Effect of Various Packaging Forms on the Freshness of Market Shell Eggs

-

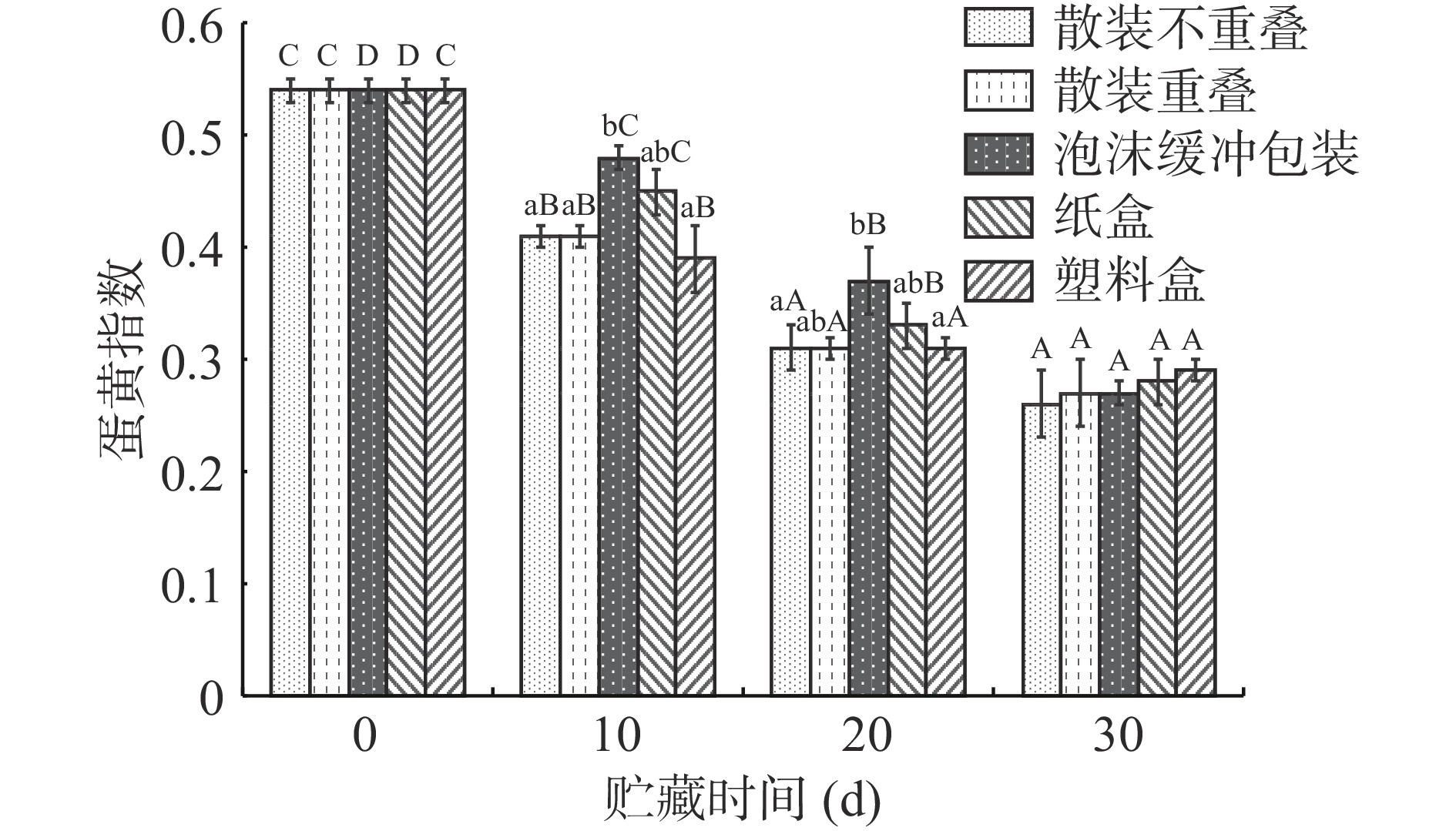

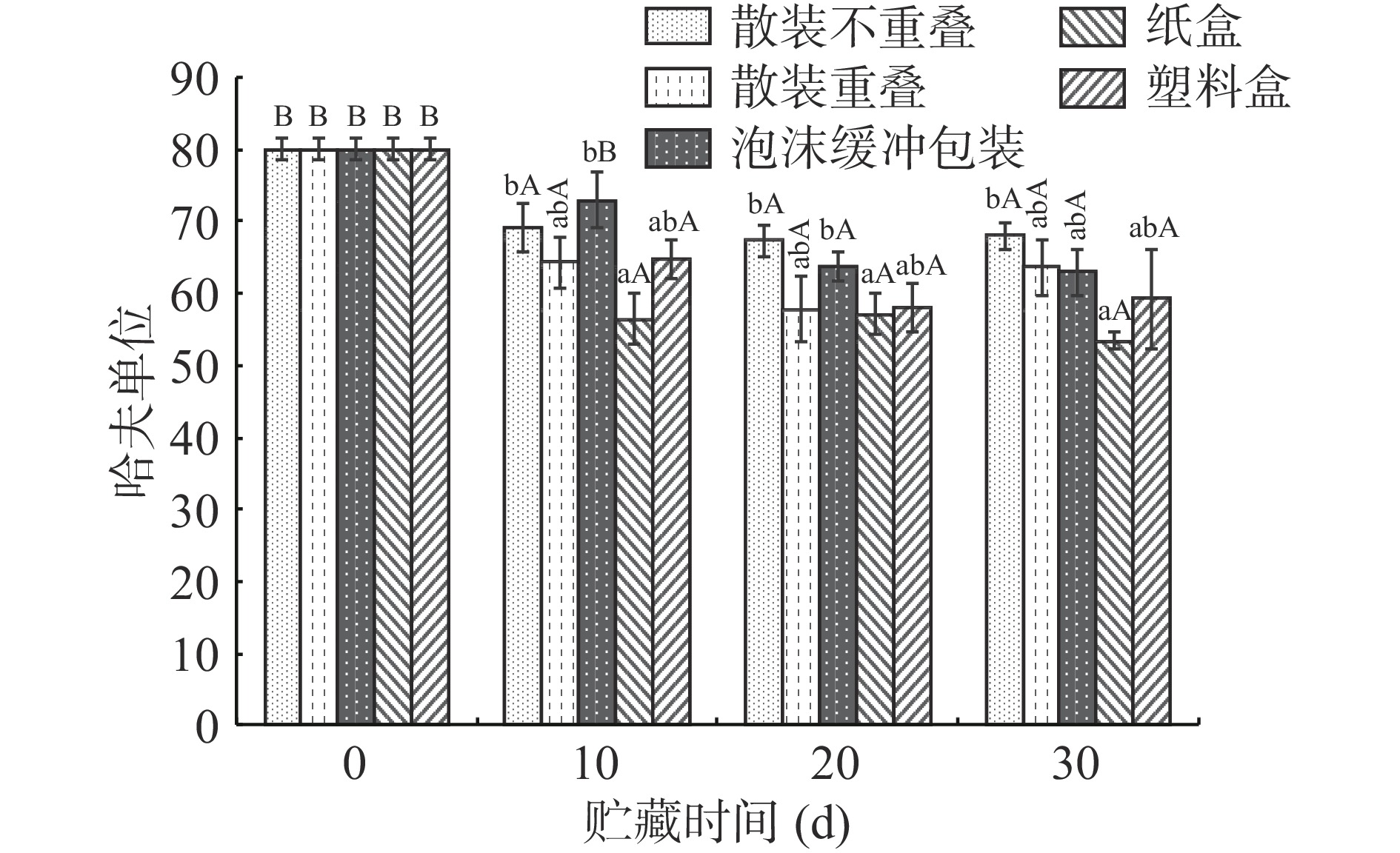

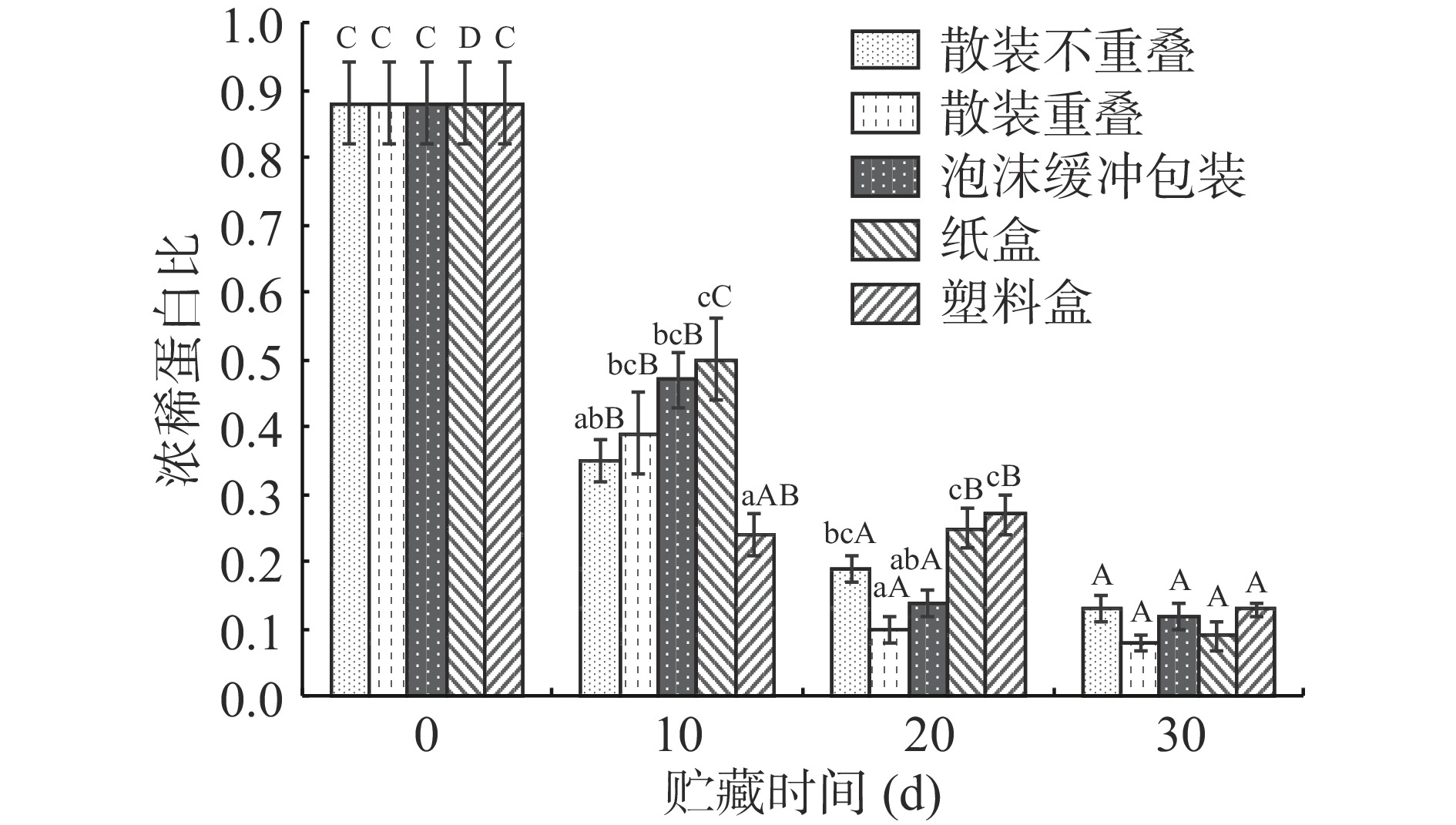

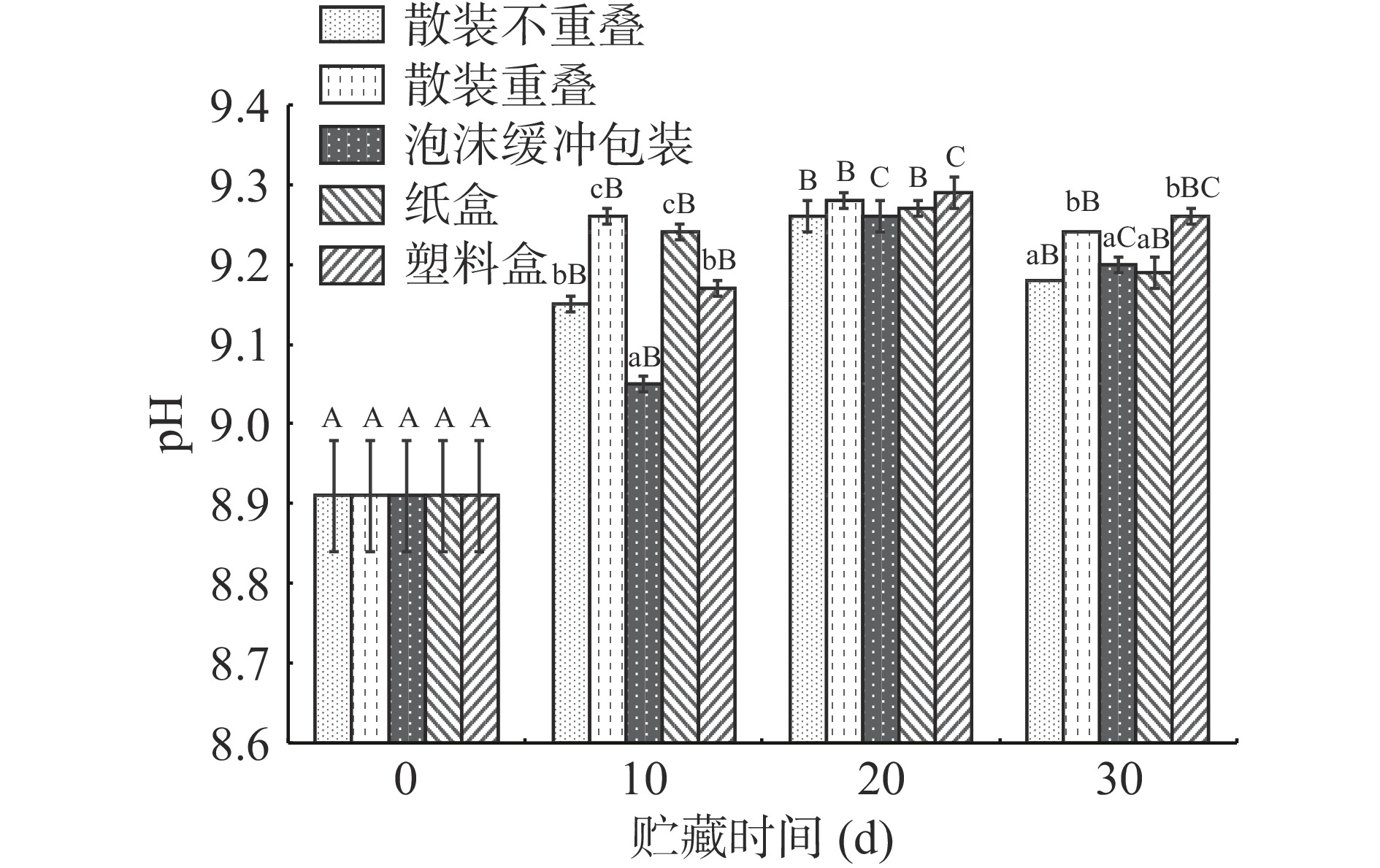

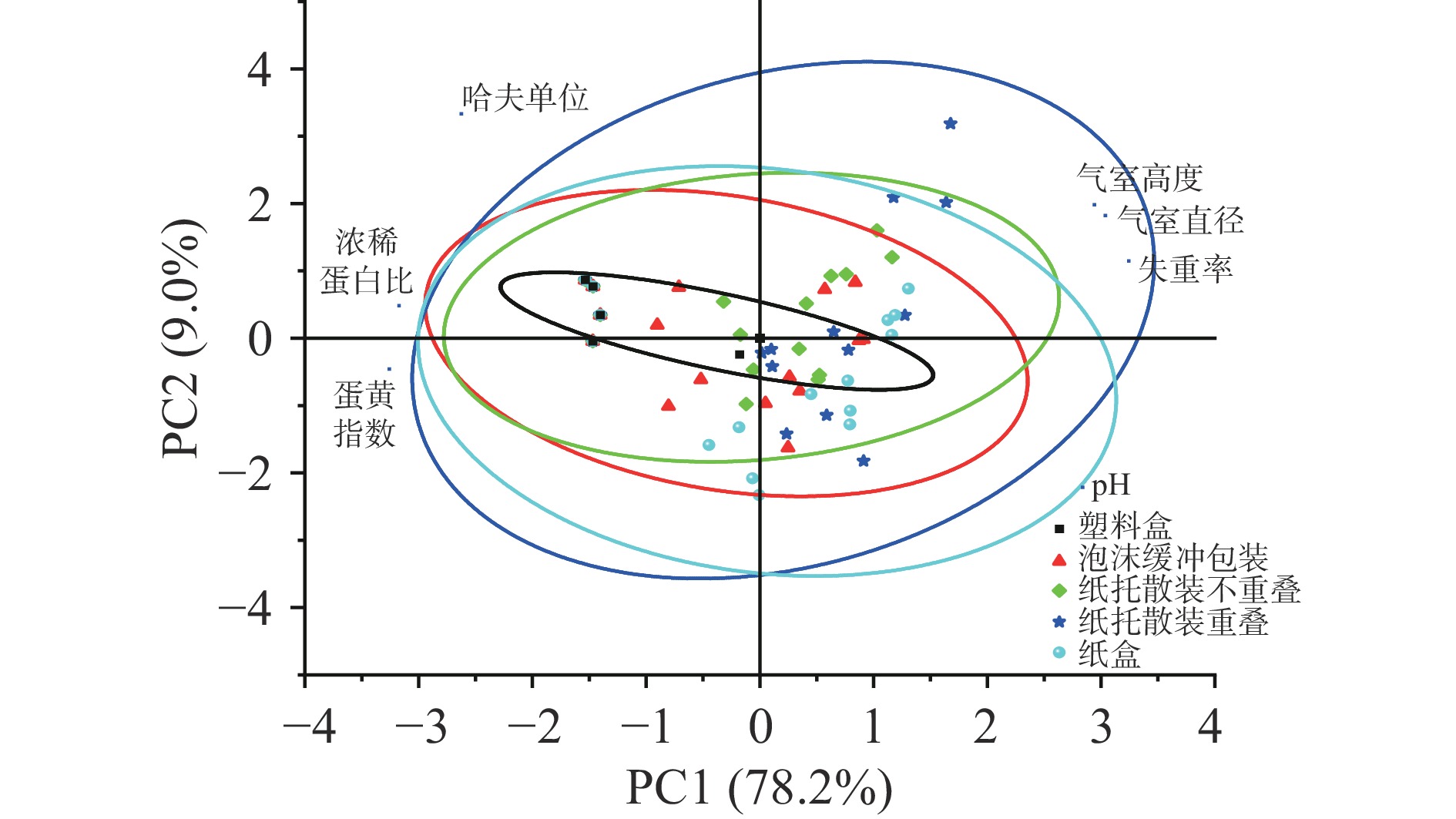

摘要: 该文以罗曼粉壳蛋为研究对象,探究市售壳蛋常用包装形式对于壳蛋新鲜度的影响,研究纸托散装不重叠组、散装重叠组、泡沫缓冲组、纸盒组和塑料盒组5种常见包装组壳蛋新鲜度指标变化,25 ℃贮藏30 d, 分别于0、10、20、30 d检测所有实验组壳蛋失重率、气室高度和气室直径、蛋黄指数、哈夫单位、浓稀蛋白比、蛋清pH。结果表明,贮藏10~30 d,纸托散装重叠组壳蛋失重率(2.33%~7.35%)、气室直径(2.46~3.17 cm)、蛋清pH(9.24~9.28)显著升高(P<0.05),而浓稀蛋白比(0.08~0.39)、蛋黄指数(0.27~0.41)显著下降(P<0.05)。纸盒组和塑料盒组壳蛋哈夫单位下降明显(P<0.05),泡沫缓冲组和纸托散装不重叠组壳蛋具有较低的气室高度。泡沫缓冲组壳蛋失重率(0.62%~5.46%)、气室直径(2.02~2.62 cm)、蛋清pH(9.05~9.26)较低,而蛋黄指数(0.27~0.48)较高。进一步通过主成分分析能较好区分塑料盒、泡沫缓冲包装组与其他3个包装组壳蛋,新鲜度指标贡献情况具有一定差异。因此,不改变环境条件,采用泡沫缓冲包装可以延缓贮藏期壳蛋新鲜度指标的劣变,该包装可应用于壳蛋贮藏与销售环节。Abstract: In order to investigate the effect of conventional packaging forms on the freshness of market shell eggs, this research investigated shell egg freshness of Roman pink in paper-based packaging without overlapped eggs arrangement, paper-based packaging with overlapped eggs arrangement, foam-based cushioning packaging, carton-based packaging, plastic-based packaging 5 groups. The shell eggs were stored at 25 ℃ for 30 d, and evaluated weight loss, air space diameter and height, yolk index, Haugh unit, thick-to-thin albumen ratio and albumen pH at 0, 10, 20, 30 d. The results showed that in shell eggs treated with paper-based packaging with overlapped eggs arrangement had significantly (P<0.05) higher values of weight loss (2.33%~7.35%), air space diameter (2.46~3.17 cm) and albumin pH (9.24~9.28), while obtained significantly (P<0.05) lower values of thick-to-thin albumen ratio (0.08~0.39) and yolk index (0.27~0.41). The Haugh unit decreased obviously (P<0.05) in shell eggs treated with carton and plastic-based packaging. Lower values of air space height were obtained in the shell eggs treated with foam-based cushioning packaging and paper-based packaging without overlapped eggs arrangement. Lower weight loss (0.62%~5.46%), air space diameter (2.02~2.62 cm), albumin pH (9.05~9.26) and higher yolk index values (0.27~0.48) were obtained in shell eggs treated with foam-based cushioning packaging. Furthermore, principal component analysis (PCA) could distinguish shell eggs treated with plastic-based packaging, foam-based cushioning packaging and other 3 packaging forms, and the contribution of freshness parameters was quite different between them. The results of this study indicated that the eggs treated with foam-based cushioning packaging could retard freshness deteriorations of shell eggs during storage, applying in shell egg storage and sale chain at the same environmental condition.

-

Keywords:

- Roman pink /

- shell egg /

- packaging /

- freshness /

- foam-based cushioning packaging

-

壳蛋富含多种人体所必需的抗氧化物、氨基酸、蛋白质、脂肪酸、维生素和矿物质等天然营养素[1],它作为一种低成本,高营养价值食品,为广大消费者喜爱。据统计,中国壳蛋产量已经达到世界总产量的35%[2]。然而,壳蛋属于高度易腐食品,其理化、营养及感官特性易受贮藏、运输、销售及加工条件影响[3−5]。壳蛋新鲜度是衡量壳蛋品质的重要参考,它影响着消费者接受程度与购买欲[6]。壳蛋蛋清稀薄化和pH增加,蛋黄膜纵向伸长、韧性下降,以及蛋黄水分增加等预示着壳蛋新鲜度指标的劣变[7]。

贮运条件是影响壳蛋新鲜度的重要因素[4]。前人开展贮藏温度、贮藏时间、运输破损情况、包装等对壳蛋新鲜度的影响[4],认为贮藏温度的升高与贮藏时间的延长是壳蛋新鲜度劣变的重要影响因素,采用杀菌、涂膜、冷藏、气调包装等方式可在某种程度上延缓贮藏壳蛋新鲜度的劣变[8]。壳蛋在生产、贮运、销售过程,都易发生破损,壳蛋包装则是一种有效防止壳蛋破损,限制壳蛋内部与环境中的气体交换,从而延缓壳蛋新鲜度劣变的重要方法[9]。Aygun等[10]研究发现,真空包装组壳蛋具有较高的哈夫单位、蛋黄指数,较低的蛋清和蛋黄pH、失重率,可将壳蛋货架期延长至42 d。Wang等[11]认为,相比对照组、塑料包装组、腊涂膜组,真空包装/腊涂膜处理组壳蛋品质维系更好。Wang等[12]发现采用明胶-细菌纤维素-MgO纳米复合薄膜包装后的壳蛋失重率明显下降。Wang等[13]认为H2-气调包装处理组壳蛋能够显著延缓壳蛋新鲜度指标中哈夫单位、蛋黄指数的下降和蛋清pH的升高,有效延长壳蛋货架期。Eddin等[14]认为可食性涂膜可作为特殊包装,有效保持壳蛋新鲜度,减少微生物污染情况。然而,上述研究仅改善包装-涂膜方式延长壳蛋新鲜度,并没有结合壳蛋贮销实际研究包装情况对壳蛋新鲜度的影响,也没有结合地方不同情况进行深入调研。因此,常见市场包装形式对壳蛋新鲜度的影响,国内外仍然鲜有模拟实际生产销售环节的系统研究,并没有形成有效指导壳蛋实际生产贮运的结论。

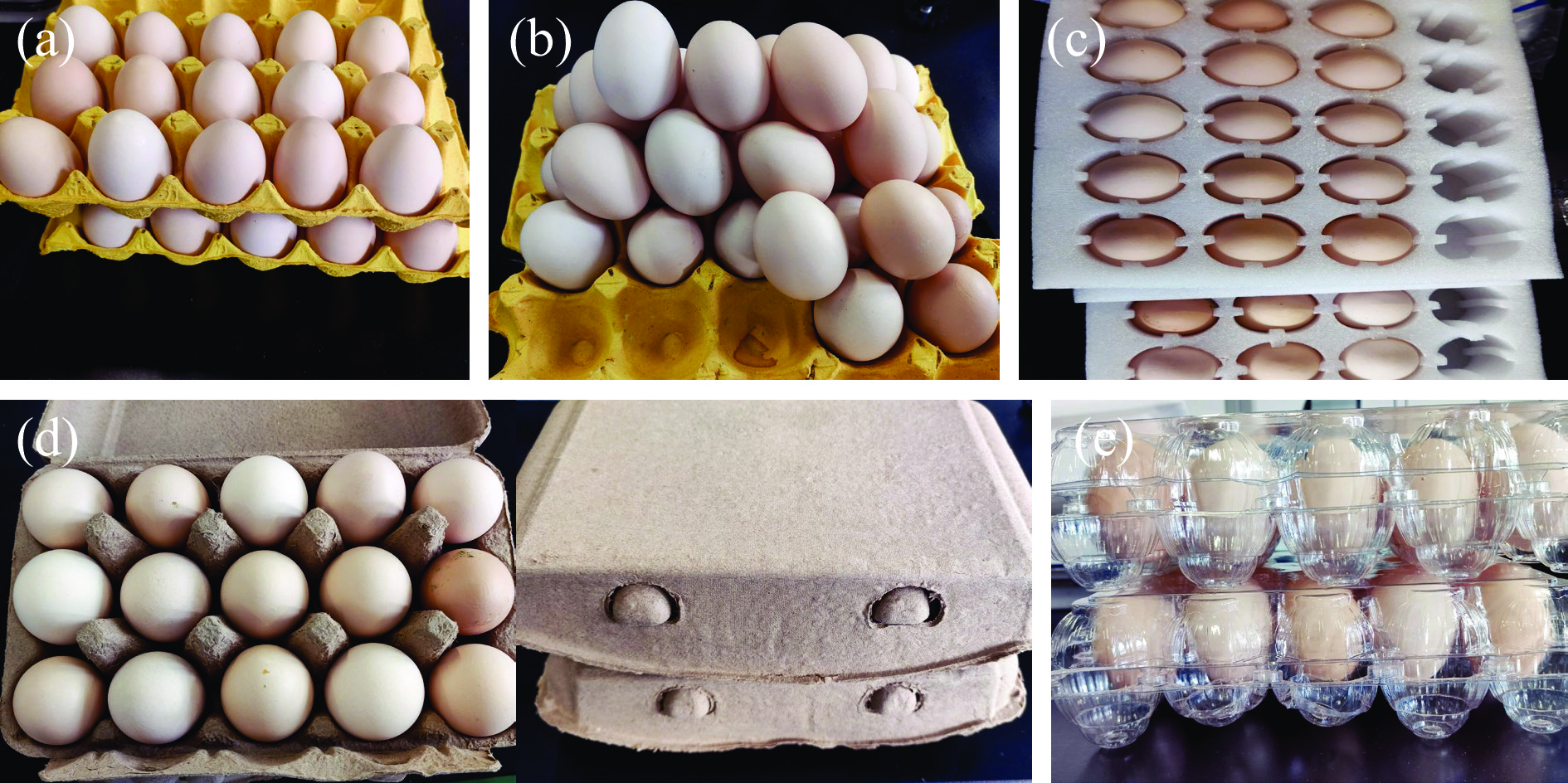

壳蛋贮销时,常采用纸/纸板[15]、塑料[16]、泡沫缓冲等为基材的蛋托[17]包装壳蛋(图1),从而减缓壳蛋贮运中的损耗,维持壳蛋新鲜度水平。然而,国内外市场零售壳蛋,仅使用简易纸/纸板包装,部分品牌壳蛋多采用纸盒或塑料盒的包装形式,泡沫缓冲通常结合纸箱包装,有效缓冲压力,避免壳蛋运输途中破损,从而延缓品质下降。然而不同原始、简易包装到底对壳蛋新鲜度有何影响,仍然无从得知。

因此,本文在深入调研壳蛋市场包装的基础上,设计了一组试验,研究以纸托为基础材料的散装不重叠、散装重叠包装,泡沫缓冲包装,纸盒包装,塑料盒包装壳蛋后,25 ℃贮藏30 d, 研究5组包装处理对贮藏壳蛋新鲜度的影响,探明在相同贮运环境下,哪种包装更适合壳蛋新鲜度保持,同时为今后壳蛋贮运保鲜提供更多实用性思路。

1. 材料与方法

1.1 材料与仪器

新鲜罗曼粉壳蛋 重庆市长寿区可美禽蛋销售中心提供;标准筛网(规格40目) 三信汇一家居专卖店。

WANTE电子天平 杭州万特衡器有限公司;FSH-2实验室高速分散均质机 常州润华电器有限公司;PHS-3C型台式酸度计 上海仪电科学仪器股份有限公司;BCD-606WKPZM型双开门控温冰箱 美的集团;LBI-150生化培养箱 上海龙跃仪器设备有限公司。

1.2 实验方法

1.2.1 样品处理

将购买的同一批次壳蛋310枚,分为5个试验组:纸托散装不重叠组、散装重叠组、泡沫缓冲组、纸盒组和塑料盒组(图2)。5组每组随机取60枚壳蛋,置于25 ℃培养箱中贮藏10、20和30 d后随机取4枚测定各项指标。

![]() 图 2 壳蛋纸托散装不重叠(a)、纸托散装重叠(b)、泡沫缓冲(c)、纸盒(d)和塑料盒(e)包装分组Figure 2. The groups of shell egg paper-based packaging without overlapped eggs arrangement (a), paper-based packaging with overlapped eggs arrangement (b), foam-based cushioning packaging (c), carton-based packaging (d), plastic based packaging (e)

图 2 壳蛋纸托散装不重叠(a)、纸托散装重叠(b)、泡沫缓冲(c)、纸盒(d)和塑料盒(e)包装分组Figure 2. The groups of shell egg paper-based packaging without overlapped eggs arrangement (a), paper-based packaging with overlapped eggs arrangement (b), foam-based cushioning packaging (c), carton-based packaging (d), plastic based packaging (e)1.2.2 失重率

参考戴妍等[4]的方法,依次测量初始鸡蛋质量,记为m1。贮藏一定时间后的鸡蛋质量,记为m2,代入公式(1)求得失重率。

(1) 1.2.3 气室直径和气室高度

参考戴妍等[4]和Zhang等[18]的方法,略有修改。将鸡蛋钝端标记、用一个细针钻孔,而后小心深入游标卡尺,直至卡尺顶端垂直接触蛋清内膜,读取数值h(mm),记录为气室高度;将游标卡尺深入壳蛋中,读出气室直径数值D(cm)。

1.2.4 蛋黄指数

参考戴妍等[4]的方法,鸡蛋磕开后,将鸡蛋内容物全部轻倒入玻璃板上,使用游标卡尺测得蛋黄高度H(cm)和横向直径D(cm),代入下列公式(2)求得蛋黄指数(Yolk Index,YI)。

(2) 1.2.5 哈夫单位

参考戴妍等[4]的方法,鸡蛋先称重,记录数据M(g),而后磕开,将鸡蛋内容物全部轻倒入玻璃板上,使用游标卡尺测得距离蛋黄1 cm处(避开系带)浓蛋白高度H(mm),代入下列公式(3)求得哈夫单位(Haugh Unit,HU)。

(3) 1.2.6 浓稀蛋白比

参考Dai等[4]的方法,将蛋壳横向磕破后,分离并弃去蛋黄和系带,称量总蛋白质量m1(g),将总蛋白全部倒入40目筛中,过滤并分离稀薄蛋白,记录稀薄蛋白质量m2(g)。代入下列公式(4)求得浓稀蛋白比。

(4) 1.2.7 蛋清pH

参考戴妍等[4]的方法,分离蛋清、蛋黄,用玻璃棒将蛋清搅匀后(弃去系带),使用均质机以10000 r/min的转速将蛋清均质10 s后,采用pH计测定蛋清样品的pH。

1.3 数据处理

在所有实验中,每项指标均测定4组平行值,实验结果以平均值±标准误差(SE)的方式表示。用SPSS 16.0数据分析软件对各指标进行单因素方差分析(One-way ANOVA),并采取多重比较法,P<0.05代表该指标存在显著性差异。采用OriginPro 2021统计软件进行主成分分析(Principal Component Analysis,PCA)。

2. 结果与分析

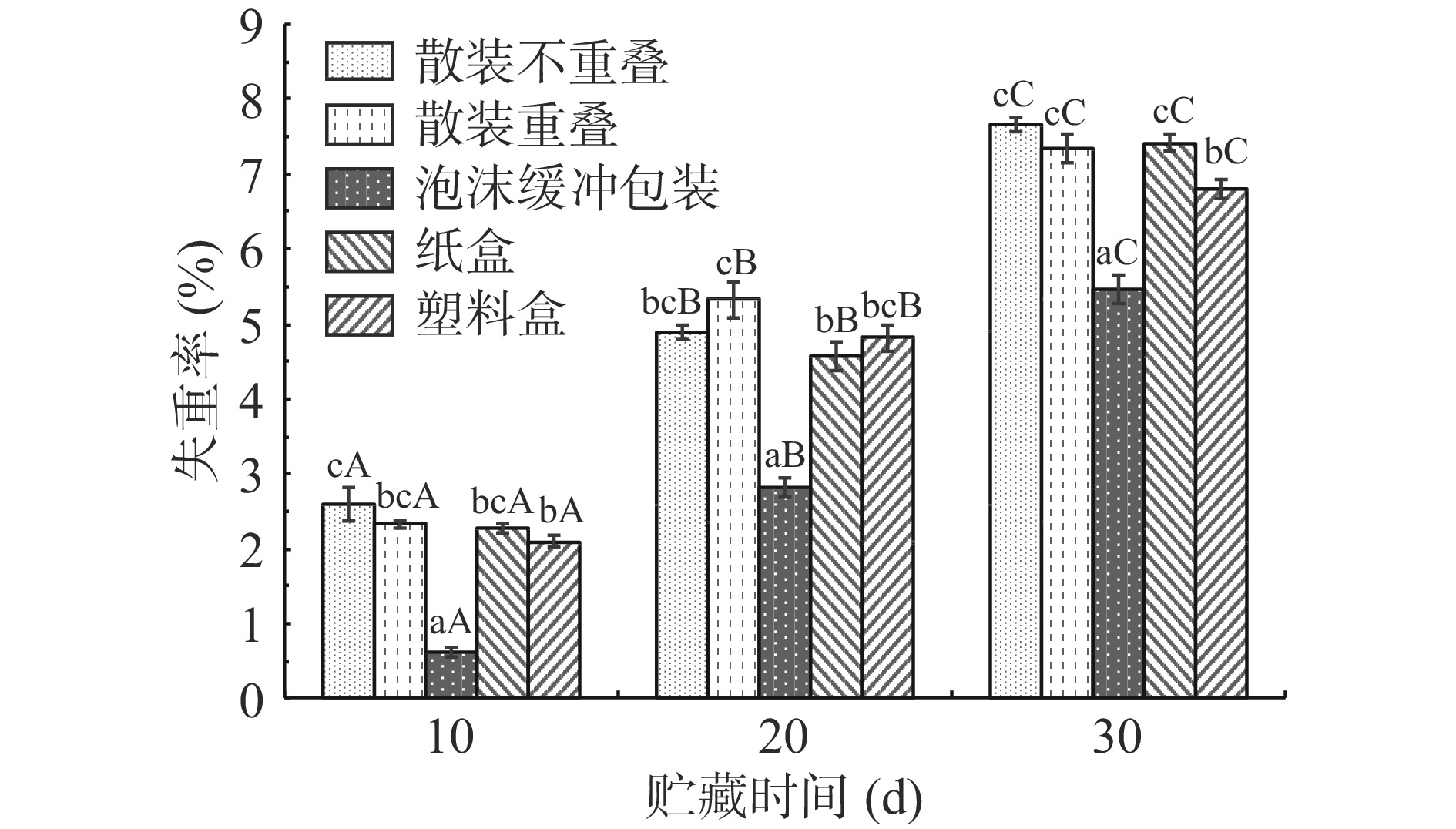

2.1 包装处理对壳蛋失重率的影响

壳蛋失重主要受环境温度、湿度及贮藏时间等的影响[19]。由图3可知,随着贮藏时间的延长,所有包装组失重率呈现显著上升(P<0.05)的趋势,与文献[19]的研究结论相似。在贮藏10~30 d时,泡沫缓冲包装组壳蛋失重率为0.62%~5.46%,显著低于(P<0.05)其他包装组。当贮藏10、30 d时,纸托散装重叠组、纸托散装不重叠组与纸盒组壳蛋失重率无显著差异(P>0.05)。因此,如果不能改变贮藏环境,泡沫缓冲包装可最大限度地减少蛋壳间摩擦破碎或“隐裂”引起的呼吸作用,从而延缓壳蛋失重情况,较低的失重率有助于延长壳蛋货架期,提升消费者接受程度。

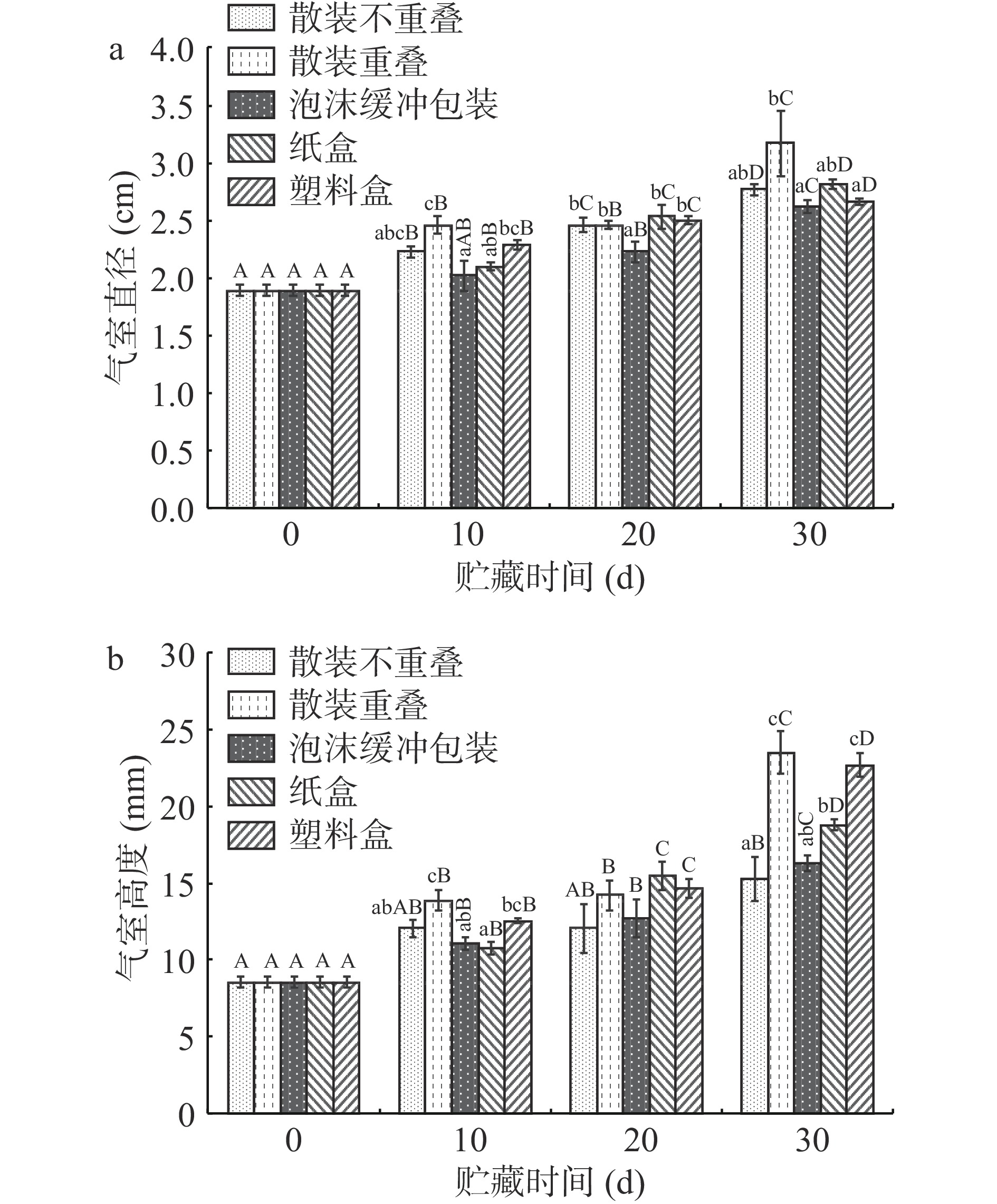

2.2 包装处理对壳蛋气室直径和气室高度的影响

贮藏期间,蛋内发生物化反应,随着水分流失和CO2逸出,壳蛋气室增大[20],贮藏时间对壳蛋气室尺寸影响显著[21]。由图4可知,贮藏20~30 d时,5组包装组气室直径显著高于(P<0.05)贮藏0 d的对照组。贮藏30 d时,5个包装处理组壳蛋气室高度(15.28~23.50 mm)显著高于(P<0.05)贮藏0 d的对照处理组(8.53 mm)。贮藏0 d时,该批次对照组壳蛋气室高度接近二级壳蛋气室标准(<8 mm),在25 ℃贮藏10~30 d,所有包装组壳蛋气室高度远未达三级壳蛋气室标准(<9.5 mm)[4]。贮藏10~30 d,纸托散装重叠包装组壳蛋气室直径(2.46~3.17 cm)显著高于(P<0.05)泡沫缓冲包装组(2.02~2.62 cm),贮藏10 d和30 d时,纸托散装重叠包装组壳蛋气室高度(13.8、23.50 mm)显著高于(P<0.05)纸托散装不重叠组、泡沫缓冲和纸盒包装处理组。纸托散装重叠组气室高度(13.88、23.50 mm)与塑料盒包装组(12.53、22.70 mm)无显著差异(P>0.05)。文献[22]发现基于纸托为基础的包装与塑料包装并不能阻止壳蛋气室高度增加的情况,与本文研究结论相似,可能纸托散装重叠组壳蛋由于壳蛋排列重叠,造成壳蛋间挤压产生微小“裂痕”,蛋内水分流失和气体逸出加剧,引起气室显著增大,泡沫缓冲包装可能有助于延缓壳蛋气室变大引起的新鲜度劣变。

2.3 包装处理对壳蛋蛋黄指数的影响

随着贮藏期的延长,壳蛋蛋黄指数随之下降[23]。由图5可知,0 d的对照组和贮藏10 d所有包装组壳蛋蛋黄指数显著高于(P<0.05)贮藏20~30 d时相同包装组。蛋黄指数的下降预示着蛋黄品质的劣变[24],贮藏10~20 d时,泡沫缓冲包装组壳蛋蛋黄指数(0.37~0.48)显著高于(P<0.05)纸托散装不重叠和塑料盒包装组。泡沫缓冲包装组(0.37~0.48)和纸盒组壳蛋蛋黄指数(0.33~0.45)无显著差异(P>0.05)。因此,泡沫缓冲包装具有延缓蛋黄膜强度弱化,阻止蛋清水分渗透导致的蛋黄指数下降引起贮藏期壳蛋新鲜度劣变的作用。

2.4 包装处理对壳蛋哈夫单位的影响

由图6可知,0 d对照组壳蛋哈夫单位(80.07)和贮藏10 d泡沫缓冲包装处理组(72.97)显著高于(P<0.05)贮藏20~30 d相同包装组(62.92~63.79)。0 d对照组哈夫单位(80.07)与贮藏10 d泡沫缓冲包装处理组(72.97)无显著差异(P>0.05)。贮藏10~30 d时,其他4个包装组壳蛋哈夫单位无明显差异(P>0.05),显著低于(P<0.05)0 d对照组。随着贮藏期的延长,哈夫单位随之下降,可能与蛋清中大量聚集素(Clusterin)、抑制蛋白(Ovoinhibitory)及蛋清蛋白无序化结构形成有关[24]。

贮藏10~20 d时,纸托散装不重叠组(67.36~69.20)和泡沫缓冲包装组壳蛋哈夫单位(63.79~72.97)显著高于(P<0.05)纸盒组(53.17~56.50)。贮藏30 d时,纸托散装不重叠组壳蛋哈夫单位(68.11)显著高于(P<0.05)纸盒组(53.37)。据分级标准,壳蛋哈夫单位≥72时,壳蛋分级为AA级,60~72为A级,30~60为B级,AA级和A级预示蛋清质量较好,适合消费者食用[25]。纸托散装不重叠和泡沫缓冲包装组壳蛋哈夫单位在30 d贮藏期内,均达到A级以上标准,蛋清品质较好。

2.5 包装处理对壳蛋浓稀蛋白比的影响

浓稀蛋白比是衡量蛋清组成的重要参数,浓稀蛋白比越高,表明蛋清中浓蛋白占比越高,蛋清品质相对较好[26],蛋清浓蛋白含量较高[27]。由图7所知,0 d对照组(0.88)、贮藏10 d纸托散装不重叠组(0.35)、重叠组(0.39)、泡沫缓冲包装组(0.47)和纸盒组(0.50)显著高于(P<0.05)贮藏20~30 d相同组壳蛋浓稀蛋白比。贮藏10~20 d时,塑料盒组壳蛋浓稀蛋白比无显著差异(P>0.05)。贮藏20 d时,塑料盒组(0.27)显著高于(P<0.05)贮藏30 d时的壳蛋浓稀蛋白比(0.13)。随着贮藏时间的延长,壳蛋浓稀蛋白比呈现明显下降的趋势[28]。贮藏10 d时,塑料盒壳蛋浓稀蛋白比(0.24)显著低于(P<0.05)纸托散装重叠组(0.39)、泡沫缓冲(0.47)及纸盒包装组(0.50),贮藏20 d时,纸托散装重叠组浓稀蛋白比(0.10)显著低于(P<0.05)纸托散装不重叠组(0.19)、纸盒组(0.25)和塑料盒组(0.27)。因此,纸盒包装对于延缓浓稀蛋白比的下降效果较好,贮藏20 d时的效果相对稳定。

2.6 包装处理对壳蛋蛋清pH的影响

随着贮藏期的延长,蛋清pH增加[29−30]。由图8可知,贮藏10~30 d时,所有5个包装组蛋清pH显著高于(P<0.05)0 d对照组(8.91)。蛋清pH的增加可能与蛋清水样化过程中,蛋清中的水分转移至蛋黄、蛋壳气体逸出有关[31]。贮藏10 d时,泡沫缓冲包装组蛋清pH显著低于(P<0.05)其他处理组,贮藏30 d时,纸托散装不重叠(9.18)、泡沫缓冲(9.20)和纸盒组蛋清pH(9.19)显著低于(P<0.05)其他包装组。高蛋清pH可进一步弱化蛋黄膜韧性,增强壳蛋中气体和水分逸出率,增加失重损失[31]。由此可见,泡沫缓冲包装可能在缓冲壳蛋外部压力的前提下,可在一定程度上阻止蛋清pH上升引起的壳蛋新鲜度劣变。

2.7 主成分分析

图9显示不同包装处理壳蛋新鲜度的PCA分析,所有壳蛋处理组新鲜度在PC1和PC2两个维度上有所区分,能反映原始数据的变异信息,其中PC1和PC2的贡献度分别为78.2%和9.0%。泡沫缓冲包装组壳蛋(红圈)均匀分布在4个象限,离浓稀蛋白比和蛋黄指数的距离比较近,纸质散装重叠组壳蛋(深蓝色)、纸质散装不重叠组壳蛋(绿色)主要分布于第2和第4象限,距离新鲜度指标(气室高度、气室直径、失重率、pH)较近。纸盒组壳蛋(浅蓝色)主要分布于第2、3、4象限,距离pH较近。塑料盒组壳蛋主要分布于第1象限,距离浓稀蛋白比较近。通过PCA分析,可以将5组不同包装处理组壳蛋良好区分,其中纸质散装重叠、纸质散装不重叠与纸盒包装组壳蛋新鲜度指标区别不大,与塑料盒、泡沫缓冲包装组壳蛋新鲜度指标有较为明显的区别。

3. 结论

该文初步研究市场常规包装对壳蛋新鲜度的影响。以贮藏0 d的壳蛋组为对照组,研究5组包装处理对壳蛋新鲜度指标(失重率、气室高度和直径、哈夫单位、蛋黄指数、浓稀蛋白比、蛋清pH)的变化。结果表明,随贮藏期的延长,所有包装组壳蛋新鲜度指标呈现出劣变的情况。泡沫缓冲包装组在保护壳蛋,缓冲压力的前提下,具有较低的失重率(0.62%~5.46%)、气室直径(2.02~2.62 cm)和蛋清pH(9.05~9.26),较高的蛋黄指数(0.27~0.48),新鲜度指标的保持较其他包装组更为稳定。PCA分析可以明显区分塑料盒、泡沫缓冲包装组与其他3个包装组壳蛋。因此,除壳蛋自身品质、贮藏环境因素外,采用泡沫缓冲包装处理可在一定程度上保持壳蛋新鲜度,未来研究可在本试验的基础上,采用复合包装(如结合涂膜法),进一步延缓壳蛋新鲜度劣变,延长货架期。

-

图 2 壳蛋纸托散装不重叠(a)、纸托散装重叠(b)、泡沫缓冲(c)、纸盒(d)和塑料盒(e)包装分组

Figure 2. The groups of shell egg paper-based packaging without overlapped eggs arrangement (a), paper-based packaging with overlapped eggs arrangement (b), foam-based cushioning packaging (c), carton-based packaging (d), plastic based packaging (e)

-

[1] BRASIL Y L, CRUZ-TIRADO J P, BARBIN D F. Fast online estimation of quail eggs freshness using portable NIR spectrometer and machine learning[J]. Food Control,2022,131:108418. doi: 10.1016/j.foodcont.2021.108418

[2] GAUTRON J, DOMBRE C, NAU F, et al. Review: Production factors affecting the quality of chicken table eggs and egg products in Europe[J]. Animal, 2022, 16(Supplement 1):100425.

[3] LOFFREDI E, GRASSI S, ALAMPRESE C. Spectroscopic approaches for non-destructive shell egg quality and freshness evaluation: Opportunities and challenges[J]. Food Control,2021,129:108255. doi: 10.1016/j.foodcont.2021.108255

[4] 戴妍, 杨兵, 蒋文明, 等. 贮藏温度-时间变化对壳蛋新鲜度影响研究[J]. 食品工业科技,2022,43(18):359−364 DAI Y, YANG B, JIANG W M, et al. Study on the effect of storage temperature-time changes on shell egg freshness[J]. Science and Technology of Food Industry,2022,43(18):359−364.

[5] 陈德会, 杜环兴, 李山海, 等. 贮藏温度变化对壳蛋新鲜度的影响[J]. 2023, 44(7):337−342 CHEN D H, DU H X, LI S H, et al. The study of shell egg freshness following storage temperature change treatments[J]. Science and Technology of Food Industry, 2023, 44(7):337−342.

[6] HASSOUN A, KAROUI R. Quality evaluation of fish and other seafood by traditional and nondestructive instrumental methods: Advantages and limitations[J]. Critical Reviews in Food Science and Nutrition,2017,57(9):1976−1998.

[7] ZHOU Y, QIU N, MINE Y, et al. Quantitative comparative proteomic analysis of chicken egg vitelline membrane proteins during high-temperature storage[J]. Journal of Agricultural and Food Chemistry,2020,68(36):9816−9825. doi: 10.1021/acs.jafc.0c03538

[8] 范巧. 富含虾青素鸡蛋的加工适应性及消化特性研究[D]. 无锡:江南大学, 2022 FAN Q. Study on processing applicability and digestibility of astaxanthin-enriched hen eggs[D]. Wuxi:Jiangnan University, 2022.

[9] SEYDIM A C, DAWSON P L. Packaging effects on shell egg breakage rates during simulated transportation[J]. Poultry science,1999,78(1):148−151. doi: 10.1093/ps/78.1.148

[10] AYGUN A, SERT D. Effects of vacuum packing on eggshell microbial activity and egg quality in table eggs under different storage temperatures[J]. Journal of the Science of Food and Agriculture,2013,93(7):1626−1632. doi: 10.1002/jsfa.5936

[11] WANG Y, XIONG C, LUO W, et al. Effects of packaging methods on the quality of heavy metals-free preserved duck eggs during storage[J]. Poultry Science,2021,100(5):101051. doi: 10.1016/j.psj.2021.101051

[12] WANG Y, LUO W, TU Y, et al. Gelatin-based nanocomposite film with bacterial cellulose-MgO nanoparticles and its application in packaging of preserved eggs[J]. Coatings,2021,11(1):39. doi: 10.3390/coatings11010039

[13] WANG Y, WANG J, KUANG Y, et al. Packaging with hydrogen gas modified atmosphere can extend chicken egg storage[J]. Journal of the Science of Food and Agriculture,2022,102(3):976−983. doi: 10.1002/jsfa.11431

[14] EDDIN A S, IBRAHIM S A, TAHERGORABI R. Egg quality and safety with an overview of edible coating application for egg preservation[J]. Food chemistry,2019,296:29−39. doi: 10.1016/j.foodchem.2019.05.182

[15] DESHWAL G K, PANJAGARI N R, ALAM T. An overview of paper and paper based food packaging materials: Health safety and environmental concerns[J]. Journal of Food Science and Technology,2019,56:4391−4403. doi: 10.1007/s13197-019-03950-z

[16] PAUNONEN S, PITKÄNEN M, VÄHÄ-NISSI M, et al. Comparison of organic food packaging in Denmark, Finland, Germany, great Britain and Italy[J]. Journal of Applied Packaging Research,2019,11(1):6.

[17] LIU G R, CHEN G, DUAN S Y. Towards total protection from impact: A viability study using EPE foam to protect falling eggs[J]. Transportation Safety and Environment,2019,1(2):154−163. doi: 10.1093/tse/tdz004

[18] ZHANG J, ZHANG M, LIANG W, et al. Green tea powder supplementation increased viscosity and decreased lysozyme activity of egg white during storage of eggs from Huainan partridge chicken[J]. Italian Journal of Animal Science,2020,19(1):586−592. doi: 10.1080/1828051X.2020.1769512

[19] KHAN M J A, KHAN S H, BUKHSH A, et al. Effect of different storage period on egg weight, internal egg quality and hatchability characteristics of Fayumi eggs[J]. Italian Journal of Animal Science,2013,12(2):e51. doi: 10.4081/ijas.2013.e51

[20] ABOONAJMI M, SETAREHDAN S K, AKRAM A, et al. Prediction of poultry egg freshness using ultrasound[J]. International Journal of Food Properties,2014,17(9):1889−1899. doi: 10.1080/10942912.2013.770015

[21] KIM J G, PARK J Y, KIM J S. Effects of storage time and temperature on the hygienic quality of shell eggs[J]. Journal of Environmental Health Sciences,2015,41(6):438−448. doi: 10.5668/JEHS.2015.41.6.438

[22] SENANAYAKE S, KARUNARATHNE K, WICKRAMASINGHE H. Preservation of quality indices of commercial eggs in different packing materials at control temperature in Sri Lanka[C]. 15th Agricultural Research Symposium (2016), Faculty of Agriculture and Plantation management, Wayamba University of Sri Lanka, 2016.

[23] WANG B, WEI W, APUTEXIAKERE J, et al. Surface decontamination of whole eggs using pulsed light technology and shelf life study of combined pulsed light and vaseline coating during room temperature storage[J]. Food Control,2022,137:108411. doi: 10.1016/j.foodcont.2021.108411

[24] SARIYEL V, AYGUN A, COKLAR H, et al. Effects of prestorage application of gum arabic coating on the quality of table eggs during storage[J]. Kafkas Üniversitesi Veteriner Fakültesi Dergisi,2022,28(3):363−370.

[25] NORTHCUTT J K, BUYUKYAVUZ A, DAWSON P L. Quality of Japanese quail ( Coturnix coturnix japonica) eggs after extended refrigerated storage[J]. Journal of Applied Poultry Research,2022,31(3):100280. doi: 10.1016/j.japr.2022.100280

[26] WAN Y, JIN S, MA C, et al. Effect of strain and age on the thick-to-thin albumen ratio and egg composition traits in layer hens[J]. Animal Production Science,2018,59(3):416−419.

[27] TAN F J, RUNGRUENGPET W, SIMSIRI U, et al. Influences of egg washing and storage temperature on quality and shelf life of duck eggs during storage[J]. Brazilian Journal of Poultry Science, 2022:1−8.

[28] WAN Y, JIN S, MA C, et al. RNA-Seq reveals seven promising candidate genes affecting the proportion of thick egg albumen in layer-type chickens[J]. Scientific Reports,2017,7(1):18083. doi: 10.1038/s41598-017-18389-5

[29] MELO E F, ARAÚJO I C S, TRIGINELLI M V, et al. Effect of egg storage duration and egg turning during storage on egg quality and hatching of broiler hatching eggs[J]. Animal,2021,15(2):100111. doi: 10.1016/j.animal.2020.100111

[30] NINGRUM A S H, THOHARI I, AL AWWALY K U, et al. The effect of using edible coating whey protein isolate and chitosan with the addition of 0.1% sodium tripolyphosphate on the quality of chicken egg[J]. International Research Journal of Advanced Engineering and Science,2022,7(4):201−205.

[31] OBIANWUNA U E, OLEFORUH-OKOLEH V U, WANG J, et al. Potential implications of natural antioxidants of plant origin on oxidative stability of chicken albumen during storage: A review[J]. Antioxidants,2022,11(4):630. doi: 10.3390/antiox11040630

-

期刊类型引用(2)

1. 韩婕珺,洪铮怡,龚天贵,王斌,张蓝月. 牡丹籽乙醇提取物对UVB诱导HaCaT细胞光老化的保护作用及机制研究. 食品工业科技. 2024(15): 351-359 .  本站查看

本站查看

2. 肖检妹,吴月亮,崔苏菲,张美玲,万彧,王兵,王军伟,熊程. 不同光质条件下植物AsA合成积累的研究进展. 辣椒杂志. 2024(02): 7-12 .  百度学术

百度学术

其他类型引用(1)

下载:

下载:

下载:

下载: