Effect of Freezing-thawing Cycle on the Quality of Prefabricated Mushroom Soup

-

摘要: 为探究冻融循环对食用菌预制菌汤的品质影响,本文以鲜菌汤为参照,对比了冻融过程中微生物数量、菌汤色泽、可溶性蛋白、还原糖、总酚含量等基本指标的变化,并基于超高效液相检测和气相色谱-质谱法分析冻融过程菌汤等鲜度和挥发性风味物质差异。研究表明,首次冻融大幅减少了菌汤的还原糖、总酚和总氨基酸含量,显著降低了菌汤等鲜度和挥发性成分含量,综合影响了菌汤的成分与风味。进一步通过冻融次数(1~5次)之间的对比,反复冻融3次菌汤可溶性蛋白含量相较于冻融1~2次显著降低(P<0.05),此外,等鲜度由1~2次冻融的0.441~0.450 g MSG/100 g直接下降至0.407 g MSG/100 g,同时微生物开始检出。在此后4~5次冻融过程中,虽然菌汤总酚、总氨基酸含量和等鲜度相对稳定,但核苷酸、可溶性蛋白和挥发性成分不断减少且菌落总数不断升高。因此,预制菌汤若需冻融处理则应控制在2次内为宜。Abstract: To investigate the influence of freezing-thawing cycle on the quality of prefabricated mushroom soup, the differences in the basic indicators of mushroom soup including microbial quantity, color, soluble protein, reducing sugar, and total phenolic content were compared among unfrozen samples (control) and repeated freezing-thawing samples. Besides that, the equivalent umami concentration (EUC) values and volatile flavor compounds in those prefabricated mushroom soup were further analyzed by high performance liquid chromatography (HPLC) and gas chromatography-mass spectrometry (GC-MS), respectively. The results showed that the first freezing-thawing treatment comprehensively affected the quality of prefabricated mushroom soup by decreasing the content of basic components (reducing sugar, total phenolics and total amino acids) and flavor (EUC value and volatile components) of mushroom soup obviously. The effect of freezing-thawing cycles (1~5 cycles) on the quality of mushroom soup was further compared. When the mushroom soup was frozen and thawed for three times, the content of soluble protein in the soup decreased significantly (P<0.05), in addition, the EUC value greatly decreased from 0.441~0.450 g MSG/100 g (1~2 freezing-thawing treatments) to 0.407 g MSG/100 g. Microorganisms began to be detected in the third freezing-thawing prefabricated mushroom soup. In the subsequent freezing-thawing treatments (4~5 times), the content of total phenolics, total amino acids, and EUC value of the mushroom soup were relatively stable, while the content of nucleotides, soluble proteins, and volatile components continuously decreased, together with the bacteria kept proliferating. Consequently, the freezing-thawing times of prefabricated mushroom soup could be monitored in twice for final consumption.

-

预制菜以农产品为主要原料,经标准化加工、包装而成,简化了菜品制作流程,用餐方便快捷、营养卫生[1−2]。近年,受疫情防控的影响及冷链技术水平的逐步完善,预制食品在居家消费的推动下走俏市场[3]。据统计,2021年我国预制菜市场规模超3000亿,预计到2025年,预制菜市场规模将会达8000亿元[4]。具有地方特色的预制菜工业化加工技术将成为该行业的核心竞争力。

食用菌风味独特、营养丰富,富含蛋白质、氨基酸、膳食纤维、维生素、矿物质、多糖、甾醇等营养成分,具有抗炎、抗肿瘤、抗氧化等功效[5−7]。此外,食用菌经加工、冷冻、复热后还能大幅度保持原有口感,是预制食品的优质原料[8−10]。“宁可食无肉,不可食无汤”,菌菇汤因其特有的营养、风味和口感,深受消费者欢迎。世界卫生组织也将菌菇汤列为六大保健饮品[11−12]。因此菌汤类食品的开发可进一步促进食用菌的精深加工,丰富预制菜品,满足市场需求。

低温冻藏是保障菌汤类预制食品品质的主要贮藏和流通方式。但是,在冷链转运或消费终端,冷冻菌汤在食用前可能出现反复冻融的情况。相关研究表明,冻融循环会造成肉制品、水产品和果蔬制品的色泽变化、风味衰减、品质劣变等不良后果。然而,冻融循环如何影响预制菌汤的品质尚未报道,冻融次数对菌汤品质影响的差异有待进一步对比[13−14]。因此,针对食用菌预制菌汤在消费终端可能出现的冻融情况,本研究以菌汤色泽、成分和风味为目标,评价冻融次数对预制菌汤的品质影响,为食用菌预制菌汤的终端消费提供食用参考。

1. 材料与方法

1.1 材料与仪器

羊肚菌、鸡油菌、蛹虫草、雪山松茸、姬松茸、鹿茸菇 2022年购于湖北伏龙山食品开发有限公司;DNS试剂、游离氨基酸和核苷酸 北京索莱宝科技有限公司;考马斯亮蓝G250、Folin-Ciocalteu 试剂 源叶生物科技有限公司;微生物检测纸片 广东达元绿洲食品安全科技股份有限公司。

Multiskan GO酶标仪 美国Thermo Fisher公司;LC-20AT 液相色谱系统 日本Shimadzu公司;PEN3电子鼻 德国Airsense公司;7890A-5975C气质联用设备 美国Agilent公司;CR-400色差仪 日本Minolta Camera公司;WQC50A5电高压锅 美的公司。

1.2 实验方法

1.2.1 预制菌汤的制作

选取云南昭通市的六珍菌汤包为实验原料,根据菌汤包各种菌菇的商业配比,结合菌汤感官评价,最终确定预制菌汤的制作方案:羊肚菌1.6 g、鸡油菌12 g、蛹虫草12 g、雪山松茸12 g、姬松茸4.0 g、鹿茸菇16 g,混合,清洗后泡发1 h,沥干后加水2 L(盐0.4%)。用电高压锅1000 W处理30 min后,开盖,漏勺过滤,终体积为1.99 L,铝箔分装(450 mL/袋),−18 ℃冻藏,备用。

1.2.2 菌汤冻融处理

−18 ℃冷冻状态菌汤置于4 ℃下解冻24 h,即为一次冻融样品,将解冻后的菌汤继续置于−18 ℃冷冻,重复上述操作,即为二次冻融,依此类推,共进行五次冻融处理。

1.2.3 菌汤基本指标分析

微生物计数分析:采用大肠菌群测试片和菌落总数测试片进行大肠杆菌和总菌落数的计数分析。取1 mL菌汤,稀释,涂布于测试片,37 ℃培养24 h,计数。

菌汤色度分析:将100 mL菌汤置于样品池中,经白板校准后,对菌汤进行L、a、b读数、测量[15]。

菌汤可溶性蛋白含量分析:采用考马斯亮蓝法检测菌汤可溶性蛋白含量,结果以每升菌汤中牛血清蛋白(BSA)当量计(g BSA/L)[16]。

菌汤还原糖含量分析:采用DNS法检测菌汤还原糖含量,结果以每升菌汤中葡萄糖(Glu)当量计(g Glu/L)。

菌汤总酚含量分析:采用Folin-Ciocalteu方法检测菌汤中的总酚含量(TPC),结果以每升菌汤中没食子酸(GAE)当量计(g GAE/L)[17]。

1.2.4 菌汤5'-核苷酸含量分析

采用HPLC检测菌汤中5'-核苷酸含量。菌汤5000 r/min离心10 min后,过0.22 μm有机滤膜,进行HPLC分析。参数设置为:流动相为A,20 mmol/L磷酸盐缓冲液(pH5.9);流动相B,100%甲醇;两者以97:3比例混合,等度洗脱。流速0.4 mL/min,进样量10 µL,在254 nm处检测。采用外标法定量分析,结果折算为每升菌汤中5'-核苷酸含量(mg/L)[18]。

1.2.5 菌汤氨基酸含量分析

采用HPLC检测菌汤中衍生化的游离氨基酸含量。取样品或游离氨基酸标准品200 μL,分别加入三乙胺溶液100 μL和异硫氰酸苯酯溶液100 μL,放置1 h,加入400 μL正己烷,振荡,静置。取下相过滤后HPLC进样,采用Sepax AAA(4.6 mm×250 mm,5 μm)氨基酸专用柱分析;流动相A:0.1 mol/L醋酸钠(pH6.5):乙腈=93:7,流动相B:80%乙腈水溶液。梯度洗脱:0 min:100% A,15 min:85% A,18 min:76% A,25 min:60% A,30 min:60% A,30.1 min:0% A,35 min:0% A;流速:1.0 mL/min;254 nm处检测;柱温:40 ℃;进样量:5 μL。采用外标法定量分析,结果折算为每100毫升菌汤中游离氨基酸含量(mg/100 mL)[19]。

1.2.6 菌汤等鲜度计算

菌汤等鲜度(EUC),由鲜味氨基酸与5'-核苷酸之间的相互作用计算而得,结果表示为每100 g菌汤中谷氨酸钠当量(g MSG/100 g)[20]:

EUC=∑aibi+1218(∑aibi)(∑ajbj) 式中:ai,鲜味氨基酸Glu或Asp的浓度(g/100 g);aj,5'-GMP,5'-AMP,5'-IMP或5'-XMP的浓度(g/100 g);bi,鲜味氨基酸的相对鲜味浓度(Asp,0.077;Glu,1);bj,5’-核苷酸的相对鲜味浓度(5'-IMP,1;5'-GMP,2.3;5'-AMP,0.18;5'-XMP,0.61)。

1.2.7 菌汤挥发性成分分析

采用GC-MS对菌汤挥发性成分进行分析,10 mL菌汤置于40 mL的顶空瓶中,40 ℃条件下水浴10 min,插入DVB/CAR/PDMS 50/30 μm萃取头,顶空吸附35 min后,插入GC进样口,250 ℃下解吸5 min[21]。程序升温和质谱条件参考之前的研究[22]。列出与质谱数据库(Wiley 7.0和NIST 05)匹配度大于80%的成分,各挥发性成分高低用其峰面积横向对比[23]。

1.3 数据处理

本文所涉及的实验均重复3次,取平均值。IBM SPSS Statistics 20.0用于样本数据差异性分析,XLSTAT 2014用于主成分分析。

2. 结果与分析

2.1 冻融循环对菌汤基本指标的影响

冻融循环过程中菌汤中微生物增殖、色泽变化、可溶性蛋白含量、还原糖含量及总酚含量等基本指标的变化如表1所示。预制食品属新兴产业,预制菌汤类食品中大肠杆菌和总菌落数尚无标准限定。本研究中,菌汤反复冻融5次过程中大肠杆菌均无检出,说明反复冻融不会引起菌汤大肠杆菌的增殖。细菌菌落总数在反复冻融3次时,菌落总数微弱增加(3 CFU/mL),而冻融第5次时菌落总数则高达22 CFU/mL,推测冻融循环过程中,菌汤温度波动,休眠状态的细菌得以繁殖,通过前4次冻融,菌汤中细菌数量形成了一定的基数,到5次冻融时菌汤中细菌数量飞速增长。

表 1 冻融循环过程中菌汤的基本指标对比Table 1. Comparison of basic indicators of mushroom soup during repeated freezing-thawing cycle指标 鲜汤 冻融1次 冻融2次 冻融3次 冻融4次 冻融5次 大肠杆菌菌落数(CFU/mL) 0 0 0 0 0 0 菌落总数(CFU/mL) 0 0 0 3 5 22 颜色 L 83.87±0.06f 84.06±0.02e 84.53±0.22d 85.36±0.11c 86.14±0.11b 86.43±0.10a a −3.82±0.24e −0.60±0.20c −1.62±0.17d −0.46±0.025b 1.24±0.16a 1.28±0.095a b 36.64±0.01d 40.12±0.47a 38.04±0.27b 38.11±0.18b 37.82±0.06bc 37.38±0.18c 可溶性蛋白含量(g BSA/L) 0.23±0.03a 0.23±0.02a 0.21±0.04a 0.16±0.01b 0.16±0.02b 0.13±0.01c 还原糖含量(g Glu/L) 2.13±0.04a 1.48±0.02c 1.47±0.01c 1.49±0.01c 1.56±0.02b 1.53±0.01b 总酚含量(g GAE/L) 0.61±0.04a 0.52±0.09b 0.51±0.05b 0.50±0.03b 0.49±0.06b 0.54±0.08b 注:同行小写字母不同表示差异显著,P<0.05;表2~表3同。 L值代表样品的亮度,随着冻融次数的增加,菌汤L值逐渐增加,可能与冷冻澄清有关。a值代表样品的红绿色,菌汤a值在1次冻融后显著增加(P<0.05),在随后菌汤反复冻融过程中(3~5次)中,a值进一步增加,说明冻融循环增加了菌汤的红褐色。b值代表样品的黄蓝色,菌汤b值在首次冻融后显著升高(P<0.05),随后随着冻融次数的增加呈现逐渐减少的趋势,但至冻融终点时菌汤b值仍显著高于(P<0.05)鲜汤。总而言之,冻融能够增加菌汤亮度,同时也加深了菌汤色泽,可能归因于菌汤冷冻过程的氧化和羰基化合物的累积而造成菌汤褐变[24]。

菌汤中可溶性蛋白是菌菇中游离出来的能溶解于汤汁中的小分子蛋白,食用菌中蛋白质和氨基酸含量丰富,前2次冻融,菌汤中可溶性蛋白含量没有显著变化,随后的冻融引起可溶性蛋白含量的显著降低(P<0.05)。首次冻融,显著降低(P<0.05)了菌汤还原糖和总酚含量,在此后的冻融过程中还原糖有微量增加,而总酚含量却无显著变化(P>0.05),说明酚类成分在菌汤2~5次冻融循环过程中稳定存在。

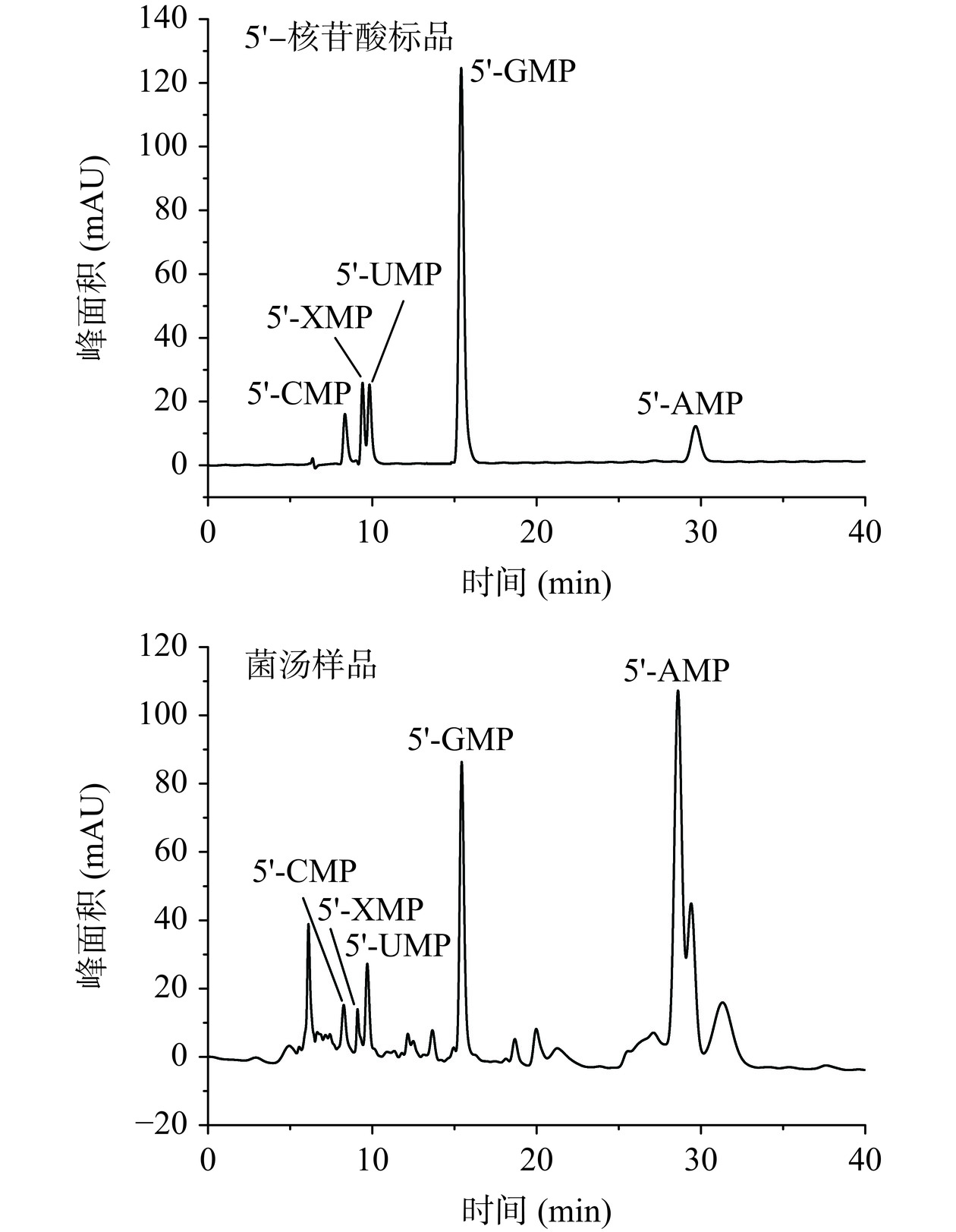

2.2 冻融循环对菌汤5'-核苷酸含量的影响

菌汤中检测出5种核苷酸,分别为5'-CMP、5'-XMP、5'-UMP、5'-GMP和5'-AMP,对应标品和菌汤样品的液相图如图1所示,菌汤冻融循环过程中各核苷酸的含量如表2所示。5'-AMP是菌汤中的主要核苷酸,约占核苷酸总含量的70%以上,此类成分与菌汤鲜甜的口感密不可分[25]。首次冻融造成此类成分的显著降低(P<0.05),在此后反复冻融过程中5'-AMP的含量微弱波动,冻融循环5次5'-AMP含量较冻融1次仅略有减少,说明首次冻融是降低此类成分的主要因素。另外两种增鲜核苷酸5'-XMP与5'-GMP含量在冻融循环过程中出现下降的趋势。菌汤中5'-CMP与5'-UMP的含量则在冻融2次时达到最高,随后逐渐降低。菌汤中的核苷酸来源于核酸类成分的降解、游离,在冷冻和解冻过程中,核酸类成分的动态水解和降解决定了其中核苷酸含量的变化。据前人报道,猪肉在冷冻过程中5-脱氧-5-甲硫腺苷和烟酰胺的含量出现增加的情况,而烟酰胺腺嘌呤二核苷酸、次黄嘌呤、芥酰胺等核苷酸成分呈现降低的趋势[26],可能归因于不同核苷酸在食品冷冻中的游离程度和降解速率不同。本研究中总5'-核苷酸在鲜汤中含量最高,得益于其中高含量的5'-AMP成分。总5'-核苷酸在2次冻融菌汤中含量次之,得益于5'-CMP与5'-UMP的累积,此后随着冻融循环次数的增加,菌汤中总5'-核苷酸含量逐渐降低,冻融次数大于2次将会造成总核苷酸类成分的减少。菌汤中鲜味核苷酸的含量随着冻融次数的增加逐渐降低。

表 2 冻融循环过程中菌汤5'-核苷酸含量对比(mg/L)Table 2. Comparison of 5'-nucleotide content in mushroom soup during freezing-thawing cycle (mg/L)鲜汤 冻融1次 冻融2次 冻融3次 冻融4次 冻融5次 5'-CMP 21.79±0.18ab 21.37±0.05ab 23.18±2.24a 19.78±0.27b 19.88±0.68b 19.89±0.32b 5'-XMP 10.57±0.08a 10.34±0.07a 10.18±0.03a 9.75±0.18b 9.61±0.28b 9.58±0.14b 5'-UMP 16.52±0.72d 15.77±0.63d 25.49±0.39a 21.22±0.57b 17.84±0.61c 18.73±0.46c 5'-GMP 15.25±0.25a 15.64±1.30a 14.83±1.73a 9.30±0.55b 8.27±0.28b 7.68±0.24b 5'-AMP 165.41±0.82a 148.18±0.90bc 146.27±2.15c 150.03±1.91b 150.15±0.65b 146.77±0.46c 鲜味核苷酸总含量 191.23±1.33a 174.16±1.28b 171.28±3.02bc 169.08±2.62bc 168.03±1.12c 164.03±0.84d 总量 229.54±1.64a 211.26±3.57c 219.95±5.62b 210.09±3.25c 205.73±2.73d 202.65±1.37d 2.3 冻融循环对菌汤氨基酸含量的影响

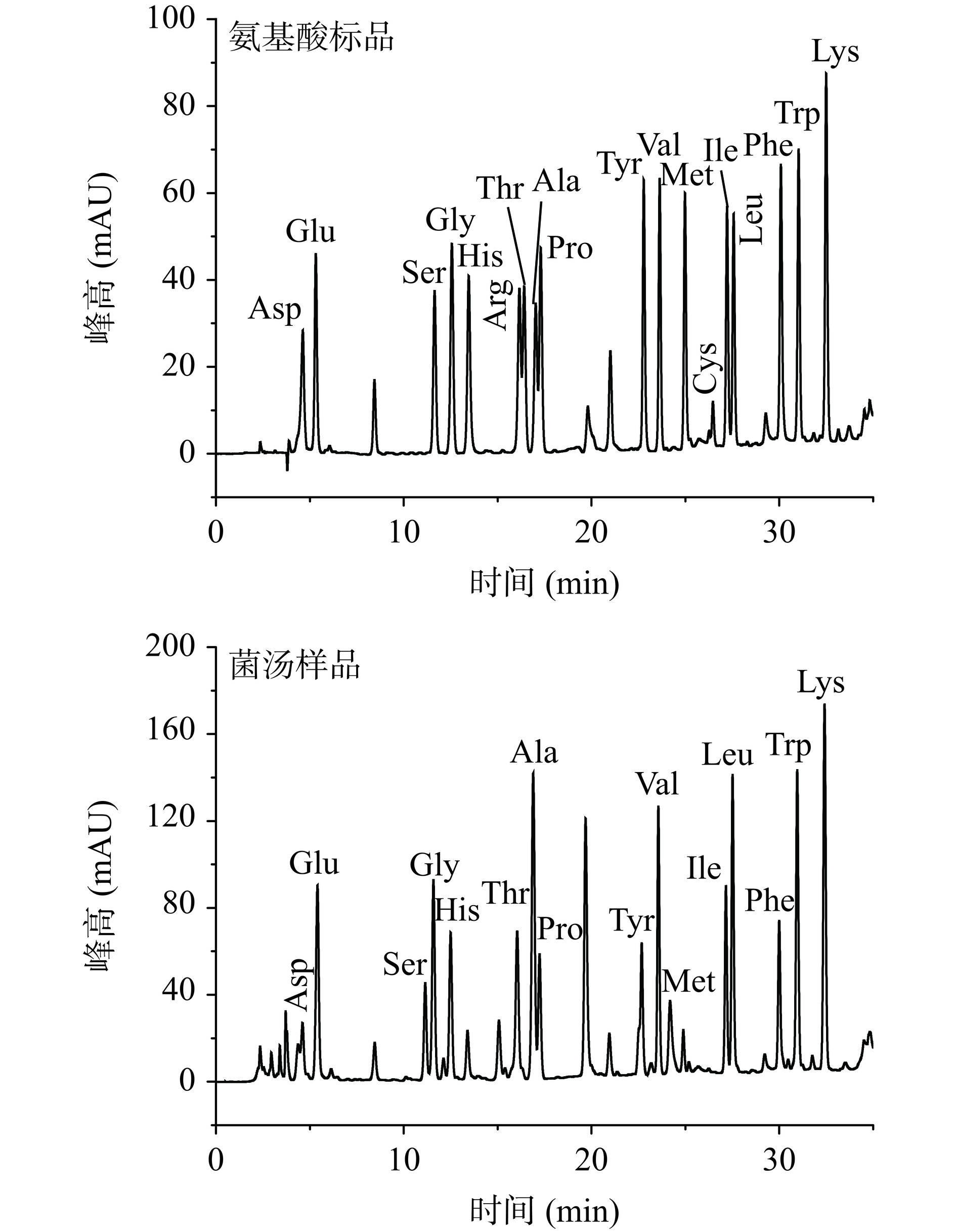

食品中常见的18种氨基酸的标准品和菌汤样品的液相色谱图如图2所示。菌汤中共检测出16种氨基酸,其中半胱氨酸和精氨酸在菌汤中尚未检出。菌汤中各氨基酸的含量如表3所示,色氨酸含量最高,占总氨基酸含量的11.78%。其次是亮氨酸(8.79%)和丙氨酸(8.38%),其中丙氨酸属于甜味氨基酸,对于菌汤口感具有一定的调和作用[27−28]。色氨酸在冻融循环过程中无显著变化(P>0.05),丙氨酸含量在2次冻融时略高于首次冻融,此后逐渐降低。

表 3 冻融循环过程中菌汤氨基酸含量对比(mg/100 mL)Table 3. Comparison of the amino acid content in mushroom soup during freezing-thawing cycle (mg/100 mL)鲜汤 冻融1次 冻融2次 冻融3次 冻融4次 冻融5次 天冬氨酸Asp 9.04±0.53a 8.51±0.44a 8.38±0.49a 8.11±0.53a 8.65±0.47a 8.51±0.39a 谷氨酸Glu 19.11±0.79a 17.93±0.50a 17.93±0.73a 17.35±0.88a 17.49±0.34a 17.35±0.37a 丝氨酸Ser 12.81±0.11a 11.97±0.11bc 12.29±0.11b 11.97±0.11bc 11.86±0.15c 11.76±0.14c 甘氨酸Gly 7.35±0.08a 6.60±0.08b 6.83±0.08b 6.68±0.08b 6.83±0.15b 6.60±0.09b 组氨酸His 5.12±0.26a 4.50±0.33a 4.80±0.16 a 4.50±0.19a 4.65±0.38a 4.81±0.39a 苏氨酸Thr 13.92±0.22a 12.02±0.13bc 12.14±0.21b 11.78±0.25cd 11.66±0.18cd 11.54±0.11d 丙氨酸Ala 17.98±0.18a 16.73±0.11b 17.44±0.36a 16.64±0.19b 16.47±0.09b 16.29±0.18b 脯氨酸Pro 8.40±0.12a 7.46±0.15b 7.71±0.13b 7.59±0.14b 7.48±0.16b 7.48±0.15b 酪氨酸Tyr 14.66±0.29a 13.94±0.25b 13.94±0.20b 13.94±0.26b 13.76±0.19b 13.76±0.21b 缬氨酸Val 14.27±0.43a 13.22±0.31a 15.09±1.29a 15.56±0.86a 14.04±2.22a 12.75±0.71a 甲硫氨酸Met 6.41±0.36a 2.24±0.17b 2.98±0.19b 2.68±0.21b 2.68±0.01b 4.02±1.51ab 异亮氨酸Ile 11.68±0.24a 9.96±0.18bc 10.35±0.23b 10.09±0.26bc 9.69±0.18c 9.83±0.22bc 亮氨酸Leu 18.86±0.26a 17.55±0.16bc 18.08±0.19ab 17.29±0.39bc 16.51±0.25c 17.03±0.54bc 苯丙氨酸Phe 12.54±0.17a 10.73±0.20b 11.06±0.22b 10.73±0.19b 10.73±0.20b 10.73±0.18b 色氨酸Trp 25.30±0.41a 24.28±0.51a 25.09±0.34a 24.07±1.02a 24.48±0.33a 24.68±0.47a 赖氨酸Lys 17.23±0.15a 15.04±0.25b 15.48±0.25b 15.18±0.44b 14.75±0.17b 15.18±0.44b 必需氨基酸 120.19±2.24a 105.02±1.62b 110.26±2.53b 107.38±3.64b 104.54±3.27b 105.76±3.58b 非必需氨基酸 94.46±1.11a 87.66±1.08b 89.31±0.72b 86.77±2.44b 87.17±1.07b 86.54±1.33b 鲜味氨基酸 28.15±0.65a 26.45±0.48a 26.31±1.19a 25.46±1.45a 26.14±0.63a 25.86±0.72a 甜味氨基酸 60.47±1.67a 54.80±1.52bc 56.40±0.72b 54.66±0.89bc 54.29±0.92bc 53.67±0.76c 苦味氨基酸 94.16±2.23a 82.46±1.27c 87.45±2.63bc 84.91±3.33bc 82.77±2.26c 83.85±3.24c 无味氨基酸 31.89±0.53a 28.98±0.48b 29.41±0.54b 29.12±0.72b 28.50±0.45b 28.94±0.62b 总氨基酸 214.65±4.20a 192.68±3.06b 199.58±4.07b 194.15±6.05b 191.71±4.53b 192.31±5.87b 必需氨基酸/总氨基酸(%) 55.99 54.51 55.24 55.31 54.53 55.00 必需氨基酸/非必需氨基酸(%) 127.24 119.82 123.45 123.76 119.92 122.22 鲜味氨基酸占比(%) 13.13 13.73 13.18 13.11 13.63 13.45 甜味氨基酸占比(%) 28.16 28.44 28.26 28.16 28.32 27.91 苦味氨基酸占比(%) 43.86 42.80 43.82 43.74 43.18 43.60 无味氨基酸占比(%) 14.85 15.04 14.74 15.00 14.87 15.05 鲜甜味/苦味 0.94 0.98 0.95 0.94 0.97 0.95 注:必需氨基酸:Lys、Trp、Phe、Met、Thr、Ile、Leu、Val;鲜味氨基酸:Asp、Glu;甜味氨基酸:Ala、Gly、Ser、Thr、Pro;苦味氨基酸:His、Ile、Leu、Met、Phe、Trp、Val;无味氨基酸:Lys、Tyr。 各样品处理之间,必需氨基酸含量/总氨基酸(54.51%~55.99%)差异不大。必需氨基酸含量/非必需氨基酸含量值(119.82%~127.24%),冻融后必需氨基酸含量/非必需氨基酸含量值均存在不同程度的下降。据报道,理想的蛋白模式为必需氨基酸含量/氨基酸总量值为40%左右,必需氨基酸含量/非必需氨基酸含量值在60%以上[29],由表3可知,各菌汤的氨基酸组成均能接近理想模式。鲜汤中总氨基酸含量最高,首次冻融后菌汤中氨基酸含量显著减少(P<0.05),但不同冻融次数之间的总氨基酸含量无显著差异(P>0.05)。冻融处理虽然降低了鲜味氨基酸、甜味氨基酸、苦味氨基酸、无味氨基酸等各类氨基酸的绝对含量,但多数冻融条件下降低了苦味氨基酸的相对含量,提升了鲜味和甜味氨基酸的相对含量,最终导致冻融菌汤中鲜甜味氨基酸含量/苦味氨基酸含量(0.94%~0.98%)大于或等于鲜汤(0.94%)。

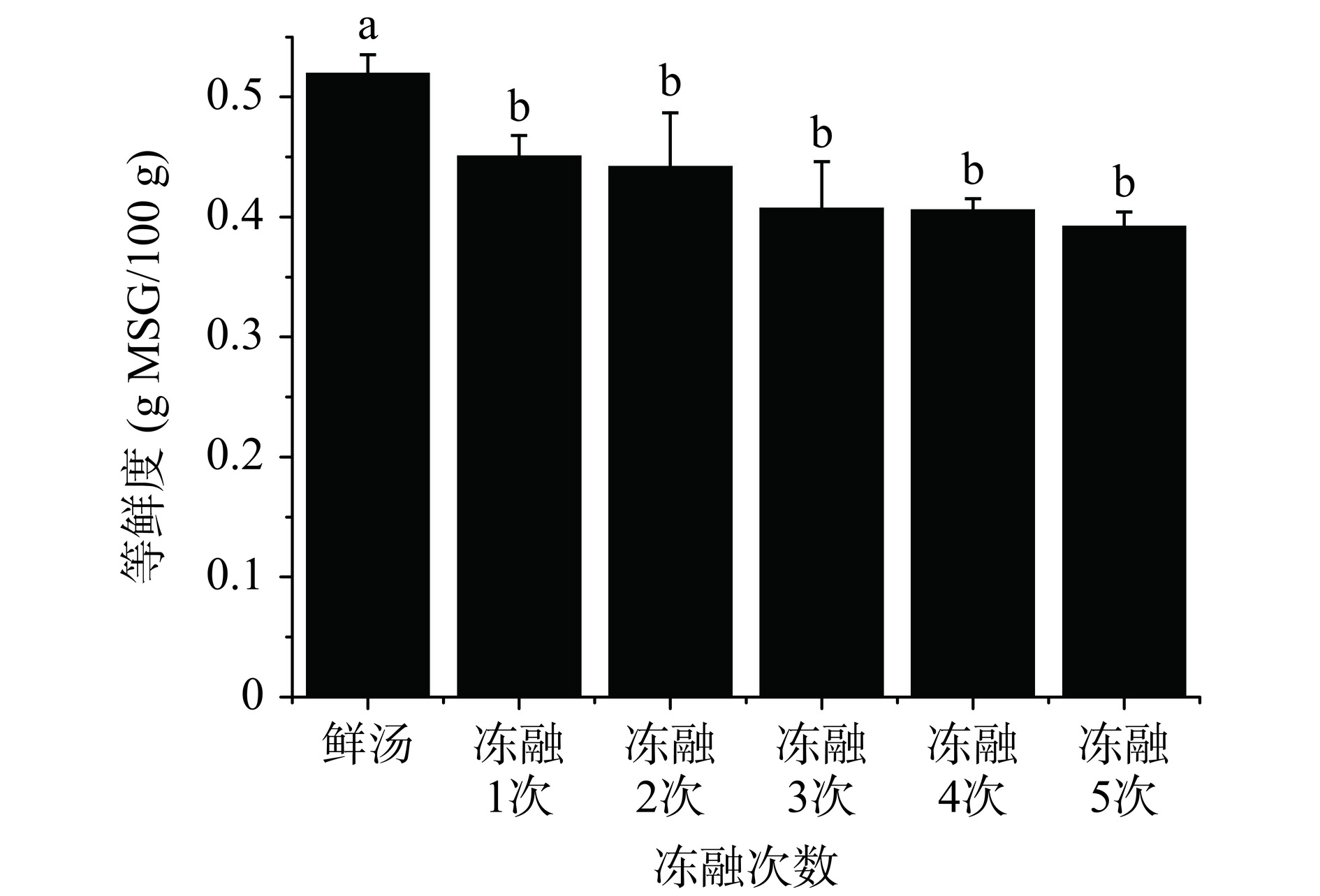

2.4 冻融循环对菌汤等鲜度的影响

菌汤等鲜度取决于其中鲜味氨基酸(Glu或Asp)与5'-核苷酸(5'-IMP、5'-GMP、5'-AMP、5'-XMP)成分含量,结果用100 g样品中的谷氨酸钠(g MSG)当量表示[30−31]。鲜汤与冻融菌汤的等鲜度如图3所示。鲜汤经冻融后等鲜度显著降低(P<0.05),且等鲜度随着冻融次数的增加逐渐减少,但冻融次数(1~5次)对菌汤等鲜度的影响不明显。然而,反复冻融过程中等鲜度的最大降幅出现在第3次,由1~2次冻融的(0.441~0.450 g MSG/100 g)直接下降至0.407 g MSG/100 g,此后等鲜度降幅缓慢。由此,推测菌汤的冻融次数应控制在2次内为宜。

2.5 冻融循环对菌汤挥发性成分的影响

通过GC-MS分析,冻融菌汤挥发性成分相对含量如表4所示。菌汤中共检测到48种挥发性成分,对应挥发性风味峰面积为9.56×108~1.96×109,包括4种胺类、8种烃类、14种醇类、8种醛酮类、5种醚类、4种杂环化合物、3种酯类、1种羧酸类和1种酚类物质(表4),由此可见菌汤中醇类物质最丰富。冻融后菌汤挥发性成分含量急剧下降,并伴随着冻融次数呈现逐渐降低的趋势,说明冻融直接减少了菌汤的挥发性成分。鲜汤中检测到挥发性成分30种,冻融循环1~5次菌汤中挥发性成分分别为20、22、24、24和20种,冻融处理减少了菌汤中挥发性成分个数。正己醇、1-辛烯-3-醇、八乙二醇、异戊醛、正己醛、苯甲醛、15-冠醚是菌汤中的主要挥发性成分,它们在各处理的菌汤中稳定存在,并且占总挥发性成分峰面积的55.93%~83.26%。

表 4 冻融循环过程中菌汤挥发性成分含量对比Table 4. Comparison of volatile compositions in mushroom soup during freezing-thawing cycle化合物 成分编号 保留时间(min) 峰面积(×106) 鲜汤 冻融1次 冻融2次 冻融3次 冻融4次 冻融5次 胺类(4) N-己基甲胺 1 4.15 41.03 草酰胺 2 4.18 7.66 − − − − − 仲丁胺 3 4.25 6.96 − − − − − N-甲基异丁基胺 4 4.85 − − − 16.17 7.65 − 烃类(8) 正己烷 5 4.32 − − 66.13 − − 138.72 十三烷 6 8.151 − − 0.89 − 0.31 − 苯乙烯 7 13.82 4.46 − − − − − 环辛四烯 8 13.85 2.79 − − − − − 甲苯 9 8.43 8.26 − − − − − 乙基苯 10 10.26 8.56 − − − − − 邻二甲苯 11 10.65 8.23 − − − − − 1,3-二叔丁基苯 12 19.52 10.04 − − − − − 醇类(14) 环丁醇 13 4.54 62.65 − − − − − 乙醇 14 6.60 32.23 15.58 20.58 20.3 20.16 − 异戊醇 15 12.52 16.23 − − − − − 正戊醇 16 13.65 2.47 1.52 2.51 2.63 9.87 − 正己醇 17 17.15 15.89 12.22 27.25 12.87 25.89 19.82 6-甲基-3-庚醇 18 18.35 4.19 − − − − − 辛醇 19 18.41 4.47 − − − − − 1-辛烯-3-醇 20 20.64 78.2 48.35 97.15 64.27 100.23 101.69 2-乙基己醇 21 22.34 5.86 − − 8.11 3.17 0.63 糠醇 22 30.22 11.02 3.34 3.71 1.58 3.54 4.11 3,6,9,12-四氧十四烷-1-醇 23 38.54 − 0.63 1.33 2.09 1.84 0.31 八乙二醇 24 39.31 395.96 49.83 70.93 47.1 92.89 15.67 六甘醇 25 39.36 − 0.26 1.15 − − 0.2 五甘醇 26 41.17 − 0.07 − − − 0.78 醛酮类(8) 异戊醛 27 6.34 125.44 86.33 98.17 81.58 93.01 111.06 正己醛 28 9.35 69.42 36.11 56.87 44.37 47.01 64.4 2-庚酮 29 11.91 11.81 − − − − − 4,6-二甲基-2-庚酮 30 13.55 2.43 − − − − − 3-辛酮 31 13.86 − − 0.85 3.61 8.24 1.34 3-糠醛 32 21.33 6.87 − − − − 7.65 糠醛 33 21.39 − 2.8 4.85 − 4.7 − 苯甲醛 34 24.01 76.01 53.96 71.34 50.96 83.76 76.61 醚类(5) 12-冠醚 35 8.84 − 0.65 − 1.43 0.33 − 乙二醇乙烯醚 36 9.11 − 3.83 4.69 1.5 1.21 − 15-冠醚 37 38.72 342.15 335.32 292.35 325.18 262.64 388.85 18-冠醚 38 39.21 60.25 7.05 7.2 6.26 4.18 6.02 六乙二醇单十二醚 39 45.46 − − − 39.68 − 7.61 酯类(3) 3-酞酰亚胺基丙酸甲酯 40 4.26 − − − 23.45 25.3 − 乙酸异丙烯酯 41 5.30 − − 12.17 13.43 13.3 − 亚胺二乙酸二乙酯 42 8.81 − − − − − 1.24 杂环化合物(4) 哌嗪 43 4.28 − 114.15 − 118.16 − − 呋喃 44 5.07 − − − − − 1.02 吡啶 45 12.18 10.85 6.27 10.45 10.28 13.65 6.41 2-甲基吡嗪 46 14.45 − − − 1.07 1.52 − 羧酸、酚类(2) 5-叔丁氧基噻吩-2-羧酸 47 4.63 − − 35.33 − − − 2,4-二叔丁基苯酚 48 46.51 532.79 423.08 280.82 265.61 159.73 − 合计 1965.18 1201.35 1166.72 1161.69 958.83 956.56 注:−表示未检测到。 菌汤中挥发性成分主要源自:菌菇中原有风味的释放,如生长过程中合成的醇类、酯类、醛类等小分子成分;风味前体物质如氨基酸、核酸的热降解;氨基酸与还原糖发生美拉德反应生成的杂环类挥发性成分[32]。食用菌在加工过程中通过内源酶和过氧化物催化脂肪酸裂解生成小分子的醇、醛类成分,其中1-辛烯-3醇是主要降解产物[25]。1-辛烯-3醇在首次冻融时含量大幅下降,随后随着冻融次数的增加呈波动性上升的趋势,最终冻融5次菌汤中1-辛烯-3醇含量高于鲜汤,可能归因于前1~2次的冻融处理造成了此类成分的减少,但随着冻融次数增加,逐渐加剧了菌汤内源酶和过氧化物对其中脂肪酸的降解,导致脂肪酸主要降解产物1-辛烯-3醇的累积。同样,菌汤中主要成分正己醇、异戊醛、正己醛、苯甲醛、15-冠醚在菌汤冻融过程中也呈现出类似1-辛烯-3醇的变化趋势。其它含量较低的挥发性成分,如六苷醇、五甘醇、3-糠醛、糠醛、12-冠醚等成分仅在部分处理样品中检测到,可能与脂肪裂解产物的聚合反应有关[33],具体原因有待进一步研究。

胺类和烃类成分在鲜汤中最为丰富,冻融处理后此类成分大幅挥发或降解,而酯类成分仅在冻融菌汤中检测到。蛋白质水解、糖酵解、脂肪氧化内源酶作用能够促进酯类成分形成[33]。此外,有机酸和醇类成分的缩合也是酯类化合物形成的重要途径,冻融循环过程中的温度波动和放置过程,可能为酯类的形成提供了条件。2,4-二叔丁基酚是一种天然化学成分,具有抗氧化活性、抗炎活性、抑菌特性等[34]。相较于鲜汤,此种成分在冻融过程中逐渐衰减,在5次冻融的菌汤中无已法检测到。

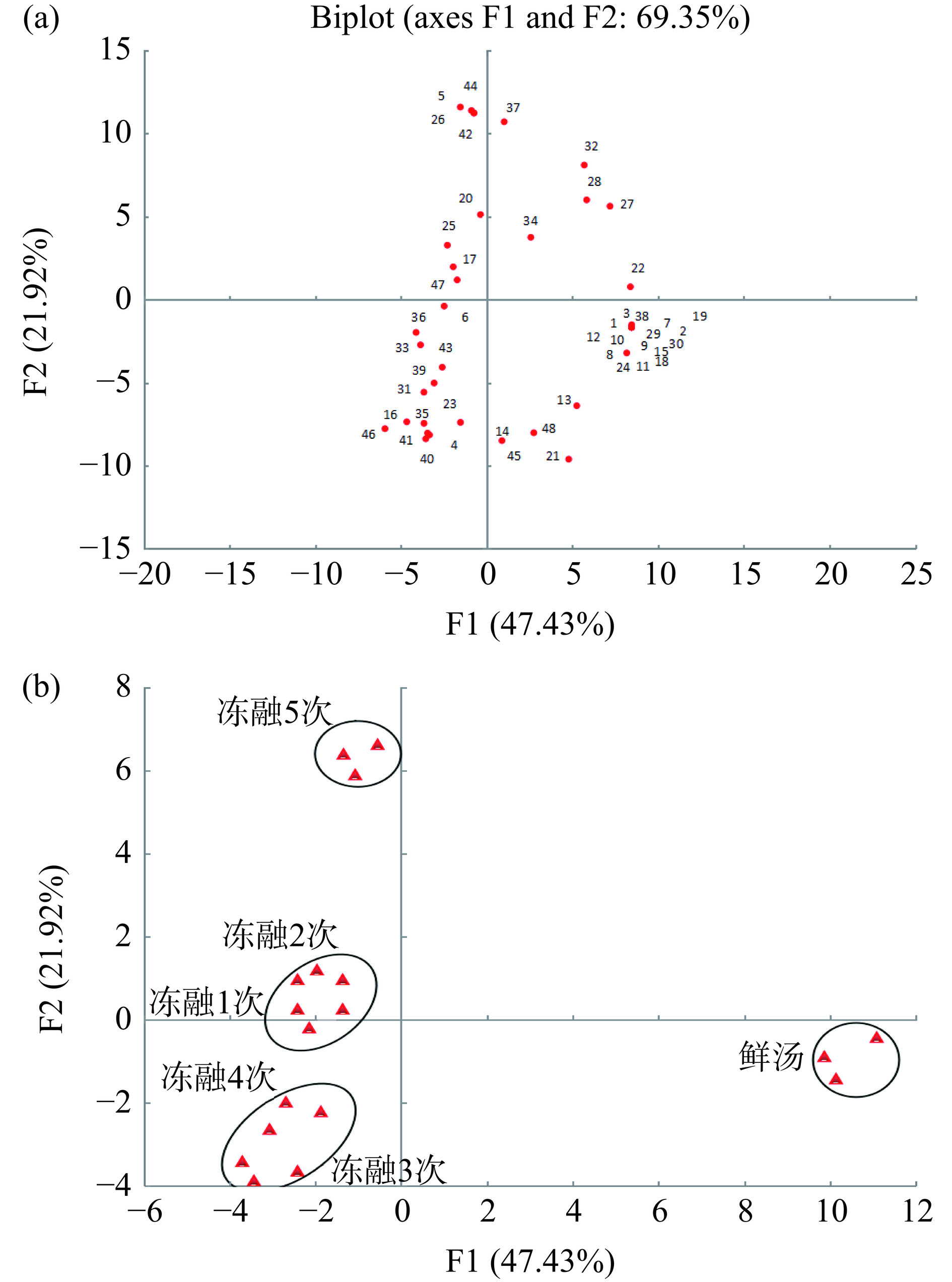

冻融循环过程中菌汤的挥发性成分的主成分分析如图4所示。本研究以冻融次数及挥发性成分为原始变量进行主成分分析,得到2个独立的主成分,F1=47.43%,F2=21.92%,两组主成分的累计贡献率高达69.35%,可以绝大部分地反映原变量信息。由图4(a),挥发性成分吡啶、2-乙基己醇、2,4-二叔丁基酚、乙醇、环丁醇、邻二甲苯、18-冠醚、1,3-二叔丁基苯、2-庚酮、辛醇、草酰胺、仲丁胺、N-己基甲胺、异戊醇、甲苯、6-甲基-3-庚醇、4,6-二甲基-2-庚酮、乙基苯等分布在第四象限,与主成分1正相关,与主成分2负相关。由图4(b)可知,鲜汤位于第四象限与此类挥发性成分高度相关。冻融1次和冻融2次菌汤的挥发性成分类似,分布于第二、三象限,与F1负相关,代表性的挥发性成分为正己醇、六甘醇、5-叔丁氧基噻吩-2-羧酸、十三烷和乙二醇乙烯醚等。冻融3次和冻融4次菌汤的挥发性成分类似,分布于第三象限,代表性的挥发性成分为3-酞酰亚胺基丙酸甲酯、N-甲基异丁基胺、乙酸异丙烯酯、2-甲基吡嗪、正戊醇、12-冠醚、3-辛酮、3,6,9,12-四氧十四烷-1-醇等。冻融5次菌汤分布于第二象限与F2正相关,代表性的挥发性成分为正己烷、呋喃、五甘醇、亚胺二乙酸二乙酯。通过冻融前后菌汤的挥发性成分分析,可将菌汤划分为四组:鲜汤、冻融1~2次、冻融3~4次和冻融5次。

![]() 图 4 冻融循环过程中菌汤挥发性成分主成分得分图(a)和变量图(b)注:图(a)中的成分编号(1~48)同表3。Figure 4. Principal component score chart (a) and variable chart (b) of volatile components in mushroom soup during freezing-thawing cycle

图 4 冻融循环过程中菌汤挥发性成分主成分得分图(a)和变量图(b)注:图(a)中的成分编号(1~48)同表3。Figure 4. Principal component score chart (a) and variable chart (b) of volatile components in mushroom soup during freezing-thawing cycle3. 结论

本文研究结果表明,冻融循环次数能不同程度地影响菌汤的色泽、成分和风味。具体而言,随着冻融处理次数的增加能使汤色更加明亮,但也伴随着菌汤可溶性蛋白质含量逐渐降低,等鲜度和挥发性成分的减少。然而菌汤的成分指标(还原糖含量、总酚含量、总氨基酸含量)和风味指标(等鲜度、挥发性成分含量)均在首次冻融时出现大幅减少,而此后的冻融次数对上述指标影响相对微弱。进一步通过冻融次数的对比,发现反复冻融3次时,菌汤中菌落总数开始检出,此后不断增加;反复冻融3次时菌汤可溶性蛋白含量相较于冻融1~2次显著降低(P<0.05),等鲜度由1~2次冻融的0.441~0.450 g MSG/100 g直接下降至0.407 g MSG/100 g,此后相对稳定,并且冻融3次菌汤的挥发性风味成分也和1~2次冻融菌汤存在较大差异。所以,本研究认为菌汤应鲜食为佳,若需冻融处理则应控制在2次内为宜。目前尚无标准规定预制菌汤的微生物限度标准,按照GB 11671-2003,罐装果蔬食品微生物应符合商业无菌的要求,本研究中菌汤属于食用菌加工的软罐装食品,微生物检测也应达到商业无菌的要求。因此,若菌汤冻融次数大于2次,可能需要充分复热后再食用。

-

图 4 冻融循环过程中菌汤挥发性成分主成分得分图(a)和变量图(b)

注:图(a)中的成分编号(1~48)同表3。

Figure 4. Principal component score chart (a) and variable chart (b) of volatile components in mushroom soup during freezing-thawing cycle

表 1 冻融循环过程中菌汤的基本指标对比

Table 1 Comparison of basic indicators of mushroom soup during repeated freezing-thawing cycle

指标 鲜汤 冻融1次 冻融2次 冻融3次 冻融4次 冻融5次 大肠杆菌菌落数(CFU/mL) 0 0 0 0 0 0 菌落总数(CFU/mL) 0 0 0 3 5 22 颜色 L 83.87±0.06f 84.06±0.02e 84.53±0.22d 85.36±0.11c 86.14±0.11b 86.43±0.10a a −3.82±0.24e −0.60±0.20c −1.62±0.17d −0.46±0.025b 1.24±0.16a 1.28±0.095a b 36.64±0.01d 40.12±0.47a 38.04±0.27b 38.11±0.18b 37.82±0.06bc 37.38±0.18c 可溶性蛋白含量(g BSA/L) 0.23±0.03a 0.23±0.02a 0.21±0.04a 0.16±0.01b 0.16±0.02b 0.13±0.01c 还原糖含量(g Glu/L) 2.13±0.04a 1.48±0.02c 1.47±0.01c 1.49±0.01c 1.56±0.02b 1.53±0.01b 总酚含量(g GAE/L) 0.61±0.04a 0.52±0.09b 0.51±0.05b 0.50±0.03b 0.49±0.06b 0.54±0.08b 注:同行小写字母不同表示差异显著,P<0.05;表2~表3同。 表 2 冻融循环过程中菌汤5'-核苷酸含量对比(mg/L)

Table 2 Comparison of 5'-nucleotide content in mushroom soup during freezing-thawing cycle (mg/L)

鲜汤 冻融1次 冻融2次 冻融3次 冻融4次 冻融5次 5'-CMP 21.79±0.18ab 21.37±0.05ab 23.18±2.24a 19.78±0.27b 19.88±0.68b 19.89±0.32b 5'-XMP 10.57±0.08a 10.34±0.07a 10.18±0.03a 9.75±0.18b 9.61±0.28b 9.58±0.14b 5'-UMP 16.52±0.72d 15.77±0.63d 25.49±0.39a 21.22±0.57b 17.84±0.61c 18.73±0.46c 5'-GMP 15.25±0.25a 15.64±1.30a 14.83±1.73a 9.30±0.55b 8.27±0.28b 7.68±0.24b 5'-AMP 165.41±0.82a 148.18±0.90bc 146.27±2.15c 150.03±1.91b 150.15±0.65b 146.77±0.46c 鲜味核苷酸总含量 191.23±1.33a 174.16±1.28b 171.28±3.02bc 169.08±2.62bc 168.03±1.12c 164.03±0.84d 总量 229.54±1.64a 211.26±3.57c 219.95±5.62b 210.09±3.25c 205.73±2.73d 202.65±1.37d 表 3 冻融循环过程中菌汤氨基酸含量对比(mg/100 mL)

Table 3 Comparison of the amino acid content in mushroom soup during freezing-thawing cycle (mg/100 mL)

鲜汤 冻融1次 冻融2次 冻融3次 冻融4次 冻融5次 天冬氨酸Asp 9.04±0.53a 8.51±0.44a 8.38±0.49a 8.11±0.53a 8.65±0.47a 8.51±0.39a 谷氨酸Glu 19.11±0.79a 17.93±0.50a 17.93±0.73a 17.35±0.88a 17.49±0.34a 17.35±0.37a 丝氨酸Ser 12.81±0.11a 11.97±0.11bc 12.29±0.11b 11.97±0.11bc 11.86±0.15c 11.76±0.14c 甘氨酸Gly 7.35±0.08a 6.60±0.08b 6.83±0.08b 6.68±0.08b 6.83±0.15b 6.60±0.09b 组氨酸His 5.12±0.26a 4.50±0.33a 4.80±0.16 a 4.50±0.19a 4.65±0.38a 4.81±0.39a 苏氨酸Thr 13.92±0.22a 12.02±0.13bc 12.14±0.21b 11.78±0.25cd 11.66±0.18cd 11.54±0.11d 丙氨酸Ala 17.98±0.18a 16.73±0.11b 17.44±0.36a 16.64±0.19b 16.47±0.09b 16.29±0.18b 脯氨酸Pro 8.40±0.12a 7.46±0.15b 7.71±0.13b 7.59±0.14b 7.48±0.16b 7.48±0.15b 酪氨酸Tyr 14.66±0.29a 13.94±0.25b 13.94±0.20b 13.94±0.26b 13.76±0.19b 13.76±0.21b 缬氨酸Val 14.27±0.43a 13.22±0.31a 15.09±1.29a 15.56±0.86a 14.04±2.22a 12.75±0.71a 甲硫氨酸Met 6.41±0.36a 2.24±0.17b 2.98±0.19b 2.68±0.21b 2.68±0.01b 4.02±1.51ab 异亮氨酸Ile 11.68±0.24a 9.96±0.18bc 10.35±0.23b 10.09±0.26bc 9.69±0.18c 9.83±0.22bc 亮氨酸Leu 18.86±0.26a 17.55±0.16bc 18.08±0.19ab 17.29±0.39bc 16.51±0.25c 17.03±0.54bc 苯丙氨酸Phe 12.54±0.17a 10.73±0.20b 11.06±0.22b 10.73±0.19b 10.73±0.20b 10.73±0.18b 色氨酸Trp 25.30±0.41a 24.28±0.51a 25.09±0.34a 24.07±1.02a 24.48±0.33a 24.68±0.47a 赖氨酸Lys 17.23±0.15a 15.04±0.25b 15.48±0.25b 15.18±0.44b 14.75±0.17b 15.18±0.44b 必需氨基酸 120.19±2.24a 105.02±1.62b 110.26±2.53b 107.38±3.64b 104.54±3.27b 105.76±3.58b 非必需氨基酸 94.46±1.11a 87.66±1.08b 89.31±0.72b 86.77±2.44b 87.17±1.07b 86.54±1.33b 鲜味氨基酸 28.15±0.65a 26.45±0.48a 26.31±1.19a 25.46±1.45a 26.14±0.63a 25.86±0.72a 甜味氨基酸 60.47±1.67a 54.80±1.52bc 56.40±0.72b 54.66±0.89bc 54.29±0.92bc 53.67±0.76c 苦味氨基酸 94.16±2.23a 82.46±1.27c 87.45±2.63bc 84.91±3.33bc 82.77±2.26c 83.85±3.24c 无味氨基酸 31.89±0.53a 28.98±0.48b 29.41±0.54b 29.12±0.72b 28.50±0.45b 28.94±0.62b 总氨基酸 214.65±4.20a 192.68±3.06b 199.58±4.07b 194.15±6.05b 191.71±4.53b 192.31±5.87b 必需氨基酸/总氨基酸(%) 55.99 54.51 55.24 55.31 54.53 55.00 必需氨基酸/非必需氨基酸(%) 127.24 119.82 123.45 123.76 119.92 122.22 鲜味氨基酸占比(%) 13.13 13.73 13.18 13.11 13.63 13.45 甜味氨基酸占比(%) 28.16 28.44 28.26 28.16 28.32 27.91 苦味氨基酸占比(%) 43.86 42.80 43.82 43.74 43.18 43.60 无味氨基酸占比(%) 14.85 15.04 14.74 15.00 14.87 15.05 鲜甜味/苦味 0.94 0.98 0.95 0.94 0.97 0.95 注:必需氨基酸:Lys、Trp、Phe、Met、Thr、Ile、Leu、Val;鲜味氨基酸:Asp、Glu;甜味氨基酸:Ala、Gly、Ser、Thr、Pro;苦味氨基酸:His、Ile、Leu、Met、Phe、Trp、Val;无味氨基酸:Lys、Tyr。 表 4 冻融循环过程中菌汤挥发性成分含量对比

Table 4 Comparison of volatile compositions in mushroom soup during freezing-thawing cycle

化合物 成分编号 保留时间(min) 峰面积(×106) 鲜汤 冻融1次 冻融2次 冻融3次 冻融4次 冻融5次 胺类(4) N-己基甲胺 1 4.15 41.03 草酰胺 2 4.18 7.66 − − − − − 仲丁胺 3 4.25 6.96 − − − − − N-甲基异丁基胺 4 4.85 − − − 16.17 7.65 − 烃类(8) 正己烷 5 4.32 − − 66.13 − − 138.72 十三烷 6 8.151 − − 0.89 − 0.31 − 苯乙烯 7 13.82 4.46 − − − − − 环辛四烯 8 13.85 2.79 − − − − − 甲苯 9 8.43 8.26 − − − − − 乙基苯 10 10.26 8.56 − − − − − 邻二甲苯 11 10.65 8.23 − − − − − 1,3-二叔丁基苯 12 19.52 10.04 − − − − − 醇类(14) 环丁醇 13 4.54 62.65 − − − − − 乙醇 14 6.60 32.23 15.58 20.58 20.3 20.16 − 异戊醇 15 12.52 16.23 − − − − − 正戊醇 16 13.65 2.47 1.52 2.51 2.63 9.87 − 正己醇 17 17.15 15.89 12.22 27.25 12.87 25.89 19.82 6-甲基-3-庚醇 18 18.35 4.19 − − − − − 辛醇 19 18.41 4.47 − − − − − 1-辛烯-3-醇 20 20.64 78.2 48.35 97.15 64.27 100.23 101.69 2-乙基己醇 21 22.34 5.86 − − 8.11 3.17 0.63 糠醇 22 30.22 11.02 3.34 3.71 1.58 3.54 4.11 3,6,9,12-四氧十四烷-1-醇 23 38.54 − 0.63 1.33 2.09 1.84 0.31 八乙二醇 24 39.31 395.96 49.83 70.93 47.1 92.89 15.67 六甘醇 25 39.36 − 0.26 1.15 − − 0.2 五甘醇 26 41.17 − 0.07 − − − 0.78 醛酮类(8) 异戊醛 27 6.34 125.44 86.33 98.17 81.58 93.01 111.06 正己醛 28 9.35 69.42 36.11 56.87 44.37 47.01 64.4 2-庚酮 29 11.91 11.81 − − − − − 4,6-二甲基-2-庚酮 30 13.55 2.43 − − − − − 3-辛酮 31 13.86 − − 0.85 3.61 8.24 1.34 3-糠醛 32 21.33 6.87 − − − − 7.65 糠醛 33 21.39 − 2.8 4.85 − 4.7 − 苯甲醛 34 24.01 76.01 53.96 71.34 50.96 83.76 76.61 醚类(5) 12-冠醚 35 8.84 − 0.65 − 1.43 0.33 − 乙二醇乙烯醚 36 9.11 − 3.83 4.69 1.5 1.21 − 15-冠醚 37 38.72 342.15 335.32 292.35 325.18 262.64 388.85 18-冠醚 38 39.21 60.25 7.05 7.2 6.26 4.18 6.02 六乙二醇单十二醚 39 45.46 − − − 39.68 − 7.61 酯类(3) 3-酞酰亚胺基丙酸甲酯 40 4.26 − − − 23.45 25.3 − 乙酸异丙烯酯 41 5.30 − − 12.17 13.43 13.3 − 亚胺二乙酸二乙酯 42 8.81 − − − − − 1.24 杂环化合物(4) 哌嗪 43 4.28 − 114.15 − 118.16 − − 呋喃 44 5.07 − − − − − 1.02 吡啶 45 12.18 10.85 6.27 10.45 10.28 13.65 6.41 2-甲基吡嗪 46 14.45 − − − 1.07 1.52 − 羧酸、酚类(2) 5-叔丁氧基噻吩-2-羧酸 47 4.63 − − 35.33 − − − 2,4-二叔丁基苯酚 48 46.51 532.79 423.08 280.82 265.61 159.73 − 合计 1965.18 1201.35 1166.72 1161.69 958.83 956.56 注:−表示未检测到。 -

[1] 范慧敏. 预制菜市场分析[J]. 合作经济与科技,2023,699(4):88−89. [FAN H M. Market analysis of prefabricated dishes[J]. Co-Operative Economy & Science,2023,699(4):88−89.] FAN H M. Market analysis of prefabricated dishes[J]. Co-Operative Economy & Science, 2023, 699(4): 88−89.

[2] 赵超凡, 陈树俊, 李文兵, 等. 预制菜产业发展问题分析[J]. 现代食品科技,2023(2):104−109. [ZHAO C F, CHEN S J, LI W B, et al. Analysis on the development problems of prepared dish industry[J]. Modern Food Science and Technology,2023(2):104−109.] ZHAO C F, CHEN S J, LI W B, et al. Analysis on the development problems of prepared dish industry[J]. Modern Food Science and Technology, 2023(2): 104−109.

[3] 王炜, 杨丹. 新冠肺炎疫情下餐饮业的新发展——预制菜肴的加工应用[J]. 食品工业,2022,43(12):169−171. [WANG W, YANG D. New developments in the catering industry in the face of COVID-19—The processing and application of prefabricated dishes[J]. The Food Industry,2022,43(12):169−171.] WANG W, YANG D. New developments in the catering industry in the face of COVID-19—The processing and application of prefabricated dishes[J]. The Food Industry, 2022, 43(12): 169−171.

[4] 邓衍军, 陈宇, 杨国栋. 广东省预制菜产业发展现状分析[J]. 现代农业装备,2022,43(6):16−19,65. [DENG Y J, CHEN Y, YANG G D. Analysis on current situation of prefabricated vegetable industry in Guangdong Province[J]. Modern Agricultural Equipment,2022,43(6):16−19,65.] DENG Y J, CHEN Y, YANG G D. Analysis on current situation of prefabricated vegetable industry in Guangdong Province[J]. Modern Agricultural Equipment, 2022, 43(6): 16−19,65.

[5] ZHANG Y R, WANG D W, CHEN Y T, et al. Healthy function and high valued utilization of edible fungi[J]. Food Science and Human Wellness,2021,10(4):408−420. doi: 10.1016/j.fshw.2021.04.003

[6] QIN P F, LI T Y, LIU C, et al. Extraction and utilization of active substances from edible fungi substrate and residue:A review[J]. Food Chemistry,2023,398:133872. doi: 10.1016/j.foodchem.2022.133872

[7] SUN Y L, ZHANG M, FANG Z X. Efficient physical extraction of active constituents from edible fungi and their potential bioactivities:A review[J]. Trends in Food Science & Technology,2020,105:468−482.

[8] 张韵, 李蕙蕙, 周圣弘. 食用菌作为预制即热菜肴的应用前景及途径[J]. 食品安全导刊,2021(34):138−140. [ZHANG Y, LI H H, ZHOU S H. Application prospect and realization of edible fungi as ready-to-heat Cuisine[J]. China Food Safety Magazine,2021(34):138−140.] ZHANG Y, LI H H, ZHOU S H. Application prospect and realization of edible fungi as ready-to-heat Cuisine[J]. China Food Safety Magazine, 2021(34): 138−140.

[9] 范秀芝, 姚芬, 殷朝敏, 等. 香菇预制菜制备工艺优化[J]. 食品工业科技,2023,44(12):223−231. [FAN X Z, YAO F, YIN C M, et al. Optimization of the preparation process of Lentinula edodes prefabricated dishes[J]. Science and Technology of Food Industry,2023,44(12):223−231.] FAN X Z, YAO F, YIN C M, et al. Optimization of the preparation process of Lentinula edodes prefabricated dishes[J]. Science and Technology of Food Industry, 2023, 44(12): 223−231.

[10] 曹晶晶, 孙达锋, 苟学磊, 等. 食用菌预制菜加工现状分析及展望[J]. 中国食用菌,2022,41(10):62−65. [CAO J J, SUN D F, GOU X L, et al. Analysis and prospect of current processing situation of the prefabricated edible fungi dishes[J]. Edible Fungi of China,2022,41(10):62−65.] CAO J J, SUN D F, GOU X L, et al. Analysis and prospect of current processing situation of the prefabricated edible fungi dishes[J]. Edible Fungi of China, 2022, 41(10): 62−65.

[11] 桑兰, 杨珍福, 王婷婷, 等. 我国食用菌汤类产品研究进展[J]. 科技创新导报,2015,12(7):10−13. [SANG L, YANG Z F, WANG T T, et al. The development of study on the soup products of edible fungi in China[J]. Science and Technology Innovation Herald,2015,12(7):10−13.] doi: 10.3969/j.issn.1674-098X.2015.07.006 SANG L, YANG Z F, WANG T T, et al. The development of study on the soup products of edible fungi in China[J]. Science and Technology Innovation Herald, 2015, 12(7): 10−13. doi: 10.3969/j.issn.1674-098X.2015.07.006

[12] 付瑞青, 王娟, 郭衍银, 等. 基于GC-MS和氨基酸分析的羊肚菌汤适宜煮制时间研究[J]. 食品工业科技,2022,43(16):290−297. [FU R Q, WANG J, GUO Y Y, et al. Suitable cooking time of Morchella soup based on GC-MS and amino acid analysis[J]. Science and Technology of Food Industry,2022,43(16):290−297.] FU R Q, WANG J, GUO Y Y, et al. Suitable cooking time of Morchella soup based on GC-MS and amino acid analysis[J]. Science and Technology of Food Industry, 2022, 43(16): 290−297.

[13] LEYGONIE C, BRITZ T J, HOFFMAN L C. Impact of freezing and thawing on the quality of meat:Review[J]. Meat Science,2012,91(2):93−98. doi: 10.1016/j.meatsci.2012.01.013

[14] HOLZWART M, KORHUMMEL S, CARLE R, et al. Evaluation of the effects of different freezing and thawing methods on color, polyphenol and ascorbic acid retention in strawberries (Fragaria×ananassa Duch.)[J]. Food Research International,2012,48(1):241−248. doi: 10.1016/j.foodres.2012.04.004

[15] 卢琪, 薛淑静, 杨德, 等. 不同干燥条件下福白菊菊花茶风味品质的比较分析[J]. 食品科学,2020,41(20):249−255 [LU Q, XUE S J, YANG D, et al. Comparative analysis of flavor quality of Chrysanthemum tea (Chrysanthemum morifolium cv. ‘Fubaiju’) processed by different drying methods[J]. Food Science,2020,41(20):249−255.] LU Q, XUE S J, YANG D, et al. Comparative analysis of flavor quality of Chrysanthemum tea (Chrysanthemum morifolium cv. ‘Fubaiju’) processed by different drying methods[J]. Food Science, 2020, 41(20): 249−255.

[16] 徐亚, 范会芬, 赵玎玲, 等. 考马斯亮蓝法测定大豆水溶性蛋白提取方法的优化[J]. 大豆科学,2022,41(2):196−202. [XU Y, FAN H F, ZHAO D L, et al. Optimization of extraction method for water-soluble protein determination by coomassie bright blue method[J]. Soybean Science,2022,41(2):196−202.] XU Y, FAN H F, ZHAO D L, et al. Optimization of extraction method for water-soluble protein determination by coomassie bright blue method[J]. Soybean Science, 2022, 41(2): 196−202.

[17] WANG Q, REHMEN M, PENG D X, et al. Antioxidant capacity and α-glucosidase inhibitory activity of leaf extracts from ten ramie cultivars[J]. Industrial Crops and Products,2018,122:430−437. doi: 10.1016/j.indcrop.2018.06.020

[18] LU Q, WANG S H, XUE S J, et al. Comparison of non-volatile flavor compounds in Stropharia rugosoannulata soup processed by different methods[J]. Journal of Food Science and Technology,2022,59(10):4025−4036. doi: 10.1007/s13197-022-05446-9

[19] VAKILI H, TALEBPOUR Z, HAGHIGHI F. Development, validation, and uncertainty measurement of HPLC-DAD method for determination of some free amino acids in infant formula and medical food products for inborn errors of metabolism[J]. Food Chemistry,2022,390:133204.

[20] 卢琪, 薛淑静, 杨德, 等. 不同加工方式对羊肚菌水提液鲜味及抗氧化性能的影响[J]. 食品工业科技,2022,43(15):27−33. [LU Q, XUE S J, YANG D, et al. Effects of different processing methods on umami taste and antioxidant capability of water extracts of Morchella esculenta[J]. Journal of Food Science and Technology,2022,43(15):27−33.] LU Q, XUE S J, YANG D, et al. Effects of different processing methods on umami taste and antioxidant capability of water extracts of Morchella esculenta[J]. Journal of Food Science and Technology, 2022, 43(15): 27−33.

[21] REN J N, TAI Y N, DONG M, et al. Characterisation of free and bound volatile compounds from six different varieties of citrus fruits[J]. Food Chemistry,2015,185:25−32. doi: 10.1016/j.foodchem.2015.03.142

[22] 卢琪, 薛淑静, 杨德, 等. 不同加工方式对大球盖菇水提液挥发性风味成分和抗氧化能力的影响[J]. 食品工业科技,2021,42(23):41−48 [LU Q, XUE S J, YANG D, et al. Effects of different processing methods on the volatile components and antioxidant ability of the water extracts from Stropharia rugosoannulata[J]. Science and Technology of Food Industry,2021,42(23):41−48.] LU Q, XUE S J, YANG D, et al. Effects of different processing methods on the volatile components and antioxidant ability of the water extracts from Stropharia rugosoannulata[J]. Science and Technology of Food Industry, 2021, 42(23): 41−48.

[23] 张莉会, 刘杜娟, 廖李, 等. 真空冷冻-热风联合干燥对草莓品质的影响[J]. 现代食品科学,2018,34(4):188−197. [ZHANG L H, LIU D J, LIAO L, et al. Effects of vacuum freezing combined with hot air drying on the quality of strawberry[J]. Modern Food Science and Technology,2018,34(4):188−197.] ZHANG L H, LIU D J, LIAO L, et al. Effects of vacuum freezing combined with hot air drying on the quality of strawberry[J]. Modern Food Science and Technology, 2018, 34(4): 188−197.

[24] 韦舟平. 冷冻工艺对中式预制菜肴品质的影响及提升策略研究[J]. 现代食品,2022,41(1):51−56 [WEI Z P. Study on the freezing technology and quality control strategy of chinese prepared dishes[J]. Modern Food,2022,41(1):51−56.] WEI Z P. Study on the freezing technology and quality control strategy of chinese prepared dishes[J]. Modern Food, 2022, 41(1): 51−56.

[25] LI Q, ZHANG H, CLAVER I P, et al. Effect of different cooking methods on the flavour constituents of mushroom (Agaricus bisporus (Lange) Sing.) soup[J]. International Journal of Food Science & Technology,2011,46(5):1100−1108.

[26] 郑小玲, 唐柏彬, 李贤良, 等. 基于超高效液相色谱-高分辨质谱法的冷冻过程中猪肉差异物质代谢组学分析[J]. 食品安全质量检测学报,2022,13(12):3825−3833. [ZHENG X L, TANG B S, LI X L, et al. Metabolomics analysis of differential substances in pork during freezing based on ultra performance liquid chromatography-high resolution mass spectrometry[J]. Journal of Food Safety & Quality,2022,13(12):3825−3833.] doi: 10.3969/j.issn.2095-0381.2022.12.spaqzljcjs202212012 ZHENG X L, TANG B S, LI X L, et al. Metabolomics analysis of differential substances in pork during freezing based on ultra performance liquid chromatography-high resolution mass spectrometry[J]. Journal of Food Safety & Quality, 2022, 13(12): 3825−3833. doi: 10.3969/j.issn.2095-0381.2022.12.spaqzljcjs202212012

[27] LI W, GU Z, YANG Y, et al. Non-volatile taste components of several cultivated mushrooms[J]. Food Chemistry,2014,143:427−431. doi: 10.1016/j.foodchem.2013.08.006

[28] YIN C M, FAN X Z, FAN Z, et al. Comparison of non-volatile and volatile flavor compounds in six Pleurotus mushrooms[J]. Journal of the Science of Food and Agriculture,2019,99(4):1691−1699. doi: 10.1002/jsfa.9358

[29] 谢丽源, 兰秀华, 唐杰等. 不同羊肚菌品种氨基酸营养评价及等鲜浓度值差异分析[J]. 天然产物研究与开发,2020,32(6):1023−1029, 979. [XIE L Y, LAN X H, TANG J, et al. Nutritional evaluation of different amino acids and difference analysis of equivalent umami concentration in Morchella spp J]. Natural Product Research and Development,2020,32(6):1023−1029, 979.

[30] HUA R, JIANG J X. Small leucine-rich proteoglycans in physiological and biomechanical function of bone[J]. Matrix Biology Plus,2021,11:100063. doi: 10.1016/j.mbplus.2021.100063

[31] YOSHIMURA Y, BISE T, SHIMAZU S R, et al. Effects of a leucine-enriched amino acid supplement on muscle mass, muscle strength, and physical function in post-stroke patients with sarcopenia:A randomized controlled trial[J]. Nutrition,2019,58:1−6. doi: 10.1016/j.nut.2018.05.028

[32] GUO Q Y, ADELINA N M, HU J T, et al. Comparative analysis of volatile profiles in four pine-mushrooms using HS-SPME/GC-MS and E-nose[J]. Food Control,2022,134:108711. doi: 10.1016/j.foodcont.2021.108711

[33] 毕永昭, 单启梅, 罗瑞明等. 不同冻结速率手抓羊肉挥发性风味物质差异分析[J]. 食品科学,2023,44(2):288−295. [BI Y Z, SHAN Q M, LUO R M, et al. Differences in volatile flavor compounds in hand-grab mutton frozen at different freezing rates[J]. Food Science,2023,44(2):288−295.] BI Y Z, SHAN Q M, LUO R M, et al. Differences in volatile flavor compounds in hand-grab mutton frozen at different freezing rates[J]. Food Science, 2023, 44(2): 288−295.

[34] 宋春燕, 王琪, 单壹壹, 等. 2, 4-二叔丁基苯酚对细叶小羽藓生理的影响[J]. 上海师范大学学报(自然科学版),2022,51(6):742−749. [SONG C Y, WANG Q, SHAN Y Y, et al. Effects of 2,4-di-tert-butyl phenol on physiology of Haplocladium microphyllum[J]. [J]. Journal of Shanghai Normal University(Natural Sciences),2022,51(6):742−749.] SONG C Y, WANG Q, SHAN Y Y, et al. Effects of 2,4-di-tert-butyl phenol on physiology of Haplocladium microphyllum[J]. [J]. Journal of Shanghai Normal University(Natural Sciences), 2022, 51(6): 742−749.

下载:

下载:

下载:

下载: