Abstract: Almond oil is a kind of functional edible oil with rich nutrition and high medicinal value. This paper reviews the various functional properties of almond oil such as antioxidation, hypoglycemic effect and cardiovascular disease prevention, as well as the extraction and microencapsulation technology at home and abroad. The benefits and drawbacks of all these technical methods are made clear by comparing various extraction techniques, such as mechanical expression, solvent extraction, and water extraction of almond oil, as well as microencapsulation techniques, such as spray drying, complex coacervation, extrusion, and freeze-drying. The study provides a feasible, quick, effective, and secure technology for the industrial production and preparation of almond oil and might serve as a theoretical reference for its stable preparation and rational utilization.

-

Keywords:

- almond oil /

- functional features /

- extraction method /

- microencapsulation

-

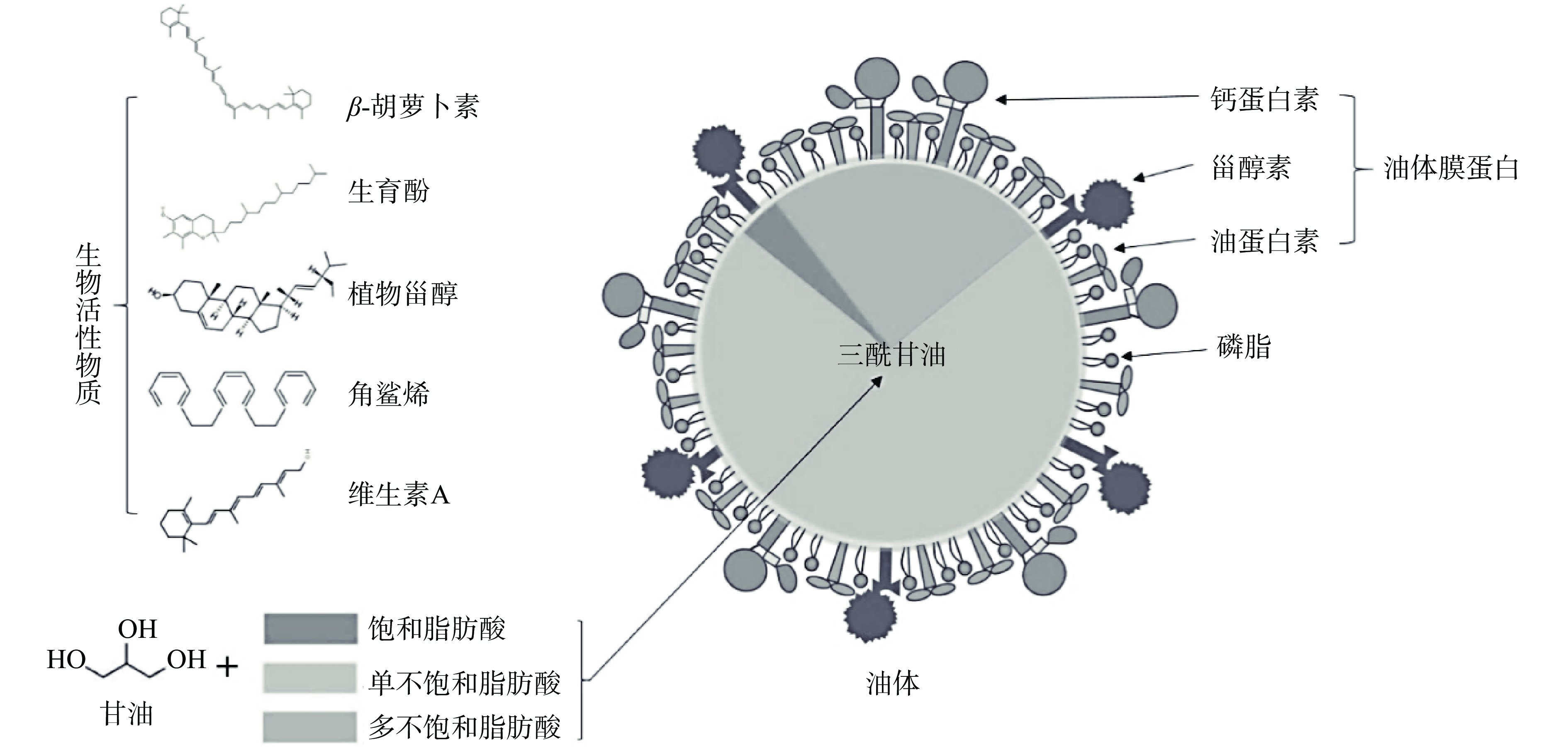

杏仁为蔷薇科李属植物杏(Prunus armeniaca L.)的种子,主要产地为美国、西班牙、伊朗等国家,在中国主要分布于新疆、河北、辽宁、山东等省区[1−2]。杏仁分为甜杏仁和苦杏仁两类。甜杏仁味甘,不含或仅含0.1%的苦杏仁苷;苦杏仁味苦,含有2%~4%苦杏仁苷[1]。杏仁含油量达45%~67%,油脂贮存在细胞器植物油体中[1]。杏仁油含有维生素、蛋白质、植物甾醇和角鲨烯等多种营养素及生物活性物质[3]。油脂中含有大量单不饱和油酸(60%~70%,ω-9),中等含量亚油酸(20%~30%,ω-6),以及少量饱和脂肪酸[4],杏仁油的组成成分如图1所示。杏仁油富含的不饱和脂肪酸具有预防心血管疾病、降血糖和降血脂等功效,是一种很好的功能性食用油[5]。适宜的提取技术是获得杏仁油的关键,传统方法多是通过低温压榨和溶剂萃取,随着水萃取、超临界萃取、亚临界萃取、超声辅助提取等新技术的出现,加快了油脂产业的发展。由于有些油脂具有特殊异味、易氧化变质,通过微胶囊化技术增强了油脂的稳定性,方便贮存和运输[6−7],大大拓展了其应用领域。本综述在介绍杏仁油的多种功能特性的基础上,对国内外现有杏仁油的提取和微胶囊化制备技术进行系统整理,对比不同技术的优缺点并进行展望,以期为稳定杏仁油的制备及其合理利用提供有价值的参考。

1. 杏仁油的功能特性

杏仁油是一种功能性食用油,富含大量油酸和亚油酸等不饱和脂肪酸,还含有维生素E、无机盐、膳食纤维及人体所需的微量元素,营养价值丰富,具有抗氧化、降血糖和预防心血管疾病等多种功能作用,可作为药物替代品[8]。

1.1 抗氧化作用

杏仁是抗氧化营养素的良好来源,食用杏仁可以减少吸烟者的氧化DNA损伤和脂质过氧化[9],增加正常人血清蛋白硫醇浓度来弱化对氧化蛋白的损伤[10]。杏仁油中总酚、类黄酮、缩合单宁和酚酸等酚类物质含量与其抗氧化能力密切相关[11],在加速氧化过程中,杏仁油含量高的调和油生育酚、植物甾醇和角鲨烯含量逐渐增加,油脂氧化稳定性好[12]。杏仁油还具有清除DPPH、ABTS+自由基和铁还原能力,能稳定血清中还原型谷胱甘肽、超氧化物歧化酶、丙二醛和过氧化氢酶水平,对铅毒性引发的氧化应激有积极影响[13]。

1.2 降血糖作用

杏仁具有辅助降血糖作用,其中杏仁油是发挥降血糖作用的主要功能成分[14−15]。杏仁油通过调节糖代谢和相关肠道微生物群等改善血糖,如在含有75 g碳水化合物的早餐中添加22.6 g杏仁油能降低糖耐量受损成人全天葡萄糖、胰岛素和血清游离脂肪酸浓度,改善激素水平,这种降血糖反应能力相当于给予28 mg阿卡波糖的效果[16];杏仁油能降低链脲佐菌素诱导的糖尿病大鼠异常升高的血糖,促进胰岛素分泌,改善糖耐量,同时调节Nrf2/HO-1通路逆转肠道微生物群变化,进而调节与葡萄糖代谢相关的肠道微生物群[8]。

1.3 预防心血管疾病作用

总胆固醇和低密度脂蛋白胆固醇是心血管疾病的危险因素[17]。补充杏仁油可显著降低模型动物血浆总胆固醇、低密度脂蛋白胆固醇和甘油三酯水平,提高高密度脂蛋白胆固醇水平[18−20],改善血脂异常和内皮功能,预防心血管疾病。临床试验与动物实验一致,如40周内每天食用4 mL杏仁油可显著降低甘油三脂[21];30 d内每天食用10 mL杏仁油两次能显著降低总胆固醇和低密度脂蛋白胆固醇[22]。综上,食用杏仁油是通过调节血脂实现对心血管疾病的保护,然而确定杏仁油降低心血管疾病风险的机制仍需进一步研究。

1.4 预防癌症作用

杏仁油含高浓度不饱和脂肪酸、多酚、类黄酮等成分,对癌症有预防作用。杏仁油能减少大鼠异常隐窝病灶的数量,降低大鼠结肠癌的发病率[23];在细胞存活及生长测定和免疫细胞化学评估中,抑制Ki-67抗原的表达,显著降低骨形态发生蛋白-2(BMP-2)和β-连环蛋白的免疫反应性,对原发性(Colo-320)和转移性(CORO-741)结肠癌细胞有抗增殖作用,预防结肠癌发生[24]。杏仁油还具有防止肿瘤中血管生成的能力,Ali等[25]在主动脉瓣环和鸡胚绒毛尿囊膜测定中发现,杏仁油与阿司匹林的协同作用可显著抑制肿瘤血管生长。

1.5 神经药理学效应作用

杏仁油具有抗抑郁症、放松情绪和减缓疼痛等神经药理学效应作用。如杏仁油、薰衣草油以及两者组合治疗大鼠会降低其强迫游泳测试中与抑郁症相关的不动特征,增加潜伏期以避免被动避让测试装置中的电击,这可能与增强海马区域功能有关,但抗抑郁特性的成分目前尚不清楚,仍需研究证实[26];Sayowan等[27]研究了20名健康志愿者在休息期间吸入杏仁油对情绪状态和神经系统生理参数的影响,发现杏仁油有放松助眠的效果并且脑电图评估的脑电波频率没有显著变化;杏仁油芳香疗法能减轻女性原发性痛经的疼痛程度[28],或与薰衣草协同作用减轻烧伤患者的焦虑和疼痛[29]。

1.6 其他作用

杏仁油还具有抗炎、增强免疫力、改善肝肾功能等作用[8],如杏仁油能显著减少早期耳肿胀炎症抗炎中冰醋酸所致扭体发生的次数,提高热板法小鼠痛阈,镇痛效果明显[30];小白杏杏仁油可能通过调节血清结合珠蛋白、角蛋白、微管蛋白α-8链、免疫球蛋白重(k)链VⅢ区、α-1-抗蛋白酶及T-激肽原等蛋白的表达水平,作用于金黄色葡萄球菌感染、吞噬体、致病性大肠杆菌感染、原发性免疫缺陷、补体和凝血级联5条先天性免疫通路而展现其免疫调节作用[31]。苦杏仁油是一种“润肠通便”的活性成分,能提高黏膜对肠内容物的润滑作用[32]。杏仁油还可用于保护皮肤,弱化紫外线诱导的皮肤光老化问题,在紫外线照射后对皮肤有光保护作用[33]。在生育方面,有研究指出杏仁油在防止精子损伤方面有很强效应[34],这种效应可能是与杏仁油抗氧化成分精氨酸、辅酶Q10和α-生育酚有关[35]。

2. 杏仁油的提取

杏仁油不仅是极具营养价值和功能特性的食用植物油,也是重要的工业用油,因此研究杏仁油的提取方法技术具有重要应用价值。在提取杏仁油之前,对杏仁进行光照、超声波或微波等干燥预处理以降低水分含量、减少微生物活性和变质等化学反应,稳定后续提取过程中杏仁油的良好质量[36−38]。杏仁油的提取方法有多种,如机械压榨法、溶剂萃取法、水萃取法、酶辅助水萃取法、超临界流体(CO2)萃取法、亚临界流体萃取法和超声辅助提取法等。

2.1 机械压榨法

机械压榨法一般利用液压机或螺旋压榨机提取[39],两种方式对杏仁油的脂肪酸组成和甾醇含量没有显著影响[40]。通过对比发现,液压压榨适合于小规模使用,能更好地保持杏仁油的物理、化学性质以及感官特性;螺杆压榨产油率高、时间与经济成本较低,具有可持续生产的特点,适合连续或半连续规模化工业生产[41]。机械压榨法根据物料处理温度可分为热榨法和冷榨法,热榨法是将油料种子捣碎并在120~130 ℃的高温下加热处理后压榨,冷榨法是将清洗后的油料种子在低于60 ℃的环境下直接压榨。杏仁油主要采用冷榨法提取,所获得的油脂油酸含量高,过氧化值和酸价低[42−43],脂肪酸、生育酚和甾醇比有机溶剂萃取含量高[44−45]。研究者们还发现,调节种子水分为8%[46]和压榨温度为43 ℃[47]可以提高螺旋压榨提取杏仁油的效率。

2.2 溶剂萃取法

溶剂萃取法又称索氏提取法或有机溶剂浸提法,利用有机溶剂将油料中油脂萃取出来,依据溶剂与油脂沸点不同原理,通过加热、蒸发、汽提的方式得到毛油。溶剂萃取法操作简单、成本低,是传统萃取方法。薛焕焕等[42]研究了不同提取方法对大扁杏仁油品质的影响,结果表明,与冷榨法和超声波辅助提取法相比,索氏提取法的杏仁油提取率最高,可达到49.00%。提取杏仁油常用的溶剂有己烷、石油醚、乙醚和氯仿-甲醇,其中己烷是提取非极性脂质和分离所有挥发性化合物的首选溶剂[48]。氯仿-甲醇(1:1)溶剂可通过提取非极性和极性脂质提高杏仁油产率和生育酚含量,不影响脂肪酸、三酰甘油和甾醇的组成[49−50]。采用溶剂萃取制备的油脂存在有机溶剂和杂质残留、异味等问题,必须经过酸炼碱炼、脱色、脱臭、冬化、保鲜等精炼工艺以去除有毒有害杂质达到人类食用标准[51]。

2.3 水萃取法

水萃取法是提取杏仁油的一种绿色方法。传统上大量水处理油籽依赖于游离氨基酸、游离脂肪酸、磷脂等化合物的完全分散或溶解,化合物的亲水和疏水性基团会形成乳液降低油回收率[52]。水萃取杏仁油的提取率为34.5%,低于己烷索氏提取率43.1%,但过氧化值、酸值、抗氧化活性、ω-6脂肪酸和总生育酚含量与低温压榨提取相似,且远优于己烷索氏提取[53]。添加少量水是一种新的水萃取方式,可以避免通过氢键聚集而成的亲水基团的溶解或分散,该方法已应用在花生、核桃和葵花籽的加工中,种子的类型直接影响萃取条件[52]。Fu等[54]研究发现,10 g经烘烤研磨过筛的杏仁原浆(无水)添加1.4 mL少量水萃取,能够从含有55.47%原油的杏仁中回收96.32%的油,并获得仅含4.38%残余油的脱油杏仁粉。少量水萃取法可生产出高质量食用油且不会产生废水,与高温压榨、溶剂萃取和传统的大量水萃取相比,这种方法的油脂提取率高,具有规模化工业应用潜力。

2.4 酶辅助水萃取法

酶辅助水萃取法制油是通过生物酶对油料细胞壁的纤维素骨架结构进行降解,增加油料组织中油的流动性,使细胞内油脂游离出来,再利用油水不相溶原理以及油和水对其他非油成分亲和力的差异将油脂分离[55−56]。水酶法制油提取率高,具有提高脂溶性微量营养素含量、保护脂肪酸组成、节能降耗等优势[57−58]。酶的添加提高了水萃取法提取机械压榨杏仁饼中杏仁油的产率[59],与己烷萃取效果相似[60]。通过与其他工艺相结合具有提高油脂提取率的效果,Sharma等[61]先对杏仁超声预辐射再采用水酶法提取,将杏仁油产率从77%提高到95%。酶解温度、pH、酶浓度、酶解时间、油料粒径、料液比和搅拌速率等多种因素均会影响水酶法提取的效率。水酶提取法具有绿色环保、节能高效的特点,但是生产成本较高且酶活性不稳定,因此在一定程度上限制了其广泛应用[62]。

2.5 超临界流体(CO2)萃取法

超临界流体(CO2)萃取是指在超临界状态下以CO2为溶剂,通过调节温度和压力,改变流体密度、粘度和扩散系数来提取油脂的一种新型清洁萃取技术[63]。超临界流体(CO2)萃取能够保留油脂中的微量活性成分,提高油脂品质。Leo等[64]通过改变压力、温度和CO2流速获得具有高生育酚含量和产量的杏仁油,脂肪酸组成与己烷-甲醇溶剂(2:1)萃取没有明显差异。朱振宝等[65]发现超临界CO2萃取杏仁油的氧化稳定性低于水酶法和索氏提取法,脂肪酸和VE含量没有区别。超临界CO2萃取与改善动力学、萃取质量和环境可持续性有关,是一种绿色安全的技术,而基础设施投资和开采工艺相关的高成本限制了其工业用途[66−67]。

2.6 亚临界流体萃取法

亚临界流体萃取技术,即依据亚临界流体特殊性质和有机物相似相溶原理,将物料置于萃取器内注入亚临界溶剂进行逆流萃取。这是一种环境友好型技术,与超临界流体萃取相比,亚临界流体萃取可以提高产率,缩短时间,具备更低的压力和温度要求,有效保护油脂中的营养成分,节省设备制造和维护成本[68]。Qi等[69]研究发现亚临界流体萃取杏仁油能获得比机械压榨法更好的品质,酚类和醇类物质含量更高,且不需要精炼。目前用于油脂提取的亚临界流体溶剂多是丁烷和R134溶剂,其他较少,不同溶剂对油脂萃取的适应性、机制以及原料组分相互作用对萃取工艺影响等还需要深入研究[70]。该方法制油成本较高,连续化、智能化和自动化配套装备还需进一步突破。

2.7 超声辅助提取法

超声辅助提取即利用高频波产生空化气泡令植物细胞壁受损,从而将细胞内物质释放出来[71]。该技术是杏仁油提取的一种强化技术。Sharma等[72]发现超声波预处理对三相分离油脂提取率有显著影响,超声2 min可使杏仁油产量增加到87%,同时增强油脂氧化稳定性。超声辅助提取常与其他方法搭配使用,如结合超临界CO2萃取使杏仁油产量达90%[73];结合水酶法将油产率从77%提高到95%,时间从18 h缩短到6 h [61];结合高压灭菌预处理杏仁粉再提取,将油回收率提高8.69%,且不影响杏仁油的组成[74]。此外,超声波处理能降低溶剂萃取苦杏仁油中氰化物含量[75]。

杏仁油的提取工艺均存在着不同的优缺点(见表1),在生产中可根据具体情况进行选择。

表 1 杏仁油提取工艺优缺点比较Table 1. Comparison of advantages and disadvantages of almond oil extraction technology制备工艺 优点 缺点 参考文献 机械压榨法

(液压法和螺旋压榨法)操作简单,成本低;保留杏仁油固有香味和滋味,

相对不含污染和有害物质出油率低,耗时长,饼粕残留油脂含量高,

VE和植物甾醇含量低[39,43] 溶剂萃取法

(有机溶剂浸提或

索氏提取法)提取率高,纯度高,VE和植物甾醇含量高 提取时间长、溶剂消耗量大、存在溶剂残留,异味 [51,65] 水萃取法 油脂品质高,少量水处理油回收率高,未产生废水 大量水处理会形成乳液致回收率低 [52−53] 酶辅助水萃取法 油脂香味和滋味浓郁,油脂稳定不易氧化,绿色环保 酶用量大且不稳定,作用时间长,生产成本高 [62,65] 超临界流体(CO2)萃取法 油脂品质高,绿色环保 技术含量高,基础设施成本高,不适合工业推广 [65,67] 亚临界流体萃取法 时间短,品质及产率高,绿色环保 设备昂贵,工业配套装备成本高 [68−69] 超声辅助提取法 产率高,绿色环保,氢化物含量低 设备昂贵,生产成本高 [72,75] 3. 杏仁油的微胶囊化制备技术

由于杏仁油不溶于水,与食品原料不易混合均匀,且富含不饱和脂肪酸,极易氧化,提取出的杏仁油在食品应用工业上仍受到很大限制[76]。微胶囊化制备技术可将脂肪酸、多酚等生物活性物质包裹在微胶囊的壁材中,增强其溶解度、分散特性及生物利用度,延长产品保质期,并赋予芯材控制释放特性[77]。有关杏仁油微胶囊化的方法主要有喷雾干燥法、复合凝聚法、挤压法和冷冻干燥法。

3.1 喷雾干燥法

喷雾干燥是一种应用广泛的微胶囊化技术,其原理是将液体原料通过雾化器形成很多微小雾滴,雾滴与干燥的热空气直接接触迅速蒸发形成干燥颗粒再收集到容器中[78]。经喷雾干燥后,杏仁油主要位于球形聚集体的内部空腔中,使其抗氧化性增加[79]。该方法可用于制备杏仁奶粉,Bueno等[80]以0、2、4 g亚麻籽油/100 g样品的浓度配制含亚麻籽油杏仁奶粉末,发现这类粉末可以替代乳制奶粉并提供多不饱和脂肪酸;Abdollahi等[81]在婴儿配方奶粉中添加喷雾干燥后的核桃油和杏仁油粉末,对产品并没有产生不利影响。喷雾干燥法制备杏仁油微胶囊大多选用多糖(麦芽糊精、芋头淀粉、阿拉伯胶等)和蛋白质(大豆分离蛋白、酪蛋白等)进行包埋[79,82−84],包埋率最高达97.28%[76]。喷雾干燥法具有运营成本低、能处理热敏材料、操作简便[85]等优点,缺点是部分芯材可能保留在胶囊表面,导致成品异味和易氧化[86],需要进一步完善加工技术。

3.2 复合凝聚法

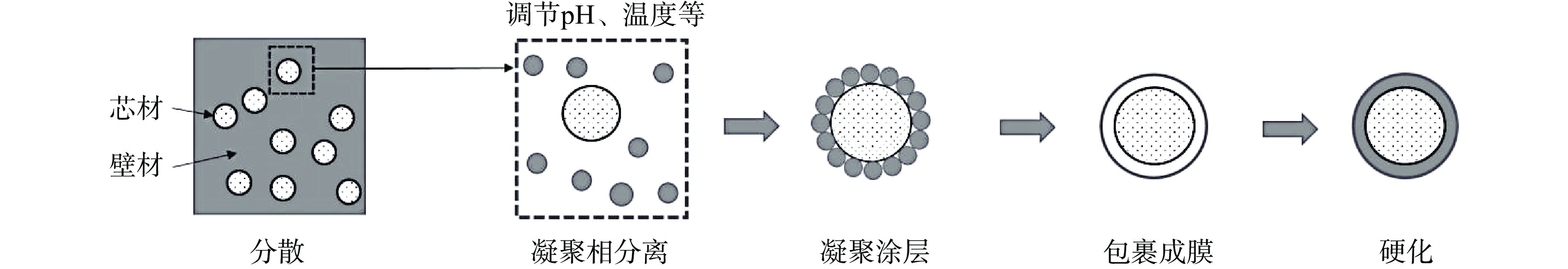

复合凝聚过程中,两种或多种带相反电荷的聚合物溶液在水中由于静电作用产生相分离,分为凝聚胶体相和稀释胶体相,凝聚胶体相作为微胶囊的囊壁[87],示意图如图2所示。复合凝聚法应用于许多水不溶性化合物,如脂肪酸、脂溶性维生素和香料[88−89],其常用的壁材为多糖和蛋白质。Prata等[90]以明胶和阿拉伯胶为壁材包埋杏仁油,包埋率达70.6%,颗粒大小为19.2 μm,并指出油回收率主要取决于均质速度、温度和聚合物配比。许多物理化学参数都会影响凝聚过程,如环境因素(pH、温度、压力和搅拌),聚合物的性质(分子量、离子强度、浓度和蛋白质/多糖比),Schmitt等[91]认为pH、离子强度、蛋白质与多糖的比例和总生物聚合物浓度是最重要因素。与喷雾干燥相比,该技术更复杂、耗时且昂贵,但温度变化温和,释控性能好,外壳完整性、堆芯负载及封装效率高[92]。

3.3 挤压法

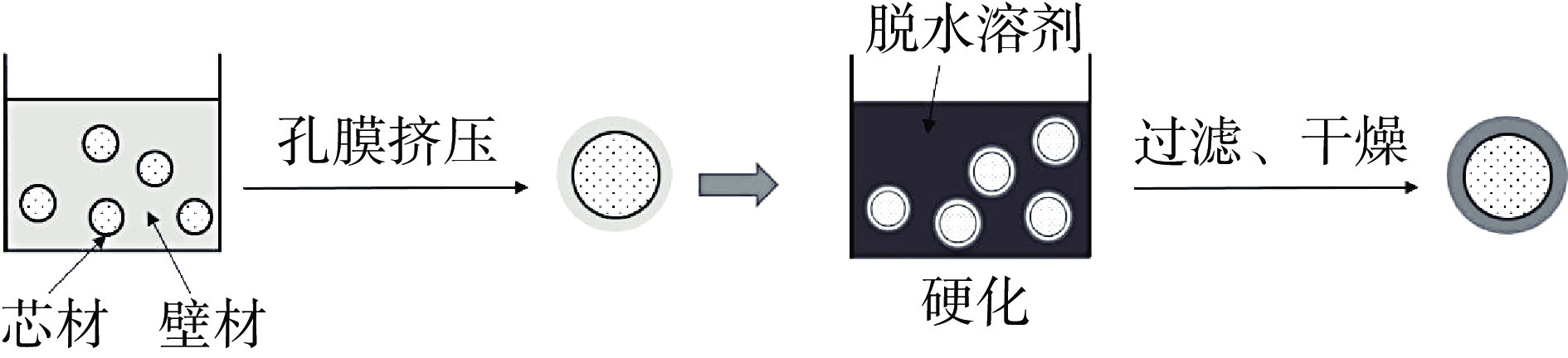

挤压法最先出现在1950年末,用来封装香料,又称熔融注射[93]。挤压法是将芯材加到熔融的碳水化合物涂层中[94],涂层在脱水溶液中硬化,然后分离、干燥的方法,示意图如图3所示。常用的涂层材料包括葡萄糖、葡萄糖浆、蔗糖、麦芽糊精和甘油,可单一或混合使用。该方法的主要优点是利用壁材完全隔离空气,保护芯材不受氧的影响[95]。Lucía等[96]以壳聚糖为壁材,通过共挤出凝胶化方式对杏仁精油进行封装,再通过振动覆盖将壁材和活性剂溶液挤出液滴,液滴落在含有胶凝剂溶液的浴槽中形成胶囊,并利用光学显微镜和降解性进行表征,实验结果发现对于1%(w/v)的壳聚糖浓度,交联剂的最佳浓度为8.0 g/L,0.45/0.90 mm的喷嘴尺寸(内部/外部)可获得合适形态的球形胶囊,即喷嘴尺寸和交联浓度是封装过程中的关键变量。

3.4 冷冻干燥法

冷冻干燥法制备微胶囊的原理为冻结的芯材与壁材的混悬乳液经由升华过程去除水分而构成微胶囊[97]。这种方法最大限度地减少了与高温相关的反应,广泛用于香精或调味剂,成品品质高,但高成本和加工时间长削弱了其商业适用性[98]。韩金承等[99]以β-环状糊精和大豆分离蛋白为原料,利用冷冻干燥法获得包埋率为84.07%的苦杏仁油微胶囊,通过烘箱加速氧化法考察其氧化稳定性,实验结果表明:微胶囊化后苦杏仁油的过氧化值、碘值、酸价、皂化值及共轭二烯烃值变化幅度较小,氧化周期明显变长,有利于延长油脂的储藏时间。杨海燕等[100]以酪蛋白、麦芽糊精为壁材,冷冻干燥制备甜杏仁油微胶囊,确定最佳配方为芯材含量22%、乳化剂含量2.2%、酪蛋白含量5%、均质时间7 min,得到粉质疏松,包埋率达85.83%的产品。

综上,杏仁油的微胶囊制备工艺存在着不同的优缺点(见表2),实际应用中可以结合具体情况选择。

表 2 杏仁油微胶囊制备工艺优缺点比较Table 2. Comparison of advantages and disadvantages of preparation technology of almond oil microcapsules4. 总结与展望

杏仁油富含不饱和脂肪酸及其他营养素,具有抗氧化、降糖脂、抗癌等多种功能特性,市场开发前景广阔。通过分析国内外现有杏仁油的提取和微胶囊化制备技术,对比不同方法对油脂产量、成分和质量的影响,对杏仁油的产业化生产具有一定指导作用。目前关于杏仁油营养成分及功能特性的研究较多,但少有研究试图探索这些不同生物活性的分子机制,后续应对其活性成分与功能作用机制相关性展开研究,以指导营养功能型杏仁油产品的开发。此外,市面上存在杏仁油掺假现象,通过采用精密仪器从标志性成分、模式识别和多组学技术等,建立现代方法技术对杏仁油进行质量分级检测是下一步关注的焦点。油脂的提取技术已经相对成熟,尤其近几年提出的少量水萃取新技术既能获得高质量的食用油又避免废水的产生,具有低碳环保的优势,助力可持续发展。杏仁油微胶囊技术的应用提高了油脂的稳定性,便于贮存与运输,其主要挑战在于开发性能优良且成本低廉的壁材、提高微胶囊包埋率和减缓贮存期间油脂氧化等问题,下一步可深入研究微胶囊乳液内两相的相互作用、纳米微胶囊及其他新型技术,扩大其应用领域,促进天然油脂深加工发展。

-

表 1 杏仁油提取工艺优缺点比较

Table 1 Comparison of advantages and disadvantages of almond oil extraction technology

制备工艺 优点 缺点 参考文献 机械压榨法

(液压法和螺旋压榨法)操作简单,成本低;保留杏仁油固有香味和滋味,

相对不含污染和有害物质出油率低,耗时长,饼粕残留油脂含量高,

VE和植物甾醇含量低[39,43] 溶剂萃取法

(有机溶剂浸提或

索氏提取法)提取率高,纯度高,VE和植物甾醇含量高 提取时间长、溶剂消耗量大、存在溶剂残留,异味 [51,65] 水萃取法 油脂品质高,少量水处理油回收率高,未产生废水 大量水处理会形成乳液致回收率低 [52−53] 酶辅助水萃取法 油脂香味和滋味浓郁,油脂稳定不易氧化,绿色环保 酶用量大且不稳定,作用时间长,生产成本高 [62,65] 超临界流体(CO2)萃取法 油脂品质高,绿色环保 技术含量高,基础设施成本高,不适合工业推广 [65,67] 亚临界流体萃取法 时间短,品质及产率高,绿色环保 设备昂贵,工业配套装备成本高 [68−69] 超声辅助提取法 产率高,绿色环保,氢化物含量低 设备昂贵,生产成本高 [72,75] 表 2 杏仁油微胶囊制备工艺优缺点比较

Table 2 Comparison of advantages and disadvantages of preparation technology of almond oil microcapsules

-

[1] 杨晓宇, 陈锦屏. 杏仁的营养保健功能及其在食品工业中的应用[J]. 食品科学,2005(9):611−613. [YANG X Y, CHEN J P. Nutritional and healthy function of apricot kernel and its application in food industry[J]. Food Science,2005(9):611−613.] doi: 10.3321/j.issn:1002-6630.2005.09.170 YANG X Y, CHEN J P . Nutritional and healthy function of apricot kernel and its application in food industry[J]. Food Science,2005 (9 ):611 −613 . doi: 10.3321/j.issn:1002-6630.2005.09.170[2] LADIZINSKY G. On the origin of almond[J]. Genetic Resources and Crop Evolution,1999,46:143−147. doi: 10.1023/A:1008690409554

[3] ALASALVAR C, PELVAN E. Fat-soluble bioactives in nuts[J]. European Journal of Lipid Science and Technology,2011,113(8):943−949. doi: 10.1002/ejlt.201100066

[4] 邓平. 杏仁氰苷及油脂组分积累模式研究[D]. 杨凌:西北农林科技大学, 2021. [DENG P. Study on the accumulation pattern of cyanogenetic glycosides and lipid components in apricot kernel[D]. Yangling:Northwestern Agriculture and Forestry University, 2021.] DENG P. Study on the accumulation pattern of cyanogenetic glycosides and lipid components in apricot kernel[D]. Yangling: Northwestern Agriculture and Forestry University, 2021.

[5] KAVEH M, JAHANBAKHSHI A, ABBASPOUR-GILANDEH Y, et al. The effect of ultrasound pre-treatment on quality, drying, and thermodynamic attributes of almond kernel under convective dryer using ANNs and ANFIS network[J]. Journal of Food Process Engineering,2018,41(7):e12868. doi: 10.1111/jfpe.12868

[6] 丁洁, 李博生. 微胶囊技术及其在食品工业中的应用[J]. 中国食物与营养,2010(3):29−31. [DING J, LI B S. Microencapsulation and its application in food industry[J]. Chinese Food and Nutrition,2010(3):29−31.] doi: 10.3969/j.issn.1006-9577.2010.03.009 DING J, LI B S . Microencapsulation and its application in food industry[J]. Chinese Food and Nutrition,2010 (3 ):29 −31 . doi: 10.3969/j.issn.1006-9577.2010.03.009[7] DRUSCH S, SCHWARZ K. Microencapsulation properties of two different types of n-octenylsuccinate-derivatised starch[J]. European Food Research and Technology,2006,222:155−164. doi: 10.1007/s00217-005-0020-3

[8] LIU R, SHU Y, QI W, et al. Protective effects of almond oil on streptozotocin-induced diabetic rats via regulating Nrf2/HO-1 pathway and gut microbiota[J]. Journal of Food Quality,2021(3):1−14.

[9] LI N, JIA X, CHEN C Y O, et al. Almond consumption reduces oxidative DNA damage and lipid peroxidation in male smokers[J]. The Journal of Nutrition,2007,137(12):2717−2722. doi: 10.1093/jn/137.12.2717

[10] JENKINS D J A, KENDALL C W C, JOSSE A R, et al. Almonds decrease postprandial glycemia, insulinemia, and oxidative damage in healthy individuals[J]. The Journal of Nutrition,2006,136(12):2987−2992. doi: 10.1093/jn/136.12.2987

[11] LIN J T, LIU S C, HU C C, et al. Effects of roasting temperature and duration on fatty acid composition, phenolic composition, Maillard reaction degree and antioxidant attribute of almond ( Prunus dulcis) kernel[J]. Food Chemistry,2016,190:520−528. doi: 10.1016/j.foodchem.2015.06.004

[12] PAN F, WANG X, WEN B, et al. Development of walnut oil and almond oil blends for improvements in nutritional and oxidative stability[J]. Grasas Y Aceites,2020,71(4):e381. doi: 10.3989/gya.0920192

[13] AL-ATTAR A M. Therapeutic influences of almond oil on male rats exposed to a sublethal concentration of lead[J]. Saudi Journal of Biological Sciences,2020,27(2):581−587. doi: 10.1016/j.sjbs.2019.12.035

[14] KATO K, VO P H T, FURUYASHIKI T, et al. Co-ingestion of whole almonds and almond oil with carbohydrate suppresses postprandial glycaemia in mice in an insulin-dependent and insulin-independent manner[J]. Journal of Nutritional Science,2019,8:e25. doi: 10.1017/jns.2019.22

[15] BERRY S E E, TYDEMAN E A, LEWIS H B, et al. Manipulation of lipid bioaccessibility of almond seeds influences postprandial lipemia in healthy human subjects[J]. The American Journal of Clinical Nutrition,2008,88(4):922−929. doi: 10.1093/ajcn/88.4.922

[16] MORI A M, CONSIDINE R V, MATTES R D. Acute and second-meal effects of almond form in impaired glucose tolerant adults:A randomized crossover trial[J]. Nutrition & Metabolism,2011,8(1):1−8.

[17] NELSON R H. Hyperlipidemia as a risk factor for cardiovascular disease[J]. Primary Care,2013,40(1):195−211. doi: 10.1016/j.pop.2012.11.003

[18] ANWAR M, SHOUSHA W G, El-MEZAYEN H A, et al. Almond oil and extracted diosmin as prophylaxis for the endothelial dysfunction in diabetic rats[J]. Journal of Chemical and Pharmaceutical Research,2014,6(11):184−194.

[19] ANWAR M, SHOUSHA W G, El-MEZAYEN H A, et al. Antiatherogenic effect of almond oil in streptozotocin induced diabetic rats[J]. Journal of Applied Pharmaceutical Science,2013,3(10):59−65.

[20] ATEF A A. Therapeutic impacts of almond oil and olive oil on cholesterol dynamics and oxidative status in rats fed on atherogenic diet:Mechanism of action[J]. Egyptian Journal of Biochemistry and Molecular Biology,2014,32(1):1−18.

[21] KASEB F, RASHIDI M, AFKHAMI-ARDEKANI M, et al. Effect of olive, almond and walnut oil on cardiovascular risk factors in type 2 diabetic patients[J]. International Journal of Diabetes in Developing Countries,2013,33(2):115−119. doi: 10.1007/s13410-012-0108-9

[22] ZIBAEENEZHAD M J, OSTOVAN P, MOSAVAT S H, et al. Almond oil for patients with hyperlipidemia:A randomized open-label controlled clinical trial[J]. Complementary Therapies in Medicine,2019,42:33−36. doi: 10.1016/j.ctim.2018.10.013

[23] DAVIS P A, IWAHASHI C K. Whole almonds and almond fractions reduce aberrant crypt foci in a rat model of colon carcinogenesis[J]. Cancer Letters,2001,165(1):27−33. doi: 10.1016/S0304-3835(01)00425-6

[24] MERICLI F, BECER E, KABADAYI H, et al. Fatty acid composition and anticancer activity in colon carcinoma cell lines of Prunus dulcis seed oil[J]. Pharmaceutical Biology,2017,55(1):1239−1248. doi: 10.1080/13880209.2017.1296003

[25] ALI Z K, SAHIB H B. Antiangiogenic activity of sweet almond ( Prunus dulcis) oil alone and in combination with aspirin in both in vivo and in vitro assays[J]. Asian Pacific Journal of Cancer Prevention,2022,23(4):1405−1413. doi: 10.31557/APJCP.2022.23.4.1405

[26] AL- SAYARI A, GHAZWANI M, ALHAMHOOM Y, et al. The antidepressant-like effect of almond oil:An additive effect with lavender oil[J]. Biomedical Research,2018,29(18):3402−3407.

[27] SAYORWAN W, SIRIPORNPANICH V, PIRIYAPUNYAPORN T, et al. The effects of lavender oil inhalation on emotional states, autonomic nervous system, and brain electrical activity[J]. Journal of the Medical Association of Thailand,2012,95(4):598−606.

[28] SADEGHI A S H, SAADAT M, KHEIRKHAH M, et al. The effect of self-aromatherapy massage of the abdomen on the primary dysmenorrhoea[J]. Journal of Obstetrics and Gynaecology,2015,35(4):382−385. doi: 10.3109/01443615.2014.958449

[29] SEYYED-RASOOLI A, SALEHI F, MOHAMMADPOORASL A, et al. Comparing the effects of aromatherapy massage and inhalation aromatherapy on anxiety and pain in burn patients:A single-blind randomized clinical trial[J]. Burns,2016,42(8):1774−1780. doi: 10.1016/j.burns.2016.06.014

[30] 郎多勇, 孙志国, 李红兵, 等. 杏仁油对BABL/c小鼠抗炎镇痛作用的研究[J]. 时珍国医国药,2012,23(6):1386−1387. [LANG D Y, SUN Z G, LI H B, et al. Effect of anti-inflammation and analgesic of almond oil on BABL/c mice[J]. Lishizhen Medicine and Materia Medica Research,2012,23(6):1386−1387.] LANG D Y, SUN Z G, LI H B, et al . Effect of anti-inflammation and analgesic of almond oil on BABL/c mice[J]. Lishizhen Medicine and Materia Medica Research,2012 ,23 (6 ):1386 −1387 .[31] 田洪磊, 詹萍, 颜海燕, 等. 基于大鼠血清差异蛋白质组学小白杏杏仁油免疫调节作用研究[J]. 中国粮油学报,2017,32(2):62−66. [TIAN H L, ZHAN P, YAN H Y, et al. Immune regulatory activities of small white apricot almond oil by differentially expressed proteomics-based approach[J]. Journal of the Chinese Cereals and Oils Association,2017,32(2):62−66.] doi: 10.3969/j.issn.1003-0174.2017.02.011 TIAN H L, ZHAN P, YAN H Y, et al . Immune regulatory activities of small white apricot almond oil by differentially expressed proteomics-based approach[J]. Journal of the Chinese Cereals and Oils Association,2017 ,32 (2 ):62 −66 . doi: 10.3969/j.issn.1003-0174.2017.02.011[32] 杨国辉, 魏丽娟, 王德功, 等. 中药苦杏仁的药理研究进展[J]. 中兽医学杂志,2017(4):75−76. [YANG G H, WEI L J, WANG D G, et al. Pharmacological research progress of traditional Chinese medicine bitter almond[J]. Chinese Journal of Traditional Veterinary Science,2017(4):75−76.] YANG G H, WEI L J, WANG D G, et al . Pharmacological research progress of traditional Chinese medicine bitter almond[J]. Chinese Journal of Traditional Veterinary Science,2017 (4 ):75 −76 .[33] SULTANA Y, KOHLI K, ATHAR M, et al. Effect of pre-treatment of almond oil on ultraviolet B–induced cutaneous photoaging in mice[J]. Journal of Cosmetic Dermatology,2007,6(1):14−19. doi: 10.1111/j.1473-2165.2007.00293.x

[34] HUSSEIN R H, RAHEEM S A. Effects of almond seed oil extraction and some antioxidant agents on sperm quality in alloxan-induced diabetes mellitus rat[J]. International Journal of Current Microbiology & Applied Sciences,2015,4(7):93−104.

[35] SOHRABVAND F, MAHROOZADE S, BIOOS S, et al. Improvement in sperm parameters with traditional Iranian remedy:A case report[J]. Journal of Evidence-based Complementary & Alternative Medicine,2017,22(2):223−226.

[36] 杨海涛. 甜杏仁油的提取研究与应用[J]. 中国油脂,2008(4):20−21. [YANG H T. Extraction of apricot kernel oil and its application[J]. China Oils and Fats,2008(4):20−21.] doi: 10.3321/j.issn:1003-7969.2008.04.005 YANG H T . Extraction of apricot kernel oil and its application[J]. China Oils and Fats,2008 (4 ):20 −21 . doi: 10.3321/j.issn:1003-7969.2008.04.005[37] HOJJATI M, LIPAN L, CARBONELL-BARRACHINA Á A. Effect of roasting on physicochemical properties of wild almonds ( Amygdalus scoparia)[J]. Journal of the American Oil Chemists' Society,2016,93(9):1211−1220. doi: 10.1007/s11746-016-2868-8

[38] GOU P, DIAZ I, GUERRERO L, et al. Physico-chemical and sensory property changes in almonds of Desmayo largueta variety during toasting/Cambios en las propiedades físico-químicas y sensoriales de almendras de la variedad Desmayo largueta durante el tostado[J]. Food Science and Technology International,2000,6(1):1−7. doi: 10.1177/108201320000600101

[39] SAVOIRE R, LANOISELLÉ J L, VOROBIEV E. Mechanical continuous oil expression from oilseeds:A review[J]. Food and Bioprocess Technology,2013,6(1):1−16. doi: 10.1007/s11947-012-0947-x

[40] SENA-MORENO E, PARDO J E, PARDO- GIMÉNEZ A, et al. Differences in oils from nuts extracted by means of two pressure systems[J]. International Journal of Food Properties,2016,19(12):2750−2760. doi: 10.1080/10942912.2016.1144068

[41] MARTÍNEZ M L, BORDÓN M G, BODOIRA R M, et al. Walnut and almond oil screw-press extraction at industrial scale:Effects of process parameters on oil yield and quality[J]. Grasas Y Aceites,2018,68(4):e216. doi: 10.3989/gya.0554171

[42] 薛焕焕, 张海生, 赵鑫帅, 等. 不同提取方法对大扁杏仁油品质的影响[J]. 江苏农业学报,2018,34(2):439−446. [XUE H H, ZHANG H S, ZHAO X S, et al. Effects of different extraction methods on the quality of Prunus armeniaca Linn oil[J]. Jiangsu Journal of Agricultural Sciences,2018,34(2):439−446.] XUE H H, ZHANG H S, ZHAO X S, et al . Effects of different extraction methods on the quality of Prunus armeniaca Linn oil[J]. Jiangsu Journal of Agricultural Sciences,2018 ,34 (2 ):439 −446 .[43] 蔡达, 刘红芝, 刘丽, 等. 不同工艺制备杏仁油品质比较及相关性分析[J]. 中国粮油学报,2014,29(2):47−52. [CAI D, LIU H Z, LIU L, et al. Quality comparison of almond oil extracted with different processes and correlation analysis of quality indexes[J]. Journal of the Chinese Cereals and Oils Association,2014,29(2):47−52.] CAI D, LIU H Z, LIU L, et al . Quality comparison of almond oil extracted with different processes and correlation analysis of quality indexes[J]. Journal of the Chinese Cereals and Oils Association,2014 ,29 (2 ):47 −52 .[44] Al JUHAIMI F, ÖZCAN M M, GHAFOOR K, et al. Comparison of cold-pressing and soxhlet extraction systems for bioactive compounds, antioxidant properties, polyphenols, fatty acids and tocopherols in eight nut oils[J]. Journal of Food Science and Technology,2018,55(8):3163−3173. doi: 10.1007/s13197-018-3244-5

[45] ÖZCAN M M, LEMIASHEUSKI V. The effect of harvest times on mineral contents of almond and walnut kernels[J]. Erwerbs-Obstbau,2020,62(4):455−458. doi: 10.1007/s10341-020-00523-9

[46] MARTÍNEZ M L, PENCI M C, MARIN M A, et al. Screw press extraction of almond ( Prunus dulcis (Miller) DA Webb):Oil recovery and oxidative stability[J]. Journal of Food Engineering,2013,119(1):40−45. doi: 10.1016/j.jfoodeng.2013.05.010

[47] MIRZAEI H, REZAEI K. Amygdalin contents of oil and meal from wild almond:Effect of different heat pretreatment and extraction methods[J]. Journal of the American Oil Chemists' Society,2019,96(10):1163−1171. doi: 10.1002/aocs.12257

[48] OZCAN M M, ENDES Z, ER F. Physical and chemical properties of some seed and kernel oils[J]. Asian Journal of Chemistry,2010,22(8):6531−6536.

[49] MIRALIAKBARI H, SHAHIDI F. Lipid class compositions, tocopherols and sterols of tree nut oils extracted with different solvents[J]. Journal of Food Lipids,2008,15(1):81−96. doi: 10.1111/j.1745-4522.2007.00104.x

[50] MIRALIAKBARI H, SHAHIDI F. Oxidative stability of tree nut oils[J]. Journal of Agricultural and Food Chemistry,2008,56(12):4751−4759. doi: 10.1021/jf8000982

[51] 左青, 左晖. 油脂精炼工艺和设备的改进实践[J]. 中国油脂,2020,45(10):22−27. [ZUO Q, ZUO H. Improvement practice of oil refining process and equipment[J]. China Oils and Fats,2020,45(10):22−27.] ZUO Q, ZUO H . Improvement practice of oil refining process and equipment[J]. China Oils and Fats,2020 ,45 (10 ):22 −27 .[52] TU J, WU W, YANG J, et al. A method of producing edible oils with high quality by water[J]. Journal of Food Processing and Preservation,2017,41(6):e13280. doi: 10.1111/jfpp.13280

[53] CHODAR MOGHADAS H, REZAEI K. Laboratory-scale optimization of roasting conditions followed by aqueous extraction of oil from wild almond[J]. Journal of the American Oil Chemists' Society,2017,94(6):867−876. doi: 10.1007/s11746-017-2995-x

[54] FU S, WU W. Optimization of conditions for producing high-quality oil and de-oiled meal from almond seeds by water[J]. Journal of Food Processing and Preservation,2019,43(8):e14050.

[55] 沈玉平, 周旭, 张祖姣, 等. 水酶法提取油脂研究进展[J]. 中国油脂,2021,46(2):14−19. [SHEN Y P, ZHOU X, ZHANG Z J, et al. Progress on aqueous enzymatic extraction of oil[J]. China Oils and Fats,2021,46(2):14−19.] SHEN Y P, ZHOU X, ZHANG Z J, et al . Progress on aqueous enzymatic extraction of oil[J]. China Oils and Fats,2021 ,46 (2 ):14 −19 .[56] VERDASCO-MARTÍN C M, DÍAZ-LOZANO A, OTERO C. Advantageous enzyme selective extraction process of essential spirulina oil[J]. Catalysis Today,2020,346:121−131. doi: 10.1016/j.cattod.2019.02.066

[57] 王亚萍, 姚小华, 常君, 等. 薄壳山核桃油水酶法提取工艺优化及品质分析[J]. 中国油脂,2022,47(5):1−6. [WANG Y P, YAO X H, CHANG J, et al. Optimization of aqueous enzymatic extraction process of pecan oil and its quality analysis[J]. China Oils and Fats,2022,47(5):1−6.] WANG Y P, YAO X H, CHANG J, et al . Optimization of aqueous enzymatic extraction process of pecan oil and its quality analysis[J]. China Oils and Fats,2022 ,47 (5 ):1 −6 .[58] 郝文杰, 黎刚刚, 周亚琼, 等. Box-Behnken优化醇酶法提取野山杏仁油工艺及脂肪酸分析[J]. 安徽农业科学,2017,45(1):108−111. [HAO W J, LI G G, ZHOU Y Q, et al. Optimization of enzymatic extraction of almond oil by Box-Behnken method and analysis of fatty acids[J]. Journal of Anhui Agricultural Sciences,2017,45(1):108−111.] doi: 10.3969/j.issn.0517-6611.2017.01.035 HAO W J, LI G G, ZHOU Y Q, et al . Optimization of enzymatic extraction of almond oil by Box-Behnken method and analysis of fatty acids[J]. Journal of Anhui Agricultural Sciences,2017 ,45 (1 ):108 −111 . doi: 10.3969/j.issn.0517-6611.2017.01.035[59] SOUZA T S P, DIAS F F G, KOBLITZ M G B, et al. Aqueous and enzymatic extraction of oil and protein from almond cake:A comparative study[J]. Processes,2019,7(7):472. doi: 10.3390/pr7070472

[60] BALVARDI M, REZAEI K, MENDIOLA J A, et al. Optimization of the aqueous enzymatic extraction of oil from Iranian wild almond[J]. Journal of the American Oil Chemists' Society,2015,92(7):985−992. doi: 10.1007/s11746-015-2671-y

[61] SHARMA A, GUPTA M N. Ultrasonic pre-irradiation effect upon aqueous enzymatic oil extraction from almond and apricot seeds[J]. Ultrasonics Sonochemistry,2006,13(6):529−534. doi: 10.1016/j.ultsonch.2005.09.008

[62] RICOCHON G, MUNIGLIA L. Influence of enzymes on the oil extraction processes in aqueous media[J]. Oléagineux, Corps gras, Lipides,2010,17(6):356−359.

[63] CHEMAT F, ABERT VIAN M, RAVI H K, et al. Review of alternative solvents for green extraction of food and natural products:Panorama, principles, applications and prospects[J]. Molecules,2019,24(16):3007. doi: 10.3390/molecules24163007

[64] LEO L, RESCIO L, CIURLIA L, et al. Supercritical carbon dioxide extraction of oil and α-tocopherol from almond seeds[J]. Journal of the Science of Food and Agriculture,2005,85(13):2167−2174. doi: 10.1002/jsfa.2244

[65] 朱振宝, 刘旷, 易建华, 等. 3种不同方法提取大扁杏仁油脂性质比较[J]. 中国粮油学报,2015,30(2):57−60. [ZHU Z B, LIU K, YI J H, et al. Comparative research on the properties of three different extraction methods of almonds oil from Prunus armeniaca Linn[J]. Journal of the Chinese Cereals and Oils Association,2015,30(2):57−60.] ZHU Z B, LIU K, YI J H, et al . Comparative research on the properties of three different extraction methods of almonds oil from Prunus armeniaca Linn[J]. Journal of the Chinese Cereals and Oils Association,2015 ,30 (2 ):57 −60 .[66] DASSOFF E S, LI Y O. Mechanisms and effects of ultrasound-assisted supercritical CO2 extraction[J]. Trends in Food Science & Technology,2019,86:492−501.

[67] RONCERO J M, ÁLVAREZ-ORTÍ M, PARDO-GIMÉNEZ A, et al. Virgin almond oil:Extraction methods and composition[J]. Grasas Y Aceites,2016,67(3):e143. doi: 10.3989/gya.0993152

[68] ZHANG J, WEN C, ZHANG H, et al. Recent advances in the extraction of bioactive compounds with subcritical water:A review[J]. Trends in Food Science & Technology,2020,95:183−195.

[69] QI Z, XIAO J, YE L, et al. The effect of the subcritical fluid extraction on the quality of almond oils:Compared to conventional mechanical pressing method[J]. Food Science & Nutrition,2019,7(7):2231−2241.

[70] 郭婷婷, 万楚筠, 黄凤洪, 等. 亚临界流体萃取油脂及微量成分研究进展[J]. 中国油料作物学报,2020,42(1):154−160. [GUO T T, WAN C Y, HUANG F H, et al. Research progress of subcritical fluid extraction of oil and minor compounds[J]. Chinese Journal of Oil Crop Sciences,2020,42(1):154−160.] GUO T T, WAN C Y, HUANG F H, et al . Research progress of subcritical fluid extraction of oil and minor compounds[J]. Chinese Journal of Oil Crop Sciences,2020 ,42 (1 ):154 −160 .[71] ROOHINEJAD S, NIKMARAM N, BRAHIM M, et al. Potential of novel technologies for aqueous extraction of plant bioactives[M]. Amsterdam:Elsevier, 2017:399−419.

[72] SHARMA A, GUPTA M N. Oil extraction from almond, apricot and rice bran by three-phase partitioning after ultrasonication[J]. European Journal of Lipid Science and Technology,2004,106(3):183−186. doi: 10.1002/ejlt.200300897

[73] RIERA E, BLANCO A, GARCÍA J, et al. High-power ultrasonic system for the enhancement of mass transfer in supercritical CO2 extraction processes[J]. Physics Procedia,2010,3(1):141−146. doi: 10.1016/j.phpro.2010.01.020

[74] ZHANG Q A, ZHANG Z Q, YUE X F, et al. Response surface optimization of ultrasound-assisted oil extraction from autoclaved almond powder[J]. Food Chemistry,2009,116(2):513−518. doi: 10.1016/j.foodchem.2009.02.071

[75] ZHANG L, ZHAO M, CHEN J, et al. Reduction of cyanide content of bitter almond and its oil using different treatments[J]. International Journal of Food Science & Technology,2019,54(11):3083−3090.

[76] 王青, 邱斌, 马燕, 等. 甜杏仁油成分分析及不同壁材微胶囊化的特性[J]. 食品科学,2009,30(24):74−76. [WANG Q, QIU B, MA Y, et al. Lipid composition and microencapsulation of sweet almond oil[J]. Food Science,2009,30(24):74−76.] doi: 10.3321/j.issn:1002-6630.2009.24.013 WANG Q, QIU B, MA Y, et al . Lipid composition and microencapsulation of sweet almond oil[J]. Food Science,2009 ,30 (24 ):74 −76 . doi: 10.3321/j.issn:1002-6630.2009.24.013[77] LEI M, JIANG F C, CAI J, et al. Facile microencapsulation of olive oil in porous starch granules:Fabrication, characterization, and oxidative stability[J]. International Journal of Biological Macromolecules,2018,111:755−761. doi: 10.1016/j.ijbiomac.2018.01.051

[78] 万锋. 喷雾干燥技术在新型制剂设计与生产中的应用[J]. 药学进展,2019,43(3):174−180. [WAN F. Application of spray-drying technique in the design and manufacture of novel formulations[J]. Progress in Pharmaceutical Sciences,2019,43(3):174−180.] WAN F . Application of spray-drying technique in the design and manufacture of novel formulations[J]. Progress in Pharmaceutical Sciences,2019 ,43 (3 ):174 −180 .[79] HOYOS-LEYVA J D, BELLO-PEREZ L A, AGAMA-ACEVEDO J E, et al. Characterization of spray drying microencapsulation of almond oil into taro starch spherical aggregates[J]. LWT,2019,101:526−533. doi: 10.1016/j.lwt.2018.11.079

[80] BUENO F, CHOULJENKO A, REYES V, et al. Spray-dried almond milk powder containing microencapsulated flaxseed oil[J]. Drying Technology,2022,40(16):3496−3508. doi: 10.1080/07373937.2022.2061507

[81] ABDOLLAHI R, SHAKERIAN A, RAHIMI E, et al. Production of infant formula using mixture of walnut and almond oil[J]. International Journal of Pharmacy and Chemistry,2022,8(1):1−6. doi: 10.11648/j.ijpc.20220801.11

[82] 郭芳, 张璐, 李鑫杰. 苦杏仁油微胶囊制备及其性质研究[J]. 农产品加工,2022(2):21−25. [GUO F, ZHANG L, LI X J. Preparation and properties of bitter almond oil microcapsules[J]. Farm Products Processing,2022(2):21−25.] GUO F, ZHANG L, LI X J . Preparation and properties of bitter almond oil microcapsules[J]. Farm Products Processing,2022 (2 ):21 −25 .[83] 辛相余, 张海生, 李琴, 等. 大扁杏杏仁油微胶囊的制备及品质研究[J]. 中国油脂,2020,45(6):76−81. [XIN X Y, ZHANG H S, LI Q, et al. Preparation and quality determination of microcapsules of almond oil from Prunus armeniaca Linn[J]. China Oils and Fats,2020,45(6):76−81.] XIN X Y, ZHANG H S, LI Q, et al . Preparation and quality determination of microcapsules of almond oil from Prunus armeniaca Linn[J]. China Oils and Fats,2020 ,45 (6 ):76 −81 .[84] 刘梦培, 铁珊珊, 胡颖喆, 等. 杏仁油微胶囊制备中超高压微射流处理工艺的研究[J]. 粮食与油脂,2017,30(6):14−16. [LIU M P, TIE S S, HU Y Z, et al. Study on the technology of ultra high-pressure micro-fluidization in preparation of almond oil microcapsules[J]. Cereals & Oils,2017,30(6):14−16.] LIU M P, TIE S S, HU Y Z, et al . Study on the technology of ultra high-pressure micro-fluidization in preparation of almond oil microcapsules[J]. Cereals & Oils,2017 ,30 (6 ):14 −16 .[85] KAUSHIK P, DOWLING K, BARROW C J, et al. Microencapsulation of omega-3 fatty acids:A review of microencapsulation and characterization methods[J]. Journal of Functional Foods,2015,19:868−881. doi: 10.1016/j.jff.2014.06.029

[86] KOLANOWSKI W, ZIOLKOWSKI M, WEIßBRODT J, et al. Microencapsulation of fish oil by spray drying-impact on oxidative stability[J]. European Food Research and Technology,2006,222(3):336−342.

[87] DHAKAL S P, HE J. Microencapsulation of vitamins in food applications to prevent losses in processing and storage:A review[J]. Food Research International,2020,137:109326. doi: 10.1016/j.foodres.2020.109326

[88] TIMILSENA Y P, AKANBI T O, KHALID N, et al. Complex coacervation:Principles, mechanisms and applications in microencapsulation[J]. International Journal of Biological Macromolecules,2019,121:1276−1286. doi: 10.1016/j.ijbiomac.2018.10.144

[89] EGHBAL N, CHOUDHARY R. Complex coacervation:Encapsulation and controlled release of active agents in food systems[J]. LWT,2018,90:254−264. doi: 10.1016/j.lwt.2017.12.036

[90] PRATA A S, GROSSO C R F. Influence of the oil phase on the microencapsulation by complex coacervation[J]. Journal of the American Oil Chemists' Society,2015,92(7):1063−1072. doi: 10.1007/s11746-015-2670-z

[91] SCHMITT C, TURGEON S L. Protein/polysaccharide complexes and coacervates in food systems[J]. Advances in Colloid and Interface Science,2011,167(1-2):63−70. doi: 10.1016/j.cis.2010.10.001

[92] GOUIN S. Microencapsulation:Industrial appraisal of existing technologies and trends[J]. Trends in Food Science & Technology,2004,15(7-8):330−347.

[93] CASTRO N, DURRIEU V, RAYNAUD C, et al. Melt extrusion encapsulation of flavors:A review[J]. Polymer Reviews,2016,56(1):137−186. doi: 10.1080/15583724.2015.1091776

[94] REINECCIUS G. Use of proteins for the delivery of flavours and other bioactive compounds[J]. Food Hydrocolloids,2019,86:62−69. doi: 10.1016/j.foodhyd.2018.01.039

[95] GIBBS B F, KERMASHA S, ALLI I, et al. Encapsulation in the food industry:A review[J]. International Journal of Food Sciences and Nutrition,1999,50(3):213−224. doi: 10.1080/096374899101256

[96] LUCÍA C, MARCELA F, AINHOA L. Encapsulation of almond essential oil by co-extrusion/gelling using chitosan as wall material[J]. Journal of Encapsulation and Adsorption Sciences,2017,7(1):67. doi: 10.4236/jeas.2017.71004

[97] 王慧梅, 范艳敏, 王连艳. 基于微胶囊技术对油脂包埋的研究进展[J]. 现代食品科技,2018,34(10):271−280. [WANG H M, FAN M, WANG L Y. Research progress of microencapsulation technologies for lipid encapsulation[J]. Modern Food Science and Technology,2018,34(10):271−280.] WANG H M, FAN M, WANG L Y . Research progress of microencapsulation technologies for lipid encapsulation[J]. Modern Food Science and Technology,2018 ,34 (10 ):271 −280 .[98] MADENE A, JACQUOT M, SCHER J, et al. Flavour encapsulation and controlled release–A review[J]. International Journal of Food science & Technology,2006,41(1):1−21.

[99] 韩金承, 孟鑫, 吴慎威, 等. 苦杏仁油微胶囊制备工艺优化及氧化稳定性研究[J]. 保鲜与加工,2023,23(1):38−46. [HAN J C, MENG X, WU S W, et al. Study on preparation process optimization and oxidation stability of bitter almond oil microcapsules[J]. Storage and Process,2023,23(1):38−46.] doi: 10.3969/j.issn.1009-6221.2023.01.006 HAN J C, MENG X, WU S W, et al . Study on preparation process optimization and oxidation stability of bitter almond oil microcapsules[J]. Storage and Process,2023 ,23 (1 ):38 −46 . doi: 10.3969/j.issn.1009-6221.2023.01.006[100] 杨海燕, 于蒙, 刘姗姗, 等. 冷冻干燥法制备甜杏仁油微胶囊[J]. 食品科学,2012,33(18):36−40. [YANG H Y, YU M, LIU S S, et al. Preparation of sweet almond oil microcapsules by freeze drying technology[J]. Food Science,2012,33(18):36−40.] YANG H Y, YU M, LIU S S, et al . Preparation of sweet almond oil microcapsules by freeze drying technology[J]. Food Science,2012 ,33 (18 ):36 −40 . -

期刊类型引用(1)

1. 钟德进,张家铭,黄汉丽,何燕凤,李军集,李开祥. 植物精油提取方法与设备分类及演变发展. 热带农业科学. 2024(08): 52-64 .  百度学术

百度学术

其他类型引用(0)

下载:

下载:

下载:

下载: