Sterilization Process Optimization and Quality Changes of Soft-boiled Marinated Eggs during Storage

-

摘要: 为了开发高品质溏心卤蛋,本文利用水浴模拟巴氏杀菌条件,优化溏心卤蛋巴氏杀菌工艺,使其更有利于工业化生产销售。研究了单因素条件下质构、感官评分和菌落总数的变化。在单因素实验基础上采用响应面优化杀菌条件,并在最佳杀菌条件下测定了溏心卤蛋的贮藏品质。结果表明,杀菌温度65 ℃,杀菌时间20 min时,杀菌效果最佳,此时菌落总数为(0.37±0.025)×103 CFU/g。贮藏实验结果表明,随着贮藏时间延长,硫代巴比妥酸值和挥发性盐基氮含量整体呈增加趋势。pH、含水量、色泽和感官评分均逐渐下降。贮藏期为16 d时,菌落总数值达到(1.47±0.063)×104 CFU/g,已超出国家标准中微生物可接受水平限量值1×104 CFU/g,其贮藏期在16 d以内。综上,巴氏杀菌技术可用于溏心卤蛋的生产加工。Abstract: In order to develop high quality soft-boiled marinated eggs, water bath was used to simulate pasteurization conditions to optimize the pasteurization process of soft-boiled marinated eggs and made them more conducive to industrial production and sales. The changes of texture, sensory score and total number of colonies were studied under single factor conditions. Based on single factors, response surface was used to optimize sterilization conditions, and the storage quality of soft-boiled marinated eggs was determined under the best sterilization conditions. The results showed that, the best sterilization effect was achieved when the sterilization temperature and time were 65 ℃ and 20 minutes respectively, and the total number of colonies was (0.37±0.025)×103 CFU/g. The results of storage experiment showed that with the extension of storage time, the thiobarbituric acid values and total volatile basic nitrogen content showed an increasing trend. The pH, water content, color and sensory scores all decreased gradually. When the storage period was 16 days, the total number of colonies reached (1.47±0.063)×104 CFU/g, which exceeded the limit value of the acceptable level of microorganisms in the national standard of 1×104 CFU/g, and the storage period within 16 days. In summary, pasteurization technology can be used for the production and processing of soft-boiled marinated eggs.

-

溏心卤蛋是指经预煮、卤制、杀菌、真空包装而成的一种新型卤蛋制品,因独特的风味与口感深受消费者喜爱。其质地软嫩,蛋黄呈流心状态,入口绵密且营养丰富[1]。由于溏心卤蛋烹饪方式独特,其蛋白消化率高于日常食用的全熟蛋、煎蛋和鲜蛋[2]。然而,溏心卤蛋在贮藏中易发生一些复杂的物理化学变化,如脂肪氧化,产生氧化哈喇味[3];同时还易受到微生物侵染,导致食品失去可食用价值。

溏心卤蛋质地特殊,其蛋黄呈流心状态,杀菌时为最大限度维持蛋黄的质构特性,通常选择较温和的杀菌技术以延长货架期。如紫外杀菌技术、高压脉冲电场杀菌[4]等冷杀菌技术,此类杀菌技术即使在非加热状态下也能将食品中微生物灭活。但由于紫外线穿透力弱、高压脉冲电场技术使用成本较高[5−6],在一定程度上限制了其应用。目前,应用于溏心卤蛋的杀菌方式主要为巴氏杀菌,该杀菌技术成本低、可操作性高,且能有效杀灭食品中微生物。巴氏杀菌处理条件相对温和,通常是将食品加热到100 ℃以下,对大多数食品的营养和感官特性影响较小[7−8]。巴氏杀菌能最大限度地减少低酸食品中病原微生物对健康的危害[9],并通过杀灭微生物或灭活酶[10]来延长食品保质期。

目前,国内外对溏心卤蛋的研究主要包括研发蒸煮设备[11−12]、探究保鲜方法[13]、开发新型制备工艺[14]等。但关于杀菌技术和贮藏期对溏心卤蛋品质影响的相关研究较少。本研究以菌落总数为响应值,采用响应面法优化杀菌参数,确定最佳杀菌条件,最后测定贮藏期间溏心卤蛋品质变化,以期为溏心卤蛋应用巴氏杀菌技术提供理论参考。

1. 材料与方法

1.1 材料与仪器

鸡蛋 湖北正大有限公司;无水乙醇、三氯乙酸、乙二胺四乙酸二钠、硫代巴比妥酸、丙二醛乙缩醛、氧化镁、甲基红、亚甲基蓝、氯化钠、盐酸 均为分析纯,国药集团化学试剂有限公司;琼脂粉 生物制剂,武汉飞扬特尔惠生物科技有限公司。

NKY6160半微量凯氏定氮仪 四川蜀玻有限责任公司;Nabodrop 2000C紫外分光光度计 美国赛默飞世尔科技公司;SPX-25085-II生化培养箱 上海新苗医疗器材制造有限公司;TA.XTPlus质构仪 英国Stable Mirco System公司;PHS-3C pH计 北京西杰天平仪器有限公司;CS-600C手持色差仪 杭州彩谱科技有限公司;ZD7-GE130煮蛋器 九阳股份有限公司;ME55分析天平 梅特勒托利多科技有限公司;DHG-9246A电热恒温鼓风干燥箱 上海精宏实验设备有限公司;DL-1万用电炉 北京市永光明医疗仪器有限公司;HA-HH-S1恒温水浴锅 武汉科尔仪器设备有限公司;CF07X7-100B真空封口机 美的集团股份有限公司。

1.2 实验方法

1.2.1 溏心卤蛋的制备

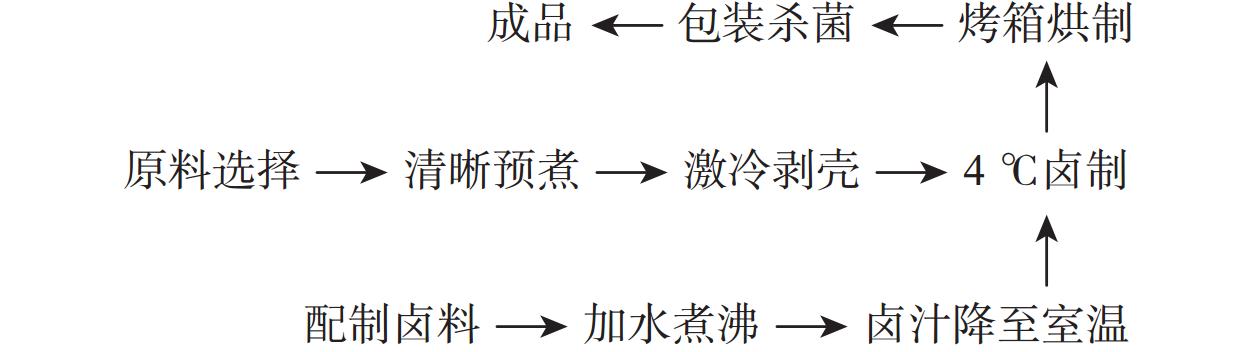

参考鲍志杰等[15]的方法并稍作修改。溏心卤蛋制备流程如下:

操作要点:通过感官鉴定挑选出新鲜、蛋壳完整、无裂纹、无霉斑的鸡蛋,鸡蛋均重55~60 g。将鸡蛋用清水洗净,放入煮蛋器蒸煮,同时严格控制蒸煮时间,预煮后的成品即为溏心蛋。预煮完毕,将鸡蛋快速放入凉水中冷却10 min,这样更有利于溏心蛋剥壳。低温卤制:溏心蛋采用4 ℃条件卤制,首先将卤汁煮沸,待卤汁度降至室温时把溏心蛋放入卤汁中,盛放卤汁的容器覆盖保鲜膜并置于4 ℃冰箱中冷卤,保证卤汁完全浸没溏心蛋,卤制36 h。卤制结束后,捞出溏心蛋,把表面水分沥干,放入烤箱烘制15 min,取出,待温度降至室温,进行真空包装。

1.2.2 单因素实验设计

参考李瑞[4]的方法并稍作修改。杀菌时间固定为15 min,水浴温度设置为56、59、62、65、68 ℃,探究不同杀菌温度对溏心卤蛋感官品质、质构特性与菌落总数的影响;杀菌温度固定为62 ℃,杀菌时间设置为5、10、15、20、25 min,探究不同杀菌时间对溏心卤蛋感官品质、质构特性与菌落总数的影响。

1.2.3 响应面试验设计

在单因素实验基础上,采用Design-Expert软件中的Central Composite Design进行2因素3水平试验,实验因素水平设计如表1所示。

表 1 响应曲面试验设计因素和水平设计Table 1. Response surface test design factors and horizontal design因素 水平 −1 0 1 杀菌温度A(℃) 62 65 68 杀菌时间B(min) 15 20 25 1.2.4 溏心卤蛋贮藏期间品质变化探究

以最优杀菌工艺条件为基础,对杀菌后的溏心卤蛋开展贮藏试验,在4 ℃冰箱贮藏,每隔4 d取一次样,测定样品品质的变化。

1.2.5 指标测定

1.2.5.1 质构测定

参考Srisai等[16]的方法并稍作改进。测定参数为:探头测试的前、中、后速度分别为5.0、1.0、5.0 mm/s,下压形变力为60%,触发力为0.5 g。探头类型为D25 mm的柱形探头,将蛋白切成为1.0 cm×1.0 cm×0.5 cm大小的方块,平行测定6次。

1.2.5.2 感官评分

本次感官评价由10名参加过感官评定培训的食品专业研究生组成评定小组,男女比例1:1。对产品的滋味、色泽、质地、风味进行评分。具体感官评价标准如表2所示。

表 2 感官评分标准Table 2. Sensory scoring criteria项目 评价标准 分值 滋味(30分) 有卤蛋特有滋味,味感醇厚 30~21 滋味协调,味感较持久均匀 20~11 滋味不协调,卤味香气淡薄 10~1 色泽(20分) 蛋白呈金黄色,有光泽,蛋黄可流动 20~16 蛋白呈黄褐色,亮度偏低,蛋黄可流动 15~11 蛋白颜色发暗,亮度降低,蛋黄可流动 10~1 质地(30分) 蛋白硬度适中,切面平整,蛋黄呈流心状态 30~21 蛋白硬度稍大,切面平整,蛋黄油脂析出 20~11 蛋白松软,切面粗糙,蛋黄油脂析出较严重 10~0 风味(20分) 卤香味浓郁,协调、丰满、无异味 20~16 酱卤香味基本协调、丰满、无明显异味 15~11 卤香味不协调,有异味,刺激性味道 10~1 1.2.5.3 菌落总数测定

菌落总数的测定参照GB 4789.2-2022《食品微生物学检验 菌落总数测定》[17]。

1.2.5.4 理化指标的测定

硫代巴比妥酸值测定参照GB/T 35252-2017的丙二醛法[18];挥发性盐基氮含量测定参照GB 5009.228-2016中的紫外分光光度计法[19];pH测定参照GB 5009.237-2016食品pH的测定[20];水分含量测定参照GB 5009.3-2016中的直接干燥法[21]。

1.2.5.5 色度的测定

用便携式色差仪测定,取不同的点测定六次,记录L*、a*、b*值,其中L*表示亮度值,a*表示红/绿值,b*表示黄/蓝值[1]。

1.3 数据处理

每组实验重复三次,使用SPSS 17.0对试验数据进行方差分析,Duncun多重比较分析,P<0.05为差异显著,结果表示为平均值±标准差;使用Origin 8.0作图;使用Design-Expert进行响应面数据统计分析。

2. 结果与分析

2.1 单因素实验结果

2.1.1 杀菌温度对溏心卤蛋质构特性的影响

巴氏杀菌处理对于溏心卤蛋来说属于二次加热,这可能会导致蛋白质受热变性引起凝胶性改变[22]。由图1可知,在不同杀菌温度下,溏心卤蛋硬度整体呈增大趋势;弹性基本保持不变;胶粘性和咀嚼性先增加后减小。其中当温度加热至56~59 ℃时,硬度、胶粘性和咀嚼性差异不显著(P>0.05),温度升高至62 ℃时,硬度、胶粘性和咀嚼性显著增加(P<0.05),持续增加杀菌温度,硬度和胶粘性变化不显著,但弹性和咀嚼性显著下降(P<0.05)。这可能是由于暴露在蛋白质表面的巯基数会因杀菌温度升高而增加,分子间和分子内相互作用增强,使得蛋白质凝胶硬度增大[23−24],从而引起了胶粘性和咀嚼性变化。研究表明在巴氏杀菌温度(60 ℃)下灭菌1~5 min,蛋白质溶解度会因蛋清蛋白重新产生热聚集而降低,这在一定程度上能够引起热凝胶特性改变[25]。另外,在本研究中杀菌温度升高对蛋白弹性变化影响不显著,但当温度加热至68 ℃时弹性数值显著下降(P<0.05),这是由于此时溏心卤蛋硬度最大,从而引起弹性减小。

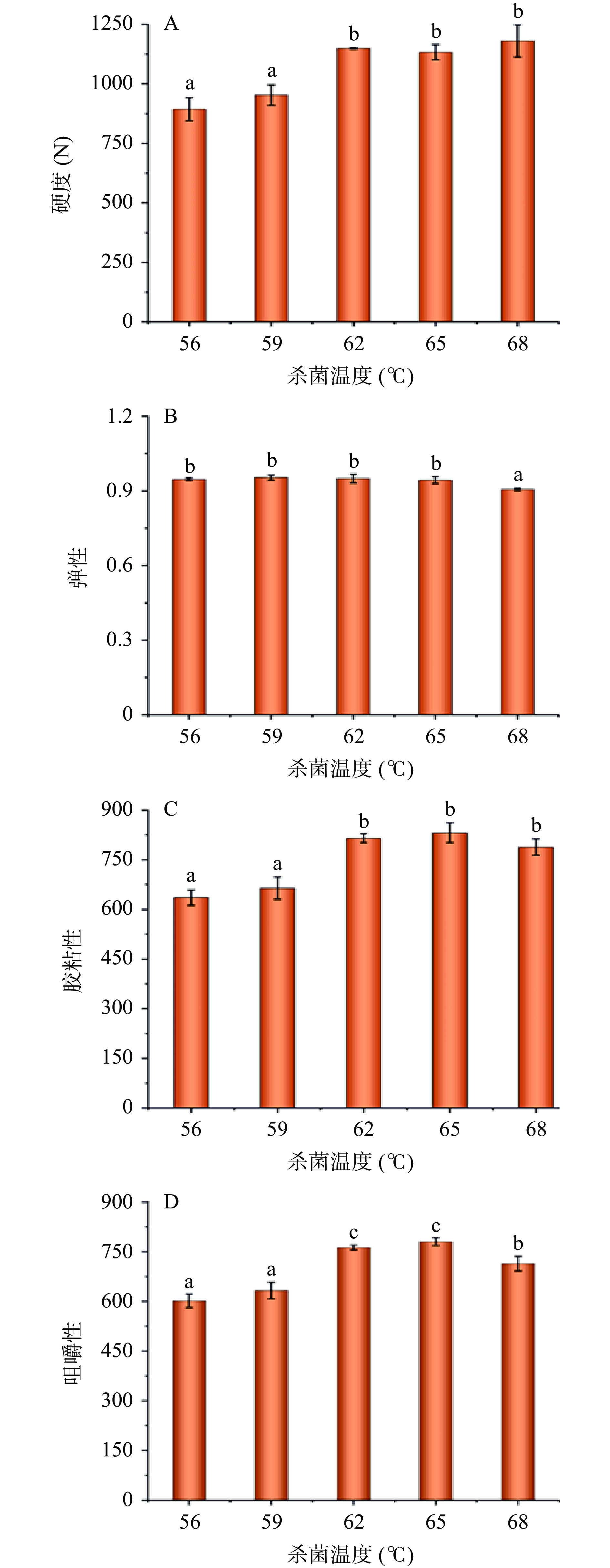

2.1.2 杀菌温度对溏心卤蛋感官评分和菌落总数的影响

从图2A中可以看出,56~59 ℃时,随着杀菌温度的不断升高,溏心卤蛋感官评分变化不显著,其原因可能是巴氏杀菌温度条件比较温和使得感官评分整体差异较小。当杀菌温度加热至62 ℃时,溏心卤蛋感官评分高达90.33分,这可能是由于蛋白之间的凝胶作用与相互作用比较弱,溏心卤蛋凝胶网络损伤小,使得水分损失率降低,有效保持了溏心卤蛋的嫩度[26]。随着杀菌温度持续增加,感官评分逐渐下降,但差异不显著(P>0.05)。同时,结合图2B中菌落总数变化结果发现,杀菌温度在56~62 ℃时,组间菌落总数差异显著(P<0.05),随后增加杀菌温度,菌落总数降幅减小。当杀菌温度为65和68 ℃时,溏心卤蛋菌落总数组间差异不显著(P>0.05),说明此时杀菌效果已经处于稳定状态。因此选择65 ℃作为中心点进行优化试验。

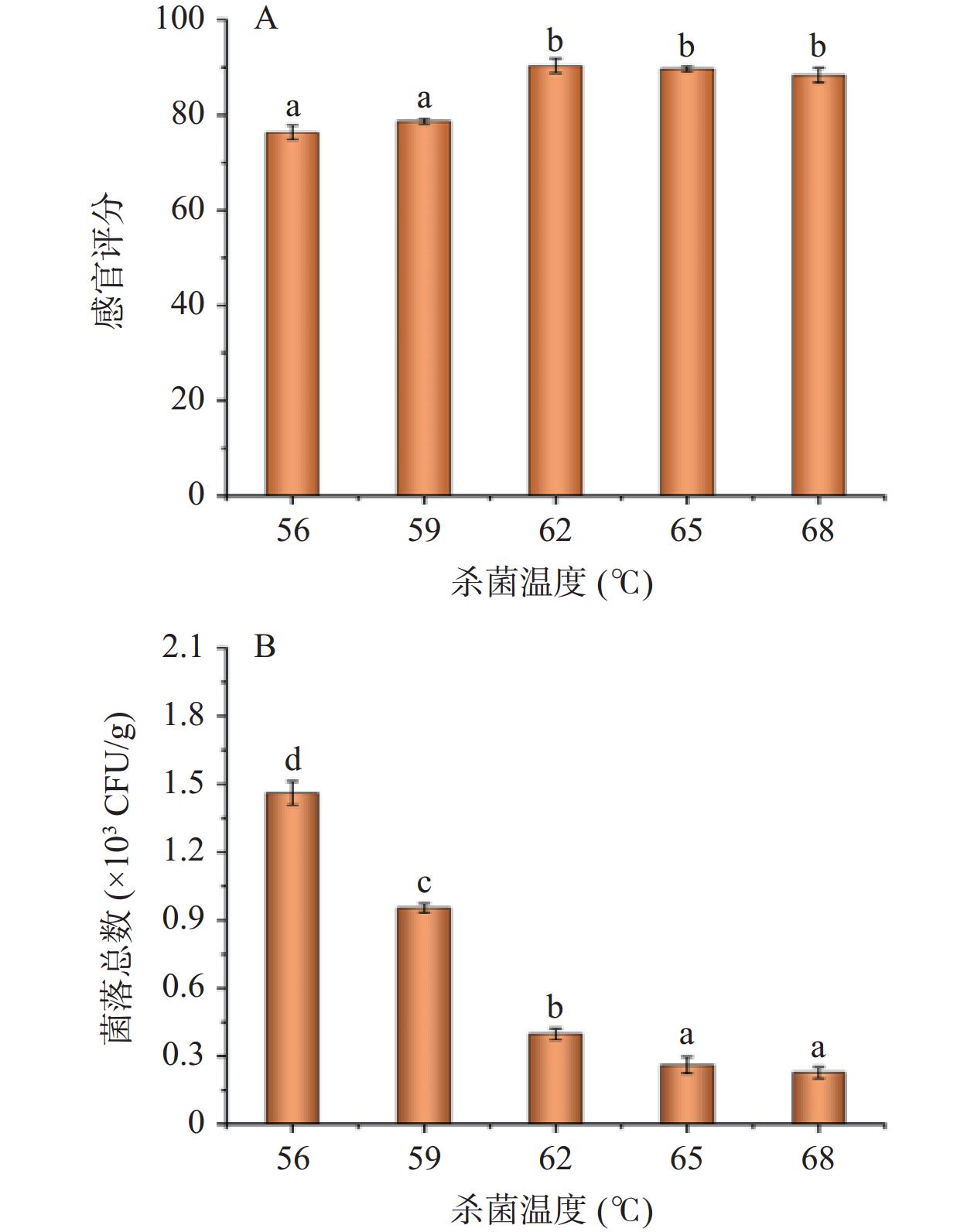

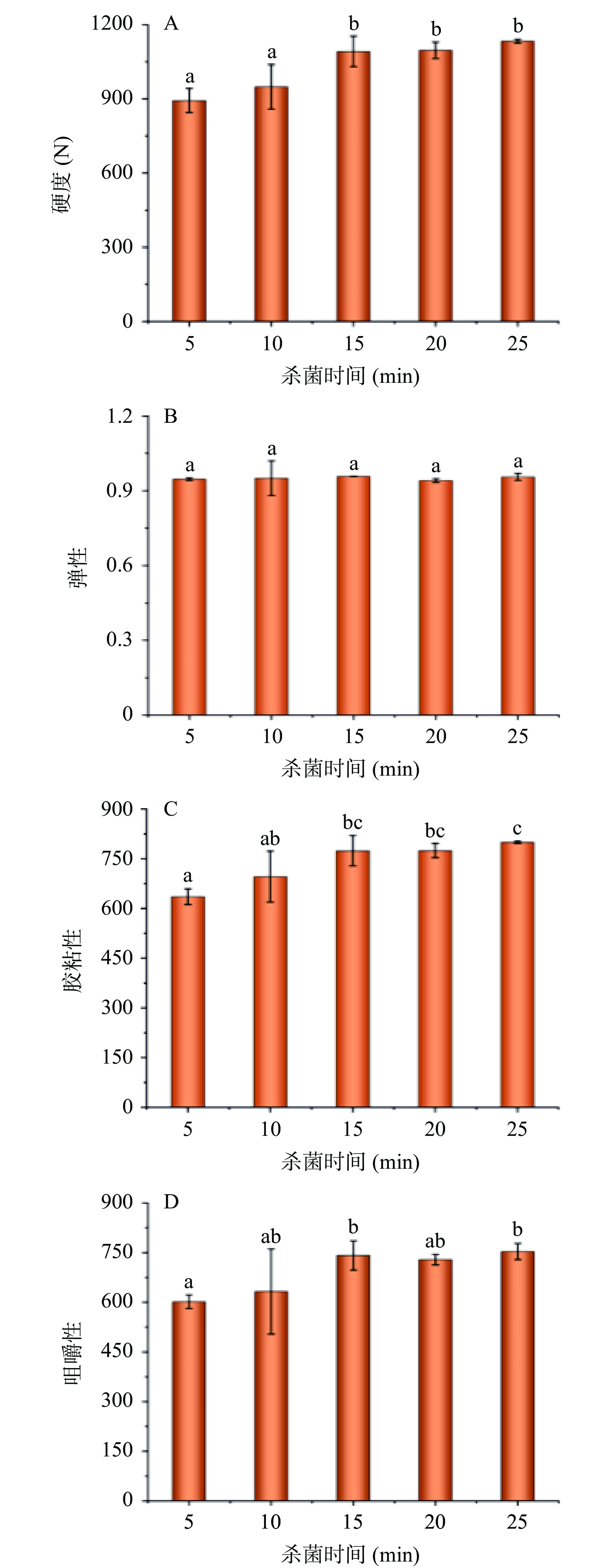

2.1.3 杀菌时间对溏心卤蛋质构的影响

杀菌时间也是影响溏心卤蛋质构特性的重要因素。由图3可知,溏心卤蛋硬度和胶粘性随着杀菌时间延长整体呈增大趋势;杀菌时间为5~15 min时咀嚼性数值持续增加,继续延长杀菌时间,咀嚼性则先减小后增大;整个杀菌过程中,弹性变化不显著。其中硬度、胶粘性和咀嚼性在杀菌时间增加至15 min时显著增大(P<0.05)。这是由于杀菌时间的延长导致样品水分析出,样品内部含水量降低,从而增加了溏心卤蛋的硬度、胶粘性和咀嚼性。同等处理条件下,巴氏杀菌时间持续增加对溏心卤蛋弹性影响不显著(P>0.05),刘鑫[27]对蛋清凝胶特性的研究中也得到了类似结论。

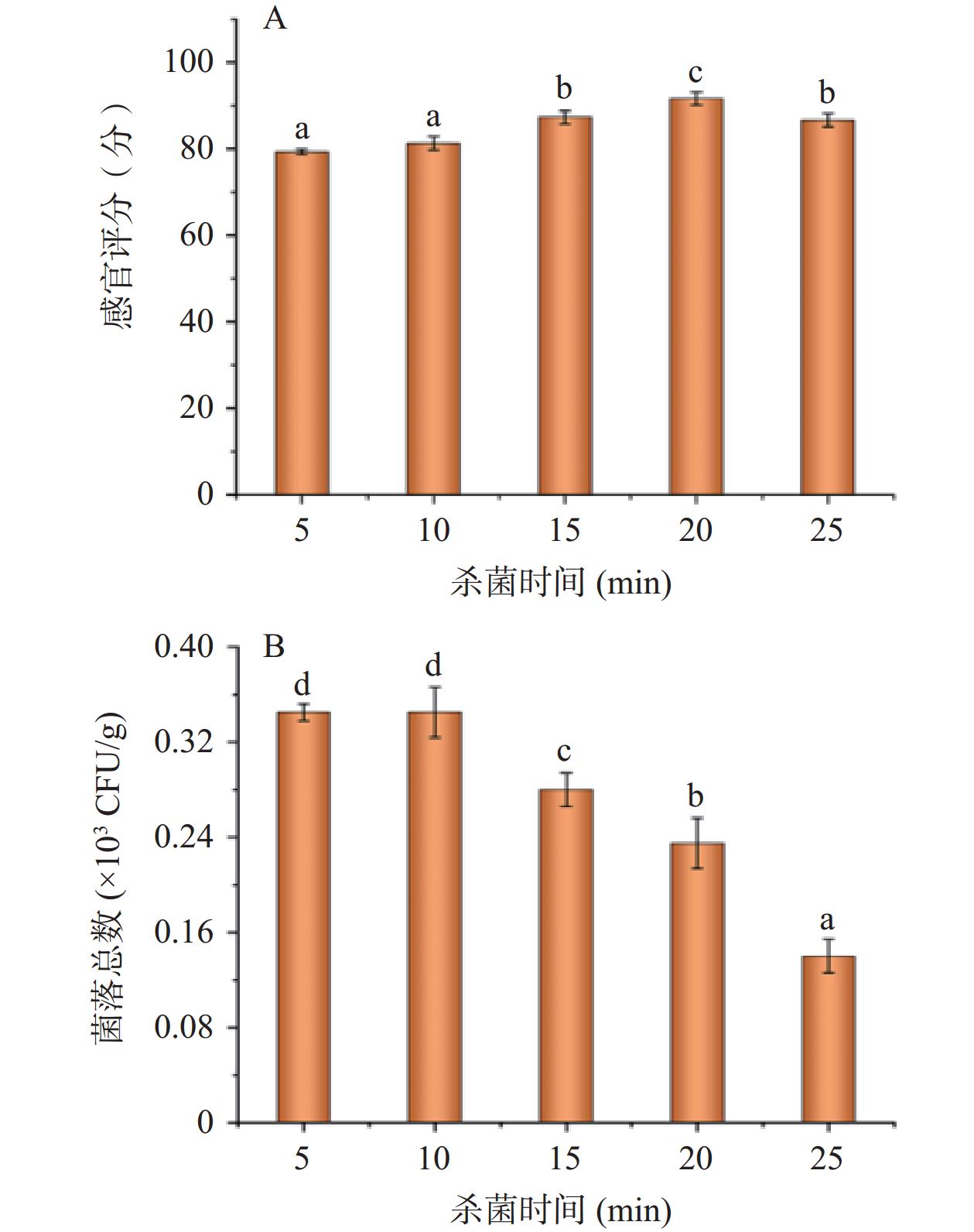

2.1.4 杀菌时间对溏心卤蛋感官评分和菌落总数的影响

从图4A中可以看出,杀菌时间延长,溏心卤蛋感官评分先增加后减小。杀菌时间为20 min时,感官评分达到最高值90分。可能是由于此杀菌条件比较温和,对于溏心卤蛋来说相当于低温卤煮,这更有利于激发溏心卤蛋的卤香味和谷氨酸钠的释放,有效保留食品原汁原味[28−29],但长时间加热杀菌也会对产品品质产生不利影响,如蒸煮异味。同时结合图4B中菌落总数变化结果来看,加热时间为5~10 min时,组间差异并不明显(P>0.05)。继续延长杀菌时间,菌落总数显著下降(P<0.05)。由于杀菌时间大于20 min时,溏心卤蛋感官评分显著下降(P<0.05);且杀菌时间为20 min和25 min时,二者菌落总数数值相差仅为0.09×103 CFU/g;因此综合感官评分与菌落总数的变化结果,以杀菌时间20 min为中心点开展后续的优化实验。

2.2 响应面试验

在单因素实验基础上,以杀菌温度和杀菌时间为自变量,菌落总数为响应值,设计2因素3水平响应面优化试验。响应面优化结果与分析如表3所示。

表 3 CCD试验设计及结果Table 3. Design and results of CCD test实验号 A杀菌温度 B杀菌时间 菌落总数

(×103 CFU/g)1 0.000 −1.414 0.46 2 −1.000 −1.000 0.53 3 0.000 0.000 0.37 4 −1.414 0.000 0.56 5 1.414 0.000 0.34 6 1.000 −1.000 0.37 7 0.000 0.000 0.36 8 0.000 1.414 0.4 9 1.000 1.000 0.36 10 0.000 0.000 0.35 11 0.000 0.000 0.37 12 −1.000 1.000 0.51 13 0.000 0.000 0.36 通过对上述试验结果进行多元回归拟合,得到菌落总数的编码回归方程:菌落总数=0.362−0.0776A−0.0144B+0.0025AB+0.0446A2+0.0346B2。

从表4中菌落总数的方差分析结果可知,回归拟合方程P=0.0001<0.01,表明回归项极显著,且失拟项不显著(P=0.2784>0.05),模型校正系数R2adj=0.9837。上述结果表明,该模型实验误差小,也说明了该试验结果建立的二次回归方程能够对响应值进行有效预测。

表 4 菌落总数二次回归与方差分析结果Table 4. Results of quadratic regression and variance analysis of total colonies方差来源 平方和 自由度 均方 F值 P值 显著性 模型 0.0696 5 0.0139 145.75 0.0001 ** A-杀菌温度 0.0482 1 0.0482 504.77 0.0001 ** B-杀菌时间 0.0016 1 0.0016 17.26 0.0043 * AB 0.0000 1 0.0000 0.2617 0.6247 A² 0.0139 1 0.0139 145.00 0.0001 ** B² 0.0083 1 0.0083 87.30 0.0001 ** 残差 0.0007 7 0.0001 失拟项 0.0004 3 0.0001 1.85 0.2784 不显著 净误差 0.0003 4 0.0001 总离差 0.0703 12 R2=0.9905 R2adj=0.9837 注:0.01<P<0.05,差异显著(*);P<0.01,差异极显著(**)。 另外,方差分析结果还表明一次项A对响应值的影响极显著(P=0.0001<0.01)、B显著(P=0.0043<0.05),二次项A2、B2极显著(P2A=0.0001<0.01、P2B=0.0001<0.01)。交互效应AB不显著(P=0.6247>0.05),故由F值可以判断单因素对菌落总数影响大小的主次顺序为:A>B。

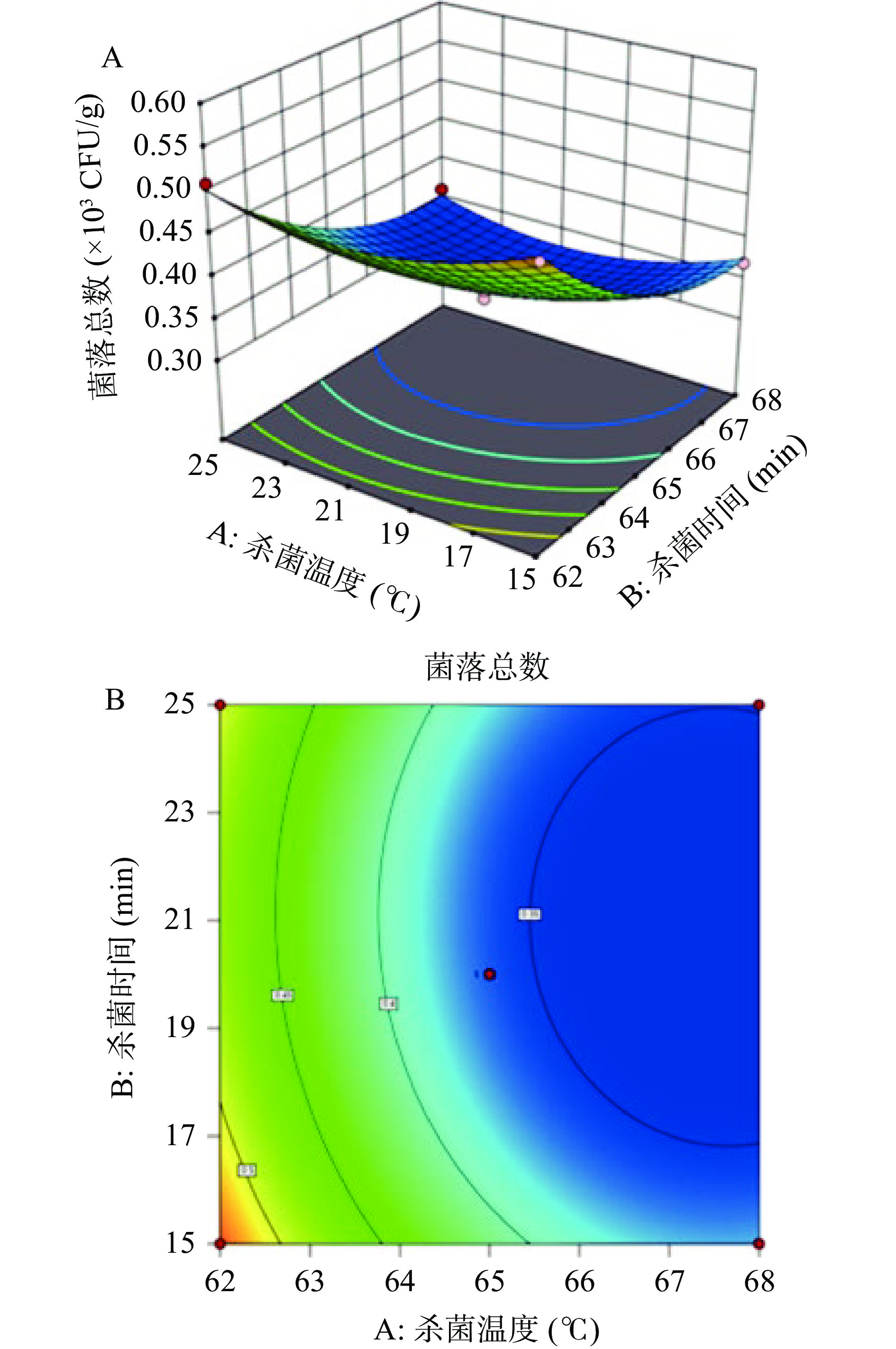

2.2.1 响应面分析

根据回归方程构建回归方程的响应面立体图与等高线图,分析两因素之间的交互作用。从响应面弯曲程度可以判断出两因素之间交互作用对响应值影响是否明显,曲面弯曲程度越大,说明因素间交互作用对响应值影响越显著;反之,因素之间交互作用对响应值影响不显著。

从图5A可以看出,溏心卤蛋菌落总数随着处理温度的增加呈下降趋势;随着处理时间的延长,菌落总数数值也逐渐降低。随着处理温度或时间的增加,响应面陡峭程度增加,表明菌落总数死亡率易受处理温度和处理时间影响。综合分析,当处理温度和处理时间逐渐接近中间值附近时,杀菌效果最好。图5B是杀菌温度和杀菌时间对菌落总数值影响的等高线图,两因素间等高线图接近圆形,说明二者交互作用不显著(P=0.6247>0.05)。

2.2.2 最佳杀菌条件的确定及验证实验

综合上述分析结果可知,响应面最佳杀菌温度、杀菌时间分别为66.02 ℃、21.08 min,此时菌落总数预测值为0.34×103 CFU/g。

根据实际情况,为便于调整工艺参数及简化实验条件,选择杀菌温度65 ℃,杀菌时间20 min做3次重复实验,此时溏心卤蛋杀菌效果好,菌落总数值为(0.37±0.025)×103 CFU/g,与预测值比较接近,符合GB 2749-2015《食品国家安全标准 蛋与蛋制品》中再制蛋菌落总数的可接受水平限量值(1×104 CFU/g)。

2.3 贮藏期间溏心卤蛋品质的变化

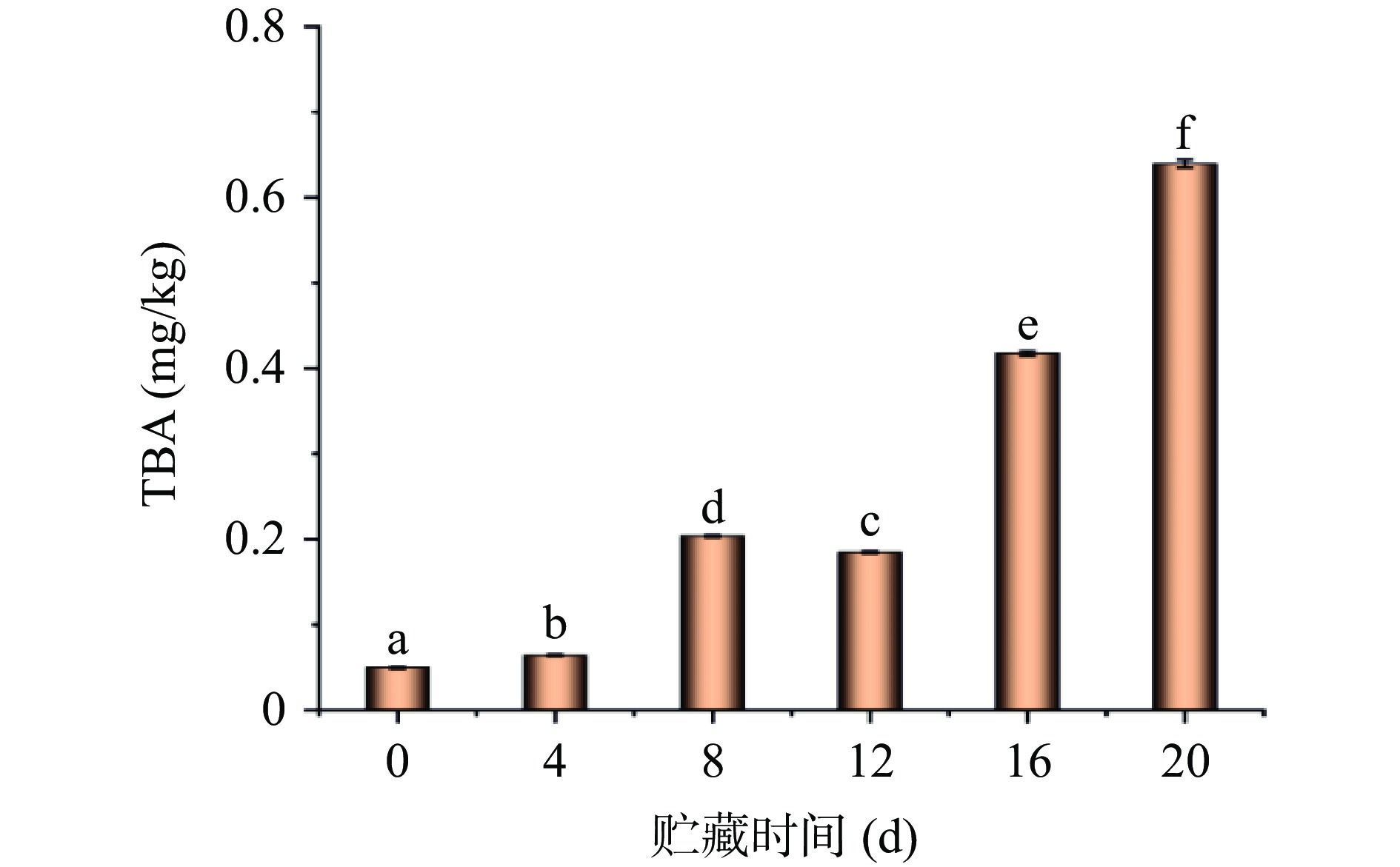

2.3.1 贮藏期间溏心卤蛋TBA的变化

从图6中可以看出,贮藏时间为0~4 d时,溏心卤蛋TBA值逐渐增大。在贮藏时间为0 d时,检测到TBA值为0.05 mg/kg,这是由于杀菌产生的二次加热导致脂质发生了微弱氧化作用。贮藏至第8 d时,溏心卤蛋TBA值显著增加(P<0.05),由初始的0.05 mg/kg增加至0.20 mg/kg;随后贮藏12 d时,TBA值逐渐下降。贮藏后期(16~20 d),TBA值增幅加快,最高值达0.64 mg/kg。这主要是由于脂肪氧化产物不断生成,因为蛋黄中含有不饱和脂肪酸,加工方式以及延长贮藏时间都会伴随脂质氧化,TBA值越高则表明脂肪氧化程度越大。贮藏至20 d时,溏心卤蛋TBA值超出限量值(0.5 mg/kg),表明此贮藏时间下以及后期贮藏中产品可能存在变质问题。还有研究表明,动物性食品的硫代巴比妥酸值≥0.5 mg/kg时,就能感觉到氧化作用产生的异味[30−31]。

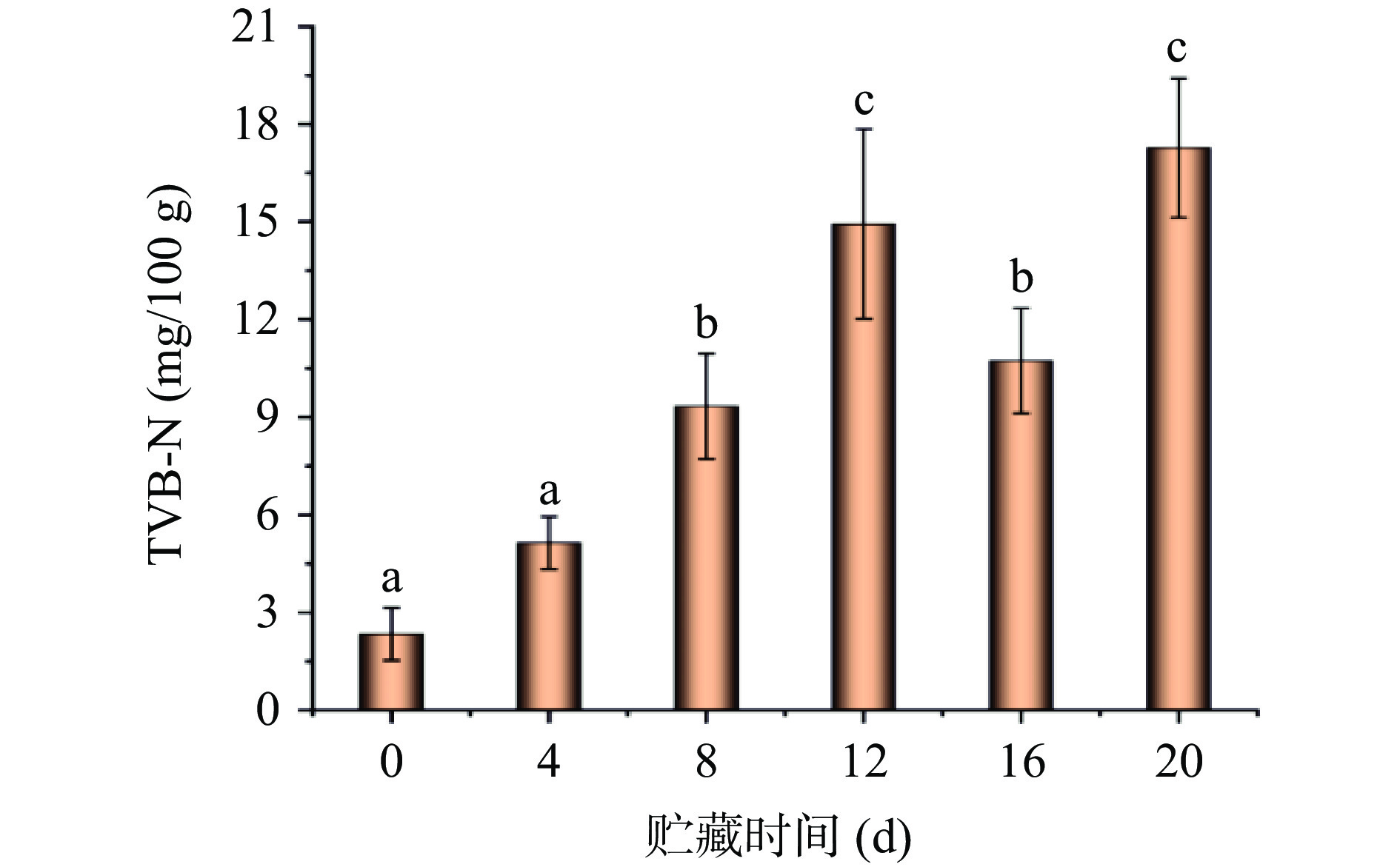

2.3.2 贮藏期间溏心卤蛋TVB-N的变化

挥发性盐基氮(TVB-N)通常指氨以及胺类等碱性物质,主要是由细菌和酶在动物性食品中分解蛋白质所产生,贮藏期间挥发性盐基氮含量越多,表明食品的腐败程度越大。由图7可知,贮藏周期为0~4 d时,溏心卤蛋TVB-N值无显著变化(P>0.05),随着贮藏时间的延长,溏心卤蛋TVB-N值在贮藏8~12 d时显著增加(P<0.05),但该数值远低于国家标准20 mg/100 g,说明此时微生物代谢活动较弱。贮藏期为16 d时,TVB-N值表现为下降趋势,这是由于低温贮藏对微生物生长繁殖仍有较好的抑制效果。随着贮藏周期增加至20 d时,溏心卤蛋TVB-N值大幅增加,达到了17.27 mg/100 g,这可能是因为食品中存在的嗜冷假单胞菌对高蛋白食物水解活性较大,其菌体产生的蛋白酶能够破坏蛋白质交联结构,从而导致食品中产生更多的胺类物质[32]。另外,有研究认为动物性食品的TVB-N值限量为20 mg/100 g,超过这个限量值即认为食品品质已经腐败劣变,不可再继续食用[33]。

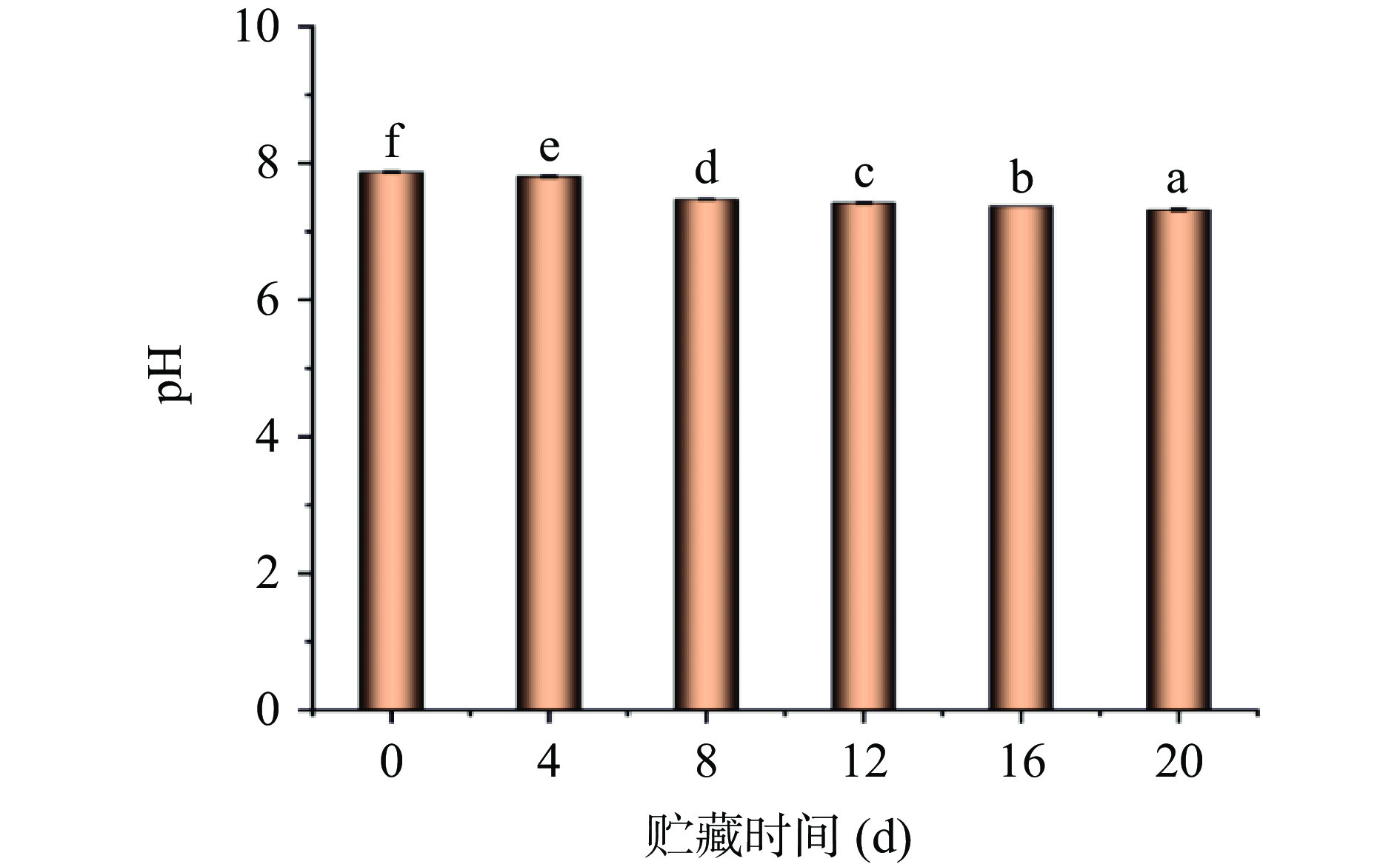

2.3.3 贮藏期间溏心卤蛋pH的变化

食品中pH是指该食品中所含有的氢离子浓度,常用来反映食品的酸碱性,因此可以作为评价食品品质的重要指标[34]。由图8可知,随着贮藏时间的延长,溏心卤蛋pH呈下降趋势(P<0.05),这与Gurunathan等[35]的研究结果一致。贮藏期间食品pH的变化主要与一些理化变化及微生物活动有关,如贮藏过程中微生物生长分解蛋白质生成了胺类化合物[36]。随着贮藏周期的增加,微生物活动增强,进而继续分解蛋白质。在此代谢过程中会产生有机酸化合物,如醋酸、氨基酸以及乳酸等其他有机酸类化合物,使得溏心卤蛋pH降低,该研究结果与李瑞[4]研究一致。

2.3.4 贮藏期间溏心卤蛋含水量的变化

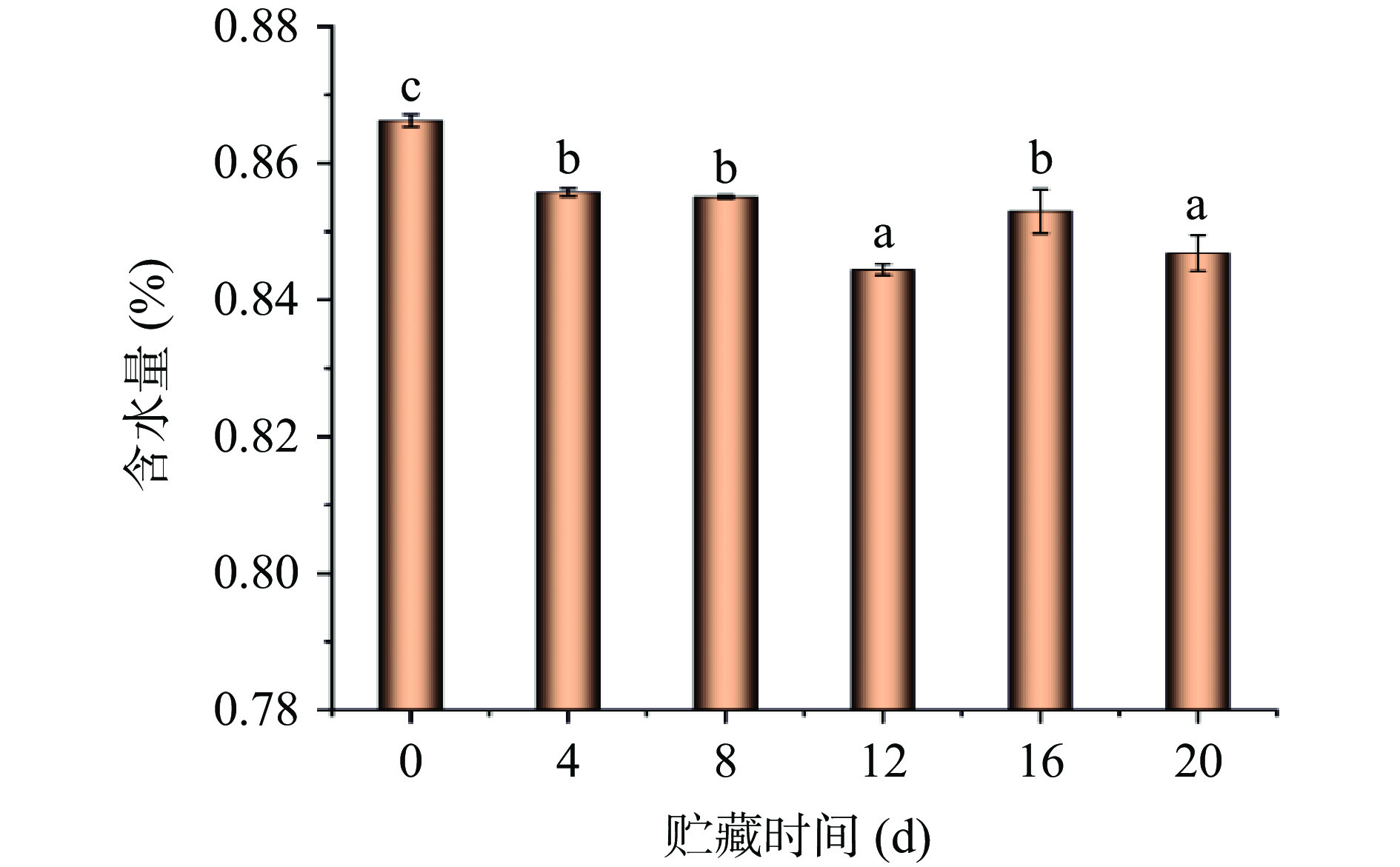

食品在贮藏过程中经常会伴有水分渗出现象,该现象主要是由于食品中发生了脱水收缩作用,使得食品水分含量下降,该现象还可能会影响食品感官质量(如质构),对于食品贮藏有不利影响[37]。

从图9可以看出,随着贮藏时间的延长,溏心卤蛋水分含量整体呈下降趋势。其中,初始贮藏(0 d)时,溏心卤蛋水分含量为86.62%;贮藏至第4 d时水分含量显著下降(P<0.05);当贮藏至第8 d时,溏心卤蛋含水量与贮藏4 d时含水量相比变化不明显。而后贮藏至第12 d时,溏心卤蛋含水量显著降低至84.4%(P<0.05),这可能是由于微生物作用使得蛋白凝胶网络结构遭到破坏,导致凝胶网络结构保持水分的能力变差[38]。王为浩[39]的研究结果也表明禽蛋贮藏期间其蛋清蛋白中水分含量会下降。贮藏至16 d时,溏心卤蛋含水量突然显著上升(P<0.05),分析原因可能是,蛋清蛋白中水分损失较大,使得蛋黄中的水分向蛋白内迁移,从而引起了蛋清蛋白中水分含量增加[40]。贮藏至20 d时,溏心卤蛋含水量又出现下降趋势,这是因为凝胶劣变程度增加,持水性降低,水分更易散失。

2.3.5 贮藏期间溏心卤蛋色泽及感官评分的变化

食品色泽的好坏对于消费者选购产品有极大参考性,它在一定程度上决定了该产品是否会被消费者选择。因此,在食品工业中稳定产品色泽也备受重视。从表5可以看出,随着贮藏天数增加,溏心卤蛋的亮度值L*显著降低(P<0.05);红度值a*整体呈下降趋势;黄度值b*均呈减小趋势。这是因为鸡蛋蛋白中含有一定量的还原糖,易发生美拉德反应[41]。该反应过程会产生棕色或黑色的类黑精色素,使得溏心卤蛋表面颜色变深,进而导致色度值减小。通过感官评分值变化可以看出,溏心卤蛋整体感官评分随着贮藏周期的延长显著下降(P<0.05),结合上述指标分析发现,溏心卤蛋理化指标整体呈现出劣势变化,因此其感官评分下降是必然趋势。

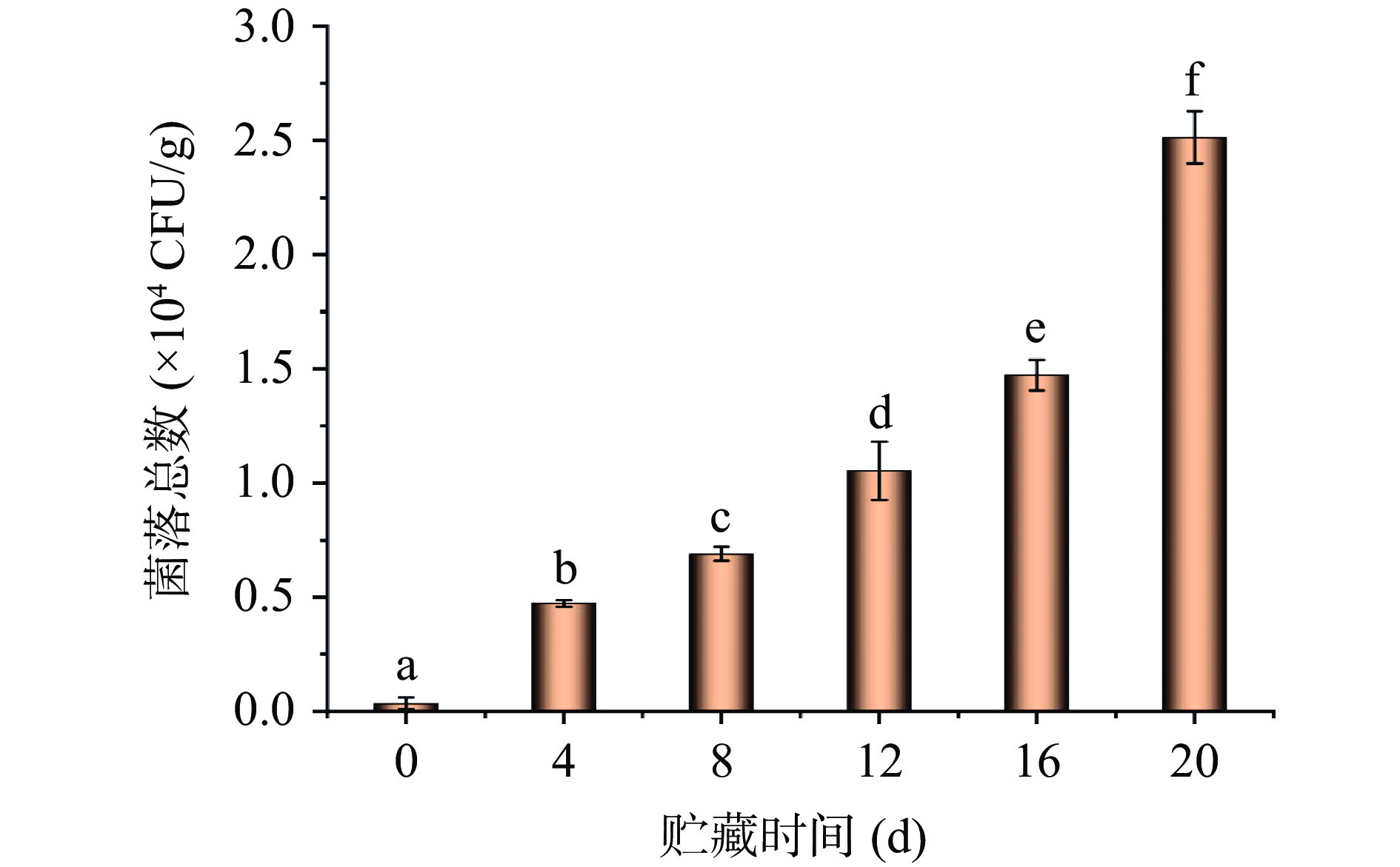

表 5 贮藏期间溏心卤蛋色泽及感官评分的变化Table 5. Changes in color and sensory score of soft-boiled marinated eggs during storage贮藏时间(d) L* a* b* 感官评分(分) 0 56.28±0.10e 12.27±0.09e 45.23±0.13f 90.66±1.53e 4 55.61±0.07d 12.14±0.06de 40.52±0.03e 87.67±1.15e 8 55.36±0.29d 11.36±0.32c 39.20±0.35d 80.33±1.52d 12 50.39±0.42c 11.72±0.25cd 34.34±0.40c 78.00±2.00c 16 48.62±0.24b 10.53±0.30b 29.9±0.91b 71.33±1.53b 20 46.49±0.55a 7.87±0.20a 27.48±0.45a 68.00±2.00a 注:不同字母上标表示组间差异显著(P<0.05)。 2.3.6 贮藏期间溏心卤蛋菌落总数的变化

由图10可以看出,溏心卤蛋菌落总数随着贮藏时间的延长逐渐增加,且组间差异显著(P<0.05)。贮藏初期(0~4 d),溏心卤蛋菌落总数值增加较缓慢,随着贮藏期达到第8 d后,其菌落总数值显著增加(P<0.05)。这是由于微生物活动逐渐增强,对溏心卤蛋中蛋白质利用率越来越高。贮藏至第16 d时溏心卤蛋菌落总数值已超出GB 2749-2015[17]中蛋制品微生物可接受水平限量值1×104 CFU/g。分析原因可能是,由于巴氏杀菌条件比较温和,不能杀死芽孢等耐高温细菌,因此贮藏时间的延长给那些未被杀死的芽孢增加了繁殖机会[42]。还有研究表明,食品经巴氏杀菌之后仍会有极少数假单胞菌存活,该菌株是一种典型嗜冷菌,能产生活性较强的蛋白酶,在低温条件仍能分解蛋白质和脂肪,并且成为食品中的优势菌[43]。

3. 结论

响应面试验结果表明:单因素对杀菌效果的影响由大到小为:杀菌温度>杀菌时间。最佳工艺参数为杀菌温度65 ℃,杀菌时间20 min,此时菌落总数值为0.37×103 CFU/g。贮藏实验结果表明:随着贮藏周期的增加,溏心卤蛋TBA值、TVB-N值整体呈上升趋势;溏心卤蛋pH、色度和感官评分、含水量整体呈下降趋势。同时,菌落总数在贮藏期间显著增加,当贮藏16 d时其数值已超出微生物可接受水平限量值。综合上述分析结果,本研究结果能够为优化溏心卤蛋杀菌工艺提供理论参考,但巴氏杀菌产品保质期较短,后续研究中可以将新型杀菌技术与巴氏杀菌技术联合处理以延长溏心卤蛋货架期。

-

表 1 响应曲面试验设计因素和水平设计

Table 1 Response surface test design factors and horizontal design

因素 水平 −1 0 1 杀菌温度A(℃) 62 65 68 杀菌时间B(min) 15 20 25 表 2 感官评分标准

Table 2 Sensory scoring criteria

项目 评价标准 分值 滋味(30分) 有卤蛋特有滋味,味感醇厚 30~21 滋味协调,味感较持久均匀 20~11 滋味不协调,卤味香气淡薄 10~1 色泽(20分) 蛋白呈金黄色,有光泽,蛋黄可流动 20~16 蛋白呈黄褐色,亮度偏低,蛋黄可流动 15~11 蛋白颜色发暗,亮度降低,蛋黄可流动 10~1 质地(30分) 蛋白硬度适中,切面平整,蛋黄呈流心状态 30~21 蛋白硬度稍大,切面平整,蛋黄油脂析出 20~11 蛋白松软,切面粗糙,蛋黄油脂析出较严重 10~0 风味(20分) 卤香味浓郁,协调、丰满、无异味 20~16 酱卤香味基本协调、丰满、无明显异味 15~11 卤香味不协调,有异味,刺激性味道 10~1 表 3 CCD试验设计及结果

Table 3 Design and results of CCD test

实验号 A杀菌温度 B杀菌时间 菌落总数

(×103 CFU/g)1 0.000 −1.414 0.46 2 −1.000 −1.000 0.53 3 0.000 0.000 0.37 4 −1.414 0.000 0.56 5 1.414 0.000 0.34 6 1.000 −1.000 0.37 7 0.000 0.000 0.36 8 0.000 1.414 0.4 9 1.000 1.000 0.36 10 0.000 0.000 0.35 11 0.000 0.000 0.37 12 −1.000 1.000 0.51 13 0.000 0.000 0.36 表 4 菌落总数二次回归与方差分析结果

Table 4 Results of quadratic regression and variance analysis of total colonies

方差来源 平方和 自由度 均方 F值 P值 显著性 模型 0.0696 5 0.0139 145.75 0.0001 ** A-杀菌温度 0.0482 1 0.0482 504.77 0.0001 ** B-杀菌时间 0.0016 1 0.0016 17.26 0.0043 * AB 0.0000 1 0.0000 0.2617 0.6247 A² 0.0139 1 0.0139 145.00 0.0001 ** B² 0.0083 1 0.0083 87.30 0.0001 ** 残差 0.0007 7 0.0001 失拟项 0.0004 3 0.0001 1.85 0.2784 不显著 净误差 0.0003 4 0.0001 总离差 0.0703 12 R2=0.9905 R2adj=0.9837 注:0.01<P<0.05,差异显著(*);P<0.01,差异极显著(**)。 表 5 贮藏期间溏心卤蛋色泽及感官评分的变化

Table 5 Changes in color and sensory score of soft-boiled marinated eggs during storage

贮藏时间(d) L* a* b* 感官评分(分) 0 56.28±0.10e 12.27±0.09e 45.23±0.13f 90.66±1.53e 4 55.61±0.07d 12.14±0.06de 40.52±0.03e 87.67±1.15e 8 55.36±0.29d 11.36±0.32c 39.20±0.35d 80.33±1.52d 12 50.39±0.42c 11.72±0.25cd 34.34±0.40c 78.00±2.00c 16 48.62±0.24b 10.53±0.30b 29.9±0.91b 71.33±1.53b 20 46.49±0.55a 7.87±0.20a 27.48±0.45a 68.00±2.00a 注:不同字母上标表示组间差异显著(P<0.05)。 -

[1] 丁波, 陈育林, 窦玉萍, 等. 溏心蛋加工工艺优化[J]. 食品工业科技,2021,42(4):35−141,148. [DING Bo, CHEN Yulin, DOU Yuping, et al. Optimization of processing technology of soft-boiled egg[J]. Science and Technology of Food Industry,2021,42(4):35−141,148.] DING Bo, CHEN Yulin, DOU Yuping, et al . Optimization of processing technology of soft-boiled egg[J]. Science and Technology of Food Industry,2021 ,42 (4 ):35 −141,148 .[2] 范巧. 富含虾青素鸡蛋的加工适应性及消化特性研究[D]. 无锡:江南大学, 2022. [FAN Qiao. Study on processing adaptability and digestive characteristics of astaxanthin rich eggs[D]. Wuxi:Jiangnan University, 2022.] FAN Qiao. Study on processing adaptability and digestive characteristics of astaxanthin rich eggs[D]. Wuxi: Jiangnan University, 2022.

[3] 曾生林, 佘艺敏, 郑鸿. 等. 盐焗鸡蛋货架期抗氧化研究[J]. 肉类工业,2022,499(11):30−34. [ZENG Shenglin, SHE Yimin, ZHENG Hong, et al. Study on shelf life antioxidant of salted eggs[J]. Meat Industry,2022,499(11):30−34.] ZENG Shenglin, SHE Yimin, ZHENG Hong, et al . Study on shelf life antioxidant of salted eggs[J]. Meat Industry,2022 ,499 (11 ):30 −34 .[4] 李瑞. 溏心蛋加工关键技术研究[D]. 长沙:湖南农业大学, 2021. [LI Rui. Research on the key technology of soft-boiled eggs processing[D]. Changsha:Hunan Agricultural University, 2021.] LI Rui. Research on the key technology of soft-boiled eggs processing[D]. Changsha: Hunan Agricultural University, 2021.

[5] 王瑶瑶. 生食鸡蛋杀菌技术研究[D]. 北京:中国农业科学院, 2020. [WANG Yaoyao. Research on sterilization technology of raw eggs[D]. Beijing:Chinese Academy of Agricultural Sciences, 2020.] WANG Yaoyao. Research on sterilization technology of raw eggs[D]. Beijing: Chinese Academy of Agricultural Sciences, 2020.

[6] SAMPEDRO F, MCALOON A, YEE W, et al. Cost analysis of commercial pasteurization of orange juice by pulsed electric fields[J]. Innovative Food Science & Emerging Technologies,2013,17:72−78.

[7] COLAIZY T T. Effects of milk banking procedures on nutritional and bioactive components of donor human milk[J]. Seminars in Perinatology,2021,45(3):151382.

[8] CHANDRAKALA R, LAKSHMI E, JAYACHANDRAN, et al. Influence of high pressure pasteurization on nutritional, functional and rheological characteristics of fruit and vegetable juices and purees-An updated review[J]. Food Control,2023,146:109516. doi: 10.1016/j.foodcont.2022.109516

[9] MA P, DL O, AJ M G, et al. The impact of thermal pasteurization on viral load in human milk and other matrices:A rapid review[J]. Cold Spring Harbor Laboratory Press,2020,46(1):10−26.

[10] WOLDEMARIAM H W, EMIRE S A. Recent trends in cold pasteurization of fruit juices using pulsed electric fields:A review[J]. Agricultural and Food Sciences, Engineering, 2020, 21(1):1−18.

[11] 陈鸣. 一种全自动的溏心蛋烹饪装置. 中国:204950541U[P]. 2016-01-13. [CHEN Ming. A fully automatic soft-boiled egg cooking device. China:204950541U[P]. 2016-01-13.] CHEN Ming. A fully automatic soft-boiled egg cooking device. China: 204950541U[P]. 2016-01-13.

[12] KIPP B. Environmental data recording analysis and simulation of transport vibrations[J]. Packaging Technology Science,2010,21(8):437−438.

[13] 史文艳, 黄露, 王艳, 等. 一种溏心蛋保鲜剂及其在溏心蛋制备中的应用:中国:202011610112.0[P]. 2020-12-29. [SHI Wenyan, HUANG Lu, WANG Yan, et al. A kind of soft-boiled egg preservative and its application in preparation of soft-boiled egg:China:202011610112.0[P]. 2020-12-29.] SHI Wenyan, HUANG Lu, WANG Yan, et al. A kind of soft-boiled egg preservative and its application in preparation of soft-boiled egg: China: 202011610112.0[P]. 2020-12-29.

[14] 屈小燕, 谢小惠, 何新, 等. 一种卤味溏心蛋的生产加工方法:中国:202211698489.5[P]. 2022-12-28. [QU Xiaoyan, XIE Xiaohui, HE Xin. A marinated soft-boiled egg production and processing method:China:202211698489.5[P]. 2022-12-28.] QU Xiaoyan, XIE Xiaohui, HE Xin. A marinated soft-boiled egg production and processing method: China: 202211698489.5[P]. 2022-12-28.

[15] 鲍志杰, 林松毅, 田阳, 等. 一种溏心卤蛋及其制备方法. 中国:202210625092.7[P]. 2022-09-27. [BAO Zhijie, LIN Songyi, TIAN Yang, et al. A soft-boiled boiled egg and its preparation method. China:202210625092.7[P]. 2022-09-27.] BAO Zhijie, LIN Songyi, TIAN Yang, et al. A soft-boiled boiled egg and its preparation method. China: 202210625092.7[P]. 2022-09-27.

[16] SRISAI P, PANSAWAT N, RATTANAAPORN K, et al. Textural and physicochemical properties of threadfin bream surimi gels prepared with salted duck egg white as substitute for hen egg white[J]. International Journal of Food Science & Technology,2022,58(3):1098−1107.

[17] 国家食品药品监督管理总局, 国家卫生和计划生育委员会. GB 4789.2-2022 食品安全国家标准 食品微生物学检验 菌落总数测定[S]. 北京:中国标准出版社, 2016. [State Food and Drug Administration, National Health and Family Planning Commission. GB 4789.2-2016 National standard for food safety. Determination of total bacterial colonies for microbiology inspection of food[S]. Beijing:Standards Press of China, 2016.] State Food and Drug Administration, National Health and Family Planning Commission. GB 4789.2-2016 National standard for food safety. Determination of total bacterial colonies for microbiology inspection of food[S]. Beijing: Standards Press of China, 2016.

[18] 中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会. GB/T 35252-2017食品安全国家标准 动植物油脂2-硫代巴比妥酸值的测定[S]. 北京:中国标准出版社, 2017. [General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of China. GB/T 35252-2017 National standard for food safety. Determination of 2-thiobarbituric acid value of animal and plant oils[S]. Beijing:Standards Press of China, 2017.] General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of China. GB/T 35252-2017 National standard for food safety. Determination of 2-thiobarbituric acid value of animal and plant oils[S]. Beijing: Standards Press of China, 2017.

[19] 中华人民共和国国家卫生和计划生育委员会. GB 5009.228-2016 食品安全国家标准 食品中挥发性盐基氮的测定[S]. 北京:中国标准出版社, 2016. [National Health and Family Planning Commission of the People's Republic of China. GB 5009.228-2016 National standard for food safety. Determination of volatile base nitrogen in food[S]. Beijing:Standards Press of China, 2016.] National Health and Family Planning Commission of the People's Republic of China. GB 5009.228-2016 National standard for food safety. Determination of volatile base nitrogen in food[S]. Beijing: Standards Press of China, 2016.

[20] 中华人民共和国国家卫生和计划生育委员会. GB 5009.237-2016 食品安全国家标准 食品中pH值的测定[S]. 北京:中国标准出版社, 2016. [National Health and Family Planning Commission of the People's Republic of China. GB 5009.237-2016 National standard for food safety. Determination of pH value in food[S]. Beijing:Standards Press of China, 2016.] National Health and Family Planning Commission of the People's Republic of China. GB 5009.237-2016 National standard for food safety. Determination of pH value in food[S]. Beijing: Standards Press of China, 2016.

[21] 中华人民共和国国家卫生和计划生育委员会. GB 5009.3-2016 食品安全国家标准 食品中水分的测定[S]. 北京:中国标准出版社, 2016. [National Health and Family Planning Commission of the People's Republic of China. GB 5009.3-2016 National standard for food safety. Determination of moisture in food[S]. Beijing:Standards Press of China, 2016.] National Health and Family Planning Commission of the People's Republic of China. GB 5009.3-2016 National standard for food safety. Determination of moisture in food[S]. Beijing: Standards Press of China, 2016.

[22] GAO Jinyan, SHI Qiang, YE Yu, et al. Effects of guar gum or xanthan gum addition in conjunction with pasteurization on liquid egg white[J]. Food Chemistry,2022,383:132378. doi: 10.1016/j.foodchem.2022.132378

[23] 施晓予, 刘雪, 刘少伟, 等. 低温贮藏对鸡胸肉肌原纤维蛋白结构及热诱导凝胶性能的影响[J]. 食品安全质量检测学报,2022,13(8):2594−2601. [SHI Xiaoyu, LIU Xue, LIU Shaowei, et al. Effect of low temperature storage on the structure and heat-induced gel properties of chicken breast myofibrillar protein[J]. Journal of Food Safety and Quality Inspection,2022,13(8):2594−2601.] SHI Xiaoyu, LIU Xue, LIU Shaowei, et al . Effect of low temperature storage on the structure and heat-induced gel properties of chicken breast myofibrillar protein[J]. Journal of Food Safety and Quality Inspection,2022 ,13 (8 ):2594 −2601 .[24] OVISSIPOUR M, RASCO B, TANG J M, et al. Kinetics of protein degradation and physical changes in thermally processed Atlantic salmon ( Salmo salar)[J]. Food and Bioprocess Technology,2017,10(10):1865−1882. doi: 10.1007/s11947-017-1958-4

[25] UYSAL R S, BOYACH, SOYKUT E A, et al. Effects of heat treatment parameters on liquid whole egg proteins[J]. Food Chemistry,2017,216:201−208. doi: 10.1016/j.foodchem.2016.08.050

[26] KATHURIA D, DHIMAN A K, ATTRI S. Sous vide, a culinary technique for improving quality of food products:A review[J]. Trends in Food Science and Technology,2022,119:57−68. doi: 10.1016/j.jpgs.2021.11.031

[27] 刘鑫. 基于蛋白质组学探究蛋清热凝胶特性的分子机理[D]. 成都:成都大学, 2021. [LIU Xin. Molecular mechanism of egg-clearing gel properties based on proteomics[D]. Chengdu:Chengdu University, 2021.] LIU Xin. Molecular mechanism of egg-clearing gel properties based on proteomics[D]. Chengdu: Chengdu University, 2021.

[28] 王立强. 黑椒牛肉粒的工艺优化及杀菌、冷藏和复热对其品质影响的研究[D]. 哈尔滨:哈尔滨商业大学, 2021. [WANG Liqiang. Study on the process optimization of beef granules with black pepper and the effects of sterilization, refrigeration and reheating on its quality[D]. Harbin:Harbin University of Commerce, 2021.] WANG Liqiang. Study on the process optimization of beef granules with black pepper and the effects of sterilization, refrigeration and reheating on its quality[D]. Harbin: Harbin University of Commerce, 2021.

[29] 刘欣睿, 孔保华, 夏秀芳, 等. 低温慢煮对肉制品食用品质及货架期影响的研究进展[J]. 肉类研究,2022,36(12):49−56. [LIU Xinrui, KONG Baohua, XIA Xiufang, et al. Research progress on effects of low temperature and slow cooking on eating quality and shelf life of meat products[J]. Meat Research,2022,36(12):49−56.] LIU Xinrui, KONG Baohua, XIA Xiufang, et al . Research progress on effects of low temperature and slow cooking on eating quality and shelf life of meat products[J]. Meat Research,2022 ,36 (12 ):49 −56 .[30] PETIT G, JURY V, LAMBALLERIE M, et al. Salt intake from processed meat products:Benefits, risks and evolving practices[J]. Comprehensive Reviews in Food Science and Food Safety,2019,18(5):1453−1473. doi: 10.1111/1541-4337.12478

[31] SAM A D, LI Cong, XU Baocai. Effect of frozen storage on the lipid oxidation, protein oxidation, and flavor profile of marinated raw beef meat[J]. Food Chemistry,2022,376:131881. doi: 10.1016/j.foodchem.2021.131881

[32] JIA Shiliang, LI Yan, ZHUANG Shuai, et al. Biochemical changes induced by dominant bacteria in chill-stored silver car and GC-IMS identification of volatile organic compounds[J]. Food Microbiology,2019,84:103248. doi: 10.1016/j.fm.2019.103248

[33] DESVITA H, FAISAL M, MAHIDIN S, et al. Preservation of meatballs with edible coating of chitosan dissolved in rice hull-based liquid smoke[J]. Heliyon,2020,6(10):5228.

[34] 周智宇, 罗正娅, 高晴, 等. 微酸性电解水杀菌工艺优化及对云南鲜米线贮藏品质影响[J]. 食品工业科技,2021,42(1):204−210. [ZHOU Zhiyu, LUO Zhengya, GAO Qing, et al. Optimization of sterilization process with slightly acidic electrolytic water and its effect on storage quality of yunnan fresh rice noodles[J]. Science and Technology of Food Industry,2021,42(1):204−210.] ZHOU Zhiyu, LUO Zhengya, GAO Qing, et al . Optimization of sterilization process with slightly acidic electrolytic water and its effect on storage quality of yunnan fresh rice noodles[J]. Science and Technology of Food Industry,2021 ,42 (1 ):204 −210 .[35] GURUNATHAN K, TAHSEEN A, MANYAM S. Effect of aerobic and modified atmosphere packaging on quality characteristics of chicken leg meat at refrigerated storage[J]. Poultry Science,2022,101(12):102170. doi: 10.1016/j.psj.2022.102170

[36] THIANSILAKUL Y, BENJAKULA S, RICHARDS M P. Retardation of myoglobin and hemoglobin-mediated lipid oxidation in washed bighead carp by phenolic compounds[J]. Food Chemistry,2012,134(2):789−796. doi: 10.1016/j.foodchem.2012.02.182

[37] SONG Xinyu, CHIOU B S, XIA Yixun, et al. The improvement of texture properties and storage stability for kappa carrageenan in developing vegan gummy candies[J]. Journal of the Science of Food and Agriculture,2022,102(9):3693−3702. doi: 10.1002/jsfa.11716

[38] XUE Hui, LIU Huilan, ZHANG Guowen, et al. Formation mechanism of salted egg yolk mudding during storage:protein oxidation, gel structure, and conformation[J]. Food Chemistry,2023,413:135632. doi: 10.1016/j.foodchem.2023.135632

[39] 王为浩. 高品质杀菌禽蛋凝胶食品加工特性研究[D]. 广州:华南理工大学, 2021. [WANG Weihao. Study on processing characteristics of high quality sterilized egg gel food[D]. Guangzhou:South China University of Technology, 2021.] WANG Weihao. Study on processing characteristics of high quality sterilized egg gel food[D]. Guangzhou: South China University of Technology, 2021.

[40] 段云霞, 赵英, 迟玉杰. 基于低场核磁共振技术分析不同贮藏条件下白煮蛋水分分布及品质变化[J]. 食品科学,2018,39(9):26−32. [DUAN Yunxia, ZHAO Ying, CHI Yujie. Analysis of Water distribution and quality of boiled egg under different storage conditions by low field nuclear magnetic resonance technique[J]. Food Science,2018,39(9):26−32.] DUAN Yunxia, ZHAO Ying, CHI Yujie . Analysis of Water distribution and quality of boiled egg under different storage conditions by low field nuclear magnetic resonance technique[J]. Food Science,2018 ,39 (9 ):26 −32 .[41] GANESAN P, BENJAKUL S, BAHARIN B S. Effect of different cations in pickling solution on FTIR characteristics of pidan white and yolk in comparison to the fresh duck egg[J]. Sains Malaysiana,2014,43(12):1883−1887. doi: 10.17576/jsm-2014-4312-09

[42] 龚周亮, 赵良忠, 刘汁琪, 等. 巴氏杀菌后湘派豆干货架期内品质变化及微生态分析[J]. 中国食品工业,2023,369(7):104−107. [GONG Zhouliang, ZHAO Liangzhong, LIU Zhiqi, et al. Quality change and microecological analysis of xiangpai dried bean during shelf life after pasteurization[J]. China Food Industry,2023,369(7):104−107.] GONG Zhouliang, ZHAO Liangzhong, LIU Zhiqi, et al . Quality change and microecological analysis of xiangpai dried bean during shelf life after pasteurization[J]. China Food Industry,2023 ,369 (7 ):104 −107 .[43] 王晶. 全蛋液冷藏期间的腐败规律及其品质控制研究[D]. 无锡:江南大学, 2022. [WANG Jing. Study on the spoilage rule and quality control of whole egg liquid during cold storage[D]. Wuxi:Jiangnan University, 2022.] WANG Jing. Study on the spoilage rule and quality control of whole egg liquid during cold storage[D]. Wuxi: Jiangnan University, 2022.

下载:

下载:

下载:

下载: