Effect of Different Treatments on the Structural Properties and Flavor of Extruded Corn Flour

-

摘要: 膨化玉米粉存在冲调时易结块、风味不佳等问题,前期研究发现经磷酸化热处理、酶处理、食用胶干热处理及复合处理其冲调结块率减小,为探究该四种处理方式对其结构特性和风味的影响,采用扫描电子显微镜、傅里叶红外光谱、X-射线衍射、顶空固相微萃取等方法结合气相质谱,研究正磷酸钠热处理(S1)、中性蛋白酶(S2)、黄原胶干热(S3)、正磷酸钠-中性蛋白酶处理(S4)对膨化玉米粉(PCF)结构特性及风味物质的变化。结果表明,4种方式处理后的膨化玉米粉仍为A型晶体结构,且没有引入和产生新的化学键或官能团;淀粉微观颗粒表面的孔洞和缝隙增多,其中正磷酸钠+中性蛋白酶处理粉较其它样品而言,表面空洞数量更多,裂纹更大。气相质谱共鉴定出130种挥发性成分,其中中性蛋白酶处理粉(57种)>正磷酸钠+中性蛋白酶处理粉(46种)>黄原胶干热处理粉(44种)>PCF(41种)>正磷酸钠热处理粉(40种)。利用ROAV法分析表明,膨化玉米粉的关键风味物质主要以酮类为主;经不同方式处理后,粉体整体风味略有差异,以醛类为主,具有青草香、橘香、脂肪味。该研究结果可为冲调谷物粉的风味改善提供理论基础。Abstract: Extruded corn flour can be easily agglomerated and poses poor flavor. Previous studies have found that phosphorylation heat treatment, enzyme treatment, edible gum dry heat treatment, and composite treatment could significantly reduce the agglomeration rate. The present study sought to explore the effects of sodium orthophosphate heat treatment (S1), neutral protease (S2), xanthan gum dry heat treatment (S3), and sodium orthophosphate-neutral protease treatment (S4) on the structural characteristics and flavor components of extruded corn flour (PCF) using scanning electron microscopy, Fourier transform infrared spectroscopy, X-ray diffraction, headspace solid phase microextraction, and gas chromatography mass spectrometry. The results showed that the extruded corn flour treated by these four methods exhibited an A-type crystal structure without the formation or introduction of any new chemical bonds or functional groups. The pores and cracks on the surface of starch microparticles significantly increased. Among them, the sodium orthophosphate+neutral protease treated powder had more surface pores and larger cracks than other samples. A total of 130 volatile components were identified by gas chromatography-mass spectrometry, including neutral protease treatment powder (57) > sodium orthophosphate+neutral protease treatment powder (46) > xanthan gum dry heat treatment powder (44) > PCF (41) > sodium orthophosphate heat treatment powder (40). ROAV analysis showed that the key flavor substances of extruded corn flour were mainly ketones. After different treatments, the overall flavor of the powder slightly differed, mainly aldehydes, with grass, orange, and fat flavor. The present study results could provide a theoretical basis to improve the flavor of blended grain powder.

-

玉米粉中富含膳食纤维、维生素、矿物质和功能元素,其中约含有62%的淀粉,8.7%的蛋白质和4%的脂肪[1],食用口感粗糙。相反,经挤压膨化技术生产的膨化玉米粉具有风味独特、口感细腻、易消化、保存时间长和安全性高等优点[2],且食用方便、冲调即食,饱腹感强。然而,膨化谷物粉类制品存在一定的冲调性和风味等问题,影响产品品质。

本课题组前期研究发现,膨化玉米粉经过磷酸化热处理、中性蛋白酶处理、黄原胶干热处理、正磷酸钠-中性蛋白酶复合处理后结块率分别降低了4.03%、3.44%、3.48%、4.71%[3],冲调性能得到改善。膨化冲调粉的冲调性指标如结块率、吸水性指数(WAI)变化与淀粉颗粒微观结构如表面孔洞、破坏程度有关[4-5]。戢得蓉等[6]研究发现,经磷酸化处理的淀粉颗粒,其表面出现裂纹,透明度、溶解度及膨润度降低;且经酶解处理后淀粉的颗粒表面失去了光滑性,出现了不规则的凹陷[7-8]。也有研究表明[9-10],湿热处理会导致淀粉分子结晶度的破坏,改变淀粉分子的亲水性,进而改变冲调性能。此外,冲调粉经过酶热处理后挥发性风味物质分布有所不同[11-12],而这些风味差异会影响冲调粉的食用品质。目前,国内外对于酶、磷酸化热处理、食用胶干热处理多集中于生粉的理化特性上,对于膨化玉米粉在几种处理方式下颗粒结构、结晶度、风味特性的变化和作用少有报道。

因此,基于本课题前期不同处理方式对膨化玉米粉冲调性能的试验结果,为探究膨化玉米粉冲调性能改善前后其冲调粉结构特性如颗粒结构、结晶度、官能团和其化学结构及风味物质变化,采用扫描电子显微镜、傅里叶红外光谱、X-射线衍射、顶空固相微萃取等方法结合气相质谱技术,分析确定膨化玉米粉的关键风味物质,以期为膨化玉米粉的生产加工提供参考。

1. 材料与方法

1.1 材料与设备

膨化玉米粉 四川省旌晶食品有限公司;中温蛋白酶(酶活50000U/g) 河南万邦化工科技有限公司;柠檬酸、正磷酸钠(Na2HPO4、NaH2PO4)、三聚磷酸盐、卡拉胶、黄原胶、海藻酸钠、羧甲基纤维素钠 分析纯,陇西科学股份有限公司。

DZKW-D-2500W恒温水浴锅 上海科恒实业发展有限公司;RT-TDL-50H离心机 无锡市瑞江分析仪器有限公司;LRH-250C生化培养箱 韶关市泰宏医疗器械有限公司;101-3HB电热鼓风干燥箱 北京中兴伟业仪器有限公司;FBS6100-B激光粒度仪 深圳弗布斯仪器有限公司;Ultra Scan VIS台式色差仪 上海韵鼎国际贸易有限公司;NDJ-8S数显黏度计 邦西仪器科技有限公司;JSM-7500F场发射扫描电镜 日本电子(JEOL);7330-USPME手动进样手柄 美国Supelco公司;50/30μm DVB/CAR/PDMS萃取头 上海安谱实验科技股份有限公司;6790N-5975B气相色谱-质谱联用仪 美国Agilent科技有限公司。

1.2 实验方法

1.2.1 不同处理方式下膨化玉米粉制备方法

正磷酸钠热处理(S1):选择正磷酸钠(Na2HPO4 0.9%、NaH2PO4 0.3%)[13]溶于水中(以玉米粉干重计,加水量为玉米粉质量的15%,下同),均匀喷淋至膨化玉米粉中。

中性蛋白酶处理(S2):根据参考文献[14]选取最适酶添加量以及酶解温度,中性蛋白酶(0.025%、50 ℃),分别溶于水中,均匀喷淋至膨化玉米粉中。

黄原胶干热处理(S3):根据GB 2760-2014食品添加剂使用标准,将0.9%黄原胶分别与膨化玉米粉直接混合均匀后,均匀喷淋玉米粉质量(以玉米粉干重计)15%的水。

正磷酸钠结合中性蛋白酶处理(S4):将S1制得的玉米粉,喷淋0.025%中性蛋白酶液(将酶溶于玉米粉质量的15%的水中制得),于50 ℃恒温培养箱中培养3 h,95 ℃灭酶15 min,研磨粉碎制得正磷酸钠和中性蛋白酶复合处理粉。

1.2.2 扫描电子显微镜(SEM)观察

参考LI等[15]的方法并略加修改,将处理后的样品均匀分散在贴有导电胶的样品台,吹去多余样品后,置于E-1045型离子溅射仪的样品舱中,加速电压15 kV的电流下喷金处理,置于扫描电子显微镜腔体内进行观察,拍摄颗粒形貌照片。

1.2.3 傅立叶变换红外光谱(FTIR)

参考高嘉星等[16]的方法并略加修改,红外光谱测试采用溴化钾压片法,称取2 mg干燥的高直链玉米淀粉样品和200 mg干燥KBr粉末,充分混合后倒入压膜,85 kPa压制5 min,压成透明薄片。在德国布鲁克Tensor Ⅱ型傅立叶变换红外光谱仪(FTIR)上进行测定,扫描范围为4000~500 cm−1,分辨率为4 cm−1。

1.2.4 X-射线衍射(XRD)

参考CUETO等[17]的方法并略加修改,X-射线衍射分析在EMPYREAN型X-射线衍射仪上进行,采用粉末制样。测试条件:Ni片滤波,Cu靶Ka射线,管压40kV,管流20 mA,扫描速度0.075°/s,扫描范围5~50°,步长0.02°。

1.2.5 挥发性风味物质

1.2.5.1 挥发性风味成分的提取

固相微萃取方法参考SUN等[5]并略作修改。准确称取1.0000 g经过不同处理的膨化玉米粉,加入6 mL饱和NaCl溶液于体积为20 mL的顶空样品瓶中,放入转子后钳紧瓶盖。顶空瓶立即放入恒温磁力搅拌浴中,平衡和萃取温度均为80 ℃,平衡5 min,然后插入SPME纤维头,顶空萃取45 min。萃取完毕后,立即将SPME纤维头插入GC-MS进样口,于230 ℃解吸3 min。

1.2.5.2 GC-MS分析条件

色谱条件:HP-5MS型(60 m×250 μm×0.25 μm)毛细管柱;载气为高纯氦气(99.999%);恒流恒压模式,流量为1.7 mL/min,压力为13.3 Psi,不分流模式;进样口温度230 ℃;升温程序:初始温度40 ℃,保持2 min,以3 ℃/min升至120 ℃,保持1 min,以5 ℃/min升至150 ℃,保持2 min,以17 ℃/min升至230 ℃,保持5 min,总运行时间约为47.373 min。

质谱条件:电子轰击离子源(EI),电子能量70 eV;传输线温度250℃,离子源温度230 ℃,四极杆温度150 ℃,接口温度280 ℃;扫描质量范围35~400 m/z。

1.2.5.3 挥发性成分的定性与定量分析

经GC-MS分析后,样品中未知挥发性成分定性分析由工作站检索完成,并与NIST11和NIST11s数据库匹配,筛选记录匹配度大于80(最大值为100)的物质,去除柱流失物质(聚甲基硅氧烷化合物)。定量分析按峰面积归一化法进行,求得各挥发性成分的相对百分含量。

1.2.6 相对气味活度值(ROAV)计算

ROAV的计算参考WANG等人[18]的方法,公式如下所示:

ROAV=100×CiCmax×TmaxTi (1) 式中:Ci为组分i的相对百分含量;Ti为组分i的感觉阈值;Cmax与Tmax为样品总体风味贡献最大组分的相对百分含量与感觉阈值,其中相对百分含量与感觉阈值之比最大的为对样品风味贡献最大的组分。

1.3 数据处理

所有测定均为5个平行,利用Excel 2010和IBM SPSS Statistics 25.0进行数据处理。

2. 结果与分析

2.1 不同处理方式对膨化玉米粉SEM的影响

不同处理方式下膨化玉米粉的SEM结果如图1所示。膨化玉米粉表面凹凸不平,颗粒大小分布不均,整体形状不规则且有较多的空洞,与YAN等[19]的报道一致。由图1可知,磷酸化热处理后,膨化玉米粉颗粒数量增加,分布较均匀,条纹破损增加,表面出现侵蚀并崩解,因此具有更高的溶解性和吸水性,这与LIU等[20]磷酸化处理板栗粉的SEM结果一致。中性蛋白酶处理后,淀粉颗粒分布均匀,颗粒破损度增加,出现明显的裂纹和空洞,是因为被蛋白包裹的玉米淀粉颗粒显露出来,且其表面光洁,易吸收水分降低冲调结块率。黄原胶干热处理后,膨化玉米粉颗粒聚集呈大颗粒,表面空洞减少且较为光滑,可能是因为黄原胶填充于淀粉颗粒片段间,淀粉分子中的羟基与黄原胶中的羧基发生了交联反应,使得体系表面孔洞缩小,表面更加光滑,形成的结构更加致密,这一点在现有的研究中也已得到证实[21-23]。正磷酸钠-中性蛋白酶处理后,颗粒分布均匀,粉末表面空洞数量多于磷酸化、中性蛋白酶处理。这是因为磷酸化处理破坏了淀粉的表面结构,增加了酶的接触位点,增大了酶解效率,导致复合处理淀粉表面产生了数量更多的孔洞[24],促进可溶物质浸出,产生了更多的糊精和小分子物质,淀粉溶解度增大[25]。图1可知,复合处理后淀粉颗粒表面被破坏,裂纹大且疏,表明越多的淀粉颗粒在加热过程中破裂,内部淀粉分子被释放出来,有利于其溶于水。综上,不同处理方式下膨化玉米粉颗粒有不同程度的破坏,表面积、孔洞增加,从而改善其吸水性等冲调性能。

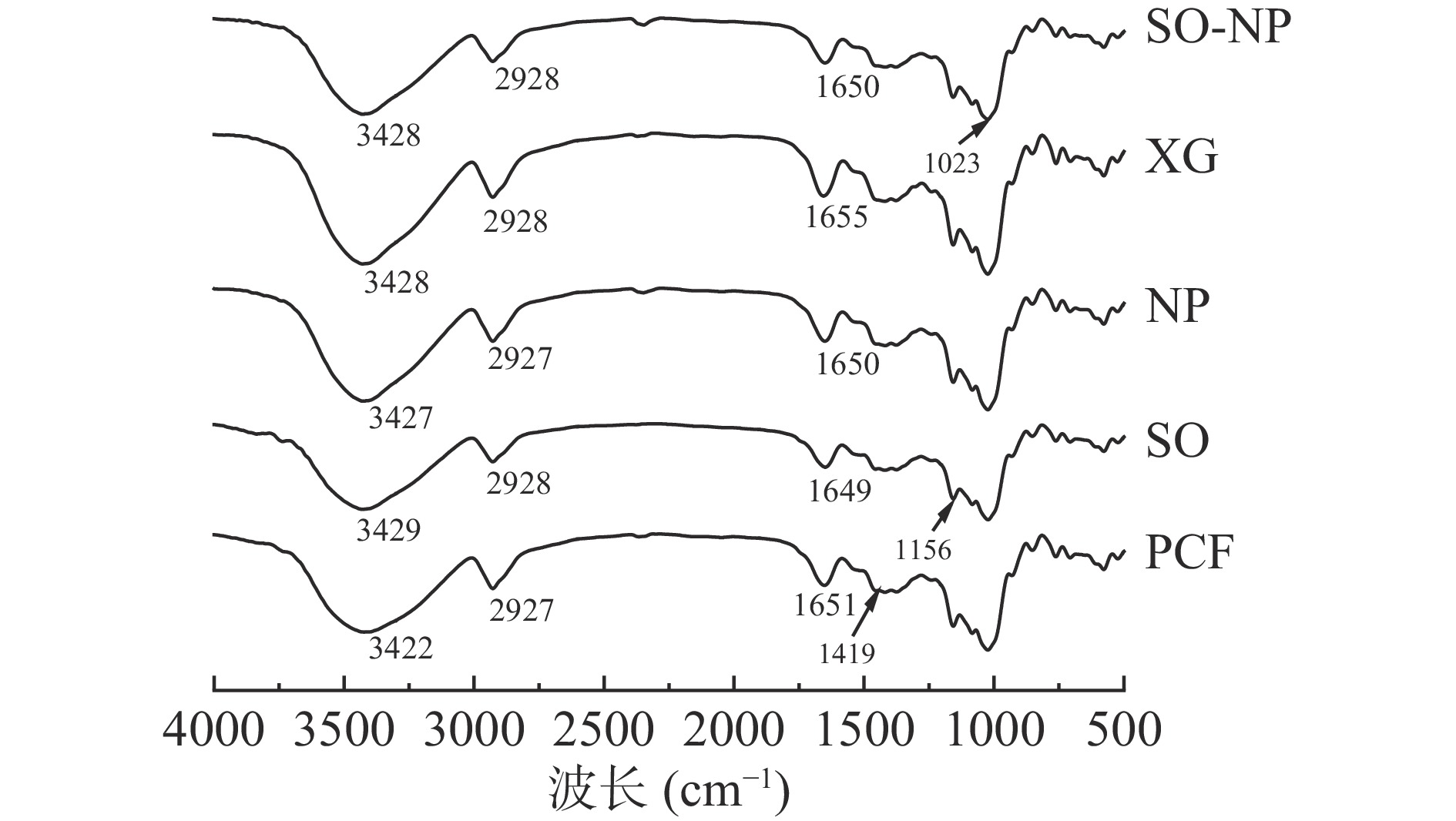

2.2 不同处理方式对膨化玉米粉红外光谱的影响

傅里叶变换红外光谱(FTIR)可以鉴定酶处理、磷酸化热处理、食用胶干热处理及复合处理对膨化玉米粉中的官能团及其化学结构变化。对膨化玉米粉,3422 cm−1处出现的峰为O-H的震动伸缩峰,在2927 cm−1处出现的峰为C-H的伸缩振动峰[26];在1651 cm−1附近有因淀粉无定形区域中吸附水的弯曲振动而引起的吸收峰出现[27]。膨化玉米粉在1156和1023 cm−1处均出现吸收峰,此为淀粉C-O-C吡喃糖环骨架振动和C-C键吸收峰[27-28]。红外光谱分析可以鉴别体系的氢键作用大小,其吸收峰的波数越大,说明氢键相互作用越弱[29]。由图2可知,经过酶处理、磷酸化热处理、食用胶干热处理后,膨化玉米粉的红外光谱曲线整体并没有发生较大的变化。但是,样品SO、NP、XG、SO-NP的O-H的振动伸缩峰略向高波段移动,这可能是由于酶、热处理在一定程度上抑制了淀粉分子间的重结晶现象,使得氢键的作用力变弱[28]。几种处理方式下的膨化玉米粉与未处理相比,均没有新的特征峰出现,这是因为在酶、热处理过程中,淀粉分子中非还原性末端的糖苷键被酶解、热处理产生孔洞和裂缝,该过程可能会影响氢键的数量,各组膨化玉米粉的大分子碳链骨架结构及一级重复单元结构基本保留,表明干热、酶处理并没有引入和产生新的化学键或官能团。

![]() 图 2 不同处理方式下膨化玉米粉红外光谱图注:PCF、SO、NP、XG、SO-NP分别为膨化玉米粉、磷酸化热处理粉、中性蛋白酶处理粉、黄原胶干热处理粉、磷酸化+中性蛋白酶处理粉;图3同。Figure 2. Infrared spectra of puffed maize flour under different treatments

图 2 不同处理方式下膨化玉米粉红外光谱图注:PCF、SO、NP、XG、SO-NP分别为膨化玉米粉、磷酸化热处理粉、中性蛋白酶处理粉、黄原胶干热处理粉、磷酸化+中性蛋白酶处理粉;图3同。Figure 2. Infrared spectra of puffed maize flour under different treatments2.3 不同处理方式对膨化玉米粉X-射线衍射的影响

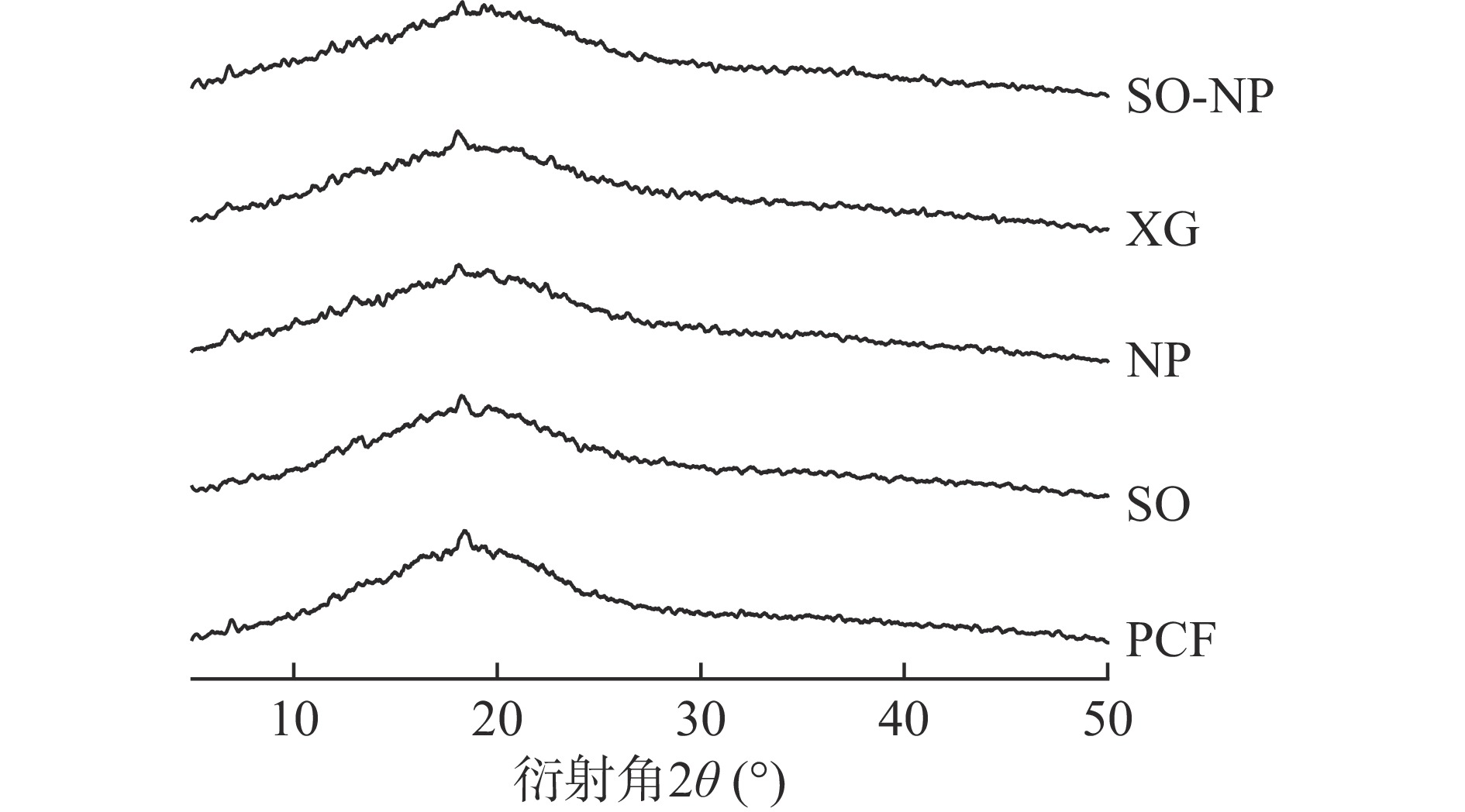

XRD可用于揭示淀粉颗粒的晶体结构特征。膨化玉米粉与不同处理方式下粉的X射线图谱如图3所示,所有样品均在17°、18°左右时有较强的衍射峰,属于A型晶体结构[15]。几个图谱之间无明显差异,表明酶处理、热处理、酶热处理并未改变膨化玉米粉分子晶体结构。PCF、SO、NP、XG、SO-NP的相对结晶度分别为25.2%、24.0%、28.8%、27.7%、24.9%。与未处理相比,磷酸化+中性蛋白酶(S4)处理膨化玉米粉的相对结晶度降低,与王亚丹等[7]对磷酸化酶热处理对玉米粉的结晶度变化一致,这说明膨化玉米粉在高温和酶的作用下,淀粉颗粒内部结晶结构向非结晶结构转变,整体结构变得稍有疏松,有利于水的进入,进而改善冲调性。食用胶干热(S3)、中性蛋白酶处理(S2)提高膨化玉米粉的相对结晶度,可能是食用胶和酶不能有效地进入颗粒内部,致使反应过程中主要集中在玉米淀粉颗粒表面的无定形区域,不能充分反应,推测是因为在干热反应过程中,黄原胶与淀粉分子的交联以及微晶片层区中支链淀粉所形成的双螺旋结构在高热环境的趋向作用下,使得分子排列更加紧密,结构更加牢固[30]。

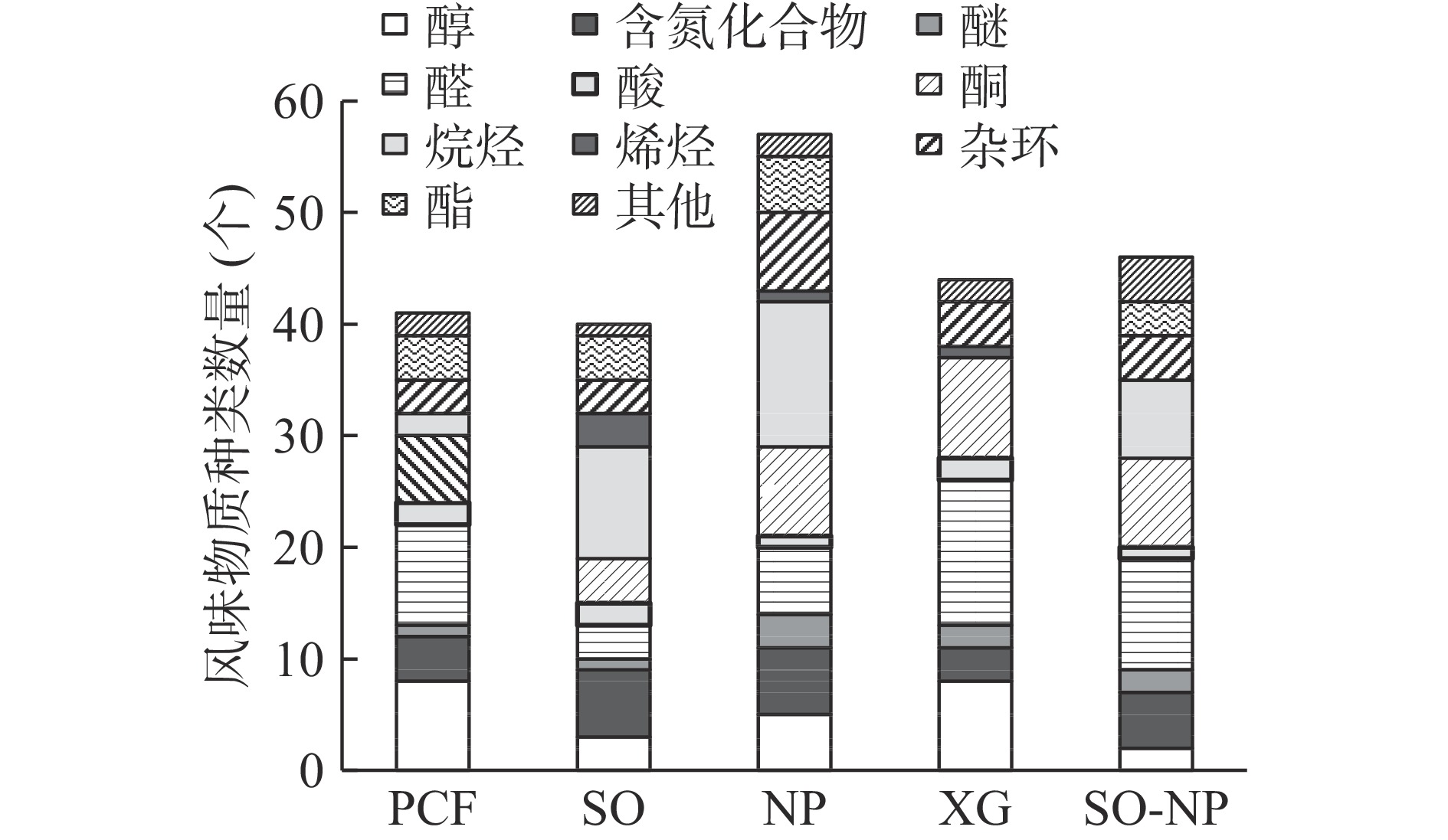

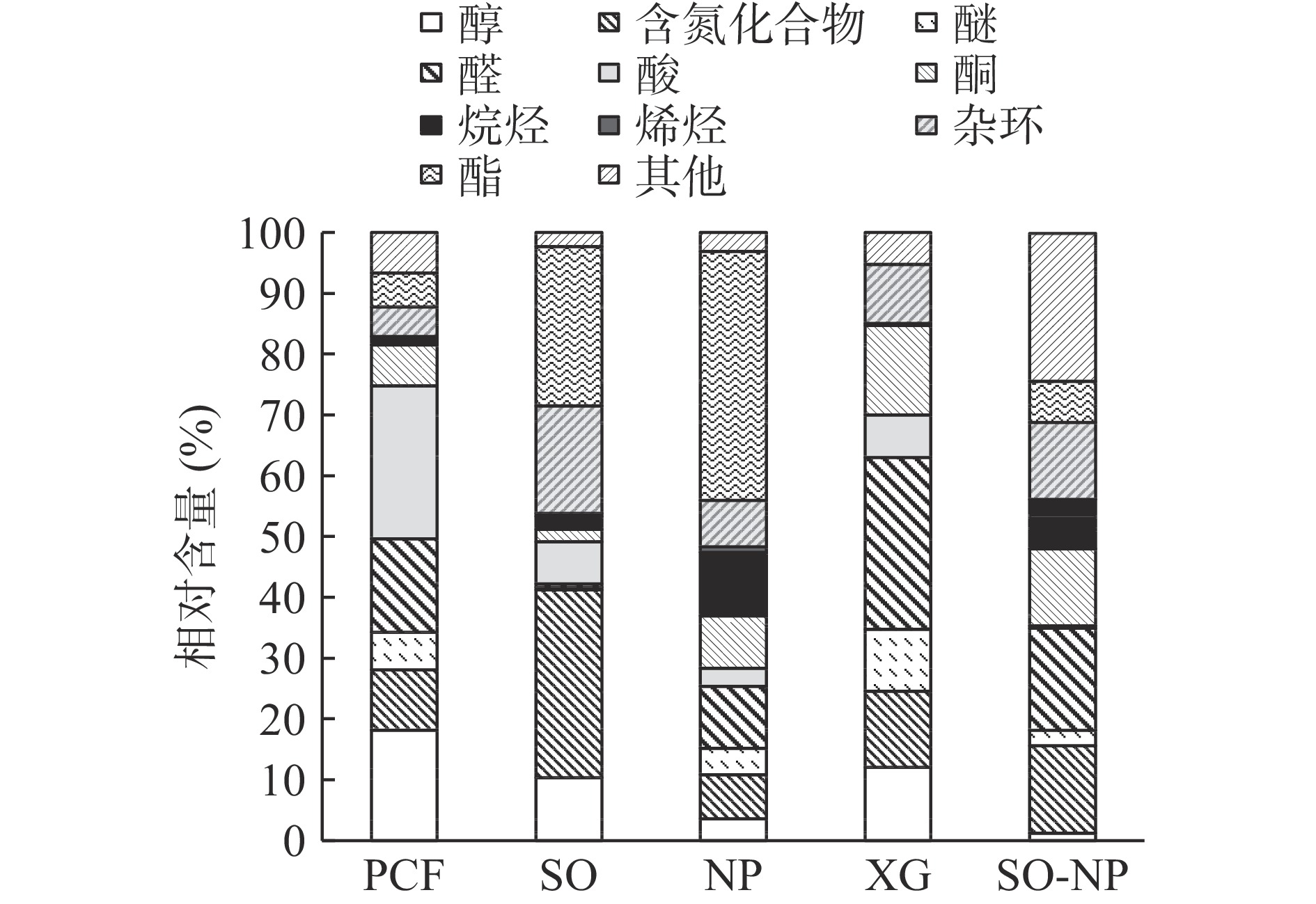

2.4 不同处理方式对膨化玉米粉风味物质成分影响

由表1结合图4、图5可知,膨化玉米粉PCF、正磷酸钠热处理粉SO、中性蛋白酶处理粉NP、黄原胶干热处理粉XG、正磷酸钠+中性蛋白酶处理粉SO-NP分别检测出41、40、57、44、46种,分别为醇类、含氮化合物、醚类、醛类、酸类、酮类、烷烃、酯类、烯烃、杂环,共130种挥发性风味物质。

表 1 不同处理方式对膨化玉米粉挥发性风味物质的影响Table 1. Effect of different treatments on the flavour substances found in puffed maize flour序号 分类 名称 相对含量(%) PCF SO NP XG SO-NP 1 醇 乙醇 0.98 − − − 0.42 2 四氢吡喃-4-醇 0.56 − − − − 3 环丙基甲醇 6.51 − 0.41 1.73 − 4 5-甲基-2-庚醇 0.08 − − 0.12 0.74 5 (S)-环氧丙醇 0.43 − − − − 6 环丁醇 2.47 9.34 1.44 − − 7 正戊醇 − − − 1.13 − 8 苯乙醇 1.64 − − − − 9 (R)-环氧丙醇 − − 0.55 − − 10 2-丁基辛醇 − 0.19 0.27 − − 11 1-辛烯-3-醇 − − − 2.12 − 12 庚醇 − − − 1.18 − 13 正辛醇 − − − 2.21 − 14 糠醇 − − − 0.88 − 15 2-乙烯氧基乙醇 5.42 0.80 0.93 2.66 − 16 含氮化合物 3-甲氨基丙胺 − − 0.42 0.26 9.83 17 丙酰胺 5.08 19.65 2.66 9.63 1.47 18 N-甲基烯丙基胺 0.95 − − − − 19 二丙烯三胺 − 0.11 − − − 20 N-甲基辛胺 − − − − 0.18 21 氰乙酰胺 − − 0.17 − − 22 N,N-二甲基甲磺酰胺 2.92 − − − 1.04 23 N-甲基苄胺 − 7.97 − − − 24 DL-天冬酰胺-水物 − − 0.32 − − 25 3-羟基-N,N-二甲基丙胺 − 0.32 0.70 − − 26 二甲胺 1.03 2.72 2.93 2.58 1.91 27 丙烯酰胺 − 0.14 − − − 28 醚 乙烯基乙醚 − − 0.46 − − 29 15-冠醚-5 − − 3.49 3.69 1.73 30 三乙二醇单乙醚 − 0.43 − − − 31 12-冠醚-4 − − 0.42 − 0.83 32 18-冠醚-6 6.16 − − − − 33 正-午基醚 − − − 6.53 − 34 醛 戊醛 0.19 − 0.63 − 0.23 35 正己醛 8.90 0.14 6.68 4.46 8.63 36 庚醛 − − 0.35 − − 37 正辛醛 − 0.14 − 1.40 − 38 2-庚醛 − − − 2.61 − 39 2,2-二甲基-3-羟基丙醛 − − − 0.38 − 40 壬醛 1.59 − 1.32 3.88 2.19 41 丁醛 0.48 − − − − 42 反-2-辛烯醛 0.38 − − 3.28 0.50 43 癸醛 − − − 0.79 0.70 44 苯甲醛 0.69 − 0.52 0.66 0.38 45 反式-2-壬醛 0.58 − − 1.46 0.91 46 反,反-2,4-壬二烯醛 − − − 0.50 − 47 2-十一烯醛 − − − 2.95 − 48 2E,4E-2,4-辛二烯醛 − − − 1.59 − 49 反,反-2,4-癸二烯醛 − 0.31 0.75 − 1.52 50 2,4-癸二烯醛 2.33 − − 4.30 − 51 5-羟甲基糠醛 − − − − 1.27 52 异戊醛 0.28 − − − − 53 甲氨基乙醛缩二甲醇 − − − − 0.42 54 酸 蝶呤-6-羧酸 16.50 6.69 − 3.20 0.44 55 壬六烷酸 − 0.21 − − − 56 酸草醯脲 8.60 − 2.90 3.84 − 57 酮 1-甲基-2-哌啶酮 0.14 − 1.12 − 0.57 58 N-甲基吡咯烷酮 0.37 − − − − 59 仲辛酮 − − − 0.37 − 60 甲基庚烯酮 − − 0.23 − 0.42 61 2-壬酮 − − − 0.36 − 62 3-辛烯-2-酮 − − − 0.82 0.38 63 2,11-十二烷烃 − − − 0.68 − 64 3-壬烯-2-酮 − − − 1.62 − 65 3,5-八二烯酮 0.70 − − − 0.47 66 E,E-3,5-辛二烯-2-酮 − − 0.41 − − 67 二正戊基酮 − − − 0.24 − 68 Z-2-甲基-1-癸烯酮 − − − 4.61 − 69 beta-二氢紫罗兰酮 0.81 0.36 0.44 − 0.92 70 橙基丙酮 − − 2.33 − 4.51 71 香叶基丙酮 3.38 0.57 1.81 4.16 3.65 72 β-紫罗兰酮 1.41 0.49 0.80 1.85 1.73 73 4-羟基-3-甲基苯乙酮 − 0.64 − − − 74 2-羟基-5-甲基苯乙酮 − − 1.55 − − 75 1-碘-2-甲基十一烷 − 0.21 − − − 76 1,1,2,3-四甲基环丙烷 − − − − 1.28 77 正十二烷 0.51 − − − − 78 正二十烷 − 0.21 − − − 79 6-甲基三甲烷 0.90 − − − − 80 2,9-二甲基十一烷 − 0.14 0.70 − − 81 3,9-二甲基十一烷 − 0.13 − − − 82 1-氟十二烷 − − 0.24 − 0.93 83 2,6,11-三甲基十二烷 − 0.16 − − − 84 植烷 − − 0.57 − − 85 4-甲基十四烷 − − 0.40 − − 86 2-甲基十八烷 − − 0.68 − − 87 2,3,5,8-四甲基癸烷 − 0.14 − − − 88 正十三烷 − 0.22 0.40 − − 89 正十四烷 − − 2.47 − − 90 癸烷 − − − − 3.02 91 溴代十八烷 − − − − 0.65 92 四十四烷 − 0.21 − − 0.81 93 氯代十八烷 − − 1.53 − − 94 十九烷 − 0.23 1.03 − 0.74 95 四环烷,3,5,24-三甲基 − − 0.71 − − 96 3-甲基十四烷 − − 0.31 − − 97 十五烷 − − 0.73 − − 98 正十六烷 − − 0.64 − 0.74 99 反式-2,3-环氧丁烷 − 0.44 − − − 100 1-戊烯 − − − 0.34 − 101 2,4,4-三甲基-1-己烯 − 0.17 − − − 102 (Z)-2-十四烯 − 0.19 − − − 103 1-十四烯 − − 0.93 − − 104 (Z)-3-乙基-2-甲基-1,3-己二烯 − 0.19 − − − 105 杂环 2-乙基吖啶 − 0.10 − − − 106 2-戊基呋喃 0.38 0.13 0.33 3.14 0.91 107 2-甲基吡嗪 − − − 0.42 − 108 1,6-二甲基萘 − − 1.13 − − 109 1,4-二甲基萘 − − − − 4.89 110 1,3-二叔丁基苯 2.56 17.45 1.47 − 3.30 111 2,3-二甲基萘 − − 0.61 − − 112 1,3-二甲基萘 − − 0.75 − − 113 2,3,5-三甲基萘 − − 2.11 − 3.52 114 4-(2-氨基丙基)苯酚 − − 1.27 − − 115 4-乙烯基-2-甲氧基苯酚 1.84 − − 6.13 − 116 酯 草酸单乙酯 − 0.45 − − − 117 甲酸乙烯酯 − − 0.19 − 0.54 118 肼基甲酸乙酯 0.14 − − − − 119 草酸酰胺乙酯 3.63 19.31 22.72 − − 120 亚硫酸二甲酯 − − 0.31 − − 121 辛酸乙酯 1.02 − − − − 122 (+/-)-β-羟基-γ-丁内酯 − 6.26 7.33 − 1.44 123 乙二醇月桂酸酯 − 0.16 − − − 124 3-酞酰亚胺基丙酸甲酯 0.81 − − − − 125 邻苯二甲酸二丁酯 − − 10.35 − − 126 棕榈酸甲酯 − − − − 4.93 127 其他 3-苯基-1H-吲哚 − − − − 2.49 128 2-(甲胺基甲基)-1,3-二氧六环 1.09 2.34 2.29 0.70 1.73 129 1,3-二氧戊环 − − − − 0.69 130 4-甲基-1,3-二氧戊环 5.61 − 0.82 4.56 19.42 注:−表示未检出或未找到风味特征;PCF、SO、NP、XG、SO-NP分别为膨化玉米粉、磷酸化热处理粉、中性蛋白酶处理粉、黄原胶干热处理粉、磷酸化+中性蛋白酶处理粉。 2.4.1 膨化玉米粉风味物质分析

膨化玉米粉中醇类和醛类所占的比例及种类都相对较多。醇类(18.09%、8种)中,苯乙醇具有玫瑰香气,该物质在生鲜玉米汁中检测出[31]。烷烃类物质含量较少(1.41%),对风味的贡献率最小,但其在风味形成过程中与酮、酸、醛和酯类等起着互补或调和的作用[32]。酯类(8.16%、5种)是脂肪氧化产生的游离脂肪酸和醇的相互作用形成的,主要呈现水果香味。醛类阈值较低,对风味贡献相对较大[33],己醛相对含量较高(8.90%),是亚油酸降解的产物[34],呈草香味;壬醛是油酸氧化的产物[35],呈清香味;牛丽影等[36]研究发现乙醛和乙醇是鲜玉米汁的最主要的挥发性成分,根据相对含量判断,乙醛和乙醇为膨化玉米粉的主要挥发性成分。杂环类中2-戊基呋喃(0.38%)是亚油酸氧化的产物[37],具有豆香、果香、青香、类似蔬菜的香气、较浓的烤坚果香气[38]。含氮化合物的产生可能来源于氨基酸的热降解以及美拉德反应[39]。酮类物质的阈值较低,具有甘草香气,在高温下不稳定,易进一步反应形成酸或醇[40],对玉米粉的整体风味贡献较小。

2.4.2 不同处理方式对膨化玉米粉风味物质成分影响分析

正磷酸钠处理后,膨化玉米粉中含氮化合物烷烃、杂环类和酯类物质含量分别增加0.64%、12.90%、20.58%,青香味减弱。热处理条件下,含氮类化合物(6种,30.91%)主要是由蛋白质、氨基酸热分解、糖与蛋白质或氨基酸的Maillard反应所形成,一般具有烤面包香气以及烤味等[41]。烷烃类物质可能来源于玉米粉中游离脂肪酸的自动氧化[42];因为磷酸化热处理是玉米粉中淀粉的羟基与磷酸根基团发生酯化反应,引起酯类相对含量增加。由图6风味物质韦恩图可知,正磷酸钠热处理粉、膨化粉共检测出13种共有风味物质。

经中性蛋白酶处理后,膨化玉米粉酮类、烷烃、烯烃、杂环、酯类相对含量增加,醇类、醛类、含氮化合物、醚类、酸类减少。与正磷酸钠热处理相比,酶处理增加了醛类和酮类物质的种类和相对含量,因为酶处理下微生物的转化和氨基酸的分解作用[43],风味物质数量高于磷酸化处理,而高温处理下醇类、醛类和杂环类物质不稳定,易分解和转化。醇和酸主要是赋予食物芳香、花香、甜味、水果味、酸味和蘑菇味的主要来源,酸可以由氨基酸降解后经氧化或还原作用产生,也可能由饱和脂肪酸本身氧化降解产生,是酯类化合物合成的前体物质[44]。酶解后戊醛相对含量较处理前增加了0.44%,醛类与酮类等挥发性化合物具有麦芽味、青草味、甜味、烤面包香、焦糖香和咖啡香等[45]。

较未处理样品而言,黄原胶干热处理粉未检测到烷烃和酯类物,醛类、酮类、杂环类物质含量分别增加12.84%、7.90%、4.91%,酸类物质含量降低18.06%,可能是因为黄原胶为酸性多糖,其羰基能与游离氨基酸或蛋白质的氨基发生美拉德反应,可产生醛、酮等多种挥发性风味物质[46]。黄原胶干热处理粉与膨化玉米粉共检测出19种共有风味物质,与正磷酸钠热处理粉、中性蛋白酶处理粉相比,黄原胶干热处理粉醇类、醛类、酮类物质的种类和含量增加,杂环类物质的相对含量(9.69%)高于其他两种单一处理方式。

复合处理后,膨化玉米粉中含氮化合物(14.43%)、醛类(16.75%)、酮类(12.65%)、烷烃(8.17%)、杂环(12.62%)和酯类物质(6.91%)的相对含量增加,因为膨化粉经过热和酶处理,饱和脂肪烃降解及微生物转化和分解,生成一些醛类、酯类和杂环类等物质。复合处理粉与磷酸化处理粉共检测出14种共同风味物质,醛类物质相对含量增加,且种类和相对含量高于单一处理粉,水果香味较强。酯类和酮类物质共存时可能对冲调粉的整体风味有协调和平衡的作用[34]。烷烃类化合物和含氮类化合物风味阈值高,对玉米粉风味的形成影响不明显,但一定浓度的这些物质可使玉米冲调粉的口感更加柔和饱满[35]。不同处理方式前后共检测到7个共有风味物质。

2.5 不同处理方式下膨化玉米粉的ROAV分析

参考《化合物香味阈值汇编》和文献[47-48],本文只对查到的感觉阈值的挥发性物质继续分析。分别计算5个样品膨化玉米粉每种挥发性风味物质相对含量与感觉阈值的比值,比较定义后发现β-紫罗兰酮为样品PCF、SO、NP、XG、SO-NP总体风味贡献最大的物质,呈花香[49]。结合挥发性成分相对含量和感觉阈值,采用ROAV分析法对不同处理方式下膨化玉米粉的挥发性风味物质进行分析,以进一步确定关键风味物质,5个样品ROAV值见表2。

表 2 不同处理方式下膨化玉米粉挥发性风味物质的相对气味活度值Table 2. Relative odour activity values of volatile flavour substances of puffed maize flour under different treatments序号 名称 风味描述 感觉阈值

(ug.kg−1)ROAV PCF SO NP XG SO-NP 1 1-辛烯-3-醇 蘑菇味 2 − − − 0.40 − 2 戊醛 杏仁味、试剂味 1.2 0.08 0.46 − − 0.08 3 己醛 青草味 4.5 0.98 1.31 0.05 0.38 0.78 4 庚醛 橘香 3 − 0.10 − − − 5 正辛醛 油脂香,甜橙香,蜂蜜香 3.4 − − 0.06 0.16 − 6 (E)-2-庚烯醛 杏仁味、油脂味 13 − − − − − 7 2-庚醛 2.8 − − − 0.36 − 8 壬醛 橘香 1 0.79 1.16 − 1.47 0.89 9 反-2-辛烯醛 油脂味 3 0.06 − − 0.41 0.07 10 癸醛 油脂味 1.5 − − − 0.20 0.19 11 反,反-2,4-癸二烯醛 鲜黄瓜香,脂肪味,香蕉味,青草香 0.027 − 24.36 16.55 − 22.80 12 2,4-癸二烯醛 甜橙脂肪香、甜香、新鲜的柑橘味 0.07 16.50 − − 23.28 − 13 异戊醛 1.1 0.12 − − − − 14 3-辛烯-2-酮 泥土香,甜香,甘草香 1.5 − − − 0.21 0.10 15 香叶基丙酮 60 0.03 0.03 0.01 0.03 0.02 16 β-紫罗兰酮 花香 0.007 100 100 100 100 100 17 正十六烷 0.5 − 1.12 − − 0.60 18 2-戊基呋喃 6 0.03 0.05 0.03 0.20 0.06 19 辛酸乙酯 15 0.04 − − − − 注:“−”代表未检出,表中只展示ROAV>0.1的物质;PCF、SO、NP、XG、SO-NP分别为膨化玉米粉、磷酸化热处理粉、中性蛋白酶处理粉、黄原胶干热处理粉、磷酸化+中性蛋白酶处理粉。 ROAV≥1的组分为所测样品的关键风味物质,0.1≤ROAV<1的组分对所测样品的总体风味起重要修饰作用。由表2可知,膨化玉米粉的中2,4-癸二烯醛、戊醛、己醛、壬醛、反-2-辛烯醛、异戊醛、香叶基丙酮、2-戊基呋喃、辛酸乙酯起重要修饰作用。正磷酸钠热处理粉中,庚醛起修饰作用,己醛、壬醛、反,反-2,4-癸二烯醛、正十六烷是关键风味物质;中性蛋白酶处理粉的关键风味物质为反,反-2,4-癸二烯醛;黄原胶干热处理粉的关键风味物质为壬醛、2,4-癸二烯醛;正磷酸钠-中性蛋白酶处理粉的关键风味物质为反,反-2,4-癸二烯醛。5个样品的关键性风味物质中只有一个主成分被提取,因此不能对几个样品的关键性风味进行主成分分析。

3. 结论

本文探究了不同处理方式对膨化玉米粉结构及风味物质的影响,与对照组(PCF)相比,处理后的4组样品中,淀粉微观颗粒表面的孔洞和缝隙增多,有利于膨化玉米粉溶于水,进而改善了它的冲调性能;4种方式处理下,复合处理后的膨化玉米粉,其淀粉结构表面裂纹最大,空洞数量最多,更有利于溶解;同时,这4种处理方式下均没有新的特征峰出现,说明并未引入新的化学键或官能团;此外,处理后的膨化玉米粉与对照组的峰形大体相似,都属于A型晶体结构,表明酶、干热处理未改变其结晶结构。5个样品共检测出130种挥发性成分,其中NP(57种)>SO-NP(46种)>XG(44种)>PCF(41种)>SO(40种),PCF的主要挥发性物质为醇类、酸类、酯类和含氮化合物;SO-NP主要挥发性物质为酯类和其他类。利用ROAV法确定5个样品的关键风味物质(ROAV≥1)不相同,PCF为2,4-癸二烯醛,XG为壬醛、2,4-癸二烯醛,SO、NP、SO-NP的共有关键风味物质为反,反-2,4-癸二烯醛。其中,对风味贡献最大的为β-紫罗兰酮,呈花香;样品PCF、XG、SO-NP的风味呈花香、脂肪香、橘香,SO、NP则呈鲜黄瓜香、脂肪味、香蕉味、青草香,风味有差异,但有重叠,均具有花香。膨化玉米粉的关键风味物质主要以酮类为主,而经过不同处理方式后的膨化玉米粉则以已醛类为主,具有青草香、橘香、脂肪味。其中,经过正磷酸钠-中性蛋白酶处理的膨化玉米粉,相对结晶度降低,淀粉颗粒内部结构向无序状态转变,整体结构更松散,更易溶于水,且GC-MS结果表明其风味浓郁。综上,选择正磷酸钠-中性蛋白酶处理方式更好。

-

图 2 不同处理方式下膨化玉米粉红外光谱图

注:PCF、SO、NP、XG、SO-NP分别为膨化玉米粉、磷酸化热处理粉、中性蛋白酶处理粉、黄原胶干热处理粉、磷酸化+中性蛋白酶处理粉;图3同。

Figure 2. Infrared spectra of puffed maize flour under different treatments

表 1 不同处理方式对膨化玉米粉挥发性风味物质的影响

Table 1 Effect of different treatments on the flavour substances found in puffed maize flour

序号 分类 名称 相对含量(%) PCF SO NP XG SO-NP 1 醇 乙醇 0.98 − − − 0.42 2 四氢吡喃-4-醇 0.56 − − − − 3 环丙基甲醇 6.51 − 0.41 1.73 − 4 5-甲基-2-庚醇 0.08 − − 0.12 0.74 5 (S)-环氧丙醇 0.43 − − − − 6 环丁醇 2.47 9.34 1.44 − − 7 正戊醇 − − − 1.13 − 8 苯乙醇 1.64 − − − − 9 (R)-环氧丙醇 − − 0.55 − − 10 2-丁基辛醇 − 0.19 0.27 − − 11 1-辛烯-3-醇 − − − 2.12 − 12 庚醇 − − − 1.18 − 13 正辛醇 − − − 2.21 − 14 糠醇 − − − 0.88 − 15 2-乙烯氧基乙醇 5.42 0.80 0.93 2.66 − 16 含氮化合物 3-甲氨基丙胺 − − 0.42 0.26 9.83 17 丙酰胺 5.08 19.65 2.66 9.63 1.47 18 N-甲基烯丙基胺 0.95 − − − − 19 二丙烯三胺 − 0.11 − − − 20 N-甲基辛胺 − − − − 0.18 21 氰乙酰胺 − − 0.17 − − 22 N,N-二甲基甲磺酰胺 2.92 − − − 1.04 23 N-甲基苄胺 − 7.97 − − − 24 DL-天冬酰胺-水物 − − 0.32 − − 25 3-羟基-N,N-二甲基丙胺 − 0.32 0.70 − − 26 二甲胺 1.03 2.72 2.93 2.58 1.91 27 丙烯酰胺 − 0.14 − − − 28 醚 乙烯基乙醚 − − 0.46 − − 29 15-冠醚-5 − − 3.49 3.69 1.73 30 三乙二醇单乙醚 − 0.43 − − − 31 12-冠醚-4 − − 0.42 − 0.83 32 18-冠醚-6 6.16 − − − − 33 正-午基醚 − − − 6.53 − 34 醛 戊醛 0.19 − 0.63 − 0.23 35 正己醛 8.90 0.14 6.68 4.46 8.63 36 庚醛 − − 0.35 − − 37 正辛醛 − 0.14 − 1.40 − 38 2-庚醛 − − − 2.61 − 39 2,2-二甲基-3-羟基丙醛 − − − 0.38 − 40 壬醛 1.59 − 1.32 3.88 2.19 41 丁醛 0.48 − − − − 42 反-2-辛烯醛 0.38 − − 3.28 0.50 43 癸醛 − − − 0.79 0.70 44 苯甲醛 0.69 − 0.52 0.66 0.38 45 反式-2-壬醛 0.58 − − 1.46 0.91 46 反,反-2,4-壬二烯醛 − − − 0.50 − 47 2-十一烯醛 − − − 2.95 − 48 2E,4E-2,4-辛二烯醛 − − − 1.59 − 49 反,反-2,4-癸二烯醛 − 0.31 0.75 − 1.52 50 2,4-癸二烯醛 2.33 − − 4.30 − 51 5-羟甲基糠醛 − − − − 1.27 52 异戊醛 0.28 − − − − 53 甲氨基乙醛缩二甲醇 − − − − 0.42 54 酸 蝶呤-6-羧酸 16.50 6.69 − 3.20 0.44 55 壬六烷酸 − 0.21 − − − 56 酸草醯脲 8.60 − 2.90 3.84 − 57 酮 1-甲基-2-哌啶酮 0.14 − 1.12 − 0.57 58 N-甲基吡咯烷酮 0.37 − − − − 59 仲辛酮 − − − 0.37 − 60 甲基庚烯酮 − − 0.23 − 0.42 61 2-壬酮 − − − 0.36 − 62 3-辛烯-2-酮 − − − 0.82 0.38 63 2,11-十二烷烃 − − − 0.68 − 64 3-壬烯-2-酮 − − − 1.62 − 65 3,5-八二烯酮 0.70 − − − 0.47 66 E,E-3,5-辛二烯-2-酮 − − 0.41 − − 67 二正戊基酮 − − − 0.24 − 68 Z-2-甲基-1-癸烯酮 − − − 4.61 − 69 beta-二氢紫罗兰酮 0.81 0.36 0.44 − 0.92 70 橙基丙酮 − − 2.33 − 4.51 71 香叶基丙酮 3.38 0.57 1.81 4.16 3.65 72 β-紫罗兰酮 1.41 0.49 0.80 1.85 1.73 73 4-羟基-3-甲基苯乙酮 − 0.64 − − − 74 2-羟基-5-甲基苯乙酮 − − 1.55 − − 75 1-碘-2-甲基十一烷 − 0.21 − − − 76 1,1,2,3-四甲基环丙烷 − − − − 1.28 77 正十二烷 0.51 − − − − 78 正二十烷 − 0.21 − − − 79 6-甲基三甲烷 0.90 − − − − 80 2,9-二甲基十一烷 − 0.14 0.70 − − 81 3,9-二甲基十一烷 − 0.13 − − − 82 1-氟十二烷 − − 0.24 − 0.93 83 2,6,11-三甲基十二烷 − 0.16 − − − 84 植烷 − − 0.57 − − 85 4-甲基十四烷 − − 0.40 − − 86 2-甲基十八烷 − − 0.68 − − 87 2,3,5,8-四甲基癸烷 − 0.14 − − − 88 正十三烷 − 0.22 0.40 − − 89 正十四烷 − − 2.47 − − 90 癸烷 − − − − 3.02 91 溴代十八烷 − − − − 0.65 92 四十四烷 − 0.21 − − 0.81 93 氯代十八烷 − − 1.53 − − 94 十九烷 − 0.23 1.03 − 0.74 95 四环烷,3,5,24-三甲基 − − 0.71 − − 96 3-甲基十四烷 − − 0.31 − − 97 十五烷 − − 0.73 − − 98 正十六烷 − − 0.64 − 0.74 99 反式-2,3-环氧丁烷 − 0.44 − − − 100 1-戊烯 − − − 0.34 − 101 2,4,4-三甲基-1-己烯 − 0.17 − − − 102 (Z)-2-十四烯 − 0.19 − − − 103 1-十四烯 − − 0.93 − − 104 (Z)-3-乙基-2-甲基-1,3-己二烯 − 0.19 − − − 105 杂环 2-乙基吖啶 − 0.10 − − − 106 2-戊基呋喃 0.38 0.13 0.33 3.14 0.91 107 2-甲基吡嗪 − − − 0.42 − 108 1,6-二甲基萘 − − 1.13 − − 109 1,4-二甲基萘 − − − − 4.89 110 1,3-二叔丁基苯 2.56 17.45 1.47 − 3.30 111 2,3-二甲基萘 − − 0.61 − − 112 1,3-二甲基萘 − − 0.75 − − 113 2,3,5-三甲基萘 − − 2.11 − 3.52 114 4-(2-氨基丙基)苯酚 − − 1.27 − − 115 4-乙烯基-2-甲氧基苯酚 1.84 − − 6.13 − 116 酯 草酸单乙酯 − 0.45 − − − 117 甲酸乙烯酯 − − 0.19 − 0.54 118 肼基甲酸乙酯 0.14 − − − − 119 草酸酰胺乙酯 3.63 19.31 22.72 − − 120 亚硫酸二甲酯 − − 0.31 − − 121 辛酸乙酯 1.02 − − − − 122 (+/-)-β-羟基-γ-丁内酯 − 6.26 7.33 − 1.44 123 乙二醇月桂酸酯 − 0.16 − − − 124 3-酞酰亚胺基丙酸甲酯 0.81 − − − − 125 邻苯二甲酸二丁酯 − − 10.35 − − 126 棕榈酸甲酯 − − − − 4.93 127 其他 3-苯基-1H-吲哚 − − − − 2.49 128 2-(甲胺基甲基)-1,3-二氧六环 1.09 2.34 2.29 0.70 1.73 129 1,3-二氧戊环 − − − − 0.69 130 4-甲基-1,3-二氧戊环 5.61 − 0.82 4.56 19.42 注:−表示未检出或未找到风味特征;PCF、SO、NP、XG、SO-NP分别为膨化玉米粉、磷酸化热处理粉、中性蛋白酶处理粉、黄原胶干热处理粉、磷酸化+中性蛋白酶处理粉。 表 2 不同处理方式下膨化玉米粉挥发性风味物质的相对气味活度值

Table 2 Relative odour activity values of volatile flavour substances of puffed maize flour under different treatments

序号 名称 风味描述 感觉阈值

(ug.kg−1)ROAV PCF SO NP XG SO-NP 1 1-辛烯-3-醇 蘑菇味 2 − − − 0.40 − 2 戊醛 杏仁味、试剂味 1.2 0.08 0.46 − − 0.08 3 己醛 青草味 4.5 0.98 1.31 0.05 0.38 0.78 4 庚醛 橘香 3 − 0.10 − − − 5 正辛醛 油脂香,甜橙香,蜂蜜香 3.4 − − 0.06 0.16 − 6 (E)-2-庚烯醛 杏仁味、油脂味 13 − − − − − 7 2-庚醛 2.8 − − − 0.36 − 8 壬醛 橘香 1 0.79 1.16 − 1.47 0.89 9 反-2-辛烯醛 油脂味 3 0.06 − − 0.41 0.07 10 癸醛 油脂味 1.5 − − − 0.20 0.19 11 反,反-2,4-癸二烯醛 鲜黄瓜香,脂肪味,香蕉味,青草香 0.027 − 24.36 16.55 − 22.80 12 2,4-癸二烯醛 甜橙脂肪香、甜香、新鲜的柑橘味 0.07 16.50 − − 23.28 − 13 异戊醛 1.1 0.12 − − − − 14 3-辛烯-2-酮 泥土香,甜香,甘草香 1.5 − − − 0.21 0.10 15 香叶基丙酮 60 0.03 0.03 0.01 0.03 0.02 16 β-紫罗兰酮 花香 0.007 100 100 100 100 100 17 正十六烷 0.5 − 1.12 − − 0.60 18 2-戊基呋喃 6 0.03 0.05 0.03 0.20 0.06 19 辛酸乙酯 15 0.04 − − − − 注:“−”代表未检出,表中只展示ROAV>0.1的物质;PCF、SO、NP、XG、SO-NP分别为膨化玉米粉、磷酸化热处理粉、中性蛋白酶处理粉、黄原胶干热处理粉、磷酸化+中性蛋白酶处理粉。 -

[1] HASSAN A B, DIETER V H, MOHAMED A. Effect of radio frequency heat treatment on protein profile and functional properties of maize grain[J]. Food Chemistry,2019,271:142−147. doi: 10.1016/j.foodchem.2018.07.190

[2] SCUDAMORE K A, GUY R C, KELLEHER B, et al. Fate of fusarium mycotoxins in maize flour and grits during extrusion cooking[J]. Food Additives and Contaminants,2008,25(11):1374−1384. doi: 10.1080/02652030802136188

[3] 曾德玉, 李京, 陈俊宏, 等. 不同处理方式下膨化玉米粉的冲调性能分析[J]. 现代食品科技,2022,38(4):182−190. [ZENG D Y, LI J, CHEN J H, et al. Effects of different treatment methods on solubility of extruded corn flour[J]. Modern Food Science and Technology,2022,38(4):182−190. ZENG D Y, LI J, CHEN J H, et al. Effects of different treatment methods on solubility of extruded corn flour[J]. Modern Food Science and Technology, 2022, 38(4): 182-190.

[4] 张弘, 温纪平, 刘帅, 等. 小麦胚芽挤压膨化工艺研究[J]. 食品科技,2021,46(12):148−154. [ZHANG H, WEN J P, LIU S, et al. Extrusion technology of wheat germ[J]. Food Science and Technology,2021,46(12):148−154. doi: 10.3969/j.issn.1005-9989.2021.12.spkj202112025 ZHANG H, WEN J P, LIU S, et al. Extrusion technology of wheat germ[J]. Food Science and Technology, 2021, 46(12): 148-154. doi: 10.3969/j.issn.1005-9989.2021.12.spkj202112025

[5] SUN Q, MIN G, YING L, et al. Effect of dry heat treatment on the physicochemical properties and structure of proso millet flour and starch[J]. Carbohydrate Polymers,2014,110:128−134. doi: 10.1016/j.carbpol.2014.03.090

[6] 戢得蓉, 雷敏, 段丽丽, 等. 六种处理方式对慈姑淀粉的理化性质影响研究[J]. 食品与发酵工业,2023,49(1):222−229. [JI D R, LEI M, DUAN L L, et al. Physicochemical properties of six modified arrowhead starches[J]. Food and Fermentation Industries,2023,49(1):222−229. JI D R, LEI M, DUAN L L, et al. Physicochemical properties of six modified arrowhead starches[J]. Food and Fermentation Industries, 2023, 49(1): 222-2291

[7] 王亚丹, 卢二帅, 刘亚伟, 等. 酶处理磷酸化玉米粉特性分析[J]. 食品科技,2018,43(4):177−183. [WANG Y D, LU E S, LIU Y W, et al. The characteristic analysis of phosphorylated corn flour treated by enzymes[J]. Food Science and Technology,2018,43(4):177−183. WANG Y D, LU E S, LIU Y W, et al. The characteristic analysis of phosphorylated corn flour treated by enzymes[J]. Food Science and Technology, 2018, 43(4): 177-183.

[8] BENAVENT-GIL Y, ROSELL C M. Comparison of porous starches obtained from different enzyme types and levels[J]. Carbohydrate Polymers,2017,157:533−540. doi: 10.1016/j.carbpol.2016.10.047

[9] LIU K, HAO Y, CHEN Y, et al. Effects of dry heat treatment on the structure and physicochemical properties of waxy potato starch[J]. International Journal of Biological Macromolecules,2019,132(7):1044−1050.

[10] SINDHU R, DEVI A, KHATKAR B S. Physicochemical, thermal and structural properties of heat moisture treated common buckwheat starches[J]. Journal of Food Science and Technology,2019,56(5):2480−2489. doi: 10.1007/s13197-019-03725-6

[11] 师小飞. 韧化与湿热处理对苦槠淀粉冲调性和挥发性风味物质的影响[D]. 南昌: 南昌大学, 2021 SHI X F. Effect of annealing and heat-moisture treatment on the instant property and volatile flavor compounds of Castanopsis sclerophylla starch[D]. Nanchang: Nanchang University, 2021.

[12] 钱蕾, 于海燕, 娄新曼, 等. 酶解联合高温处理对可可粉风味的影响[J]. 食品工业科技,2022,43(18):80−88. [QIAN L, YU H Y, LOU X M, et al. Effect of enzymatic hydrolysis combined with high temperature processing on the flavor of cocoa powder[J]. Science and Technology of Food Industry,2022,43(18):80−88. QIAN L, YU H Y, LOU X M, et al. Effect of enzymatic hydrolysis combined with high temperature processing on the flavor of cocoa powder[J]. Science and Technology of Food Industry, 2022, 43(18): 80-88.

[13] 王香丽, 刘洁, 卢二帅, 等. 酶处理磷酸化玉米粉的制备工艺研究[J]. 食品科技,2018,43(3):142−148. [WANG X L, LIU J, LU E S, et al. The preparation process of phosphorylated corn flour with treated by enzymes[J]. Food Science and Technology,2018,43(3):142−148. WANG X L, LIU J, LU E S, et al. The preparation process of phosphorylated corn flour with treated by enzymes[J]. Food Science and Technology, 2018, 43(3): 142-148.

[14] 王富盛, 刘景圣. 多酶复合对玉米粉质构特性的影响[J]. 中国食物与营养,2012,18(3):49−53. [WANG F S, LIU J S. Influence of texture properties of corn flour by multienzyme[J]. Food and Nutrition in China,2012,18(3):49−53. WANG F S, LIU J S. Influence of texture properties of corn flour by multienzyme[J]. Food and Nutrition in China, 2012, 18(3): 49-53.

[15] LI W D, GU Z B, CHENG L, et al. Effect of endogenous proteins and heat treatment on the in vitro digestibility and physicochemical properties of corn flour[J]. Food Hydrocolloids, 2023, 135.

[16] 高嘉星, 张国权, 方丝云, 等. 荞麦淀粉-小麦淀粉混配体系理化特性的研究[J]. 食品研究与开发,2017,38(20):25−30. [GAO J X, ZHANG G Q, FANG S Y, et al. Effects of mix on the physiochemical properties of buckwheat starch and wheat starch[J]. Food Research and Development,2017,38(20):25−30. GAO J X, ZHANG G Q, FANG S Y, et al. Effects of mix on the physiochemical properties of buckwheat starch and wheat starch[J]. Food Research and Development, 2017, 38(20): 25-30.

[17] CUETO M, FARRONI A, RODRÍGUEZ S D, et al. Assessing changes in enriched maize flour formulations after extrusion by means of FTIR, XRD, and chemometric analysis[J]. Food and Bioprocess Technology,2018,11(8):1586−1595.

[18] WANG X J, LIU F J, ZHENG J, et al. Effects of different extrusion temperatures on the flavor ccomponents of qatmeal[J]. Modern Food Science and Technology,2018,34(6):188−196,309.

[19] YAN X, WU Z Z, LI M Y, et al. The combined effects of extrusion and heat-moisture treatment on the physicochemical properties and digestibility of corn starch[J]. International Journal of Biological Macromolecules,2019,134(3):1108−1112.

[20] LIU C, YAN H, LIU S, et al. Influence of phosphorylation and acetylation on structural, physicochemical and functional properties of chestnut starch[J]. Polymers,2022,14(1):1−26.

[21] 范欣, 李小平, 胡经纬, 等. 亲水胶体对淀粉理化性质的影响及机理研究进展[J]. 中国粮油学报,2020,35(9):195−202. [FAN X, LI X P, HU J W, et al. Review on effects and mechanism of hydrocolloids on physicochemical properties of starch[J]. Journal of the Chinese Cereals and Oils Association,2020,35(9):195−202. FAN X, LI X P, HU J W, et al. Review on effects and mechanism of hydrocolloids on physicochemical properties of starch[J]. Journal of the Chinese Cereals and Oils Association, 2020, 35(9): 195-202.

[22] 唐敏敏, 洪雁, 顾正彪, 等. 黄原胶对大米淀粉长期回生的影响[J]. 食品与生物技术学报,2013,32(7):692−697. [TANG M M, HONG Y, GU Z B, et al. Effect of xanthan on long-term retrogradation of rice starch[J]. Journal of Food Science and Biotechnology,2013,32(7):692−697. TANG M M, HONG Y, GU Z B, et al. Effect of xanthan on long-term retrogradation of rice starch[J]. Journal of Food Science and Biotechnology, 2013, 32(7): 692-697.

[23] JIAN S, CHOTINEERANAT S, LAOKA B, et al. Effect of dry heat treatment with xanthan gum on physicochemical properties of different amylose rice starches[J]. Starch-Stärke,2018,70(3−4):1700142.

[24] XIE Y, ZHANG B, LI M N, et al. Effects of cross-linking with sodium trimetaphosphate on structural and adsorptive properties of porous wheat starches[J]. Food Chem,2019,289(15):187−194.

[25] 王子妍, 刘颖, 贾健辉, 等. 预糊化-复合酶解法制备婴幼儿留胚米粉及其理化性质研究[J]. 食品工业科技,2022,43(20):228−234. [WANG Z Y, LIU Y, JIA J H, et al. Preparation and physicochemical properties of pregelatinization-composite enzymatic digestion of rice flour with embryos for infants and children[J]. Science and Technology of Food Industry,2022,43(20):228−234. WANG Z Y, LIU Y, JIA J H, et al. Preparation and physicochemical properties of pregelatinization-composite enzymatic digestion of rice flour with embryos for infants and children[J]. Science and Technology of Food Industry, 2022, 43(20): 228-234.

[26] HAN X Y, WEN H L, LUO Y, et al. Effects of chitosan modification, cross-linking, and oxidation on the structure, thermal stability, and adsorption properties of porous maize starch[J]. Food Hydrocolloids, 2022, 124: 107288.

[27] 杨丽, 李子钰, 张福娟, 等. 黑豆皮乙醇提取物/玉米淀粉/卡拉胶复合膜的物化性质及生物活性表征[J]. 食品与发酵工业,2022,48(10):164−171. [YANG L, LI Z Y, ZHANG F J, et al. Physicochemical properties and biological activity characterization of ethanol extract of black soybean coat/corn starch/carrageenan composite films[J]. Food and Fermentation Industries,2022,48(10):164−171. YANG L, LI Z Y, ZHANG F J, et al. Physicochemical properties and biological activity characterization of ethanol extract of black soybean coat/corn starch/carrageenan composite films[J]. Food and Fermentation Industries, 2022, 48(10): 164-171.

[28] WANG K, WANG W, YE R, et al. Mechanical properties and solubility in water of corn starch-collagen composite films: Effect of starch type and concentrations[J]. Food Chemistry,2017,216:209−216. doi: 10.1016/j.foodchem.2016.08.048

[29] PAWLAK A, MUCHA M. Thermogravimetric and FTIR studies of chitosan blends[J]. Thermochimica Acta,2003,396(1):153−166.

[30] 曾绍校, 刘匀昀, 陈秉彦, 等. 黄原胶协同干热变性对紫薯淀粉特性的影响[J]. 中国粮油学报,2015,30(11):42−48. [ZENG S X, LIU Y Y, CHEN B Y, et al. Effects of xanthan gum addition and dry-heat treatment on characteristics of purple sweet potato starch[J]. Journal of the Chinese Cereals and Oils Association,2015,30(11):42−48. ZENG S X, LIU Y Y, CHEN B Y, et al. Effects of xanthan gum addition and dry-heat treatment on characteristics of purple sweet potato starch [J]. Journal of the Chinese Cereals and Oils Association, 2015, 30(11): 42-48.

[31] 程媛, 吴继军, 刘忠义, 等. 不同杀菌方式的甜玉米饮料挥发性风味成分分析[J]. 现代食品科,2019,35(5):281−288. [CHEN Y, WU J J, LIU Z Y, et al. Analysis of volatile compounds in sweet corn beverage with different sterilizations[J]. Modern Food Science and Technology,2019,35(5):281−288. CHEN Y, WU J J, LIU Z Y, et al. Analysis of volatile compounds in sweet corn beverage with different sterilizations[J]. Modern Food Science and Technology, 2019, 35(5): 281-288.

[32] 康志敏, 郭东, 何梦影, 等. 不同干燥工艺对鲜玉米粉品质及风味的影响[J]. 食品工业科技,2020,41(18):58−63,69. [KANG Z M, GUO D, HE M Y, et al. Effect of different drying methods on the quality and flavor profiles of fresh corn flour[J]. Science and Technology of Food Industry,2020,41(18):58−63,69. KANG Z M, GUO D, HE M Y, et al. Effect of different drying methods on the quality and flavor profiles of fresh corn flour[J]. Science and Technology of Food Industry, 2020, 41(18): 58-63, 69.

[33] 蒋华彬, 张小飞, 覃先武, 等. 酵母抽提物的不同添加方式对藜麦膨化粉感官品质、味觉特性和挥发性风味物质的影响[J]. 食品科技,2022,47(1):277−285. [JIANG H B, ZHANG X F, QIN X W, et al. Effect of different addition methods of yeast extract on sensory quality, taste characteristics and volatile flavor compounds of quinoa puffed powder[J]. Food Science and Technology,2022,47(1):277−285. JIANG H B, ZHANG X F, QIN X W, et al. Effect of different addition methods of yeast extract on sensory quality, taste characteristics and volatile flavor compounds of quinoa puffed powder[J]. Food Science and Technology, 2022, 47(1): 277-285.

[34] 王建辉, 王秀, 陈奇, 等. 氧化分解过程中亚油酸组成成分及挥发性物质的变化[J]. 食品与机械,2016,32(5):5−10. [WANG J H, WANG X, CHEN Q, et al. Study on oxidation degradation products of linoleic acid[J]. Food & Machinery,2016,32(5):5−10. WANG J H, WANG X, CHEN Q, et al. Study on oxidation degradation products of linoleic acid[J]. Food & Machinery, 2016, 32(5): 5-10.

[35] 曹君. 不同脂肪酸结构食用油的氧化规律及其动力学研究[D]. 南昌: 南昌大学, 2015 CAO J. Oxidative patterns and kinetics of edible oils with different fatty acid compositions[D]. Nanchang: Nanchang University, 2015.

[36] 牛丽影, 刘夫国, 李大婧, 等. 热处理对乳熟期玉米汁挥发性风味成分的影响[J]. 核龙学报,2014,28(3):446−452. [NIU L Y, LIU F G, LI D J, et al. Effect of heat processing on the volatile flavor components of milk-stage corn juice[J]. Journal of Nuclear Agricultural Sciences,2014,28(3):446−452. NIU L Y, LIU F G, LI D J, et al. Effect of heat processing on the volatile flavor components of milk-stage corn juice[J]. Journal of Nuclear Agricultural Sciences, 2014, 28(3): 446-452.

[37] 陈焱芳, 张名位, 张雁, 等. 发芽及挤压膨化对糙米挥发性风味物质的影响[J]. 中国农业科学,2021,54(1):190−202. [CHEN Y F, ZHANG M W, ZHANG Y, et al. Effects of germination and extrusion on volatile flavor compounds in brown rice[J]. Scientia Agricultura Sinica,2021,54(1):190−202. CHEN Y F, ZHANG M W, ZHANG Y, et al. Effects of germination and extrusion on volatile flavor compounds in brown rice[J]. Scientia Agricultura Sinica, 2021, 54(1): 190-202.

[38] 张文刚, 张垚, 杨希娟, 等. 不同品种青稞炒制后挥发性风味物质GC-MS分析[J]. 食品科学,2019,40(8):192−201. [ZHANG W G, ZHANG Y, YANG X J, et al. GC-MS analysis of volatile flavor substances in different varieties of roasted hulless barley[J]. Food Science,2019,40(8):192−201. ZHANG W G, ZHANG Y, YANG X J, et al. GC-MS analysis of volatile flavor substances in different varieties of roasted hulless barley[J]. Food Science, 2019, 40(8): 192-201.

[39] 贾梦, 刘金光, 康学栋, 等. 海南特色米中营养成分及挥发性风味物质的分布特征[J]. 中国粮油学报,2022,37(7):31−38. [JIA M, LIU J G, KANG X D, et al. Distribution characteristics of the nutritional composition and volatile compounds for the typical rice in Hainan[J]. Journal of the Chinese Cereals and Oils Association,2022,37(7):31−38. JIA M, LIU J G, KANG X D, et al. Distribution characteristics of the nutritional composition and volatile compounds for the typical rice in Hainan[J]. Journal of the Chinese Cereals and Oils Association, 2022, 37(7): 31-38.

[40] 汪新洁, 刘凤杰, 郑俊, 等. 不同挤压膨化温度对燕麦片风味成分的影响[J]. 现代食品科技,2018,34(6):188−196,309. [WANG X J, LIU F J, ZHENG J, et al. Effects of different extrusion temperatures on the flavor components of oatmeal[J]. Modern Food Science and Technology,2018,34(6):188−196,309. WANG X J, LIU F J, ZHENG J, et al. Effects of different extrusion temperatures on the flavor components of oatmeal[J]. Modern Food Science and Technology, 2018, 34(6): 188-196, 309.

[41] 彭超, 王亚琦. 热处理小麦粉对豆酱风味的影响研究[J]. 中国调味品,2019,44(3):5. [PENG C, WANG Y Q. Study on the effect of heat-treated wheat flour on the fflavor of soybean paste[J]. China Condiment,2019,44(3):5. PENG C, WANG Y Q. Study on the effect of heat-treated wheat flour on the fflavor of soybean paste[J]. China Condiment, 2019, 44(3): 5.

[42] SHIRATSUCHI H, SHIMODA M, IMAYOSHI K, et al. Volatile flavor compounds in spray-dried skim milk powder[J]. Journal of Agricultural & Food Chemistry,1994,42(6):1323−1327.

[43] 王艳玲, 周盼盼, 李楠楠, 等. 蛋白酶制剂对发酵牛肉酱风味物质的影响[J]. 中国酿造,2016,35(10):27−30. [WANG Y L, ZHOU P P, LI N N, et al. Effect of protease on the flavor substances of fermented beef paste[J]. China Brewing,2016,35(10):27−30. WANG Y L, ZHOU P P, LI N N, et al. Effect of protease on the flavor substances of fermented beef paste[J]. China Brewing, 2016, 35(10): 27-30.

[44] 吉艳莉, 李瑞英, 郭萌, 等. 不同发酵菌种及发酵时间对蛋酪风味成分的影响[J]. 食品与发酵工业,2020,46(2):214−221. [JI Y L, LI R Y, GUO M, et al. Effect of different fermentation strains and fermentation time on the flavor components of egg cheese[J]. Food and Fermentation Industries,2020,46(2):214−221. JI Y L, LI R Y, GUO M, et al. Effect of different fermentation strains and fermentation time on the flavor components of egg cheese[J]. Food and Fermentation Industries, 2020, 46(2): 214-221.

[45] LIGUORI L, FRANCESCO G D, OORILIO P, et al. Influence of malt composition on the quality of a top fermented beer[J]. Journal of Food Science and Technology,2020,58(6):2295−2303.

[46] 林瑞榕, 杨清羽, 罗富靖, 等. 黄原胶对卤肉酱品质及风味的影响[J]. 食品安全质量检测学报,2022,13(21):6844−6854. [LIN R R, YANG Q Y, LUO F J, et al. Effects of xanthan gum on quality and flavor of braised meat sauce[J]. Journal of Food Safety and Quality,2022,13(21):6844−6854. LIN R R, YANG Q Y, LUO F J, et al. Effects of xanthan gum on quality and flavor of braised meat sauce[J]. Journal of Food Safety and Quality, 2022, 13(21): 6844-6854.

[47] 里奥·范海默特. 化合物香味阈值汇编(第二版)[M]. 北京: 科学出版社, 2015 VAN GEMERTL L J. Compilations of flavour threshold values in water and other media (2nd ed)[M]. Beijing: Science Press, 2015.

[48] 程玉娇, 李贵节, 欧阳祝, 等. 基于气相色谱-质谱/脉冲火焰检测器和主成分分析对不同品种柚汁挥发性风味组分的分析[J]. 食品与发酵工业,2022,48(10):255−263. [CHENG Y J, LI G J, OUYANG Z, et al. Analysis of aroma compounds in different varieties of pomelo juice based on gas chromatography-mass spectrometry/pulsed flame photometric detector and principal component analysis method[J]. Food and Fermentation Industries,2022,48(10):255−263. CHENG Y J, LI G J, OUYANG Z, et al. Analysis of aroma compounds in different varieties of pomelo juice based on gas chromatography-mass spectrometry/pulsed flame photometric detector and principal component analysis method[J]. Food and Fermentation Industries, 2022, 48(10): 255-263.

[49] 朱明明, 樊明涛, 何鸿举. 类胡萝卜素降解方式的研究进展[J]. 食品科学,2017,38(11):308−317. [ZHU M M, FAN M T, HE H J. Advances in methods for the degradation of carotenoids[J]. Food Science,2017,38(11):308−317. ZHU M M, FAN M T, HE H J. Advances in methods for the degradation of carotenoids[J]. Food Science, 2017, 38(11): 308-317.

-

期刊类型引用(10)

1. 王扬铎,苏永昌,王晓燕,施文正,刘智禹. 仿刺参不同部位ACE抑制活性分析及活性肽制备工艺优化. 食品工业科技. 2024(10): 187-197 .  本站查看

本站查看

2. 张薇,李爱琳,李书国. 超声辅助酶解制备大米蛋白黄嘌呤氧化酶活性抑制肽的工艺条件优化. 中国粮油学报. 2024(06): 51-58 .  百度学术

百度学术

3. 梁劲杰,赵艺,褚辉程,郭嵩然,陈海英,张文静,陈祖君,王灵芝. 薏苡仁谷蛋白胃肠模拟消化及工艺优化. 中南药学. 2024(09): 2307-2313 .  百度学术

百度学术

4. 张嫚,张国治,张康逸,何梦影. 超声辅助酶解法制备小麦ACE抑制肽及其稳定性研究. 轻工学报. 2024(05): 29-39 .  百度学术

百度学术

5. 卢蔼纯,苏嘉毅,杨迅,冉佳鑫,郭俊斌,唐德剑,祁蒙,夏曾润,梁兴唐,尹艳镇,曹庸,苗建银. 富硒核桃粕蛋白降血压肽的酶解制备及硒含量分析. 现代食品科技. 2023(02): 161-169 .  百度学术

百度学术

6. 叶灏铎,管晓盛,马凤,毛远辉,孙世利,曹庸,苗建银. 英红九号茶蛋白降尿酸肽的酶解制备及不同分子量组分的活性对比. 现代食品科技. 2023(03): 147-155 .  百度学术

百度学术

7. 汪文青,廖涛,熊光权,王炬光,邱亮,白婵,王雅. 超声辅助复合酶法提取小龙虾虾壳蛋白及其性质研究. 食品安全质量检测学报. 2023(11): 52-61 .  百度学术

百度学术

8. 马凤,叶灏铎,夏珍,徐燕,孙世利,曹庸,苗建银. 英红九号茶蛋白ACE抑制肽的制备、氨基酸组成及不同超滤组分的活性评价. 现代食品科技. 2023(07): 237-245 .  百度学术

百度学术

9. 卢忠魁,张璐璐,张雷. 油莎豆粕小分子肽的制备、鉴定及功能分析. 食品安全质量检测学报. 2023(22): 305-312 .  百度学术

百度学术

10. 代成,谭梓铭,张阳,李璐,李雁,解新安. 超声波预处理酶解制备茶渣蛋白ACE抑制肽及其活性分析. 食品工业科技. 2022(16): 192-200 .  本站查看

本站查看

其他类型引用(8)

下载:

下载:

下载:

下载: