Effect of Exogenous Protease on Flavor of Soymilk Made by Automatic Soymilk Maker

-

摘要: 为研究蛋白酶影响豆浆风味的作用机理,在豆浆机制备豆浆中分别添加不同浓度的木瓜蛋白酶(15000、30000、45000、60000、75000 U/L)、氨基肽酶(500、1000、1500、2000、2500 U/L)、风味蛋白酶(100、150、200、250、300 U/L)和碱性蛋白酶(500、1500、2500、3500、4500 U/L)进行酶解,以不加酶的豆浆机制备豆浆为空白对照组、传统方法制备的豆浆为生豆对照组,对热生香后的豆浆进行感官评价,测定酶解、热生香后豆浆中的多肽和氨基酸态氮含量及变化量,并分析其与感官风味指标的相关性。采用顶空固相微萃取结合气相色谱-质谱联用技术,分析了豆浆中的挥发性风味物质。结果表明,空白对照组热生香后豆浆的豆腥味、豆香味比生豆对照组更淡,而多肽和氨基酸含量分别比生豆对照组降低了37.98%和25.78%。实验组添加250 U/L风味蛋白酶的豆浆感官评分最高,与空白对照组相比提高了118.41%。除添加4500 U/L碱性蛋白酶处理组外,添加蛋白酶后豆浆的感官评分均显著高于空白对照组(P<0.05)。加酶样品中与豆腥味相关的正己醛、2-戊基呋喃、正己醇、反,反-2,4-癸二烯醛等挥发性化合物含量均低于空白对照组和生豆对照组,与豆香气相关的挥发性化合物含量和种类均有不同程度提升。添加外源蛋白酶处理能明显提高豆浆中多肽和氨基酸含量,其中添加4500 U/L碱性蛋白酶时多肽含量最高(2.30±0.15 g/L),添加2500 U/L氨基肽酶时氨基酸含量最高(0.087±0.0045 g/L)。风味蛋白酶处理组中酶解豆浆氨基酸态氮含量与豆香味得分呈显著正相关(P<0.05),其他三种酶的多肽增加量均与豆腥味得分呈显著或极显著正相关(P<0.05,P<0.01),氨基肽酶处理组中,氨基酸态氮增加量与豆腥味、豆香味和总分呈显著负相关(P<0.05)。以上结果表明,添加外源蛋白酶可以增加豆浆中多肽和氨基酸等风味前体物质的含量,制成豆腥味更淡、豆香味更丰富的豆浆。本研究为豆浆制备工艺的优化提供了理论指导。Abstract: In order to study the mechanism of protease which influences on the flavor of soymilk, different kinds and concentrations of protease (papain, 15000, 30000, 45000, 60000 and 75000 U/L, aminopeptidase, 500, 1000, 1500, 2000 and 2500 U/L, flavor protease, 100, 150, 200, 250 and 300 U/L, alkaline protease, 500, 1500, 2500, 3500 and 4500 U/L) were added to the soymilk made by automatic soymilk maker. Sensory evaluation was carried out on the soymilk after heating. The content and difference of polypeptide and amino acid nitrogen in the soymilk after enzymatic hydrolysis and heating were determined, and the correlation between them and sensory flavor indexes was analyzed. The volatile flavor components of soymilk were analyzed by headspace solid-phase microextraction combined with gas chromatography-mass spectrometry (GC-MS). The results showed that in the blank control group prepared by automatic soymilk maker without protease, the unpleasant beany odor and pleasant bean aroma of soymilk after heating were both lighter than those prepared by traditional method named the raw bean control group, while the contents of polypeptide and amino acid nitrogen showed reductions of 37.98% and 25.78% as compared to the raw bean control group, respectively. The sensory evaluation was carried out after adding different proteases to the soymilk prepared by automatic soymilk maker. The results showed that the soymilk added with 250 U/L flavor protease had the highest sensory score, which increased by 118.41% compared with the blank control group. In all groups added with proteases, the sensory score was significantly higher (P<0.05) except when it was added with 4500 U/L alkaline protease, compared with blank control group. The contents of hexanal, 2-pentyl furan, hexanol, trans,trans-2,4-decadienal and other volatile compounds related to beany ador in the enzyme added samples were lower than those in the blank control group and the raw bean control group, and the contents and types of volatile compounds related to bean aroma were increased to varying degrees. The addition of exogenous protease could significantly improve the contents of polypeptide and amino acid nitrogen in soymilk, among which the content of polypeptide was the highest when adding 4500 U/L alkaline protease (2.30±0.15 g/L), and the content of amino acid nitrogen was the highest when adding 2500 U/L aminopeptidase (0.087±0.0045 g/L). The amino acid nitrogen content of enzymolized soymilk in the group added with flavor protease was significantly positively correlated with the score of bean aroma (P<0.05), the increase of polypeptide in groups added with the other three enzymes were significantly or extremely significantly positively correlated with the score of beany odor (P<0.05, P<0.01). The increase of amino acid nitrogen was significantly negatively correlated with the beany odor, bean aroma and total score in the group added with aminopeptidase (P<0.05). The above results indicated that proteases are beneficial for increasing the content of polypeptides and amino acids as flavor precursors, which give a lighter beany odor and a richer bean aroma to the soymilk. This study provides theoretical guidance for the optimization of soymilk preparation technology.

-

Keywords:

- soymilk /

- protease /

- heating /

- flavor /

- polypeptide /

- amino acid nitrogen /

- gas chromatography-mass spectrometry (GC-MS) /

- correlation analysis

-

豆浆是中国传统的植物蛋白饮料,具有悠久的饮用历史。豆浆组成成分中有大豆蛋白、大豆油脂,果糖、水苏糖、鼠李糖等可溶性糖类及磷脂、异黄酮等活性因子[1],其中蛋白质含量几乎和牛奶相同[2],且不会引起乳糖不耐受,可以作为牛奶替代品,被欧美国家称为“植物奶”。由于豆浆营养丰富、价格低廉,越来越受到广大消费者的青睐。

传统豆浆制作工艺一般为浸泡大豆、加水研磨、过滤去渣和煮浆[3]。制作过程中,由于大豆内源酶及外界环境的共同作用,会产生具有豆腥味、花香味、水果味等的小分子化合物[4]。尤其是在生豆研磨过程中,广泛存在于大豆中的脂肪氧化酶被氧气和水激活,将大豆中的多不饱和脂肪酸氧化,产生了多种具有豆腥味的挥发性成分[5],影响消费者对豆浆的接受程度[6]。由于80 ℃以上的高温可以灭活绝大部分脂肪氧化酶,抑制豆腥味的生成[7],因此商业化豆浆的加工方法是加入热水磨浆或在豆浆中通入热蒸汽灭酶,然后进行包装和杀菌。由此制作出的豆浆虽然降低了豆腥味,但豆香味也较低,导致产品风味寡淡,因此如何提高豆浆的风味成为改善豆浆品质的主要难题。

蛋白酶可以将蛋白质水解成多肽、寡肽和游离氨基酸,从而改变蛋白质的功能、营养和感官特性[8]。其中肽、游离氨基酸等也是重要的风味前体物质,在高温下可以经过美拉德反应等一系列生物化学反应生成挥发性风味物质[9],对食品风味的形成有着重要的作用,因此各种蛋白酶经常被用于食品加工。木瓜蛋白酶可水解蛋白质和多肽中精氨酸和赖氨酸的羧基端,有研究采用木瓜蛋白酶水解传统生浆工艺制备的豆乳,在最佳反应条件下可以完全水解豆乳中的β-伴球蛋白的α'、α亚基,降低其致敏性[10]。氨基肽酶广泛存在于大豆等植物的种子中[11],其作用机理是从多肽链N末端顺序逐个水解氨基酸,氨基肽酶还可以减少大豆蛋白酶解产物的苦味[12]。风味蛋白酶是复配酶制剂,同时具有内切酶和外切酶活性,可使水解液形成独特的风味,还可有效降低大豆抗原性,获得较好的乳化、发泡性等[13]。碱性蛋白酶诱导的限制性水解可以大幅降低大豆蛋白的抗原性,还可以用于生产生物活性肽等[14-15],向豆浆中添加外源蛋白酶以改善豆浆风味还未见研究。

家用豆浆机的工作原理为先预热然后边加热边打浆,与商业豆浆杀菌前的制作步骤相似。本研究在豆浆机制成的豆浆中添加不同浓度的木瓜蛋白酶、风味蛋白酶、氨基肽酶和碱性蛋白酶,酶解后用高压蒸汽灭菌锅灭菌,探讨外源蛋白酶对豆浆中蛋白质的降解和风味物质形成的作用机理,以期为生产出风味更佳的豆浆提供工艺指导。

1. 材料与方法

1.1 材料与仪器

柴火大院黑龙江黄豆 网购;良食记白砂糖 购自超市;木瓜蛋白酶(100000 U/g,最适反应温度50~55 ℃) 南宁庞博生物工程有限公司;风味蛋白酶(50000 U/g,最适反应温度50~60 ℃)、氨基肽酶(5000 U/g,最适反应温度50~60 ℃)、碱性蛋白酶(200000 U/g,最适反应温度45~55 ℃) 沧州夏盛酶生物技术有限公司;其他实验试剂 均为分析纯。

DJ16G-D2575型全自动家用豆浆机 九阳股份有限公司;JYL-C012型榨汁搅拌机 九阳股份有限公司;B-220型恒温水浴锅 上海亚荣生化仪器厂;LDZX-40B1型立式自动电热压力蒸汽灭菌锅 上海申安医疗器械厂;TU-1810型紫外可见分光光度计 北京普析通用仪器有限公司;57348-U型PDMS/CAR/DVB 固相微萃取头 美国Supelco公司;7890B-5977B型气相色谱-质谱联用仪 美国Agilent公司。

1.2 实验方法

1.2.1 豆浆的制备

挑选大小均匀、外表完整的大豆,浸没于自来水中,室温浸泡至大豆吸水率130%。按1:10(g /g)的豆水比(干质)加入饮用水,豆浆机制作豆浆,200目筛过滤去渣,得到待酶解的豆浆。生豆对照组浸泡后用搅拌机18000 r/min打浆3 min(打浆过程中不加热)后过滤。

1.2.2 豆浆的酶解及热生香

取200 mL待酶解豆浆,分别添加1~5不同浓度梯度的四种酶,具体添加量为:木瓜蛋白酶15000(梯度1)、30000(梯度2)、45000(梯度3)、60000(梯度4)、75000 U/L(梯度5),氨基肽酶500(梯度1)、1000(梯度2)、1500(梯度3)、2000(梯度4)、2500 U/L(梯度5),风味蛋白酶100(梯度1)、150(梯度2)、200(梯度3)、250(梯度4)、300 U/L(梯度5),碱性蛋白酶500(梯度1)、1500(梯度2)、2500(梯度3)、3500(梯度4)、4500 U/L(梯度5)。50 ℃水浴保温酶解1 h,得到酶解豆浆样品。酶解结束后,沸水浴灭酶10 min,然后放入高压灭菌锅121 ℃热生香15 min得到热生香豆浆样品。生豆对照组和空白对照组不加酶,其他处理方式相同。

1.2.3 豆浆风味感官评价方法

评定小组由6名食品专业的人员组成,分别对不同处理组的热生香豆浆在常温下进行感官评价,评价标准如表1。评定过程中要求感官评定人员在进行评定前有专业感官评定的知识学习,12 h内不吸烟,不喝酒,不进食辛辣等刺激性食物。每评定完一个样品后,要用清水漱口3次,并间隔10 min再评定下一个样品,以保证结果的有效性[16]。

表 1 豆浆主要感官特性指标及评价标准Table 1. Main sensory evaluation indexes and criteria of soymilk指标(分数) 评价标准(分值) 豆腥味(20) 无豆腥味(15~20) 略有豆腥味(8~14) 豆腥味浓(1~7) 豆香味(20) 豆香味浓厚(15~20) 豆香味平淡(8~14) 无香气(1~7) 甜香(10) 具有豆浆固有的甜香味(7~10) 甜香味较淡(4~6) 无甜香味(1~3) 异香味(−10):非豆浆风味特征的香气 无异香味(−3~0) 略有异香味(−6~−4) 异香味浓(−10~−7) 苦味(−10) 无苦味(−3~0) 稍有苦味(−6~−4) 苦味重(−10~−7) 涩感(−10) 无涩感(−3~0) 稍有涩感(−6~−4) 涩感重(−10~−7) 1.2.4 豆浆挥发性物质测定方法

参考何剑等[17]的方法,吸取10 mL热生香豆浆样品,置于20 mL顶空瓶中,加入10 μL内标苯甲醇(0.1 g溶于10 mL甲醇,最终质量浓度10 mg/L),密封瓶口,插入萃取头,于40 ℃水浴萃取40 min,萃取头距离液面约1 cm。随后,在GC进样口热解吸5 min(250 ℃)进行气相色谱-质谱(GC-MS)分析。色谱条件:色谱柱:(DB-WAX,30 m×0.25 mm,0.25 μm),进样口温度:230 ℃,程序升温:40 ℃,保持3 min,6 ℃/min升温至100 ℃,再10 ℃/min升至230 ℃,保持7 min,进样方式:不分流进样(1.0 mL/min),载气:氦气(99.999%)。质谱条件:接口温度:250 ℃,离子源温度:200 ℃,离子化方式:EI,电子能量:70 eV,扫描质量范围m/z:29~500。

样品经GC-MS分析后,所得到的质谱图利用随机的Xcalibμr工作站NIST 2002标准谱库自动检索各成分质谱数据,同时查阅文献,对各挥发性香气物质的成分进行定性分析。按内标法对挥发性成分进行定量分析。

1.2.5 多肽含量的测定

参考夏玉等[18]的方法,分别取5 mL酶解豆浆和热生香豆浆样品,加5 mL 10% TCA溶液沉淀后,8000 r/min转速下离心3 min,取上清液0.8 mL,加3.2 mL双缩脲试剂常温反应30 min后,在540 nm下测吸光度值,代入酪蛋白标准曲线计算多肽含量。

酪蛋白标准曲线的绘制:分别吸取浓度为0、2、4、6、8、10 g/L的酪蛋白溶液0.8 mL,加3.2 mL双缩脲试剂常温反应30 min后,在540 nm下测吸光度值。以酪蛋白浓度为横坐标,吸光度值为纵坐标,制作标准曲线,得回归方程y=0.0554x+0.0111,R2=0.9958。

1.2.6 氨基酸态氮含量的测定

参照GB 5009.235-2016及刘爱洁等[19]的方法,分别取5 mL酶解豆浆和热生香豆浆样品,加入60 mL去离子水,用0.1 mol/L NaOH标准溶液滴定至pH8.2,加入20 mL甲醛溶液(36%~38%),继续滴定到pH9.2。记录加入甲醛后消耗的体积V1。用去离子水代替待测样品,方法同上,记录加入甲醛后消耗的体积V0。根据下式计算氨基酸态氮含量。

式中:X表示氨基酸态氮含量;c表示NaOH标准溶液浓度,mol/L;V表示待测豆浆样品体积,mL。

1.3 数据处理

实验均重复3次,结果用平均值±标准差表示。采用SPSS 24.0软件进行相关性分析和显著性分析,用Origin 9.0软件进行作图。

2. 结果与分析

2.1 外源蛋白酶酶解及热生香对豆浆感官品质的影响

将多名感官评价员的评分汇总如表2。由表可知,与生豆对照组相比,豆浆机制作的豆浆可以大幅降低豆腥味,但豆香味也有所降低,涩感更重。适量的酶浓度下,添加四种外源蛋白酶均可提高豆浆的感官品质。其中添加木瓜蛋白酶处理组总体对豆浆感官评分的提升程度相对较低。添加氨基肽酶对豆香味提升效果较好,但添加浓度大于1500 U/L时开始产生类似蘑菇味的异香,与预期的豆浆特征风味不符。添加250 U/L风味蛋白酶时豆浆感官评分最高。多肽的肽段末端为疏水性氨基酸和碱性氨基酸时,水解物的苦味最重。与其他蛋白酶相比,碱性蛋白酶水解蛋白质极易产生苦味肽[20]。由表2可知,碱性蛋白酶添加量超过3500 U/L时,豆浆开始出现苦味,继续增大加酶量,豆浆苦味加剧,且出现沉淀甚至严重分层现象,失去了饮用价值。

表 2 豆浆感官评分Table 2. Sensory evaluation scores of soymilk组别 豆腥味 豆香味 甜香味 异香味 苦味 涩感 总分 生豆 5.6±0.7a 8.1±0.9ab 4.4±0.5bcd 0 0 −3.3±0.6efgh 14.8±1.4a 空白 15.5±1.3b 6.2±0.3a 4.3±0.3bcd 0 0 −5.9±0.2ab 20.1±1.6b 15000 U/L木瓜蛋白酶 16.4±1.2bcd 11.1±1.3cd 5.6±0.2bcde 0 0 −6.8±0.1a 26.3±1.5cd 30000 U/L木瓜蛋白酶 17.2±0.7bcde 14.3±1.1efg 6.3±0.3cde 0 0 −3.5±0.6defgh 34.3±2.2efg 45000 U/L木瓜蛋白酶 17.5±0.5bcde 12.5±0.7de 5.7±0.4bcde 0 0 −4.3±0.3cde 31.4±1.9ef 60000 U/L木瓜蛋白酶 17.4±0.8bcde 11.4±0.9cd 5.4±0.3bcde 0 0 −4.6±0.2bcde 29.6±1.7cde 75000 U/L木瓜蛋白酶 17.2±1.1bcde 8.3±0.6ab 5.2±0.5bcde 0 0 −5.0±0.4bc 25.7±1.8c 500 U/L氨基肽酶 15.7±0.6bc 9.6±0.5bc 5.4±0.3bcde 0 0 −4.7±0.1bcd 26.0±1.5c 1000 U/L氨基肽酶 18.1±0.9cde 13.3±1.1def 5.7±0.4bcde 0 0 −3.5±0.5defgh 33.6±2.3efg 1500 U/L氨基肽酶 19.5±0.5e 16.0±0.9gh 7.3±1.3e 0.0±0.3c 0 −1.8±0.7ij 41.0±2.5hi 2000 U/L氨基肽酶 19.2±0.7e 15.2±0.8fgh 4.1±1.3bc −2.7±0.4b 0 −1.4±0.3j 34.4±1.7efg 2500 U/L氨基肽酶 19.0±1.3de 14.3±1.2efg 3.2±1.3b −3.8±0.6a 0 −1.7±0.6ij 31.0±1.5de 100 U/L风味蛋白酶 17.2±0.9bcde 13.1±0.8def 5.2±0.4bcde 0 0 −4.6±0.3bcde 30.9±1.6de 150 U/L风味蛋白酶 18.3±1.1de 15.3±0.6fgh 6.4±0.2cde 0 0 −3.3±0.7cdefg 36.7±2.2fgh 200 U/L风味蛋白酶 19.2±0.7e 17.6±0.7hi 6.6±0.4de 0 0 −2.4±0.6hij 41.0±1.9hi 250 U/L风味蛋白酶 19.8±0.3e 19.5±1.1i 7.3±0.5e 0 0 −2.7±0.5fghij 43.9±2.1i 300 U/L风味蛋白酶 19.3±0.8e 17.4±0.9hi 4.4±0.7bcd 0 0 −4.6±0.4bcde 36.5±1.7fgh 500 U/L碱性蛋白酶 17.3±0.8bcde 15.2±0.9fgh 6.3±1.3cde 0 0 −2.5±0.4ghij 36.3±1.5fgh 1500 U/L碱性蛋白酶 18.6±1.1de 15.4±1.2fgh 7.2±0.5e 0 −0.9±0.1d −2.6±0.4fghij 37.7±2.2gh 2500 U/L碱性蛋白酶 18.4±0.7de 14.6±0.8efg 6.4±1.3cde 0 −2.4±0.4c −2.8±0.9fghi 34.2±1.6efg 3500 U/L碱性蛋白酶 18.2±0.9cde 11.6±0.6cd 4.1±1.3bc 0 −4.3±0.3b −3.9±0.2cdef 25.7±1.7c 4500 U/L碱性蛋白酶 17.9±0.6bcde 11.2±0.9cd 1.3±1.3a 0 −5.9±0.7a −7.1±0.3a 17.4±1.4ab 注:同一列中字母不同表示差异显著(P<0.05)。 2.2 外源蛋白酶酶解及热生香对豆浆风味物质的影响

分别选取生豆对照组、空白对照组和四种蛋白酶处理组中感官评分最高的三组豆浆样品,利用GC-MS分别对其进行挥发性物质分析,结果如表3所示。由表可知,生豆处理组中共检测到11种挥发性物质,空白对照组中只检测到8种;与生豆处理组相比,空白对照组中正己醛、2-戊基呋喃、正己醇和反,反-2,4-癸二烯醛含量均有不同程度的降低,加酶组中上述物质含量与空白对照组相比也均有所降低,这些物质被认为是豆腥味物质,且阈值较低,分别为4.50、6.00、9.94和2.15 μg/kg,因此对豆浆风味贡献较大[7,21-23]。添加氨基肽酶的处理组中检测出12种以上的挥发性物质,其中3-辛酮、1-辛烯-3-醇和对仲丁基苯酚含量比对照组和其他蛋白酶处理组相对较高,前两种物质具有蘑菇味[24-25]。1-辛烯-3-醇的阈值为10.00 μg/kg,在2000 U/L氨基肽酶处理组中的相对含量高达7.04 mg/L,这与感官评价结果一致。风味蛋白酶处理组中2-庚酮和正己酸乙酯含量高于其他处理组,这两种物质有水果香气,其中正己酸乙酯嗅觉阈值为55.33 μg/kg[26-27]。生成的非豆腥味物质中,氨基肽酶处理组含量最高,其次为风味蛋白酶、木瓜蛋白酶、碱性蛋白酶和生豆对照组,除2500 U/L碱性蛋白酶以外,空白对照组的非豆腥味物质含量最低。这一结果与氨基酸态氮含量基本一致。生豆豆浆在内源酶作用下可以生成更丰富的香气,这与吕艳春等[28]的研究结果相符。而外源添加蛋白酶可以生成更多小分子多肽和氨基酸,进而生成更多非豆腥味物质,同时正己醛等物质可以与大豆蛋白中的末端氨基和羧基牢固结合,形成较为复杂的化合物,使不良风味更容易除去[29],酶解有利于释放这些豆腥味物质,最终生产出豆腥味更淡、豆香味更浓的豆浆。

表 3 豆浆挥发性风味物质成分及相对含量Table 3. The composition and relative content of volatile compounds in soymilk编号 名称 相对含量(mg/L) 生豆 空白 30000 U/L

木瓜

蛋白酶45000 U/L

木瓜

蛋白酶60000 U/L

木瓜

蛋白酶1000 U/L

氨基

肽酶1500 U/L

氨基

肽酶2000 U/L

氨基

肽酶150 U/L

风味

蛋白酶200 U/L

风味

蛋白酶250 U/L

风味

蛋白酶500 U/L

碱性

蛋白酶1500 U/L

碱性

蛋白酶2500 U/L

碱性

蛋白酶1 氰基频那酮 − − − − − − 0.86 − − − − − − − 2 2-乙基环丁醇 − − − − − − − − − − 0.74 − − − 3 正己醛 2.89 2.23 2.19 2.09 1.89 2.01 1.03 0.45 1.73 0.49 − 2.12 1.13 0.37 4 2-庚酮 − − − − − − − − 0.30 0.67 1.33 − − − 5 2-戊基呋喃 0.61 0.59 0.57 0.41 0.23 0.3 0.33 0.13 0.18 0.11 − 0.57 0.42 0.27 6 正己酸乙酯 0.86 0.13 − − 0.20 0.36 0.40 0.35 0.5 0.76 0.88 0.16 0.33 0.32 7 2-乙基丁醇 − − − − − − − − − − 0.82 − − − 8 3-辛酮 − 0.15 − − 0.30 0.98 1.12 1.49 − 0.35 0.48 0.26 − 0.19 9 正戊醇 0.25 − − − − − − − − − − − 0.19 − 10 正己醇 2.31 1.59 − − − 1.13 0.78 0.24 0.28 − − 1.28 0.37 − 11 十四烷 − − − − − − − 0.14 − − − − − 0.28 12 反-2-辛烯醛 − − − − − 0.32 − 0.12 − − − − − − 13 壬醛 0.12 − − − − − − − − − − − − − 14 1-辛烯-3-醇 1.94 1.50 1.33 1.24 0.87 1.65 5.18 7.04 1.90 1.36 0.67 2.10 1.84 1.20 15 2-乙酰基-2-

甲基四氢呋喃0.41 − − − − − − − − − − − − − 16 2-乙基-1-己醇 0.13 − − − − − − − − − − − − − 17 苯甲醛 0.27 1.17 1.03 0.29 0.57 0.67 0.81 0.46 0.69 0.42 0.36 1.08 0.47 0.45 18 对仲丁基苯酚 − − − − − 0.34 0.60 0.11 − − − − − − 19 反,反-2,4-癸二烯醛 0.17 0.12 − − − 0.07 0.01 − − − − − 0.09 0.13 20 甲氧基乙酸乙酯 − − − 0.37 − 1.22 − − − − − − − − 21 七聚乙二醇 − − − − − 3.22 − − − − − − − − 22 四聚乙醛 − − − − − 1.97 1.45 − − − − − − − 23 1,3-二氧杂烷-2-甲醇 − − − − − − − 0.54 − − − − − − 24 六聚乙二醇 − − − 1.39 1.68 − 1.55 − - - - - 0.58 - 25 15-冠醚-5 − − − − − − − 0.81 − − − − − − 26 乙酸对硝基苯酯 − − − − − − − 0.29 − − − − − − 27 2-乙氧基戊烷 − − − − − − − − − − 1.57 − − − 2.3 外源蛋白酶酶解及热生香对豆浆中多肽含量的影响

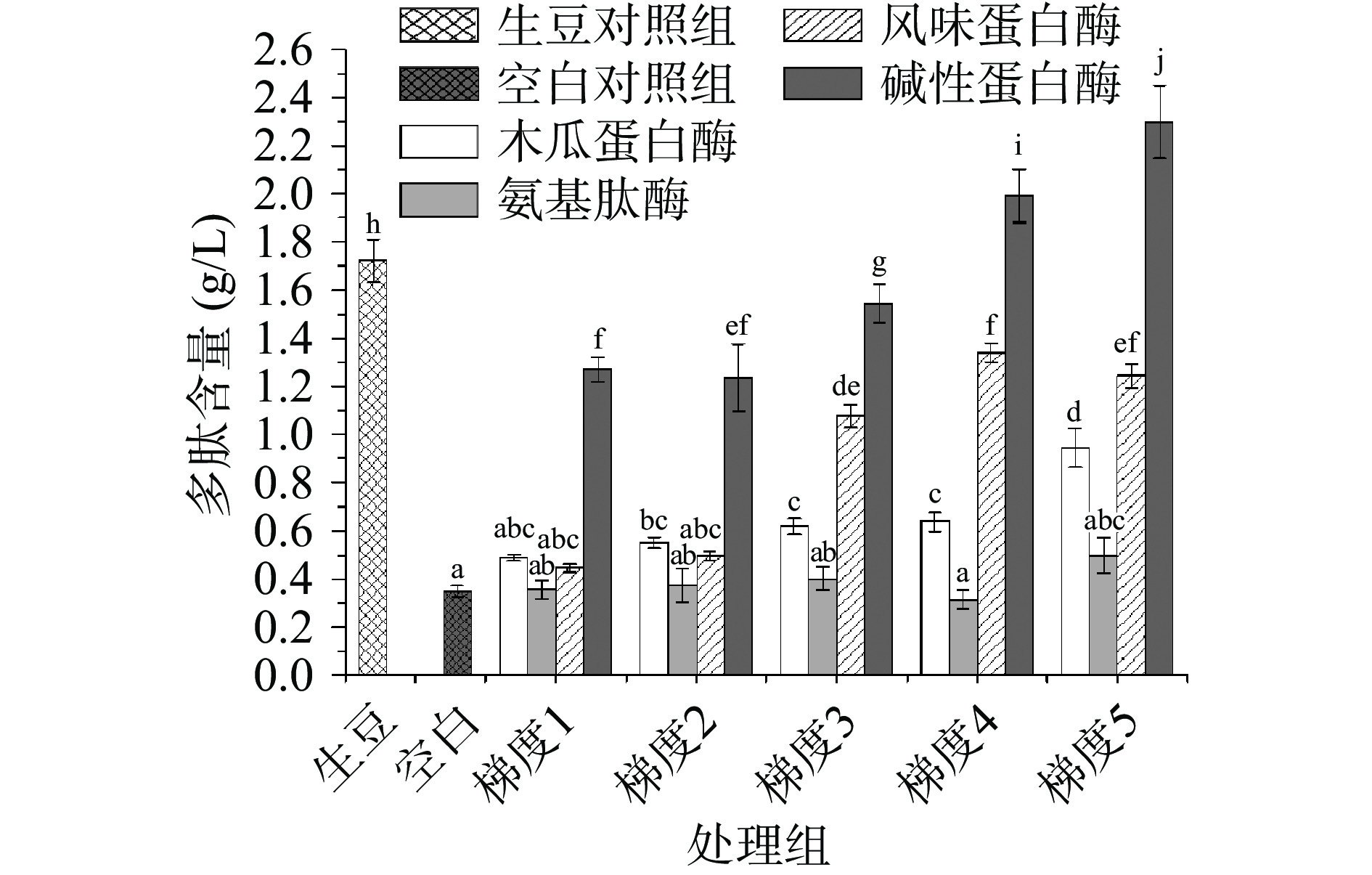

多肽是蛋白质酶解的主要产物,也可以成为风味前体物质。测定酶解产物多肽的含量可以反映豆浆中蛋白质的降解程度。由图1可知,由于内源酶的作用,生豆对照组中多肽含量较高。而豆浆机采用边加热边研磨的工艺,制作过程中的高温条件使蛋白酶失活,因此空白对照组中多肽含量仅为生豆对照组的20.29%。在机制豆浆中外源添加蛋白酶后,多肽含量均有不同程度上升。碱性蛋白酶酶解生成的多肽含量随酶浓度增大而增加,且明显高于其他三种酶,添加量为4500 U/L时多肽含量达2.30±0.15 g/L,与空白对照组相比增加了558.67%,与生豆对照组相比增加了33.64%。风味蛋白酶在低浓度梯度时,多肽含量随浓度增加上升,但浓度继续增大时多肽含量呈降低趋势,可能是由于生成的多肽进一步降解成氨基酸造成的。总体来说,外源添加四种蛋白酶酶解后的豆浆中,多肽含量均高于不酶解的豆浆。

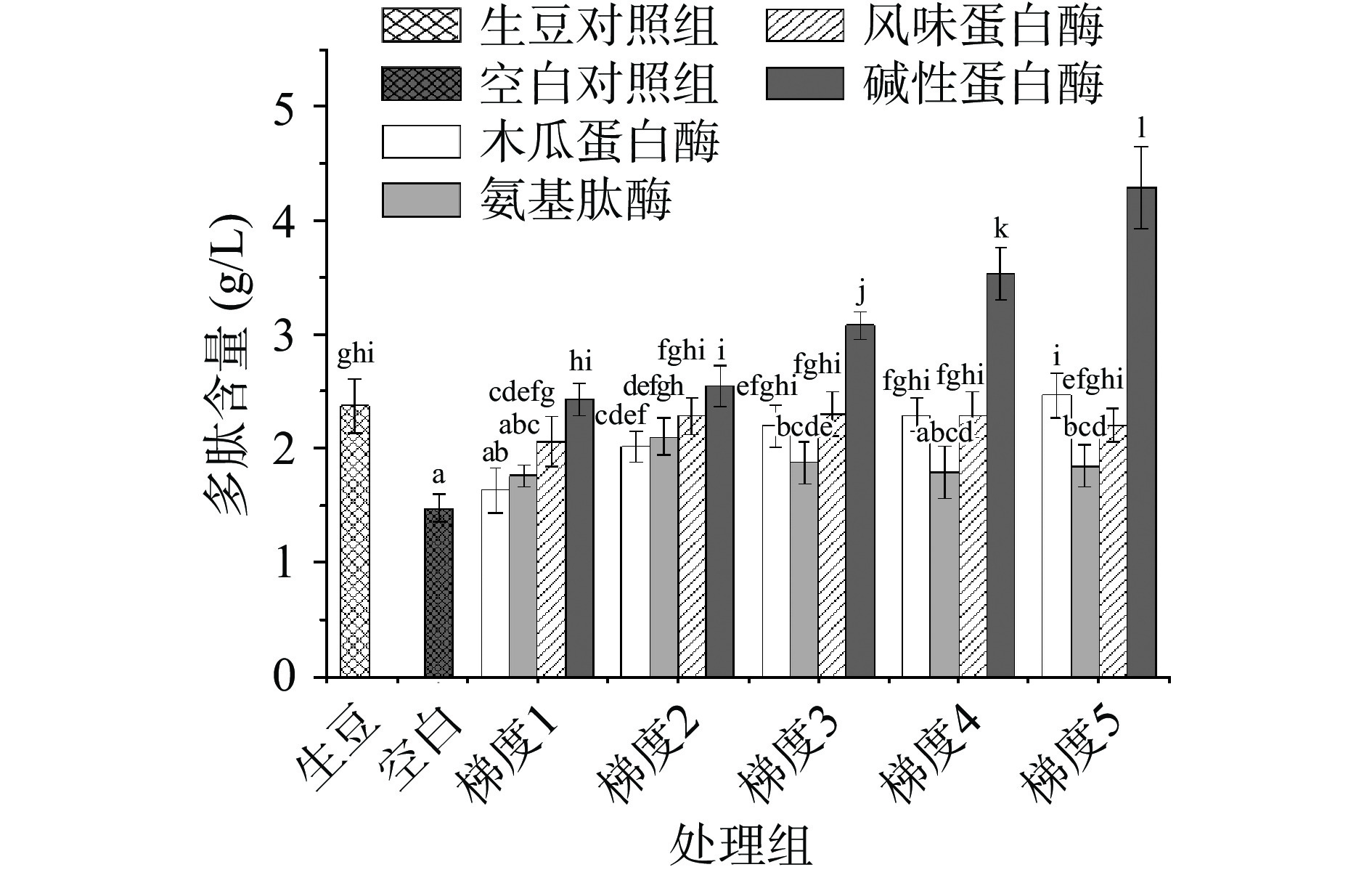

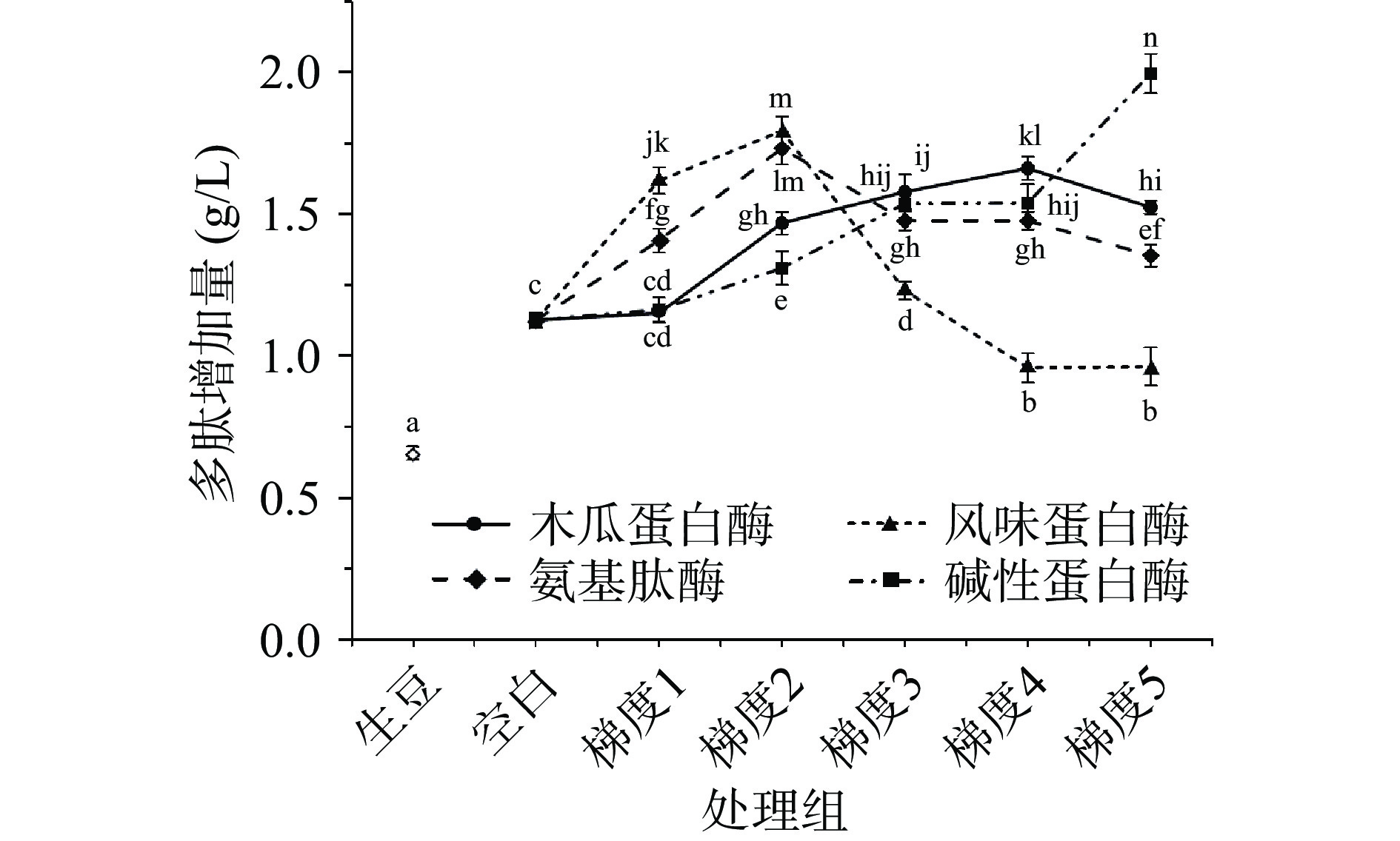

在热生香的高温条件下,豆浆内部的风味前体物质会发生美拉德反应等一系列复杂的化学变化,生成挥发性风味物质[30]。热生香后豆浆中多肽的含量测定结果如图2。经过热生香处理后,各组豆浆中的多肽含量均比热生香前增加,可能是由于部分蛋白质在高温下断裂形成多肽[31]。不同加酶处理组中热生香豆浆与酶解豆浆相比多肽的增加量如图3所示。除碱性蛋白酶外,添加其他三种蛋白酶的豆浆中多肽增加量随酶浓度增大均呈现先上升后下降的趋势,尤其是风味蛋白酶添加量大于200 U/L时,多肽的增加量反而低于空白对照组。推测是由于加酶浓度高时,生成的小分子多肽发生反应形成了风味物质,因此增加量降低。生豆对照组由于内源酶的作用,在经过热生香处理后多肽增加量最低。

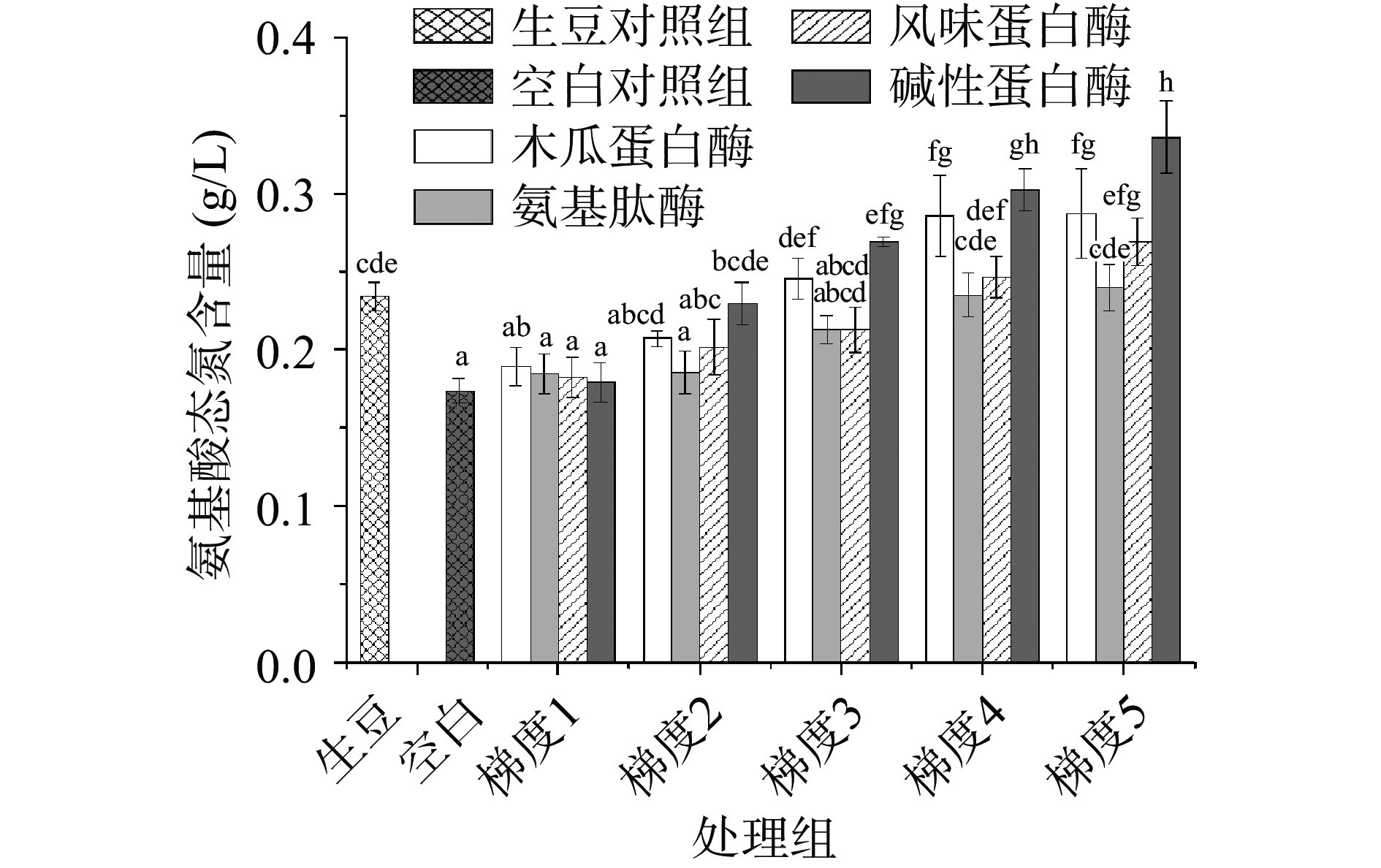

2.4 外源蛋白酶酶解及热生香对豆浆中氨基酸态氮含量的影响

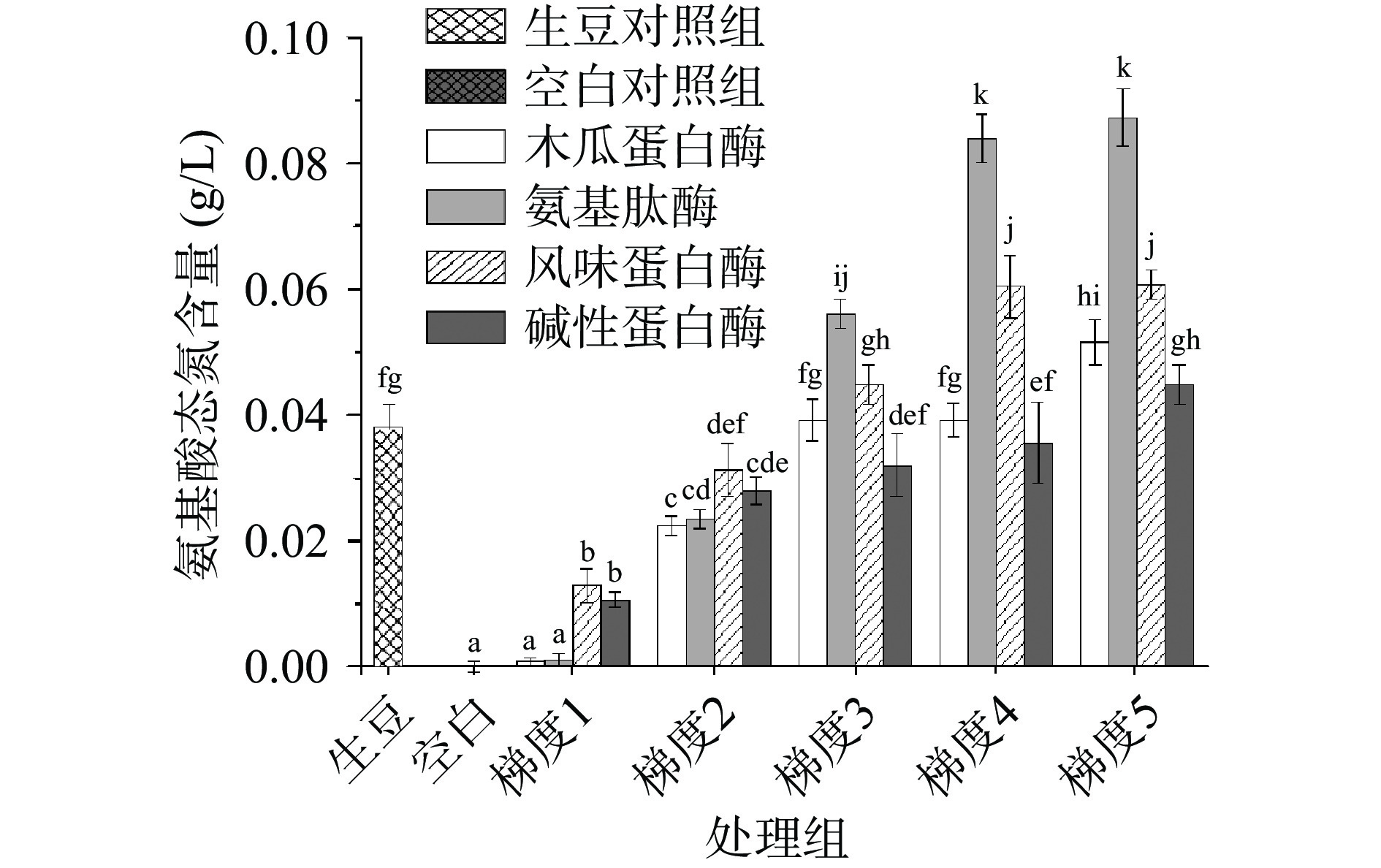

氨基酸态氮主要用来表征蛋白质降解并释放出的游离氨基的含量。由图4可知,生豆对照组豆浆在内源酶酶解后氨基酸态氮含量可达0.038±0.0009 g/L,但空白对照组中几乎检测不到氨基酸态氮。添加外源蛋白酶后(除浓度梯度为1的木瓜蛋白酶和氨基肽酶),豆浆中的氨基酸态氮含量均显著增加(P<0.05),与蛋白酶浓度呈正相关。添加氨基肽酶的浓度梯度为4~5(>1500 U/g)时,生成氨基酸态氮的含量显著高于其他三种蛋白酶(P<0.05),含量最高为0.087±0.0045 g/L,与生豆对照组相比增加了17.59%。氨基肽酶的添加量大于1000 U/g时,生成多肽的含量有所下降,但氨基酸态氮含量仍有较大幅度增长,说明氨基肽酶浓度增大时主要将蛋白质和多肽水解成游离氨基酸,这与氨基肽酶的作用机理一致[32]。木瓜蛋白酶实验组也表现出相似的趋势。经热生香处理后豆浆中氨基酸态氮含量如图5所示,氨基酸态氮的增加可能是小肽在高温下裂解生成的。氨基酸态氮的增加量如图6所示,酶解豆浆经热生香处理后,氨基肽酶处理组增加量相对最少,其次是风味蛋白酶、木瓜蛋白酶和碱性蛋白酶。可能是由于碱性蛋白酶内切产生的大量多肽片段在高温条件下更易生成氨基酸,而氨基肽酶等外切酶主要在酶解过程中生成游离氨基酸,后者在后续热生香工艺中生成较少而消耗较多。游离氨基酸可作为重要的风味物质和风味前体物质[33-34],在高温过程中经一系列反应生成挥发性风味物质[35]。例如α-氨基酸热降解会产生大量氨基,这些氨基经美拉德反应可以生成吡嗪、吡咯、吡啶等含氮风味物质[36]。因此推测经过热生香后氨基酸态氮增加量少的处理组,生成香气更多。

2.5 不同外源蛋白酶酶解及热生香后豆浆多肽、氨基酸态氮量和感官风味的相关性分析

为了明确添加蛋白酶后生成的酶解产物与豆浆风味的关系,对添加不同蛋白酶处理组的多肽、氨基酸态氮含量及增加量和豆浆感官评价中与风味相关的指标进行了相关性分析。由表4可以看出,木瓜蛋白酶处理组中酶解豆浆多肽含量与豆腥味得分呈显著负相关(P<0.05);多肽增加量和豆腥味得分呈极显著正相关(P<0.01),和总分呈显著正相关(P<0.05)。由表5可知,氨基肽酶处理组中酶解豆浆多肽含量与豆腥味得分呈极显著负相关(P<0.01);多肽增加量与豆腥味得分呈极显著正相关(P<0.01),和总分呈显著正相关(P<0.05);酶解豆浆氨态氮含量与豆香味得分呈显著正相关(P<0.05);氨态氮增加量与豆腥味得分呈极显著负相关(P<0.01),和豆香味得分、总分均呈显著负相关(P<0.05)。由表6可知,风味蛋白酶处理组中酶解豆浆氨态氮含量与豆香味得分呈显著正相关(P<0.05)。由表7可知,碱性蛋白酶处理组中多肽增加量与豆腥味得分呈显著正相关(P<0.05)。

表 4 木瓜蛋白酶处理组豆浆多肽、氨基酸态氮量和感官风味指标的相关性分析Table 4. Correlation analysis of polypeptide, amino acid nitrogen contents and sensory flavor indexes of soymilk in papain treatment group指标 豆腥味

得分豆香味

得分甜香味

得分总分 酶解豆浆多肽含量 皮尔逊相关性 −0.862* −0.293 −0.42 −0.612 显著性(双尾) 0.013 0.524 0.349 0.144 热生香豆浆多肽含量 皮尔逊相关性 −0.22 0.146 0.104 0.058 显著性(双尾) 0.636 0.755 0.824 0.901 多肽增加量 皮尔逊相关性 0.890** 0.537 0.659 0.861* 显著性(双尾) 0.007 0.213 0.107 0.013 酶解豆浆氨态氮含量 皮尔逊相关性 −0.099 0.107 0.091 0.11 显著性(双尾) 0.833 0.819 0.846 0.814 热生香豆浆氨态氮含量 皮尔逊相关性 0.106 0.106 0.127 0.197 显著性(双尾) 0.82 0.822 0.786 0.672 氨态氮增加量 皮尔逊相关性 0.127 −0.077 −0.02 0.055 显著性(双尾) 0.785 0.869 0.967 0.908 注:*表示在0.05级别(双尾),相关性显著;**表示在0.01级别(双尾),相关性显著;表5~表7同。 表 5 氨基肽酶处理组豆浆多肽、氨基酸态氮量和感官风味指标的相关性分析Table 5. Correlation analysis of polypeptide, amino acid nitrogen contents and sensory flavor indexes of soymilk in aminopeptidase treatment group指标 豆腥味

得分豆香味

得分甜香味

得分总分 酶解豆浆多肽含量 皮尔逊相关性 −0.923** −0.395 −0.191 −0.66 显著性(双尾) 0.003 0.381 0.682 0.106 热生香豆浆多肽含量 皮尔逊相关性 −0.582 0.096 0.1 −0.172 显著性(双尾) 0.171 0.838 0.831 0.712 多肽增加量 皮尔逊相关性 0.891** 0.667 0.368 0.840* 显著性(双尾) 0.007 0.102 0.417 0.018 酶解豆浆氨态氮含量 皮尔逊相关性 0.334 0.758* −0.293 0.488 显著性(双尾) 0.464 0.048 0.524 0.267 热生香豆浆氨态氮含量 皮尔逊相关性 −0.114 0.48 −0.386 0.117 显著性(双尾) 0.808 0.276 0.392 0.803 氨态氮增加量 皮尔逊相关性 −0.897** −0.823* −0.013 −0.845* 显著性(双尾) 0.006 0.023 0.978 0.017 表 6 风味蛋白酶处理组豆浆多肽、氨基酸态氮量和感官风味指标的相关性分析Table 6. Correlation analysis of polypeptide, amino acid nitrogen contents and sensory flavor indexes of soymilk in flavor protease treatment group指标 豆腥味

得分豆香味

得分甜香味

得分总分 酶解豆浆多肽含量 皮尔逊相关性 −0.412 0.227 0.035 −0.009 显著性(双尾) 0.359 0.625 0.94 0.984 热生香豆浆多肽含量 皮尔逊相关性 −0.059 0.609 0.471 0.407 显著性(双尾) 0.901 0.147 0.286 0.364 多肽增加量 皮尔逊相关性 0.503 0.178 0.324 0.334 显著性(双尾) 0.25 0.702 0.478 0.464 酶解豆浆氨态氮含量 皮尔逊相关性 0.236 0.769* 0.412 0.593 显著性(双尾) 0.611 0.043 0.358 0.16 热生香豆浆氨态氮含量 皮尔逊相关性 0.037 0.547 0.083 0.332 显著性(双尾) 0.938 0.204 0.859 0.466 氨态氮增加量 皮尔逊相关性 −0.005 0.347 −0.081 0.183 显著性(双尾) 0.991 0.446 0.864 0.694 表 7 碱性蛋白酶处理组豆浆多肽、氨基酸态氮量和感官风味指标的相关性分析Table 7. Correlation analysis of polypeptide, amino acid nitrogen contents and sensory flavor indexes of soymilk in alkaline protease treatment group指标 豆腥味

得分豆香味

得分甜香味

得分总分 酶解豆浆多肽含量 皮尔逊相关性 0 0.253 −0.474 0.167 显著性(双尾) 1 0.584 0.283 0.72 热生香豆浆多肽含量 皮尔逊相关性 0.354 0.334 −0.518 0.362 显著性(双尾) 0.436 0.464 0.233 0.425 多肽增加量 皮尔逊相关性 0.771* 0.346 −0.415 0.536 显著性(双尾) 0.043 0.448 0.354 0.215 酶解豆浆氨态氮含量 皮尔逊相关性 −0.124 0.173 −0.385 0.056 显著性(双尾) 0.79 0.711 0.394 0.905 热生香豆浆氨态氮含量 皮尔逊相关性 0.226 0.125 −0.578 0.179 显著性(双尾) 0.627 0.79 0.174 0.701 氨态氮增加量 皮尔逊相关性 0.333 0.101 −0.612 0.211 显著性(双尾) 0.466 0.829 0.144 0.649 虽然不同蛋白酶处理组间各指标有着不同的相关性,而且各指标间也存在着一定的相关性,难以通过某个指标来评判豆浆风味,但除风味蛋白酶外,其他三种酶的多肽增加量均与豆腥味得分呈较强的正相关,说明多肽增加量越多,豆腥味越淡。氨基肽酶处理组中,氨基酸态氮增加量与豆腥味、豆香味和总分呈强负相关(相关性系数绝对值>0.8),说明氨基酸态氮增加越少,生成香气越多,与2.4中的推测一致。

3. 结论

本研究测定了豆浆中的多肽和氨基酸态氮含量,结合感官评价和GC-MS联用技术分析了添加外源蛋白酶对机制豆浆中风味物质的影响。结果表明:由于工业上的豆浆生产工艺多采用高温灭活脂肪氧化酶的工艺去除豆腥味,同时也灭活了其他内源酶,导致产品的豆香味也较低。额外添加蛋白酶对香气寡淡的豆浆进行酶解和热生香处理后,感官评分均有所提升。GC-MS从加酶处理组中检测到的正己醛、2-戊基呋喃、正己醇和反,反-2,4-癸二烯醛等豆腥味挥发性成分的含量均不同程度下降,从氨肽酶处理组的豆浆样品中检测到非豆腥味挥发性成分含量最高,主要是3-辛酮、1-辛烯-3-醇和对仲丁基苯酚等;风味蛋白酶处理组检测出的2-庚酮和正己酸乙酯含量较高。外源添加蛋白酶可以提高豆浆中多肽和氨基酸态氮含量,其中添加木瓜蛋白酶、氨基肽酶、碱性蛋白酶处理组的多肽增加量均与豆腥味得分呈显著正相关,氨基肽酶处理组中,氨基酸态氮增加量与豆腥味、豆香味和总分呈强负相关。本研究表明外源添加蛋白酶可以通过水解豆浆中的蛋白质生成多肽、氨基酸等风味前体物质,在高温热生香后增加豆浆香气,解决了灭酶工艺除去豆腥味的同时,导致豆浆香气也不足的问题,为豆浆生产的新工艺提供了参考。接下来可以通过进一步实验探究酶解生成的具体风味前体物质。

-

表 1 豆浆主要感官特性指标及评价标准

Table 1 Main sensory evaluation indexes and criteria of soymilk

指标(分数) 评价标准(分值) 豆腥味(20) 无豆腥味(15~20) 略有豆腥味(8~14) 豆腥味浓(1~7) 豆香味(20) 豆香味浓厚(15~20) 豆香味平淡(8~14) 无香气(1~7) 甜香(10) 具有豆浆固有的甜香味(7~10) 甜香味较淡(4~6) 无甜香味(1~3) 异香味(−10):非豆浆风味特征的香气 无异香味(−3~0) 略有异香味(−6~−4) 异香味浓(−10~−7) 苦味(−10) 无苦味(−3~0) 稍有苦味(−6~−4) 苦味重(−10~−7) 涩感(−10) 无涩感(−3~0) 稍有涩感(−6~−4) 涩感重(−10~−7) 表 2 豆浆感官评分

Table 2 Sensory evaluation scores of soymilk

组别 豆腥味 豆香味 甜香味 异香味 苦味 涩感 总分 生豆 5.6±0.7a 8.1±0.9ab 4.4±0.5bcd 0 0 −3.3±0.6efgh 14.8±1.4a 空白 15.5±1.3b 6.2±0.3a 4.3±0.3bcd 0 0 −5.9±0.2ab 20.1±1.6b 15000 U/L木瓜蛋白酶 16.4±1.2bcd 11.1±1.3cd 5.6±0.2bcde 0 0 −6.8±0.1a 26.3±1.5cd 30000 U/L木瓜蛋白酶 17.2±0.7bcde 14.3±1.1efg 6.3±0.3cde 0 0 −3.5±0.6defgh 34.3±2.2efg 45000 U/L木瓜蛋白酶 17.5±0.5bcde 12.5±0.7de 5.7±0.4bcde 0 0 −4.3±0.3cde 31.4±1.9ef 60000 U/L木瓜蛋白酶 17.4±0.8bcde 11.4±0.9cd 5.4±0.3bcde 0 0 −4.6±0.2bcde 29.6±1.7cde 75000 U/L木瓜蛋白酶 17.2±1.1bcde 8.3±0.6ab 5.2±0.5bcde 0 0 −5.0±0.4bc 25.7±1.8c 500 U/L氨基肽酶 15.7±0.6bc 9.6±0.5bc 5.4±0.3bcde 0 0 −4.7±0.1bcd 26.0±1.5c 1000 U/L氨基肽酶 18.1±0.9cde 13.3±1.1def 5.7±0.4bcde 0 0 −3.5±0.5defgh 33.6±2.3efg 1500 U/L氨基肽酶 19.5±0.5e 16.0±0.9gh 7.3±1.3e 0.0±0.3c 0 −1.8±0.7ij 41.0±2.5hi 2000 U/L氨基肽酶 19.2±0.7e 15.2±0.8fgh 4.1±1.3bc −2.7±0.4b 0 −1.4±0.3j 34.4±1.7efg 2500 U/L氨基肽酶 19.0±1.3de 14.3±1.2efg 3.2±1.3b −3.8±0.6a 0 −1.7±0.6ij 31.0±1.5de 100 U/L风味蛋白酶 17.2±0.9bcde 13.1±0.8def 5.2±0.4bcde 0 0 −4.6±0.3bcde 30.9±1.6de 150 U/L风味蛋白酶 18.3±1.1de 15.3±0.6fgh 6.4±0.2cde 0 0 −3.3±0.7cdefg 36.7±2.2fgh 200 U/L风味蛋白酶 19.2±0.7e 17.6±0.7hi 6.6±0.4de 0 0 −2.4±0.6hij 41.0±1.9hi 250 U/L风味蛋白酶 19.8±0.3e 19.5±1.1i 7.3±0.5e 0 0 −2.7±0.5fghij 43.9±2.1i 300 U/L风味蛋白酶 19.3±0.8e 17.4±0.9hi 4.4±0.7bcd 0 0 −4.6±0.4bcde 36.5±1.7fgh 500 U/L碱性蛋白酶 17.3±0.8bcde 15.2±0.9fgh 6.3±1.3cde 0 0 −2.5±0.4ghij 36.3±1.5fgh 1500 U/L碱性蛋白酶 18.6±1.1de 15.4±1.2fgh 7.2±0.5e 0 −0.9±0.1d −2.6±0.4fghij 37.7±2.2gh 2500 U/L碱性蛋白酶 18.4±0.7de 14.6±0.8efg 6.4±1.3cde 0 −2.4±0.4c −2.8±0.9fghi 34.2±1.6efg 3500 U/L碱性蛋白酶 18.2±0.9cde 11.6±0.6cd 4.1±1.3bc 0 −4.3±0.3b −3.9±0.2cdef 25.7±1.7c 4500 U/L碱性蛋白酶 17.9±0.6bcde 11.2±0.9cd 1.3±1.3a 0 −5.9±0.7a −7.1±0.3a 17.4±1.4ab 注:同一列中字母不同表示差异显著(P<0.05)。 表 3 豆浆挥发性风味物质成分及相对含量

Table 3 The composition and relative content of volatile compounds in soymilk

编号 名称 相对含量(mg/L) 生豆 空白 30000 U/L

木瓜

蛋白酶45000 U/L

木瓜

蛋白酶60000 U/L

木瓜

蛋白酶1000 U/L

氨基

肽酶1500 U/L

氨基

肽酶2000 U/L

氨基

肽酶150 U/L

风味

蛋白酶200 U/L

风味

蛋白酶250 U/L

风味

蛋白酶500 U/L

碱性

蛋白酶1500 U/L

碱性

蛋白酶2500 U/L

碱性

蛋白酶1 氰基频那酮 − − − − − − 0.86 − − − − − − − 2 2-乙基环丁醇 − − − − − − − − − − 0.74 − − − 3 正己醛 2.89 2.23 2.19 2.09 1.89 2.01 1.03 0.45 1.73 0.49 − 2.12 1.13 0.37 4 2-庚酮 − − − − − − − − 0.30 0.67 1.33 − − − 5 2-戊基呋喃 0.61 0.59 0.57 0.41 0.23 0.3 0.33 0.13 0.18 0.11 − 0.57 0.42 0.27 6 正己酸乙酯 0.86 0.13 − − 0.20 0.36 0.40 0.35 0.5 0.76 0.88 0.16 0.33 0.32 7 2-乙基丁醇 − − − − − − − − − − 0.82 − − − 8 3-辛酮 − 0.15 − − 0.30 0.98 1.12 1.49 − 0.35 0.48 0.26 − 0.19 9 正戊醇 0.25 − − − − − − − − − − − 0.19 − 10 正己醇 2.31 1.59 − − − 1.13 0.78 0.24 0.28 − − 1.28 0.37 − 11 十四烷 − − − − − − − 0.14 − − − − − 0.28 12 反-2-辛烯醛 − − − − − 0.32 − 0.12 − − − − − − 13 壬醛 0.12 − − − − − − − − − − − − − 14 1-辛烯-3-醇 1.94 1.50 1.33 1.24 0.87 1.65 5.18 7.04 1.90 1.36 0.67 2.10 1.84 1.20 15 2-乙酰基-2-

甲基四氢呋喃0.41 − − − − − − − − − − − − − 16 2-乙基-1-己醇 0.13 − − − − − − − − − − − − − 17 苯甲醛 0.27 1.17 1.03 0.29 0.57 0.67 0.81 0.46 0.69 0.42 0.36 1.08 0.47 0.45 18 对仲丁基苯酚 − − − − − 0.34 0.60 0.11 − − − − − − 19 反,反-2,4-癸二烯醛 0.17 0.12 − − − 0.07 0.01 − − − − − 0.09 0.13 20 甲氧基乙酸乙酯 − − − 0.37 − 1.22 − − − − − − − − 21 七聚乙二醇 − − − − − 3.22 − − − − − − − − 22 四聚乙醛 − − − − − 1.97 1.45 − − − − − − − 23 1,3-二氧杂烷-2-甲醇 − − − − − − − 0.54 − − − − − − 24 六聚乙二醇 − − − 1.39 1.68 − 1.55 − - - - - 0.58 - 25 15-冠醚-5 − − − − − − − 0.81 − − − − − − 26 乙酸对硝基苯酯 − − − − − − − 0.29 − − − − − − 27 2-乙氧基戊烷 − − − − − − − − − − 1.57 − − − 表 4 木瓜蛋白酶处理组豆浆多肽、氨基酸态氮量和感官风味指标的相关性分析

Table 4 Correlation analysis of polypeptide, amino acid nitrogen contents and sensory flavor indexes of soymilk in papain treatment group

指标 豆腥味

得分豆香味

得分甜香味

得分总分 酶解豆浆多肽含量 皮尔逊相关性 −0.862* −0.293 −0.42 −0.612 显著性(双尾) 0.013 0.524 0.349 0.144 热生香豆浆多肽含量 皮尔逊相关性 −0.22 0.146 0.104 0.058 显著性(双尾) 0.636 0.755 0.824 0.901 多肽增加量 皮尔逊相关性 0.890** 0.537 0.659 0.861* 显著性(双尾) 0.007 0.213 0.107 0.013 酶解豆浆氨态氮含量 皮尔逊相关性 −0.099 0.107 0.091 0.11 显著性(双尾) 0.833 0.819 0.846 0.814 热生香豆浆氨态氮含量 皮尔逊相关性 0.106 0.106 0.127 0.197 显著性(双尾) 0.82 0.822 0.786 0.672 氨态氮增加量 皮尔逊相关性 0.127 −0.077 −0.02 0.055 显著性(双尾) 0.785 0.869 0.967 0.908 注:*表示在0.05级别(双尾),相关性显著;**表示在0.01级别(双尾),相关性显著;表5~表7同。 表 5 氨基肽酶处理组豆浆多肽、氨基酸态氮量和感官风味指标的相关性分析

Table 5 Correlation analysis of polypeptide, amino acid nitrogen contents and sensory flavor indexes of soymilk in aminopeptidase treatment group

指标 豆腥味

得分豆香味

得分甜香味

得分总分 酶解豆浆多肽含量 皮尔逊相关性 −0.923** −0.395 −0.191 −0.66 显著性(双尾) 0.003 0.381 0.682 0.106 热生香豆浆多肽含量 皮尔逊相关性 −0.582 0.096 0.1 −0.172 显著性(双尾) 0.171 0.838 0.831 0.712 多肽增加量 皮尔逊相关性 0.891** 0.667 0.368 0.840* 显著性(双尾) 0.007 0.102 0.417 0.018 酶解豆浆氨态氮含量 皮尔逊相关性 0.334 0.758* −0.293 0.488 显著性(双尾) 0.464 0.048 0.524 0.267 热生香豆浆氨态氮含量 皮尔逊相关性 −0.114 0.48 −0.386 0.117 显著性(双尾) 0.808 0.276 0.392 0.803 氨态氮增加量 皮尔逊相关性 −0.897** −0.823* −0.013 −0.845* 显著性(双尾) 0.006 0.023 0.978 0.017 表 6 风味蛋白酶处理组豆浆多肽、氨基酸态氮量和感官风味指标的相关性分析

Table 6 Correlation analysis of polypeptide, amino acid nitrogen contents and sensory flavor indexes of soymilk in flavor protease treatment group

指标 豆腥味

得分豆香味

得分甜香味

得分总分 酶解豆浆多肽含量 皮尔逊相关性 −0.412 0.227 0.035 −0.009 显著性(双尾) 0.359 0.625 0.94 0.984 热生香豆浆多肽含量 皮尔逊相关性 −0.059 0.609 0.471 0.407 显著性(双尾) 0.901 0.147 0.286 0.364 多肽增加量 皮尔逊相关性 0.503 0.178 0.324 0.334 显著性(双尾) 0.25 0.702 0.478 0.464 酶解豆浆氨态氮含量 皮尔逊相关性 0.236 0.769* 0.412 0.593 显著性(双尾) 0.611 0.043 0.358 0.16 热生香豆浆氨态氮含量 皮尔逊相关性 0.037 0.547 0.083 0.332 显著性(双尾) 0.938 0.204 0.859 0.466 氨态氮增加量 皮尔逊相关性 −0.005 0.347 −0.081 0.183 显著性(双尾) 0.991 0.446 0.864 0.694 表 7 碱性蛋白酶处理组豆浆多肽、氨基酸态氮量和感官风味指标的相关性分析

Table 7 Correlation analysis of polypeptide, amino acid nitrogen contents and sensory flavor indexes of soymilk in alkaline protease treatment group

指标 豆腥味

得分豆香味

得分甜香味

得分总分 酶解豆浆多肽含量 皮尔逊相关性 0 0.253 −0.474 0.167 显著性(双尾) 1 0.584 0.283 0.72 热生香豆浆多肽含量 皮尔逊相关性 0.354 0.334 −0.518 0.362 显著性(双尾) 0.436 0.464 0.233 0.425 多肽增加量 皮尔逊相关性 0.771* 0.346 −0.415 0.536 显著性(双尾) 0.043 0.448 0.354 0.215 酶解豆浆氨态氮含量 皮尔逊相关性 −0.124 0.173 −0.385 0.056 显著性(双尾) 0.79 0.711 0.394 0.905 热生香豆浆氨态氮含量 皮尔逊相关性 0.226 0.125 −0.578 0.179 显著性(双尾) 0.627 0.79 0.174 0.701 氨态氮增加量 皮尔逊相关性 0.333 0.101 −0.612 0.211 显著性(双尾) 0.466 0.829 0.144 0.649 -

[1] PENG X Y, WANG Y H, XING J Y, et al. Characterization of particles in soymilks prepared by blanching soybeans and traditional method: A comparative study focusing on lipid-protein interaction[J]. Food Hydrocolloids,2017,63(Feb.):1−7.

[2] ZHANG Wei, LIU Xiaosheng, YANG Zhengmao, et al. Effect of soaking and temperature process on the volatile compounds in soymilk made by soymilk maker[J]. Journal of Food Science and Technology,2018,55(4):1591−1598. doi: 10.1007/s13197-018-3072-7

[3] CHONG W K, MAH S Y, EASA A M, et al. Thermal inactivation of lipoxygenase in soya bean using superheated steam to produce low beany flavour soya milk[J]. Journal of Food Science and Technology,2019,56(9):4371−4379. doi: 10.1007/s13197-019-03905-4

[4] KIN-CHOR K, KESHAVAN N. Review: Effect of thermal processing on soymilk[J]. International Journal of Food Science& Technology,1995,30(3):263−295.

[5] 曾祥博. 不同脂肪氧化酶缺失型大豆制备豆浆中挥发性组分及其中间产物比较和分析[D]. 长春: 吉林农业大学, 2019. ZENG X B. Comparison and analysis on the volatility components and intermediate products in soymilk prepared from different lipoxygenase-free soybean varieties[D]. Changchun: Jilin Agricultural University, 2019.

[6] 单长松, 宋华鲁, 刘锦, 等. 欧姆加热对豆浆风味物质的影响[J]. 食品科学,2018,39(22):195−201. [SHAN C S, SONG H L, LIU J, et al. Effects of ohmic heating on the volatile compounds of soymilk[J]. Food Science,2018,39(22):195−201. SHAN C S, SONG H L, LIU J, et al. Effects of ohmic heating on the volatile compounds of soymilk[J]. Food Science, 2018, 39(22): 195-201.

[7] 田怀香, 何晓葳, 李立, 等. 豆浆中豆腥味影响因素及消除方法的研究进展[J]. 现代食品科技,2021,37(10):340−347. [TIAN H X, HE X W, LI L, et al. Research progress about the affecting factors and eliminating methods of beany flavor in soymilk[J]. Modern Food Science and Technology,2021,37(10):340−347. TIAN H X, HE X W, LI L, et al. Research progress about the affecting factors and eliminating methods of beany flavor in soymilk[J]. Modern Food Science and Technology, 2021, 37(10): 340-347.

[8] MAZORRA-MANZANO M A, RAMIREZ-SUAREZ J C, YADA R Y. Plant proteases for bioactive peptides release: A review[J]. Critical Reviews in Food Science and Nutrition,2018,58(13/15):2147−2163.

[9] LUO W, XUE H, XIONG C, et al. Effects of temperature on quality of preserved eggs during storage[J]. Poultry Science,2020,99(6):3144−3157.

[10] 赵巧丽, 王丽, 廖振林, 等. 木瓜蛋白酶水解对豆乳中抗原蛋白含量和亚基构成的影响[J]. 食品工业科技,2017,38(15):117−121, 128. [ZHAO Q L, WANG L, LIAO Z L, et al. Effect of papain hydrolysis on the components of antigen proteins and subunits composition in soybean milk[J]. Science and Technology of Food Industry,2017,38(15):117−121, 128. ZHAO Q L, WANG L, LIAO Z L, et al. Effect of papain hydrolysis on the components of antigen proteins and subunits composition in soybean milk[J]. Science and Technology of Food Industry, 2017, 38(15): 117-121, 128.

[11] CUTON J M, SARATH G, WAGNER F W. Purification and characterization of a soybean cotyledon aminopeptidase[J]. Plant Science,1991,75(1):9−17. doi: 10.1016/0168-9452(91)90003-Q

[12] LEI F F, ZHAO Q Z, SUN-WATERHOUSE D X, et al. Characterization of a salt-tolerant aminopeptidase from marine Bacillus licheniformis SWJS33 that improves hydrolysis and debittering efficiency for soy protein isolate[J]. Food Chemistry,2017,214:347−353. doi: 10.1016/j.foodchem.2016.07.028

[13] 王章存, 王佩, 安广杰, 等. 风味蛋白酶水解大豆分离蛋白的抗原性及功能特性变化[J]. 中国粮油学报,2018,33(3):48−52. [WANG Z C, WANG P, AN G J, et al. Changes in allergenicity and functional property of soy protein isolates hydrolyzed with flavourzyme[J]. Journal of the Chinese Cereals and Oils Association,2018,33(3):48−52. WANG C ZH, WANG P, AN G J, et al. Changes in allergenicity and functional property of soy protein isolates hydrolyzed with flavourzyme[J]. Journal of the Chinese Cereals and Oils Association, 2018, 33(3): 48-52.

[14] WALTER J, GREENBERG Y, SRIRAMARAO P, et al. Limited hydrolysis combined with controlled Maillard-induced glycation does not reduce immunoreactivity of soy protein for all sera tested[J]. Food Chemistry,2016,213:742−752.

[15] XU Z Q, WU C P, SUN-WATERHOUSE D X, et al. Identification of post-digestion angiotensin-I converting enzyme (ACE) inhibitory peptides from soybean protein isolate: Their production conditions and in silico molecular docking with ACE[J]. Food Chemistry,2021,345:128855.1−128855.8.

[16] 沈明浩, 谢主兰. 食品感官评定[M]. 郑州: 郑州大学出版社, 2011. SHEN M H, XIE Z L. Food sensory evaluation[M]. Zhengzhou: Zhengzhou University Press, 2011.

[17] 何剑, 徐军, 孙超, 等. 豆浆制备过程中大豆脂肪氧化酶的抑制与豆腥味量的关系[J]. 饮料工业,2022,25(1):18−25. [HE J, XU J, SUN C, et al. Correlation between inactivating soybean lipoxygenase and minimizing beany flavor in the production of soymilk[J]. Beverage Industry,2022,25(1):18−25. HE J, XU J, SUN C, et al. Correlation between inactivating soybean lipoxygenase and minimizing beany flavor in the production of soymilk[J]. Beverage Industry, 2022, 25(1): 18-25.

[18] 夏玉, 郑华, 林捷, 等. 发酵乳中多肽含量测定方法的研究[C]. //广东省食品学会2013年年会暨学会成立30周年纪念大会论文集. 广州: 2013: 52−56 XIA Y, ZHENG H, LIN J, et al. Determination of content of peptides in fermented milk[C]. //Proceedings of the 2013 Annual Meeting of Guangdong Food Society and the 30th Anniversary Meeting of the Society. Guangzhou: 2013: 52−56.

[19] 刘爱洁, 李理. 豆浆保温处理对大豆酸奶品质的影响[J]. 现代食品科技,2013,29(1):68−72. [LIU A J, LI L. Effect of soymilk heat-processing on the quality of soy yogurt[J]. Modern Food Science and Technology,2013,29(1):68−72. LIU Aijie, LI Li. Effect of soymilk heat-processing on the quality of soy yogurt[J]. Modern Food Science and Technology, 2013, 29(1): 68-72.

[20] 范巍巍. 鳕鱼骨蛋白酶解过程中苦味形成机制及其控制方法研究[D]. 大连: 大连工业大学, 2018 FAN W W. Mechanism of bitterness formation and control methods of protein hydrolysis of cod bone[D]. Dalian: Dalian Polytechnic University, 2018.

[21] WILKENS W F, LIN F M. Gas chromatographic and mass spectral analyses of soybean milk volatiles[J]. Journal of Agricultural & Food Chemistry,1970,18(3):333−336.

[22] KANEKO S, KUMAZAWA K, NISHIMURA O. Studies on the key aroma compounds in soy milk made from three different soybean cultivars[J]. Journal of Agricultural and Food Chemistry,2011,59:12204−12209. doi: 10.1021/jf202942h

[23] LÜ Y C, SONG H L, LI X, et al. Influence of blanching and grinding process with hot water on beany and non-beany flavor in soymilk[J]. Journal of Food Science,2011,76(1):S20−S25. doi: 10.1111/j.1750-3841.2010.01947.x

[24] 杨绍祥, 穆旻, 何昕, 等. 食用香料3-辛酮的合成[J]. 中国调味品,2014(8):93−95. [YANG S X, MU M, HE X, et al. Study on the synthesis of flavoring agent 3-octanone[J]. China Condiment,2014(8):93−95. YANG S X, MU M, HE X, et al. Study on the synthesis of flavoring agent 3-Octanone[J]. China Condiment, 2014(8): 93-95.

[25] CORDOVEZ V, MOMMER L, MOISAN K, et al. Plant phenotypic and transcriptional changes induced by volatiles from the fungal root pathogen rhizoctonia solani[J]. Front Plant Science,2017,8:1262. doi: 10.3389/fpls.2017.01262

[26] 济南市轻工研究所. 合成食用香料手册[M]. 北京: 轻工业出版社, 1985: 230. Jinan Light Industry Institute: Handbook of synthetic flavorings[M]. Beijing: Light Industry Press, 1985: 230.

[27] 裴鹏正, 贠建民, 贾琦, 等. 软儿梨果酒发酵过程中挥发性风味物质变化分析[J]. 生物技术进展,2021,11(6):758−769. [PEI P Z, YUN J M, JIA Q, et al. Analysis on changes of volatile flavor compounds in ruan'er pear wine during fermentation[J]. Current Biotechnology,2021,11(6):758−769. PEI P Z, YUN J M, JIA Q, et al. Analysis on changes of volatile flavor compounds in ruan′er pear wine during fermentation[J]. Current Biotechnology, 2021, 11(6): 758-769.

[28] 吕艳春, 郭顺堂. 三种方法加工的豆乳的风味特点[J]. 大豆科学,2010,29(3):494−497. [LÜ Y C, GUO S T. Flavor characteristic of soymilk made by three differernt processing methods[J]. Soybean Science,2010,29(3):494−497. LÜ Y C, GUO S T, Flavor characteristic of soymilk made by three differernt processing methods[J]. Soybean Science, 2010, 29(3): 494-497.

[29] RACKIS J J. Spectrophotometric method for determination of lipoxidase activity[J]. Journal of the American Oil Chemists' Society,1979,56:262−268. doi: 10.1007/BF02671470

[30] ECHAVARRIA A P, PAGAN J, IBARZ A. Kinetics of color development in glucose/amino acid model systems at different temperatures[J]. Scientia Agropecuaria,2016,7(1):15−21.

[31] NEETY S, SHILPA P, SUNAINA S, et al. Non-mulberry and mulberry silk protein sericins as potential media supplement for animal cell culture[J]. BioMed Research International,2016(13):7461041−7461053.

[32] LOMATE P R, JADHAV B R, GIRI A P, et al. Alterations in the Helicoverpa armigera midgut digestive physiology after ingestion of pigeon pea inducible leucine aminopeptidase[J]. PLoS One,2013,8(9):e74889. doi: 10.1371/journal.pone.0074889

[33] WEN D L, LIU Y, YU Q. Metabolomic approach to measuring quality of chilled chicken meat during storage[J]. Poultry Science,2020,99(5):2543−2554.

[34] GAO B H , HU X B, XUE H, et al. The changes of umami substances and influencing factors in preserved egg yolk: pH, endogenous protease, and proteinaceous substance[J]. Frontiers in Nutrition, 2022, 9: 998448.

[35] 丁耐克. 食品风味化学[M]. 北京: 中国轻工业出版社, 1996 DING N K. Food flavor chemistry[M]. Beijing: Chinalight Industry Press, 1996.

[36] 施小迪. 豆乳及豆乳发酵液不良风味的形成及改善途径研究[D]. 北京: 中国农业大学, 2017 SHI X D. Study on the formation and improving methods for off-flavor of soymilk and soymilk fermented liquid[D]. Beijing: China Agricultural University, 2017.

-

期刊类型引用(3)

1. 王海利,陈安琪,郭旭,黄俊杰,林艳翎,张文森. 桂圆红枣复合发酵果酱的工艺优化. 福建轻纺. 2024(03): 17-20+30 .  百度学术

百度学术

2. 曹永华,李祥睿. 金银花精油对葵花籽油氧化稳定性及煎炸品质的影响. 中国食品添加剂. 2024(06): 137-144 .  百度学术

百度学术

3. 蔡荣,徐春芳,李珊,夏伯候,李亚梅,刘武,谢菁琛,张智敏,林丽美. 山银花茎叶与花化学成分和抗炎活性比较研究. 湖南中医药大学学报. 2023(09): 1598-1608 .  百度学术

百度学术

其他类型引用(2)

下载:

下载:

下载:

下载: