Effects of Salting Conditions on the Morphology and Composition of Cooked Salted Duck Eggs Yolk

-

摘要: 为探索咸鸭蛋腌制条件对熟制后蛋黄组织形态及组成的影响,以期减少熟制咸鸭蛋蛋黄中的硬芯含量,通过称量法、原子火焰吸收光谱分析、凯氏定氮法、差示量热扫描分析、红外光谱分析和扫描电子显微镜观察等方法对不同腌制浓度和时间下咸蛋黄不同部位理化性质以及生熟咸蛋黄微观结构的不同进行分析。结果表明,蛋黄硬芯从鸭蛋腌制的第2周出现,随着腌制时间延长,硬芯逐渐变大,腌制完成后占蛋黄总质量的33.64%~44.80%,水分含量约为21.47%~23.49%。硬芯的Na+含量在10.66~11.47 mg/g之间。腌制完成后,蛋黄外部的游离脂肪含量约为34.79%~36.34%,与外部相比,硬芯的游离脂肪含量更低,约为17.71%~27.90%,且随着腌制液盐浓度的上升而增加。腌制后蛋黄硬芯蛋白质含量上升至30%以上,高于外部。蛋黄经加热后,硬芯部分蛋黄微粒颗粒度较小,且形成间隙较小的连续结构。盐分渗透的先后顺序导致蛋黄中不同部位在组织结构和组成成分的差异,这些差异导致了熟制后蛋黄硬芯及外部的差别,且较高的腌制时间和浓度均会加剧硬芯的形成。在15%盐浓度条件下腌制4周后,得到的成熟咸蛋黄在熟制后硬芯含量较少,食用品质更好。本文分析了咸鸭蛋腌制条件对熟制蛋黄组成及组织形态的影响,对于提升咸鸭蛋蛋黄品质具有一定的指导意义。Abstract: In order to explore the effects of salting conditions on the morphology and composition of cooked salted duck egg yolk (SDEY), and reduce the content of hard core in the cooked SDEY, the physicochemical properties of different parts of salted egg yolk and the microstructure of raw and cooked salted egg yolk were analyzed through weighing, atomic flame absorption spectrometry, Kjeldahl method, differential scanning calorimetry (DSC), Fourier transform infrared spectroscopy (FTIR) and scanning electron microscope (SEM). The results revealed an appearance of the hard core of SDEY in the second week of the pickling process, which gradually increased with time. Specifically, the yolk hard core of the well-pickled salted duck egg accounted for 33.64%~44.80% of the total mass of the yolk and 21.47%~23.49% of the moisture content. The Na+ content of the hard core was 10.66~11.47 mg/g. Notably, the hard core of SDEY had lower free fat content, which was about 17.71%~27.90% compared with 34.79%~36.34% of the outer layer, while the free fat content of the hard core was positively correlated with the salt concentration of the pickling liquid. In addition, the protein content of the hard core of egg yolk increased to more than 30% after salted, which was higher than the outside. Moreover, it was found that the particle size of the yolk particles in the hard core was smaller after heating, which presented a continuous structure with smaller gaps. Thus, from the results, the order of salt penetration led to the differences in the structure and composition of different parts of salted egg yolk, which led to the differences in the hard core and the outside of the yolk after heating. Higher pickling time and salt concentration significantly aggravated the formation of the hard core. Therefore, using a concentration of 15% and pickling time for 4 week could make less hard core and better food quality. Hence, this study provides a guide to improving the quality of SDEY.

-

Keywords:

- salted egg yolk /

- hard core /

- protein /

- microstructure

-

咸鸭蛋是一种通过盐水、黄泥或草木灰等含盐腌料浸泡或包裹鸭蛋腌制而成的中国传统蛋品食物,具有悠久的历史[1]。熟制的咸蛋分为蛋白和蛋黄两个部分,其中蛋黄由于咸淡适中、颜色鲜艳、松沙可口、含油丰富,受到消费者的广泛欢迎。当鸭蛋处在高盐环境中时,外部环境中的盐分首先穿透蛋壳进入蛋清中,并随着蛋清中盐分浓度的增加最终透过蛋黄膜进入蛋黄。随着蛋黄内部盐分的增加,蛋白质发生变性并形成特定凝胶结构[2]。蛋黄中的水分从结合状态转变为自由状态并向盐分浓度更高的蛋清部分转移,随着蛋白质变性和水分散失,蛋黄的硬度和粘弹性上升,最终形成成熟的咸蛋黄[3-5]。作为我国最主要的加工蛋品之一,咸鸭蛋的腌制方法及机理已被学者广泛研究[6-9],但在目前的工业生产中,蛋黄仍然会出现硬芯、黑圈、沙质感不够、不出油等质量问题[10],其中尤以蛋黄硬芯问题最为常见,蛋黄硬芯是经过蒸煮后出现在咸蛋黄内部的硬块结构,其较外层蛋黄偏硬,颜色偏白,不留油,不起沙。由于其较差的口感,在蛋黄的二次加工中常常需要事先剔除,造成原料的浪费及人工成本的增加,因此对咸蛋黄硬芯变化规律及形成原因的研究是十分必要的。

腌制时间和腌制液浓度是咸蛋黄品质的重要影响因素,这些因素对蛋黄中硬芯的形成也具有影响,有研究表明,腌制时间与硬芯硬度呈正相关[11]。而王梦林[12]通过降低腌制液盐含量和添加白酒的方式缩小了硬芯的体积。上述研究的内容均为通过改变腌制条件改善硬芯问题,而并未对硬芯的各项理化性质和组织形态变化进行深入研究。本文将以腌制时间和腌制液浓度作为切入点,研究不同腌制条件对咸蛋黄不同部位水分、盐分、油脂和蛋白质含量等组成成分以及蛋白质二级结构和蛋黄微观结构等组织形态的影响,探索咸蛋黄中硬芯的变化规律,并通过优化蛋黄腌制时间和腌制液浓度改善咸蛋黄硬芯等问题,以降低咸蛋黄生产的次品率。

1. 材料与方法

1.1 材料与仪器

新鲜鸭蛋 广东省广州市天河区铁路市场;硝酸 分析纯,上海阿拉丁生化科技有限公司;过氧化氢、硫酸钾、硫酸 分析纯,广州化学试剂厂;石油醚、正己烷 分析纯,天津市富宇精细化工有限公司;异丙醇 分析纯,上海润捷化学试剂有限公司;硫酸铜 分析纯,天津市大茂化学试剂厂;5-5二硫代二硝基苯甲酸 分析纯,合肥巴斯夫生物科技有限公司。

Z-2000原子吸收光谱仪 日本日立公司;KDN812自动凯氏定氮仪 上海纤检仪器有限公司;Spectrumlab 752S紫外可见光分光光度计 上海棱光技术有限公司;200F3示差量热扫描仪(DSC) 德国NETZSCH公司;Nicolet IS50傅里叶变换红外光谱仪 美国Thermo Fisher科技有限公司;EM-30Plus超高分辨率台式扫描电子显微镜 韩国COXEM公司;ETHOS 1微波消解仪 意大利麦尔斯通公司。

1.2 实验方法

1.2.1 咸鸭蛋蛋黄的制备

采用水泡法腌制咸鸭蛋。取新鲜鸭蛋数枚,使用自来水洗净鸭蛋表面的泥土和排泄物残留,晾晒干。将鸭蛋放入洗净的陶罐中,参考刘蒙佳等[13]、龙门等[14]的研究,分别采用质量分数为15%、20%、25%的NaCl水溶液浸没鸭蛋,排出顶部空气后封口腌制。

1.2.2 蛋黄硬芯比重的测定

于腌制0~6周时每周取鸭蛋分离整个蛋黄并蒸制15 min作为熟蛋黄样品。取熟蛋黄样品称重后,用手轻搓蛋黄以分离外部松散部分,将剩下的蛋黄部分记为蛋黄硬芯,蛋黄硬芯比重计算公式为:

式中:X为硬芯质量占蛋黄总质量的比重,%;M1为熟蛋黄样品的总质量,g;M2为蛋黄硬芯的质量,g。

1.2.3 蛋黄盐分含量的测定

以钠离子(Na+)含量表示蛋黄中的盐分含量,参考GB 5009.91-2017食品安全国家标准 食品中钾、钠的测定中的原子火焰吸收法测定蛋黄中的钠含量[15]。于腌制0~6周时每周取0.2~0.5 g熟蛋黄样品于微波消解内罐中,加入4 mL硝酸、2 mL过氧化氢和2 mL超纯水,置于微波消解仪中进行消解。取出消解后样品于加热板过夜赶酸后,定容至25 mL,稀释10倍后使用原子吸收光谱仪检测蛋黄样品中的Na离子含量。蛋黄Na离子含量的计算公式为:

式中:X为测试样品中Na离子的含量,mg/g;C为测试样液中Na离子的含量,mg/L;V为定容试样的总体积25 mL;D为测试样品的稀释系数10;M为消化样品的质量,g。

1.2.4 蛋黄水分含量的测定

在腌制0~6周内每周取熟蛋黄样品,参照GB 5009.3-2016食品安全国家标准 食品中水分的测定中的第一法测定蛋黄中的水分[16]。

1.2.5 蛋黄游离脂肪含量的测定

以25 ℃时游离脂肪占全部脂肪的比例表示蛋黄的游离脂肪含量[17]。采用索氏抽提法检测蛋黄中总脂肪含量[18]。于腌制4周时取2 g熟蛋黄样品用滤纸包裹后装入内含石油醚的抽提筒中,70 ℃恒温水浴抽提过夜。风干后称取纸筒重量,抽提前后纸筒的重量差记为样品总脂肪含量。另取熟蛋黄样品5 g于25 mL蒸馏水中,在25 ℃条件下以5000 r/min速度离心30 min,用滴管吸出上层油脂加入分液漏斗中,并向分液漏斗中加入正己烷-异丙醇溶剂(V/V=3:2)振荡混匀。分离有机相倒入圆底烧瓶中,55 ℃旋转浓缩5 min后转移到105 ℃烘箱中烘至恒重。烘干后烧瓶的总质量和烧瓶本身质量之差记为游离脂肪质量。

游离脂肪含量的计算公式如下:

式中:X为试样的游离脂肪含量,%;M1为圆底烧瓶和游离脂肪的质量,g;M3为圆底烧瓶的质量,g;M2为油脂抽提前纸筒的质量,g;M4为抽提后纸筒的质量,g。

1.2.6 蛋黄蛋白质含量的测定

参考GB 5009.5-2016食品安全国家标准 食品中蛋白质的测定中的自动凯氏定氮法对蛋黄中的蛋白质含量进行检测[19]。于腌制0、4、8周时称取2 g生蛋黄样品加入消化管后,分别加入0.4 g硫酸铜、6 g硫酸钾和20 mL硫酸于消化炉中至管内仅剩蓝绿透明液体,取出后加入50 mL蒸馏水于自动凯氏定氮仪中进行自动滴定。蛋白质含量的计算公式如下:

式中:X为试样中蛋白质的含量,g/100 g;V1为试液消耗标准滴定液的体积,mL;V2为消化液的体积,mL;c为标准滴定溶液浓度,mol/L;M为样品的质量,g;F为蛋黄氮换算为蛋白质的系数6.12。

1.2.7 差示扫描量热(DSC)检测

参照Wang等[6]的方法进行DSC检测。将蛋黄样品水分含量调整至48%,于腌制0、4、8周时称取15 mg生蛋黄样品于坩埚中,以空白坩埚作为对照,按照5 ℃/min的升温速度在20~110 ℃区间内进行差示扫描量热,通过测量曲线峰出现的位置和峰面积的变化情况估算Tmax和变性焓(ΔH)。

1.2.8 巯基含量的检测

参照Beveridge等[20]的方法对巯基进行检测。称取20 mg 5’, 5’二硫代二硝基苯甲酸(DTNB)加入5 mL Tris-Gly缓冲液(将5.2 g Tris,3.45 g Gly和0.6 g DTNB溶于500 mL去离子水中,调节pH8.0)制作Ellman试剂。于腌制0、4、8周时称取1.0 g生蛋黄样品加入磷酸缓冲液(PBS,pH8.0)混匀定容至10 mL,加入Ellman试剂25 ℃避光反应30 min后检测412 nm下的吸光度。取10 mL PBS直接加入Ellman试剂中作为对照组。巯基含量的计算公式为:

式中:SH为试样中巯基的含量,mmol/g;A412为412 nm下的实验组和对照组吸光度的差值;D为样品稀释倍数10;C为蛋白质含量,mg/mL。

1.2.9 蛋白质二级结构的检测

采用傅立叶红外变换(FTIR)测定蛋白质二级结构[21]。将腌制0、4、8周后的蛋黄冻干后与KBr(光谱级)混合,制备片剂。使用FTIR在500~3500 cm−1波段内进行扫描。自动信号采集32次扫描,分辨率为4 cm−1。利用OMNIC 9.0数据采集软件程序(Thermo Scientific Nicolet iS5, USA)对光谱数据进行分析。使用PEAKFIT对酰胺I带(1600~1700 cm−1)进行分峰拟合后得到各蛋白质二级结构吸光度峰,定义各光谱所有综合峰的总面积为100%,单个峰面积表示为相应二级结构元素的比例(%)。

1.2.10 微观结构分析

参考Tang等[22]的方法,采用扫描电子显微镜(SEM)对蛋黄微观结构进行检测。取0.5 g蛋黄样品,用2.5%戊二醛固定2 h后放入蒸馏水中漂洗3次,每次15 min。分别采用质量分数为60%、70%、80%、90%、95%的乙醇溶液梯度处理漂洗过的样品,每次30 min。将处理完成的样品放入冻干机中过夜冻干。样品镀金后,使用SEM在低真空模式下观察蛋黄的微观结构,仪器的加速电压为10 kV,放大倍数为100~2000倍。

1.3 数据处理

每次试验重复三次,结果以平均值±标准差(

2. 结果与分析

2.1 蛋黄硬芯比重的变化

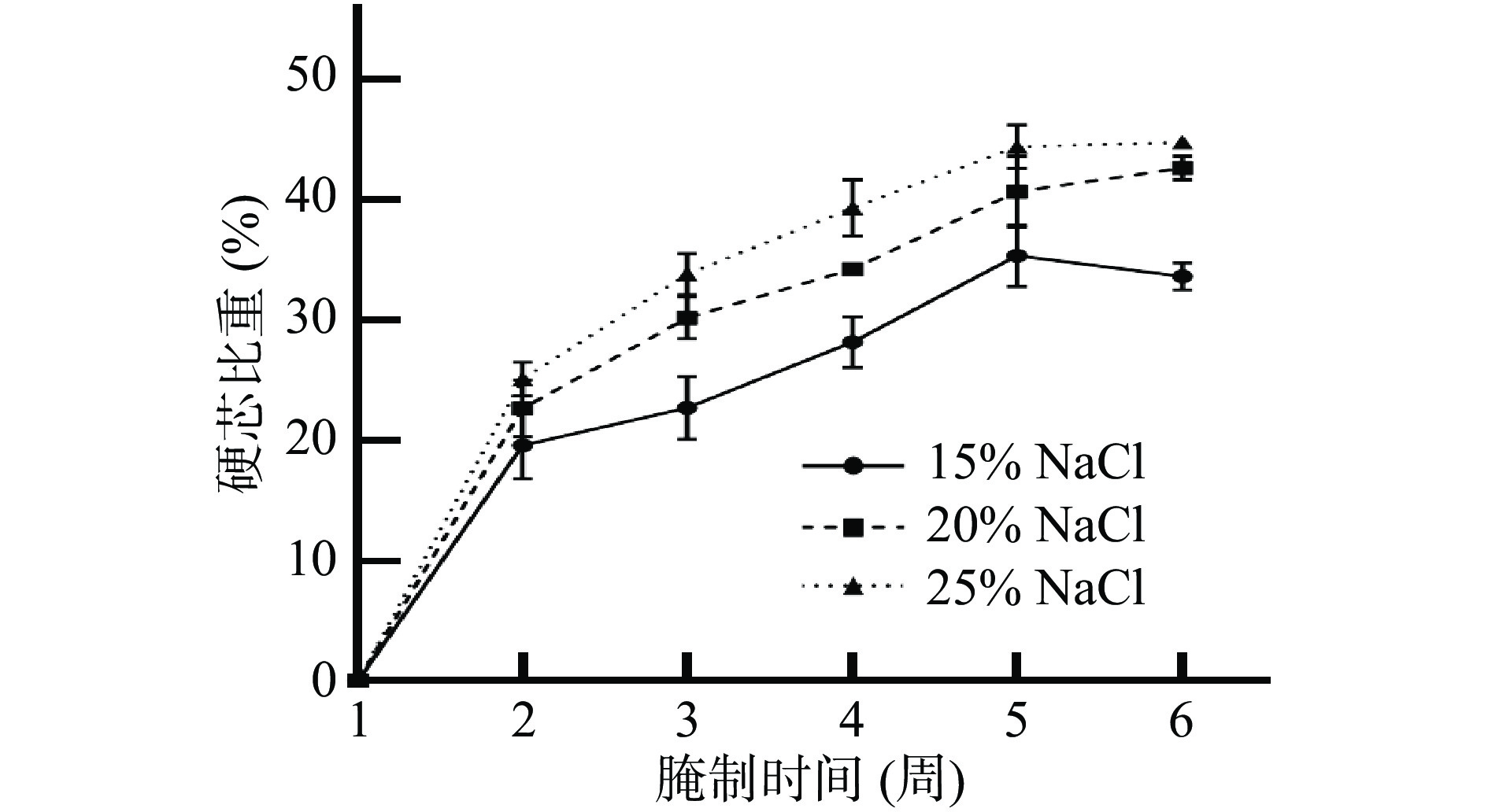

不同腌制浓度下蛋黄硬芯比重随时间变化如图1所示,各组蛋黄硬芯均在腌制的第2周出现,且随着腌制时间的延长,蛋黄硬芯的比重呈现上升趋势,至第5周质量增加幅度减缓或略有下降,腌制6周后,15%、20%、25% NaCl腌制下的硬芯比重分别为33.64%、42.61%和44.80%。15%腌制浓度腌制5周后可以得到硬芯比重相对较小的蛋黄。通过对不同盐浓度腌制下蛋黄硬芯质量分析发现腌制浓度越高,硬芯质量增长越快,比重越高,这可能是因为较高的腌制浓度可以促进NaCl更快渗入蛋黄内部,使蛋黄变性聚集的时间更长,形成更大的硬芯结构[23]。

2.2 蛋黄盐分含量的变化

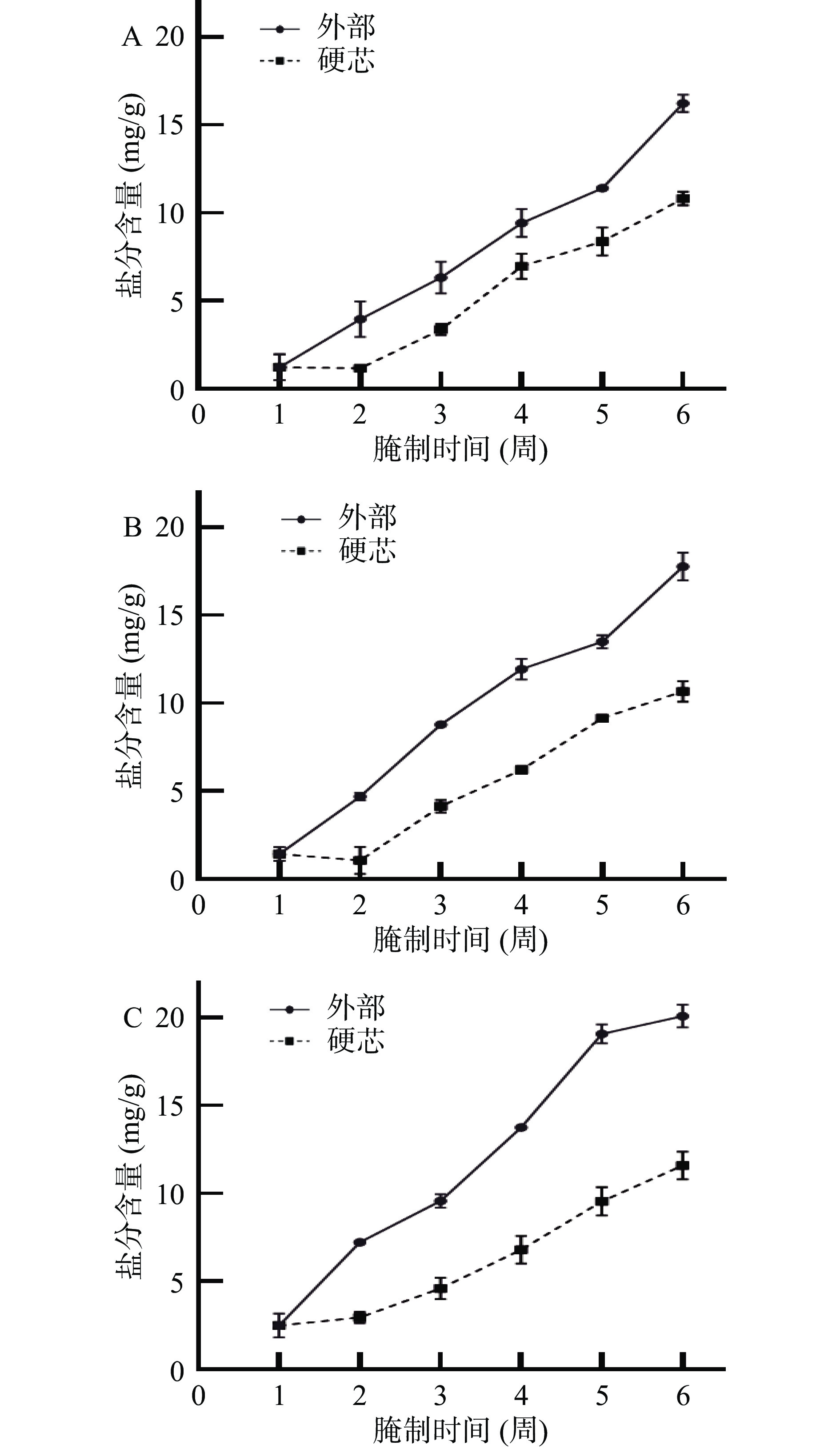

不同腌制浓度下蛋黄外部和硬芯部分钠含量变化如图2所示。钠元素在蛋黄中的主要存在方式为NaCl,因此可以通过Na+含量变化表征腌制过程中蛋黄的盐分含量。随着腌制时间的增加,蛋黄各部分Na+含量均增加,但蛋黄外部增加快于硬芯,且腌制液盐浓度越高,蛋黄中的Na+含量增长越快,蛋黄外部和硬芯部分差距越大。采用15%腌制浓度腌制的咸蛋黄不同部位盐浓度差距较小,咸度更为均一。蛋黄的腌制是一种盐分从外向内渗透蛋黄的过程,盐分含量的增长是腌制过程中蛋黄性质变化的主要诱因。在腌制过程中,相比于较低的腌制浓度,较高的腌制浓度可以更快增加蛋黄硬芯部分的含盐量,但最终硬芯部分的Na+含量均在10.66~11.47 mg/g之间,无显著差异(P>0.05)。这说明更高的腌制浓度确实可以促进盐分渗透进蛋黄,但在腌制过程中产生的游离脂肪阻止了盐分向蛋黄内部的渗透,这种阻碍可能是蛋黄硬芯形成的原因[24]。

![]() 图 2 不同腌制浓度下咸蛋黄盐分含量的变化注:A:15% NaCl;B:20% NaCl;C:25% NaCl;图3同。Figure 2. Changes of salt content in salted egg yolk in different curing concentrations

图 2 不同腌制浓度下咸蛋黄盐分含量的变化注:A:15% NaCl;B:20% NaCl;C:25% NaCl;图3同。Figure 2. Changes of salt content in salted egg yolk in different curing concentrations2.3 蛋黄水分含量的变化

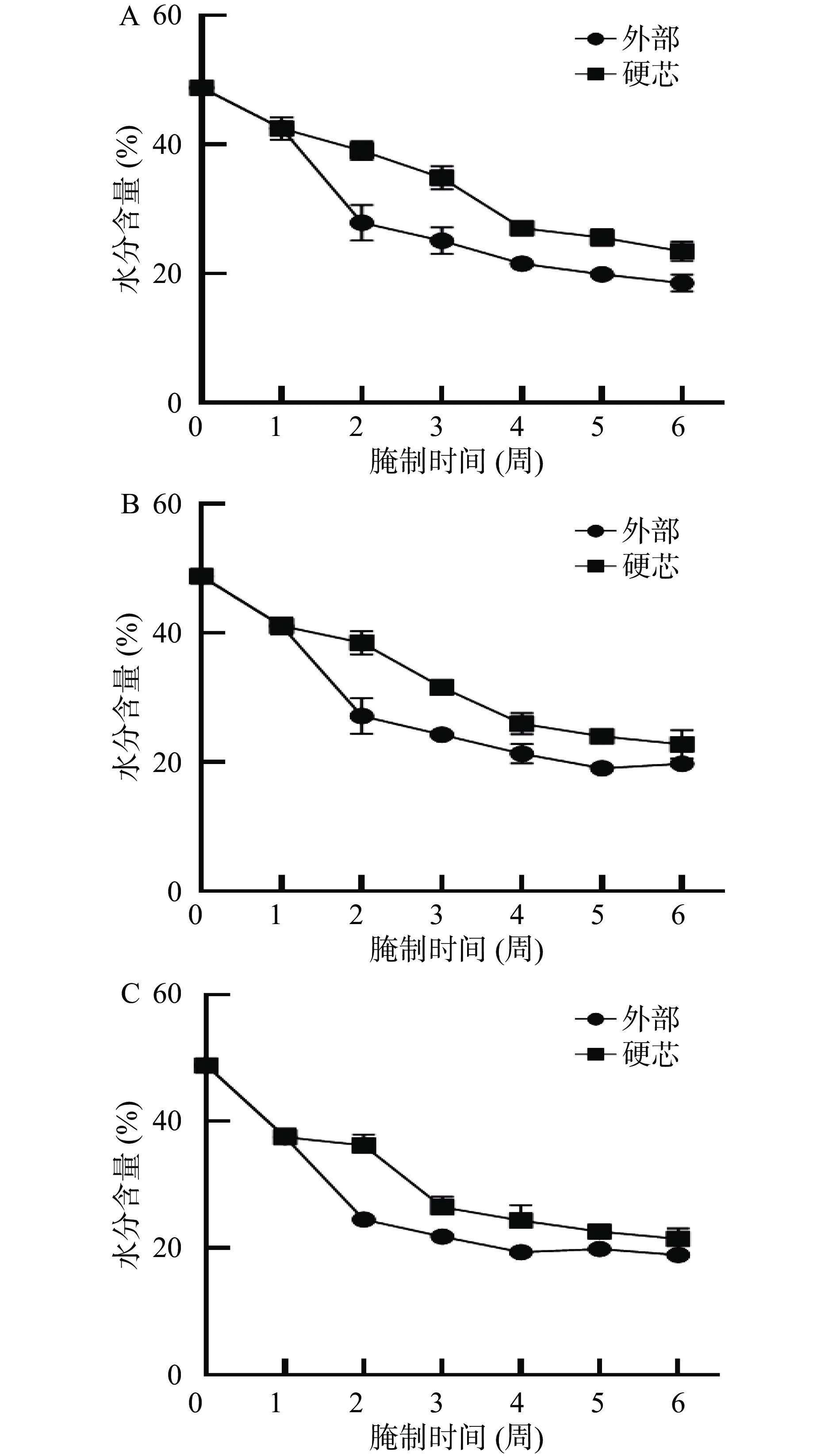

不同腌制浓度下蛋黄外部和硬芯部分水分含量变化如图3所示,新鲜鸭蛋黄的水分约为48.84%,随着腌制时间的增加,不同部位水分含量均呈先下降后平缓的趋势,最终外部含水量稳定在20%以下,硬芯含水量约为21.47%~23.49%。水分含量下降的速度与腌制浓度呈正相关,且同一腌制浓度下,相同腌制阶段的蛋黄硬芯部分水分含量高于外部。随着盐分渗透进蛋黄,不同部位盐分的差异导致蛋黄水分迁移,即蛋黄中的水分逐渐向盐分含量更高的蛋清中移动,这种水分的流失导致蛋黄口感由黏转沙。不同浓度条件下腌制4周后,咸蛋黄各部分的水分含量变化均趋于稳定,这说明腌制4周后,蛋黄腌制成熟,因此可以选取4周作为蛋黄的腌制时间。蛋黄腌制过程中盐分的渗透是由外向内的过程,这决定了蛋黄内部的水分减少慢于外部。随着腌制时间的增加,蛋黄水分含量变化减缓,外部蛋黄水分含量差距较小,与硬芯之间的差距随着腌制浓度的增加而减小,蛋黄内外部的水分不同在一定程度上导致了蛋黄硬芯部分与其他部分在口感上的差异。

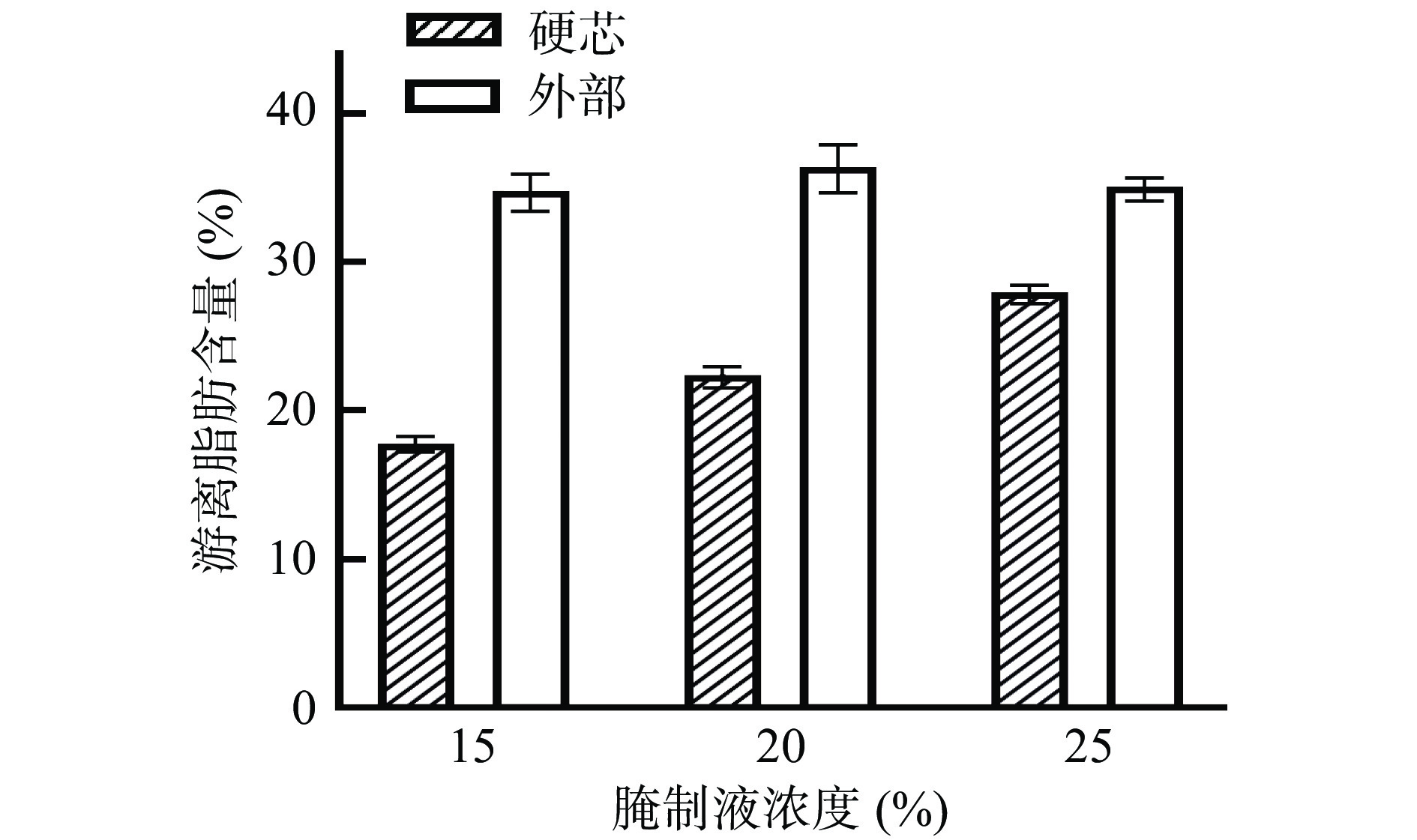

2.4 蛋黄游离脂肪含量

不同浓度盐水腌制4周后的蛋黄游离脂肪的含量如图4所示。在咸蛋黄的工业生产中,一般认为经过4周腌制的蛋黄为腌制成熟的蛋黄,在腌制成熟后,蛋黄的游离脂肪含量变化较小,因此可以根据此时游离脂肪的含量,对比得到不同部位游离脂肪含量受腌制影响的差异[18]。腌制成熟后,蛋黄外部的游离脂肪含量约为34.79%~36.34%,而蛋黄硬芯部分的游离脂肪含量随着腌制浓度的增加而升高,但与外部蛋黄仍具有一定差异。蛋黄中的脂质主要以低密度脂蛋白(LDL)和高密度脂蛋白(HDL)的形式存在,蛋黄腌制过程中分离出的脂质主要来自LDL[25-26]。蛋黄腌制成完成后,外部蛋黄中的LDL几乎全部被破坏并释放脂肪,因此不同腌制浓度下,外部蛋黄的游离脂肪含量并无显著差异(P>0.05)。腌制浓度对蛋黄出油的影响主要体现在蛋黄硬芯的部分,高腌制浓度促使盐分较快进入到蛋黄内部并促进硬芯中游离脂肪的产生,这在一定程度上导致高腌制浓度下的咸蛋黄出油量更多。蛋黄外部油脂的产生可能是导致盐分无法进入蛋黄内部的原因之一,NaCl作为一种无机盐几乎不溶于油脂,在腌制过程中产生的游离脂肪很可能阻碍了盐分进入蛋黄内部,最终导致盐分进入蛋黄内部的时间更长,含量更少,这一推断可以与上述实验中蛋黄不同部位含盐量的差异相互印证[24]。

2.5 蛋黄蛋白质含量与性质

2.5.1 蛋黄蛋白质含量变化

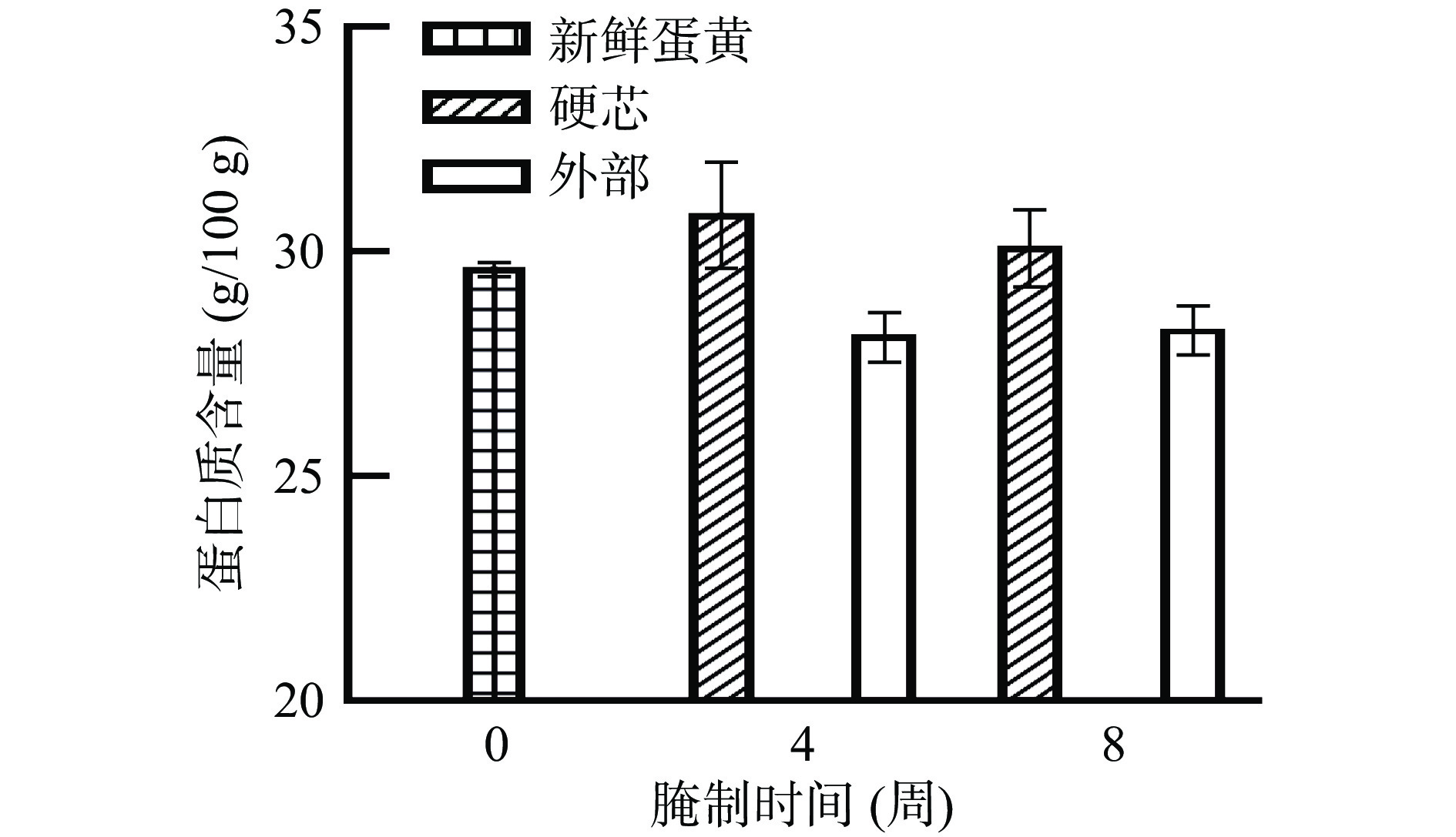

在腌制过程中,蛋白质变性是蛋黄性状发生改变的主要原因之一,因此对蛋黄中蛋白质变化的研究有助于理解蛋黄腌制过程中硬芯形成的原因。咸蛋黄的腌制是一个持续的过程,尽管大部分研究认为3~4周腌制的蛋黄具有较好的性质,但4周后蛋黄蛋白质的各项理化性质变化仍在进行[27-29]。在工业生产中往往采用4~8周的腌制时间[30]。因此,选取腌制0、4、8周的蛋黄样品用于比较和分析蛋黄在腌制过程中的变化较为合理。图5揭示了蛋黄硬芯部分和外部总蛋白含量的差异,新鲜蛋黄的总蛋白含量约为29.65%。腌制后硬芯部分的蛋白质含量上升而外部蛋白质含量相应下降,这说明蛋黄在腌制的过程中发生了蛋白质的迁移。

2.5.2 蛋黄DSC特征值变化

蛋黄不同部位的DSC结果显示(表1),腌制8周的蛋黄,外部和硬芯蛋白质的焓变值分别从−0.5592 w/g持续上升到了−0.3978 w/g和−0.4091 w/g,这说明了蛋白质腌制过程中发生不断变性。对比不同部位的转变温度发现,尽管不同部位的转变温度均有上升,但硬芯部分在腌制前期发生了更大幅度的变化。蛋黄中的蛋白质包括变性温度较小的LDL、变性温度较大的HDL和卵黄蛋白等,Tmax的增长可能是LDL的率先变性引起的,而在腌制4周时,蛋黄硬芯的Tmax发生了较为显著的变化,这说明硬芯部分具有较多的HDL和卵黄蛋白等变性温度更大的蛋白质,这与上述蛋白质迁移的结论一致。

表 1 腌制过程中蛋黄不同部位的DSC特征值Table 1. Characteristic values of DSC in different parts of egg yolk during curing蛋黄样品 腌制时间(周) DSC特征值 Tmax(℃) ΔH(w/g) 新鲜蛋黄 0 80.52±0.16 −0.5592±0.0012 蛋黄外部 4 80.77±0.13 −0.4200±0.0124 蛋黄硬芯 4 81.30±0.14 −0.4545±0.0014 蛋黄外部 8 81.75±0.07 −0.3978±0.0072 蛋黄硬芯 8 81.25±0.07 −0.4091±0.0233 2.5.3 蛋黄巯基含量变化

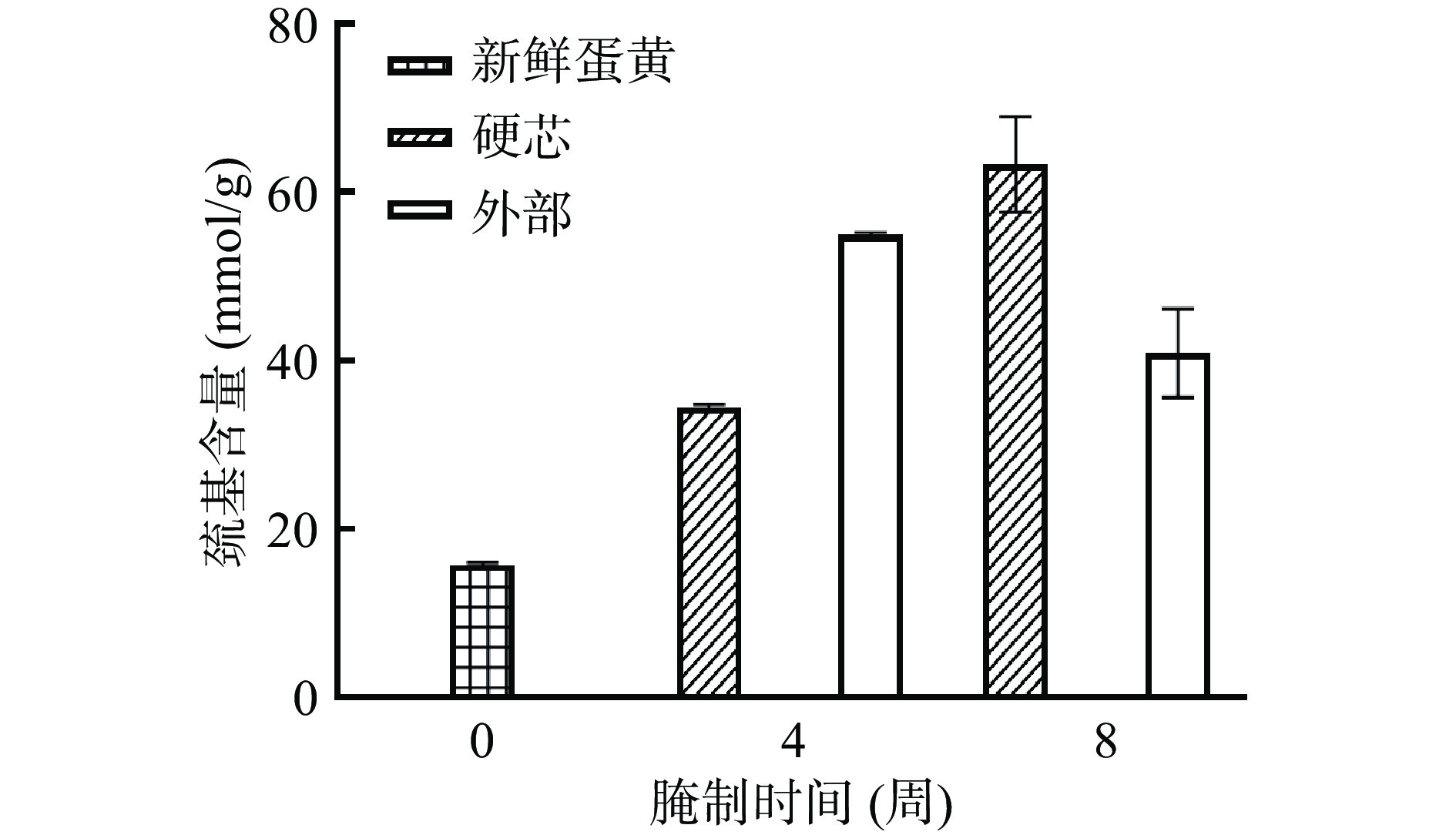

蛋黄巯基含量如图6所示,蛋黄在腌制过程中,外部蛋黄巯基在腌制4周后由15.75 mmol/g增加至54.97 mmol/g,但在腌制8周后下降到40.93 mmol/g,而硬芯部分巯基含量持续上升并在8周后达到63.34 mmol/g,巯基含量的变化趋势与蛋黄腌制过程中不同部位的不均匀失水有关,这与Xu等[31]的实验结果一致。

2.5.4 蛋黄蛋白质二级结构变化

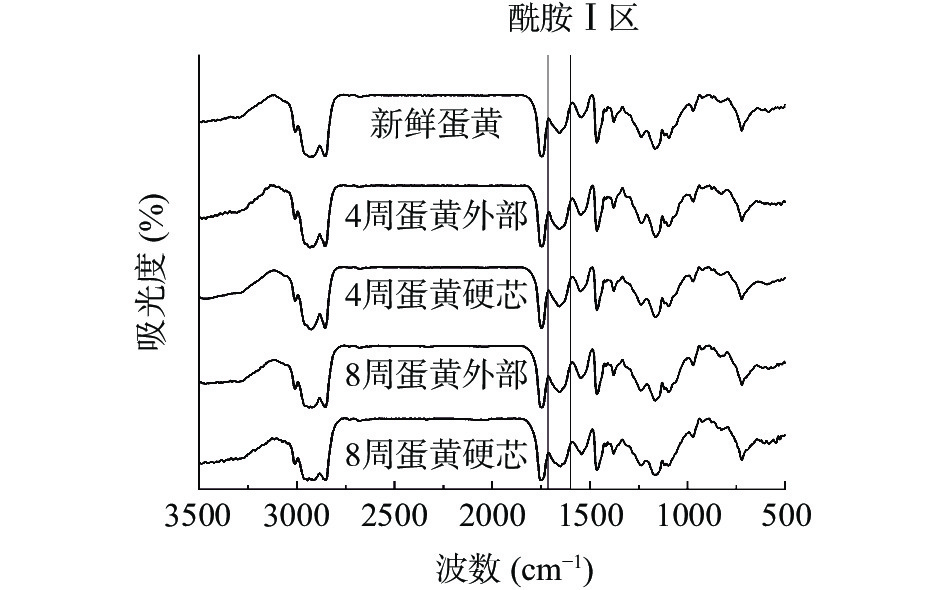

蛋白质的主要二级结构包括α-螺旋、β-折叠、β1-折叠、β2-折叠、β-转角、无规则卷曲等,其中,α-螺旋和β-折叠是蛋白质分子内最常见的二级结构,代表蛋白质分子的紧密程度;β1-折叠为分子间的强相互作用氢键、β2-折叠代表蛋白质分子间的非平面弱氢键,β1与β2的红外特征信号强度比例反映了分子间的总相互作用的强弱[32]。酰胺I带是红外光谱中定量分析蛋白质结构最常用的区域,通过对此区域光谱进行二重积分后进行分峰拟合,可以得到不同蛋白质二级结构的含量。本研究不同蛋黄样品FTIR谱图如图7所示,参照郑华等[32]、Ulrichs等[33]的方法对酰胺I带拟合单峰的区域进行了分配:1600~1625 cm−1和1690~1700 cm−1之间的峰分别对应β1-折叠和β2-折叠的特征吸收,1660~1690 cm−1之间的峰对应β转角的特征吸收,1625~1640 cm−1和1650~1660 cm−1的峰对应β-折叠和α-螺旋的特征吸收;对不同蛋黄样品的红外谱图的酰胺I带分峰拟合得到了其蛋白质二级结构的定量结果列入表2。显然,蛋白质腌制变性的过程中二级结构主要的变化是α-螺旋和β-折叠向无规则卷曲之间的转化,外部和硬芯蛋黄中α-螺旋和β-折叠的加和比例在腌制8周后由0周的约67.59%分别下降至43.76%和40.07%,而无规则卷曲蛋白质的含量不断上升。无规则卷曲比例的上升体现了蛋白质变性程度的加深,在腌制早期阶段,硬芯部分的蛋白质变性程度低于外部,但这一差异在8周后不再体现。蛋黄β1-折叠与β2-折叠总含量的上升,代表了蛋白质与脂质的相互作用以及蛋白质分子之间氢键作用的加强[30]。

表 2 不同咸蛋黄样品不同部位二级结构构成变化(%)Table 2. Changes of secondary structure in different parts of different salted egg yolk samples (%)样品 1600~1625 cm−1 1625~1640 cm−1 1640~1650 cm−1 1650~1660 cm−1 1660~1690 cm−1 1690~1700 cm−1 α+β β1-折叠 β-折叠 无规则卷曲 α-螺旋 β-转角 β2-折叠 新鲜蛋黄 1.33 29.64 3.73 37.95 19.98 7.38 67.59 4周硬芯 4.01 27.51 8.34 38.52 18.63 2.99 66.03 4周外部 4.25 27.77 19.13 33.60 13.21 2.04 61.38 8周硬芯 11.30 18.10 22.05 21.98 16.78 9.80 40.07 8周外部 12.76 23.58 27.66 20.18 13.17 2.65 43.76 2.5.5 蛋黄蛋白质变化与硬芯形成的关系

通过对比不同部位蛋白质在腌制中的变化可以发现,蛋黄腌制过程中蛋白质主要发生了移动和变性。蛋黄中的蛋白质组成了浆液和微粒两个部分,其中浆液中的蛋白质成分主要为LDL,而微粒中主要蛋白质为HDL和高磷蛋白等[34-35]。焓变温度和二级结构的变化表明,蛋白质的迁移主要是微粒的移动引起的,向内收缩的微粒使蛋黄硬芯具有了更大的蛋白密度。蛋白质结构变化的区别是蛋黄不同部位产生差异的主要原因,与其他理化性质的变化规律相似,硬芯蛋白质在腌制中的结构变化也存在滞后性,这一点在巯基含量和二级结构比例变化中均有体现。在外部蛋黄中,蛋白质结构的变化导致巯基的暴露,但巯基在腌制过程中逐渐氧化形成二硫键,这一过程会让蛋白质的结构更加松散[31]。充满游离脂肪的环境下,蛋黄外部的蛋白质分子难以形成连续结构,最终形成了具有沙感的颗粒状结构[36]。硬芯部分的巯基含量持续上升,油脂对蛋白质的阻隔较少,且在腌制较长时间后,蛋白质分子间存在更多的分子间氢键[37]。在加热后,蛋白质分子间更容易发生相互作用,进一步加剧了蛋黄内部紧密硬芯结构的形成。

2.6 蛋黄不同部分显微结构

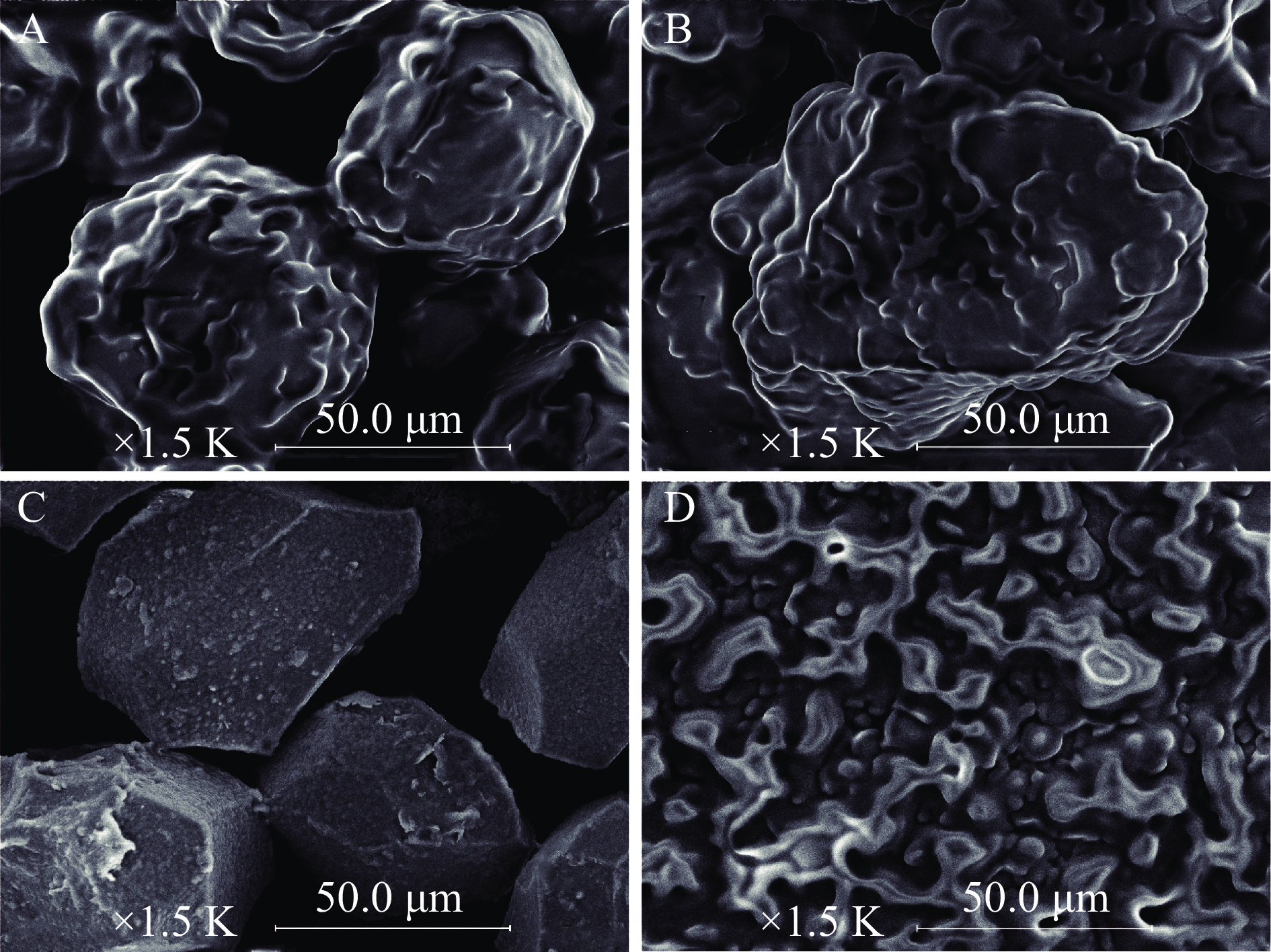

采用扫描电子显微镜在1500倍对腌制4周后咸蛋黄的外部和硬芯进行扫描,结果如图8所示。在盐的作用下,外部蛋黄的脂蛋白发生分离,形成了表面遍布油脂,大小均一的多面型颗粒(图8A),同外部相比,硬芯微粒体积更大且不再具有均一形状(图8B)。在熟制后,游离的油脂离开蛋白质的表面,外部蛋黄的多边形结构更为清晰且呈现颗粒状独立结构(图8C),而硬芯部分在加热后,颗粒体积和颗粒间隙明显降低,形成较为连续的结构(图8D)。通过对比蛋黄不同部位微观结构可以发现,在生蛋黄样品中,硬芯部分的微粒体积更大且呈现不规则的形态。在加热后,硬芯部分的颗粒体积小于外部,且颗粒之间间隙几乎不可见。熟制后,蛋黄蛋白质发生变性,蛋白质之间发生结合导致了蛋黄微粒之间结合紧密,颗粒间的间隙较小,在宏观上表现为整块的硬芯结构。

3. 结论

本研究就腌制条件对熟制咸鸭蛋蛋黄组织形态及组成的影响进行探究,结果表明蛋黄硬芯从鸭蛋腌制的第2周开始出现,随着腌制时间的延长,硬芯的质量逐渐变大,并在腌制完成后占总质量33.64%~44.80%。腌制完成后,硬芯的Na+含量在10.66~11.47 mg/g之间,水分含量约为21.47%~23.49%。较高的腌制液浓度和腌制时间均会加剧硬芯形成,当采用15%浓度腌制液腌制4周可以得到硬芯较小的咸蛋黄。盐分渗透的先后顺序导致硬芯部分各项指标的变化对比外层均呈现一定的滞后性,并导致了蛋黄中的微粒向内迁移,使蛋黄内部具有更高的蛋白含量。在盐分作用下,蛋白质变性导致了结构的变化,并在加热后相互聚集,不同微粒之间交联导致间隙缩小,形成蛋黄内部紧密连续的硬芯结构。较高的盐分含量会导致外部蛋黄以更快的速度变性,游离油脂对盐分渗透的阻碍更大,内部可供微粒迁移的空间更多,最终形成的硬芯更大。在工业生产中采用低盐短时腌制蛋黄可以降低硬芯对蛋黄品质的影响。本实验阐述了蛋黄硬芯形成的规律,有利于咸蛋黄工业化生产过程中改进生产工艺及提高产品品质。

-

图 2 不同腌制浓度下咸蛋黄盐分含量的变化

注:A:15% NaCl;B:20% NaCl;C:25% NaCl;图3同。

Figure 2. Changes of salt content in salted egg yolk in different curing concentrations

表 1 腌制过程中蛋黄不同部位的DSC特征值

Table 1 Characteristic values of DSC in different parts of egg yolk during curing

蛋黄样品 腌制时间(周) DSC特征值 Tmax(℃) ΔH(w/g) 新鲜蛋黄 0 80.52±0.16 −0.5592±0.0012 蛋黄外部 4 80.77±0.13 −0.4200±0.0124 蛋黄硬芯 4 81.30±0.14 −0.4545±0.0014 蛋黄外部 8 81.75±0.07 −0.3978±0.0072 蛋黄硬芯 8 81.25±0.07 −0.4091±0.0233 表 2 不同咸蛋黄样品不同部位二级结构构成变化(%)

Table 2 Changes of secondary structure in different parts of different salted egg yolk samples (%)

样品 1600~1625 cm−1 1625~1640 cm−1 1640~1650 cm−1 1650~1660 cm−1 1660~1690 cm−1 1690~1700 cm−1 α+β β1-折叠 β-折叠 无规则卷曲 α-螺旋 β-转角 β2-折叠 新鲜蛋黄 1.33 29.64 3.73 37.95 19.98 7.38 67.59 4周硬芯 4.01 27.51 8.34 38.52 18.63 2.99 66.03 4周外部 4.25 27.77 19.13 33.60 13.21 2.04 61.38 8周硬芯 11.30 18.10 22.05 21.98 16.78 9.80 40.07 8周外部 12.76 23.58 27.66 20.18 13.17 2.65 43.76 -

[1] 张晓维, 郑萍, 高洁, 等. 3种方法腌制咸蛋理化性质的对比[J]. 食品研究与开发,2020,41(12):108−116. [ZHANG Xiaowei, ZHENG Ping, GAO Jie, et al. Comparison of physicochemical properties of salted eggs by three pickling methods[J]. Food Research and Development,2020,41(12):108−116. doi: 10.12161/j.issn.1005-6521.2020.12.018 [2] DENMAT M L, ANTON M, GANDEMER G. Protein denaturation and emulsifying properties of plasma and granules of egg yolk as related to heat treatment[J]. Journal of Food Science,1999,64(2):194−197. doi: 10.1111/j.1365-2621.1999.tb15863.x

[3] KAEWMANEE T, BENJAKUL S, VISESSANGUAN W. Changes in chemical composition, physical properties and microstructure of duck egg as influenced by salting[J]. Food Chemistry,2009,112(3):560−569. doi: 10.1016/j.foodchem.2008.06.011

[4] 吕蕙, 马美湖, 刘远远. 稻秸灰水提物对咸蛋黄理化特性的影响[J]. 现代食品科技,2019,35(4):148−156. [LÜ Hui, MA Meihu, LIU Yuanyuan. Effects of straw ash aqueous extracts on physicochemical characteristics of salted egg yolk[J]. Modern Food Science and Technology,2019,35(4):148−156. [5] KAEWMANEE T, BENJAKUL S, VISESSANGUAN W, et al. Effect of sodium chloride and osmotic dehydration on viscoelastic properties and thermal-induced transitions of duck egg yolk[J]. Food and Bioprocess Technology,2013,6(2):367−376. doi: 10.1007/s11947-011-0667-7

[6] WANG X, HUANG Y, ZHOU B, et al. Improvement of quality and flavor of salted egg yolks by ultrasonic assisted cooking[J]. Ultrasonics Sonochemistry,2021,75:105579. doi: 10.1016/j.ultsonch.2021.105579

[7] 李子康. 低量钙镁盐与钾盐对咸蛋腌制影响[J]. 广东化工,2019,46(13):65−67. [LI Zikang. Effect of low calcium magnesium salt and potassium salt on salted eggs[J]. Guangdong Chemistry Industry,2019,46(13):65−67. doi: 10.3969/j.issn.1007-1865.2019.13.031 [8] XU L, ZHAO Y, XU M, et al. Effects of salting treatment on the physicochemical properties, textural properties, and microstructures of duck eggs[J]. Plos One,2017,12(8):e182912.

[9] HARLINA P W, SHAHZAD R, MA M, et al. Effects of galangal extract on lipid oxidation, antioxidant activity and fatty acid profiles of salted duck eggs[J]. Journal of Food Measurement and Characterization,2019,13(3):1820−1830. doi: 10.1007/s11694-019-00100-z

[10] 杜金平. 鸭蛋加工技术与质量控制: 第八届(2019)中国水禽发展大会暨第二届鸭饲料营养与养殖技术研讨会[C]. 中国广东云浮, 2019. DU Jinping. Duck egg processing technology and quality control: The 8th (2019) China waterfowl development conference and the 2nd symposium on duck feed nutrition and breeding technology[C]. China Guangdong Yunfu, 2019.

[11] 戴幽. 咸蛋黄硬心现象形成原因初探[D]. 长沙: 湖南农业大学, 2020. DAI You. A preliminary study on the causes of the formation of salted egg yolk hard heart[D]. Changsha: Hunan Agriculture University, 2020.

[12] 王梦林. 优质咸蛋黄腌制新工艺及品质分析[D]. 南昌: 南昌大学, 2015. WANG Menglin. Study on new pickling technique of high quality salted egg yolk and its quality analysis[D]. Nanchang: Nanchang University, 2015.

[13] 刘蒙佳, 周强, 刘禹. 腌制条件对咸鸭蛋品质的影响及熟化工艺研究[J]. 中国调味品,2019,44(1):50−53. [LIU Mengjia, ZHOU Qiang, LIU Yu. Effect of curing conditions on quality of salted duck eggs and research on the maturation process[J]. China Condiment,2019,44(1):50−53. doi: 10.3969/j.issn.1000-9973.2019.01.011 [14] 龙门, 宋野, 杜庆飞, 等. 腌制温度和食盐用量对咸鸭蛋蛋黄脂质的影响[J]. 农业工程学报,2015,31(18):281−288. [LONG Men, SONG Ye, DU Qingfei, et al. Study on the variation of relevant indicators and selection of the optimum formula in pickling process of salted duck egg[J]. Guangdong Agricultural Sciences,2015,31(18):281−288. doi: 10.11975/j.issn.1002-6819.2015.18.038 [15] 中华人民共和国国家卫生和计划生育委员会, 国家食品药品监督管理总局. GB 5009.91-2017食品安全国家标准 食品中钾、钠的测定[S]. 北京: 中国标准出版社, 2017. National Health and Family Planning Commission of the People's Republic of China, State Food and Drug Administration. GB 5009.91-2017 National standard of food safety Determination of potassium and sodium in food[S]. Beijing: Standards Press of China, 2017.

[16] 中华人民共和国国家卫生和计划生育委员会, 国家食品药品监督管理总局. GB 5009.3-2016食品安全国家标准 食品中水分的测定[S]. 北京: 中国标准出版社, 2016. National Health and Family Planning Commission of the People's Republic of China, State Food and Drug Administration. GB 5009.3-2016 National standard of food safety Determination of water in food[S]. Beijing: Standards Press of China, 2016.

[17] 曾舟, 马美湖, 何兰, 等. 不同腌制添加剂对咸蛋腌制效果的影响[J]. 中国食品学报,2012,12(10):140−148. [ZENG Zhou, MA Meihu, HE Lan, et al. Effect of different pickle additives on preserved salted egg[J]. Journal of Chinese Institute of Food Science and Technology,2012,12(10):140−148. [18] LAI K M, CHUNG W H, JAO C L, et al. Oil exudation and histological structures of duck egg yolks during brining[J]. Poult Sci,2010,89(4):738−744. doi: 10.3382/ps.2009-00334

[19] 中华人民共和国国家卫生和计划生育委员会, 国家食品药品监督管理总局. GB 5009.5-2016食品安全国家标准 食品中蛋白质的测定[S]. 北京: 中国标准出版社, 2016. National Health and Family Planning Commission of the People's Republic of China, State Food and Drug Administration. GB 5009.5-2016 National standard of food safety Determination of protein in food[S]. Beijing: Standards Press of China, 2016.

[20] BEVERIDGE T, TOMA S J, NAKAI S. Determination of SH and SS groups in some food proteins using Ellman's reagent[J]. Journal of Food Science,1974,39(1):49−51. doi: 10.1111/j.1365-2621.1974.tb00984.x

[21] HIDAS K I, NYULAS-ZEKE I C, VISY A, et al. Effect of combination of salt and pH on functional properties of frozen-thawed egg yolk[J]. Agriculture,2021,11(3):257. doi: 10.3390/agriculture11030257

[22] TANG H G, TAN L, CHEN Y, et al. Effect of k-carrageenan addition on protein structure and gel properties of salted duck egg white[J]. Journal of the Science of Food and Agriculture,2021,101(4):1389−1395. doi: 10.1002/jsfa.10751

[23] LIU Y, MA Y, CHI Y, et al. Change in rapid salting kinetics and characteristics of hen egg yolks[J]. Journal of Food Engineering,2022,329:111090. doi: 10.1016/j.jfoodeng.2022.111090

[24] 荣建华, 张正茂, 冯磊, 等. 咸蛋盐水腌制动力学研究[J]. 农业工程学报,2007(2):263−266. [RONG Jianhua, ZHANG Zhengmao, FENG Lei, et al. Pickling dynamics of salted egg[J]. Transactions of the CSAE,2007(2):263−266. doi: 10.3321/j.issn:1002-6819.2007.02.051 [25] ANTON M, LE DENMAT M, BEAUMAL V, et al. Filler effects of oil droplets on the rheology of heat-set emulsion gels prepared with egg yolk and egg yolk fractions[J]. Colloids Surf B Biointerfaces,2001,21(1-3):137−147. doi: 10.1016/S0927-7765(01)00167-9

[26] ZHAO Y, FENG F, YANG Y, et al. Gelation behavior of egg yolk under physical and chemical induction: A review[J]. Food Chemistry,2021,355:129569. doi: 10.1016/j.foodchem.2021.129569

[27] 何家林, 欧阳玲花, 付晓记, 等. 有机酸预处理对腌制咸蛋的影响[J]. 江西农业学报,2015,27(11):61−63. [HE Jialin, OUYANG Linghua, FU Xiaoji, et al. Effect of pretreatment with organic acids on salted duck eggs[J]. Acta Agriculturae Jiangxi,2015,27(11):61−63. doi: 10.3969/j.issn.1001-8581.2015.11.015 [28] VENKATACHALAM K. Influence of prolonged salting on the physicochemical properties of duck egg white[J]. Brazilian Archives of Biology and Technology, 2018, 61.

[29] YUAN L, ZHANG J, WU J, et al. The effect on quality of pickled salted duck eggs using the novel method of pulsed pressure osmotic dehydration[J]. Journal of Food Processing and Preservation,2018,42(4):e13581. doi: 10.1111/jfpp.13581

[30] 孙秀秀, 何立超, 杨海燕, 等. 间歇超声辅助加快咸蛋腌制速度工艺优化[J]. 食品工业科技,2018,39(22):204−211. [SUN Xiuxiu, HE Lichao, YANG Haiyan, et al. Intermittent ultrasound assisted in speeding up the pickling speed of salted eggs[J]. Science and Techology of Food Industry,2018,39(22):204−211. [31] XU L, ZHAO Y, XU M, et al. Changes in aggregation behavior of raw and cooked salted egg yolks during pickling[J]. Food Hydrocolloids,2018,80:68−77. doi: 10.1016/j.foodhyd.2018.01.026

[32] 郑华, 彭辉, 林捷, 等. 食盐对咸蛋黄蛋白质特性的影响[J]. 食品科学,2013,34(1):83−87. [ZHENG Hua, PENG Hui, LIN Jie, et al. Effect of salt on properties of salted yolk protein[J]. Food Science,2013,34(1):83−87. [33] ULRICHS T, DROTLEFF A M, TERNES W. Determination of heat-induced changes in the protein secondary structure of reconstituted livetins (water-soluble proteins from hen’s egg yolk) by FTIR[J]. Food Chemistry,2015,172:909−920. doi: 10.1016/j.foodchem.2014.09.128

[34] 谢云霄, 耿放, 王金秋. 蛋黄主要蛋白质研究进展[J]. 食品工业,2019,40(7):266−270. [XIE Yunxiao, GENG Fang, WANG Jinqiu. Research advances in the major proteins of egg yolk[J]. The Food Industry,2019,40(7):266−270. [35] 徐丽兰, 赵燕, 徐明生, 等. 食盐诱导的蛋黄凝聚行为研究进展[J]. 中国食品学报,2019,19(3):317−325. [XU Lilan, ZHAO Yan, XU Mingsheng, et al. Research progress in the aggregation behavior of egg yolk induced by salt[J]. Journal of Chinese Institute of Food Science and Technology,2019,19(3):317−325. [36] 杨海燕, 金永国, 孙秀秀, 等. 添加不同水平NaCl对蛋黄浆质凝胶性的影响研究[J]. 现代食品科技,2018,34(8):165−171. [YANG Haiyan, JIN Yongguo, SUN Xiuxiu, et al. Effects of different NaCl addition levels on the gel properties of egg yolk plasma[J]. Modern Food Science and Technology,2018,34(8):165−171. [37] 张根生, 俆旖梦, 遇仕友, 等. 蛋黄凝胶形成机理及影响因素研究进展[J]. 食品与机械,2021,37(4):1−5. [ZHANG Gengsheng, XU Yimeng, YU Shiyou, et al. Research progress on formation mechanism and influencing factors of egg yolk gel[J]. Food and Machinery,2021,37(4):1−5. -

期刊类型引用(6)

1. 杨悦,刘梦圆,肖文军. 表没食子儿茶素没食子酸酯与L-茶氨酸对乙醇脱氢酶和乙醛脱氢酶活性的体外协同作用. 食品安全质量检测学报. 2024(04): 260-265 .  百度学术

百度学术

2. 丁树洽,谢昕雅,刘助生,廖贤军,刘仲华,蔡淑娴. 茶叶成分EGCG与L-theanine联合应用的神经保护作用研究. 茶叶科学. 2024(05): 779-792 .  百度学术

百度学术

3. 韦柳花,赖兆荣,邓慧群,罗小梅,邱勇娟,诸葛天秋,黄金丽. 茶树良种紫鹃不同茶类适制性研究. 农业与技术. 2023(12): 4-6 .  百度学术

百度学术

4. 薛璐,邢宇航,段志豪,陈绵鸿,周伟,李如一,李积华. 表没食子儿茶素没食子酸酯与燕麦β-葡聚糖复合物的形成及表征. 食品工业科技. 2022(08): 124-132 .  本站查看

本站查看

5. 吴颖,曲爱丽,纪荣全,王程安. 高花青素柏塘紫芽茶适制性的研究. 食品安全质量检测学报. 2022(12): 3875-3883 .  百度学术

百度学术

6. 程倩,冯雪萍,陈昭,李春阳,张雪,张海波. 高效液相色谱法测定复合果汁饮品中茶氨酸的含量. 食品安全导刊. 2022(24): 87-91 .  百度学术

百度学术

其他类型引用(3)

下载:

下载:

下载:

下载: