Analysis of Physicochemical Quality and Flavor Differences of Five Commercially Available Tiger Nut Oils with Different Processes Based on GC-IMS Technique

-

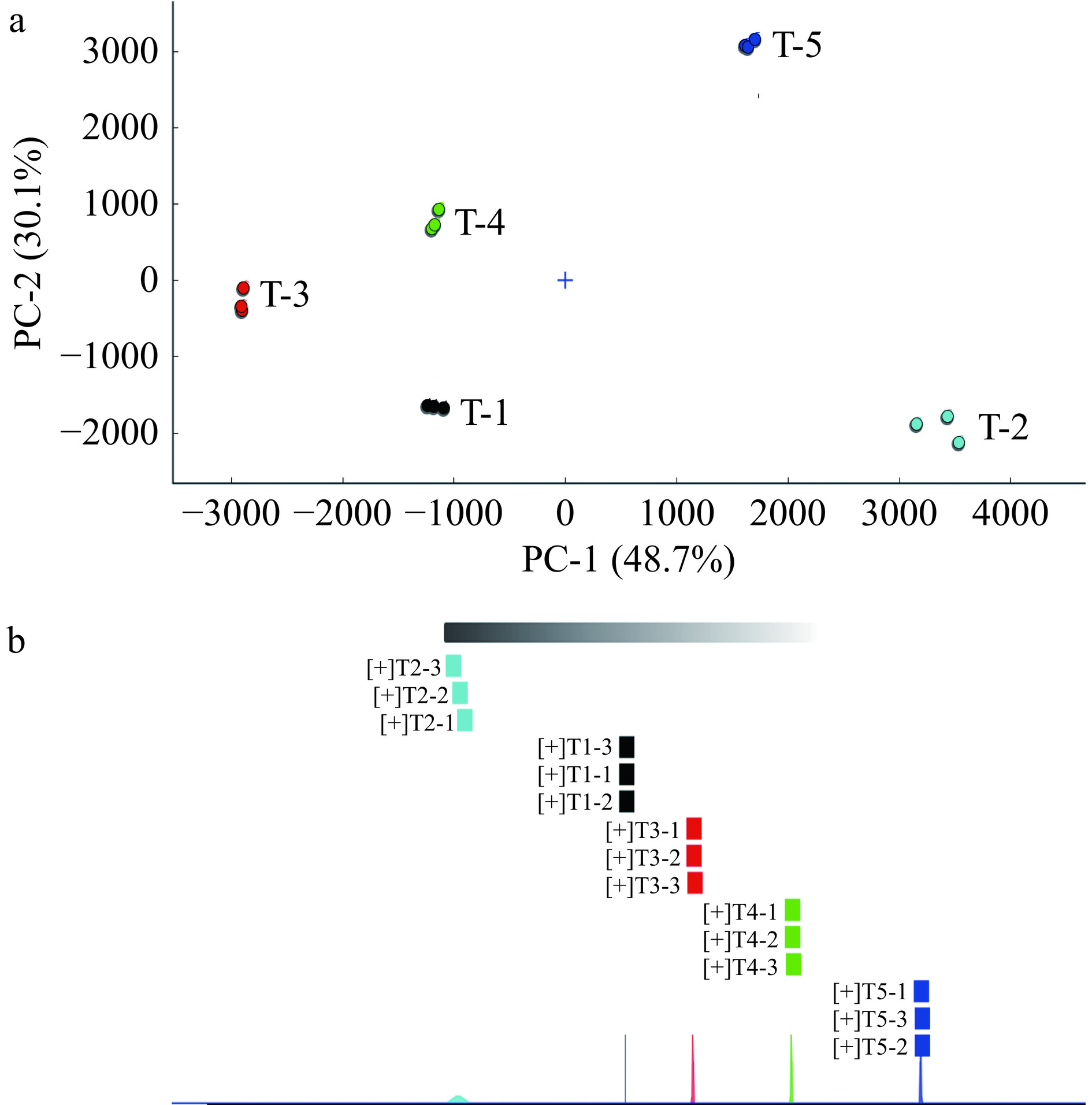

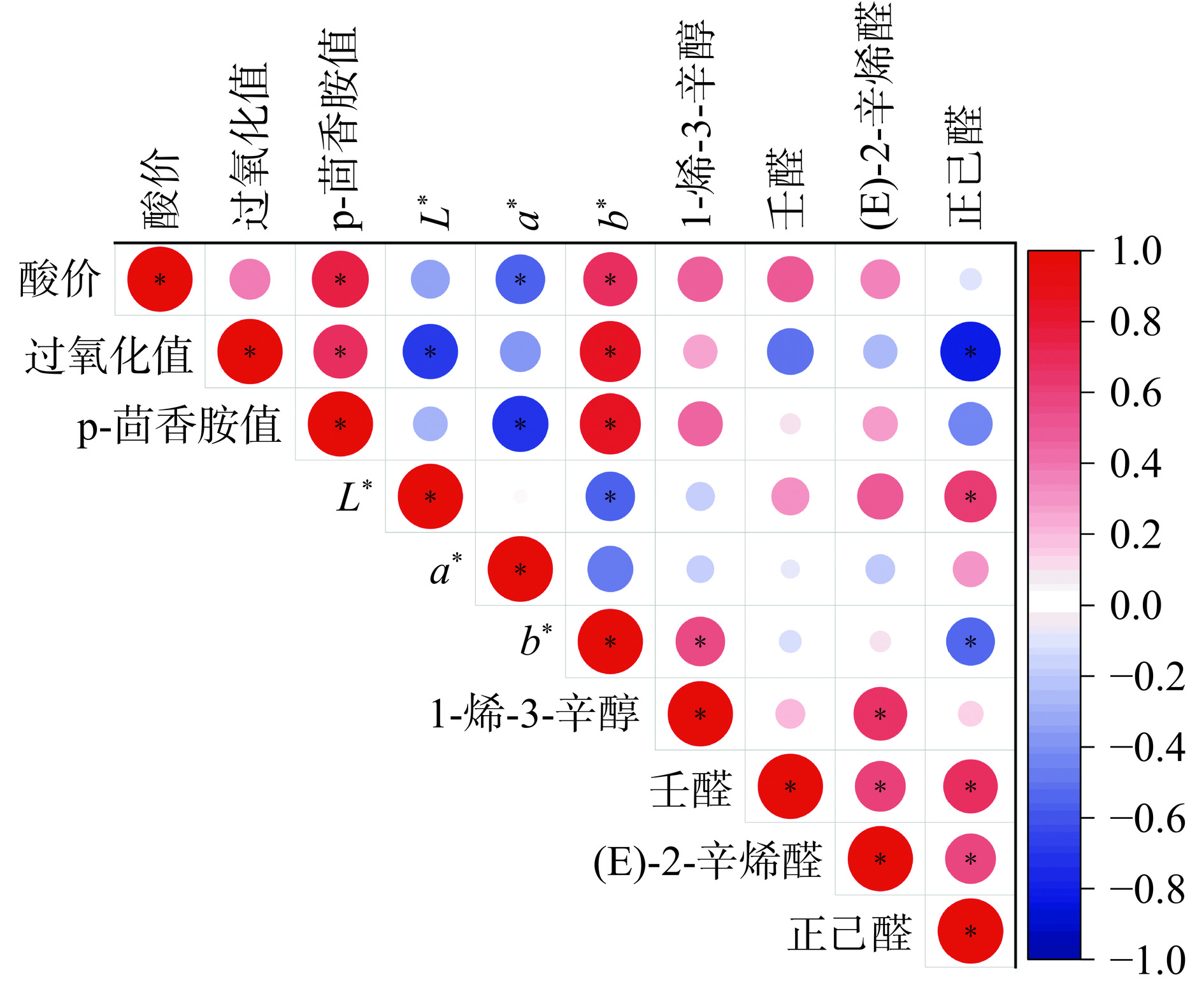

摘要: 为研究市售不同工艺油莎豆油理化品质与风味的差异性,采用气相离子迁移谱(Gas Chromatography-Ion Mobility Spectroscopy,GC-IMS)技术结合主成分分析法对比不同工艺(物理压榨、热榨、亚临界萃取、高压冷榨和冷榨工艺)油莎豆油挥发性化合物之间的差异性。GC-IMS结果显示,不同工艺油莎豆油中共鉴定出76种挥发性化合物,其中包括酯类12种、醇类16种、醛类29种、酮类9种、酸类5种、呋喃类3种、吡嗪类1种、硫类1种。热榨组醛类、酯类和呋喃类物质相对含量较高(53.54%,13.06%,5.41%)。不同工艺油莎豆油风味差异性主要来源于四种关键风味物质:1-烯-3-辛醇、壬醛、(E)-2-辛烯醛和己醛。主成分分析(Principal Component Analysis,PCA)结果表明PC1和PC2分别为48.7%和30.1%,累计差异贡献率为78.8%,不同工艺油莎豆油风味物质差异显著,能够对不同工艺油莎豆油良好区分。Pearson相关性分析结果表明不同工艺油莎豆油b*值与酸价、过氧化值、p-丙二醛值和1-烯-3-辛醇之间呈显著正相关(0.57<r<0.88,P<0.05)。本研究结对市售油莎豆油生产加工、理论研究和质量检测等领域具有一定的参考价值。

-

关键词:

- 气相色谱-离子迁移谱(GC-IMS) /

- 油莎豆油 /

- 不同工艺 /

- 挥发性化合物 /

- 主成分分析(PCA)

Abstract: In order to evaluate the differences in physicochemical quality and flavor of commercially edible tiger nut oil, gas chromatography-ion mobility spectroscopy (GC-IMS) combined with principal component analysis was used to compare the volatile compounds in tiger nut oil from different extraction methods (physical pressing, hot pressing, subcritical extraction, high-pressure cold pressing and cold pressing). The GC-IMS results showed that 76 volatile compounds including 12 esters, 16 alcohols, 29 aldehydes, 9 ketones, 5 acids, 3 furans, 1 pyrazine and 1 sulfur compound were identified in the oil from different extraction methods. The relative content of aldehydes, esters and furans (53.54%, 13.06%, 5.41%) in the hot-pressing group were higher than others. The flavor differences of tiger nut oil from different processes were mainly derived from four key flavor substances as 1-octen-3-ol, nonanal, (E)-2-octenal and hexanal. The results of principal component analysis (PCA) showed that PC1 and PC2 were 48.7% and 30.1%, respectively, with a cumulative difference contribution of 78.8%, and the differences in volatile compounds between different processes were significant, which could be well distinguished by different extraction methods. The results of pearson correlation analysis showed that there was a significant positive correlation between b* value and acid value, peroxide value, p-malondialdehyde value and 1-octen-3-ol (0.57<r<0.88, P<0.05). The research could provide some reference value for the production and processing, theoretical research and quality inspection of commercial tiger nut oil. -

油莎豆油指由油莎豆果实块茎部位压榨得到的植物油。油莎豆油色泽鲜明,有坚果的香味,维生素E和不饱和脂肪酸含量较高,其中单不饱和脂肪酸油酸含量高达50%~70%远高于大豆油[1−2]。油莎豆油品质可与橄榄油相媲美,其独特的坚果香气引起学者们的兴趣[3]。食用植物油是人们维持机体正常工作不可或缺的营养素[4]。它不仅为消费者的身体提供营养,还可以增加食物的色泽、香气与风味。风味通常决定了食物独特的感官特征,对食物的营养价值和新鲜度十分重要。目前对于油莎豆油的研究大多集中于对其提取工艺的探索[5−7],但对油莎豆油挥发性化合物组成及特点研究甚少,而油脂的生产工艺对其风味形成有着重要影响。近年来,提取工艺对油脂风味的影响研究引起学者们的广泛关注:蒋凌燕等[8]对比了鲜榨、閟制和超临界萃取三种不同工艺制备藤椒油对风味的影响,发现麻味成分含量和挥发性风味成分的种类及相对含量存在差异;周易枚等[9]通过对比水代法与压榨法加工工艺生产的芝麻油中的挥发性物质,发现从水代法生产的芝麻油中鉴定出61种主要挥发性风味物质,相比于压榨一级芝麻油中挥发性风味物质较多;夏纯凤等[10]通过对比热榨与湿法制油对茶籽油风味成分的差异,发现二者差异源自于醛类与醇类物质的种类及含量。市售油莎豆油的风味是其吸引消费者的最直观的特征之一。而市售油莎豆油制备工艺种类繁多,加工工艺与风味成分的研究鲜有报道,油莎豆油的关键风味物质以及不同工艺油莎豆油的风味差异尚不清楚,这一定程度上阻碍了油莎豆油产业的发展,使其相较于大宗植物油产业发展缓慢。

目前植物油挥发性化合物的检测技术种类多样,其中气相色谱-离子迁移谱分析技术是近年来新兴起的一种挥发性化合物检测手段,其原理是基于不同离子在电场中的迁移速度差异来鉴定化学离子物质的分析技术,是一种快速、方便、低成本的分析方法[11]。随着气相色谱-离子迁移谱技术的快速发展,其在食品领域的应用也逐渐演进,可用于对油脂挥发性风味物质检测与鉴定[12−16],但是有关油莎豆油气相色谱-离子迁移谱技术的相关研究未见报道。

综上,本研究采用气相色谱-离子迁移谱(GC-IMS)分析技术并联用主成分分析法,对五种市售不同工艺油莎豆油的挥发性物质进行对比分析,并通过Pearson相关性分析确定不同工艺条件下油莎豆油的理化特性与关键香气成分之间的联系。本研究旨在通过一种特异性、便捷的方法来鉴定并寻找不同工艺油莎豆油风味的差异性,为油莎豆油生产工艺、风味研究、精深加工等相关研究提供一定的理论研究基础。

1. 材料与方法

1.1 材料与仪器

油莎豆油 市售(品种均为“中油莎1号”),市售不同工艺油莎豆油相关信息如表1所示,所有油莎豆油样品在4 ℃保存;95%冰乙酸、三氯甲烷、乙醇、异辛烷溶液 均为分析纯,天津市风船化学试剂科技有限公司;酚酞、氢氧化钠、碘化钾、硫代硫酸钠、无水硫酸钠、可溶性淀粉、茴香胺试剂 天津市致远化学试剂有限公司。

表 1 市售油莎豆油样品相关信息Table 1. Relevant commodity information of tiger nut oil samples样品 提取工艺 产地 T-1 物理压榨法 昌平,北京 T-2 热榨法 长沙,湖南 T-3 亚临界萃取 铁门关,新疆 T-4 高压冷榨法 保定,河北 T-5 冷榨法 北京 XB 220A型分析天平 上海精若科学仪器有限公司;FlavourSpec®风味分析仪、MXT-5色谱柱(15 m×0.53 mm,1 μm) 德国G.A.S公司;XD110色差仪 上海现代环境有限公司;B250智能数显恒温油水浴锅 上海予卓仪器有限公司。

1.2 实验方法

1.2.1 油莎豆油理化指标的测定

色度值L*、a*、b*值由XD 110色差仪直接测定;酸价、过氧化值和p-茴香胺值均按照国标GB 5009.229-2016《食品安全国家标准 食品中酸价的测定》、GB 5009.227-2016《食品安全国家标准 食品中过氧化值的测定》、GB/T 24304-2009《动植物油脂 茴香胺值的测定》测定。

1.2.2 GC-IMS测定

采用配备自动顶空进样器的GC-IMS风味分析仪对不同工艺的油莎豆油挥发性化合物进行分析。设置自动顶空进样器的进样体积500 μL,孵育时间为15 min,孵育温度为80 ℃,进样针温度为85 ℃,孵化转速为500 r/min。气相离子迁移谱采用色谱柱(MXT-5,15 m×0.53 mm,1 µm)。色谱柱温度设定为60 ℃,载气为N2(纯度≥99.999%),载气流速设定为:2 mL/min,总运行时间为20 min。设置IMS温度为45 ℃,漂移气体为N2(纯度≥99.999%),漂移气体流速为150 mL/min,总运行时间为20 min。每个样品重复进行三次。挥发性化合物采用NIST 11保留指数数据库的标准质谱图对获得的谱图进行串联检索和人工解析,通过二维正交进行定性分析;以C4~C9的正构酮为外标物,计算各化合物的保留指数,用作辅助定性;最后,采用面积归一法计算不同组分的峰面积占总峰面积的比值,表示为不同挥发性化合物的相对含量[17]。保留指数(Retention Index,RI)计算公式如下[18]:

RI=100n+100×TRx−TRnTRn+1−TRn (1) 式中:RI表示待测组分的保留指数;TRx表示为待测组分的保留时间,s;n和n+1分别表示为外标物的碳原子数;TRn<TRx<TRn+1。

1.2.3 相对香气活力值的计算

相对气味活力值(Relative Odor Activity Value,ROAV)通常被用于评价物质中的关键挥发性化合物。本研究中参考符成刚等[19]确定关键风味化合物的方法,定义对样品风味贡献最大的挥发性化合物组分的ROAVmax=100,分别计算各个挥发性化合物的相对气味活度阈值,具体计算公式如下:

ROAV=CiCmax×TmaxTi×100 (2) 式中:ROAV表示挥发性化合物的相对气味活度阈值;Ti与Ci分别表示感觉阈值与各个物质的相对含量,%;Tmax与Cmax分别表示对样品风味贡献最大的组分的感觉阈值与相对含量,%。若ROAV≥1,则表明该挥发性化合物为关键风味物质,且ROAV值越大,表明对总体风味的构建贡献越大;若0.1≤ROAV<1,则说明该物质对整体风味具有一定的修饰作用。

1.3 数据处理

所有数据均测量三次,表示为平均±标准差。采用SPSS统计软件(IBM Watson Analytics,北京,中国)对数据进行单因素方差分析(ANOVA),样本间多重比较采用Duncan检验(P<0.05)。采用Origin 2021(Originlab,美国)、VOCal分析软件和仪器自带插件进行定性定量分析与绘图。

2. 结果与分析

2.1 不同工艺对油莎豆油理化指标的影响

2.1.1 不同工艺对油莎豆油色泽的影响

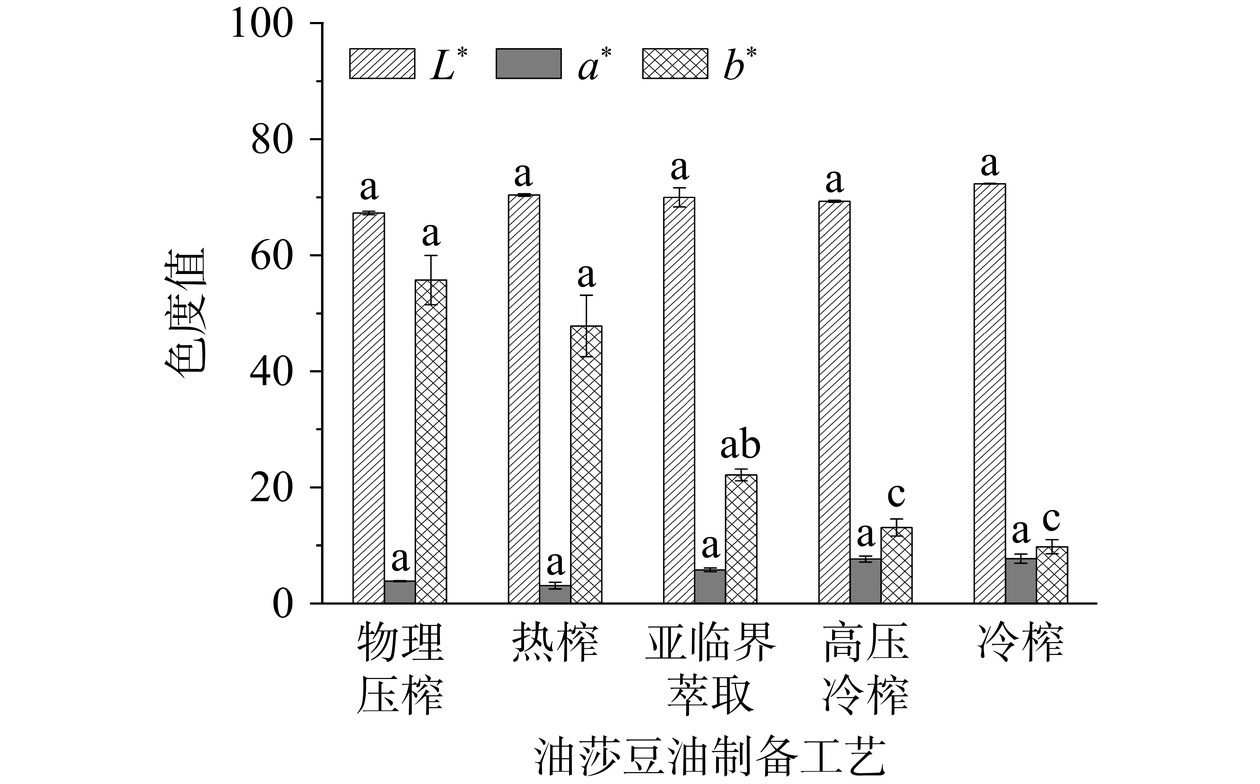

色泽是评价油脂品质的重要指标之一,不同工艺对油莎豆油色泽的影响如图1所示。L*、a*、b*分别表示色度值中的亮度、红绿和黄蓝值。不同工艺油莎豆油L*和a*值变化均不显著(P>0.05),而b*值具有显著性差异(P<0.05),其中物理压榨法所得油莎豆油与热榨法所得油莎豆油的b*值显著增加(P<0.05),分别为55.50±4.23和47.82±5.31。造成这一现象的原因可能是高温与机械热致使压榨过程中蛋白质与碳水化合物发生美拉德反应产生了深棕色物质[20]。

![]() 图 1 不同制备工艺对油莎豆油色泽的影响注:图中不同小写字母表示存在显著性差异(P<0.05),图2同。Figure 1. Effects of different pressing processes on the color of tiger nut oil

图 1 不同制备工艺对油莎豆油色泽的影响注:图中不同小写字母表示存在显著性差异(P<0.05),图2同。Figure 1. Effects of different pressing processes on the color of tiger nut oil2.1.2 不同工艺对油莎豆油氧化指标的影响

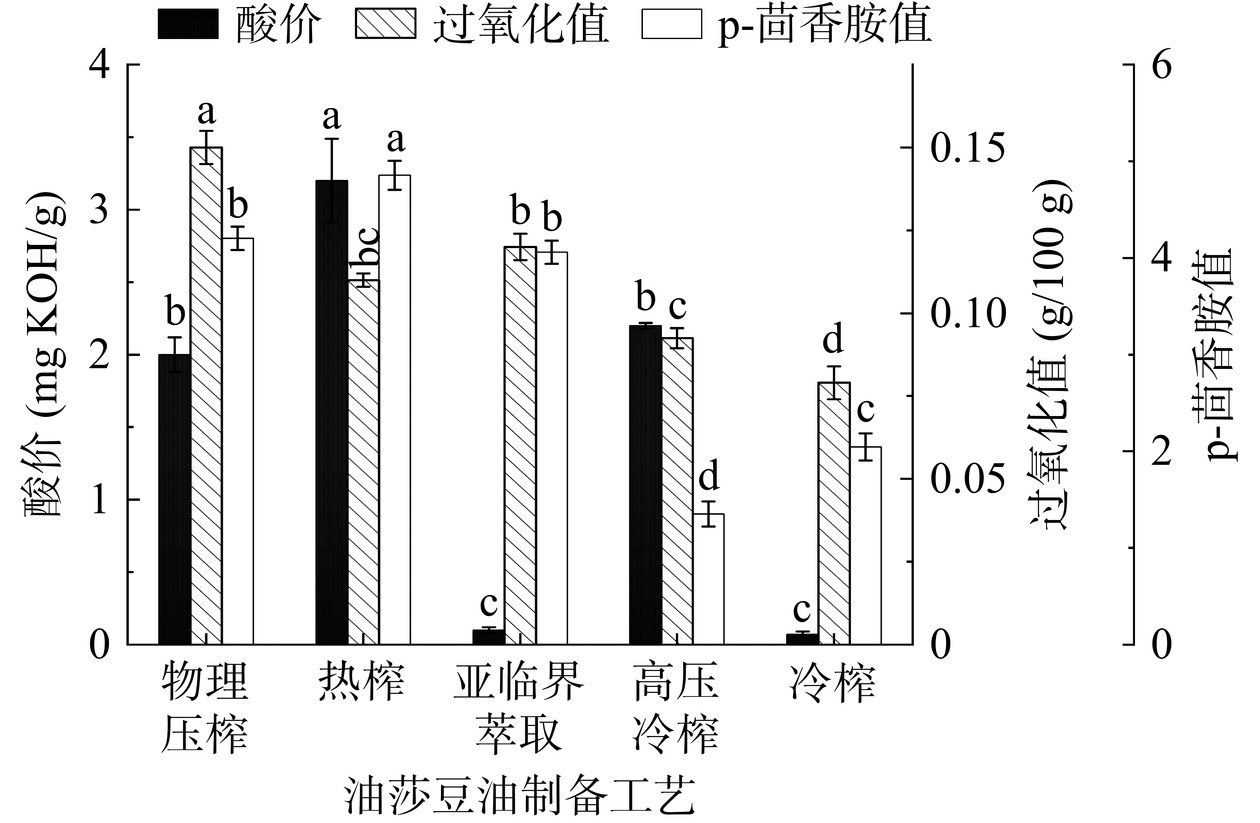

如图2所示,不同工艺的油莎豆油的氧化指标差异较大。油酸价范围为0.07~3.20 mg KOH/g。其中热榨工艺油莎豆油样品酸价最高,其次为物理压榨与高压冷榨工艺油莎豆油。冷榨工艺油莎豆油酸价最低,为0.07±0.02 mg KOH/g。冷榨工艺与亚临界萃取工艺均对油莎豆油酸价无显著差异(P>0.05)。不同工艺油莎豆油的过氧化值可以反映初级氧化产物氢过氧化物的含量,进而反映油脂的氧化程度[21]。由图2可知,物理压榨工艺油莎豆油的过氧化值最高(0.148 g/100 g),冷榨工艺所得油莎豆油过氧化值最低(0.079 g/100 g),表明物理压榨工艺所得油莎豆油初级氧化产物含量较高,较其他工艺相比氧化程度更高,与其他工艺相比具有显著差异(P<0.05),这可能是由于物理压榨工艺中产生的热量导致油脂氧化较强。p-茴香胺值可以反映油脂氧化过程中次级氧化产物含量的变化,进而反映油脂的理化品质[22]。如图2所示,物理压榨工艺与热榨工艺所得油莎豆油具有更高的p-茴香胺值,分别为4.20±0.12和4.86±0.15,而高压冷榨工艺所得油莎豆油的p-茴香胺值最低(1.35±0.13),这可能是由于热榨工艺中高温与物理压榨法中挤压的剪切应力、压力等作用力产生的热量,促使油莎豆油中氢过氧化物分解,导致醛、酮、酸等次级氧化产物生成,进而影响p-茴香胺值的不同。而高压冷榨工艺和冷榨工艺所得油莎豆油p-茴香胺值显著性差异(P<0.05),但是这两种工艺所得油莎豆油氧化程度仍处于较低水平,表明高压可能对油脂氧化有一定影响。

2.2 不同工艺对油莎豆油挥发性风味物质的影响

2.2.1 不同工艺油莎豆油GC-IMS地势图与俯视图分析

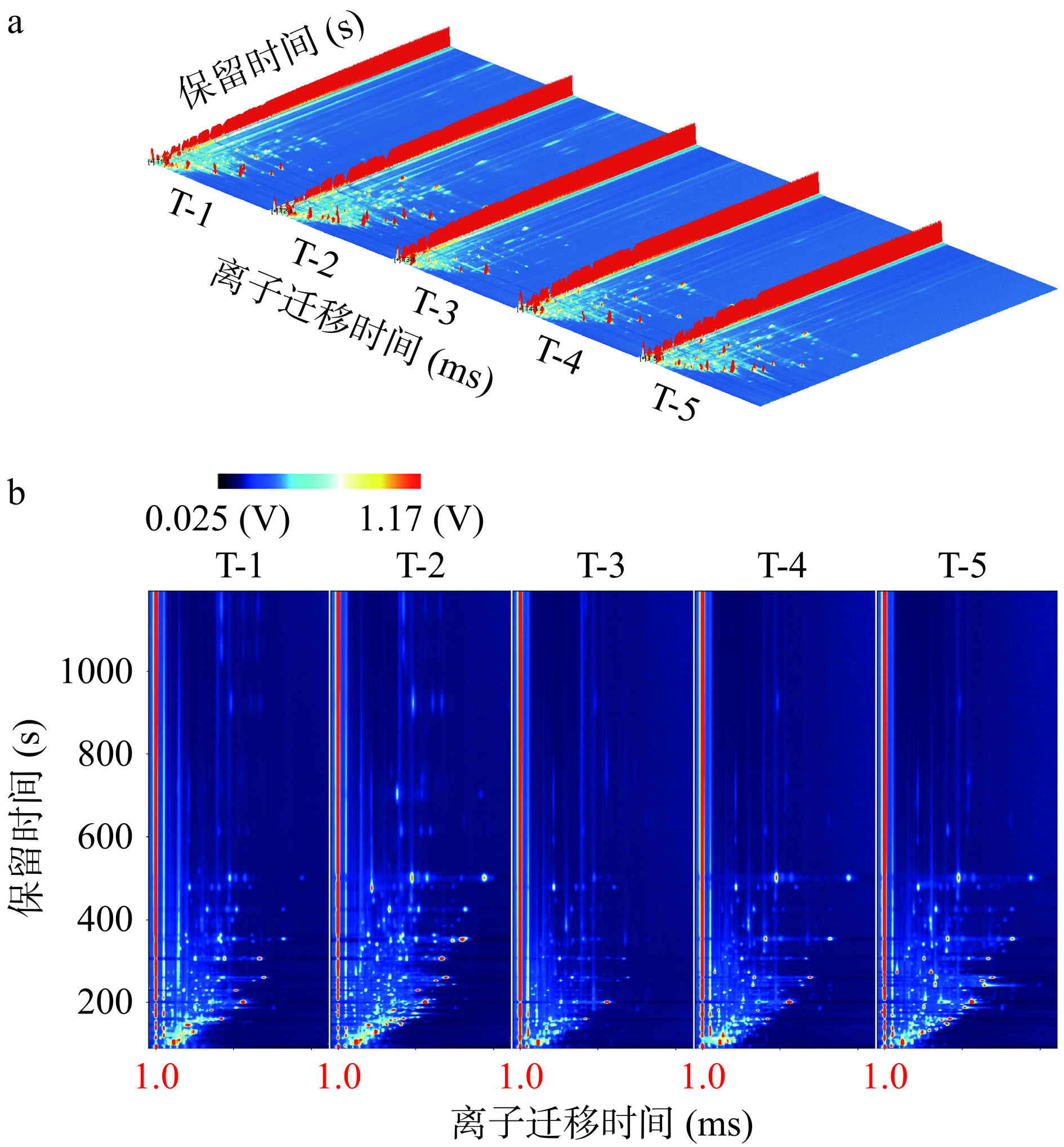

采用GC-IMS技术分析不同工艺油莎豆油中挥发性化合物的差异,地势图如图3a所示,x轴为离子迁移时间(ms),y轴为保留时间(s),z轴为离子峰强度。可以看出,三维地势图中分布的离子峰表示不同工艺油莎豆油样品的挥发性化合物,分布规律较为相似,但是位置与峰强度差异较大。

不同工艺油莎豆油的俯视图如图3b所示。GC-IMS俯视图谱是通过对离子迁移时间和反应离子峰(Reaction Ion Peak,RIP)位置进行归一化处理得到。整个图谱以蓝色为背景,横坐标表示离子迁移时间(ms),纵坐标表示保留时间(s),横坐标于1.0处的红色竖线为RIP峰。在GC-IMS中检测到的单个挥发性物质,单独分布在反应离子峰右侧。离子峰的强度用图中点颜色的深浅表示,白色表示强度较低,红色表示强度较高,颜色越深表示离子峰强度越高。可以看出,不同工艺油莎豆油挥发性有机物在俯视图中由于保留时间、漂移时间和离子峰强度的不同,导致所形成的点位置与颜色深浅不同,不同工艺油莎豆油中挥发性有机物成分差异显著。

从图3b可以看出,大部分挥发性化合物的信号处于保留时间100~600 s之间,但是个别挥发性化合物信号保留时间处于500~1200 s之间,这可能是由于这些化合物具有更低的极性,导致这些挥发性成分在非极性柱上保留时间比极性化合物长[23]。GC-IMS俯视图从俯视角度直观地观测到五种样品在俯视图中离子峰形成的光斑具有一定差异性。物理压榨法与热榨工艺所得油莎豆油风味物质较为丰富,这是由于在物理压榨与热榨工艺制备的油莎豆油诱导醛、酮、酸等其他次级氧化产物的产生,与周靖等[24]热榨工艺番茄籽油具有较高含量挥发性化合物的结果相似。

2.2.2 不同工艺油莎豆油挥发性物质指纹图谱分析

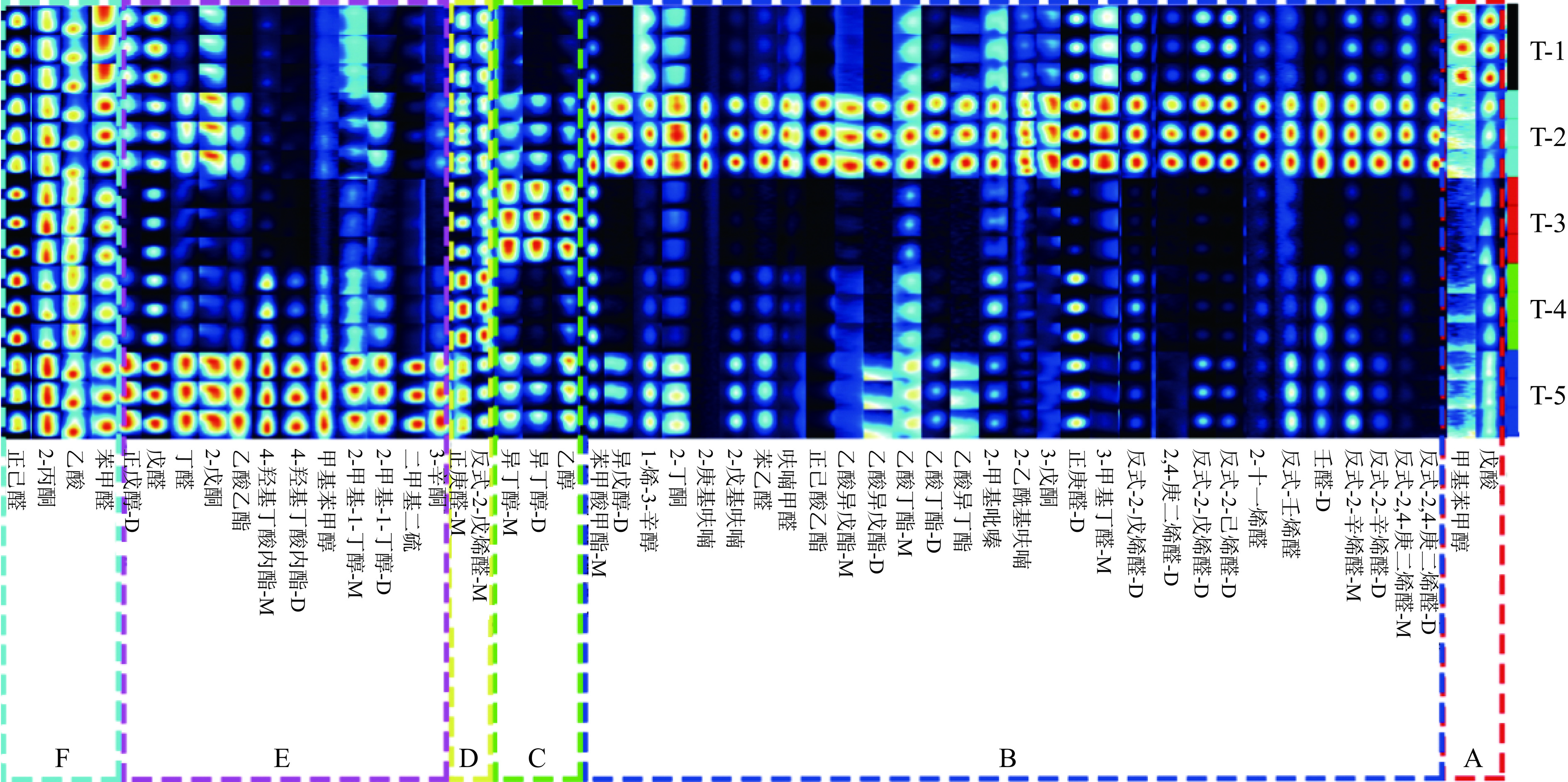

不同工艺油莎豆油样品中挥发性物质指纹图谱如图4所示。由图4可知,在不同工艺油莎豆油样品中,通过GC-IMS共检测到96种挥发性有机物,其中76种被鉴定,包括酯类12种、醇类16种、醛类29种、酮类9种、酸类5种、呋喃类3种、吡嗪类1种、硫类1种。

结果表明,不同工艺油莎豆油样品被直观地区分(图中所示A、B、C、D、E区域),而F区为五种不同工艺油莎豆油挥发性物质离子峰强度均处于较高水平的区域。图4中A、B、C、D、E分别表示物理压榨、热榨、亚临界萃取、高压冷榨和冷榨工艺制得油莎豆油各自挥发性物质离子峰强度较为突出的区域。其中,热榨(B)与冷榨(E)工艺所得油莎豆油的挥发性有机物更为丰富,热榨油莎豆油中(E,E)-2,4-庚二烯醛、(E)-2-辛烯醛、壬醛、2-十一烯醛、(E)-2-壬烯醛、(E)-2-己烯醛、(E)-2-庚烯醛、(E)-2-庚二烯醛、(E)-2-戊烯醛、3-甲基丁醛、庚醛、3-戊酮、2-乙酰呋喃、甲基吡嗪、2-甲基乙酸丙酯、乙酸丁酯、3-乙酸甲酯、己酸乙酯、糠醛、苯乙醛、戊基呋喃、庚基呋喃、2-丁酮、1-烯-3-辛醇、3-甲基-1-丁醇和苯甲酸甲酯的离子峰强度呈现出较强的信号,而冷榨油莎豆油中3-辛酮、2-戊酮、二甲基二硫、苯乙醇、丁内脂、乙酸乙酯、丁醛、戊醛呈现出较强的离子峰强度信号。重叠部分F表示五种不同工艺样品共有挥发性物质离子峰强度相对显著的区域,主要有苯甲醛、乙酸、2-丙酮和正己醛。

2.2.3 不同工艺油莎豆油挥发性成分分析

不同工艺油莎豆油挥发性化合物及其相对含量如表2所示。醛类是样品中种类最丰富的挥发性化合物,五种不同工艺油莎豆油中醛类物质共计29种,大多数醛类对植物油的风味起到了积极的作用[2]。其中,壬醛一般被认为是亚油酸的氧化分解产物,而苯甲醛一般被认为是苯丙氨酸的降解产物,二者为油莎豆油提供油腻、柑橘、杏仁和焦糖风味[25]。己醛是油脂中的一种重要的风味化合物,然而,它产生了一种令人不快的草味[26]。己醛和2,4-庚二烯醛的相对含量较高,这可能是由于在油莎豆油的生产过程中,油莎豆油中的亚油酸和亚麻酸水解导致[27]。由表2可知,物理压榨法与热榨法所制得油莎豆油具有相对含量较高的醛类物质(54.01%、53.50%),这是由于物理压榨过程中局部热效应与温度所致。亚临界萃取和冷榨法所得油莎豆油中醛类物质相对含量分别为35.32%和42.86%,同处于相对较低的水平,而高压冷榨法由于工艺的不同其醛类物质相对含量为51.89%,与冷榨法相比醛类物相对含量显著提高,这表明高压可能促进压榨过程中醛类物质的生成。

表 2 不同工艺油莎豆油挥发性成分分析Table 2. Analysis of volatile components in tiger nut oil with different processes化合物种类 化合物名称 RI Rt(s) Dt(ms) 相对含量(%) T-1 T-2 T-3 T-4 T-5 酯类 5-羟基癸酸-δ-内酯 1550.3 1156.21 1.43 4.18±0.16a 2.32±0.07b 1.97±0.24c 0.97±0.05d 0.55±0.03e 苯甲酸甲酯M 1088.8 478.34 1.22 2.24±0.03d 3.95±0.03b 4.96±0.12a 3.44±0.02c 2.33±0.04d 苯甲酸甲酯D 1088.8 478.34 1.6 0.30±0.03d 0.21±0.01e 0.85±0.02a 0.60±0.00b 0.46±0.02c 正己酸乙酯 1003.3 352.87 1.8 0.50±0.02d 4.86±0.02a 0.20±0.01e 1.01±0.02b 0.86±0.02c 乙酸异戊酯M 867.4 244.95 1.31 0.03±0.00d 0.19±0.00a 0.07±0.01c 0.08±0.01b 0.06±0.00c 乙酸异戊酯D 866.9 244.64 1.75 0.02±0.01d 0.24±0.01b 0.06±0.01c 0.05±0.01c 0.29±0.01a 乙酸丁酯M 801.7 209.39 1.24 0.19±0.01ab 0.14±0.01c 0.18±0.00b 0.20±0.01a 0.15±0.01c 乙酸丁酯D 799.4 208.14 1.62 0.08±0.00c 0.29±0.01a 0.05±0.01d 0.08±0.00c 0.14±0.00b 乙酸异丁酯 760.1 189.74 1.61 0.09±0.00b 0.14±0.00a 0.04±0.00c 0.03±0.00d 0.15±0.00a 乙酸乙酯 614.9 137.4 1.34 0.05±0.00e 0.29±0.00c 0.36±0.02b 0.26±0.01d 0.85±0.01a 4-羟基丁酸内酯M 911.9 274.33 1.08 0.45±0.02c 0.29±0.01d 0.44±0.03c 2.21±0.03b 2.55±0.01a 4-羟基丁酸内酯D 910.5 273.19 1.3 0.16±0.01c 0.13±0.01c 0.20±0.00c 1.07±0.06b 3.09±0.11a 醇类 苯乙醇 1116.1 518.46 1.28 0.30±0.03a 0.13±0.01b 0.28±0.03a 0.25±0.02a 0.18±0.01b 1-烯-3-辛醇 981.6 330.76 1.16 2.33±0.01a 1.15±0.06b 0.50±0.09d 0.58±0.01d 0.94±0.00c 正戊醇M 757.4 188.58 1.26 1.41±0.01b 0.68±0.02e 0.88±0.00d 1.27±0.01c 1.45±0.01a 正戊醇D 756.2 188.09 1.52 1.65±0.03b 0.89±0.00c 0.19±0.01e 0.61±0.02d 2.04±0.00a 正己醇M 861.1 241.52 1.33 0.43±0.01d 0.67±0.00c 0.34±0.02e 2.10±0.04a 1.79±0.03b 正己醇D 862.2 242.14 1.65 0.08±0.01d 0.43±0.02c 0.09±0.02d 0.89±0.02b 2.12±0.04a 异戊醇M 723.1 174.15 1.25 0.16±0.01e 0.46±0.02b 0.25±0.02d 0.38±0.01c 0.55±0.01a 异戊醇D 723.1 174.15 1.49 0.04±0.01e 0.99±0.03a 0.07±0.00d 0.11±0.01c 0.58±0.00b 异丁醇M 622.2 139.61 1.17 0.33±0.01c 0.39±0.01c 1.91±0.10a 0.38±0.01c 0.60±0.01b 异丁醇D 621.6 139.44 1.37 0.04±0.01e 0.27±0.01c 1.55±0.05a 0.10±0.01d 0.38±0.01b 乙醇 474.8 95.18 1.05 0.77±0.01e 1.04±0.02d 5.38±0.11a 1.44±0.04c 2.37±0.09b 庚醇 974.7 325.21 1.4 0.77±0.04c 0.73±0.02c 0.59±0.06d 1.23±0.04b 1.45±0.03a 甲基苯甲醇 1050.3 421.79 1.19 0.21±0.01c 0.13±0.01d 0.15±0.01d 0.32±0.00b 0.51±0.02a 2-甲基-1-丁醇M 745.3 183.49 1.22 0.16±0.01b 0.09±0.01c 0.17±0.02b 0.23±0.01a 0.25±0.01a 2-甲基-1-丁醇D 744.8 183.29 1.49 0.10±0.00e 0.20±0.00c 0.15±0.01d 0.29±0.01b 0.42±0.01a 1-辛醇 1075.4 458.66 1.48 0.59±0.03c 0.86±0.07b 0.67±0.07c 0.98±0.03a 0.98±0.01a 醛类 2-十一烯醛 1392.3 924.14 1.49 2.61±0.14b 3.42±0.10a 2.53±0.13b 2.46±0.10b 1.39±0.05c (E)-2-壬烯醛 1181.9 615.08 1.41 0.71±0.05c 1.01±0.02a 1.09±0.01a 0.72±0.05c 0.87±0.01b 壬醛M 1104.1 500.83 1.48 2.80±0.00d 3.96±0.00c 1.52±0.06e 7.41±0.06a 4.37±0.02b 壬醛D 1104.1 500.83 1.95 0.51±0.02c 3.32±0.13a 0.26±0.01d 3.18±0.06a 1.48±0.01b (E)-2-辛烯醛M 1052.8 425.46 1.33 1.69±0.00b 2.39±0.06d 0.93±0.03e 1.28±0.04c 1.76±0.04b (E)-2-辛烯醛D 1052.8 425.46 1.82 0.34±0.01b 1.24±0.08a 0.16±0.02c 0.19±0.01c 0.38±0.01b (E,E)-2,4-庚二烯醛M 1010.7 363.63 1.2 1.28±0.01a 1.28±0.03a 0.51±0.04b 0.44±0.01c 0.21±0.01d (E,E)-2,4-庚二烯醛D 1010.7 363.63 1.62 0.26±0.02b 0.90±0.08a 0.15±0.01c 0.13±0.01c 0.11±0.00c 2,4-庚二烯醛M 999.5 347.2 1.2 1.09±0.01a 0.60±0.01b 0.60±0.03b 0.45±0.02c 0.22±0.01d 2,4-庚二烯醛D 1000.1 348.14 1.63 0.37±0.01b 0.78±0.04a 0.12±0.01d 0.16±0.01cd 0.17±0.02c 正辛醛M 1004.3 354.24 1.41 1.79±0.01c 0.77±0.00e 0.85±0.06d 3.00±0.03a 1.88±0.01b 正辛醛D 1004.3 354.24 1.83 0.90±0.01c 0.77±0.02d 0.10±0.01e 1.81±0.03a 1.38±0.00b (E)-2-庚烯醛M 953.2 307.73 1.26 2.75±0.01a 1.67±0.03e 2.39±0.03b 1.84±0.01d 2.01±0.02c (E)-2-庚烯醛D 952.7 307.36 1.67 4.61±0.07b 5.45±0.19a 0.79±0.02d 0.71±0.01d 1.85±0.02c 正庚醛M 894.7 260.42 1.34 1.83±0.04b 1.04±0.02c 1.83±0.07b 2.67±0.05a 1.77±0.01b 正庚醛D 895.6 261.16 1.7 2.75±0.10b 2.87±0.09b 0.75±0.03d 3.35±0.07a 2.48±0.02c (E)-2-己烯醛M 839.6 229.9 1.18 1.37±0.02a 0.76±0.02b 0.69±0.01c 0.73±0.02b 0.69±0.01c (E)-2-己烯醛D 840.1 230.14 1.52 2.99±0.18a 2.50±0.03b 0.22±0.02e 0.45±0.01d 0.76±0.00c 己醛 787.3 201.54 1.56 9.61±0.35b 5.81±0.07d 10.94±0.16a 11.24±0.09a 7.95±0.27c (E)-2-戊烯醛M 743.4 182.71 1.11 1.41±0.03c 0.72±0.02e 2.09±0.04a 1.82±0.02b 0.79±0.00d (E)-2-戊烯醛D 742.3 182.22 1.36 2.54±0.13b 3.32±0.05a 0.57±0.01d 1.82±0.02c 0.71±0.01d 戊醛 693 161.44 1.42 5.14±0.17a 2.08±0.06e 3.17±0.13c 2.85±0.10d 4.08±0.03b 3-甲基丁醛 645.4 146.58 1.2 2.65±0.02a 1.91±0.04b 1.20±0.09c 0.79±0.10d 0.36±0.03e 苯乙醛 1026.4 386.82 1.26 0.15±0.02d 0.54±0.03a 0.18±0.01d 0.29±0.01c 0.39±0.00b 苯甲醛 958.6 312.12 1.15 0.76±0.01a 0.32±0.03d 0.60±0.01b 0.37±0.01c 0.39±0.01c 呋喃甲醛 821.3 220 1.34 0.46±0.01b 1.04±0.03a 0.18±0.03d 0.37±0.02c 0.32±0.03c 2-甲基丁醛 661.4 151.41 1.4 0.22±0.00d 1.53±0.07b 0.22±0.02d 0.63±0.02c 1.83±0.03a 异戊醛 643.1 145.88 1.41 0.03±0.01c 0.73±0.08a 0.06±0.01c 0.20±0.03b 0.82±0.05a 丁醛 598.9 132.57 1.29 0.39±0.00e 0.77±0.01b 0.62±0.02c 0.53±0.03d 1.44±0.01a 酮类 2-庚酮M 884.3 254.08 1.26 0.71±0.01c 0.77±0.03b 0.95±0.03a 1.00±0.02a 0.99±0.00a 2-庚酮D 883.6 253.71 1.64 0.45±0.02c 1.17±0.06b 0.21±0.01d 0.45±0.01c 1.72±0.02a 2-戊酮 682.3 157.69 1.37 0.92±0.02b 0.63±0.01c 0.34±0.01e 0.41±0.00d 1.06±0.02a 2-丁酮 593.5 130.95 1.25 3.09±0.03ab 3.44±0.15a 2.35±0.26c 1.09±0.19d 2.84±0.05b 丙酮 504.2 104.03 1.12 11.08±0.18b 6.87±0.24e 18.46±0.34a 10.39±0.23c 9.77±0.1d 2-己酮M 775.7 196.29 1.19 0.41±0.01a 0.22±0.02c 0.30±0.01b 0.28±0.01b 0.29±0.00b 2-己酮D 776.4 196.6 1.5 0.18±0.01b 0.20±0.00b 0.09±0.01d 0.120±0.00c 0.23±0.01a 3-戊酮 679.8 156.94 1.34 0.83±0.01b 0.92±0.02a 0.70±0.03c 0.52±0.03d 0.35±0.00e 3-辛酮 988.5 336.38 1.31 0.14±0.01c 0.16±0.01c 0.19±0.02c 0.35±0.05b 0.77±0.1a 酸类 己酸 910.8 382.46 1.3 0.81±0.02d 0.62±0.02e 2.18±0.02a 1.79±0.07b 1.60±0.10c 丙酸 1023.5 155.94 1.26 0.87±0.08b 0.33±0.07d 1.33±0.05a 0.67±0.09c 0.18±0.02e 戊酸 676.4 273.45 1.23 0.74±0.01b 0.29±0.05e 0.83±0.05a 0.60±0.03c 0.49±0.01d 乙酸 575 125.39 1.05 4.35±0.06c 2.17±0.10e 8.30±0.13a 5.22±0.08b 3.65±0.01d 丁酸 817.4 217.87 1.16 0.31±0.01c 0.11±0.01e 0.45±0.02a 0.34±0.01b 0.27±0.01d 呋喃类 2-庚基呋喃 1241.3 702.43 1.39 0.80±0.16cd 2.98±0.08a 1.78±0.18b 0.90±0.06c 0.55±0.03d 2-正戊基呋喃 993.9 340.74 1.25 0.26±0.01d 1.21±0.06a 0.34±0.03d 0.56±0.02c 0.99±0.01b 2-乙酰基呋喃 906.5 269.92 1.12 0.57±0.00c 1.20±0.07a 0.79±0.05b 0.48±0.02c 0.29±0.01d 吡嗪 2-甲基吡嗪 820.2 219.37 1.08 1.06±0.02a 0.76±0.03b 0.84±0.10b 0.77±0.06b 0.38±0.02c 其他 二甲基二硫 733.8 178.67 0.98 0.75±0.01d 0.26±0.03e 1.61±0.07b 0.89±0.02c 2.58±0.01a 注:RI表示保留指数;Rt表示保留时间;Dt表示迁移时间;M与D分别表示为Monomer单体与Diner二聚体;同行a~e不同字母表示显著性差异(P<0.05)。 酯类主要由有机酸和醇类酯化生成,具有怡人的果香[28]。样品中检测了5-羟基癸酸-δ-内酯、苯甲酸甲酯、己酸乙酯、乙酸异戊酯、乙酸丁酯、乙酸异丁酯、乙酸乙酯、4-羟基丁酸内酯等12种酯类化合物。5-羟基癸酸-δ-内酯能够为油莎豆油提供浓郁的牛奶、坚果和水果味[29],其在热榨油莎豆油中相对含量(2.32%±0.07%)显著高于冷榨油(0.55%±0.03%)(P<0.05),这表明温度可能对δ-十内酯的产生有具有一定的促进作用。

杂环化合物,包括呋喃类、吡嗪类和噻唑类,被认为是美拉德反应和Strecker降解反应的产物,可以导致食品的烘焙味和坚果味[30]。呋喃是油料作物加工工艺中常见的挥发性有机化合物,在油脂的风味中发挥着重要作用,为油脂提供焦糖、甜味和烘烤的风味[31]。物理压榨、热榨、亚临界萃取、高压冷榨、冷榨工艺所制油莎豆油呋喃类物质含量分别为1.63%、5.39%、2.91%、1.94%、1.83%,其中,热榨法与亚临界萃取制得油莎豆油中呋喃类物质相对含量相较于其他工艺显著较高。共在五种不同工艺油莎豆油中检测出2-庚基呋喃、2-正戊基呋喃、2-乙酰基呋喃三种呋喃类,热榨油中2-庚基呋喃、2-正戊基呋喃和2-乙酰基呋喃相对含量分别为2.98%±0.08%、1.21%±0.06%、1.20%±0.07%,显著高于其他工艺组(P<0.05),这可能是由于热榨工艺中较高的加工温度导致美拉德反应与Strecker降解反应所致。

不同工艺油莎豆油中共检测出16种醇类、9种酮类和5种酸类物质。醇类是长链酯类化合物的重要前体物质,不饱和醇类中的1-烯-3-辛醇(表3)具有较低的阈值(0.001),更易被感知,呈蘑菇香味,对油莎豆油整体风味贡献较为显著。乙醇对油脂风味具有一定的消极作用[32],虽然亚临界萃取工艺所得的油莎豆油乙醇含量相对较高(5.38%±0.11%),但其乙醇含量仍处于较低的范围,对亚临界萃取油莎豆油的整体风味起到修饰作用。大部分酮类物质具有较高的香气阈值,不易被人们所感知,在五种不同工艺制得的油莎豆油中相对含量较为相似,亚临界提取制得的油莎豆油酮类物质相对含量处于较高的水平(23.59%)。酮类物质与酸类物质都是油脂的氧化产物之一,主要通过脂质氧化、美拉德反应和醇类氧化产生[25]。物理压榨、热榨、亚临界萃取、高压冷榨、冷榨工艺所制油莎豆油酮类含量分别为17.81%、14.38%、23.59%、14.61%、18.02%,酸类含量分别为7.08%、3.52%、13.09%、8.62%、6.19%,亚临界萃取油莎豆油中醛类与酸类物质相对含量最高。其中丙酮、2-丁酮与乙酸含量处于较高水平,所有样品中均检测到较强的丙酮和乙酸信号(图4F),这可能与油脂加工过程中的氧化有关。

表 3 不同工艺油莎豆油挥发性有机化合物的ROAV值结果Table 3. Results of ROAV values of volatile organic compounds in different processes of tiger nut oil序号 化合物名称 阈值[33](μg/g) T-1 T-2 T-3 T-4 T-5 香气描述[33] 1 苯乙醇 0.211 0.06 0.05 0.26 0.05 0.06 玫瑰味 2 1-烯-3-辛醇 0.001 100 89.50 100 24.33 66.54 青草味、蘑菇味 3 壬醛 0.0031 38.76 100 97.96 100 100 青草味、甜橙味 4 (E)-2-辛烯醛 0.003 24.16 62.43 61.85 17.89 41.64 黄瓜味、鸡肉味 5 (E)-2,4-庚二烯醛 0.06 0.91 1.67 1.69 0.31 0.25 油脂味 6 正辛醛 0.17 0.45 0.36 1.00 0.74 0.79 青草味、油脂味 7 (E)-2-庚烯醛 0.75 0.16 0.17 0.63 0.10 0.19 青草味 8 正庚醛 0.25 0.31 0.32 1.46 0.45 0.50 果香味 9 (E)-2-己烯醛 0.32 0.18 0.19 0.43 0.10 0.15 芳香味、杏仁味 10 己醛 0.23 1.79 1.98 9.49 2.04 2.45 青草味、果香味 11 (E)-2-戊烯醛 0.3 0.20 0.19 1.39 0.25 0.19 — 12 戊醛 0.24 0.92 0.68 2.63 0.50 1.21 具有特殊香味 13 苯乙醛 0.022 0.29 1.92 1.64 0.55 1.25 玉簪花香气 14 2-戊基呋喃 0.1 0.11 0.95 0.67 0.24 0.70 豆香味、果香味 注:“—”表示未查询到。 表2为各个化合物相对含量,根据相对应阈值计算出不同工艺油莎豆油挥发性有机物的ROAV值,不同工艺油莎豆油风味物质的ROAV值结果如表3所示。

由表3可知,不同工艺下油莎豆油的关键挥发性香气成分差异显著,物理压榨法T-1的关键挥发性香气成分为:1-烯-3-辛醇、壬醛、(E)-2-辛烯醛、己醛;热榨法T-2的关键挥发性香气成分为:1-烯-3-辛醇、壬醛、(E)-2-辛烯醛、(E)-2,4-庚二烯醛、己醛、苯乙醛;亚临界萃取T-3的关键挥发性香气成分为:1-烯-3-辛醇、壬醛、(E)-2-辛烯醛、(E)-2,4-庚二烯醛、正辛醛、正庚醛、己醛、(E)-2-戊烯醛、戊醛、苯乙醛;高压冷榨法T-4关键挥发性香气成分为:1-烯-3-辛醇、壬醛、(E)-2-辛烯醛、己醛;冷榨法T-5关键挥发性香气成分为:1-烯-3-辛醇、壬醛、(E)-2-辛烯醛、己醛、戊醛、苯乙醛。不同工艺ROAV差异主要来源于醛类物质((E)-2,4-庚二烯醛、正辛醛、正庚醛、(E)-2-戊烯醛、戊醛、苯乙醛)。热榨工艺油莎豆油中的(E)-2,4-庚二烯醛是其关键挥发性风味物质之一(ROAV=1.67),其ROAV值明显高于高压冷榨工艺(ROAV=0.31)与冷榨工艺(ROAV=0.25)。热榨工艺制得的油莎豆油中2-戊基呋喃虽然不是关键挥发性香气物质(ROAV=0.95),但是对油莎豆油整体风味构成具有修饰作用,不同工艺之间仍具有一定差异,其ROAV值显著高于(P<0.05)高压冷榨工艺(ROAV=0.24)与冷榨工艺(ROAV=0.70)。油莎豆油中共有四种主体挥发性香气成分(ROAV≥1),分别是1-烯-3-辛醇、壬醛、(E)-2-辛烯醛和己醛,这归因于这些挥发性化合物较低的感觉阈值和较高的相对含量,剩余的挥发性化合物起修饰作用(0.1≤ROAV<1)。

综上,成功构建市售不同工艺油莎豆油的指纹图谱(图4),可以清晰、直观地观察到不同油莎豆油挥发性化合物组成的差异性,可将五种不同工艺有效区分。市售不同工艺油莎豆油风味物质种类与含量差异较大,物理压榨工艺与热榨工艺中检测出含量较高的醛类物质(54.01%、53.5%),并且热榨工艺中酯类(13.05%)与呋喃类物质(5.39%)的相对含量较高,亚临界萃取工艺生产的油莎豆油醛类物质相对含量较少(35.32%),酸类物质相对含量较多(13.09%)。通过ROAV值确定了不同工艺油莎豆油的关键风味物质为1-烯-3-辛醇、壬醛、(E)-2-辛烯醛和己醛。

2.3 不同工艺油莎豆油挥发性成分主成分分析

主成分分析是一种典型的特征提取和数据分析技术,已被广泛应用于多学科的多元统计分析[34]。主成分分析法通过确定几个主成分因子来呈现原始样本中复杂且难以发现的变量,然后根据不同样本间主成分的贡献率来评价样本间的规律性和差异性。不同工艺油莎豆油挥发性物质的主成分分析结果如图5a所示。

由图5a可知,PC1与PC2的分别为48.7%和30.1%累积贡献率达78.8%,这说明通过主成分分析能够获取表征样品挥发性成分中的大部分信息。PCA结果表明,不同工艺油莎豆油在图中占据了相对独立的空间,不同工艺油莎豆油挥发性成分差异显著。由于油莎豆油制备工艺中温度参数的不同,图中的各组数据沿纵坐标方向得到了完全的分离。最近邻指纹分析结果显示(图5b),不同工艺油莎豆油样品之间都具有一定欧氏距离,说明挥发性化合物各组分之间差异显著。但是物理压榨和热榨工艺之间、高压冷榨和冷榨工艺之间仍具有一定的欧式距离,造成这一结果的原因可能是市售油莎豆油的压榨工艺的不同[35]。

2.4 不同工艺油莎豆油理化品质与关键风味物质Pearson相关性分析

在油脂的风味物质中,醛类物质是最为重要的组成成分,其产生途径主要为脂肪酸的氧化,而不同的榨油工艺导致油料在压榨过程中油脂所受温度、氧气、光照等因素不同,进而使得产品油脂氧化程度、色泽和风味各具差异,同时致使关键性风味物质相对含量存在较大的差异性。为了探究不同工艺下油莎豆油理化品质与关键风味物质之间的关系,进行Pearson相关性分析,结果如图6所示。

由相关性分析结果可知,酸价、过氧化值和p-茴香胺值与b*之间呈显著正相关(r=0.69,r=0.87,r=0.88,P<0.05),说明有不同工艺油莎豆油的氧化程度对油脂的色泽影响显著,油莎豆油的b*越高,氧化程度也随之增加。过氧化值与风味物质正己醛呈显著负相关(r=-0.84,P<0.05),表明随着工艺温度的提高,油莎豆油中亚油酸的水解,己醛不断积累,与此同时随着工艺温度的提高,油莎豆油中过氧化物进一步分解而导致过氧化值的降低。己醛与其他三种特征挥发性物质呈正相关(0.16<r<0.69),与L*值呈正相关。氧化指标之间互呈正相关(0.39<r<0.77),1-烯-3-辛醇、壬醛、(E)-2-辛烯醛和己醛互呈正相关(0.21<r<0.68),这是可能是由于随工艺温度变化而导致的油脂氧化,致使油莎豆油氧化指标、黄蓝值b*和关键风味物质之间呈现出不同程度的正相关性。挖掘不同工艺油莎豆油理化品质与风味物质之间的内在联系有助于更深层次地理解油莎豆油风味物质的形成与油脂氧化的关系,为油莎豆油的工业化生产及其风味的理论化研究提供一定参考依据。

3. 结论

本研究采用GC-IMS技术探究了五种不同工艺油莎豆油理化指标与风味之间的差异性,理化指标结果显示,物理压榨与热榨油莎豆油的色度值b*(55.5±4.23和47.82±5.31)显著高于(P<0.05)其他工艺油莎豆油,物理压榨工艺油莎豆油的过氧化值最高(0.148 g/100 g),冷榨工艺所得油莎豆油过氧化值最低(0.079 g/100 g)氧化程度也显著高于其他工艺油莎豆油,而亚临界萃取油莎豆油的氧化程度最低;物理压榨工艺与热榨工艺所得油莎豆油具有更高的p-茴香胺值(4.20±0.12、4.86±0.15),而高压冷榨工艺所得油莎豆油的p-茴香胺值最低(1.35±0.13)。GC-IMS结果表明不同工艺油莎豆油风味物质种类与含量差异较大,物理压榨工艺与热榨工艺中检测出含量较高的醛类物质(54.01%、53.5%),并且热榨工艺中酯类(13.05%)与呋喃类物质(5.39%)的相对含量较高,亚临界萃取工艺生产的油莎豆油醛类物质相对含量较少(35.32%),酸类物质相对含量较多(13.09%)。通过ROAV值确定了不同工艺油莎豆油的关键风味物质为1-烯-3-辛醇、壬醛、(E)-2-辛烯醛和己醛。主成分分析结果表明,累计差异贡献率为78.8%(PC1和PC2分别为48.7%、30.1%),能够在一定程度上基于挥发性化合物将不同工艺油莎豆油进行良好区分。通过对比ROAV值筛选出油莎豆油中四种关键风味物质为1-烯-3-辛醇、壬醛、(E)-2-辛烯醛和己醛(ROAV≥1)。Pearson相关性分析结果表明b*与氧化指标和1-烯-3-辛醇之间呈显著正相关性(P<0.05)。本研究结果对市售油莎豆油生产加工、风味研究和质量检测等领域具有一定参考价值。

-

图 1 不同制备工艺对油莎豆油色泽的影响

注:图中不同小写字母表示存在显著性差异(P<0.05),图2同。

Figure 1. Effects of different pressing processes on the color of tiger nut oil

表 1 市售油莎豆油样品相关信息

Table 1 Relevant commodity information of tiger nut oil samples

样品 提取工艺 产地 T-1 物理压榨法 昌平,北京 T-2 热榨法 长沙,湖南 T-3 亚临界萃取 铁门关,新疆 T-4 高压冷榨法 保定,河北 T-5 冷榨法 北京 表 2 不同工艺油莎豆油挥发性成分分析

Table 2 Analysis of volatile components in tiger nut oil with different processes

化合物种类 化合物名称 RI Rt(s) Dt(ms) 相对含量(%) T-1 T-2 T-3 T-4 T-5 酯类 5-羟基癸酸-δ-内酯 1550.3 1156.21 1.43 4.18±0.16a 2.32±0.07b 1.97±0.24c 0.97±0.05d 0.55±0.03e 苯甲酸甲酯M 1088.8 478.34 1.22 2.24±0.03d 3.95±0.03b 4.96±0.12a 3.44±0.02c 2.33±0.04d 苯甲酸甲酯D 1088.8 478.34 1.6 0.30±0.03d 0.21±0.01e 0.85±0.02a 0.60±0.00b 0.46±0.02c 正己酸乙酯 1003.3 352.87 1.8 0.50±0.02d 4.86±0.02a 0.20±0.01e 1.01±0.02b 0.86±0.02c 乙酸异戊酯M 867.4 244.95 1.31 0.03±0.00d 0.19±0.00a 0.07±0.01c 0.08±0.01b 0.06±0.00c 乙酸异戊酯D 866.9 244.64 1.75 0.02±0.01d 0.24±0.01b 0.06±0.01c 0.05±0.01c 0.29±0.01a 乙酸丁酯M 801.7 209.39 1.24 0.19±0.01ab 0.14±0.01c 0.18±0.00b 0.20±0.01a 0.15±0.01c 乙酸丁酯D 799.4 208.14 1.62 0.08±0.00c 0.29±0.01a 0.05±0.01d 0.08±0.00c 0.14±0.00b 乙酸异丁酯 760.1 189.74 1.61 0.09±0.00b 0.14±0.00a 0.04±0.00c 0.03±0.00d 0.15±0.00a 乙酸乙酯 614.9 137.4 1.34 0.05±0.00e 0.29±0.00c 0.36±0.02b 0.26±0.01d 0.85±0.01a 4-羟基丁酸内酯M 911.9 274.33 1.08 0.45±0.02c 0.29±0.01d 0.44±0.03c 2.21±0.03b 2.55±0.01a 4-羟基丁酸内酯D 910.5 273.19 1.3 0.16±0.01c 0.13±0.01c 0.20±0.00c 1.07±0.06b 3.09±0.11a 醇类 苯乙醇 1116.1 518.46 1.28 0.30±0.03a 0.13±0.01b 0.28±0.03a 0.25±0.02a 0.18±0.01b 1-烯-3-辛醇 981.6 330.76 1.16 2.33±0.01a 1.15±0.06b 0.50±0.09d 0.58±0.01d 0.94±0.00c 正戊醇M 757.4 188.58 1.26 1.41±0.01b 0.68±0.02e 0.88±0.00d 1.27±0.01c 1.45±0.01a 正戊醇D 756.2 188.09 1.52 1.65±0.03b 0.89±0.00c 0.19±0.01e 0.61±0.02d 2.04±0.00a 正己醇M 861.1 241.52 1.33 0.43±0.01d 0.67±0.00c 0.34±0.02e 2.10±0.04a 1.79±0.03b 正己醇D 862.2 242.14 1.65 0.08±0.01d 0.43±0.02c 0.09±0.02d 0.89±0.02b 2.12±0.04a 异戊醇M 723.1 174.15 1.25 0.16±0.01e 0.46±0.02b 0.25±0.02d 0.38±0.01c 0.55±0.01a 异戊醇D 723.1 174.15 1.49 0.04±0.01e 0.99±0.03a 0.07±0.00d 0.11±0.01c 0.58±0.00b 异丁醇M 622.2 139.61 1.17 0.33±0.01c 0.39±0.01c 1.91±0.10a 0.38±0.01c 0.60±0.01b 异丁醇D 621.6 139.44 1.37 0.04±0.01e 0.27±0.01c 1.55±0.05a 0.10±0.01d 0.38±0.01b 乙醇 474.8 95.18 1.05 0.77±0.01e 1.04±0.02d 5.38±0.11a 1.44±0.04c 2.37±0.09b 庚醇 974.7 325.21 1.4 0.77±0.04c 0.73±0.02c 0.59±0.06d 1.23±0.04b 1.45±0.03a 甲基苯甲醇 1050.3 421.79 1.19 0.21±0.01c 0.13±0.01d 0.15±0.01d 0.32±0.00b 0.51±0.02a 2-甲基-1-丁醇M 745.3 183.49 1.22 0.16±0.01b 0.09±0.01c 0.17±0.02b 0.23±0.01a 0.25±0.01a 2-甲基-1-丁醇D 744.8 183.29 1.49 0.10±0.00e 0.20±0.00c 0.15±0.01d 0.29±0.01b 0.42±0.01a 1-辛醇 1075.4 458.66 1.48 0.59±0.03c 0.86±0.07b 0.67±0.07c 0.98±0.03a 0.98±0.01a 醛类 2-十一烯醛 1392.3 924.14 1.49 2.61±0.14b 3.42±0.10a 2.53±0.13b 2.46±0.10b 1.39±0.05c (E)-2-壬烯醛 1181.9 615.08 1.41 0.71±0.05c 1.01±0.02a 1.09±0.01a 0.72±0.05c 0.87±0.01b 壬醛M 1104.1 500.83 1.48 2.80±0.00d 3.96±0.00c 1.52±0.06e 7.41±0.06a 4.37±0.02b 壬醛D 1104.1 500.83 1.95 0.51±0.02c 3.32±0.13a 0.26±0.01d 3.18±0.06a 1.48±0.01b (E)-2-辛烯醛M 1052.8 425.46 1.33 1.69±0.00b 2.39±0.06d 0.93±0.03e 1.28±0.04c 1.76±0.04b (E)-2-辛烯醛D 1052.8 425.46 1.82 0.34±0.01b 1.24±0.08a 0.16±0.02c 0.19±0.01c 0.38±0.01b (E,E)-2,4-庚二烯醛M 1010.7 363.63 1.2 1.28±0.01a 1.28±0.03a 0.51±0.04b 0.44±0.01c 0.21±0.01d (E,E)-2,4-庚二烯醛D 1010.7 363.63 1.62 0.26±0.02b 0.90±0.08a 0.15±0.01c 0.13±0.01c 0.11±0.00c 2,4-庚二烯醛M 999.5 347.2 1.2 1.09±0.01a 0.60±0.01b 0.60±0.03b 0.45±0.02c 0.22±0.01d 2,4-庚二烯醛D 1000.1 348.14 1.63 0.37±0.01b 0.78±0.04a 0.12±0.01d 0.16±0.01cd 0.17±0.02c 正辛醛M 1004.3 354.24 1.41 1.79±0.01c 0.77±0.00e 0.85±0.06d 3.00±0.03a 1.88±0.01b 正辛醛D 1004.3 354.24 1.83 0.90±0.01c 0.77±0.02d 0.10±0.01e 1.81±0.03a 1.38±0.00b (E)-2-庚烯醛M 953.2 307.73 1.26 2.75±0.01a 1.67±0.03e 2.39±0.03b 1.84±0.01d 2.01±0.02c (E)-2-庚烯醛D 952.7 307.36 1.67 4.61±0.07b 5.45±0.19a 0.79±0.02d 0.71±0.01d 1.85±0.02c 正庚醛M 894.7 260.42 1.34 1.83±0.04b 1.04±0.02c 1.83±0.07b 2.67±0.05a 1.77±0.01b 正庚醛D 895.6 261.16 1.7 2.75±0.10b 2.87±0.09b 0.75±0.03d 3.35±0.07a 2.48±0.02c (E)-2-己烯醛M 839.6 229.9 1.18 1.37±0.02a 0.76±0.02b 0.69±0.01c 0.73±0.02b 0.69±0.01c (E)-2-己烯醛D 840.1 230.14 1.52 2.99±0.18a 2.50±0.03b 0.22±0.02e 0.45±0.01d 0.76±0.00c 己醛 787.3 201.54 1.56 9.61±0.35b 5.81±0.07d 10.94±0.16a 11.24±0.09a 7.95±0.27c (E)-2-戊烯醛M 743.4 182.71 1.11 1.41±0.03c 0.72±0.02e 2.09±0.04a 1.82±0.02b 0.79±0.00d (E)-2-戊烯醛D 742.3 182.22 1.36 2.54±0.13b 3.32±0.05a 0.57±0.01d 1.82±0.02c 0.71±0.01d 戊醛 693 161.44 1.42 5.14±0.17a 2.08±0.06e 3.17±0.13c 2.85±0.10d 4.08±0.03b 3-甲基丁醛 645.4 146.58 1.2 2.65±0.02a 1.91±0.04b 1.20±0.09c 0.79±0.10d 0.36±0.03e 苯乙醛 1026.4 386.82 1.26 0.15±0.02d 0.54±0.03a 0.18±0.01d 0.29±0.01c 0.39±0.00b 苯甲醛 958.6 312.12 1.15 0.76±0.01a 0.32±0.03d 0.60±0.01b 0.37±0.01c 0.39±0.01c 呋喃甲醛 821.3 220 1.34 0.46±0.01b 1.04±0.03a 0.18±0.03d 0.37±0.02c 0.32±0.03c 2-甲基丁醛 661.4 151.41 1.4 0.22±0.00d 1.53±0.07b 0.22±0.02d 0.63±0.02c 1.83±0.03a 异戊醛 643.1 145.88 1.41 0.03±0.01c 0.73±0.08a 0.06±0.01c 0.20±0.03b 0.82±0.05a 丁醛 598.9 132.57 1.29 0.39±0.00e 0.77±0.01b 0.62±0.02c 0.53±0.03d 1.44±0.01a 酮类 2-庚酮M 884.3 254.08 1.26 0.71±0.01c 0.77±0.03b 0.95±0.03a 1.00±0.02a 0.99±0.00a 2-庚酮D 883.6 253.71 1.64 0.45±0.02c 1.17±0.06b 0.21±0.01d 0.45±0.01c 1.72±0.02a 2-戊酮 682.3 157.69 1.37 0.92±0.02b 0.63±0.01c 0.34±0.01e 0.41±0.00d 1.06±0.02a 2-丁酮 593.5 130.95 1.25 3.09±0.03ab 3.44±0.15a 2.35±0.26c 1.09±0.19d 2.84±0.05b 丙酮 504.2 104.03 1.12 11.08±0.18b 6.87±0.24e 18.46±0.34a 10.39±0.23c 9.77±0.1d 2-己酮M 775.7 196.29 1.19 0.41±0.01a 0.22±0.02c 0.30±0.01b 0.28±0.01b 0.29±0.00b 2-己酮D 776.4 196.6 1.5 0.18±0.01b 0.20±0.00b 0.09±0.01d 0.120±0.00c 0.23±0.01a 3-戊酮 679.8 156.94 1.34 0.83±0.01b 0.92±0.02a 0.70±0.03c 0.52±0.03d 0.35±0.00e 3-辛酮 988.5 336.38 1.31 0.14±0.01c 0.16±0.01c 0.19±0.02c 0.35±0.05b 0.77±0.1a 酸类 己酸 910.8 382.46 1.3 0.81±0.02d 0.62±0.02e 2.18±0.02a 1.79±0.07b 1.60±0.10c 丙酸 1023.5 155.94 1.26 0.87±0.08b 0.33±0.07d 1.33±0.05a 0.67±0.09c 0.18±0.02e 戊酸 676.4 273.45 1.23 0.74±0.01b 0.29±0.05e 0.83±0.05a 0.60±0.03c 0.49±0.01d 乙酸 575 125.39 1.05 4.35±0.06c 2.17±0.10e 8.30±0.13a 5.22±0.08b 3.65±0.01d 丁酸 817.4 217.87 1.16 0.31±0.01c 0.11±0.01e 0.45±0.02a 0.34±0.01b 0.27±0.01d 呋喃类 2-庚基呋喃 1241.3 702.43 1.39 0.80±0.16cd 2.98±0.08a 1.78±0.18b 0.90±0.06c 0.55±0.03d 2-正戊基呋喃 993.9 340.74 1.25 0.26±0.01d 1.21±0.06a 0.34±0.03d 0.56±0.02c 0.99±0.01b 2-乙酰基呋喃 906.5 269.92 1.12 0.57±0.00c 1.20±0.07a 0.79±0.05b 0.48±0.02c 0.29±0.01d 吡嗪 2-甲基吡嗪 820.2 219.37 1.08 1.06±0.02a 0.76±0.03b 0.84±0.10b 0.77±0.06b 0.38±0.02c 其他 二甲基二硫 733.8 178.67 0.98 0.75±0.01d 0.26±0.03e 1.61±0.07b 0.89±0.02c 2.58±0.01a 注:RI表示保留指数;Rt表示保留时间;Dt表示迁移时间;M与D分别表示为Monomer单体与Diner二聚体;同行a~e不同字母表示显著性差异(P<0.05)。 表 3 不同工艺油莎豆油挥发性有机化合物的ROAV值结果

Table 3 Results of ROAV values of volatile organic compounds in different processes of tiger nut oil

序号 化合物名称 阈值[33](μg/g) T-1 T-2 T-3 T-4 T-5 香气描述[33] 1 苯乙醇 0.211 0.06 0.05 0.26 0.05 0.06 玫瑰味 2 1-烯-3-辛醇 0.001 100 89.50 100 24.33 66.54 青草味、蘑菇味 3 壬醛 0.0031 38.76 100 97.96 100 100 青草味、甜橙味 4 (E)-2-辛烯醛 0.003 24.16 62.43 61.85 17.89 41.64 黄瓜味、鸡肉味 5 (E)-2,4-庚二烯醛 0.06 0.91 1.67 1.69 0.31 0.25 油脂味 6 正辛醛 0.17 0.45 0.36 1.00 0.74 0.79 青草味、油脂味 7 (E)-2-庚烯醛 0.75 0.16 0.17 0.63 0.10 0.19 青草味 8 正庚醛 0.25 0.31 0.32 1.46 0.45 0.50 果香味 9 (E)-2-己烯醛 0.32 0.18 0.19 0.43 0.10 0.15 芳香味、杏仁味 10 己醛 0.23 1.79 1.98 9.49 2.04 2.45 青草味、果香味 11 (E)-2-戊烯醛 0.3 0.20 0.19 1.39 0.25 0.19 — 12 戊醛 0.24 0.92 0.68 2.63 0.50 1.21 具有特殊香味 13 苯乙醛 0.022 0.29 1.92 1.64 0.55 1.25 玉簪花香气 14 2-戊基呋喃 0.1 0.11 0.95 0.67 0.24 0.70 豆香味、果香味 注:“—”表示未查询到。 -

[1] YU Y, LU X, ZHANG T, et al. Tiger nut (Cyperus esculentus L.):Nutrition, processing, function and applications[J]. Foods,2022,11(4):601−604. doi: 10.3390/foods11040601

[2] LIU X, WANG S, TAMOGAMI S, et al. Volatile profile and flavor characteristics of ten edible oils[J]. Analytical Letters,2020,54(9):1423−1438.

[3] EZEH O, GORDON M H, NIRANJAN K. Tiger nut oil ( Cyperus esculentus L. ):A review of its composition and physico-chemical properties[J]. European Journal of Lipid Science and Technology,2014,116(7):783−794.

[4] CHEN T, QI X, LU D, et al. Gas chromatography-ion mobility spectrometric classification of vegetable oils based on digital image processing[J]. Journal of Food Measurement and Characterization,2019,13(3):1973−1979. doi: 10.1007/s11694-019-00116-5

[5] 李志军, 王绛, 刘和, 等. 油莎豆产业发展现状及建议[J]. 现代农业科技,2022(8):225−231. [LI Zhijun, WANG Jiang, LIU He, et al. Current situation and suggestions on the development of Cyperus esculentus industry[J]. Modern Agricultural Science and Technology,2022(8):225−231.] doi: 10.3969/j.issn.1007-5739.2022.08.072 LI Zhijun, WANG Jiang, LIU He, et al. Current situation and suggestions on the development of Cyperus esculentus industry[J]. Modern Agricultural Science and Technology, 2022(8): 225−231. doi: 10.3969/j.issn.1007-5739.2022.08.072

[6] 杨帆, 朱文学. 油莎豆研究现状及展望[J]. 粮食与油脂,2020,33(7):4−6. [YANG Fan, ZHU Wenxue. Research status and prospect ofCyperus esculentus[J]. Grain and Oil,2020,33(7):4−6.] YANG Fan, ZHU Wenxue. Research status and prospect of Cyperus esculentus[J]. Grain and Oil, 2020, 33(7): 4−6.

[7] 刘红艳, 王丽华, 刘意元. 我国油莎豆制品开发现状[J]. 农产品加工,2021(14):97−99. [LIU Hongyan, WANG Lihua, LIU Yiyuan. Current situation of bean products development in Cyperus esculentus[J]. Agricultural Products Processing,2021(14):97−99.] LIU Hongyan, WANG Lihua, LIU Yiyuan. Current situation of bean products development in Cyperus esculentus[J]. Agricultural Products Processing, 2021(14): 97−99.

[8] 蒋凌燕, 朱翔, 赵麟, 等. 不同加工工艺藤椒油的麻味物质和风味成分研究[J]. 食品与发酵工业,2023,49(2):202−211. [JIANG Lingyan, ZHU Xiang, ZHAO Lin, et al. Study on the hemp flavor and flavor components of Zanthoxylum bungeanum oil with different processing techniques[J]. Food and Fermentation Industry,2023,49(2):202−211.] JIANG Lingyan, ZHU Xiang, ZHAO Lin, et al. Study on the hemp flavor and flavor components of Zanthoxylum bungeanum oil with different processing techniques[J]. Food and Fermentation Industry, 2023, 49(2): 202−211.

[9] 周易枚, 吴达, 蒋林惠, 等. 两种不同工艺制取芝麻油中的挥发性风味物质的鉴别分析[J/OL]. 中国油脂:1−11[2023-04-06]. http://kns.cnki.net/kcms/detail/61.1099.TS.20220915.0854.002.html. [ZHOU Yimei, WU Da, JIANG Linhui, et al. Identification and analysis of volatile flavor compounds in sesame oil prepared by two different processes [J/OL]. China Oil:1−11[2023-04-06]. http://kns.cnki.net/kcms/detail/61.1099.TS.20220915.0854.002.html.] ZHOU Yimei, WU Da, JIANG Linhui, et al. Identification and analysis of volatile flavor compounds in sesame oil prepared by two different processes [J/OL]. China Oil: 1−11[2023-04-06]. http://kns.cnki.net/kcms/detail/61.1099.TS.20220915.0854.002.html.

[10] 夏纯凤, 吴苏喜, 王彦心, 等. 基于气相-离子迁移谱技术分析热榨和湿法制油工艺油茶籽油风味的差异[J/OL]. 中国油脂:1−8 [2023-04-06]. http://kns.cnki.net/kcms/detail/61.1099.TS.20220516.1740.004.html. [XIA Chunfeng, WU Suxi, WANG Yanxin, et al. Analysis of flavor differences of oil-tea seed oil processed by hot pressing and wet method based on gas phase-ion mobility spectrometry [J/OL]. China Grease:1−8 [2023-04-06]. http://kns.cnki.net/kcms/detail/61.1099.TS.20220516.1740.004.html.] XIA Chunfeng, WU Suxi, WANG Yanxin, et al. Analysis of flavor differences of oil-tea seed oil processed by hot pressing and wet method based on gas phase-ion mobility spectrometry [J/OL]. China Grease: 1−8 [2023-04-06]. http://kns.cnki.net/kcms/detail/61.1099.TS.20220516.1740.004.html.

[11] WANG S, CHEN H, SUN B. Recent progress in food flavor analysis using gas chromatography-ion mobility spectrometry (GC-IMS)[J]. Food Chemistry,2020(315):126158.

[12] BARBIERI S, CEVOLI C, BENDINI A, et al. Flash gas chromatography in tandem with chemometrics:A rapid screening tool for quality grades of virgin olive oils[J]. Foods,2020,9(7):862−865. doi: 10.3390/foods9070862

[13] 杨永兴, 孟新涛, 许铭强, 等. 基于GC-IMS技术分析不同提取方式对辣椒籽油挥发性成分的影响[J]. 食品研究与开发,2023,44(6):184−192. [YANG Yongxing, MENG Xintao, XU Mingqiang, et al. Effects of different extraction methods on volatile components of pepper seed oil based on GC-IMS technology[J]. Food Research and Development,2023,44(6):184−192.] YANG Yongxing, MENG Xintao, XU Mingqiang, et al. Effects of different extraction methods on volatile components of pepper seed oil based on GC-IMS technology[J]. Food Research and Development, 2023, 44(6): 184−192.

[14] 杨芳, 袁海彬, 贾洪锋, 等. 基于GC-IMS结合多元统计方法分析辣椒品种对辣椒油理化性质和风味物质的影响[J/OL]. 食品与发酵工业:1−13 [2023-04-06]. doi:10.13995/j.cnki.11-1802/ts.033362. [YANG Fang, YUAN Haibin, JIA Hongfeng, et al. Analysis of the effects of pepper varieties on the physical and chemical properties and flavor substances of pepper oil based on GC-IMS and multivariate statistical methods [J/OL]. Food and Fermentation Industry:1−13[2023-04-06]. doi:10.13995/j.cnki.11-1802/ts.033362.] YANG Fang, YUAN Haibin, JIA Hongfeng, et al. Analysis of the effects of pepper varieties on the physical and chemical properties and flavor substances of pepper oil based on GC-IMS and multivariate statistical methods [J/OL]. Food and Fermentation Industry: 1−13[2023-04-06]. doi: 10.13995/j.cnki.11-1802/ts.033362.

[15] 陈丽兰, 杨心怡, 乔明锋, 等. 基于 GC-IMS、GC-MS和OAV法分析花椒粉颗粒度对花椒油挥发性香气成分的影响[J]. 食品工业科技,2023,44(80):301−310. [CHEN Lilan, YANG Xinyi, QIAO Mingfeng, et al. Analysis of the effect of pepper powder granularity on volatile aroma components of pepper oil based on GC-IMS, GC-MS and OAV methods[J]. Science and Technology of Food Industry,2023,44(80):301−310.] CHEN Lilan, YANG Xinyi, QIAO Mingfeng, et al. Analysis of the effect of pepper powder granularity on volatile aroma components of pepper oil based on GC-IMS, GC-MS and OAV methods[J]. Science and Technology of Food Industry, 2023, 44(80): 301−310.

[16] 白万明, 王菊花, 马赛买, 等. 基于GC-IMS分析陇南主栽品种初榨橄榄油的风味特征成分[J/OL]. 中国油脂:1−13. [2023-04-06]. doi:10.19902/j.cnki.zgyz.1003-7969.220666. [BAI Wanming, WANG Juhua, MA Saibai, et al. Analysis of flavor components of virgin olive oil from Longnan main cultivars based on GC-IMS[J/OL]. China Fats and Oils:1−13. [2023-04-06]. doi:10.19902/j.cnki.zgyz.1003-7969.220666.] BAI Wanming, WANG Juhua, MA Saibai, et al. Analysis of flavor components of virgin olive oil from Longnan main cultivars based on GC-IMS[J/OL]. China Fats and Oils: 1−13. [2023-04-06]. doi: 10.19902/j.cnki.zgyz.1003-7969.220666.

[17] 马士成, 王梦琪, 刘春梅, 等. 六堡茶挥发性成分中关键香气成分分析[J]. 食品科学,2020,41(20):191−197. [MA Shicheng, WANG Mengqi, LIU Chunmei, et al. Analysis of key aroma components in volatile components of Liubao tea[J]. Food Science,2020,41(20):191−197.] MA Shicheng, WANG Mengqi, LIU Chunmei, et al. Analysis of key aroma components in volatile components of Liubao tea[J]. Food Science, 2020, 41(20): 191−197.

[18] LI M Q, YANG R W, ZHANG H, et al. Development of a flavor fingerprint by HS-GC-IMS with PCA for volatile compounds of Tricholoma matsutake Singer[J]. Food Chemistry,2019,290:32−39. doi: 10.1016/j.foodchem.2019.03.124

[19] 符成刚, 刘文玉, 陈友志, 等. 加热温度对新疆马脂理化性质、脂肪酸及挥发性风味化合物的影响[J]. 食品科学,2021,42(16):54−60. [FU Chenggang, LIU Wenyu, CHEN Youzhi, et al. Effects of heating temperature on physicochemical properties, fatty acids and volatile flavor compounds of Xinjiang horse fat[J]. Food Science,2021,42(16):54−60.] FU Chenggang, LIU Wenyu, CHEN Youzhi, et al. Effects of heating temperature on physicochemical properties, fatty acids and volatile flavor compounds of Xinjiang horse fat[J]. Food Science, 2021, 42(16): 54−60.

[20] 张翼鹏, 段焰青, 刘自单, 等. 美拉德反应在食品和生物医药产业中的应用研究进展[J]. 云南大学学报(自然科学版),2022,44(1):203−212. [ZHANG Yipeng, DUAN Yanqing, LIU Zidan, et al. Research progress of Maillard reaction in food and biomedical industry[J]. Journal of Yunnan University (Natural Science Edition),2022,44(1):203−212.] ZHANG Yipeng, DUAN Yanqing, LIU Zidan, et al. Research progress of Maillard reaction in food and biomedical industry[J]. Journal of Yunnan University (Natural Science Edition), 2022, 44(1): 203−212.

[21] 王亚杰, 韩佳佳, 谭志发, 等. 制备工艺对油莎豆油理化性质、营养成分和氧化稳定性的影响[J/OL]. 食品科学:1−12. [2023-04-06]. http://kns.cnki.net/kcms/detail/11.2206.TS.20220729.1059.058.html. [WANG Yajie, HAN Jiajia, TAN Zhifa, et al. Effect of preparation process on physicochemical properties, nutritional composition and oxidative stability of Olea europaea oil[J/OL]. Food Science:1−12. [2023-04-06]. http://kns.cnki.net/kcms/detail/11.2206.TS.20220729.1059.058.] WANG Yajie, HAN Jiajia, TAN Zhifa, et al. Effect of preparation process on physicochemical properties, nutritional composition and oxidative stability of Olea europaea oil[J/OL]. Food Science: 1−12. [2023-04-06]. http://kns.cnki.net/kcms/detail/11.2206.TS.20220729.1059.058.

[22] 孙雪莲, 张波, 魏长庆, 等. 冷榨胡麻油在加速氧化过程中品质变化的研究[J]. 中国粮油学报,2022,37(7):115−121. [SUN Xuelian, ZHANG Bo, WEI Changqing, et al. Study on quality change of cold-pressed linseed oil during accelerated oxidation[J]. Journal of China Cereals and Oils,2022,37(7):115−121.] SUN Xuelian, ZHANG Bo, WEI Changqing, et al. Study on quality change of cold-pressed linseed oil during accelerated oxidation[J]. Journal of China Cereals and Oils, 2022, 37(7): 115−121.

[23] CHEN T, CHEN X, LU D, et al. Detection of adulteration in canola oil by using GC-IMS and chemometric analysis[J]. International Journal Analytical Chemistry,2018(2018):316265.

[24] 周靖, 刘文玉, 陈友志, 等. 制备工艺对番茄籽油品质的影响[J]. 食品科学,2022,43(5):76−83. [ZHOU Jing, LIU Wenyu, CHEN Youzhi, et al. Effect of preparation technology on the quality of tomato seed oil[J]. Food Science,2022,43(5):76−83.] ZHOU Jing, LIU Wenyu, CHEN Youzhi, et al. Effect of preparation technology on the quality of tomato seed oil[J]. Food Science, 2022, 43(5): 76−83.

[25] STUMPF P. Lipid metabolism[J]. Annual Review of Biochemistry,1960,29:261−294. doi: 10.1146/annurev.bi.29.070160.001401

[26] CHOE E, MIN D B. Mechanisms and factors for edible oil oxidation[J]. Comprehensive Reviews in Food Science and Food safty,2006,5(4):169−186. doi: 10.1111/j.1541-4337.2006.00009.x

[27] KALUA C M, ALLEN M S, BEDGOOD D R, et al. Olive oil volatile compounds, flavour development and quality:A critical review[J]. Food Chemistry,2007,100(1):273−286. doi: 10.1016/j.foodchem.2005.09.059

[28] SUN X, WANG Y, LI H, et al. Changes in the volatile profile, fatty acid composition and oxidative stability of flaxseed oil during heating at different temperatures[J]. LWT-Food Science and Technology,2021(10):112137.

[29] MULYADI A F, SCHREINER M, DEWI I A. Phenolic and volatile compounds, antioxidant activity, and sensory properties of virgin coconut oil:Occurrence and their relationship with quality[J]. The 8th Annual Basic Science International Conference:Coverage of Basic Sciences toward the World’s Sustainability Challanges, 2018:2−5.

[30] ALLEN R R, FORMO M W, KRISHNAMURTHY R G, et al. Bailey's industrial oil and fat products[M]. 1982:15−25.

[31] ELMONFALOUTI H, CHARROUF Z, GIORDANO M, et al. Volatile compound formation during Argan Kernel roasting[J]. Natural Product Communications,2013,8(1):33−36.

[32] LEE S, CHO H, LEE K G. Volatile compounds as markers of tofu (soybean curd) freshness during storage[J]. Journal of Agricultural Food Chemistry,2014,62(3):772−779. doi: 10.1021/jf404847g

[33] 里奥·范海默特. 化合物香味阈值汇编[M]. 化合物香味阈值汇编, 2015. [VAN GEMERT L J. Compilation of aroma thresholds of compounds[M]. Compilation of Aroma Thresholds of Compounds, 2015.] VAN GEMERT L J. Compilation of aroma thresholds of compounds[M]. Compilation of Aroma Thresholds of Compounds, 2015.

[34] JOLLIFFE I T, CADIMA J. Principal component analysis:A review and recent developments[J]. Philosophical Transactions of the Royal Society Mathematical Physical & Engineering Sciences,2016,374(2065):20150202.

[35] DUN Q, YAO L, DENG Z, et al. Effects of hot and cold-presse1d processes on volatile compounds of peanut oil and corresponding analysis of characteristic flavor components[J]. LWT-Food Science and Technology,2019,112:107648−107648. doi: 10.1016/j.lwt.2018.11.084

下载:

下载:

下载:

下载: