Optimization of Enzymatic Hydrolysis of Chicken Skeleton and Chicken Breast Composite Substrate and Flavor Properties of Hydrolysates

-

摘要: 为了提升鸡骨架和鸡胸肉复合底物酶解产物的风味,利用生物酶解技术对鸡骨架和鸡胸肉复合底物进行酶解,通过单因素实验与正交试验优化了酶解工艺,并分析了酶解物中的游离氨基酸含量及肽分子量分布情况。结果表明:复合蛋白酶与风味蛋白酶以3:1复配比同步酶解时风味最佳,最佳酶解条件是:鸡骨架与鸡胸肉比例9:1,料液比1:2 g/mL,温度50 ℃,pH7.5,酶添加量0.6%,酶解时间3 h。该条件下水解度达13.60%,感官评分4.7,制得的酶解物具有突出的鲜味和肉香味,呈味效果良好。随着酶解时间的延长,产物中游离氨基酸总量和小分子肽含量不断增加。最优工艺条件下,酶解产物中苦味氨基酸含量为2.74 mg/mL,占总游离氨基酸的71.73%,是主要的氨基酸;相对分子质量小于3 kDa的肽含量为93.26%。该研究结果为低值鸡骨架的综合开发和应用提供了参考。Abstract: In order to enhance the flavor of hydrolysate from the mixture of chicken skeleton and chicken breast, the hydrolysis of chicken skeleton and chicken breast composite substrate was carried out by biological enzymatic hydrolysis technology. The enzymatic hydrolysis process was optimized by single factor experiment and orthogonal experiment. Furthermore, the free amino acid content and molecular weight distribution of peptide in hydrolysates were analyzed. The results pointed out that the flavor of hydrolysate was better using simultaneous hydrolysis with protamex and flavourzyme by the ratio of 3:1. The optimal enzymolysis conditions were as follows: Ratio of chicken skeleton to chicken breast 9:1, solid-liquid ratio 1:2 g/mL, temperature 50 ℃, pH7.5, enzyme dosage 0.6%, and hydrolysis time 3 h. Under these conditions, the hydrolysate had a prominent umami taste, obvious meat flavor and good taste, with hydrolysis degree and sensory score of 13.60% and 4.7, respectively. With the prolongation of enzymatic hydrolysis time, the content of total free amino acids and peptides with low molecular weight increased continuously. Under the optimal process conditions, the content of bitter amino acids in the hydrolysate was 2.74 mg/mL, accounting for 71.73% of the total free amino acids, which were the main amino acids, and the content of peptides with molecular weight less than 3 kDa was 93.26%. The results provide a reference for the comprehensive development and application of low-value chicken skeleton.

-

我国作为鸡肉生产大国,2020年鸡肉产量达到了1865.6万吨,2021年上半年,鸡肉产量同比增长10.8%[1]。鸡骨是鸡肉加工过程中的副产物,蛋白质含量达16.3%,为畜禽骨肉蛋白质之最[2]。此外,鸡骨架中鲜味氨基酸(18.37%)和含硫氨基酸(1.22%)含量较高,是生产鸡肉风味基料的理想原料[3]。目前,鸡骨主要作为宠物饲料或直接被丢弃,利用率低。如何将鸡骨进行深加工,提高产品附加值,对于低值禽骨的开发具有重要意义。

蛋白在蛋白酶的作用下被水解成小肽或氨基酸的过程称作蛋白的酶解[4]。酶解主要有反应条件温和、专一性强、安全性高以及能耗低等优点,已成为食品加工领域中提高蛋白质价值的有效方法[5-6]。肉类蛋白经酶解后可生成大量游离氨基酸和小肽,其组成和含量变化显著影响酶解液的呈味特点。杨波等[7]研究发现,随着酶解时间的延长,脱脂蚕蛹蛋白酶解物中苦味氨基酸含量不断增加,一些苦味氨基酸有增强酶解液呈味复杂性的作用;多数鲜味氨基酸以肽的形式存在于酶解液,更加有利于产生鲜味肽。这些经酶解后产生的呈味肽和呈味氨基酸等,可用于制备呈味基料[8]。目前研究者多以鸡肉或鸡骨架单一底物酶解制备调味基料。张永生等[9]利用复合蛋白酶和胰蛋白酶同步酶解(酶配比1:1)鸡胸肉,制得的酶解液苦味轻柔,有浓郁鸡肉味和鲜味。赵永珍等[10]以鸡骨为原料,采用风味蛋白酶与复合蛋白酶2:1酶解制备的产物总体风味较好。以鸡肉为底物得到的产品香味浓郁,但是成本较高;而酶解鸡骨架生产呈味基料,成本相对低,但风味较淡[11]。因此,针对酶解单一底物存在的弊端,研究一种以鸡胸肉和鸡骨架为复合底物酶解制备呈味基料的工艺,在实现提升产品风味的同时可以降低生产成本。

本研究采用鸡骨架和鸡胸肉作为复合底物,选用不同的蛋白酶进行酶解,通过考察水解度和酶解产物感官评价,确定复配酶的最佳酶解工艺条件,并分析了酶解产物中的游离氨基酸及肽分子量分布变化规律,为风味浓郁、安全营养的调味品研发提供理论基础。

1. 材料与方法

1.1 材料与仪器

新鲜鸡骨架、鸡胸肉 购于农贸市场;木瓜蛋白酶(Papain,8×105 U/g)、菠萝蛋白酶(Bromelain,6×105 U/g)、碱性蛋白酶(Alcalase,2×105 U/g) 北京Solarbio公司;中性蛋白酶(Neutrase,0.8 AU/g)、复合蛋白酶(Protamex,1.6 AU/g)、风味蛋白酶(Flavourzyme,500 LAPU/g) 丹麦诺维信公司;水合茚三酮 上海麦克林生化科技有限公司;细胞色素C(Mw=12384 Da)、抑肽酶(Mw=6511 Da,3 TIU/mg)、杆菌肽(Mw=1422 Da)、乙氨酸-乙氨酸-酪氨酸-精氨酸(Mw=451 Da)、乙氨酸-乙氨酸-乙氨酸(Mw=189 Da) 美国Sigma公司;其他试剂均为国产分析纯。

SP36S搅拌机 浙江绍兴苏泊尔生活电器有限公司;PHS-3E pH计 上海仪电科学仪器股份有限公司;HSHZ-B水浴摇床 上海跃进医疗器械有限公司;TDL-5-A离心机 上海安亭科学仪器厂;722s可见分光光度计 上海仪电分析仪器有限公司;Waters 2695高效液相色谱仪 美国Waters公司;S-433(D)氨基酸分析仪 德国Sykam。

1.2 实验方法

1.2.1 样品前处理

新鲜的鸡骨架、鸡胸肉清洗干净,去除鸡骨架表面的鸡皮、鸡油以及附着的鸡肉等。将鸡骨架与鸡胸肉按一定比例混合,放入杀菌锅中130 ℃蒸煮60 min,然后放入搅拌机进行粉碎,即为鸡肉糜。

1.2.2 酶解工艺

将鸡肉糜与蒸馏水按1:2 g/mL比例均匀混合,调节至每种酶适宜的温度及pH,添加0.2%蛋白酶(以鸡肉糜质量计)酶解3 h;灭酶(90 ℃,15 min);冷却后调节pH至中性,取部分酶解液离心20 min,转速为4000 r/min;收集上清液测定水解度,剩余的冷冻干燥用于感官评价。

1.2.3 单一酶的筛选

选取木瓜蛋白酶(pH6.5,50 ℃)、菠萝蛋白酶(pH6.5,50 ℃)、中性蛋白酶(pH7.0,50 ℃)、复合蛋白酶(pH8.0,50 ℃)、碱性蛋白酶(pH8.0,50 ℃)和风味蛋白酶(pH8.0,50 ℃),在各酶适宜的温度和pH条件下进行酶解,考察蛋白酶对水解度及酶解物感官评价的影响。

1.2.4 复配酶的筛选

根据单一酶筛选结果,选取产物风味较好的蛋白酶与其他五种蛋白酶分别复配(酶配比1:1),考察复配酶对水解度和酶解物感官特征的影响。

1.2.5 复配酶酶解单因素实验

1.2.5.1 底物比例

将鸡骨架:鸡胸肉按9:1、8:2、7:3、6:4、5:5的比例分别混合处理,固定料液比为1:2,添加0.2%酶配比为1:1的复合蛋白酶与风味蛋白酶进行酶解,在50 ℃、pH8.0条件下酶解3 h,通过考察酶解物水解度和整体风味,确定最佳底物比例。

1.2.5.2 酶配比

选择上述确定的底物比例,复合蛋白酶与风味蛋白酶配比分别为3:1、2:1、1:1、1:2、1:3,其他酶解条件保持不变,以水解度和整体风味为指标,选择最优酶配比。

1.2.5.3 料液比

选定最优底物比例和酶配比,在料液比1:1、1:2、1:3、1:4、1:5(g/mL)的条件下分别酶解3 h,根据测定酶解物水解度和整体风味结果,确定最佳料液比。

1.2.5.4 酶解温度

固定上述最佳底物比例、酶配比以及料液比,酶解温度选择45、50、55、60、65 ℃五种不同水平,其他酶解条件不变,根据酶解液水解度及所得酶解物风味评价结果,确定最佳酶解温度。

1.2.5.5 酶解pH

在其他酶解条件固定的情况下,选择pH为6.5、7.0、7.5、8.0、8.5分别进行酶解,根据酶解液水解度和酶解物风味结果,确定最佳酶解pH。

1.2.5.6 加酶量

选择上述最佳酶解条件,加酶量为0.2%、0.4%、0.6%、0.8%、1.0%,在其他酶解条件保持不变的情况下分别进行酶解,考察酶解物水解度和整体风味评分,确定最佳加酶量。

1.2.5.7 酶解时间

保持上述所选酶解条件不变,酶解时间选择1、2、3、4、5 h不同水平,通过考察酶解产物水解度和整体风味评分,确定最佳酶解时间。

1.2.6 复配酶正交试验设计

选取料液比、酶解温度、加酶量及酶解时间4个因素作为研究对象,以单因素实验结果为基础,设计L9(34)正交试验。水平及因素选取如表1所示。

表 1 复配酶酶解正交试验因素水平表Table 1. Factor level of orthogonal experiment of enzymatic hydrolysis of complex enzyme水平 因素 A 料液比

(g/mL)B 酶解温度

(℃)C 加酶量

(%)D 酶解时间

(h)1 1:1 45 0.4 2 2 1:2 50 0.6 3 3 1:3 55 0.8 4 1.2.7 水解度测定方法

利用茚三酮比色法[12]测定水解度。将酶解液稀释一定倍数后,吸取1 mL于25 mL比色管中,然后加入1 mL的pH8.0的磷酸盐缓冲液和1 mL的茚三酮混合均匀,沸水浴煮沸15 min,立即冷却至室温,定容至25 mL,摇匀,静置15 min后在波长570 nm处测定其吸光度值。按照公式(1)计算水解度。

水解度(%)=酶解后游离氮含量-酶解前游离氮含量样品总氮含量×100 (1) 1.2.8 感官评价方法

感官评价采用5分制评分法,由7个经感官评价培训的食品专业人员对鸡肉酶解物的滋味(包括鲜味、咸味、苦味、酸味、整体风味)及风味特征进行评价(表2)。标准品分别为0.25%味精、0.5%氯化钠、0.05%咖啡因、0.025%柠檬酸,滋味标准品记为5分。取1 g冻干后的酶解物,加入100 mL纯净水混合均匀,与4种标准品分别进行比较打分。取评分的平均值作为滋味评价结果。

表 2 酶解物滋味评分标准Table 2. Taste scoring criteria of enzymatic hydrolysates滋味 分数S 0≤S≤1 1<S≤2 2<S≤3 3<S≤4 4<S≤5 鲜味 略有 较弱 一般 偏重 很重 咸味 略有 较弱 一般 偏重 很重 苦味 略有 较弱 一般 偏重 很重 酸味 略有 较弱 一般 偏重 很重 整体风味 非常厌恶 较厌恶 一般 较喜欢 非常喜欢 1.2.9 游离氨基酸组成测定

首先,取400 μL酶解液与100 μL 10%磺基水杨酸混合均匀,在4 ℃条件下静置60 min;然后在14500 r/min转速下离心15 min,上层清液二次离心5 min,以pH为2.2的柠檬酸缓冲液1:50稀释上层清液,经0.22 μm过滤器过滤,转入进样瓶中通过氨基酸自动分析仪分析测定。

1.2.10 肽分子量分布分析

采用高效液相色谱仪(配2487紫外检测器和Empower工作站GPC软件)测定肽分子量分布[13]。样品制备:将100 mg样品用水溶解于10 mL容量瓶内,超声5 min后以10000 r/min转速离心5 min,进样前经0.22 μm滤膜过滤处理。色谱条件:色谱柱为TSKgel 2000 SWXL(300 mm×7.8 mm);流动相由乙腈/水/三氟乙酸40/60/0.1(v/v/v)组成;流速0.5 mL/min;柱温30 ℃,进样量10 μL。

1.3 数据处理

相同条件下,所有实验均重复3次,数据表示为平均值±标准偏差;统计分析利用SPSS进行(P<0.05);绘图采用Origin 2018。

2. 结果与分析

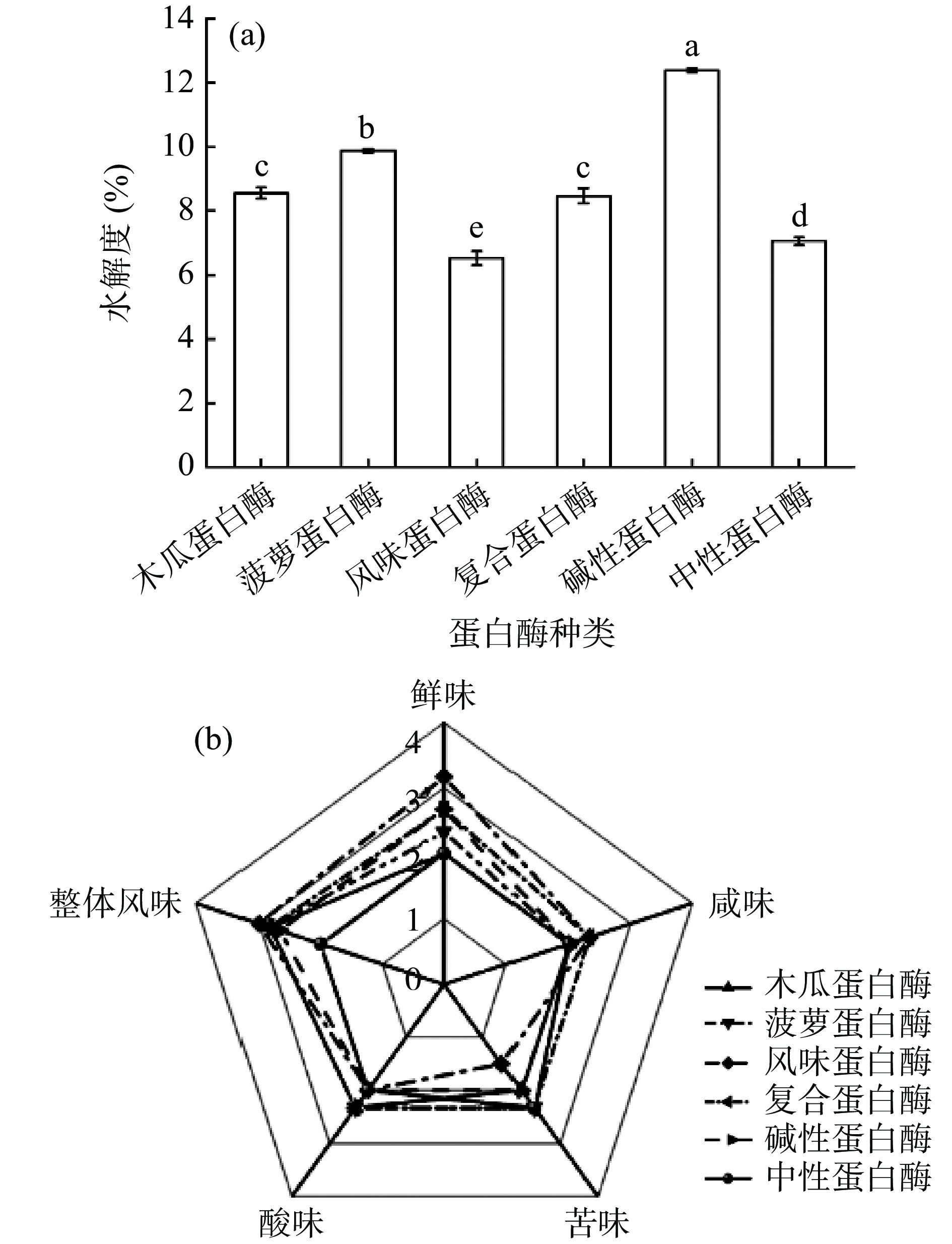

2.1 单一酶筛选

酶的特异性是影响水解产物特性的主要因素[14]。由图1(a)可知,碱性蛋白酶酶解后的水解度最高,达到12.39%,风味蛋白酶酶解后的水解度最低,为6.53%;由于风味酶是外切蛋白酶,只能酶解肽链的两端,酶切位点不足,故水解度较低[15]。结合图1(b)发现,使用碱性蛋白酶酶解制得的产物鲜味评分不高、有明显苦味,且腥味、碱味较重。而经风味蛋白酶酶解制备的酶解物鲜味评分最高,苦味较低。有研究表明,风味蛋白酶可以有效改善酶解液风味[16-17]。因此,选定风味蛋白酶与其他五种单酶进行复配酶解。

![]() 图 1 不同蛋白酶对水解度和感官评价的影响注:图中不同小写字母表示差异显著(P<0.05),图2同。Figure 1. Effects of different proteases on the degree of hydrolysis and sensory evaluation

图 1 不同蛋白酶对水解度和感官评价的影响注:图中不同小写字母表示差异显著(P<0.05),图2同。Figure 1. Effects of different proteases on the degree of hydrolysis and sensory evaluation2.2 复配酶筛选

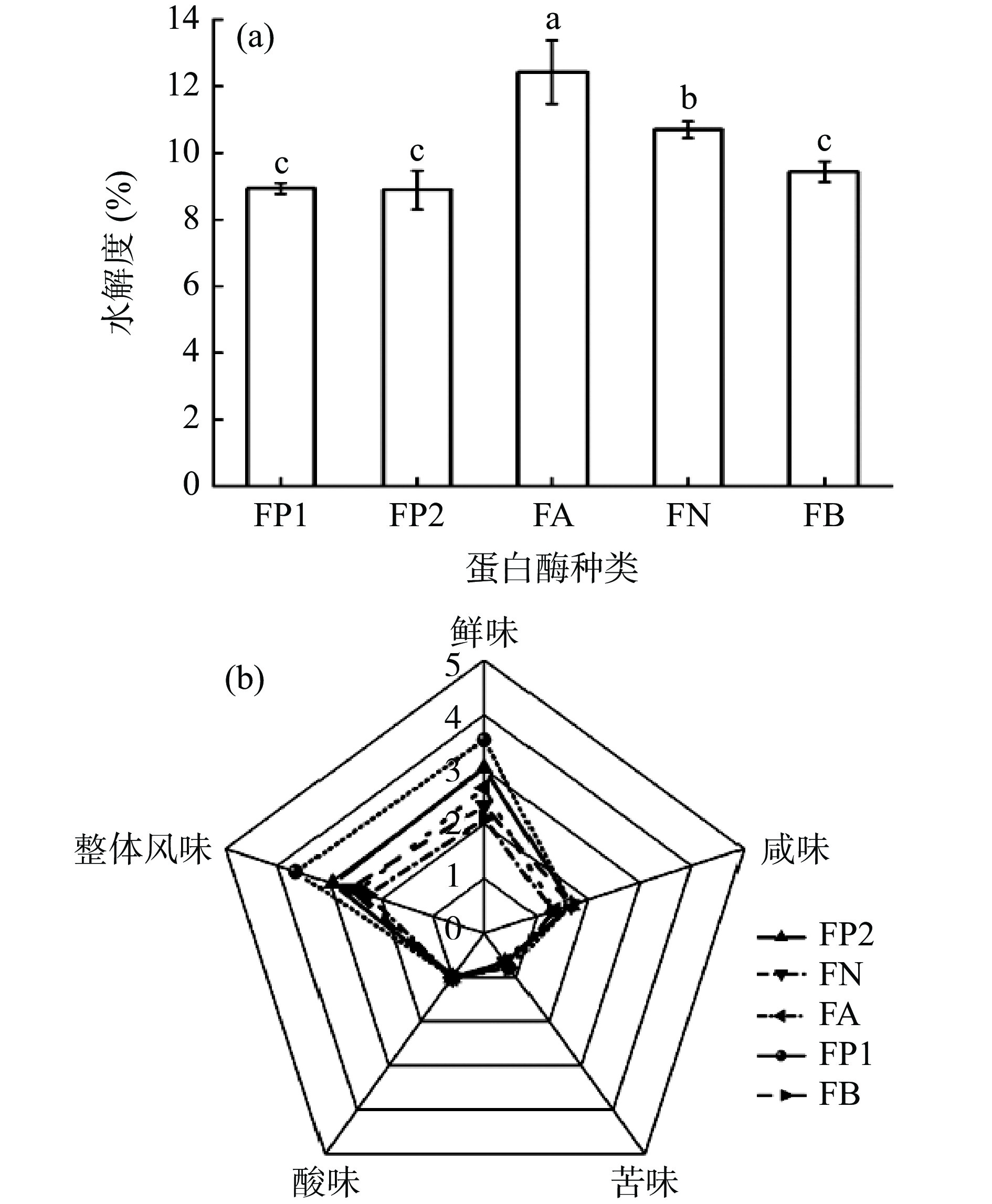

复配酶解包括分步酶解和同步酶解两种方式,多酶分步酶解一般较同步酶解的水解效果好,而多酶同步酶解工艺操作简单[18]。有研究发现,分步水解与同步水解对鸡骨酶解物影响并不显著[19],为了简化工艺,本文采用同步酶解工艺。由图2(a)可知,风味蛋白酶与碱性蛋白酶复配后酶解效果最佳,此时水解度为12.43%,风味蛋白酶与复合蛋白酶、木瓜蛋白酶、菠萝蛋白酶分别复配后水解度无明显差异,分别为8.93%、8.89%和9.43%。图2(b)显示,与其他复配酶相比,风味蛋白酶与复合蛋白酶复配酶解时,所得酶解产物鲜味和整体风味较突出,酸味、苦味不明显;且腥味较淡、肉香浓郁。邱燕翔等[20]发现,仅使用复合蛋白酶或风味蛋白酶单酶水解鸡肉时存在苦味重、鸡肉风味较淡或水解度不高等缺点,而复配酶可以有效提高水解度以及保持鸡肉风味。因此,选择风味蛋白酶与复合蛋白酶作为复配的两种蛋白酶。

2.3 复配酶酶解单因素实验

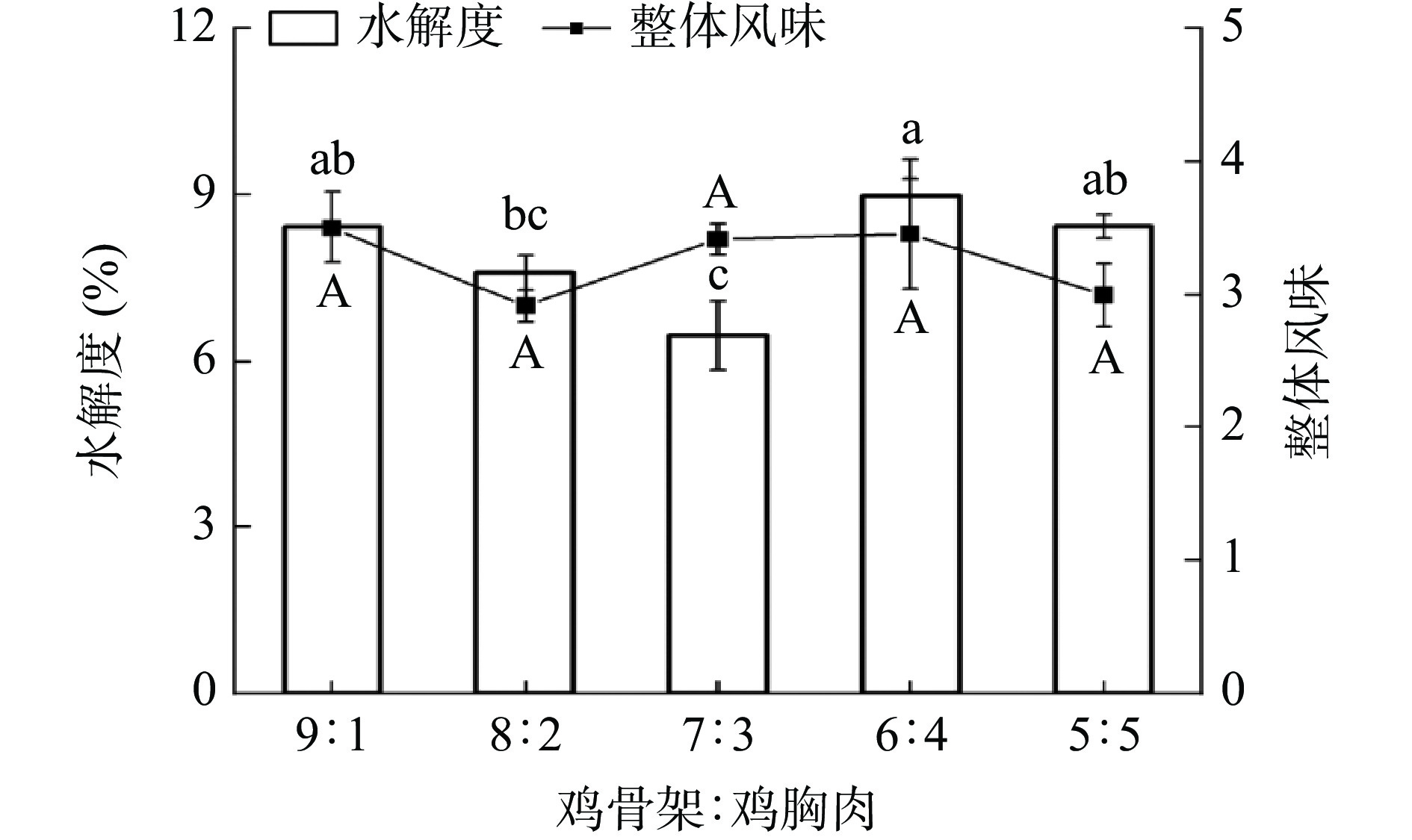

2.3.1 底物比例的确定

由图3可知,鸡骨架和鸡胸肉的比例为6:4、5:5和9:1时,酶解液水解度较高,水解度分别为8.98%、8.44%和8.42%,比例为7:3时制得酶解液水解度最低,为6.47%。在酶解液整体风味评分方面,五种比例底物的酶解液风味没有显著差异(P>0.05),综合考虑水解度和成本因素,故选择9:1的比例进行后续实验。

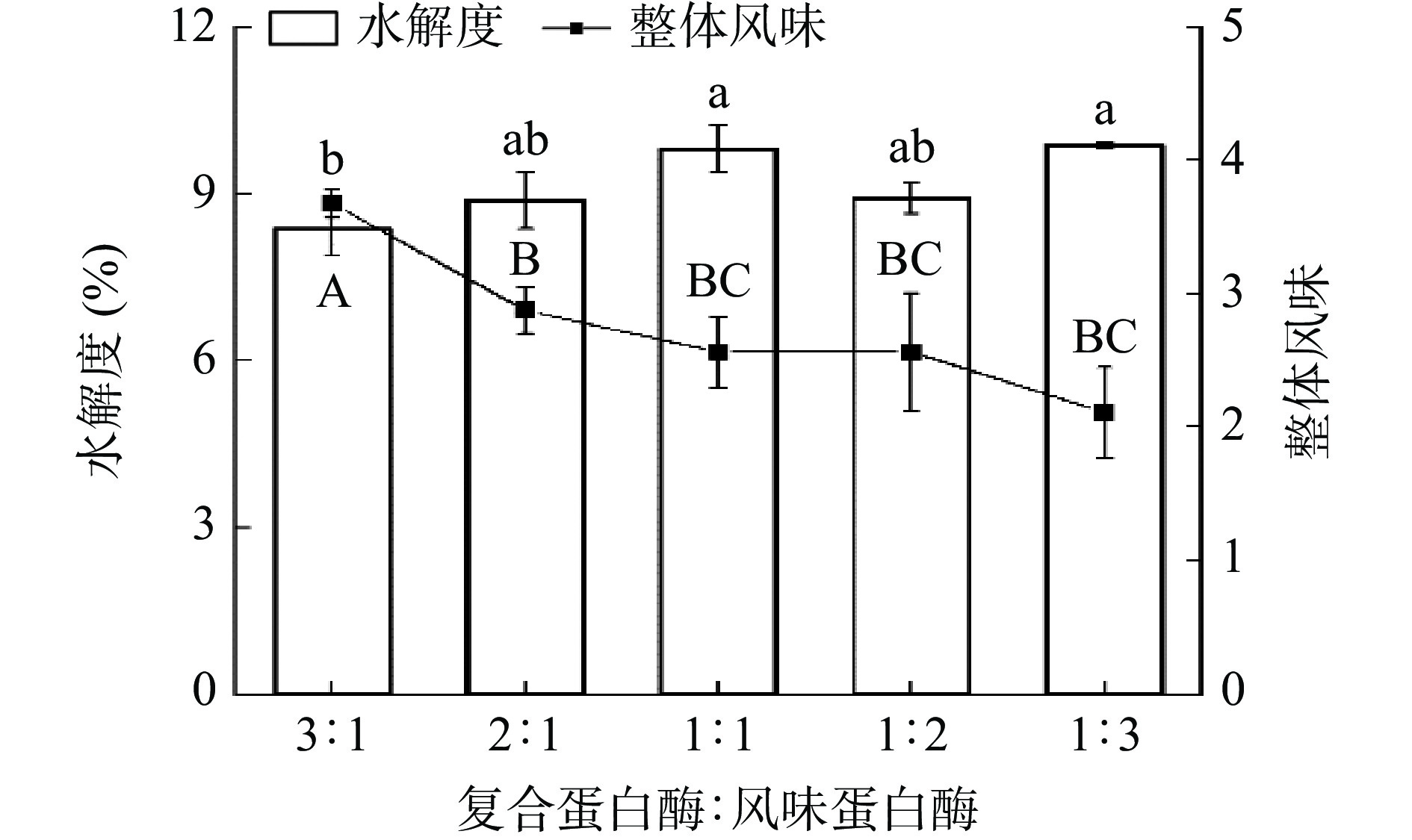

2.3.2 水解酶复配比例确定

由图4可知,随着风味蛋白酶添加量的增加,水解度先上升后下降,之后又有所上升。当复合蛋白酶与风味蛋白酶复配比为1:3时水解效果最佳,此时水解度为9.86%,这可能与两种酶不同的特异性有关。复合蛋白酶与风味蛋白酶复配比为3:1时酶解物整体评分最高,肉香味浓郁,故酶配比选择3:1。

2.3.3 料液比的选择

由图5可知,料液比1:1 g/mL时水解度最高为15.18%,料液比持续增加,水解度降低,1:5 g/mL时水解度最低,为3.72%。这说明当加酶量固定时,底物浓度不断减小,酶与底物接触几率降低,反应受限,水解度不断降低[21]。料液比1:2 g/mL时整体评分最高,所得产物有肉香味,而料液比为1:1 g/mL时虽然肉香味较浓,但有腥味,因此,选择料液比为1:1、1:2、1:3 g/mL进行优化实验。

2.3.4 酶解温度的选择

由图6可知,水解度首先随温度的上升而增加,在50 ℃时水解度最高,为9.47%,而后继续升高温度水解度又逐渐降低。其主要原因是在某一特定的温度区间,酶解效率随温度升高相应加快,但蛋白酶在较高温度下会变性,导致酶解效率降低[2]。整体风味评分随温度的升高先上升后降低,50 ℃时风味评分最高,肉香味厚重。因此,选择45、50、55 ℃进行优化实验。

2.3.5 酶解pH的确定

如图7所示,pH为7.0(10.96%)、7.5(11.17%)和8.0(10.56%)时水解度没有显著差异(P>0.05)。结合感官评分,pH7.5时,整体风味最高,肉香味浓厚,而pH为7.0和8.0时,酶解产物的肉香味较淡,且有腥味。因此,复合蛋白酶与风味蛋白酶复配作用的适宜pH为7.5。

2.3.6 加酶量的选择

由图8可知,复配酶总加酶量为0.6%时,水解度最大,为13.44%,继续加酶时水解度有所降低。可能是酶解过程是底物与酶的特异性结合过程,在料液比保持不变的情况下,随着加酶量的增加,酶解效率大幅度增加。同时,复配酶之间可能还存在相互作用,在加酶量少时,相互作用影响不明显,而加酶量大时,相互作用明显,可能造成酶活力降低[22]。加酶量为0.6%和0.8%时,整体风味评分较高,且产品肉香味浓郁。选取0.4%、0.6%、0.8%进行优化实验。

2.3.7 酶解时间的选择

由图9可知,水解度在酶解1~2 h过程中迅速增加,之后上升平缓,3 h时水解度为14.43%,时间延长,水解度增加不显著(P>0.05)。这可能是因为酶在与底物完全结合之后会随时间而趋于饱和,继续延长时间,酶解速率降低,水解度上升缓慢[23]。酶解时间3 h时,鲜味较突出,肉香味浓厚。酶解4 h和5 h制得的酶解物可能会有部分短肽类的苦味物质生成,导致整体风味下降。选择2、3、4 h进行后续优化实验。

2.4 酶解工艺的正交试验结果

如表3极差R结果可知,四因素对水解度的影响大小次序为:B>A>D>C,最佳水平组合取为A2B2C2D3;对感官效果的影响次序为:B>D>C>A,最佳水平组合为A2B2C3D2。由表4得知,四因素对水解度均有极显著的影响(P<0.01);对感官评分影响极显著的因素是酶解温度(P<0.01),加酶量等其余因素对感官评分均没有显著影响(P>0.05)。为了得到整体风味较高的酶解产物,考虑酶成本,最终的酶解工艺选为:料液比1:2 g/mL、酶解温度50 ℃、加酶量0.6%、酶解时间3 h。对该条件进行了验证性实验,所得酶解物水解度为13.60%,酶解产物肉香味突出,感官评分为4.7。

表 3 复配酶酶解正交试验结果Table 3. Orthogonal test results of compound enzyme enzymolysis试验号 A 料液比

(g/mL)B 酶解

温度(℃)C 加酶

量(%)D 酶解

时间(h)水解度(%) 整体风味 1 1:1 45 0.4 2 6.09±0.20 3.7±0.01 2 1:1 50 0.6 3 9.95±0.77 4.4±0.08 3 1:1 55 0.8 4 8.26±0.56 4.1±0.14 4 1:2 45 0.6 4 13.68±0.19 3.8±0.07 5 1:2 50 0.8 2 13.70±0.38 4.6±0.34 6 1:2 55 0.4 3 7.43±0.29 4.3±0.27 7 1:3 45 0.8 3 9.19±0.27 4.2±0.18 8 1:3 50 0.4 4 13.48±0.59 4.2±0.44 9 1:3 55 0.6 2 9.27±0.86 4.1±0.11 水解度k1 8.10 9.65 9.00 9.69 水解度k2 11.60 12.38 10.97 8.86 水解度k3 10.65 8.32 10.38 11.81 极差R 3.50 4.06 1.97 2.95 因素主次:B>A>D>C 感官评分k1 4.07 3.90 4.07 4.13 感官评分k2 4.23 4.40 4.10 4.30 感官评分k3 4.17 4.17 4.30 4.03 极差R 0.17 0.50 0.23 0.27 因素主次:B>D>C>A 表 4 水解度和感官评分试验结果方差分析Table 4. Analysis of variance of hydrolysis degree and sensory evaluation test results方差来源 自由度 离差平方和 均方 F值 显著性 水解度 感官评分 水解度 感官评分 水解度 感官评分 水解度 感官评分 料液比 2 39.413 0.084 19.707 0.042 74.589 1.087 <0.0001** 0.349 酶解温度 2 51.268 0.751 25.634 0.376 97.024 10.563 <0.0001** 0.004** 加酶量 2 12.202 0.191 6.101 0.096 23.093 2.687 0.0003** 0.122 酶解时间 2 27.730 0.218 13.865 0.109 52.478 3.063 <0.0001** 0.097 注:**表示差异极显著(P<0.01)。 2.5 不同水解时间游离氨基酸分析

氨基酸可以改善食品的口感[24]。其按照呈味特性可以划分为四种,即鲜味、甜味、苦味及无味氨基酸[25]。如表5所示,酶解0 h时,游离氨基酸总量为2.02 mg/mL,其中,鲜甜味氨基酸与苦味氨基酸含量分别为0.52 mg/mL和0.99 mg/mL,苦味氨基酸占总游离氨基酸的49.01%;最优工艺条件下,游离氨基酸总量增至3.82 mg/mL,鲜甜味氨基酸含量为0.61 mg/mL,苦味氨基酸含量为2.74 mg/mL,占总游离氨基酸的71.73%;酶解时间延长至5 h,产物中苦味氨基酸含量显著(P<0.05)增加,含量达3.44 mg/mL,占总游离氨基酸的73.19%,这可能是酶解5 h后产物产生苦味的原因。这与Kong等[26]研究结果相似,其指出苦味氨基酸是鸡肉酶解产物中的主要氨基酸,占游离氨基酸总量的一半以上。酶解液中还检测出了芳香族氨基酸苯丙氨酸,芳香族氨基酸是构成蛋白质、维持生命的基本物质,是人体不可或缺的成分[27]。由表5可知,酶解液中共检测出了8种必需氨基酸,总含量显著(P<0.05)高于酶解前,可以很好地补充身体需要的氨基酸,因此其具有很高的营养价值。

表 5 不同酶解时间产物的游离氨基酸含量Table 5. Contents of free amino acids in hydrolysates at different enzymolysis times滋味 氨基酸 含量(mg/mL) 0 h 1 h 3 h 5 h 鲜味 天冬氨酸 0.06±0.01c 0.09±0.00ab 0.08±0.01b 0.09±0.00a 谷氨酸 0.20±0.03a 0.18±0.01a 0.16±0.03a 0.20±0.02a 小计 0.26 0.27 0.24 0.29 甜味 苏氨酸* 0.05±0.00c 0.08±0.00b 0.09±0.01b 0.13±0.00a 丝氨酸 0.08±0.00c 0.09±0.01bc 0.11±0.02ab 0.13±0.00a 甘氨酸 0.05±0.00a 0.05±0.00a 0.05±0.01a 0.06±0.01a 丙氨酸 0.08±0.00c 0.08±0.00c 0.12±0.02b 0.15±0.00a 小计 0.26 0.30 0.37 0.47 苦味 缬氨酸* 0.08±0.00d 0.15±0.00c 0.20±0.03b 0.27±0.01a 甲硫氨酸* 0.11±0.01c 0.15±0.00b 0.15±0.01b 0.18±0.00a 异亮氨酸* 0.03±0.00c 0.16±0.00b 0.19±0.02b 0.25±0.01a 亮氨酸* 0.05±0.00d 0.42±0.01c 0.52±0.06b 0.66±0.00a 苯丙氨酸* / 0.15±0.02c 0.22±0.01b 0.28±0.01a 组氨酸 0.52±0.01d 0.94±0.00c 1.07±0.05b 1.22±0.04a 色氨酸* 0.03±0.00a 0.08±0.06a 0.03±0.00a 0.03±0.00a 赖氨酸* 0.07±0.00c 0.10±0.00c 0.14±0.02b 0.20±0.00a 精氨酸 0.10±0.01c 0.17±0.01b 0.22±0.03b 0.35±0.02a 小计 0.99 2.32 2.74 3.44 无味 半胱氨酸 0.51±0.02a 0.46±0.02a 0.47±0.01a 0.50±0.02a 总游离氨基酸 2.02 3.35 3.82 4.70 必需氨基酸 0.35 1.19 1.54 2.00 注:*表示必需氨基酸;“/”表示未检测到,同行不同小写字母表示不同酶解时间差异显著(P<0.05);表6同。 不同氨基酸的味觉阈值存在差异,尽管样品中一些风味物质含量偏低,但因为它们的阈值较低而对口感有很大的影响。常采用滋味活性值(Taste activity value,TAV)评估物质对样品呈味的贡献程度,其计算方法是样品测定浓度与其阈值之比[28]。TAV>1时,表明这种物质促进了样品整体滋味的改善,其值越大促进效果越好。相反,认为这种物质对于样品的呈味作用没有明显促进作用[29]。由表6可知,酶解3 h时,除谷氨酸和甘氨酸外的其余游离氨基酸TAV值明显增大。继续延长酶解时间,苦味氨基酸TAV值持续升高,5 h时的TAV值显著高于3 h的TAV值。在酶解前后检测出的16种氨基酸中组氨酸TAV值最高(TAV>1),并且随着时间的延长TAV值不断提高。其余呈味氨基酸TAV均小于1,说明组氨酸对酶解液呈味贡献较大。组氨酸是苦味氨基酸,可以增加呈味复杂性和提升鲜度[30]。研究表明,通常呈苦味的氨基酸不具备味觉活性,其苦味易被其他呈味氨基酸的味道掩盖,另外,芳香族氨基酸含量低于其阈值时,可以提高酶解液的鲜味和甜味[31]。

表 6 不同酶解时间酶解产物游离氨基酸的TAVTable 6. TAV of free amino acids of hydrolysates at different enzymolysis times氨基酸 阈值[26]

(mg/mL)滋味活性值TAV 0 h 1 h 3 h 5 h 天冬氨酸 1.0 0.06±0.01c 0.09±0.00ab 0.08±0.01b 0.09±0.00a 谷氨酸 0.3 0.67±0.10a 0.60±0.02a 0.55±0.11a 0.68±0.08a 苏氨酸* 2.6 0.02±0.00c 0.03±0.00b 0.04±0.00b 0.05±0.00a 丝氨酸 1.5 0.05±0.00c 0.06±0.01bc 0.07±0.01ab 0.08±0.00a 甘氨酸 1.3 0.04±0.00a 0.04±0.00a 0.04±0.01a 0.05±0.01a 丙氨酸 0.6 0.14±0.00c 0.14±0.01c 0.19±0.03b 0.25±0.01a 缬氨酸* 0.4 0.19±0.03d 0.37±0.00c 0.49±0.06b 0.68±0.02a 甲硫氨酸* 0.3 0.37±0.02c 0.51±0.02b 0.51±0.03b 0.59±0.01a 异亮氨酸* 0.9 0.03±0.00c 0.18±0.00b 0.22±0.03b 0.28±0.01a 亮氨酸* 1.9 0.02±0.00d 0.22±0.01c 0.27±0.03b 0.35±0.00a 苯丙氨酸* 0.9 / 0.17±0.03c 0.25±0.01b 0.31±0.01a 组氨酸 0.2 2.62±0.04d 4.68±0.00c 5.37±0.27b 6.11±0.21a 色氨酸* — — — — — 赖氨酸* 0.5 0.13±0.00d 0.20±0.01c 0.29±0.04b 0.40±0.00a 精氨酸 0.5 0.20±0.02c 0.34±0.03b 0.45±0.06b 0.70±0.05a 半胱氨酸 — — — — — 注:“—”表示文献中未查阅到。 2.6 不同水解时间肽分子量分布分析

酶解液的呈味特性与酶解液中含有的小分子肽有密切关系[32]。由表7可以看出,酶解前以大分子肽为主,分子量>10 kDa的多肽含量最高,为54.09%,分子量<3 kDa的肽含量为29.84%;肽分子量分布随酶解时间的延长整体上呈现分子量>5 kDa的多肽减少,分子量<3 kDa的肽含量逐渐增多的趋势。其中1~5 kDa的肽含量先增加后降低,这主要是因为随着酶解的进行,多肽被酶解成更小的肽和氨基酸,这与杨波等[7]研究结果相一致。最优工艺条件下,>10 kDa的肽含量仅为0.10%,而<3 kDa的肽占93.26%,其中<1 kDa的肽含量为69.36%。继续酶解至5 h,<1 kDa的肽含量增加至73.25%。酶解程度影响呈味肽的组成和含量,进而影响产物的整体风味。Chen等[33]研究发现风味肽的主要分子量分布小于3 kDa。鲜味肽通常为分子量小于1 kDa的小分子肽,相对分子量较小的肽作为肉的风味物质前体物易于产生更多的挥发性化合物[34]。

表 7 酶解产物的肽分子量分布Table 7. Peptide molecular weight distribution of enzymatic hydrolysis products时间(h) 分子量分布(%) >10 kDa 5~10 kDa 3~5 kDa 1~3 kDa <1 kDa 0 54.09 11.49 4.58 5.11 24.73 1 0.25 2.14 6.74 25.07 65.80 3 0.10 1.39 5.25 23.90 69.36 5 0.05 0.93 4.02 21.75 73.25 3. 结论

选用风味蛋白酶与复合蛋白酶酶解鸡骨架和鸡胸肉复合底物,通过正交试验优选出的最佳酶解工艺为:鸡骨架与鸡胸肉配比为9:1,料液比1:2 g/mL,温度50 ℃,pH7.5,酶添加量分别为复合蛋白酶0.45%和风味蛋白酶0.15%,酶解时间3 h。经验证得到的水解度为13.60%,酶解产物肉香味浓郁,鲜味突出,呈味效果好。此条件下,游离氨基酸中的苦味氨基酸含量较高,其中组氨酸的TAV值>1,是主要的呈味贡献氨基酸;酶解产物中<3 kDa的肽含量高于90%。本研究可为酶解鸡骨架与鸡胸肉复合底物制备呈味基料提供理论依据。酶解过程中,游离氨基酸、多肽、核苷酸、有机酸等组成和含量的变化共同作用导致了酶解液的呈味变化。后续将进一步研究鸡骨架与鸡胸肉复合酶解物中的其他呈味物质变化规律,分离鉴定其中的鲜味肽,解析风味形成机制,为鸡骨架在呈味基料开发中的应用提供参考。

-

图 1 不同蛋白酶对水解度和感官评价的影响

注:图中不同小写字母表示差异显著(P<0.05),图2同。

Figure 1. Effects of different proteases on the degree of hydrolysis and sensory evaluation

表 1 复配酶酶解正交试验因素水平表

Table 1 Factor level of orthogonal experiment of enzymatic hydrolysis of complex enzyme

水平 因素 A 料液比

(g/mL)B 酶解温度

(℃)C 加酶量

(%)D 酶解时间

(h)1 1:1 45 0.4 2 2 1:2 50 0.6 3 3 1:3 55 0.8 4 表 2 酶解物滋味评分标准

Table 2 Taste scoring criteria of enzymatic hydrolysates

滋味 分数S 0≤S≤1 1<S≤2 2<S≤3 3<S≤4 4<S≤5 鲜味 略有 较弱 一般 偏重 很重 咸味 略有 较弱 一般 偏重 很重 苦味 略有 较弱 一般 偏重 很重 酸味 略有 较弱 一般 偏重 很重 整体风味 非常厌恶 较厌恶 一般 较喜欢 非常喜欢 表 3 复配酶酶解正交试验结果

Table 3 Orthogonal test results of compound enzyme enzymolysis

试验号 A 料液比

(g/mL)B 酶解

温度(℃)C 加酶

量(%)D 酶解

时间(h)水解度(%) 整体风味 1 1:1 45 0.4 2 6.09±0.20 3.7±0.01 2 1:1 50 0.6 3 9.95±0.77 4.4±0.08 3 1:1 55 0.8 4 8.26±0.56 4.1±0.14 4 1:2 45 0.6 4 13.68±0.19 3.8±0.07 5 1:2 50 0.8 2 13.70±0.38 4.6±0.34 6 1:2 55 0.4 3 7.43±0.29 4.3±0.27 7 1:3 45 0.8 3 9.19±0.27 4.2±0.18 8 1:3 50 0.4 4 13.48±0.59 4.2±0.44 9 1:3 55 0.6 2 9.27±0.86 4.1±0.11 水解度k1 8.10 9.65 9.00 9.69 水解度k2 11.60 12.38 10.97 8.86 水解度k3 10.65 8.32 10.38 11.81 极差R 3.50 4.06 1.97 2.95 因素主次:B>A>D>C 感官评分k1 4.07 3.90 4.07 4.13 感官评分k2 4.23 4.40 4.10 4.30 感官评分k3 4.17 4.17 4.30 4.03 极差R 0.17 0.50 0.23 0.27 因素主次:B>D>C>A 表 4 水解度和感官评分试验结果方差分析

Table 4 Analysis of variance of hydrolysis degree and sensory evaluation test results

方差来源 自由度 离差平方和 均方 F值 显著性 水解度 感官评分 水解度 感官评分 水解度 感官评分 水解度 感官评分 料液比 2 39.413 0.084 19.707 0.042 74.589 1.087 <0.0001** 0.349 酶解温度 2 51.268 0.751 25.634 0.376 97.024 10.563 <0.0001** 0.004** 加酶量 2 12.202 0.191 6.101 0.096 23.093 2.687 0.0003** 0.122 酶解时间 2 27.730 0.218 13.865 0.109 52.478 3.063 <0.0001** 0.097 注:**表示差异极显著(P<0.01)。 表 5 不同酶解时间产物的游离氨基酸含量

Table 5 Contents of free amino acids in hydrolysates at different enzymolysis times

滋味 氨基酸 含量(mg/mL) 0 h 1 h 3 h 5 h 鲜味 天冬氨酸 0.06±0.01c 0.09±0.00ab 0.08±0.01b 0.09±0.00a 谷氨酸 0.20±0.03a 0.18±0.01a 0.16±0.03a 0.20±0.02a 小计 0.26 0.27 0.24 0.29 甜味 苏氨酸* 0.05±0.00c 0.08±0.00b 0.09±0.01b 0.13±0.00a 丝氨酸 0.08±0.00c 0.09±0.01bc 0.11±0.02ab 0.13±0.00a 甘氨酸 0.05±0.00a 0.05±0.00a 0.05±0.01a 0.06±0.01a 丙氨酸 0.08±0.00c 0.08±0.00c 0.12±0.02b 0.15±0.00a 小计 0.26 0.30 0.37 0.47 苦味 缬氨酸* 0.08±0.00d 0.15±0.00c 0.20±0.03b 0.27±0.01a 甲硫氨酸* 0.11±0.01c 0.15±0.00b 0.15±0.01b 0.18±0.00a 异亮氨酸* 0.03±0.00c 0.16±0.00b 0.19±0.02b 0.25±0.01a 亮氨酸* 0.05±0.00d 0.42±0.01c 0.52±0.06b 0.66±0.00a 苯丙氨酸* / 0.15±0.02c 0.22±0.01b 0.28±0.01a 组氨酸 0.52±0.01d 0.94±0.00c 1.07±0.05b 1.22±0.04a 色氨酸* 0.03±0.00a 0.08±0.06a 0.03±0.00a 0.03±0.00a 赖氨酸* 0.07±0.00c 0.10±0.00c 0.14±0.02b 0.20±0.00a 精氨酸 0.10±0.01c 0.17±0.01b 0.22±0.03b 0.35±0.02a 小计 0.99 2.32 2.74 3.44 无味 半胱氨酸 0.51±0.02a 0.46±0.02a 0.47±0.01a 0.50±0.02a 总游离氨基酸 2.02 3.35 3.82 4.70 必需氨基酸 0.35 1.19 1.54 2.00 注:*表示必需氨基酸;“/”表示未检测到,同行不同小写字母表示不同酶解时间差异显著(P<0.05);表6同。 表 6 不同酶解时间酶解产物游离氨基酸的TAV

Table 6 TAV of free amino acids of hydrolysates at different enzymolysis times

氨基酸 阈值[26]

(mg/mL)滋味活性值TAV 0 h 1 h 3 h 5 h 天冬氨酸 1.0 0.06±0.01c 0.09±0.00ab 0.08±0.01b 0.09±0.00a 谷氨酸 0.3 0.67±0.10a 0.60±0.02a 0.55±0.11a 0.68±0.08a 苏氨酸* 2.6 0.02±0.00c 0.03±0.00b 0.04±0.00b 0.05±0.00a 丝氨酸 1.5 0.05±0.00c 0.06±0.01bc 0.07±0.01ab 0.08±0.00a 甘氨酸 1.3 0.04±0.00a 0.04±0.00a 0.04±0.01a 0.05±0.01a 丙氨酸 0.6 0.14±0.00c 0.14±0.01c 0.19±0.03b 0.25±0.01a 缬氨酸* 0.4 0.19±0.03d 0.37±0.00c 0.49±0.06b 0.68±0.02a 甲硫氨酸* 0.3 0.37±0.02c 0.51±0.02b 0.51±0.03b 0.59±0.01a 异亮氨酸* 0.9 0.03±0.00c 0.18±0.00b 0.22±0.03b 0.28±0.01a 亮氨酸* 1.9 0.02±0.00d 0.22±0.01c 0.27±0.03b 0.35±0.00a 苯丙氨酸* 0.9 / 0.17±0.03c 0.25±0.01b 0.31±0.01a 组氨酸 0.2 2.62±0.04d 4.68±0.00c 5.37±0.27b 6.11±0.21a 色氨酸* — — — — — 赖氨酸* 0.5 0.13±0.00d 0.20±0.01c 0.29±0.04b 0.40±0.00a 精氨酸 0.5 0.20±0.02c 0.34±0.03b 0.45±0.06b 0.70±0.05a 半胱氨酸 — — — — — 注:“—”表示文献中未查阅到。 表 7 酶解产物的肽分子量分布

Table 7 Peptide molecular weight distribution of enzymatic hydrolysis products

时间(h) 分子量分布(%) >10 kDa 5~10 kDa 3~5 kDa 1~3 kDa <1 kDa 0 54.09 11.49 4.58 5.11 24.73 1 0.25 2.14 6.74 25.07 65.80 3 0.10 1.39 5.25 23.90 69.36 5 0.05 0.93 4.02 21.75 73.25 -

[1] 郑麦青, 何洋, 孙志华, 等. 2021年上半年肉鸡生产形势分析及后市展望[J]. 中国畜牧业,2021(14):45. [ZHENG M Q, HE Y, SUN Z H, et al. Analysis of broiler production situation and outlook for the first half of 2021[J]. Chinese Journal of Animal Science,2021(14):45. doi: 10.3969/j.issn.2095-2473.2021.14.022 ZHENG M Q, HE Y, SUN Z H, et al. Analysis of broiler production situation and outlook for the first half of 2021[J]. Chinese Journal of Animal Science, 2021(14): 45. doi: 10.3969/j.issn.2095-2473.2021.14.022

[2] 李泽林, 王秋婷, 郭其洪, 等. 鸡骨液酶解工艺优化及其酶解前后风味物质分析[J]. 食品工业科技,2022,43(10):206−215. [LI Z L, WANG Q T, GUO Q H, et al. Optimization of enzymatic hydrolysis process of chicken bone homogenate and its flavor components analysis before and after enzymatic hydrolysis[J]. Science and Technology of Food Industry,2022,43(10):206−215. doi: 10.13386/j.issn1002-0306.2021080186 LI Z L, WANG Q T, GUO Q H, et al. Optimization of enzymatic hydrolysis process of chicken bone homogenate and its flavor components analysis before and after enzymatic hydrolysis[J]. Science and Technology of Food Industry, 2022, 43(10): 206-215. doi: 10.13386/j.issn1002-0306.2021080186

[3] 曹雁平. 我国禽畜骨综合加工利用的现状[J]. 粮油加工与食品机械,2001(9):6−8. [CAO Y P. Current situation of comprehensive processing and utilization of poultry and animal bone in my country[J]. Cereals and Oils Processing,2001(9):6−8. CAO Y P. Current situation of comprehensive processing and utilization of poultry and animal bone in my country[J]. Cereals and Oils Processing, 2001(9): 6-8.

[4] WANG K, ARNTFIELD S D. Effect of protein-flavour binding on flavour delivery and protein functional properties: A special emphasis on plant-based proteins[J]. Flavour and Fragrance Journal,2017,32(2):92−101. doi: 10.1002/ffj.3365

[5] MARCINIAK A, SUWAL S, NADERI N, et al. Enhancing enzymatic hydrolysis of food proteins and production of bioactive peptides using high hydrostatic pressure technology[J]. Trends in Food Science & Technology,2018,80:187−198.

[6] 王迪, 代蕾, 高彦祥. 蛋白质酶法改性研究进展[J]. 食品科学,2018,39(15):233−239. [WANG D, DAI L, GAO Y X. Progress in enzymatic modification of proteins[J]. Food Science,2018,39(15):233−239. doi: 10.7506/spkx1002-6630-201815034 WANG D, DAI L, GAO Y X. Progress in enzymatic modification of proteins[J]. Food Science, 2018, 39(15): 233-239. doi: 10.7506/spkx1002-6630-201815034

[7] 杨波, 刘小玲, 赵谋明. 酶解脱脂蚕蛹蛋白过程中鲜味规律研究[J]. 食品科学,2017,38(18):119−125. [YANG B, LIU X L, ZHAO M M. Variations in umami amino acids of defatted silkworm pupa protein during enzymatic hydrolysis[J]. Food Science,2017,38(18):119−125. doi: 10.7506/spkx1002-6630-201718019 YANG B, LIU X L, ZHAO M M. Variations in umami amino acids of defatted silkworm pupa protein during enzymatic hydrolysis[J]. Food Science, 2017, 38(18): 119-125. doi: 10.7506/spkx1002-6630-201718019

[8] FU Y, ZHANG Y, SOLADOYE O P, et al. Maillard reaction products derived from food protein-derived peptides: Insights into flavor and bioactivity[J]. Critical Reviews in Food Science and Nutrition,2020,60(20):3429−3442. doi: 10.1080/10408398.2019.1691500

[9] 张永生, 靳慧慧, 江方, 等. 酶解工艺对炖煮风味鸡肉香精特征香味的影响[J]. 食品研究与开发,2017,38(15):68−75. [ZHANG Y S, JIN H H, JIANG F, et al. Effects of enzymatic hydrolysis on the taste characteristic of boiled chicken flavor[J]. Food Research and Development,2017,38(15):68−75. doi: 10.3969/j.issn.1005-6521.2017.15.015 ZHANG Y S, JIN H H, JIANG F, et al. Effects of enzymatic hydrolysis on the taste characteristic of boiled chicken flavor[J]. Food Research and Development, 2017, 38(15): 68-75. doi: 10.3969/j.issn.1005-6521.2017.15.015

[10] 赵永珍, 张慜, 陈志雄. 酶解鸡骨架制备热反应底物的研究[J]. 食品与生物技术学报,2013,32(1):56−61. [ZHAO Y Z, ZHANG M, CHEN Z X. Study on enzymatic hydrolysis of chicken bone as substrate of Maillard reaction[J]. Journal of Food Science and Biotechnology,2013,32(1):56−61. doi: 10.3969/j.issn.1673-1689.2013.01.009 ZHAO Y Z, ZHANG M, CHEN Z X. Study on enzymatic hydrolysis of chicken bone as substrate of maillard reaction[J]. Journal of Food Science and Biotechnology, 2013, 32(1): 56-61. doi: 10.3969/j.issn.1673-1689.2013.01.009

[11] 孙丽霞, 陈穗, 王聪, 等. 鸡脯肉和鸡骨架制备鸡精原料的最佳工艺条件研究[J]. 安徽农业科学,2016,44(14):114−117. [SUN L X, CHEN S, WANG C, et al. Study on the optimum technology of chicken essence-producing with chicken meat and skeleton[J]. Journal of Anhui Agricultural Sciences,2016,44(14):114−117. doi: 10.3969/j.issn.0517-6611.2016.14.039 SUN L X, CHEN S, WANG C, et al. Study on the optimum technology of chicken essence-producing with chicken meat and skeleton[J]. Journal of Anhui Agricultural Sciences, 2016, 44(14): 114-117. doi: 10.3969/j.issn.0517-6611.2016.14.039

[12] 宿小杰, 王珊珊, 崔青曼, 等. 不同蛋白酶对红鳍笛鲷鱼排酶解液风味影响[J]. 食品研究与开发,2021,42(21):29−35. [SU X J, WANG S S, CUI Q M, et al. Effect of different proteases on the flavor of enzymatic hydrolysate of crimson snapper frame[J]. Food Research and Development,2021,42(21):29−35. doi: 10.12161/j.issn.1005-6521.2021.21.005 SU X J, WANG S S, CUI Q M, et al. Effect of different proteases on the flavor of enzymatic hydrolysate of crimson snapper frame[J]. Food Research and Development, 2021, 42(21): 29-35. doi: 10.12161/j.issn.1005-6521.2021.21.005

[13] HUANG M, LIU P, SONG S, et al. Contribution of sulfur-containing compounds to the colour-inhibiting effect and improved antioxidant activity of Maillard reaction products of soybean protein hydrolysates[J]. Journal of the Science of Food and Agriculture,2011,91(4):710−720. doi: 10.1002/jsfa.4240

[14] TAN X, QI L, FAN F, et al. Analysis of volatile compounds and nutritional properties of enzymatic hydrolysate of protein from cod bone[J]. Food Chemistry,2018,264:350−357. doi: 10.1016/j.foodchem.2018.05.034

[15] 陈海涛, 徐晓兰, 张宁, 等. 鸡肉酶解工艺对热反应鸡肉香精香气的影响[J]. 食品科学,2013,34(9):150−154. [CHEN H T, XU X L, ZHANG N, et al. Optimal chicken enzymatic hydrolysate for the preparation of chicken flavoring[J]. Food Science,2013,34(9):150−154. doi: 10.7506/spkx1002-6630-201309031 CHEN H T, XU X L, ZHANG N, et al. Optimal chicken enzymatic hydrolysate for the preparation of chicken flavoring[J]. Food Science, 2013, 34(9): 150-154. doi: 10.7506/spkx1002-6630-201309031

[16] CHIANG J H, LOVEDAY S M, HARDACRE A K, et al. Effects of enzymatic hydrolysis treatments on the physicochemical properties of beef bone extract using endo- and exoproteases[J]. International Journal of Food Science and Technology,2019,54(1):111−120. doi: 10.1111/ijfs.13911

[17] 姜淼, 李欣怡, 宋志远, 等. 酶法联合Plastein反应制备海参肠调味料[J]. 中国调味品,2020,45(4):107−114. [JIANG M, LI X Y, SONG Z Y, et al. Preparation of sea cucumber intestinal seasoning by enzymatic hydrolysis coupled with Plastein reaction[J]. China Condiment,2020,45(4):107−114. doi: 10.3969/j.issn.1000-9973.2020.04.023 JIANG M, LI X Y, SONG Z Y, et al. Preparation of sea cucumber intestinal seasoning by enzymatic hydrolysis coupled with Plastein reaction[J]. China Condiment, 2020, 45(4): 107-114. doi: 10.3969/j.issn.1000-9973.2020.04.023

[18] 肖雪, 钱明莉, 范江平, 等. 鸡肉酶解工艺及其产物功效研究进展[J]. 食品工业科技,2021,42(14):394−400. [XIAO X, QIAN M L, FAN J P, et al. Research progress of enzymatic hydrolysis of chicken and the efficacy of its products[J]. Science and Technology of Food Industry,2021,42(14):394−400. doi: 10.13386/j.issn1002-0306.2020070239 XIAO X, QIAN M L, FAN J P, et al. Research progress of enzymatic hydrolysis of chicken and the efficacy of its products[J]. Science and Technology of Food Industry, 2021, 42(14): 394-400. doi: 10.13386/j.issn1002-0306.2020070239

[19] 丁小燕, 张雯, 倪莉, 等. 双酶水解鸡骨泥的工艺优化[J]. 食品与机械,2018,34(1):205−208. [DING X Y, ZHANG W, NI L, et al. The study on the enzymatic hydrolysis process on chicken bone paste with double enzyme combination[J]. Food & Machinery,2018,34(1):205−208. doi: 10.13652/j.issn.1003-5788.2018.01.041 DING X Y, ZHANG W, NI L, et al. The study on the enzymatic hydrolysis process on chicken bone paste with double enzyme combination[J]. Food & Machinery, 2018, 34(1): 205-208. doi: 10.13652/j.issn.1003-5788.2018.01.041

[20] 邱燕翔, 陆志鸿, 许守庆, 等. 鸡肉蛋白酶解工艺及水解产物成分研究[J]. 食品科技,2017,42(3):284−287. [QIU Y X, LU Z H, XU S Q, et al. Optimum technical conditions of chicken hydrolysis and composition of hydrolysate[J]. Food Science and Technology,2017,42(3):284−287. doi: 10.13684/j.cnki.spkj.2017.03.055 QIU Y X, LU Z H, XU S Q, et al. Optimum technical conditions of chicken hydrolysis and composition of hydrolysate[J]. Food Science and Technology, 2017, 42(3): 284-287. doi: 10.13684/j.cnki.spkj.2017.03.055

[21] 安攀宇, 赵珊, 张淼, 等. 响应面法优化鸡胸肉蛋白酶解工艺[J]. 肉类研究,2018,32(11):22−29. [AN P Y, ZHAO S, ZHANG M, et al. Optimization of enzymatic hydrolysis of chicken breast proteins by response surface methodology[J]. Meat Research,2018,32(11):22−29. AN P Y, ZHAO S, ZHANG M, et al. Optimization of enzymatic hydrolysis of chicken breast proteins by response surface methodology[J]. Meat Research, 2018, 32(11): 22-29.

[22] 张庆春, 余晓婉, 相兴伟, 等. 复配酶法制备南极磷虾鲜味酶解液的工艺优化[J]. 食品工业科技,2022,43(2):195−205. [ZHANG Q C, YU X W, XIANG X W, et al. Optimization of preparation process of antarctic krill hydrolysate with delicate taste by compound enzyme method[J]. Science and Technology of Food Industry,2022,43(2):195−205. doi: 10.13386/j.issn1002-0306.2021040293 ZHANG Q C, YU X W, XIANG X W, et al. Optimization of preparation process of antarctic krill hydrolysate with delicate taste by compound enzyme method[J]. Science and Technology of Food Industry, 2022, 43(2): 195-205. doi: 10.13386/j.issn1002-0306.2021040293

[23] 侯钰柯, 陆逸峰, 蒋宇飞, 等. 肉杂鸡鸡骨架酶解工艺优化及其分析评价[J]. 食品工业科技,2022,43(9):232−242. [HOU Y K, LU Y F, JIANG Y F, et al. Optimization and evaluation of enzymatic hydrolysis process of hybrid broilers skeleton[J]. Science and Technology of Food Industry,2022,43(9):232−242. doi: 10.13386/j.issn1002-0306.2021100097 HOU Y K, LU Y F, JIANG Y F, et al. Optimization and evaluation of enzymatic hydrolysis process of hybrid broilers skeleton[J]. Science and Technology of Food Industry, 2022, 43(9): 232-242. doi: 10.13386/j.issn1002-0306.2021100097

[24] SUN H, LIU F, SUN L, et al. Proteomic analysis of amino acid metabolism differences between wild and cultivated Panax ginseng[J]. Journal of Ginseng Research,2016,40(2):113−120. doi: 10.1016/j.jgr.2015.06.001

[25] ZHENG J Y, TAO N P, GONG J, et al. Comparison of non-volatile taste-active compounds between the cooked meats of pre- and post-spawning Yangtze Coilia ectenes[J]. Fisheries Science,2015,81(3):559−568. doi: 10.1007/s12562-015-0858-7

[26] KONG Y, YANG X, DING Q, et al. Comparison of non-volatile umami components in chicken soup and chicken enzymatic hydrolysate[J]. Food Research International,2017,102:559−566. doi: 10.1016/j.foodres.2017.09.038

[27] 王均胜, 韩小琴, 朱燕舞, 等. 氢化可的松与芳香族氨基酸作用的荧光光谱研究[J]. 合肥工业大学学报(自然科学版),2018,41(2):245−249, 272. [WANG J S, HAN X Q, ZHU Y W, et al. Study of interaction of hydrocortisone with haromatic amino acids by fluorescence spectroscopy[J]. Journal of Hefei University of Technology (Natural Science),2018,41(2):245−249, 272. doi: 10.3969/j.issn.1003-5060.2018.02.020 WANG J S, HAN X Q, ZHU Y W, et al. Study of interaction of hydrocortisone with haromatic amino acids by fluorescence spectroscopy[J]. Journal of Hefei University of Technology(Natural Science), 2018, 41(2): 245-249, 272. doi: 10.3969/j.issn.1003-5060.2018.02.020

[28] QI J, LIU D Y, ZHOU G H, et al. Characteristic flavor of traditional soup made by stewing Chinese yellow-feather chickens[J]. Journal of Food Science,2017,82(9):2031−2040. doi: 10.1111/1750-3841.13801

[29] 徐永霞, 曲诗瑶, 李涛, 等. 不同蛋白酶对蓝蛤酶解液风味特性的影响[J]. 食品科学,2021,42(4):190−196. [XU Y X, QU S Y, LI T, et al. Effects of different proteases on the flavor characteristics of aloididae aloidi hydrolysates[J]. Food Science,2021,42(4):190−196. doi: 10.7506/spkx1002-6630-20190823-248 XU Y X, QU S Y, LI T, et al. Effects of different proteases on the flavor characteristics of aloididae aloidi hydrolysates[J]. Food Science, 2021, 42(4): 190-196. doi: 10.7506/spkx1002-6630-20190823-248

[30] 孙颖, 张莉莉, 张玉玉, 等. 3种酶解液中游离氨基酸的分析[J]. 精细化工,2018,35(6):1004−1008, 1014. [SUN Y, ZAHNG L L, ZHANG Y Y, et al. Analysis of free amino acids in three kinds of enzymatic hydrolysates[J]. Fine Chemicals,2018,35(6):1004−1008, 1014. doi: 10.13550/j.jxhg.20170581 SUN Y, ZAHNG L L, ZHANG Y Y, et al. Analysis of free amino acids in three kinds of enzymatic hydrolysates[J]. Fine Chemicals, 2018, 35(6): 1004-1008, 1014. doi: 10.13550/j.jxhg.20170581

[31] CHEN D W, ZHANG M. Non-volatile taste active compounds in the meat of Chinese mitten crab (Eriocheir sinensis)[J]. Food Chemistry,2007,104(3):1200−1205. doi: 10.1016/j.foodchem.2007.01.042

[32] OGASAWARA M, KATSUMATA T, EGI M. Taste properties of Maillard-reaction products prepared from 1000 to 5000 Da peptide[J]. Food Chemistry,2006,99(3):600−604. doi: 10.1016/j.foodchem.2005.08.040

[33] CHEN M, GAO X, PAN D, et al. Taste characteristics and umami mechanism of novel umami peptides and umami-enhancing peptides isolated from the hydrolysates of Sanhuang chicken[J]. European Food Research and Technology,2021,247(7):1633−1644. doi: 10.1007/s00217-021-03734-w

[34] 刘希, 谭志辉, 朱立才, 等. 食品中鲜味肽和浓厚味肽的研究进展[J]. 广东化工,2020,47(8):91−93. [LIU X, TAN Z H, ZHU L C, et al. Research progress of umami and kokumi peptides in food[J]. Guangdong Chemical Industry,2020,47(8):91−93. doi: 10.3969/j.issn.1007-1865.2020.08.041 LIU X, TAN Z H, ZHU L C, et al. Research progress of umami and kokumi peptides in food[J]. Guangdong Chemical Industry, 2020, 47(8): 91-93. doi: 10.3969/j.issn.1007-1865.2020.08.041

-

期刊类型引用(15)

1. 刘荣倩,杨申明,李新会,王振吉,彭润,解健翠. 百香果壳总三萜提取工艺优化及抗氧化性能评价. 饲料工业. 2025(01): 118-126 .  百度学术

百度学术

2. 景炳年,李宁洁,魏磊,谢晓阳,刘雨晴,王学方,王韬,王伟. 连翘三萜酸提取工艺优化及抗氧化活性研究. 中国食品添加剂. 2025(03): 64-74 .  百度学术

百度学术

3. 黄瑜,张锡宇,赵海桃,石统帅,邱隽蒙,符群. 沙棘叶提取物的体外抗氧化及乙酰胆碱酯酶抑制能力. 精细化工. 2024(02): 391-400 .  百度学术

百度学术

4. 温舒然,马占山,詹冬玲. 灵芝三萜提取工艺的优化. 吉林大学学报(理学版). 2024(02): 452-463 .  百度学术

百度学术

5. 岳洪霞,胡娜,隆海燕,王洪伦,栾广祥. 响应面法优化超声辅助提取蕨麻总三萜工艺研究. 中国野生植物资源. 2024(03): 28-33+66 .  百度学术

百度学术

6. 杨洪飞,卢雨菲,葛婷婷,王洁琼,陈祺,孟丽媛,要辉,闵清. 星点设计-效应面法优化超声提取桂籽中三萜化合物的工艺研究. 湖北科技学院学报(医学版). 2024(03): 214-220 .  百度学术

百度学术

7. 曹柏营,杨海蛟,侯宇,王家利,乔新宇,陈英伟,刘馨阳. 蓝靛果花青素抗氧化作用及机制. 食品研究与开发. 2024(19): 53-59 .  百度学术

百度学术

8. 张剑林,张亮亮,姜露熙,裴龙英,王寒博,孙博,梁睿武,房丹丹. 基于人工神经网络优化黑木耳红枣发酵乳及其抗氧化分析. 食品研究与开发. 2023(05): 141-147 .  百度学术

百度学术

9. 沈柯辰,宋亚茹,高琳,张仁堂. 红枣固态发酵黑化前后苯甲酸及农药残留含量比较分析. 食品研究与开发. 2023(05): 177-183 .  百度学术

百度学术

10. 刘树萍,陆家慧,张佳美,彭秀文,苏晓文,石长波. 奇亚籽胶提取工艺优化及其理化性质. 食品研究与开发. 2023(22): 53-60 .  百度学术

百度学术

11. 林瑞,杜秋旻,李永春,闫美霖,何家丽,苗晶囡,徐丹,邱军强. 黄药子中黄独乙素提取工艺研究. 吉林医药学院学报. 2022(02): 91-94 .  百度学术

百度学术

12. 李金金,孟琦,崔馨燕,石汝杰,吴应梅,杨玲,周浓. 响应面法优化地参三萜酸提取工艺及抗氧化活性分析. 南方农业学报. 2022(08): 2261-2271 .  百度学术

百度学术

13. 刘嘉鑫,陈小梅,曾慧,王淑美,向丽敏. 响应面法优化蒲桃籽中三萜类化合物的提取工艺及其抗氧化活性分析. 食品工业科技. 2022(23): 192-199 .  本站查看

本站查看

14. 周海旭,苏同超,李姝,冉军舰,李波,高晗,余梦薇,薛静丽,李婧瑜,李晓晴,李忠海. 樟叶木脂素的提取纯化及其抗氧化性、抗癌活性. 食品工业科技. 2021(13): 170-178 .  本站查看

本站查看

15. 王吉宇,李成文,徐彦靖,于青,刘楠,刘东春. 响应面法优化藏红花素碱水解制备反式藏红花酸工艺. 食品工业科技. 2021(23): 176-183 .  本站查看

本站查看

其他类型引用(9)

下载:

下载:

下载:

下载: