Preparation and Characterization of Pickering Emulsion of Soybean Protein Isolate-Carrageenan-Xanthan Terpolymer

-

摘要: 本研究制备大豆分离蛋白(Soybean protein isolate,SPI)-卡拉胶-黄原胶三元复合Pickering乳液,考察不同SPI与卡拉胶-黄原胶配比、乳液pH、卡拉胶质量浓度、黄原胶质量浓度以及大豆油内相体积对三元Pickering乳液体系的粒径、Zeta电位、乳化活性指数(Emulsifying activity index,EAI)、乳化稳定性(Emulsifying stability index,ESI)和SPI二级结构的影响,并研究常温贮藏条件下不同内相体积乳液体系的特性变化。结果表明:当SPI与复合多糖的质量浓度比为1:10,pH为9.0,卡拉胶和黄原胶质量浓度均为0.2%,油相体积为10%~85%时,SPI-卡拉胶-黄原胶三元复合Pickering乳液的稳定性均较好,平均粒径达351±24.12 nm,Zeta电位绝对值达99.4±1.4 mV。随着大豆油内相体积从10%增大至85%,Pickering乳液颗粒的粒径分布更加均一、稳定,当油相体积分数为75%时,乳液颗粒分散状态最佳,EAI和ESI达到最大值,SPI α-螺旋和β-折叠含量最高。常温贮藏实验表明,随着时间的延长,不同内相体积Pickering乳液粒径整体呈升高趋势,Zeta电位的绝对值、EAI和ESI整体呈下降趋势;所有乳液的α-螺旋含量和β-转角含量有所下降,β-折叠有所增加,无规卷曲含量变化不明显;内相体积75%和85%的高内相乳液较10%~50%的乳液显示出更好的稳定性。综上,本研究探讨了SPI-卡拉胶-黄原胶三元复合Pickering乳液的制备及特性表征,为功能性物质靶向递送和脂肪代替物应用创新提供了技术参考。

-

关键词:

- SPI-卡拉胶-黄原胶 /

- Pickering乳液 /

- 制备 /

- 特性表征

Abstract: In this study, the Pickering emulsion of soybean protein isolate (SPI)-carrageenan-xanthan terpolymer was prepared. The effects of ratio of SPI to carraneenan-xanthan, pH, mass concentration of carraneenan, mass concentration of xanthan and volume of soybean oil on the particle size, Zeta potential, emulsifying activity index (EAI), emulsifying stability index (ESI) and SPI secondary structure of Pickering emulsion system were all investigated. Besides, the characteristics of emulsion system with different volume of inner phase during storage at normal temperature were studied. The results showed that the stability of Pickering emulsion of SPI-carrageenan-xanthan terpolymer was good, when the mass concentration ratio of SPI to the complex polysaccharide was 1:10, pH was 9.0, the mass concentration of carrageenan and xanthan both were 0.2%, and the oil volume was 10%~85%. Under this conditions, the average particle size of Pickering emulsion of SPI-carrageenan-xanthan terpolymer was 351±24.12 nm, and the absolute value of Zeta potential was 99.4±1.4 mV. As the inner phase volume of soybean oil increased from 10% to 85%, the particles size distribution of Pickering emulsion became more uniform and stable. When the oil volume was 75%, the dispersion state of emulsion particles was the best, EAI and ESI reached the maximum, and α-helix and β-fold contents of SPI were the highest. In addition, the storage experiments at normal temperature showed that the particle size of Pickering emulsion with different volume of inner phase showed an overall increasing trend, and the absolute value of zeta potential, EAI and ESI showed an overall decreasing trend with the storage time extending. The α-helix content and β-angle content of all emulsions decreased, while β-folding increased, and random crimp content did not change significantly. High inner phase emulsions with 75% and 85% inner phase volume showed better stability than those with 10%~50% inner phase volume. In conclusion, this study explored the preparation and characterization of Pickering emulsion of SPI-carrageenan-xanthan terpolymer, aimed to provide technical reference for targeted delivery of functional substances and application innovation of fat substitutes. -

皮克林乳液(Pickering emulsions)是采用胶体粒子取代传统表面活性剂进行稳定的乳液,较传统乳液更环保、安全和稳定,因其可以包埋生物活性物质、且能够用于制备新型材料而在多个领域广泛应用[1-2]。以食品科学领域为例,食品级颗粒的应用赋予了Pickering乳液极广阔的前景,食品级颗粒大体分为三种类型:多糖颗粒、蛋白质基颗粒以及复合物颗粒[3]。其中,研究较多的是多糖和蛋白质复合颗粒,颗粒间通过静电吸引、氢键、疏水相互作用等非共价键结合[4-5],复合体系能够提高单一颗粒的ESI以及乳液的热稳定性、pH稳定性等环境应变能力,从而增强乳液及其凝胶体系的稳定性[6]。

SPI(Soybean protein isolate)是一种优质的植物蛋白,含有近20种氨基酸,包括了人体必需的8种氨基酸,其具有凝胶性、吸水性、乳化性、起泡性等多种功能特性[7-9]。卡拉胶(Carrageenan)是从红藻类海草中提炼出来的亲水性胶体,具有较强的稳定性,在食品工业中通常将其用作胶凝剂、乳化剂和稳定剂等,同时,它又因具有可溶性膳食纤维的基本特性而成为益生菌的能量源,具有一定的健康价值[10]。研究显示,卡拉胶添加能够显著提升乳液凝胶的可塑性、持水性、物理稳定性、硬度和粘弹性[11]。黄原胶(Xanthan)是一种由黄单胞菌属经有氧发酵产生的细胞外杂多糖,属于阴离子多糖,因其具有良好的水溶性、热稳定性等特点,在食品、石油、医药等十几个领域有着极其广泛的应用[12-13]。姜宗伯等[14]报道,黄原胶浓度的增加能够增加初榨椰子油乳液的机械强度,且降低油凝胶中油脂的损失。

研究显示,单一的大分子物质制备的Pickering乳液稳定性及流变特性较差,而通过分子间交联制备的复合乳液则表现出良好的理化性质[15]。朱秀清等[16]用不同添加量的不同种类多糖与SPI复合,制备多糖-蛋白复合体系乳液及乳液凝胶,发现一定的多糖添加可以显著提高乳液及乳液凝胶体系的稳定性,并且可以改变SPI的二级结构。SPI与多糖复合,能够显著提高乳液凝胶体系的质构、保水性能及稳定性[17],且不同原料添加顺序的复合物其结合过程不同[18]。黄欢等[19]利用酪蛋白酸钠和黄原胶的复合物作为乳化剂,制备了具有高稳定性的椰子油乳液。

综上可知,SPI、卡拉胶和黄原胶都是稳定乳液及凝胶的原材料,但鉴于不同大分子性质各异,以不同配比制备的复合乳液及凝胶体系有着不同的理化特性。目前尚未见有关SPI-卡拉胶-黄原胶三元复合Pickering乳液的报道。由此,本研究拟选用SPI、卡拉胶和黄原胶作为基础原料,通过调节SPI与复合多糖(卡拉胶和黄原胶)的配比、乳液pH、卡拉胶质量浓度、黄原胶质量浓度以及大豆油内相体积等条件,制备具有良好稳定性的SPI-卡拉胶-黄原胶三元复合Pickering乳液,并表征其理化特性,为功能性物质靶向递送和脂肪代替物的应用创新提供了技术参考。

1. 材料与方法

1.1 材料与仪器

SPI、卡拉胶、黄原胶 浙江一诺生物科技有限公司;大豆油 上海益海嘉里金龙鱼粮油食品股份有限公司;甘氨酸、浓盐酸、柠檬酸、磷酸氢二钠(AR)、磷酸二氢钾(AR)、氢氧化钠 均为分析纯,西陇科学股份有限公司。

DF-101S集热式恒温磁力搅拌器 上海力辰邦西仪器科技有限公司;AT12CN电子天平 奥豪斯仪器(上海)有限公司;RMRH高速剪切乳化机 江苏鲁米智能装备制造有限公司;NanoZS90纳米粒度、Zeta电位分析仪 马尔文仪器有限公司;Vortex-5涡旋振荡仪 海门市其林贝尔仪器制造有限公司;CT3-10K质构仪 美国博勒飞公司;UV5100B紫外分光光度计 上海元析仪器有限公司;Nicolet iS50傅里叶红外分光光度计 美国赛默飞世尔公司;DM500-ICC50W生物数码显微镜 徕卡显微系统有限公司。

1.2 实验方法

1.2.1 SPI-卡拉胶-黄原胶复合乳液的制备

参考Feng等[20]的研究方法,略有修改。

SPI溶液的制备:称取50 g的SPI粉,分散于1000 mL的蒸馏水中,使得SPI浓度为5%,在室温环境下1500 r/min转速搅拌2 h,于4 ℃条件下过夜水化。调整pH至7.0,于80 ℃加热1500 r/min转速搅拌30 min,冷却至室温。

卡拉胶-黄原胶溶液的制备:分别称取一定质量的卡拉胶与黄原胶粉末,各自分散于1000 mL的蒸馏水中,制得卡拉胶和黄原胶原液,将两种溶液按1:1(v/v)混合,充分搅拌均匀得卡拉胶-黄原胶溶液,于4 ℃存放备用。

SPI-卡拉胶-黄原胶复合乳液的制备:将SPI与卡拉胶-黄原胶溶液以1:1(v/v)比例混合,用1 mol/L的HCl或NaOH调整混合溶液的pH,于65 ℃持续搅拌1 h,即得SPI-卡拉胶-黄原胶复合乳液。

1.2.2 SPI-卡拉胶-黄原胶复合乳液制备条件优化

在SPI与卡拉胶-黄原胶配比1:10 g/g、pH6.0、卡拉胶质量分数0.3%、黄原胶质量分数0.3%的条件下,分别考察不同SPI与卡拉胶-黄原胶配比(1:20、1:10、1:5、1:1 g/g),pH(3.0、4.5、6.0、7.5、9.0、10.5),卡拉胶质量分数(0.1%、0.2%、0.3%、0.4%、0.5%),黄原胶质量分数(0.1%、0.2%、0.3%、0.4%、0.5%)条件下,SPI-卡拉胶-黄原胶三元复合乳液颗粒的粒径与Zeta电位的变化。其他制备条件为:将制备的三元复合溶液于65 ℃ 1500 r/min转速条件下持续搅拌1 h使其充分混匀。

1.2.3 不同内相体积SPI-卡拉胶-黄原胶Pickering乳液的表征及理化特性分析

1.2.3.1 不同内相体积SPI-卡拉胶-黄原胶Pickering乳液的制备

基于1.2.2的优化实验结果,向制备的三元复合乳液中分别加入体积分数为10%、30%、50%、75%、85%的大豆油,利用高速剪切乳化机将200 mL不同油相体积分数的乳液在12000 r/min下均质2 min制备Pickering乳液[21]。根据高内相乳液的定义,当内相体积大于74%的乳液即认为是高内相乳液[3],因此当大豆油体积大于74%时,即形成SPI-卡拉胶-黄原胶复合高内相Pickering乳液。

1.2.3.2 Pickering乳液的粒度及Zeta电位测定

参照文献[22]的方法,在25 ℃下,采用纳米粒度及Zeta电位分析仪测定Pickering乳液的粒径及Zeta电位。用移液枪吸取20 μL样品于玻璃容器中,加入20 mL的0.01 mol/L磷酸缓冲液(pH9.0)稀释1000倍。在颗粒折射率:1.450;颗粒吸收率:0.001;分散剂折射率:1.330的参数设置下测定样品的粒径。

1.2.3.3 Pickering乳液的EAI及ESI测定

根据Zhang等[23]的方法稍微改动,测定Pickering乳液的EAI及ESI。取上述新鲜制备的乳状液70 μL,加入14 mL 0.1%十二烷基磺酸钠(SDS)溶液稀释200倍,用涡旋振荡仪振荡30 s使其充分混匀。以0.1% SDS为空白,使用紫外分光光度计在500 nm波长下测量稀释样品的吸光值,记为A0;静置10 min后再次在500 nm波长下测量样品的吸光值,记为A10。EAI和ESI测定公式如下:

EAI(m2⋅g−1)=2×2.303×N×A0L×C×φ×10000 ESI(%)=10A10(A0−A10) 式中:EAI为乳化活性指数(m2·g−1);ESI为乳化稳定性指数(%);N为稀释倍数(200);C为SPI的质量浓度(g/mL);φ为乳化液中油相的体积分数;L为比色杯厚度,取1 cm;A0、A10分别为开始时稀释样品溶液的吸光值以及静置10 min时稀释样品溶液的吸光值。

1.2.3.4 不同内相体积SPI-卡拉胶-黄原胶Pickering乳液的微观结构分析

使用生物数码显微镜对Pickering乳液进行微观观察。吸取20 μL Pickering乳液滴到显微镜载玻片上,小心地使用盖玻片从一端开始缓慢盖上,固定乳液并确保内部没有气泡,图像以50倍放大率拍摄[24]。

1.2.3.5 不同内相体积SPI-卡拉胶-黄原胶Pickering乳液的红外光谱(FTIR)分析

以大气作为背景,用酒精对测定台等进行擦拭消毒后,用移液枪吸取20 μL乳液,小心滴在测定台上,设置测定参数:波数为4000~500 cm−1,扫描次数为64,分辨率4 cm−1,得到红外吸收曲线,分析乳液中SPI在不同条件下的二级结构含量变化。

1.2.3.6 不同内相体积SPI-卡拉胶-黄原胶Pickering乳液的环境稳定性

将不同油相体积分数的Pickering乳液置于常温25 ℃贮藏条件下,分别测定其1~5 d的粒径、电位、EAI、ESI及SPI二级结构变化。

1.3 数据处理

本实验均进行三次平行,结果表示为平均值±标准差,采用SPSS 25.0软件对数据进行处理,并用ANOVA和Duncan检验(P<0.05)进行统计分析,用Excel软件进行作图。

2. 结果与分析

2.1 不同条件下SPI-卡拉胶-黄原胶复合乳液的粒径及电位分析

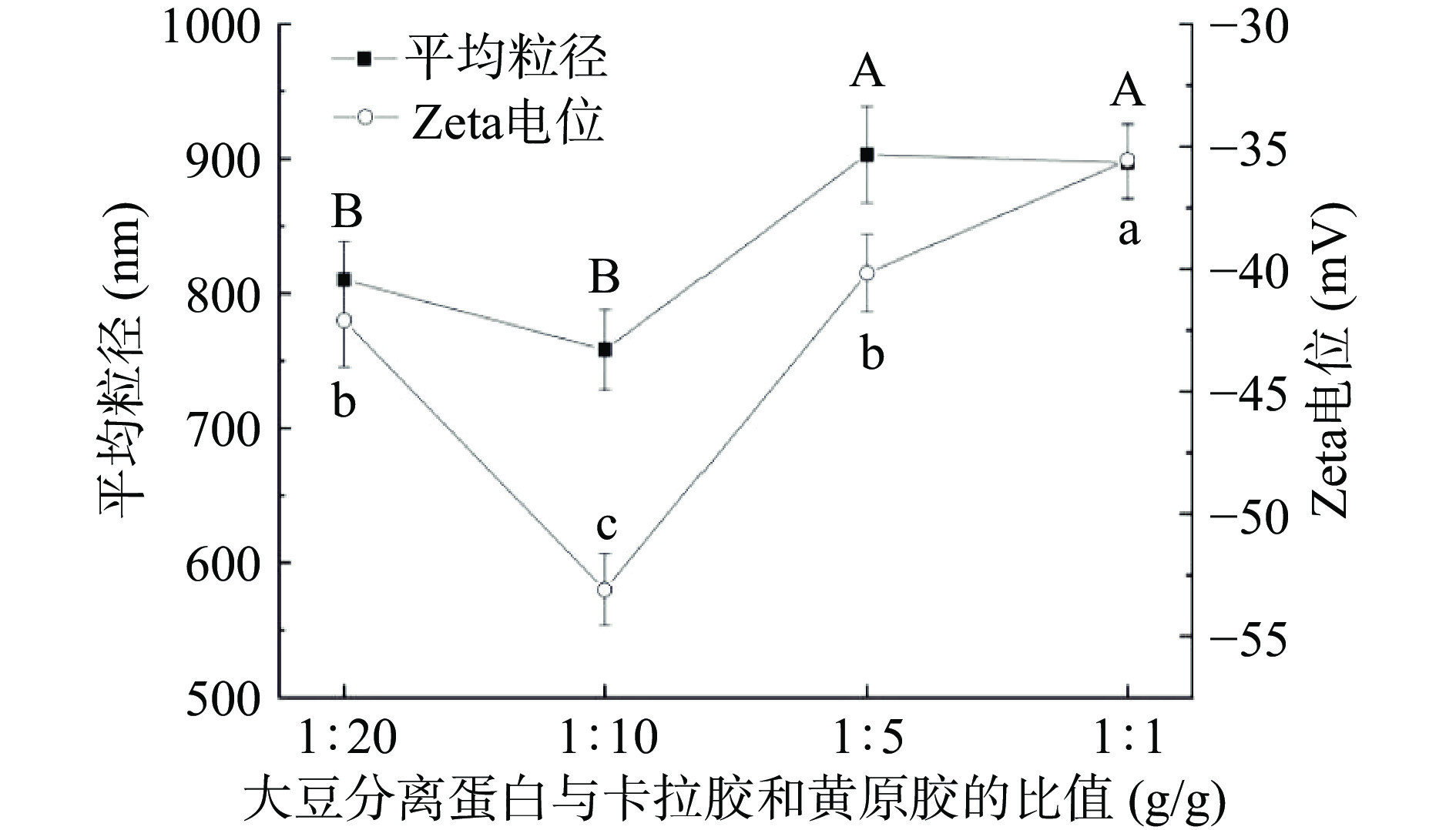

2.1.1 不同SPI与卡拉胶-黄原胶配比复合乳液的粒径及Zeta电位变化

由图1可知,随着SPI与卡拉胶-黄原胶配比的升高,三元复合乳液中颗粒物的平均粒径呈现先平缓降低后显著升高的趋势,Zeta电位呈现先显著下降后升高的趋势(P<0.05)。当SPI与复合多糖的质量浓度比为1:10时,三元复合乳液的颗粒平均粒径最小为758.23±29.47 nm,电位绝对值达到最大值53.1±1.45 mV,颗粒分布均一、稳定,形成良好的蛋白质-多糖复合凝胶体系。基于此,选择SPI与复合多糖的质量浓度比为1:10进行后续实验。

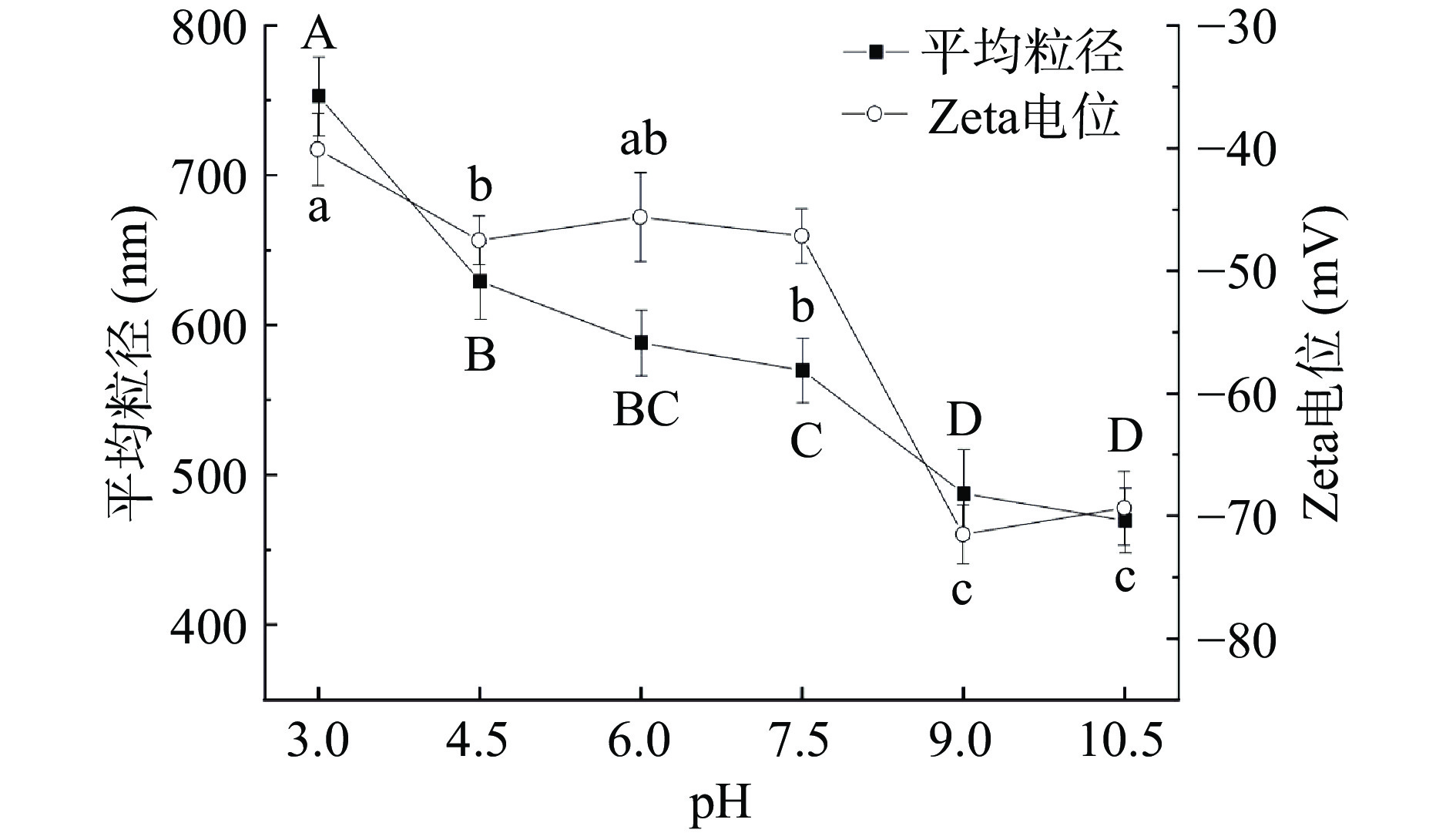

2.1.2 不同pH环境下复合乳液的粒径及Zeta电位变化

如图2所示,随着分散液pH的逐渐升高,SPI-卡拉胶-黄原胶三元复合乳液的平均粒径和Zeta电位均呈现整体下降趋势(Zeta电位的绝对值显著升高)(P<0.05),在pH4.5~7.5范围内,乳液中颗粒物的平均粒径和Zeta电位下降相对平缓,当pH9.0~10.0时,粒径和Zeta电位显著下降,但pH9.0和pH10.0环境下差异不显著(P>0.05)。江连洲等[25]研究显示,SPI凝胶颗粒对pH变化非常敏感,当Zeta电位绝对值较小时,凝胶颗粒表面所带的同性电荷较少,减小了静电排斥作用,进而降低了分散液稳定性,使体系中蛋白分子倾向于相互聚集,在碱性条件下SPI凝胶颗粒表面同性电荷增多,同性电荷间的相互排斥使蛋白质溶液更稳定,从而促进SPI凝胶颗粒作为Pickering高内相乳液的稳定剂,这与本文结果基本一致。当pH为9.0时,三元复合乳液颗粒物的粒径较小(487.33±29.74 nm),此时电位绝对值最大(71.5±5.41 mV),颗粒粒度分布均匀,状态相对稳定,故调节体系pH为9.0进行后续实验。

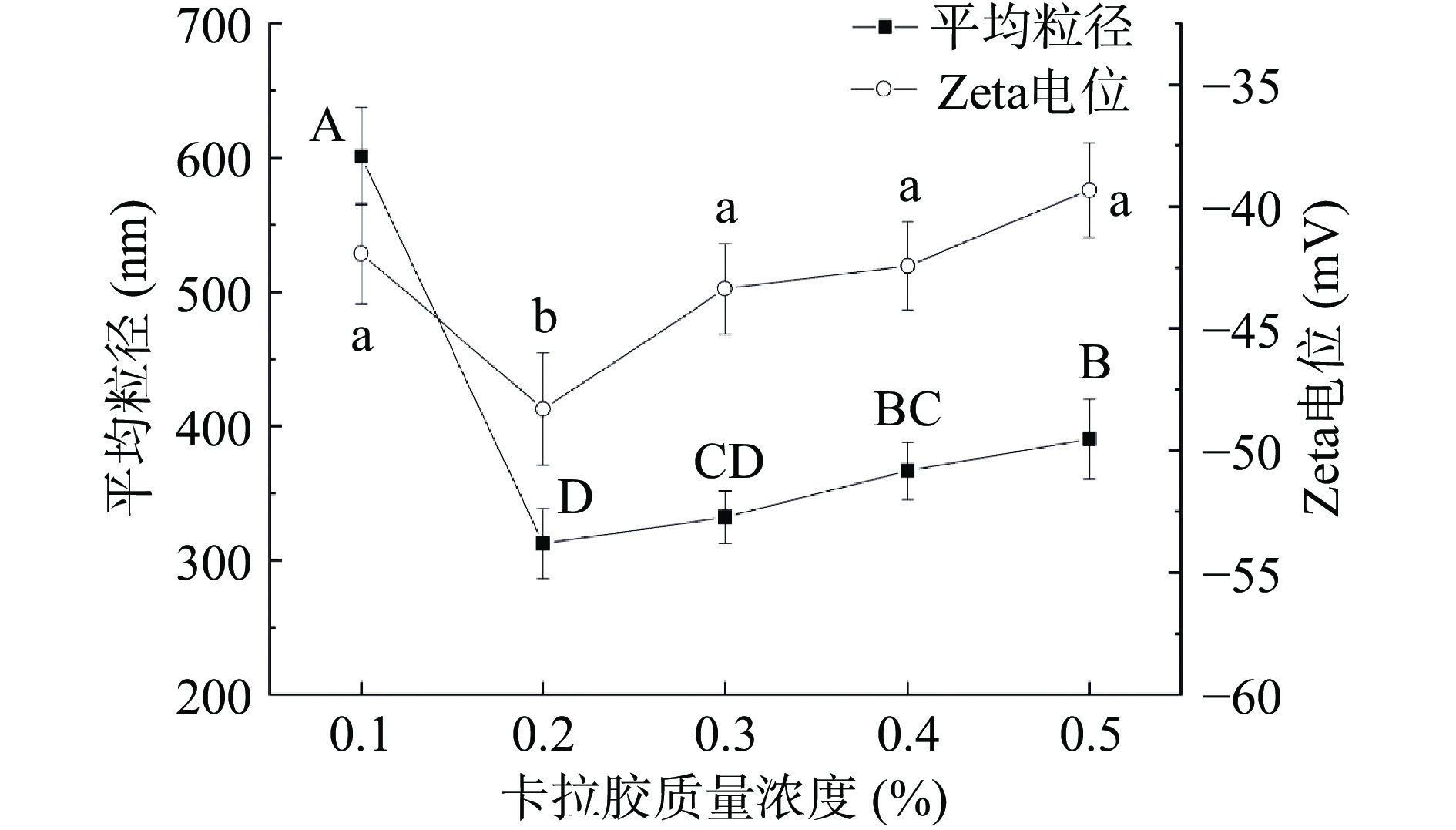

2.1.3 不同卡拉胶质量分数复合乳液的粒径及Zeta电位变化

如图3所示,随着卡拉胶质量浓度的升高,三元复合乳液中颗粒的平均粒径呈先显著减小后增大的趋势(P<0.05),Zeta电位呈现先显著降低后平缓升高的趋势。较低浓度卡拉胶的加入有利于复合多糖与SPI形成多糖-蛋白复合物,颗粒的稳定性增大,当卡拉胶质量浓度为0.2%时,SPI-卡拉胶-黄原胶三元复合乳液平均粒径有最小值,且Zeta电位绝对值有最大值,故选择卡拉胶质量浓度0.2%进行后续实验。

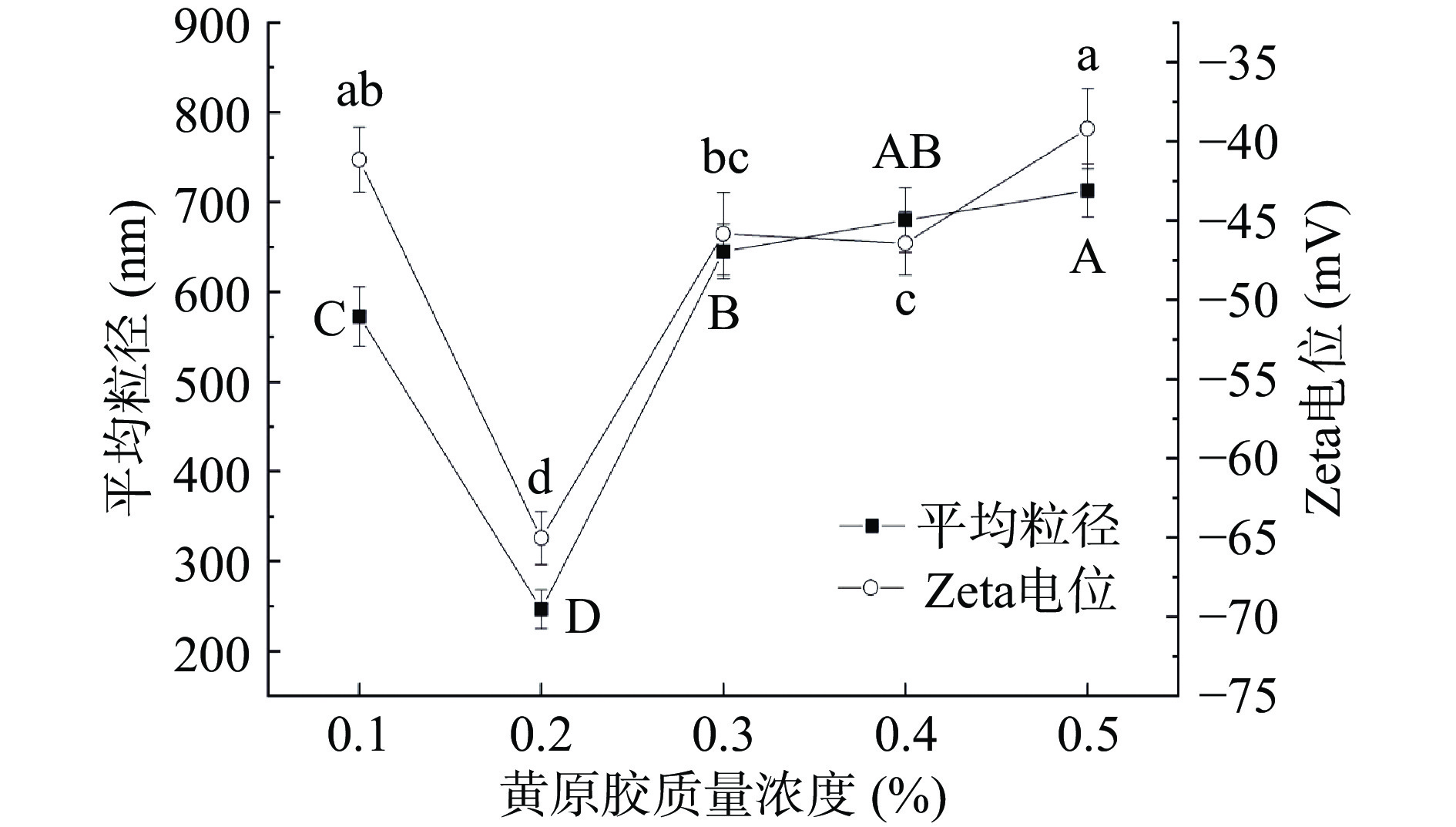

2.1.4 不同黄原胶质量分数复合乳液的粒径及Zeta电位变化

如图4所示,随着黄原胶质量浓度的升高,三元复合乳液中颗粒的平均粒径和Zeta电位呈现先减小后增大的趋势(P<0.05),当黄原胶浓度在0.2%时颗粒粒径达到最小值246.7±21.65 nm,颗粒粒径小于300 nm,复合颗粒物粒度分布均一稳定,此时Zeta电位的绝对值达65.03±1.67 mV,形成了较稳定的多糖-蛋白复合胶体体系,因此选择黄原胶质量浓度0.2%进行后续实验。该结果与Pickering粒子浓度充足时可稳定更大的油水界面,从而形成总表面积较大的小液滴的研究结果一致[26]。当与Pickering粒子浓度较低或者较高时,这些粒子不足以吸附到油水界面以形成粒径较小的乳液液滴,当SPI与复合多糖的质量浓度比为1:10,pH为9.0,卡拉胶质量浓度0.2%,黄原胶质量浓度0.2%时,粒子浓度充足且合适,能够形成具有更大总表面积且粒径较小的乳液液滴[27]。

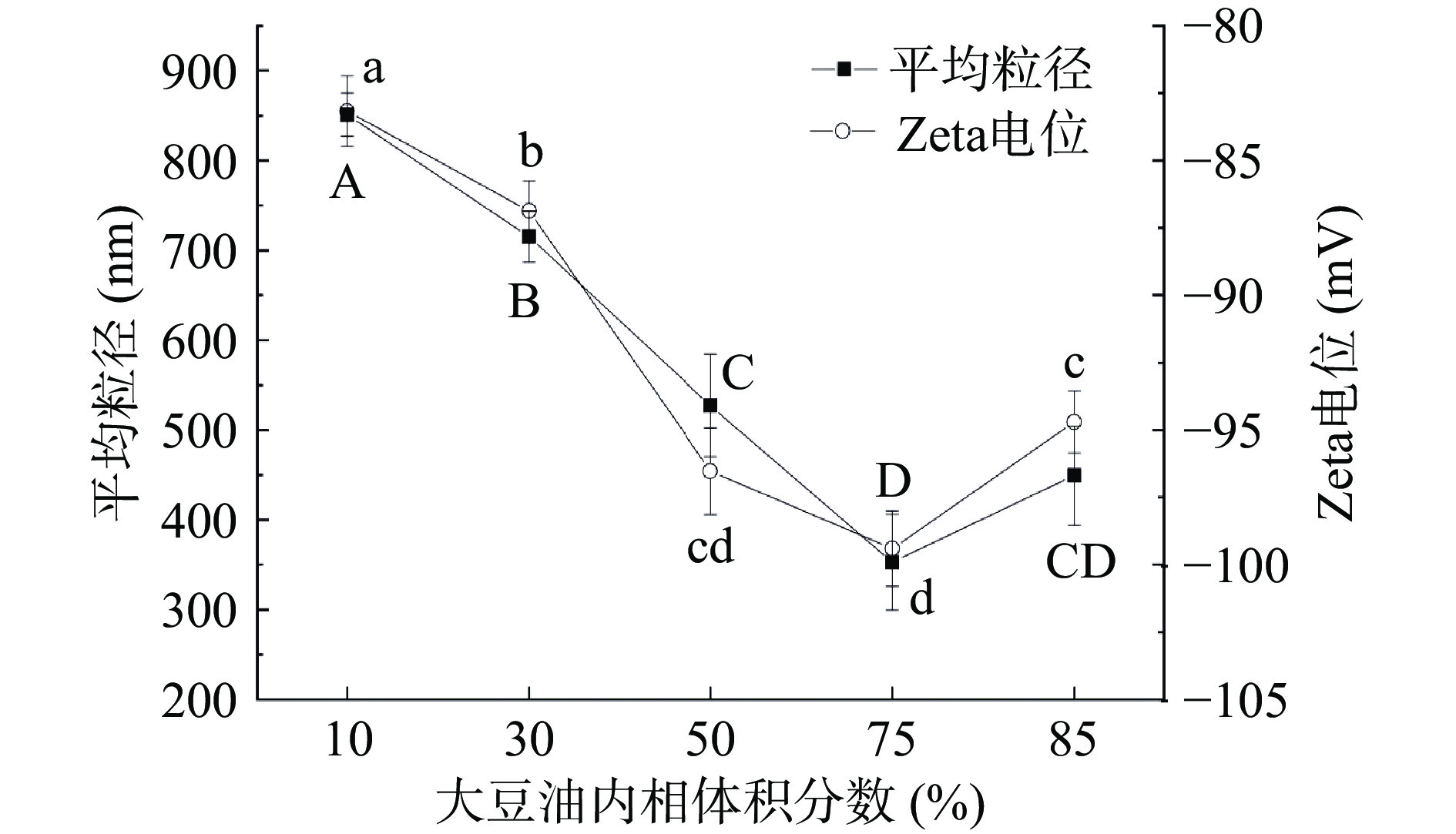

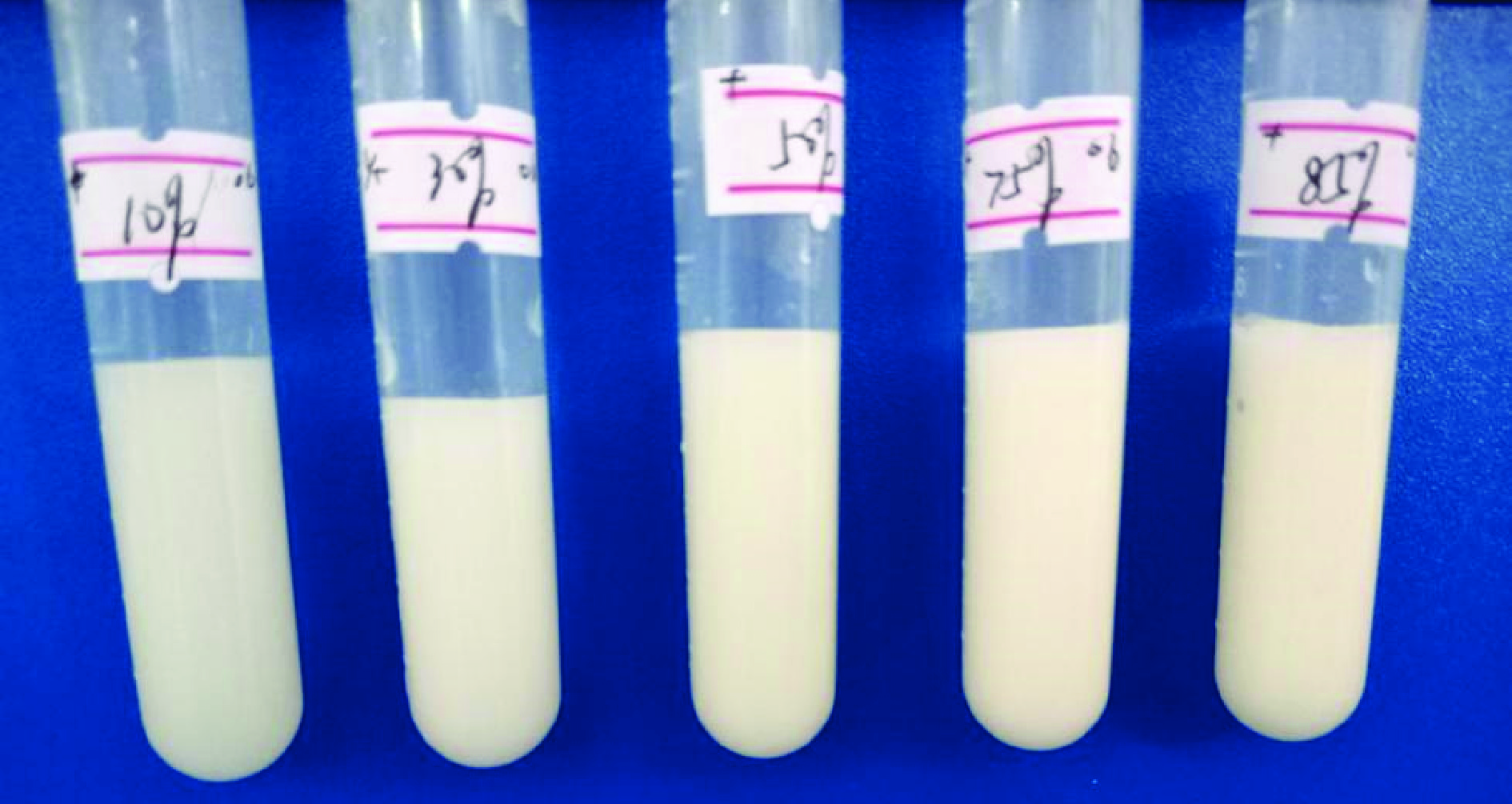

2.2 不同内相体积SPI-卡拉胶-黄原胶Pickering乳液的粒度及Zeta电位分析

基于2.1的研究结果,在SPI与复合多糖质量比例1:10,溶液pH9.0,卡拉胶质量浓度0.2%,黄原胶质量浓度0.2%的条件下,随着大豆油内相体积分数的增加,三元复合乳液的平均粒径呈现逐渐下降的趋势(P<0.05);当大豆油体积10%~85%时,Zeta电位绝对值显著增大(P<0.05)(如图5)。当油相体积10%~85%范围内,三元乳液能够形成较稳定的Pickering乳液(图6),当油相体积75%~85%时,三元乳液能够形成较稳定的高内相Pickering乳液,当油相体积75%时,乳液平均粒径有较小值(平均粒径达351±24.12 nm),Zeta电位绝对值有最大值(99.4±1.4 mV),稳定性较其他组更优。Li等[28]报道,随着内相体积分数的增加,液滴排列更加紧密、整齐,并相互连接,形成了致密的网络状油滴填充体系,此时乳液的液滴尺寸逐渐减小。内相体积分数的增大有利于油滴分散成更小的颗粒,形成更稳定的凝胶状结构[29]。高内相Pickering乳液具有内相比例大、稳定性极佳、模版材料空隙均匀等特性,可应用于食品加工、医药用品[25,30]、生物组织工程[31]、化妆品[32]等多领域中。

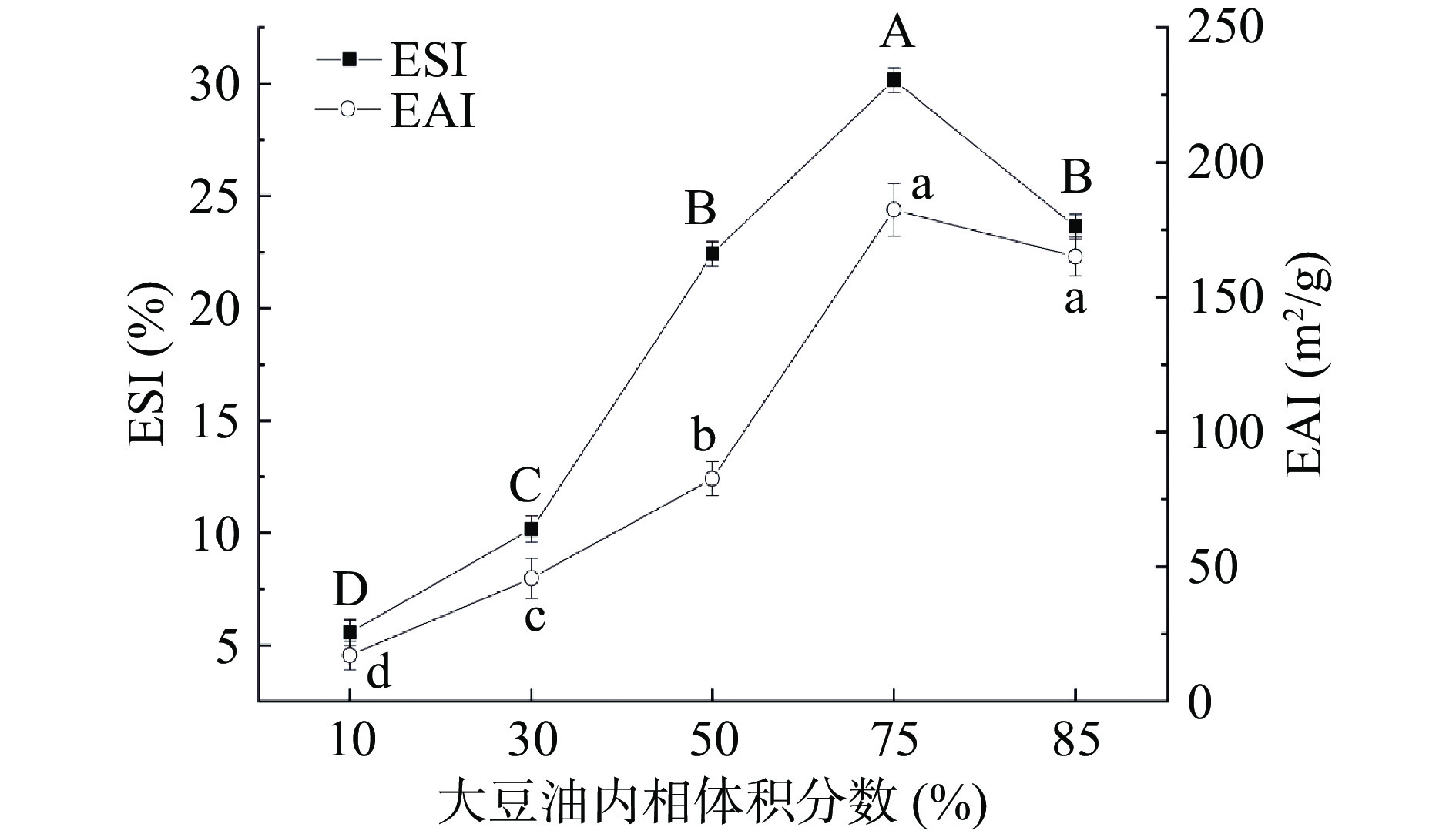

2.3 不同内相体积分数下Pickering乳液的EAI及ESI

不同内相体积分数下Pickering乳液的EAI及ESI变化如图7所示。在大豆油内相体积10%~75%范围内,EAI和ESI均显著升高(P<0.05)。在添加量为75%时,乳液的EAI和ESI稳定性均达到最大值,此时,SPI-卡拉胶-黄原胶包埋了75%的油相,形成了紧密的填充状态,网络结构较强,而油相体积分数达85%时,乳液的EAI和ESI稍有下降,说明当油相体积75%时,SPI-卡拉胶-黄原胶乳液达到饱和状态,填充状态相对最为稳定。这与前文粒径结果一致,这是因为Pickering乳液颗粒间的排斥力决定乳液稳定性,Zeta电位的绝对值越大,说明分子间静电斥力越大,液滴之间不容易絮凝,乳液稳定性则越高[33]。

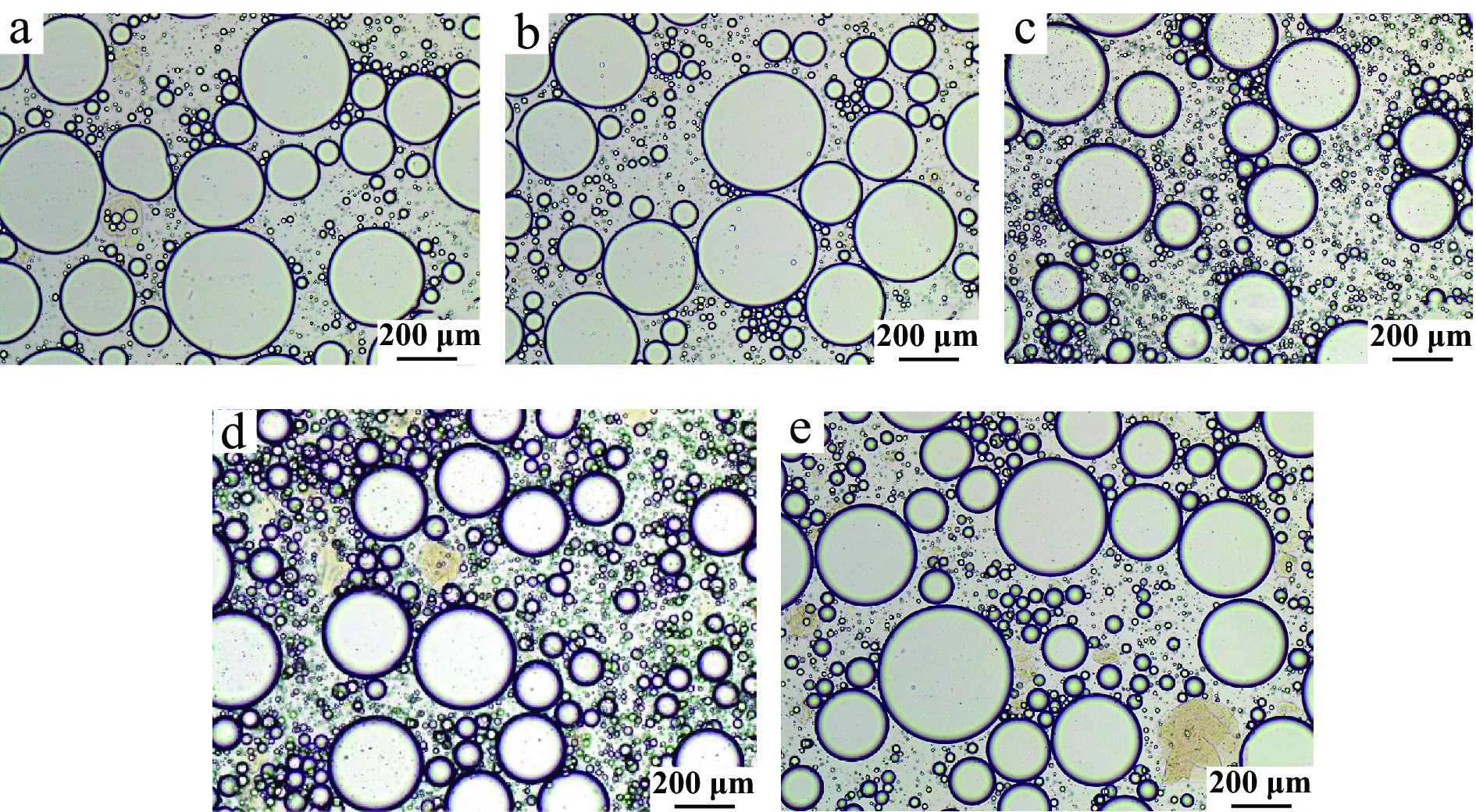

2.4 不同内相体积分数Pickering乳液的微观结构

光学显微镜观察10%~85%大豆油内相体积分数下Pickering乳液的微观结构如图8所示,随着大豆油内相体积的增大,Pickering乳液颗粒的粒径分布更加均一、稳定,当油相体积分数为75%时,乳液颗粒分散状态最佳,这与粒径、电位以及EAI、ESI的分析结果一致。

2.5 不同内相体积分数Pickering乳液的红外光谱(FTIR)分析

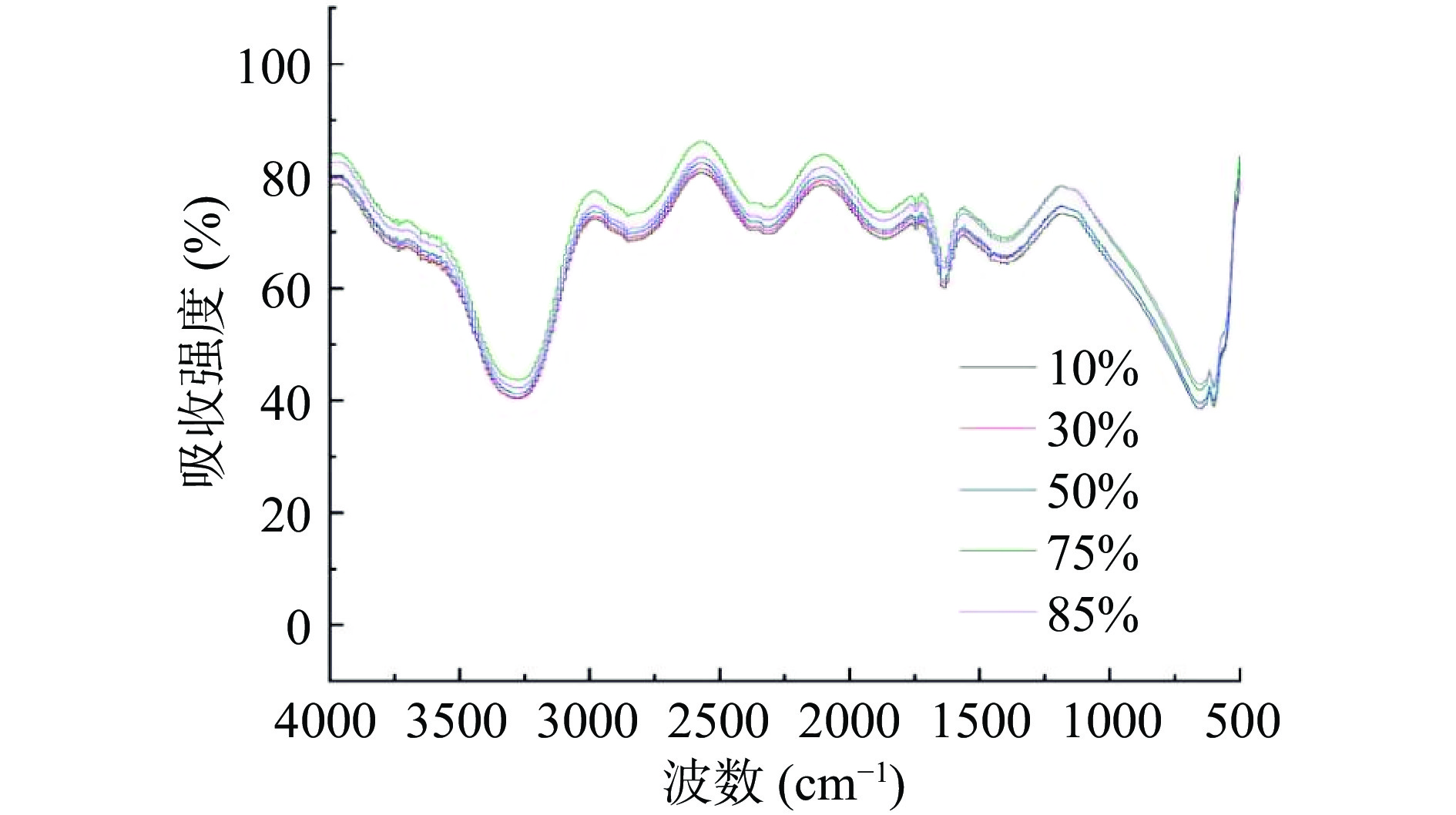

通过傅里叶红外分光光度计测定乳液在不同内相体积分数下的红外光谱,表征不同内相体积分数SPI-卡拉胶-黄原胶三元复合Pickering乳液中SPI二级结构含量变化(如图9所示)。不同内相体积分数Pickering乳液存在典型的蛋白特性峰,即1700~1600 cm−1的酰胺Ⅰ区和1230~1320 cm−1的酰胺Ⅲ区;同时,3500~3250 cm−1范围内的吸收峰反映O-H、N-H伸缩振动;2800~3000 cm−1范围内的吸收峰反映脂肪族C-H伸缩振动峰;1700~1600 cm−1范围内的吸收峰反映C=O和C-N伸缩振动的酰胺I带;1600~1500 cm−1范围内的吸收峰反映C-N伸缩振动的酰胺Ⅱ带,1300~1000 cm−1左右的吸收峰主要反映C-O键、C-N-C键的伸缩振动[34-35]。

同时,利用PeakFit拟合软件分析计算图谱分析(表1),当大豆油内相体积分数低于75%时,乳液中SPI α-螺旋含量整体随着内相体积分数的增加而增加,β-转角和无规则卷曲含量则整体随之减少。当大豆油内相体积分数达到75%时,α-螺旋含量最高,α-螺旋与蛋白质分子展开程度有关,其含量高说明蛋白分子展开程度低,结构稳定性较强[34]。随着油相体系的升高,β-转角的含量先下降后升高,而β-折叠的含量先升高后下降,β-转角的含量与蛋白柔性结构稳定相关,β-折叠的含量与蛋白分子聚集程度有关;SPI无规则卷曲含量变化较小,无规则卷曲的柔性构象结构利于连接结构相对刚性的α-螺旋和β-折叠[34]。

表 1 不同油相体积分数Pickering乳液SPI的二级结构分析Table 1. Secondary structure analysis of SPI in Pickering emulsion with different inner phase volume of oil fraction大豆油内相

体积分数(%)α-螺旋(%) β-转角(%) β-折叠(%) 无规则卷曲(%) 10 13.73±0.06bc 26.50±0.05a 45.56±0.12bc 14.22±0.05ab 30 13.68±0.01c 26.47±0.09a 45.65±0.10b 14.20±0.03ab 50 13.77±0.04bc 26.21±0.11b 45.80±0.12ab 14.23±0.01ab 75 15.22±1.90a 24.77±1.43c 45.88±0.27a 14.14±0.06b 85 13.82±0.01b 26.42±0.03a 45.50±0.03c 14.26±0.04a 注:同列不同字母表示同一结构不同大豆油内相体积分数差异显著(P<0.05)。 2.6 不同内相体积Pickering乳液的环境稳定性

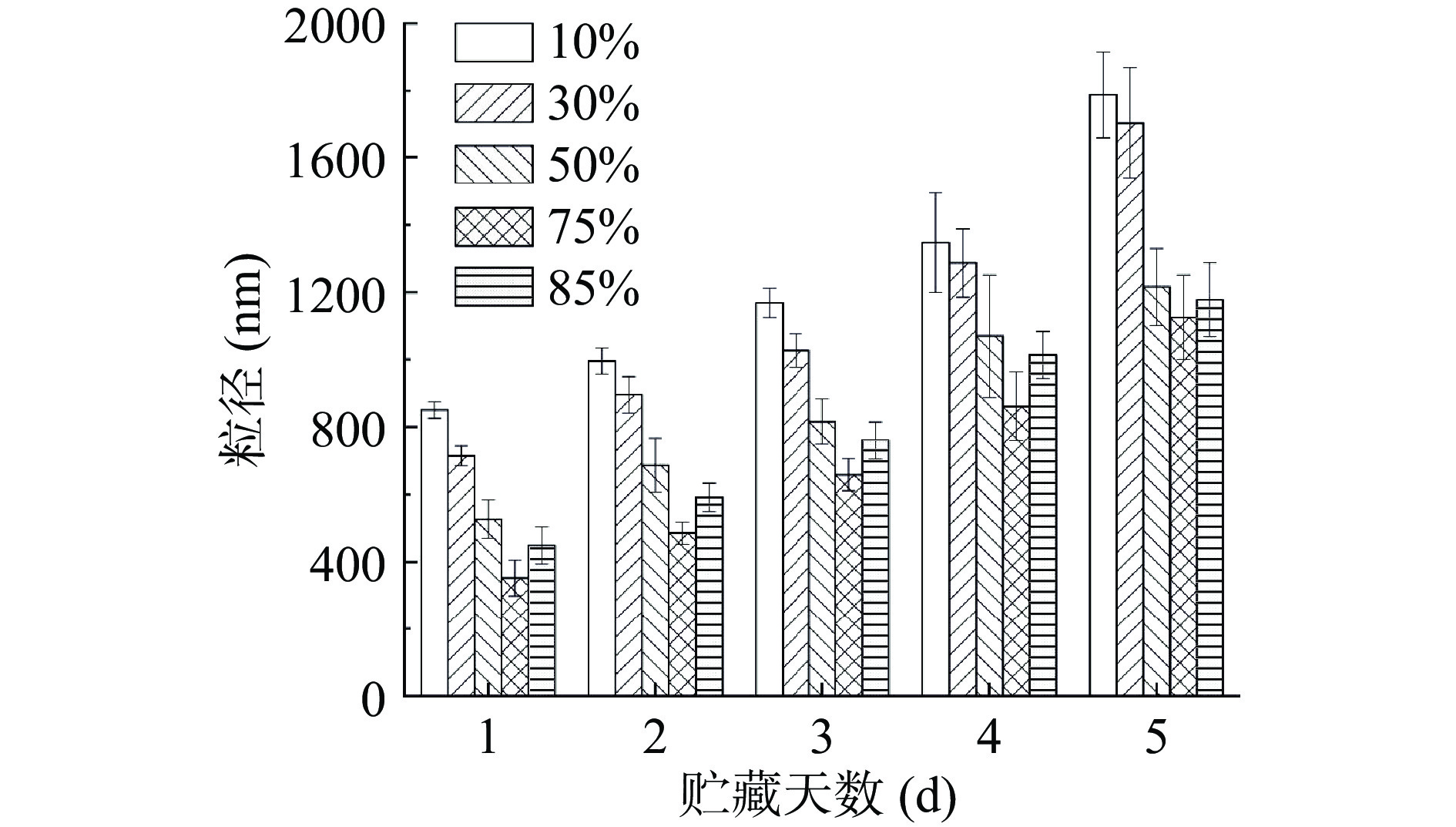

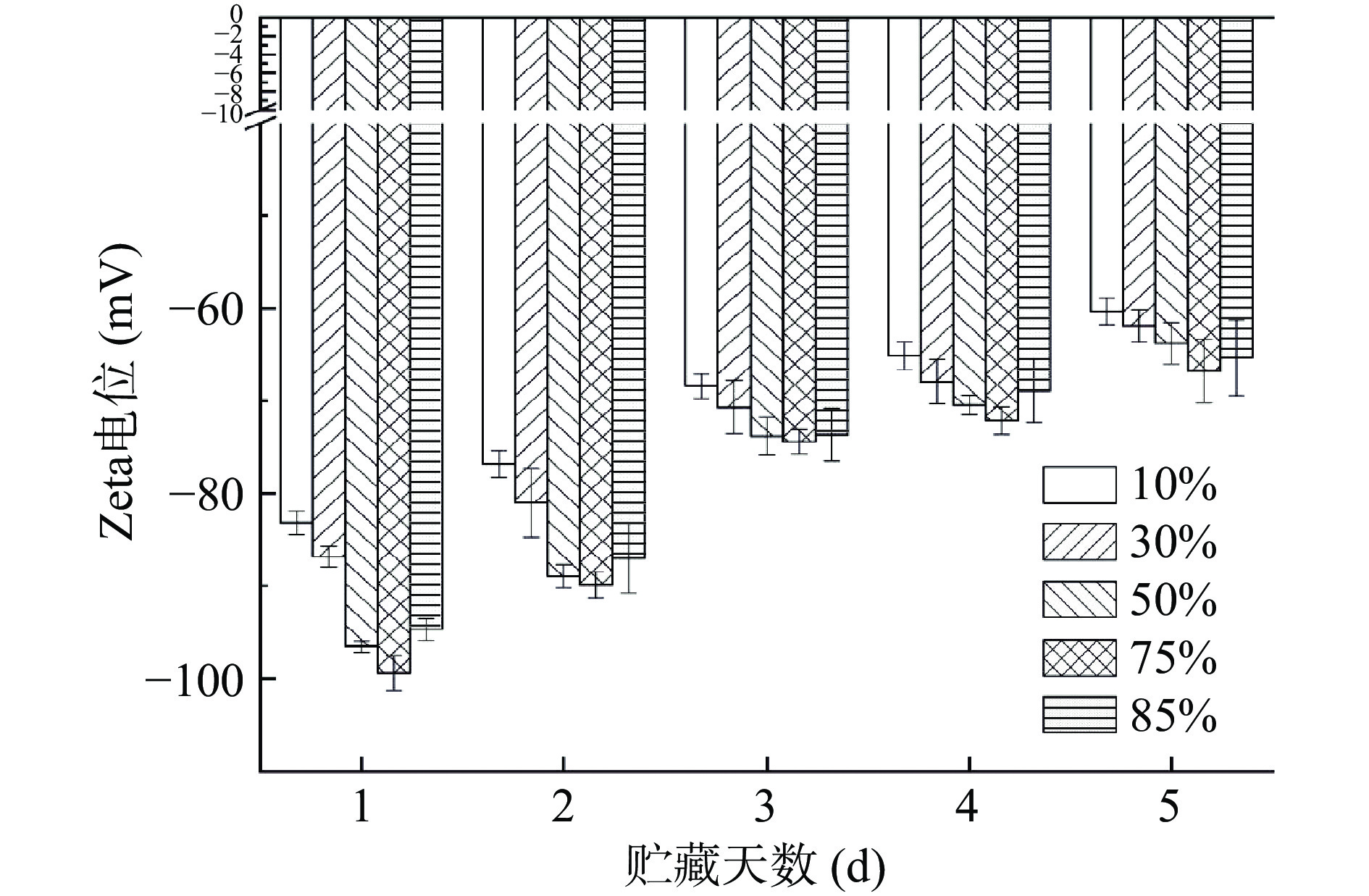

2.6.1 贮藏期间不同内相体积Pickering乳液粒径及电位变化

贮藏期间不同大豆油内相体积Pickering乳液粒径及电位变化分别见图10和图11,随着贮藏时间的延长,不同内相体积Pickering乳液粒径呈整体升高趋势,Zeta电位的绝对值呈整体下降趋势。当大豆油内相体积为10%~30%的乳液粒径在贮藏期间升高幅度较内相体积50%~85%的乳液更大,且贮藏后期(3~5 d)的粒径和Zeta电位变化较之贮藏前期(1~2 d)更明显。许馨予等[15]研究显示,随着油脂内相体积的升高,析乳现象会明显降低,随着贮藏时间的延长乳液的粒径明显增大,乳液稳定性下降,这可能是因为常温条件下微生物生长繁殖破坏了乳液中的营养物质(蛋白质、多糖等),扰乱了乳液结构[36]。

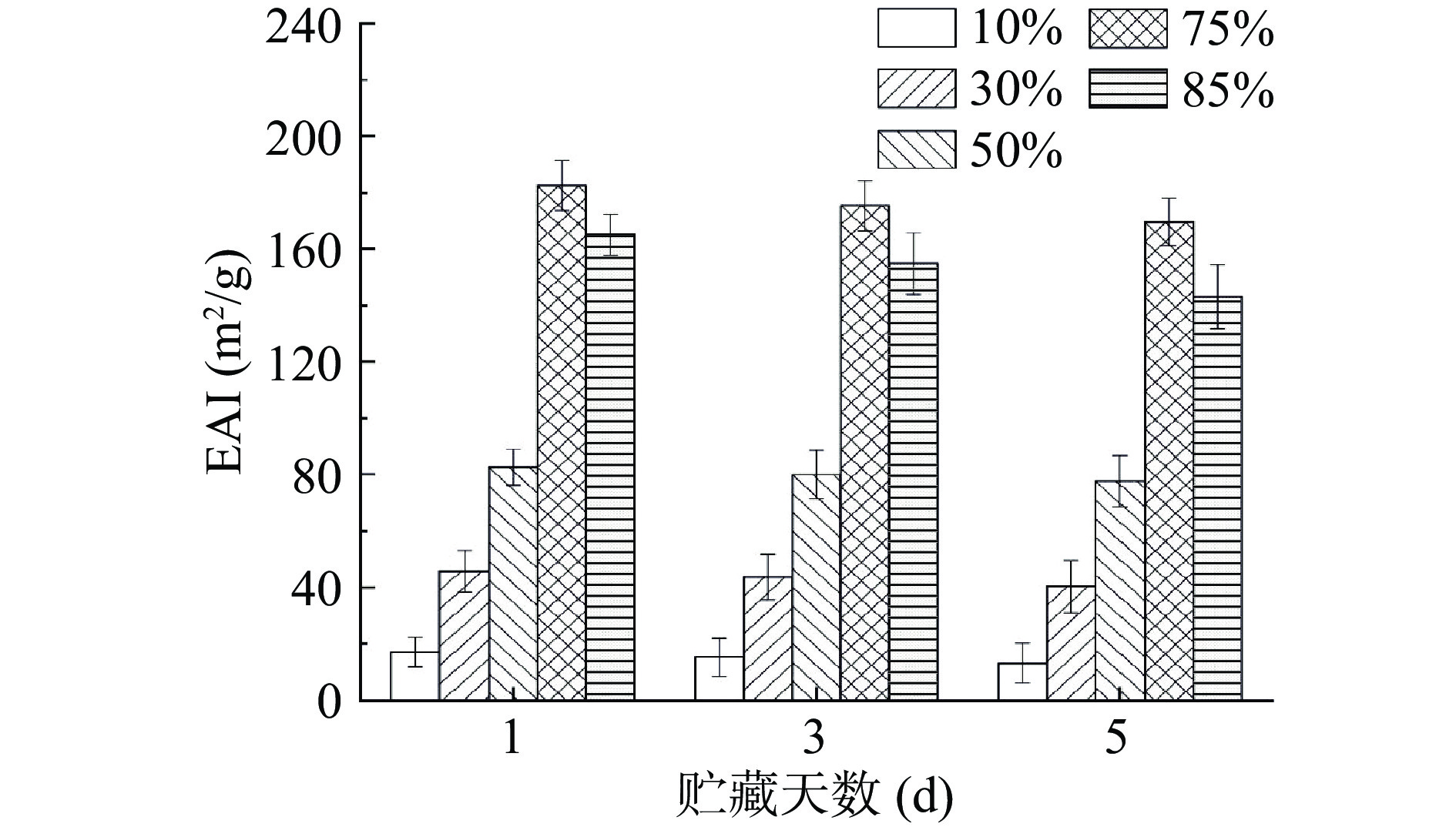

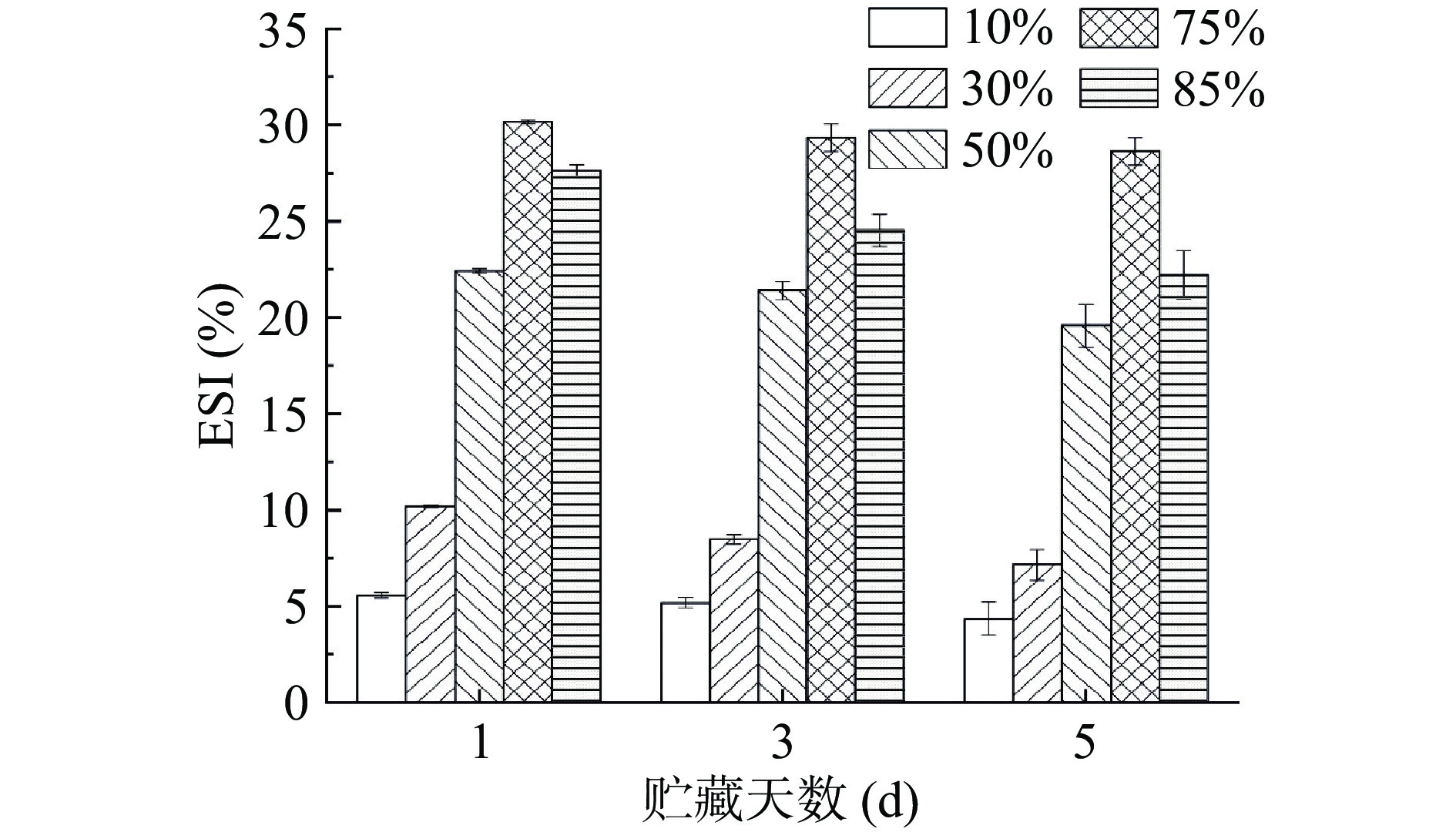

2.6.2 贮藏期间不同内相体积Pickering乳液EAI及ESI变化

贮藏期间不同内相体积Pickering乳液EAI及ESI变化如图12和图13所示。随着贮藏时间的延长,Pickering乳液EAI和ESI呈下降趋势,在贮藏后期下降较前期更明显;内相体积75%的三元Pickering乳液EAI和ESI最高,且随着贮藏时间的延长下降幅度不明显;总体而言75%和85%的高内相乳液显示出更好的稳定性,这与前文研究一致。

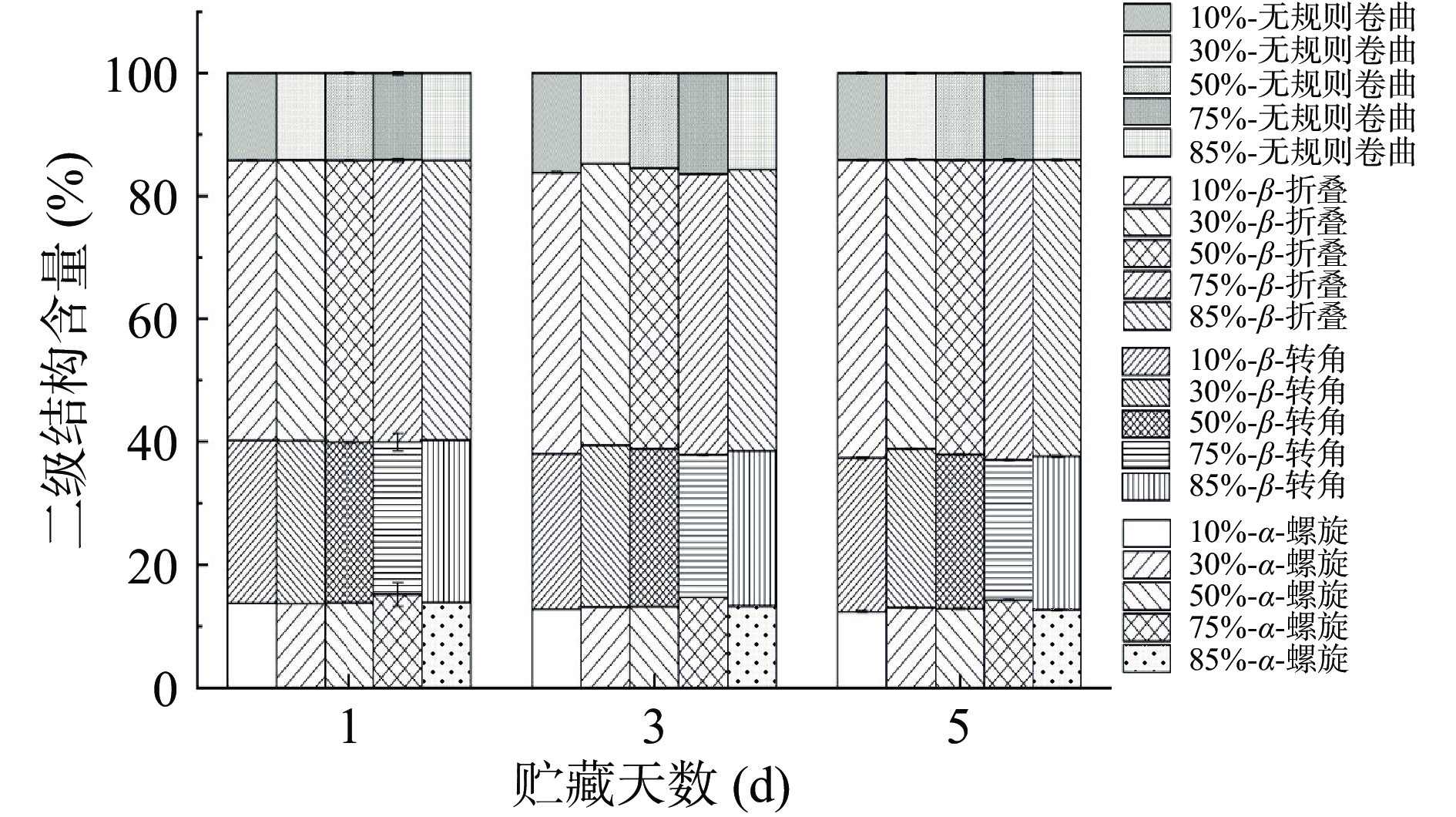

2.6.3 贮藏期间不同内相体积Pickering乳液SPI二级结构变化

贮藏期间10%~85%内相体积Pickering乳液SPI二级结构(α-螺旋、β-转角、β-折叠和无规则卷曲)变化如图14所示。随着贮藏时间的延长,所有乳液的α-螺旋含量和β-转角含量有所下降,β-折叠有所增加,无规卷曲含量变化不明显。在常温贮藏条件下,油脂内相体积10%、30%、50%、75%和85%的Pickering乳液α-螺旋分别从13.73%、13.68%、13.77%、15.22%、13.82%下降到12.39%、13.07%、12.85%、14.27%、12.71%,β-转角分别从26.50%、26.47%、26.21%、24.77%、26.42%下降到24.98%、25.77%、25.08%、22.82%、24.96%,β-折叠分别从45.56%、45.65%、45.80%、45.88%、45.50%升高至48.46%、47.08%、47.88%、48.76%、48.21%。以上变化说明贮藏期间Pickering乳液SPI分子展开程度有所增加,蛋白柔性结构的稳定性也有所降低,蛋白分子有所聚集[34-35]。相对而言,油相体积分数50%、75%和85%的Pickering乳液均显示出较好的耐贮性,其中油相体积分数75%的Pickering乳液贮藏期间稳定性最强,且变化幅度最低。

3. 结论

当SPI与复合多糖的质量浓度比为1:10,pH为9.0,卡拉胶和黄原胶质量浓度均为0.2%,油相体积10%~85%时,均能够制备出具有较稳定体系的SPI-卡拉胶-黄原胶复合Pickering乳液,当油相体积分数为75%时,乳液颗粒分散状态最佳,EAI和ESI达到最大值,SPI α-螺旋和β-折叠含量最高。在常温贮藏条件下,随着时间的延长,不同内相体积Pickering乳液粒径呈整体升高趋势,Zeta电位的绝对值、EAI和ESI呈整体下降趋势,α-螺旋含量和β-转角含量有所下降,β-折叠有所增加,无规卷曲含量变化不明显,其中内相体积75%和85%的高内相乳液显示出更好的稳定性。本研究制备的SPI-卡拉胶-黄原胶三元复合Pickering乳液显示出优良的理化特性及贮藏稳定性,这为功能性物质靶向递送和脂肪代替物创新提供了一定技术参考,同时,其加工稳定性及体内功效特性将有待进一步探究。

-

表 1 不同油相体积分数Pickering乳液SPI的二级结构分析

Table 1 Secondary structure analysis of SPI in Pickering emulsion with different inner phase volume of oil fraction

大豆油内相

体积分数(%)α-螺旋(%) β-转角(%) β-折叠(%) 无规则卷曲(%) 10 13.73±0.06bc 26.50±0.05a 45.56±0.12bc 14.22±0.05ab 30 13.68±0.01c 26.47±0.09a 45.65±0.10b 14.20±0.03ab 50 13.77±0.04bc 26.21±0.11b 45.80±0.12ab 14.23±0.01ab 75 15.22±1.90a 24.77±1.43c 45.88±0.27a 14.14±0.06b 85 13.82±0.01b 26.42±0.03a 45.50±0.03c 14.26±0.04a 注:同列不同字母表示同一结构不同大豆油内相体积分数差异显著(P<0.05)。 -

[1] LIN D Q, KELLY A L, MIAO S. Preparation, structure-property relationships and applications of different emulsion gels: Bulk emulsion gels, emulsion gel particles, and fluid emulsion gels[J]. Trends in Food Science & Technology,2020,102:123−137.

[2] 郭璐, 黄亮, 张斌, 等. 疏水淀粉皮克林乳液凝胶的稳定机理及影响因素[J]. 食品科学,2023,44(2):101−108. [GUO L, HUANG L, ZHANG B, et al. Stabilization Mechanism and impact factors of hydrophobic starch pickering emulsion gels[J]. Food Science,2023,44(2):101−108. doi: 10.7506/spkx1002-6630-20220322-263 GUO L, HUANG L, ZHANG B, et al. Stabilization Mechanism and impact factors of hydrophobic starch pickering emulsion gels[J]. Food Science, 2023, 44(2): 101-108. doi: 10.7506/spkx1002-6630-20220322-263

[3] 汤洋, 高成成, 张岩, 等. 多糖基颗粒稳定的Pickering乳液凝胶研究进展[J]. 食品科学,2022,43(3):341−351. [TANG Y, GAO C C, ZHANG Y, et al. A review of literature on Pickering emulsion gels stabilized by polysaccharide-based particles[J]. Food Science,2022,43(3):341−351. doi: 10.7506/spkx1002-6630-20201030-316 TANG Y, GAO C C, ZHANG Y, et al. A review of literature on Pickering emulsion gels stabilized by polysaccharide-based particles[J]. Food Science, 2022, 43(3): 341-351. doi: 10.7506/spkx1002-6630-20201030-316

[4] BU X T, GUAN M H, DAI L, et al. Fabrication of starch-based emulsion gel beads by an inverse gelation technique for loading proanthocyanidin and curcumin[J]. Food Hydrocolloids,2022,137(2):108336.

[5] FARJAMI T, MADADLOU A. An overview on preparation of emulsion-filled gels and emulsion particulate gels[J]. Trends in Food Science and Technology,2019,86:85−94. doi: 10.1016/j.jpgs.2019.02.043

[6] ABDULLAH, WEISS J, AHMAD T, et al. A review of recent progress on high internal-phase Pickering emulsions in food science[J]. Trends in Food Science & Technology,2020,106(n/a):91−103.

[7] MATSUMURA Y, SIRISON J, ISHI T, et al. Soybean lipophilic proteins-origin and functional properties as affected by interaction with storage proteins[J]. Current Opinion in Colloid & Interface Science,2017,28:120−128.

[8] KOSHY R R, MARY S K, THOMAS S, et al. Environment friendly green composites based on soy protein isolate: A review[J]. Food Hydrocolloids,2015,50:174−192. doi: 10.1016/j.foodhyd.2015.04.023

[9] 皇甫云鹏, 包怡红, 赵鑫磊, 等. 大豆分离蛋白-单宁酸-多糖三元复合物的功能特性及结构表征[J]. 食品科学技术学报,2022,40(6):37−51. [HUANGFU Y P, BAO Y H, ZHAO X L, et al. Functional properties and structural characterization of soybean protein isolate-tannic acid-polysaccharide ternary conjugates[J]. Journal of Food Science and Technology,2022,40(6):37−51. doi: 10.12301/spxb202200864 HUANGFU Y P, BAO Y H, ZHAO X L, et al. Functional properties and structural characterization of soybean protein isolate-tannic acid-polysaccharide ternary conjugates[J]. Journal of Food Science and Technology, 2022, 40(6): 37-51. doi: 10.12301/spxb202200864

[10] QIN X S, CHEN S, LI X J, et al. Gelation properties of transglutaminase induced soy protein isolate and wheat gluten mixture with ultrahigh pressure pretreatment[J]. Food and Bioprocess Technology,2017,10(5):866−874. doi: 10.1007/s11947-017-1864-9

[11] 孙雅晖, 韩立娟, 苏凌志, 等. κ-卡拉胶对蜂蜡基乳液凝胶微观结构和性质的影响[J/OL]. 食品科学: 1−15 [2022-12-08]. https://kns.cnki.net/kcms/detail//11.2206.TS.20221207.1626.027.html. SUN Y H, HAN L J, SU L Z, et al. Effect of κ-carrageenan on the microstructure and properties of beeswax-based emulsion gels[J/OL]. Food Science: 1−15 [2022-12-08]. https://kns.cnki.net/kcms/detail//11.2206.TS.20221207.1626.027.html.

[12] HABIBI H, KHOSRAVI-DARANI K. Effective variables on production and structure of xanthan gum and its food applications: A review[J]. Biocatalysis and Agricultural Biotechnology,2017,10(9):130−140.

[13] 李梦飞, 李博睿, 孙梦雅, 等. 具有“核壳”结构的乳清分离蛋白-黄原胶复合颗粒的构建[J]. 食品科学,2022,43(20):1−6. [LI M F, LI B R, SUN M Y, et al. Construction of whey protein isolate-xanthan gum “core-shell” composite particles[J]. Food Science,2022,43(20):1−6. doi: 10.7506/spkx1002-6630-20210906-073 LI M F, LI B R, SUN M Y, et al. Construction of whey protein isolate-xanthan gum “core-shell” composite particles[J]. Food Science, 2022, 43(20): 1-6. doi: 10.7506/spkx1002-6630-20210906-073

[14] 姜宗伯, 徐军, 石芬, 等. 羟丙基甲基纤维素和黄原胶浓度对初榨椰子油乳液及其模板油凝胶构建的影响[J]. 食品工业科技,2022,43(7):102−109. [JIANG Z B, XU J, SHI F, et al. Effects of hydroxypropyl methylcellulose and xanthan gum concentrations on virgin coconut oil emulsion and construction of template oleogel[J]. Science and Technology of Food Industry,2022,43(7):102−109. JIANG Z B, XU J, SHI F, et al. Effects of hydroxypropyl methylcellulose and xanthan gum concentrations on virgin coconut oil emulsion and construction of template oleogel[J]. Science and Technology of Food Industry, 2022, 43(7): 102−109.

[15] 许馨予, 杨鹄隽, 贾斌, 等. 大豆分离蛋白-高酯柑橘果胶-没食子酸复合Pickering乳液制备及其稳定性分析[J]. 食品科学,2022,43(24):42−51. [XU X Y, YANG H J, JIA B, et al. Preparation and stability analysis of soy protein isolate-high methoxyl citrus pectin-gallic acid Pickering emulsion[J]. Food Science,2022,43(24):42−51. doi: 10.7506/spkx1002-6630-20210929-353 XU X Y, YANG H J, JIA B, et al. Preparation and stability analysis of soy protein isolate-high methoxyl citrus pectin-gallic acid Pickering emulsion[J]. Food Science, 2022, 43(24): 42-51. doi: 10.7506/spkx1002-6630-20210929-353

[16] 朱秀清, 王婵, 孙禹凡, 等. 多糖对SPI乳液及乳液凝胶性质的影响[J]. 东北农业大学学报,2019,51(2):45−52. [ZHU X Q, WANG C, SUN Y F, et al. Effect of polysaccharides on soybean protein isolate emulsion and emulsion gel[J]. Journal of Northeast Agricultural University,2019,51(2):45−52. ZHU X Q, WANG C, SUN Y F, et al. Effect of polysaccharides on soybean protein isolate emulsion and emulsion gel[J]. Journal of Northeast Agricultural University, 2019, 51(2): 45-52.

[17] 邢琳琳, 朱力杰. 大豆分离蛋白-多糖体系对甜菊糖苷苦味的抑制作用及复合乳液稳定性研究[J]. 中国食品学报,2022,22(9):153−162. [XING L L, ZHU L J. Inhibitory effect of soybean protein isolate-polysaccharide system on stevia glycoside bitterness and stability of composite emulsion[J]. Journal of Chinese Institute of Food Science and Technology,2022,22(9):153−162. XING L L, ZHU L J. Inhibitory effect of soybean protein isolate-polysaccharide system on stevia glycoside bitterness and stability of composite emulsion[J]. Journal of Chinese Institute of Food Science and Technology, 2022, 22(9): 153-162.

[18] 王艳红, 田少君, 张争全, 等. SPI-黄原胶-茶多酚复合物的制备及其乳液性质表征[J]. 中国油脂,2021,46(4):38−42. [WANG Y H, TIAN S J, ZHANG Z Q, et al. Preparation of SPI-XG-TP complex and characterization of its emulsion properties[J]. China Oils and Fats,2021,46(4):38−42. WANG Y H, TIAN S J, ZHANG Z Q, et al. Preparation of SPI-XG-TP complex and characterization of its emulsion properties[J]. China Oils and Fats, 2021, 46(4): 38-42.

[19] 黄欢, 田燕, 刘一哲, 等. 椰子油纳米乳液制备工艺优化及其稳定性分析[J]. 食品工业科技,2023,44(9):10−19. [HUANG H, TIAN Y, LIU Y Z, et al. Optimization of preparation technology and stability analysis coconut oil nanoemulsion[J]. Science and Technology of Food Industry,2023,44(9):10−19. HUANG H, TIAN Y, LIU Y Z, et al. Optimization of preparation technology and stability analysis coconut oil Nanoemulsion[J]. Science and Technology of Food Industry, 2023, 44(9): 10-19.

[20] FENG T, WANG X, WANG X, et al. High internal phase Pickering emulsions stabilized by pea protein isolate-high methoxyl pectin-EGCG complex: Interfacial properties and microstructure[J]. Food Chemistry,2021,350(12):354−369.

[21] LIU Z B, LI Y, GENG S, et al. Fabrication of food-grade Pickering high internal phase emulsions stabilized by the mixture of β-cyclodextrin and sugar beet pectin[J]. International Journal of Biological Macromolecules,2021,182(1):252−263.

[22] 毕爽, 朱颖, 齐宝坤, 等. SPI与卵磷脂间相互作用对O/W型乳状液稳定性的影响[J]. 食品科学,2017,38(9):79−84. [BI S, ZHU Y, QI B K, et al. Effect of interaction between soybean protein isolate and lecithin on stability of oil-in-water emulsion[J]. Food Science,2017,38(9):79−84. doi: 10.7506/spkx1002-6630-201709013 BI S, ZHU Y, QI B K, et al. Effect of interaction between soybean protein isolate and lecithin on stability of oil-in-water emulsion[J]. Food Science, 2017, 38(9): 79-84. doi: 10.7506/spkx1002-6630-201709013

[23] ZHANG Q T, TU Z C, XIAO H, et al. Influence of ultrasonic treatment on the structure and emulsifying properties of peanut protein isolate[J]. Food & Bioproducts Processing,2014,92(1):30−37.

[24] 葛慧娟, 肖军霞, 黄国清. 乳清分离蛋白-果胶复合物在Pickering乳液制备中的应用[J]. 中国食品学报,2021,21(3):161−172. [GE H J, XIAO J X, HUANG G Q. The application of whey protein isolate-pectin complex in the preparation of Pickering emulsions[J]. Journal of Chinese Institute of Food Science and Technology,2021,21(3):161−172. doi: 10.16429/j.1009-7848.2021.03.019 GE H J, XIAO J X, HUANG G Q. The application of whey protein isolate-pectin complex in the preparation of Pickering emulsions[J]. Journal of Chinese Institute of Food Science and Technology, 2021, 21(3): 161-172. doi: 10.16429/j.1009-7848.2021.03.019

[25] 江连洲, 温家煜, 王禹涵, 等. SPI凝胶颗粒制备及其Pickering高内相乳液特性研究[J]. 农业机械学报,2020,51(12):348−355. [JIANG L Z, WEN J Y, WANG Y H, et al. Fabrication and characterization of high internal phase pickering emulsion manipulated by gel particles of soy protein[J]. Transactions of the Chinese Society of Agricultural Machinery,2020,51(12):348−355. doi: 10.6041/j.issn.1000-1298.2020.12.038 JIANG L Z, WEN J Y, WANG Y H, et al. Fabrication and characterization of high internal phase pickering emulsion manipulated by gel particles of soy protein[J]. Transactions of the Chinese Society of Agricultural Machinery, 2020, 51(12): 348-355. doi: 10.6041/j.issn.1000-1298.2020.12.038

[26] JIANG Y, ZHU Y Z, LI P, et al. Gliadin/amidated pectin core-shell nanoparticles for stabilization of Pickering emulsion[J]. International Journal of Food Science and Technology,2020,55:3278−3288. doi: 10.1111/ijfs.14590

[27] 敬雪莲, 蔡勇建, 陈碧芬, 等. 基于大豆酶解聚集体制备Pickering乳液凝胶及环境稳定性分析[J]. 食品科学,2022,43(20):7−17. [JING X L, CAI Y J, CHEN B F, et al. Analysis of environmental stability of Pickering emulsion gels prepared with insoluble soy peptide aggregates[J]. Food Science,2022,43(20):7−17. doi: 10.7506/spkx1002-6630-20211123-288 JING X L, CAI Y J, CHEN B F, et al. Analysis of environmental stability of Pickering emulsion gels prepared with insoluble soy peptide aggregates[J]. Food Science, 2022, 43(20): 7-17. doi: 10.7506/spkx1002-6630-20211123-288

[28] LI Y, LIU B, FAN J, et al. Effects of ultrasound and high pressure homogenization treatment on the interaction of soybean protein-phosphatidylcholine[J]. Journal of Chinese Institute of Food Science and Technology,2017,218(1):165−172.

[29] ZONG X X, ZHANG X, BI K, et al. Novel emulsion film based on gelatin/polydextrose/camellia oil incorporated with Lactobacillus pentosus: Physical, structural, and antibacterial properties[J]. Food Hydrocolloids,2021,121(6):127−141.

[30] LIU F, ZHENG J, HUANG C, et al. Pickering high internal phase emulsions stabilized by protein-covered cellulose nanocrystals[J]. Food Hydrocolloids,2018,82(32):96−105.

[31] WANG J, LI Y, GAO Y, et al. Cinnamon oil-loaded composite emulsion hydrogels with antibacterial activity prepared using concentrated emulsion templates[J]. Industrial Crops and Products,2018,112(1):281−289.

[32] XU Y, TANG C, LIU T, et al. Ovalbumin as an outstanding Pickering nano-stabilizer for high internal phase emulsions[J]. Journal of Agricultural & Food Chemistry,2018,66(33):8795−8804.

[33] 陈海华, 于芮, 王雨生. 明胶与海藻酸钠的静电复合机制及热动力学分析[J]. 食品科学,2021,42(8):52−59. [CHEN H H, YU R, YU Y S. Mechanism and thermodynamic characterization of electrostatic complexation between gelatin and sodium alginate[J]. Food Science,2021,42(8):52−59. doi: 10.7506/spkx1002-6630-20200322-321 CHEN H H, YU R, YU Y S. Mechanism and thermodynamic characterization of electrostatic complexation between gelatin and sodium alginate[J]. Food Science, 2021, 42(8): 52-59. doi: 10.7506/spkx1002-6630-20200322-321

[34] 裴志胜, 冯紫蓝, 王会博, 等. 金鲳鱼肌原纤维蛋白乳液凝胶的制备及表征[J]. 食品工业科技,2023,44(6):201−208. [PEI Z S, FENG Z L, WANG H B, et al. Fabrication and characterization of high internal phase pickering emulsion manipulated by gel particles of soy protein[J]. Food Industry Science and Technology,2023,44(6):201−208. PEI Z S, FENG Z L, WANG H B, et al. Fabrication and characterization of high internal phase pickering emulsion manipulated by gel particles of soy protein[J]. Food Industry Science and Technology, 2023, 44(6): 201-208.

[35] 万红兵, 李海鹏, 雷元华, 等. 二维红外相关光谱研究熟度对肌原纤维蛋白构象的影响[J]. 光谱学与光 谱分析,2021,41(7):2082−2086. [WANG H B, LI H P, LEI Y H, et al. Two-dimensional infrared correlation spectroscopy to study the effect of maturity on myofibrillar protein conformation[J]. Spectroscopy and Spectral Analysis,2021,41(7):2082−2086. WANG H B, LI H P, LEI Y H, et al. Two-dimensional infrared correlation spectroscopy to study the effect of maturity on myofibrillar protein conformation[J]. Spectroscopy and Spectral Analysis, 2021, 41(7): 2082-2086.

[36] TAN H, ZHANG R, HAN L, et al. Pickering emulsions stabilized by aminated gelatin nanoparticles: Are gelatin nanoparticles acting as genuine Pickering stabilizers or structuring agents?[J]. Food Hydrocolloids,2021,376(1):644−659.

下载:

下载:

下载:

下载: