Improvement of Rice Flour, Rice Dough and Rice Bread by Transglutaminase

-

摘要: 为改善米面包品质,揭示转谷氨酰胺酶(TG酶)对米粉、米面团和米面包品质的影响及各指标之间的联系,对添加不同质量分数TG酶的米粉的粉质特性和糊化特性,米面团的水分分布、流变特性和发酵特性,以及米面包的比容、气孔和质构等指标进行了测定。结果表明,0.60% TG酶能够改善米粉的粉质特性和糊化特性,将米粉的稳定时间提高至8.00±0.77 min,峰值粘度(PV)、谷值粘度(VV)和最终粘度(FV)分别提升为5801.00±30.41、3805.67±76.14和5836.33±106.17 cP,降低米粉的衰减值(BD)和回生值(SB)等糊化参数至1990.00±128.11和1991.67±34.08 cP;同时TG酶增加米面团中水分结合的紧密程度,改善米面团的流变特性和发酵特性,将S21升至9.24%±13.07%和将T21和T22分别降至1.40±1.80和30.45±2.28 ms,Hm提高至8.60±0.11 mm;孔隙率提高至50.51%±0.90%,降低米面包的硬度、胶粘性和咀嚼性,提高米面包的弹性,改良米面包的质构。相关性分析表明,T23和形成时间呈负相关,Hm与C3、C3~C2和VV呈正相关,与BD和SB呈负相关,咀嚼性和C1呈正相关,比容与FV和PV呈正相关。实验结果说明,TG酶可以改善米粉、米面团和米面包的品质,且改良的各指标间存在不同程度的相关性。Abstract: In order to improve the quality of rice bread and reveal the effects of transglutaminase (TGase) on the quality of rice flour, rice dough and rice bread, and reveal the relationship among the indexes. The silty properties and pasting properties of TGase containing different mass fractions in rice flour, the water distribution, rheological properties and fermentation capability of rice dough, and the specific volume, gas cells and texture of bread were tested. The results showed that 0.60% TGase could improve the silty and pasting properties of rice flour, and increase the stabilization time of rice flour to 8.00±0.77 min. The peak viscosity (PV), valley viscosity (VV) and final viscosity (FV) were increased to 5801.00±30.41, 3805.67±76.14 and 5836.33±106.17 cP, respectively. Breakdown (BD) and setback (SB) of rice flour were reduced to 1990.00±128.11 and 1991.67±34.08 cP. At the same time, TGase increased the tightness of water binding, improved the rheological properties and fermentation capability of rice dough, increased S21 to 9.24%±13.07%, decreased T21 and T22 to 1.40±1.80 and 30.45±2.28 ms, and increased Hm to 8.60±0.11 mm. The porosity was increased to 50.51%±0.90%, which reduced the hardness, adhesiveness and chewiness of rice bread, improved the springiness of rice bread and improved the textural properties of rice bread. Correlation analysis showed that T23 was negatively correlated with the formation time, and Hm was positively correlated with C3, C3~C2 and VV. And BD and SB were negatively correlated, chewiness was positively correlated with C1, specific volume was positively correlated with FV and PV were positively correlated. The results showed that TGase improved the quality of rice flour, rice dough and rice bread, and there were different degrees of correlation among the improved indexes.

-

面包是世界上2/3人群的主食,一般含有麸质成分[1]。研究发现,世界上约1%的人口表现出不同程度的麸质不耐受。针对麸质不耐受人群,目前对其治疗的方法是坚持无麸质饮食[2]。但无麸质面包质地易碎、面团结构薄弱、醒发不良以及韧性不足,致使其整体可接受度较低。小麦中的麸质,不仅有助于提高小麦粉的稳定时间和降低小麦粉的回生值,改善小麦粉的粉质特性和糊化特性,还能改善面包的比容、质构和气孔等多项理化特性。麸质中的醇溶蛋白和谷蛋白分别为面团提供粘性和弹性,并且影响面团的流变和结构等品质[3-4]。由于蛋白质的功能性可以通过交联来修饰,因此蛋白质分子间形成分子间交联是改良无麸质面包缺陷的有效途径。研究发现,转谷氨酰胺酶(transglutaminase,TG酶)可以使蛋白质发生共价交联,将可溶蛋白质转化为不溶于水的高分子聚合物,形成稳定的蛋白质网络,使含荞麦粉和大豆粉的小麦面包比容增大,外观接受度更好,取得更高的感官评分值[5]。

大米价格低廉、营养丰富、易于消化且致敏性低,是无麸质产品中最受欢迎的原料。除此之外,大米蛋白质中含有丰富的赖氨酸(可以作为TG酶底物)。虽然已有相关研究TG酶对玉米和鹰嘴豆等无麸质原料的粉质特性、糊化特性和流变参数的影响[6-7],但是TG酶对米粉、米面团和米面包的影响及其各参数之间的联系仍未完全揭示。本研究以米粉、米面团以及米面包作为研究对象,对比小麦粉及相关制品的特性参数,分别研究了TG酶对米粉、米面团和米面包品质改良的作用效果,分析各指标的相关性,揭示TG酶对米粉、米面团和米面包品质改良的作用机理,为TG酶在米制品中的应用提供理论依据和实践基础,为后续改良米面包品质的添加剂和加工工艺的选择提供准确可靠的支撑。

1. 材料与方法

1.1 材料与仪器

大米 黑龙江武昌市金河米业有限公司;高筋小麦粉 益海小麦工业有限公司;酵母 河北马利食品有限公司;绵白糖 吉林省杞参食品有限公司;盐 中国盐业股份有限公司;黄油 山东培元粮油食品有限公司;奶粉 齐齐哈尔市碾子山乳品有限责任公司;鸡蛋 市售;谷氨酰胺转氨酶(酶活力为100 U/g) 泰兴市东圣生物科技有限公司。

HMJ-A20E1和面机 小熊电器有限公司;VF-12湿温自控醒发箱 沈阳市华恒伟业食品机械厂;JE1002电子天平 上海浦春计量仪器有限公司;YLBD-3A电烤箱 上海多力食品机械制造有限公司;Mixolab混合实验仪 法国肖邦技术公司;TCW3.17.3.509快速黏度分析仪 波通瑞华科学仪器有限公司;NH300色差仪 深圳市三恩驰科技有限公司;RS-FS1406粉碎机 合肥荣事达小家电有限公司;TA.XT-Plus质构仪 北京盈盛恒泰科技有限责任公司;NMI20核磁共振成像仪 上海纽曼电子科技有限公司;F4发酵流变仪 法国肖邦技术公司;MCR102流变仪 奥地利安东帕公司。

1.2 实验方法

1.2.1 米粉制备及水分含量的测定

用粉碎机将3.50 kg大米研磨成粉并过0.18 mm孔径筛,然后装入密封袋4 ℃保存备用。按表1比例用电子天平将称取TG酶和米粉充分混合,获得含不同质量分数TG酶(0、0.20%、0.40%、0.60%、0.80%)的米粉。

表 1 混合粉配制Table 1. Mix powder configuration实验组 质量(g) 小麦粉 米粉 TG酶 小麦粉 700.00 0.00 0.00 米粉 0.00 700.00 0.00 含0.20%TG酶的米粉 0.00 698.60 1.40 含0.40%TG酶的米粉 0.00 697.20 2.80 含0.60%TG酶的米粉 0.00 695.80 4.20 含0.80%TG酶的米粉 0.00 694.40 5.60 米粉和小麦粉的水分含量按照GB 5009.3-2016《食品安全国家标准食品中水分的测定》在105.00 ℃恒重测定[8]。每个样品重复测定三次,取平均值。

1.2.2 米粉粉质特性的测定

参照Santos等[7]的方法稍作修改,采用Mixolab混合实验仪的梗米粉新协议测试方案测试表1混合粉的粉质特性,小麦粉和米粉分别为对照和空白。混合实验仪运作程序如下:首先,将仪器温度设置为30 ℃,保持8 min;然后,以4 ℃/min的速度升至90 ℃,并保持7 min;最后,以4 ℃/min的速度降至50 ℃,并保持5 min。整个测定过程的搅拌速度为80 r/min,面团总重为90.00 g,加水量以满足面团在和面时最大扭矩达到1.10±0.05 nm为准,测试时物料如表2。最终测得吸水率、C1(和面阶段的最大扭矩)、C2(加热阶段的最小扭矩)、C3(加热阶段的最大扭矩)、C1~C2(蛋白质弱化度)和C3~C2(糊化速率)。

表 2 面团的制备Table 2. Preparation of dough实验组 混合粉(g) 水(g) 小麦粉 55.29 34.71 米粉 51.58 38.42 含0.20%TG酶的米粉 51.99 38.91 含0.40%TG酶的米粉 51.99 38.91 含0.60%TG酶的米粉 51.99 38.91 含0.80%TG酶的米粉 51.99 38.91 1.2.3 米粉糊化特性的测定

参照Palabiyik等[9]的方法稍作修改,用TCW 3.17.3.509快速粘度分析仪分析表1混合粉的糊化特性,小麦粉和米粉分别为对照和空白。分别取表1中4.00 g物料置于样品池,然后加入25.00 mL蒸馏水,用仪器自带的塑料搅拌器混匀后上机测试。测试程序:初始搅拌速度为960 r/min,持续10 s,然后搅拌速度控制在160 r/min。首先,以10 ℃/min的速率将样品加热至50 ℃;然后,在50 ℃下保持1 min之后,以12 ℃/min的速率将样品继续加热至95 ℃,并保持2.50 min;最后,以12 ℃/min的速度将样品冷却至50 ℃,并持续2 min。获得VV(谷值粘度)、PV(峰值粘度)、FV(最终粘度)、BD(衰减值)和SB(回生值)等糊化参数。每个样品重复测定三次,取平均值。

1.2.4 米面团水分分布的测定

参照Niu等[10]的方法稍作修改,使用NMI20低场核磁分析表1混合粉所制成面团的水分分布,小麦粉和米粉分别为对照和空白。分别取表1中10.00 g物料加入水(按表2最佳吸水率添加水)揉搓成团后,将面团用聚乙烯保鲜膜包裹放置30.00 min,切2.00~3.00 g面团用聚乙烯保鲜膜包裹并放入试管中进行测试,使用Carr-Purcell-Meibom-Gill(CPMG)脉冲序列测定面团的T2(横向弛豫时间)。通过分布指数拟合分析面团的T2,以此来获得面团的T21(结合水横向弛豫时间)、T22(不易流动水横向弛豫时间)和T23(自由水横向弛豫时间),并通过累积积分确定面团相应的S21(结合水含量)、S22(不易流动水含量)和S23(自由水含量)。每个样品重复测定三次,取平均值。

1.2.5 米面团流变特性的测定

参照Li等[11]的方法稍作修改,用MCR102流变仪分析表1混合粉的所制成面团的流变特性,小麦粉和米粉分别为对照和空白。分别取表1中10.00 g物料加入水(按表2最佳吸水率添加水)揉搓成团后,将得到的面团用聚乙烯保鲜膜包裹放置30 min,然后将面团用擀面杖制成厚度为2.00 mm的面皮,立即将面皮放到流变仪上,刮除多余的面皮。选取直径40.00 mm平板,设定两板之间的间隙为2.00 mm。在30 ℃下,面团以0.50%的应变进行范围为0.1~40 Hz的对数频率扫描,共记录了21个检测点,获得面团在频率扫描过程中的G'(储能模数)和G''(损耗模数)。

1.2.6 米面团发酵特性的测定

参照Cao等[12]的方法稍作修改,用Chopin Technologies发酵流变仪测定表1混合粉所制成面团的发酵力,小麦粉和米粉分别为对照和空白。分别取表1中200.00 g物料、2.40 g干酵母和4.00 g盐加入水(按表2最佳吸水率减去2.00 %添加水)和成面团,取315.00 g面团迅速置于发酵篮中,将面团用手压平至发酵篮的孔隙之下,安上未放置圆柱形砝码的活塞开始测量。面团在35 ℃下发酵3 h得到面团在发酵过程中的Hm(最大高度)、Tx(开始泄露CO2的时间)和R(气体保持系数)。

1.2.7 面包制作工艺

分别取表1物料200.00 g,加入12.00 g奶粉和36.00 g白糖均匀,获得干料。称量16.00 g蛋液获得湿料A;将2.40 g酵母用少量38±2 ℃的温水活化5 min,获得湿料B。

将干料、湿料A和湿料B混合均匀,加剩余的温水(总用水量为吸水率的85.00%)[13],揉搓成团后加入16.00 g黄油,待黄都融入面团后再加入1.60 g盐搅拌后获得最终面团。称取300.00 g面团在环境湿度为85.00%、温度为37 ℃的醒发箱中醒发2 h后,放入上火185 ℃,下火180 ℃的烤箱中烤20 min取出,获得面包。

1.2.8 米面包比容的测定

比容的测定参照Kim等[14]的方法稍作修改。面包充分冷却后称量面包的重量。将面包包裹在两层聚乙烯薄膜中(抑制水的渗透),然后浸入水中以获得面包的体积。每个面包重复测量三次,取平均值。然后使用以下公式计算每个面包的比容:

式中:V为面包体积,mL;M为面包质量,g。

1.2.9 米面包气孔的测定

参照Santos等[7]的方法稍作修改。烘焙出炉的面包在室温冷却2.00 h后,切成厚度为25.00 mm薄片,采集照片后用image软件对面包的孔隙率进行分析。

1.2.10 质构的测定

参照Calle等[15]的方法稍作修改,采用TA.XT-Plus质构仪测定面包的质构。面包冷却2.00 h后,从每个面包中心取三个2.00 cm×2.00 cm×3.00 cm的面包芯用于质构检测,取样时避免选取大气孔区域。使用直径为25.00 mm的圆柱形探头,探头以1.00 mm/s的下降速度进行试验,探头下压距离为37.00 mm,面包的压缩深度为50.00%。根据压缩曲线计算硬度、弹性、胶粘性和咀嚼性。每个样品重复三次,取平均值。

1.3 数据处理

数据分析运用SPSS 19软件进行单因素方差分析(ANOVA),平均数之间的显著差异通过Duncan确定。当P<0.05时,差异显著,数据显示为平均值±标准差。采用Origin绘制图形和采用皮尔逊检验进行相关性分析。

2. 结果与分析

2.1 TG酶对米粉粉质特性的影响

混合实验仪能够描述加热和冷却期间面团的稠度,测量米粉的蛋白质和淀粉特性。如表3所示,纯米粉的吸水率(68.80%±1.92%)高于小麦粉的吸水率(60.00%±1.72%),可能是由于米粉中高含量的淀粉破损导致吸水率升高[16]。添加TG酶后,米粉的吸水率进一步升高,这与单成俊等[17]用TG酶作用于糯小麦粉后吸水率升高的结论一致,可能是添加TG酶后,米蛋白中谷氨酰胺残基和赖氨酸残基之间通过ε-(γ-谷氨酰基)赖氨酸异肽键连接后使整个米蛋白的持水能力增强,也可能是脱氨基化反应使谷蛋白分子内的谷氨酰胺水解生成亲水性更强的谷氨酸残基,致使蛋白质亲水性的增强[18]。吸水率升高有利于降低米面包因水分含量少而产生的淀粉回生、开裂和收缩,从而提高米面包品质。在米粉中TG酶含量持续增加,吸水率保持不变(70.40%),但C1值逐渐降低(1.12~1.05 Nm),说明在相同加水量条件下TG酶含量的增加使米面团搅拌的扭矩越来越小,即面团越来越软。稳定时间代表米面团的耐揉性,稳定时间越长,米面团越耐揉。米粉的稳定时间比小麦粉短,TG酶的添加使得米粉的稳定时间升高,米粉中含0.60%TG酶时稳定时间高达8.00±0.77 min(最高),这可能与TG酶催化蛋白质与蛋白质之间形成交联,使蛋白的二硫键更牢固,增加米面团的延伸性有关,因此米面团稳定时间增加[17]。与含0.60%TG酶的米粉相比,含0.80%TG酶的米粉稳定时间有所降低,这可能是因为交联过度破坏了部分蛋白和淀粉分子网络结构。C1~C2是米面团对机械搅拌的承受能力,该值越大表明米面团不易成型,易塌陷。与纯米粉相比(0.60±0.03 Nm),添加TG酶后的米粉C1~C2值均降低TG酶含量为0.60%时达到最低值(0.40±0.01 Nm),因此添加TG酶的米面团不易塌陷而易于成型。C3~C2代表淀粉的糊化特性,该值越大说明越容易糊化。和纯米粉相比(1.36±0.10 Nm),添加TG酶后米粉易于糊化,其中TG酶含量为0.40%时米粉最易糊化(1.54±0.12 Nm)。形成时间是指粉质从加水开始至达到最大稠度所需要的时间,既反映粉质水合速度的快慢,也表明蛋白网络结构的强弱[7]。米粉的形成时间比小麦粉低,一方面是小麦面团的吸水速率低于米面团(与最佳吸水率有关),另一方面是小麦面团最后所形成的蛋白网络结构强于米面团(与稳定时间有关)。随着纯米粉中TG酶含量的增加,米面团形成时间呈现先减后增的趋势(米粉中含0.4%TG酶时面团形成时间最短)。仅从粉质特性角度分析,米粉中含0.60 %TG酶时改良的效果最优。

表 3 不同TG酶含量对米粉粉质特性的影响Table 3. Effects of different TGase content on the properties of rice flour酶含量

(%)最佳吸水率

(%)扭矩(Nm) 稳定时间

(min)形成时间

(min)C1 C2 C3 C1~C2 C3~C2 小麦粉 60.00±1.72c 1.07±0.14c 0.48±0.01d 1.88±0.16c 0.59±0.02a 1.40±0.11b 7.10±0.68b 3.35±0.30a 0.00 68.80±1.92b 1.12±0.19a 0.52±0.03c 1.89±0.17c 0.60±0.03a 1.36±0.10c 3.50±0.32d 1.02±0.07b 0.20 70.40±2.07a 1.10±0.17b 0.63±0.08ab 2.14±0.16b 0.46±0.02b 1.51±0.12b 6.30±0.60c 0.87±0.05c 0.40 70.40±2.09a 1.07±0.15c 0.62±0.06b 2.16±0.19a 0.45±0.01b 1.54±0.12a 6.50±0.52c 0.78±0.04d 0.60 70.40±1.98a 1.05±0.15c 0.65±0.09a 2.15±0.18b 0.40±0.01d 1.50±0.11b 8.00±0.77a 0.87±0.05c 0.80 70.40±1.96a 1.05±0.14c 0.65±0.08a 2.16±0.19a 0.40±0.01c 1.51±0.12b 7.60±0.73b 1.05±0.08b 注:每列不同的上标小写字母代表浓度之间的差异显著(P<0.05);表4~表7同。 2.2 TG酶对米粉糊化特性的影响

糊化特性在一定程度上反映面制品的品质,这对于面包品质有一定的参考价值。PV是淀粉膨胀至极限(即将破裂)的粘度,VV代表加热阶段结束时的最低粘度,FV是测试结束时粘度。BD代表热糊稳定性,SB反映冷糊稳定性,BD和SB是判断米面包老化的常用指标,其值越大米面包越易老化[19]。如表4所示,与小麦粉相比,米粉的PV、VV、BD、FV和SB较高。Bruneel等[20]表明,当用DTT破坏蛋白质的网络结构时面粉的黏度降低。本实验中添加TG酶后米粉粘度增加,这可能与TG酶增强蛋白网络结构有关。因为TG酶可以增加米粉的最终粘度,因此使米粉易于糊化而被淀粉酶水解,更有利于人体的消化吸收。当米粉中含0.60%TG酶时,米粉的PV、VV和FV均达到最高,分别为5801.00±30.41、3805.67±76.14和5836.33±106.17 cP。随着TG酶含量的进一步增大,蛋白质与水的共价结合增强导致淀粉对水的竞争力相对减弱,与淀粉结合的水量减少,从而抑制淀粉溶胀,使淀粉不易糊化[21],因此含0.80%TG酶的米粉最终粘度低于含0.60%TG酶。与小麦粉相比,米粉的BD和SB值较大,而TG酶的加入降低了米粉的BD和SB,可能是TG酶交联形成的蛋白网络结构可以构建一个更连续的相,淀粉颗粒镶嵌其中,因此当淀粉吸水溶胀即将破裂时被周围的蛋白网络所抑制,从而降低米粉的BD和SB,抑制米面包的老化从而提高储藏性能[22]。其中,TG酶含量为0.40%时,米粉的BD和SB降至最低,分别为1981.67±140.01和1968.67±58.23 cP,具有较好的抗老化效果。糊化特性结果表明,当TG酶含量为0.60%时米粉易于糊化。不仅因为测量时粉与水的比例相差太大,更因Mixolab和RVA仪器测定对象和目的不一样。Mixolab前段需要模拟面团揉混,需要持续更长时间,所以其最低扭矩是蛋白弱化后的值,而RVA针对的就是淀粉的糊化过程,因此糊化测定的结果与2.1部分中粉质特性的C3~C2结果不完全相同。

表 4 不同TG酶含量对米粉糊化特性的影响Table 4. Effects of different TGase content on gelatinization characteristics of rice flour酶含量

(%)粘度(cP) PV VV BD FV SB 小麦粉 3432.67±32.01d 2358.67±44.74e 1062.33±30.53d 3780.33±51.08e 1429.00±8.00d 米粉 5655.33±115.60c 3457.67±67.06b 2197.67±94.82a 5580.00±74.08d 2122.33±7.02a 0.20 5651.33±43.68c 3669.67±156.15c 2053.00±64.90b 5638.33±108.51c 2039.33±115.63b 0.40 5779.67±20.74b 3726.67±82.37b 1981.67±140.01c 5766.00±104.31b 1968.67±58.23c 0.60 5801.00±30.41a 3805.67±76.14a 1990.00±128.11c 5836.33±106.17a 1991.67±34.08c 0.80 5670.67±229.24c 3680.67±116.00c 1995.33±81.38c 5672.33±131.80c 2030.67±31.82b 2.3 TG酶对米面团水分分布的影响

粉中各种颗粒与水发生水合作用,形成具有黏弹性的面团。面团中水分的分布影响着面团多种性质,与面团的品质有很大关系。如表5所示,本实验中横向弛豫时间分布曲线有3个CMPG质子群:T21、T22和T23,T21代表与蛋白网络紧密结合的结合水,T22对应于蛋白网络内部存在的不易流动水,T23代表蛋白网络结构之外的自由水[22]。T2时间越低表明水与蛋白质的结合越紧密,S值越小代表该部分水分的含量越低。与小麦面团相比,纯米面团的T23值较高,即米面团中自由水的结合程度低于小麦粉。和纯米粉相比,当TG酶含量为0.40%时米面团中S21为21.02%±0.21%,此时米面团中S22和S23最低,因为一定含量的TG酶交联米蛋白后米蛋白与淀粉等大分子物质形成更加稳定的蛋白网络体系,有助于提高面团的持水能力,将部分不易流动水与自由水转变为结合水。随着TG酶含量增加,米面团的T22减少,当米粉中含0.80% TG酶时米面团的T22降至28.45±0.04 ms,因为偶极子之间的相互作用变弱致使蛋白质聚集降低氢质子的弛豫时间,所以TG酶使米面团中的不易流动水的结合程度较为紧密。综上,米面团中水分结合程度不如小麦面团,而TG酶可通过增加米面团中T22和S21来提高米面团的水分结合程度。相比之下,含0.40% TG酶的米面团S21最大,其持水力最强,对米面团中水分分布改良效果最优。

表 5 不同TG酶含量对米面团水分分布的影响Table 5. Effects of different TGase content on water distribution in rice dough酶含量

(%)时间(ms) 含量(%) T21 T22 T23 S21 S22 S23 小麦粉 0.00±0.00c 49.76±0.56a 220.76±21.75c 0.00±0.00c 99.46±0.02a 0.54±0.02a 米粉 0.00±0.00c 32.37±0.38b 407.19±74.71b 0.00±0.00c 99.90±0.02a 0.10±0.02cd 0.20 0.00±0.00c 32.48±0.03b 464.73±165.11b 0.00±0.00c 99.72±0.08a 0.28±0.08bcd 0.40 3.76±0.00a 30.56±3.47c 733.93±49.15a 21.02±0.21a 78.94±0.21b 0.04±0.01d 0.60 1.40±1.80b 30.45±2.28c 618.29±298.20ab 9.24±13.07b 90.40±12.86a 0.36±0.21ab 0.80 0.00±0.00c 28.45±0.04d 271.44±97.14c 0.00±0.00c 99.70±0.10a 0.30±0.10abc 2.4 TG酶对米面团流变特性的影响

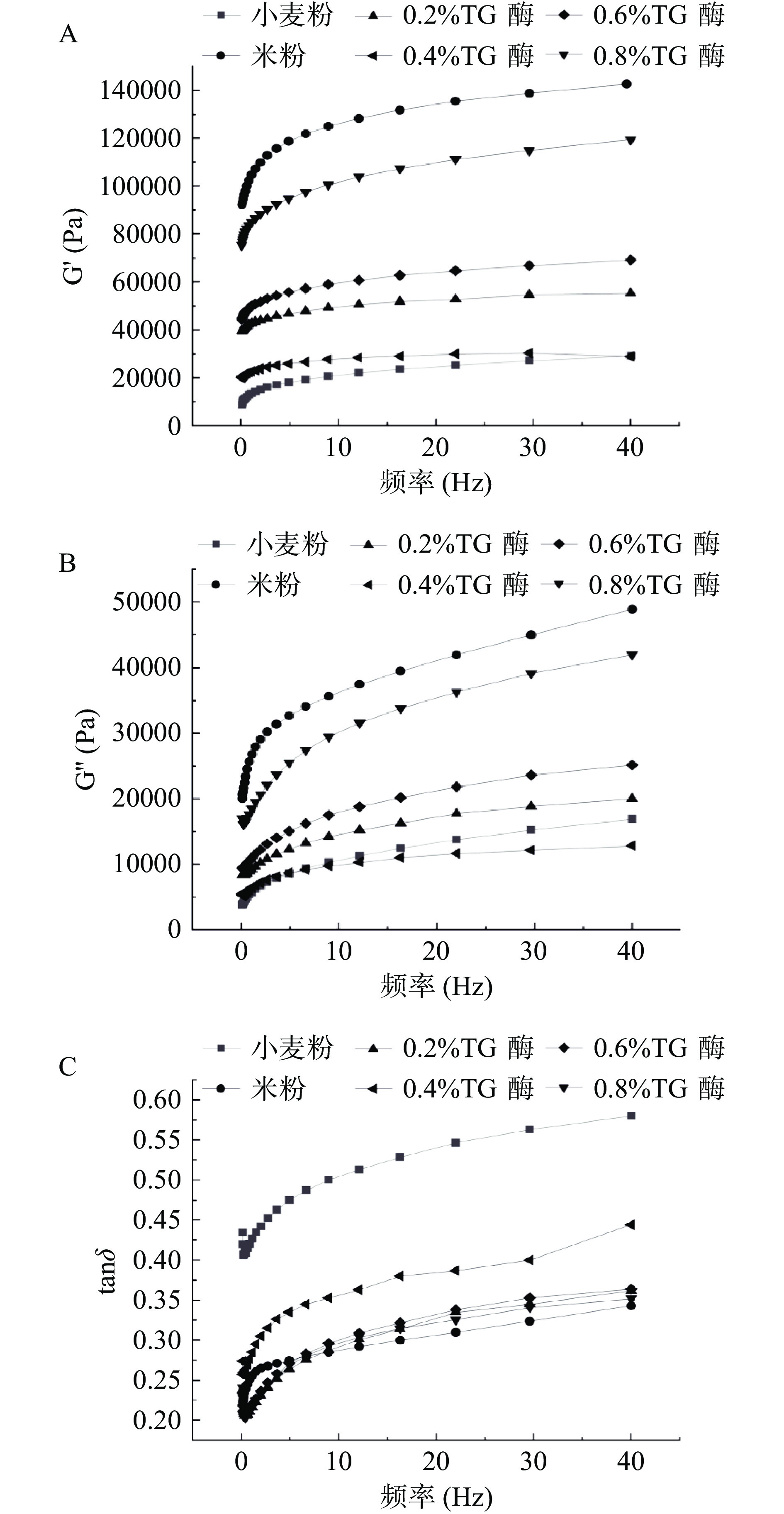

面团流变性的检验评价是谷物加工的基础。通常来讲,米粉对面团的流变性的影响主要是通过影响蛋白网络的形成和结构来实现。图1为米面团的G'、G''和tanδ随着频率变化的曲线。G'反映弹性物质的类固性质,G''反映粘性物质的类液性质,tanδ是G''与G'的比值[23]。由图1A和图1B可知,与小麦粉面团相比,米面团的G'和G''值较高,TG酶降低米面团的G'和G'',使米面团的流变特性接近于小麦面团。Tomi等[24]通过将0.50%TG酶加入含有米蛋白的小米面团后也观察到G'与G''降低的现象。研究蛋白质聚合与流变特性的关系发现,当蛋白质发生聚合时G'和G''下降,本实验发现G'与G''下降,可能是TG酶聚合米蛋白而造成[25]。也可能与米面团水分分布有关,TG酶通过增加米面团中水分结合的紧密程度使米面团的抗变形能力降低而软化[26]。由图1C可知,所有面团的tanδ均小于1.00,说明面团弹性要比面团粘性大,具有类固性质。且面团tanδ随频率的增加而升高,说明面团在迅速变形时具有更强的液体性质[27]。与小麦面团相比,米面团的tanδ较低,TG酶含量的增加使米面团的tanδ升高,说明TG酶使米面团从弹性固体向粘性液体转变,接近小麦面团的流变性质。从流变特性来看,米面团比小麦面团硬,TG酶使米面团从弹性固体向粘性液体转变,其中0.40% TG酶的作用效果最好,最接近小麦面团的流变特性。

2.5 TG酶对米面团发酵特性的影响

面团的发酵能力是保证发酵面制品的关键因素,通常以面团发酵过程中的膨胀体积和产气能力来评估。Hm与米面包的比容有关,综合反映米面团的产气性和持气性;Tx和R与米面团持气性有关,Tx越大表明CO2气体溢出晚,即持气性好;R为保留CO2与总CO2的比值,R越大表明米面团持气性越好[28]。如表6所示,与小麦面团相比,米面团的Hm值较小。一方面,米面团的产气性(总CO2体积)弱于小麦面团。另一方面,米面团的蛋白网络结构较差,使米面团的持气性差,出现Tx时间短(面团气体过早的出现损失),即产气性和持气性差,严重限制了米面团的Hm[29]。TG酶能在一定程度上改良米面团的发酵特性,将面团的Hm从7.00±0.06 mm提高至8.90±0.13 mm,这主要是TG酶能增加米面团的持气性,将米面团的R值从84.90%±0.35%提升至86.20%±0.25%。米面团的持气性主要取决于流变特性,所以TG酶通过交联米蛋白获得与小麦面团类似的流变特性有助于截留CO2,提高米面团的持气性,改良米面团的发酵特性,但是交联过度破坏了部分蛋白和淀粉分子网络结构降低米面团持气性[12]。从发酵特性来看,米面团的产气和持气性低于小麦面团,TG酶在一定程度上改良米面团的持气性,其中0.4% TG酶的持气性最好。

表 6 不同TG酶含量对米面团发酵力的影响Table 6. Effects of different TGase content on fermentation capacity of rice dough酶含量(%) Hm(mm) Tx(min) 总CO2(mL) 损失CO2(mL) R(%) 小麦粉 35.80±0.32a 88.50±3.02a 2357.00±9.78a 245.00±0.92a 99.90±0.31a 米粉 7.00±0.06e 37.50±1.48c 1436.00±6.13b 217.00±0.83c 84.90±0.35c 0.20 7.90±0.07d 33.00±1.35d 1407.00±7.92c 222.00±0.70c 84.30±0.23c 0.40 8.90±0.13b 40.50±1.52b 1318.00±5.42d 183.00±0.82d 86.20±0.25b 0.60 8.60±0.11c 31.50±1.22d 1441.00±6.82b 235.00±0.78b 83.70±0.46d 0.80 8.40±0.09c 30.50±1.09d 1395.00±6.24c 239.00±0.85b 82.80±0.49e 2.6 TG酶对米面包比容的影响

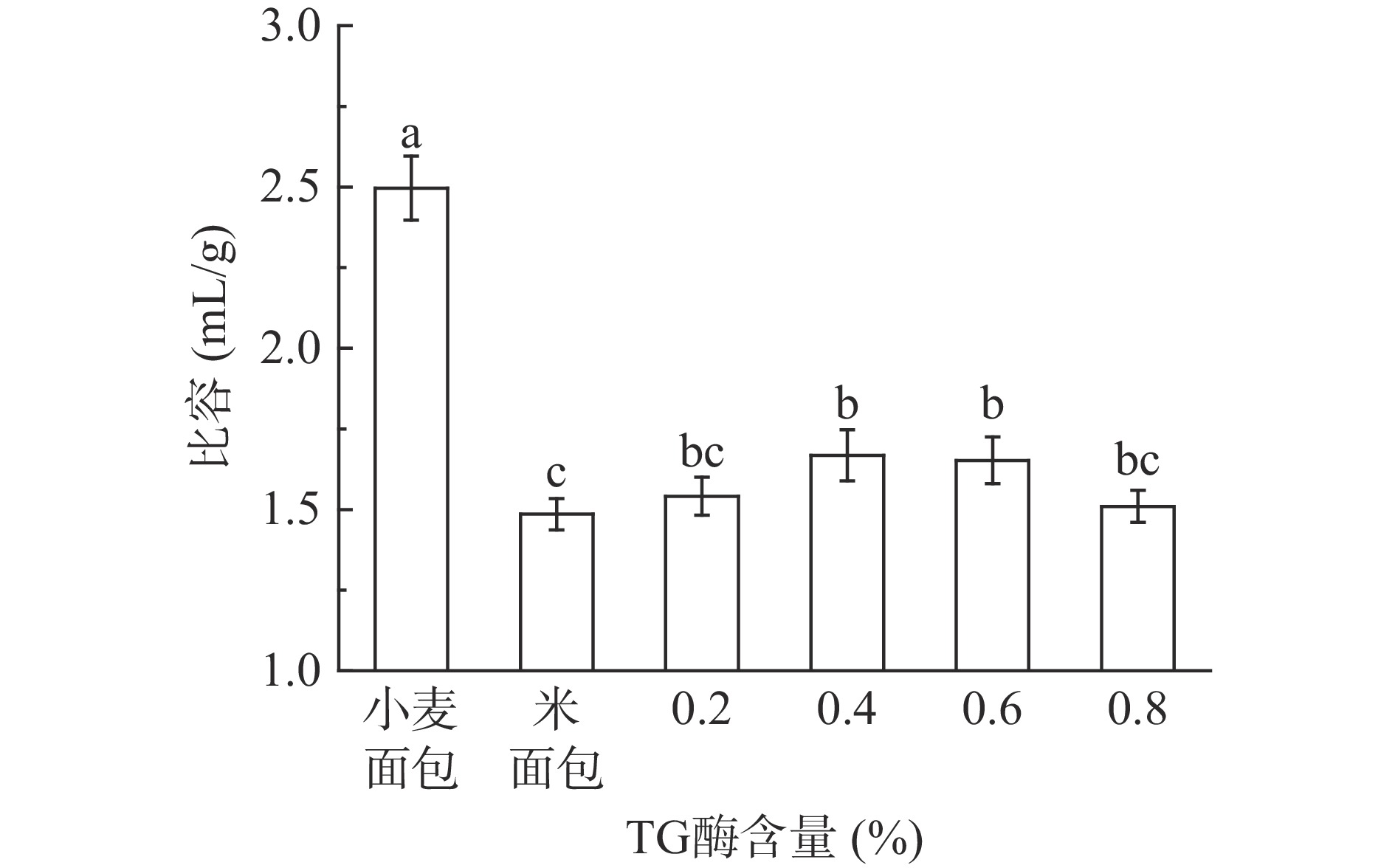

比容是米面包品质的主要参数[30]。如图2可知,小麦面包比容(2.50±0.19 mL/g)明显高于米面包(1.49±0.15 mL/g),不同含量的TG酶均能提高米面包的比容(1.51~1.67 mL/g),改良米面包的品质。当TG酶含量为0.40%时米面包的比容最大(1.67±0.17 mL/g),此结果与含0.40% TG酶的米面团持气性最好相符。随着米粉中TG酶含量的进一步提高,但随着TG酶添加量增加,蛋白聚合程度升高,面包内部组织结构致密、紧实,发酵性能降低,造成面包比容减小。米面包的比容出现一定的下降。所以,米粉中含0.40% TG酶时米面包的比容最大,但是与小麦面包的比容还是存在一定的差距。

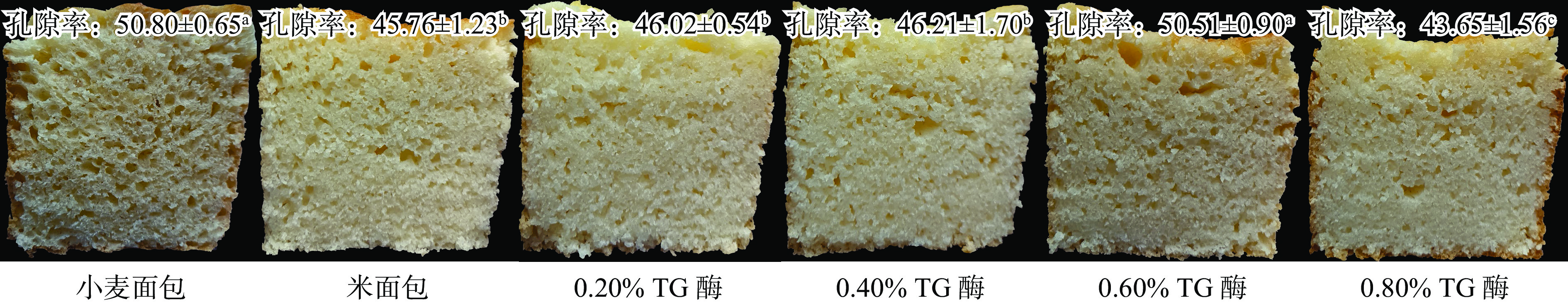

2.7 TG酶对米面包气孔的影响

一般来说,气孔结构数量多、分布均匀、大小统一的米面包其品质较好、口感最佳[7]。如图3所示,和小麦面包相比,米面包的气孔较少,孔隙率低。随着TG酶含量的增加,米面包的孔隙率呈现先增后减的趋势,其中0.60% TG酶的米面包的孔隙率最高(50.51%±0.90%),与小麦面包的孔隙率(50.80%±0.65%)相近,因为一定含量的TG酶使米面团中的米蛋白交联,形成更均匀、完整的蛋白网络,其持气性增强。所以从气孔来看含0.60% TG酶的米面包孔隙率大、气孔较明显而品相最好。

2.8 TG酶对米面包质构的影响

硬度、胶粘性和咀嚼性数值越大,米面包表现为缺乏弹性,质地较差。由表7可知,和小麦面包相比,米面包的硬度、胶粘性和咀嚼性较高,弹性较低。TG酶降低米面包的硬度、胶粘性和咀嚼性,增加米面包的弹性。0.40% TG酶将米面包的胶粘性从2.28±0.53 N降至1.54±0.40 N。随着TG酶含量的增加,米面包的硬度降低并逐渐接近小麦面包,因为TG酶增加米面包孔隙率,使面包变软而出现硬度下降。米面包的弹性随着TG酶含量增大呈现先增后降,0.40% TG酶将米面包的弹性从12.75±0.54 mm升至13.17±0.76 mm,与小麦面包的13.18±1.28 mm相接近。所以,TG酶通过降低硬度、胶粘性和咀嚼性,提高弹性来改良米面包的质构性能,其中米粉中含0.40% TG酶和0.60% TG酶时米面包结构更为蓬松,口感更为柔软,在咀嚼时,耐咀嚼性较好且所需要的能量相对较小,与小麦面包的质构参数相近。

表 7 不同TG酶含量对米面包的质构的影响Table 7. Effects of different TGase content on texture of rice bread酶含量(%) 硬度(N) 弹性(mm) 胶粘性(N) 咀嚼性(mJ) 小麦粉 1.75±0.23d 13.18±1.28a 1.06±0.12a 14.07±2.76ab 米粉 3.85±0.90a 12.75±0.54b 2.28±0.53b 28.87±5.71c 0.20% 3.75±0.14a 11.44±0.44b 3.38±0.06c 28.70±2.18c 0.40% 3.34±0.82b 13.17±0.76a 1.54±0.40ab 20.21±4.43b 0.60% 3.24±0.60b 12.54±0.24b 1.60±0.07ab 20.10±0.44b 0.80% 2.57±1.60c 12.27±0.51b 1.65±0.93ab 12.91±0.95a 2.9 米粉、米面团和米面包各指标之间的相关性分析

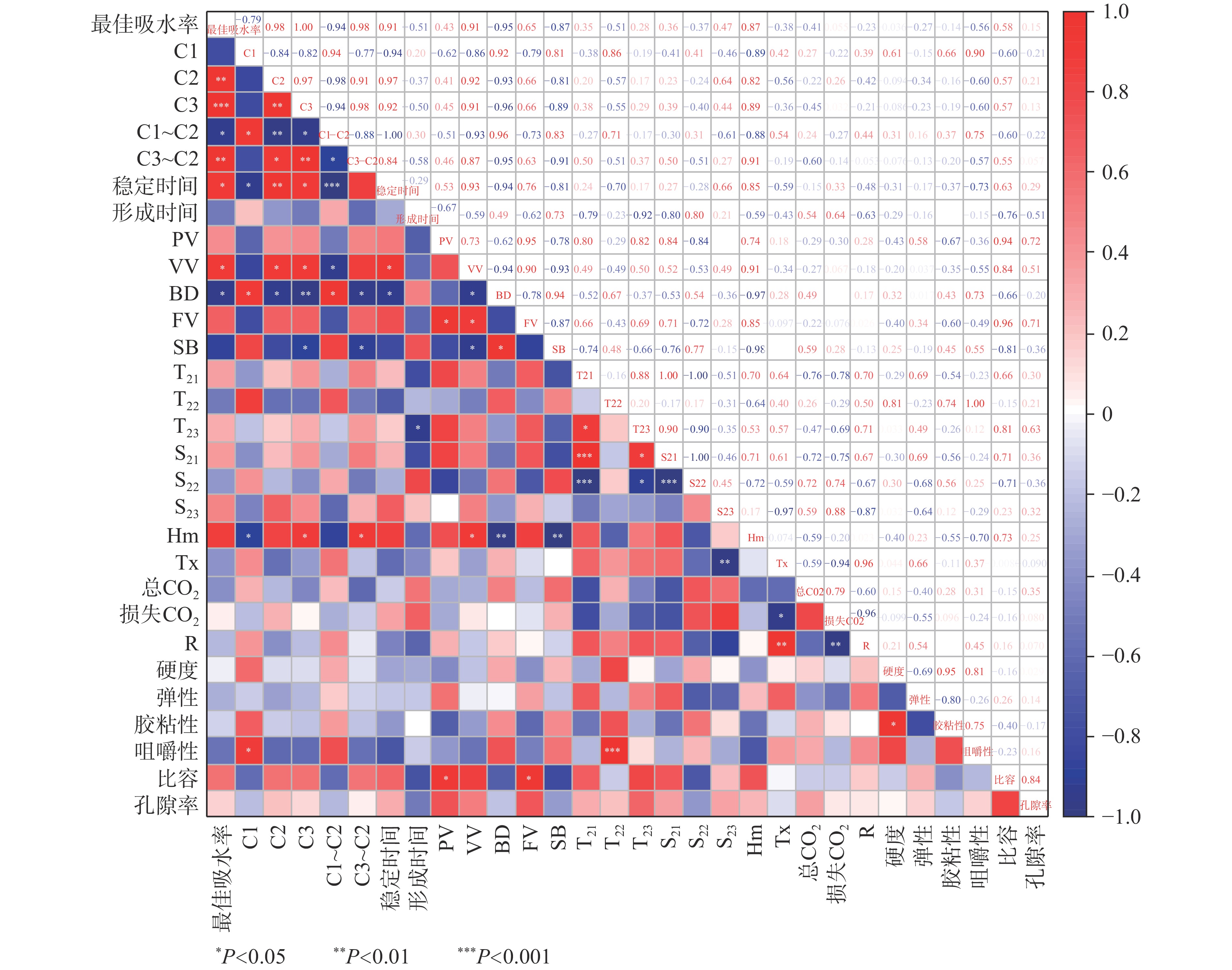

图4为米粉、米面团和米面包各指标间相关性分析图。TG酶的添加,增加了米粉的C3、C3~C2、PV、VV和FV,降低了米粉的形成时间、C1、BD、SB。米面团的形成时间能反映米面团的吸水情况,T23和形成时间呈负相关(R2=−0.92,P<0.05),即米面团自由水结合程度的降低与形成时间的变短有关,所以TG酶降低米面团的T23。Hm的影响因素持气性与米面团中蛋白网络结构有关,而蛋白网络结构可以构建一个更连续的相,使得淀粉颗粒镶嵌在其中影响米粉的糊化特性,因此Hm与C3(R2=0.89,P<0.05)、C3~C2(R2=0.91,P<0.05)和VV(R2=0.91,P<0.05)呈正相关,与BD(R2=−0.97,P<0.01)和SB(R2=−0.98,P<0.01)呈负相关,由此可见TG酶增加米面团的Hm后米面包易于糊化且不易老化。C1越小说明搅拌时扭矩较小,即米面团较软,而咀嚼性是将米面包咀嚼成能够吞咽状态所需要的能量,其值越小代表米面包越柔软,因此咀嚼性和C1呈正相关(R2=0.90,P<0.05),所以TG酶降低米面包的咀嚼性与米粉的C1降低有关。粘度较高有利于与面筋蛋白相互作用产生更强的网络结构,改良蛋白网络结构的持气性,使得面包比容增大[31],所以比容与FV(R2=0.96,P<0.05)和PV(R2=0.94,P<0.05)呈正相关。并且与小麦粉相比,米粉中缺少为面团提供粘性的醇溶蛋白,说明了TG酶通过增加粘度而改良无面筋米面包的应用是合理的。通过相关性分析表明,米粉、米面团和米面包各指标之间存在显著的相关性,TG酶通过影响米粉的粉质特性和糊化特性,从而改良了米面团的T23和Hm,降低米面包的咀嚼性和提高比容。

3. 结论

本研究通过在米粉中添加转谷氨酰胺酶,探究转谷氨酰胺酶对米粉、米面团和米面包的影响,得出以下结论:相比小麦粉,米粉稳定时间短和易老化;米面团中水分结合程度不够紧密,呈现弹性固体的流变特性,且持气性能差;米面包的比容小、孔隙率低、质构差。添加TG酶能够改善米粉的粉质特性和糊化特性;同时增加米面团中水分结合的紧密程度,改善米面团的流变特性和持气性;增加米面包的比容,改善气孔和质构,使米面包的咀嚼性降低,从而解决因缺乏面筋蛋白而导致的米粉、米面团和米面包品质不良的问题。相关性分析表明,转谷氨酰胺酶通过影响米粉的粉质特性和糊化特性改善米面团的水分分布和发酵特性,使米面包的咀嚼性降低和比容提高。但是与小麦面包的硬度、咀嚼性还是存在一定的差距,这方面在以后的研究中可以结合加工工艺进行深入研究探讨,提高米面包的可接受度,使米面包得以商品化、市场化。

-

表 1 混合粉配制

Table 1 Mix powder configuration

实验组 质量(g) 小麦粉 米粉 TG酶 小麦粉 700.00 0.00 0.00 米粉 0.00 700.00 0.00 含0.20%TG酶的米粉 0.00 698.60 1.40 含0.40%TG酶的米粉 0.00 697.20 2.80 含0.60%TG酶的米粉 0.00 695.80 4.20 含0.80%TG酶的米粉 0.00 694.40 5.60 表 2 面团的制备

Table 2 Preparation of dough

实验组 混合粉(g) 水(g) 小麦粉 55.29 34.71 米粉 51.58 38.42 含0.20%TG酶的米粉 51.99 38.91 含0.40%TG酶的米粉 51.99 38.91 含0.60%TG酶的米粉 51.99 38.91 含0.80%TG酶的米粉 51.99 38.91 表 3 不同TG酶含量对米粉粉质特性的影响

Table 3 Effects of different TGase content on the properties of rice flour

酶含量

(%)最佳吸水率

(%)扭矩(Nm) 稳定时间

(min)形成时间

(min)C1 C2 C3 C1~C2 C3~C2 小麦粉 60.00±1.72c 1.07±0.14c 0.48±0.01d 1.88±0.16c 0.59±0.02a 1.40±0.11b 7.10±0.68b 3.35±0.30a 0.00 68.80±1.92b 1.12±0.19a 0.52±0.03c 1.89±0.17c 0.60±0.03a 1.36±0.10c 3.50±0.32d 1.02±0.07b 0.20 70.40±2.07a 1.10±0.17b 0.63±0.08ab 2.14±0.16b 0.46±0.02b 1.51±0.12b 6.30±0.60c 0.87±0.05c 0.40 70.40±2.09a 1.07±0.15c 0.62±0.06b 2.16±0.19a 0.45±0.01b 1.54±0.12a 6.50±0.52c 0.78±0.04d 0.60 70.40±1.98a 1.05±0.15c 0.65±0.09a 2.15±0.18b 0.40±0.01d 1.50±0.11b 8.00±0.77a 0.87±0.05c 0.80 70.40±1.96a 1.05±0.14c 0.65±0.08a 2.16±0.19a 0.40±0.01c 1.51±0.12b 7.60±0.73b 1.05±0.08b 注:每列不同的上标小写字母代表浓度之间的差异显著(P<0.05);表4~表7同。 表 4 不同TG酶含量对米粉糊化特性的影响

Table 4 Effects of different TGase content on gelatinization characteristics of rice flour

酶含量

(%)粘度(cP) PV VV BD FV SB 小麦粉 3432.67±32.01d 2358.67±44.74e 1062.33±30.53d 3780.33±51.08e 1429.00±8.00d 米粉 5655.33±115.60c 3457.67±67.06b 2197.67±94.82a 5580.00±74.08d 2122.33±7.02a 0.20 5651.33±43.68c 3669.67±156.15c 2053.00±64.90b 5638.33±108.51c 2039.33±115.63b 0.40 5779.67±20.74b 3726.67±82.37b 1981.67±140.01c 5766.00±104.31b 1968.67±58.23c 0.60 5801.00±30.41a 3805.67±76.14a 1990.00±128.11c 5836.33±106.17a 1991.67±34.08c 0.80 5670.67±229.24c 3680.67±116.00c 1995.33±81.38c 5672.33±131.80c 2030.67±31.82b 表 5 不同TG酶含量对米面团水分分布的影响

Table 5 Effects of different TGase content on water distribution in rice dough

酶含量

(%)时间(ms) 含量(%) T21 T22 T23 S21 S22 S23 小麦粉 0.00±0.00c 49.76±0.56a 220.76±21.75c 0.00±0.00c 99.46±0.02a 0.54±0.02a 米粉 0.00±0.00c 32.37±0.38b 407.19±74.71b 0.00±0.00c 99.90±0.02a 0.10±0.02cd 0.20 0.00±0.00c 32.48±0.03b 464.73±165.11b 0.00±0.00c 99.72±0.08a 0.28±0.08bcd 0.40 3.76±0.00a 30.56±3.47c 733.93±49.15a 21.02±0.21a 78.94±0.21b 0.04±0.01d 0.60 1.40±1.80b 30.45±2.28c 618.29±298.20ab 9.24±13.07b 90.40±12.86a 0.36±0.21ab 0.80 0.00±0.00c 28.45±0.04d 271.44±97.14c 0.00±0.00c 99.70±0.10a 0.30±0.10abc 表 6 不同TG酶含量对米面团发酵力的影响

Table 6 Effects of different TGase content on fermentation capacity of rice dough

酶含量(%) Hm(mm) Tx(min) 总CO2(mL) 损失CO2(mL) R(%) 小麦粉 35.80±0.32a 88.50±3.02a 2357.00±9.78a 245.00±0.92a 99.90±0.31a 米粉 7.00±0.06e 37.50±1.48c 1436.00±6.13b 217.00±0.83c 84.90±0.35c 0.20 7.90±0.07d 33.00±1.35d 1407.00±7.92c 222.00±0.70c 84.30±0.23c 0.40 8.90±0.13b 40.50±1.52b 1318.00±5.42d 183.00±0.82d 86.20±0.25b 0.60 8.60±0.11c 31.50±1.22d 1441.00±6.82b 235.00±0.78b 83.70±0.46d 0.80 8.40±0.09c 30.50±1.09d 1395.00±6.24c 239.00±0.85b 82.80±0.49e 表 7 不同TG酶含量对米面包的质构的影响

Table 7 Effects of different TGase content on texture of rice bread

酶含量(%) 硬度(N) 弹性(mm) 胶粘性(N) 咀嚼性(mJ) 小麦粉 1.75±0.23d 13.18±1.28a 1.06±0.12a 14.07±2.76ab 米粉 3.85±0.90a 12.75±0.54b 2.28±0.53b 28.87±5.71c 0.20% 3.75±0.14a 11.44±0.44b 3.38±0.06c 28.70±2.18c 0.40% 3.34±0.82b 13.17±0.76a 1.54±0.40ab 20.21±4.43b 0.60% 3.24±0.60b 12.54±0.24b 1.60±0.07ab 20.10±0.44b 0.80% 2.57±1.60c 12.27±0.51b 1.65±0.93ab 12.91±0.95a -

[1] 胡宇薇, 高梦祥. 气相离子迁移色谱解析白砂糖和黄油对面包感官品质和风味物质的影响[J]. 食品科学,2022,43(10):66−72. [HU Y W, GAO M X. Effects of sugar and butter on sensory quality and flavor of bread by gas phase ion migration chromatography[J]. Food Science,2022,43(10):66−72. doi: 10.7506/spkx1002-6630-20210810-136 HU Y W, GAO M X. Effects of sugar and butter on sensory quality and flavor of bread by gas phase ion migration chromatography[J]. Food Science, 2022, 43(10): 66-72. doi: 10.7506/spkx1002-6630-20210810-136

[2] 袁娟丽, 单玲克, 高金燕, 等. 品质改良剂及燕麦酸面团对燕麦面团黏弹特性的改善[J]. 食品科学,2016,37(15):56−62. [YUAN J L, SHAN L K, GAO J Y, et al. Improvement of viscoelastic properties of oat dough by quality improver and oat sour dough[J]. Food Science,2016,37(15):56−62. doi: 10.7506/spkx1002-6630-201615010 YUAN J L, SHAN L K, GAO J Y, et al. Improvement of viscoelastic properties of oat dough by quality improver and oat sour dough[J]. Food science, 2016, 37(15): 56-62. doi: 10.7506/spkx1002-6630-201615010

[3] 杨剑婷, 夏树凤, 周琴, 等. 面筋蛋白对小麦粉理化性质及面包烘焙品质的影响[J]. 麦类作物学报,2020,40(5):620−629. [YANG J T, XIA S F, ZHOU Q, et al. Effects of gluten protein on physical and chemical properties of wheat flour and bread baking quality[J]. Journal of Triticeae Crops,2020,40(5):620−629. doi: 10.7606/j.issn.1009-1041.2020.05.14 YANG J T, XIA S F, ZHOU Q, et al. Effects of gluten protein on physical and chemical properties of wheat flour and bread baking quality[J]. Journal of Triticeae Crops, 2020, 40(5): 620-629. doi: 10.7606/j.issn.1009-1041.2020.05.14

[4] BARAK S, MUDGIL D, KHATKAR B S. Relationship of gliadin and glutenin proteins with dough rheology, flour pasting and bread making performance of wheat varieties[J]. LWT-Food Science and Technology,2013,51(1):211−217. doi: 10.1016/j.lwt.2012.09.011

[5] 侯东丽, 张正茂, 师俊玲, 等. 谷氨酰胺转胺酶和大豆粉在荞麦面包加工中的应用[J]. 西北农业学报,2010,19(5):191−196. [HOU D L, ZHANG Z M, SHI J L, et al. Application of transglutaminase and soybean flour in the processing of buckwheat bread[J]. Acta Agriculturae Boreali-Occidentalis Sinica,2010,19(5):191−196. HOU D L, ZHANG Z M, SHI J L, et al. Application of transglutaminase and soybean flour in the processing of buckwheat bread, 2010, 19 (5): 191-196.

[6] 郜怀帅, 杨嘉琪, 宋春丽, 等. 转谷氨酰胺酶对玉米面团加工特性的影响[J]. 食品工业,2020,41(4):157−160. [GAO H S, YANG J Q, SONG C L, et al. Effect of transglutaminase on processing characteristics of corn dough[J]. Food Industry,2020,41(4):157−160. GAO H S, YANG J Q, SONG C L, et al. Effect of transglutaminase on processing characteristics of corn dough[J]. Food Industry, 2020, 41(4): 157-160.

[7] SANTOS F G, AGUIAR E V, CENTENO A, et al. Effect of added psyllium and food enzymes on quality attributes and shelf life of chickpea-based gluten-free bread[J]. LWT-Food Science and Technology,2020,134:110025. doi: 10.1016/j.lwt.2020.110025

[8] 中华人民共和国国家卫生和计划生育委员会. GB 5009.3-2016 食品安全国家标准 食品中水分的测定[S]. 北京: 中国标准出版社, 2016: 1-2. National Health and Family Planning Commission of the People's Republic of China. GB 5009.3-2016 National standard for food safety-determination of moisture in food[S]. Beijing: Standards Press of China, 2016: 1-2.

[9] PALABIYIK I, YILDIZ O, TOKER O S, et al. Investigating the addition of enzymes in gluten-free flours-The effect on pasting and textural properties[J]. LWT-Food Science and Technology,2016,69:633−641. doi: 10.1016/j.lwt.2016.01.019

[10] NIU M, XING L, ZHANG B, et al. Comparative study on protein polymerization in whole-wheat dough modified by transglutaminase and glucose oxidase[J]. LWT,2017,90:323−330.

[11] LI D, ZHAO Y, FEI T, et al. Effects of Streptococcus thermophilus GtfB enzyme on dough rheology, bread quality and starch digestibility[J]. Food Hydrocolloids,2019,96:134−139. doi: 10.1016/j.foodhyd.2019.05.009

[12] CAO Y, JIANG L, SUO W, et al. Influence of emulsifiers and enzymes on dough rheological properties and quality characteristics of steamed bread enriched with potato pulp[J]. Food Chemistry,2021,360(5):130015.

[13] 王强. 糜米粉对面团特性及其面包品质影响研究[D]. 天津: 天津科技大学, 2019. WANG Q. Effects of mi rice flour on dough characteristics and bread quality[D]. Tianjin: Tianjin University of Science and Technology, 2019.

[14] KIM E A, LEE S Y. Quality characteristics of steamed rice bread prepared with different contents of proteolytic enzyme[J]. Applied Biological Chemistry,2016,59(1):95−102. doi: 10.1007/s13765-015-0145-4

[15] CALLE J, BENAVENT G Y, ROSELL C M. Development of gluten free breads from colocasia esculenta flour blended with hydrocolloids and enzymes[J]. Food Hydrocolloids,2020,98:105243. doi: 10.1016/j.foodhyd.2019.105243

[16] 沈莎莎, 田建珍, 郑学玲, 等. 淀粉及热损伤淀粉对小麦粉品质的影响初探[J]. 食品研究与开发,2013,34(24):5−8. [SHEN S S, TIAN J Z, ZHENG X L, et al. Effects of starch and heat-damaged starch on wheat flour quality[J]. Food Research and Development,2013,34(24):5−8. doi: 10.3969/j.issn.1005-6521.2013.24.002 SHEN S S, TIAN J Z, ZHENG X L, et al. Effects of starch and heat-damaged starch on wheat flour quality[J]. Food Research and Development, 2013, 34(24): 5-8. doi: 10.3969/j.issn.1005-6521.2013.24.002

[17] 单成俊, 周剑忠. 谷氨酰胺转氨酶和葡萄糖氧化酶改善糯小麦粉粉质特性的研究[J]. 江苏农业科学,2008(6):229−230. [SHAN C J, ZHOU J Z. Effects of transaminase and glucose oxidase on the properties of glutinous wheat flour[J]. Jiangsu Agricultural Sciences,2008(6):229−230. doi: 10.3969/j.issn.1002-1302.2008.06.103 SHAN C J, ZHOU J Z. Effects of transaminase and glucose oxidase on the properties of glutinous wheat flour[J]. Jiangsu Agricultural Sciences, 2008(6): 229-230. doi: 10.3969/j.issn.1002-1302.2008.06.103

[18] ROMEIH E, WALKER G. Recent advances on microbial transglutaminase and dairy application[J]. Trends in Food Science & Technology,2017,62:133−140.

[19] 王佳玉, 陈凤莲, 吴迪, 等. 谷氨酰胺转氨酶对全麦面团特性及微观结构的影响[J]. 食品科学,2021,42(4):51−57. [WANG J Y, CHEN F L, WU D, et al. Effects of transaminase on properties and microstructure of whole wheat dough[J]. Food Science,2021,42(4):51−57. doi: 10.7506/spkx1002-6630-20191129-312 WANG J Y, CHEN F L, WU D, et al. Effects of transaminase on properties and microstructure of whole wheat dough[J]. Food Science, 2021, 42 (4): 51-57. doi: 10.7506/spkx1002-6630-20191129-312

[20] BRUNEEL C, PAREVT B, BRIIS K, et al. The impact of the protein network on the pasting and cooking properties of dry pasta products[J]. Food Chemistry,2010,120(2):371−378. doi: 10.1016/j.foodchem.2009.09.069

[21] GUI Y F, ZOU F X, ZHU Y, et al. The structural, thermal, pasting and gel properties of the mixtures of enzyme-treated potato protein and potato starch[J]. LWT,2021,154(15):112882.

[22] XIAO H, LI C, YAN H, et al. Impact of celluloses and pectins restrictions on gluten development and water distribution in potato-wheat flour dough[J]. International Journal of Biological Macromolecules,2022,206(1):534−542.

[23] SARABHAI S, TAMILSELVAN T. Role of enzymes for improvement in gluten-free foxtail millet bread: It’s effect on quality, textural, rheological and pasting properties[J]. LWT,2021,137:110365. doi: 10.1016/j.lwt.2020.110365

[24] TOMI J, TORBICA A, BELOVI M. Effect of non-gluten proteins and transglutaminase on dough rheological properties and quality of bread based on millet (Panicum miliaceum) flour[J]. LWT,2020,118:108852. doi: 10.1016/j.lwt.2019.108852

[25] 王香玉. 馒头制作过程中蛋白交联行为及其对品质的影响[D]. 无锡: 江南大学, 2016. WANG X Y. Protein cross-linking behavior and its effect on quality in steamed bread production[D]. Wuxi: Jiangnan University, 2016.

[26] ALTUNA L, RIBOTTA P D, TADINI C C. Effect of a combination of enzymes on the fundamental rheological behavior of bread dough enriched with resistant starch[J]. LWT-Food Science & Technology,2016,73:267−273.

[27] ILKEM D. Rheological properties of gluten-free bread formulations[J]. Journal of Food Engineering,2009,96(2):295−303.

[28] 刘彦, 黄卫宁. 阿拉伯胶和羧甲基纤维素钠对荞麦面团发酵流变学及烘焙特性的影响[J]. 食品科学,2013,34(17):5−9. [LIU Y, HUANG W N. Effects of gum arabic and sodium carboxymethyl cellulose on fermentation rheology and baking properties of buckwheat dough[J]. Food Science,2013,34(17):5−9. doi: 10.7506/spkx1002-6630-201317002 LIU Y, HUANG W N. Effects of gum arabic and sodium carboxymethyl cellulose on fermentation rheology and baking properties of buckwheat dough[J]. Food science, 2013, 34(17): 5-9. doi: 10.7506/spkx1002-6630-201317002

[29] ARAI C , HIROSE R , TOZAKI M, et al. Effect of adding acid-soluble wheat protein to dough on the quality stabilization of wheat flour and rice flour blend bread[J]. Nippon Shokuhin Kagaku Kogaku Kaishi,2018,65(11):518−528. doi: 10.3136/nskkk.65.518

[30] MUDGIL D, BARAK S, KHATKAR B S. Optimization of bread firmness, specific loaf volume and sensory acceptability of bread with soluble fiber and different water levels[J]. Journal of Cereal Science,2016,70:186−191. doi: 10.1016/j.jcs.2016.06.009

[31] 刘然然, 范素琴, 王晓梅, 等. 不同黏度海藻酸丙二醇酯(PGA)对面包品质改良效果研究[J]. 中国食品添加剂,2018,6(6):137−140. [LIU R R, FAN S Q, WANG X M, et al. Effects of different viscosity of propylene glycol alginate (PGA) on bread quality improvement[J]. China Food Additives,2018,6(6):137−140. LIU R R, FAN S Q, WANG X M, et al. Effects of different viscosity of propylene glycol alginate (PGA) on bread quality improvement[J]. China Food Additives, 2018(6): 137-140.

-

期刊类型引用(24)

1. 于纯淼,廖贤,陈小倩,李艾欣,陈佳,于苗苗. 复合酶法提取诺丽多糖的工艺优化及其体外抗氧化活性. 食品研究与开发. 2025(03): 142-151 .  百度学术

百度学术

2. 张彪,杨晓宽. 纳豆菌发酵板栗渣工艺优化及其多糖的抗氧化性. 食品研究与开发. 2025(03): 160-166 .  百度学术

百度学术

3. 杨胜男,赵斗,刘宇桂,仇燕. 菜芙蓉花黄酮的超声协同双水相提取、成分分析及抗氧化性. 食品研究与开发. 2025(05): 102-113 .  百度学术

百度学术

4. 王红,彭励,宋乐,冯璐,李振凯,李彦青,高跳. 银柴胡多糖超声辅助提取工艺优化及抗氧化活性分析. 食品工业科技. 2024(01): 185-191 .  本站查看

本站查看

5. 张欣,刘盈,刘会平,马笑笑,李灿,张慧慧,王兵. 荠菜粗多糖提取优化及其理化功能与抗氧化性. 食品研究与开发. 2024(02): 103-111 .  百度学术

百度学术

6. 李春晓,宋庆琳,焦旭,冯慧程,陈虞超,郭生虎,张波,薛涛. 金莲花多糖提取工艺优化及其抗氧化活性评价. 药学研究. 2024(01): 24-29 .  百度学术

百度学术

7. 梁金月,周洪鑫,张雨晴,王玲娜,李佳,赵东升. 金银花多酚和多糖同步提取工艺优化及其抗氧化活性研究. 中国食品添加剂. 2024(03): 1-10 .  百度学术

百度学术

8. 任晓莉,杨璐,乔鹏,缪奕锴,杨懿昂,代秋红,张贤德. 复合酶法提取槐花多糖的工艺优化及其抗氧化活性. 食品工业科技. 2024(07): 8-14 .  本站查看

本站查看

9. 高长久,李文超,张朝立,孟令锴,王春辉. 红瑞木果多糖抗氧化活性的初步研究. 中国中医药现代远程教育. 2024(10): 139-141 .  百度学术

百度学术

10. 陈美花,黄舒喆,牛改改,蓝尉冰,覃媚. 白茅根金银花复合果冻的研制. 中国食品添加剂. 2024(08): 129-138 .  百度学术

百度学术

11. 唐一诺,章肖肖,宋文文,宋盈萱,高露,陈晓乐,郑振佳. 胭脂虫红色素口红制备工艺优化及品质分析. 中国食品添加剂. 2024(08): 139-147 .  百度学术

百度学术

12. 高昕冉,李心圆,王绍倩,沈一凡,刘克海. 石榴籽多糖的提取、纯化及体外抗氧化和降血糖活性分析. 山东农业大学学报(自然科学版). 2024(04): 516-525 .  百度学术

百度学术

13. 石云鑫,杨家,潘诗琴,曾诚,郭荣荣,李晓蝶,宋旭琴,杨剑,宋亚. 不同方法提取的山茱萸多糖品质特征. 南方农业学报. 2024(07): 2031-2043 .  百度学术

百度学术

14. 苏宁,刘志明,王海英. 木醋液型饲料添加剂储藏稳定性研究. 中国饲料. 2024(21): 67-73 .  百度学术

百度学术

15. 罗雨菲,黄秀壁,苏芬安,谭义秋,陈永,刘小玲. 姑辽茶粗多糖提取工艺优化及其免疫调节活性评价. 食品工业科技. 2024(23): 161-169 .  本站查看

本站查看

16. 王国霞,牛祎琳,牛富婷,程莹莹. 不同提取方法对密银花多糖理化性质及抗氧化活性的影响. 食品工业科技. 2024(24): 196-203 .  本站查看

本站查看

17. 吴霞,周攀,常雪婷,李耀竞,吴科锋,邓路铭. 响应面法优化羊栖菜多糖脱蛋白工艺及其抗氧化活性分析. 粮食与油脂. 2024(12): 135-141 .  百度学术

百度学术

18. 刘丽桃,傅春燕,刘诗薇,周秀娟,谢雨芊,欧阳玉珍,王彪,葛金文. 响应面法优化降脂通脉方多糖的提取工艺研究. 中医药导报. 2024(12): 58-62 .  百度学术

百度学术

19. 李梦娜,黄佳蓉,马俊炜,张泓瑞,陈博儒,曾新安,朱峰,黄燕燕. 天然多糖的提取纯化及其对食品物理特性改善的应用研究. 食品科技. 2024(12): 204-212 .  百度学术

百度学术

20. 许梦粤,曾长立,王红波. 药食同源植物多糖提取方法、结构解析和生物活性研究进展. 食品研究与开发. 2023(19): 216-224 .  百度学术

百度学术

21. 黄明浩,黄泰奇,邓丽娟. 响应面法优化白英粗多糖提取工艺及其体外抗氧化活性的分析. 食品工业科技. 2023(22): 219-225 .  本站查看

本站查看

22. 赵燕燕,房世杰,张政,祁华梅,薄学敏,魏佳,吴斌. 沙枣花多糖提取工艺优化及其对益生菌的增殖作用. 食品工业科技. 2023(22): 134-142 .  本站查看

本站查看

23. 冉俊枫,张文明,张静雯,任艳,吕露阳,曾锐. 苦竹笋多糖提取工艺优化及其抗氧化活性研究. 食品科技. 2023(10): 165-172 .  百度学术

百度学术

24. 蒋大珍,马佰诚,杨皎,罗进城,孙雪薇,李佳琳. 槲寄生多糖提取工艺优化及抗氧化活性研究. 北方农业学报. 2023(05): 84-92 .  百度学术

百度学术

其他类型引用(7)

下载:

下载:

下载:

下载: