Effects of Different Vacuum Freeze-drying Processes on Rehydration and Quality Characteristics of Freeze-dried Rice Noodles

-

摘要: 近年来,干制方便米线作为一种方便食品发展迅速,但是干制方便米线存在复水时间长、易糊汤、易断条、口感不理想、质构特性较差等问题。为了改善干制方便米线的这些特性,本研究采用−10、−20和−40 ℃ 三种冻结温度对米线进行真空冷冻干燥,分别得到三种冻干米线FDRN10、FDRN20、FDRN40样品,通过分析冻干米线在不同水温下的复水速度、微观结构、淀粉回生程度和质构特性的变化,探讨了冻结温度对冻干米线复水品质的影响。结果表明,在相同水温下经相同浸泡时间复水处理后,FDRN10含水量最高,表明其复水速度最快。外表面和横断面微观结构观察发现,三种冻干米线样品中FDRN10结构最为疏松,孔隙最大,为72.58 µm,是孔隙最小的FDRN40的4倍,结构吸水性最好。进一步的DSC检测发现FDRN10焓值最高,为92.98 J/g,焓值最低的FDRN40为12.39 J/g,表明FDRN10在三种冻干米线样品中回生程度最高,淀粉吸水溶胀最慢。同时硬度分析结果表明,在相同浸泡时间下FDRN10硬度值随水温的升高而降低,采用70 ℃热水复水8 min,FDRN10质构特性最接近鲜湿米线。以上结果表明,冻结温度和复水温度对冻干米线品质形成起到关键作用,本研究结果可为方便米线工艺改进提供理论依据。Abstract: Dried instant rice noodles are a convenience food, and they have shown rapid development in recent years. However, there are many disadvantages of dried instant rice noodles, such as long rehydration time, high turbidity of soup, high break rate, poor taste, and disappointing textural properties. In this study, to overcome these disadvantages, freeze-dried rice noodles were prepared at freezing temperatures of −10, −20, and −40 ℃ by the vacuum freeze-drying process, which were called FDRN10, FDRN20, and FDRN40, respectively. The factors that affected the rehydration quality of freeze-dried rice noodles were investigated by analyzing the rehydration speed, microstructure, starch retrogradation, and texture characteristics at different water temperatures. The results showed that FDRN10 had the highest water content of the three freeze-dried rice noodles for the same water temperature and rehydration time. This indicated that the rehydration speed of FDRN10 was the fastest. The microstructures of the external surface and cross section were observed. FDRN10 had the loosest structure and largest aperture. The diameter of the aperture of FDRN10 was 72.58 µm, which was four times larger than that of FDRN40. This microstructure led to FDRN10 showing good water absorption. Differential scanning calorimetry showed that the enthalpy of FDRN10 was 92.98 J/g. The enthalpy of FDRN40 was the lowest (12.39 J/g). Thus, FDRN10 had the highest level of starch retrogradation among the three freeze-dried rice noodle samples, and the lowest level of starch water-absorbing swelling. Hardness analysis showed that the hardness value of FDRN10 decreased with increasing water temperature for the same rehydration time. The texture characteristics of FDRN10 were the closest to those of fresh rice noodles after rehydrating with water at 70 ℃ for 8 min. The above results indicate that the freezing temperature and rehydration temperature play important roles in the quality of freeze-dried rice noodles. This study provides an innovative process for improvement of instant-rice-noodle production.

-

Keywords:

- rice noodle /

- vacuum freeze drying /

- rehydration /

- microstructure /

- texture properties

-

米线是我国一种传统食物已具有2300多年的历史,深受广大消费者喜爱,需求量巨大[1]。方便米线是以大米为主要原料,通过非油炸蒸煮的先进工艺,配以不同风味调料,用开水冲泡即可食用的米线[2]。方便米线因其非油炸符合人们对“健康、营养、安全、方便”食品的追求,成为一种发展较快的方便食品[2]。

方便米线分为鲜湿方便米线和干制方便米线。鲜湿方便米线因保质期短、易断条等问题发展较慢[3],干制方便米线保质期较长,消费者接受度较高,为干制方便米线产品的研发和销售提供了很大的发展空间[4]。干燥技术是影响干制方便米线品质的关键工艺之一,目前米线的干燥技术主要有高温高湿干燥、热风干燥、微波干燥、油炸干燥、热风-微波干燥、快速微膨化三段式干燥等[5-8]。采用这些干燥技术生产的方便米线虽然保质期长、韧性好,但由于干燥时温度较高,米线极容易壳化和收缩限制了米线组织的疏松性,使得方便米线冲泡时易糊汤、不耐泡或泡不透、复水时间长、汤料渗透性差,口感难以达到鲜米线的爽滑程度。这些不利因素影响了消费者对方便米线的接受程度,制约了方便米线产业的发展[9-10]。为了改善干制方便米线的品质,有学者在米线的原料中添加马铃薯淀粉、酶制剂、蛋白、膳食纤维素、功能性物质,如白芸豆提取、紫苏叶粉等,改进方便米线的组织微观结构、营养组成、品质特性[11-13],但干燥过程的高温会造成营养成分的大量损失。因此,需要寻找一种更有效的干燥方法,既能提高方便米线复水性、外观品质、食味品质等,又能最大限度地保留营养成分。

真空冷冻干燥(vacuum freeze drying,VFD)技术是国际上公认的高品质干燥加工技术,结合真空、低温、传热于一体,可以最大限度保留食物原料组织结构和营养功能,被誉为20世纪食品工业技术进步的重要标志之一[14]。VFD产品具有很多优点,与高温干燥方式相比VFD产品基本可以保持物料的色泽、风味、营养成分,具有多孔结构能够速溶或快速复水,含水量低货架期和保质期较长。利用VFD技术还可以实现单一物料的复合再造,满足方便即食和营养健康等需求[15]。目前,VFD技术已经广泛应用于谷物类、果蔬类、肉禽水产类、调味食品类、饮料类、野生菌、中药等的加工[16-21]。VFD技术在方便主食的加工中也有研究,如方便米饭、方便粥、馄饨、饺子等[22]。周国燕等[22]采用VFD技术制备方便米饭具有新鲜米饭原有的香味,米饭的可溶性固形物等营养物质破坏较小。陈天鹏等[23]对方便米饭品质的研究发现,VFD技术可在米饭内部形成疏松的多孔结构,降低了米饭的老化程度,提高了方便米饭的复水速度和品质。李新建等[24]采用−40 ℃冻结温度制得的冻干糯米粥米色纯白,组织状态均匀完整,口感韧性佳。陈树俊等[25]用VFD技术制作的方便小米粥复水性好,营养成分基本无损失。VFD技术已成为了生产和开发高品质米淀粉产品的新兴加工技术。在VFD工艺中冻结速率等因素与物料种类存在显著相关性[26],米线与方便米饭都属于大米制品,是否也能通过VFD技术改善干制米线内部结构、缩短复水时间、提高品质,值得进行探索和研究。目前,用真空冷冻干燥技术制备方便米线的相关研究报道还较少。

本研究采用不同的真空冷冻干燥工艺对鲜湿米线进行干燥,研究冻结温度对冻干米线复水速度、微观结构、淀粉回生程度的影响,以及复水水温对冻干米线的复水后质构特性的影响,为方便米线工艺创新和品质提升提供理论依据和技术基础。

1. 材料和方法

1.1 材料与仪器

米线制作的大米原料为桂潮早籼米 于2019年采收,由云南农业科学院粮食作物研究所提供。

LGJ-25C真空冷冻干燥机 四环福瑞科仪科技发展(北京)有限公司;HWS-26电热恒温水浴锅 上海一恒科学仪器有限公司;TMS-Touch质构分析仪 美国FTC公司;NETZSCH DSC 200F3差示扫描量热仪 德国Netzsch集团;TESCAN MIRA3扫描电子显微镜 捷克泰思肯贸易(上海)有限公司;MFD50Y一步成型米粉机、6-2YH1015B蒸汽优化箱 湖南米师傅机械科技有限公司。

1.2 实验方法

1.2.1 鲜湿米线制备

根据一步成型米粉机操作步骤进行鲜湿米线制备。称取2 kg无病虫害、无霉变的优质早籼米经淘洗、浸泡过夜后,放入一步成型米粉机中采用直径为1.5 mm的筛孔制作米线;米线悬挂于蒸汽优化箱中40 ℃优化处理4 h以上,将优化好的米线放入沸水中,加盖焖8~15 min,用手指轻轻捻米线感觉没有硬芯为止,将米线捞出立刻放入5~15 ℃水中10 min,即为鲜湿米线。

1.2.2 冻干米线的制备

参考陈天鹏等[23]的方法进行修改,将制备好的鲜湿米线单层平铺在物料盘上,放入−20 ℃冰箱中冷冻24 h,将冻后的样品放入真空冷冻干燥机中,分别在−10、−20、−40 ℃的冻结温度下制作,搁板温度为45 ℃、冷阱温度−55 ℃、真空度在80 Pa以下,干燥27 h取出,得到真空冷冻干燥米线,简称冻干米线,并分别命名为FDRN10(vacuum freeze-dried rice noodle 10)、FDRN20(vacuum freeze-dried rice noodle 20)、FDRN40(vacuum freeze-dried rice noodle 40)。

1.2.3 冻干米线复水后的水分含量测定

参考陈天鹏等[23]的方法,称取3 g冻干米线,记重量为W0,放入烧杯中,加入装有300 mL 50 ℃的热水,分别于50 ℃的水浴保温3、5、8、10、15、20 min时取出,放在滤纸上吸干表面多余水分,称量并记为重量W1,按公式计算水分含量(W,%)。按照上述方法依次测定水温为70和90 ℃时三种冻干米线复水时的水分含量,每组处理重复3次。

式中:W0为复水前冻干米线的重量(g);W1为复水后冻干米线的重量(g)。

1.2.4 冻干米线微观结构观察

参考陈天鹏等[23]的方法,将冻干米线剪成长5 mm的短条并固定于金属桩上,喷金处理2 min,再在20 kV条件下通过扫描电子显微镜观察冻干样品表面(1000倍)和内部断面(100倍)的孔隙结构。

1.2.5 DSC法测定淀粉的回生

按照龙成[27]的方法略有修改,将冻干米线打粉,过120目筛,称取2 mg 制备好的粉末置于铝皿中,加入6 µL蒸馏水,压盖密封,室温平衡15 h~1 d,用差示扫描量热仪(differential scanning calorimetry,DSC)进行测定。DSC使用前用金属铟校准,初始温度为25 ℃,终止温度为120 ℃,升温速率10 ℃/min,以氮气为载气,流速为20 mL/min。回生度用焓的变化值(ΔH)表示,ΔH值越大,回生程度越高。

1.2.6 质构特性测定

参考张玮等[28]的方法,将冻干米线于不同温度的热水中复水不同的时间捞出,吸干表面多余的水分,截取3 cm平放于检测台,在TPA模式中选择75 mm直径圆盘、50 N的感应元,形变量为 75%,测前、后速度均为 40 mm/min,触发力为5 g,参数获取速率为 500 pps,进行两次压缩,分别测定三种冻干米线在50、70、90 ℃的水浴锅中浸泡3、5、8、10、15、20 min后的硬度、粘度、弹性、胶粘性和咀嚼性,每个处理重复测定10次。同时鲜湿米线以相同的参数进行测定。

1.3 数据处理

采用 SPSS 22.0和Origin 2017软件分别进行数据方差分析和绘图处理。

2. 结果与分析

2.1 冻干米线复水后水分含量的变化

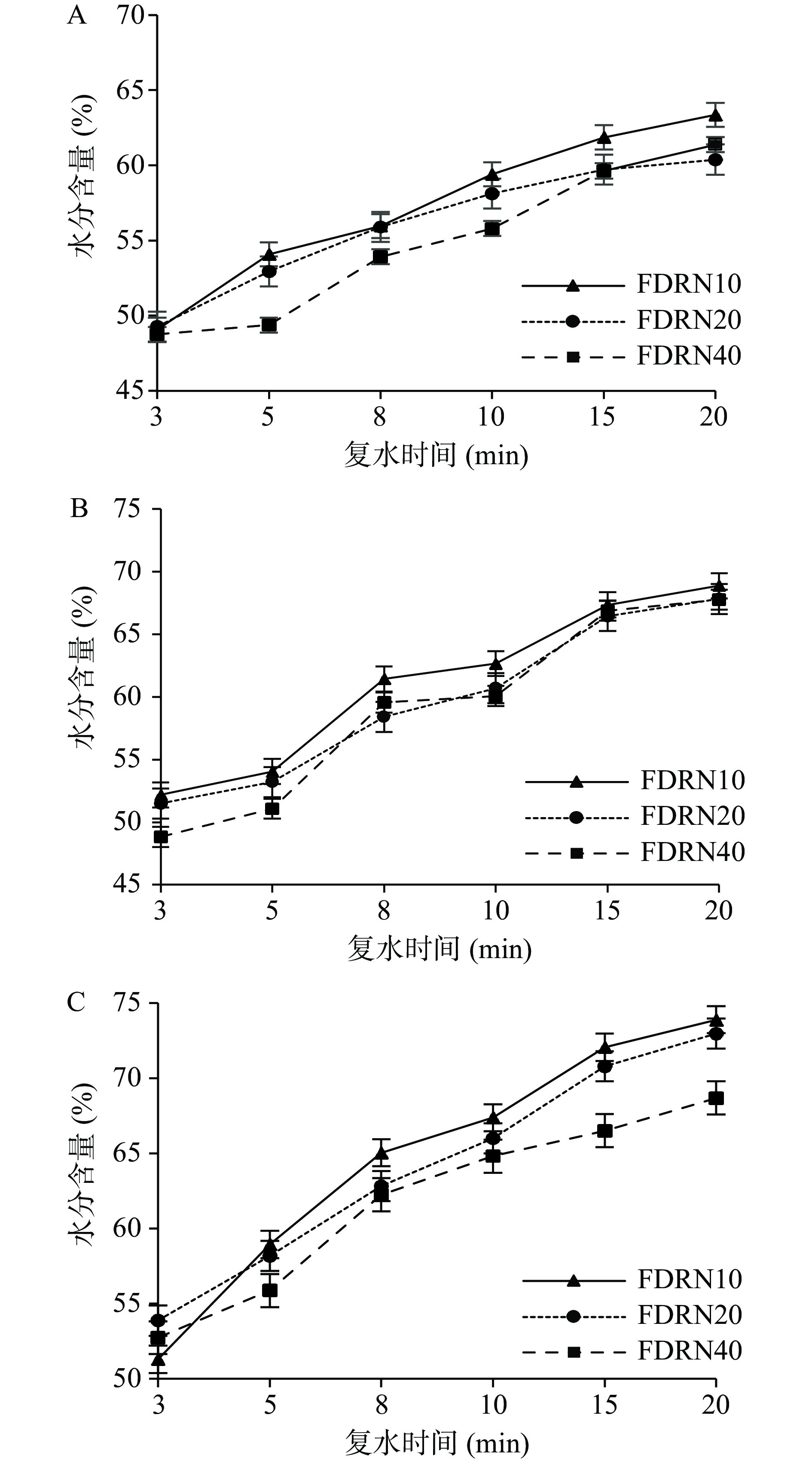

快速复水是方便食品所需的基本品质之一[29],冻干米线复水速率是决定其能否作为方便食品进行开发的重要因素。三种冻干米线(FDRN10、FDRN20、FDRN40)经不同水温和不同浸泡时间处理水分含量变化如图1所示,三种冻干米线的水分含量都随复水时间的延长而增加,并在复水15 min后趋于稳定,复水20 min时水分含量增加幅度极小,表明冻干米线复水基本完成。三种冻干米线的复水能力不同,FDRN10在不同的水温下复水水分含量高于其它两个样品,复水速率是三个样品中最高的,其次是FDRN20,最低的是FDRN40,表明冻结温度的高低影响冻干米线的复水能力。

复水水温也是影响冻干米线复水能力的重要因素。对比不同复水水温下三种冻干米线的水分含量测定结果发现,复水5 min前三种冻干米线在90 ℃水温下水分含量高于50和70 ℃下的水分含量,复水速率最快;复水10 min后,三种冻干米线在90 ℃水温下水分含量的增加幅度高于50 ℃下的增幅,复水持续时间较长。复水水温影响冻干大米制品的结构吸水和淀粉吸水溶胀两个方面[30],水温高,水分子能量高,能够快速填充组织中的孔隙,加快结构吸水[31],同时高温还能使回生淀粉重新糊化,促进淀粉吸水溶胀[32]。冻干米线与冻干大米制品具有相同的复水机制,复水能力受温度影响,水温越高冻干米线的水分含量越高,复水速率越快。

2.2 冻结温度对冻干米线微观结构的影响

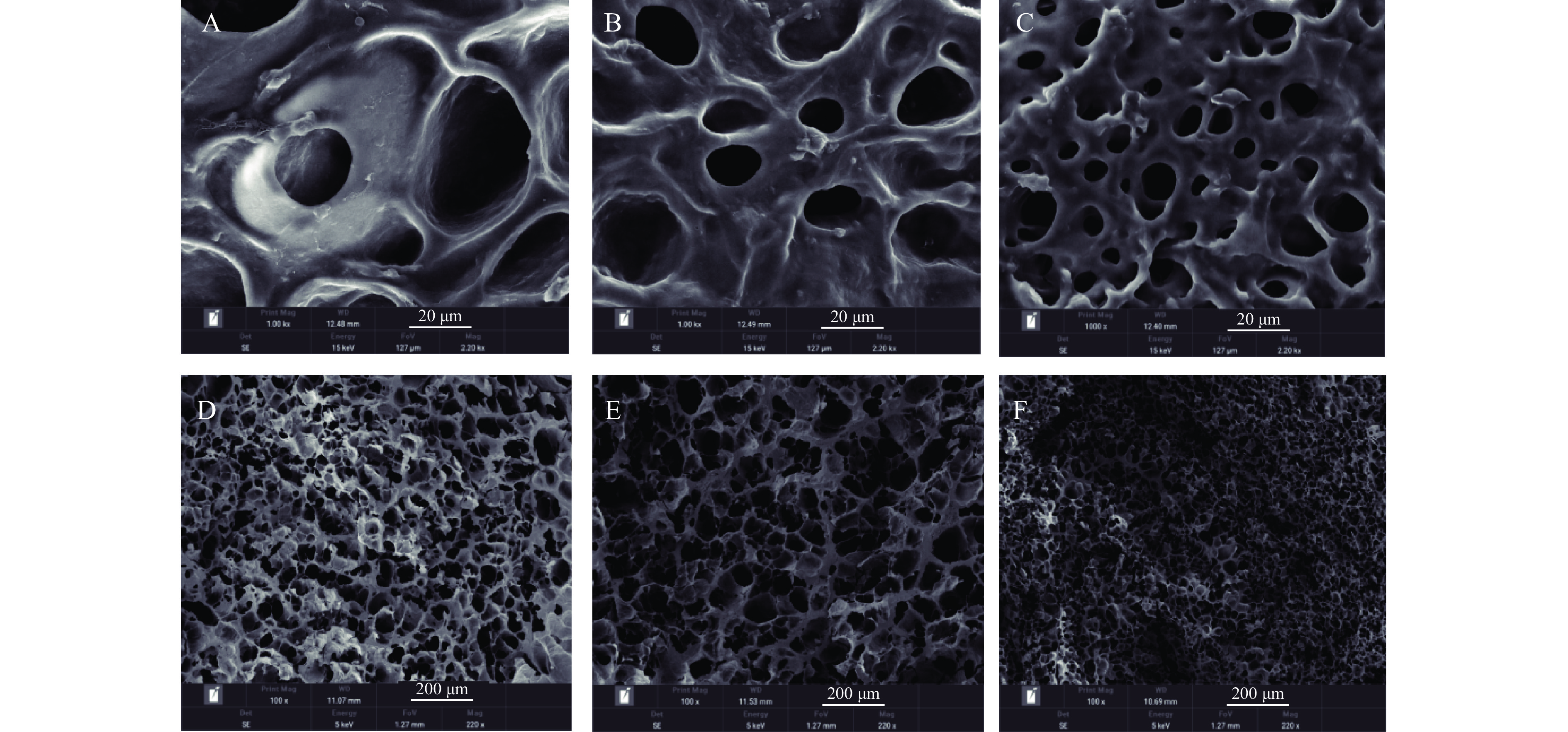

以上研究结果证实相同复水水温下,不同冻结温度制备的冻干米线的复水速率差异显著,推测这与冻结温度影响米线组织结构,并导致结构吸水差异有关[27]。采用扫描电镜分别对三种冻干米线的外表面和横断面进行了观察,FDRN10外表面孔隙较大,孔隙直径平均达到72.58 µm,从横断面观察组织结构疏松但分布不均匀;而FDRN40外表面孔隙直径平均只有18.01 µm,横断面结构较致密且均匀(图2,表1)。这样的结构特征与冻干米饭的微观结构特征[23]有很大相似性,表明鲜湿米线在较高的温度下缓慢冻结,组织内形成的冰晶体积较大、易脱水,干燥升华时可留下较大的孔隙,使冻干米线具有疏松的、分布不均匀的多孔结构;而低温快速冻结形成的冰晶体积较小,降低了脱水性,干燥升华时留下的孔隙也较小,冻干米线的多孔结构致密且均匀。冻干米线遇水后水分能快速填充组织内部的孔隙使米线软化,孔隙越大,米线的吸水回软速度也越快[33]。结合水分含量测定结果,FDRN10制备时采用较高的冻结温度,其孔隙大、结构疏松有利于复水;FDRN20虽然表面孔隙较小但结构疏松,复水性也较好;而FDRN40则表面孔隙小、结构致密,复水时结构吸水能力差。

表 1 冻干米线孔隙大小的对比Table 1. Comparison of pore of the freeze-dried rice noodlesFDRN10 FDRN20 FDRN40 外表面孔隙(µm) 72.58±6.97a 36.07±2.78b 18.01±1.46c 横截面孔隙(µm) 32.35±2.89a 33.12±2.29a 22.94±1.66b 注:结果以平均值±标准差的形式表示;同行不同小写字母表明差异显著(P<0.05)。 2.3 冻结温度对冻干米线回生的影响

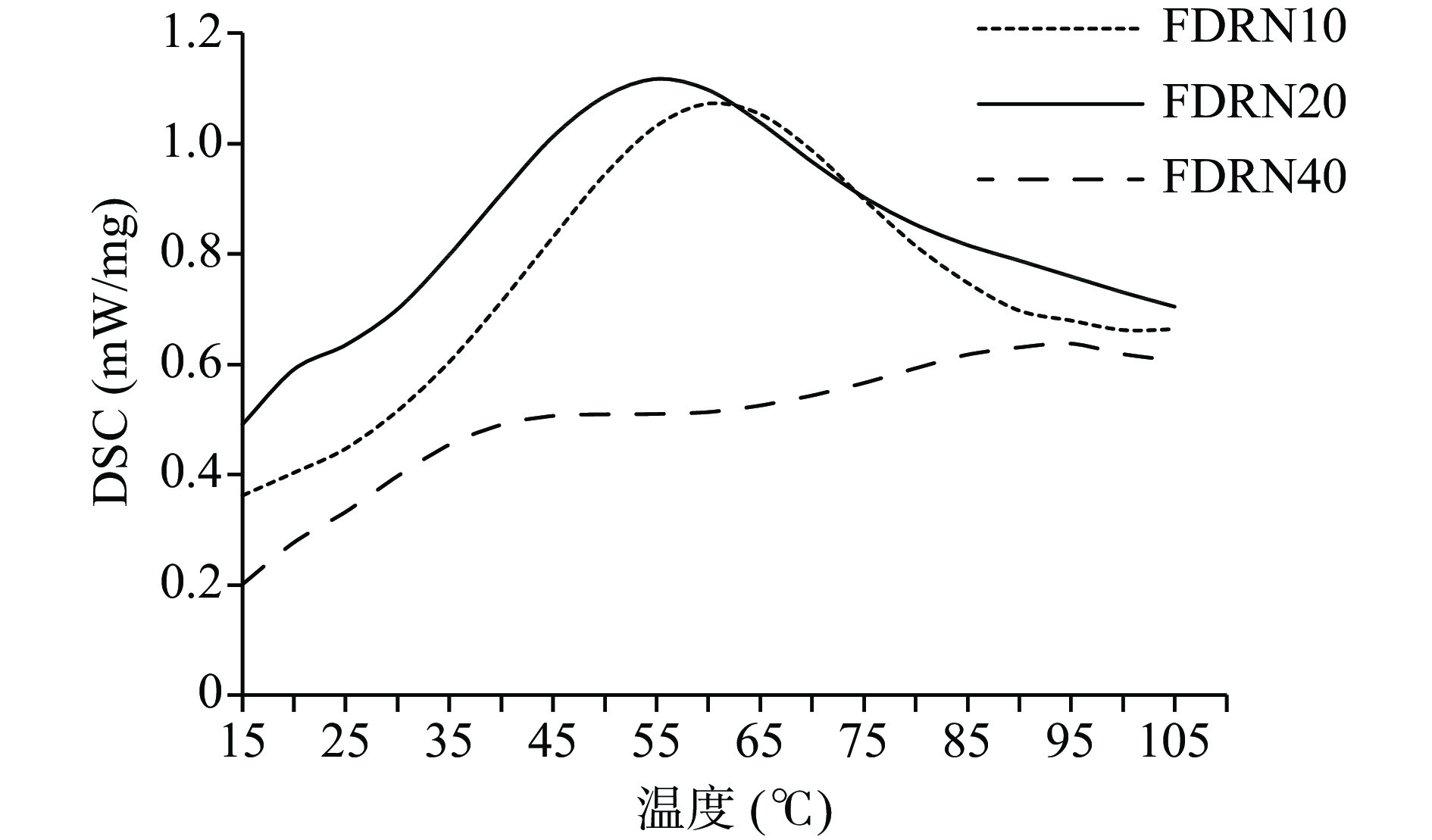

回生是糊化的淀粉由无序状态向有序的结晶状态的变化过程[34],温度降低糊化的淀粉分子间的氢键趋向平行排列,淀粉链形成不完全呈放射排列的混合微晶束[35],导致淀粉形成难以复水的高度结晶体,因此淀粉回生程度越高,吸水能力越差[36]。冻干米线的DSC测试结果显示FDRN10的DSC曲线观察到了吸热峰,糊化温度61.0 ℃;FDRN20峰略微提前,糊化温度55.2 ℃;FDRN40的DSC曲线上却没有观测到吸热峰,糊化温度有小幅度降低为54.9 ℃(图3)。淀粉回生焓值反映了老化过程中重新有序排列堆积而成的晶体熔化所吸收的热量,回生程度越大所吸收的热量越多焓值也越大[37]。图4的结果显示三种冻干米线间焓值差异显著,其中最高的是FDRN10,为92.98 J/g,最低的是FDRN40,为12.39 J/g,可见冻结温度与米线的回生关系密切。FDRN10在较高温度下缓慢冻结,糊化淀粉分子重新排列较完全,回生程度较高;而FDRN40在低温快速冻结条件下,淀粉能较快越过最易老化的温度阶段,淀粉不易发生回生或回生程度较低。综合冻结温度对冻干米线微观结构影响的结果,发现在冻干米线制备时增大孔隙和抑制淀粉回生存在着矛盾。

2.4 冻干米线复水后硬度的变化

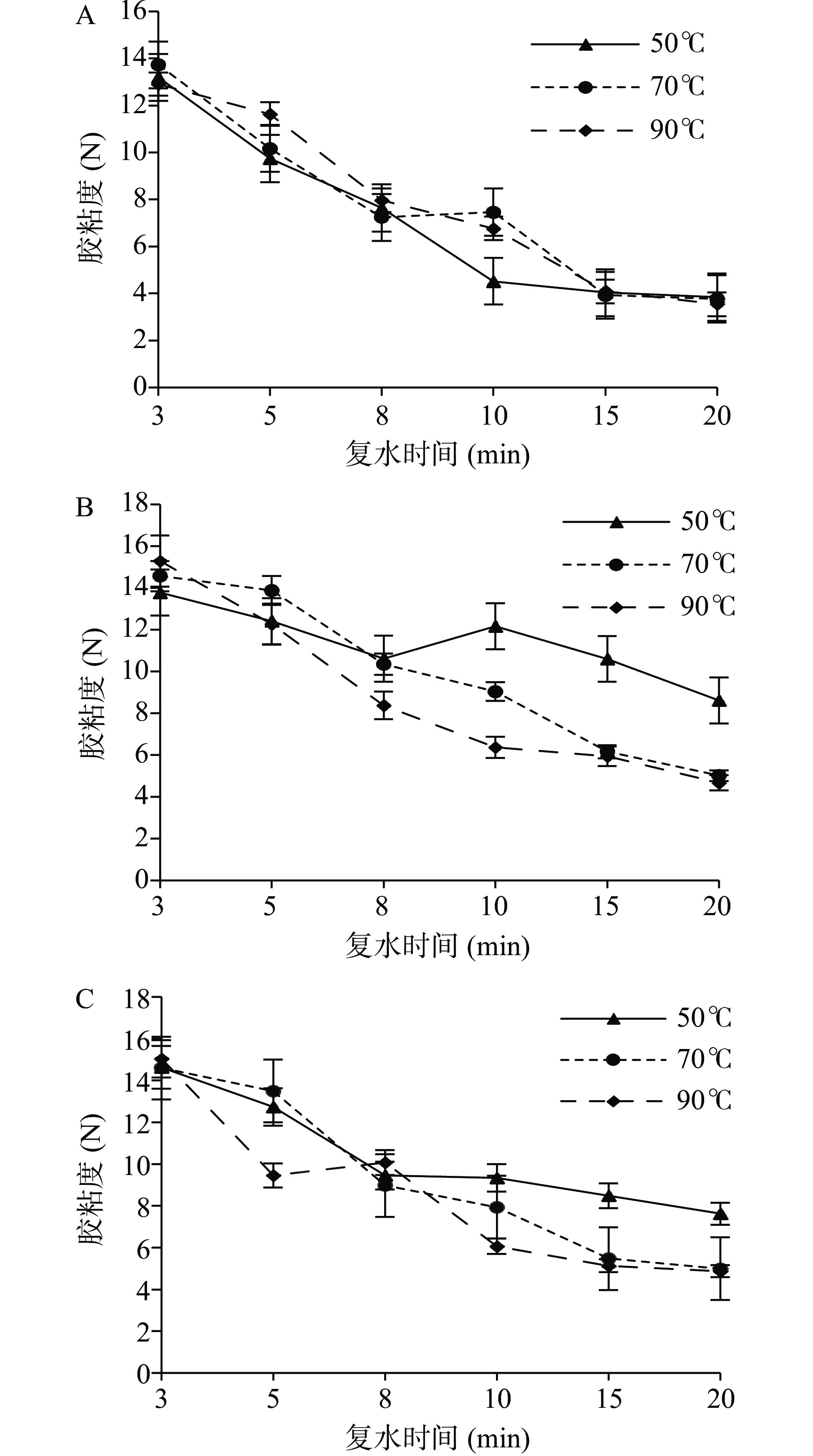

复水冻干米线的质构变化也反映了复水机制和米线品质,本研究采用质构仪检测三种冻干米线复水后的硬度变化,结果显示(图5),随着复水时间的延长,水分逐渐进入冻干米线中,将组织软化,压缩时感应力逐渐减少,硬度值也逐渐降低。同一种冻干米线复水时,水温越高,硬度值降得越低,90 ℃条件下整个复水过程硬度降低的程度最大;50和70 ℃时,复水前10 min硬度值降低程度相似,10 min后70 ℃复水米线比50 ℃复水米线的硬度值降低的快。这是因为,较高的复水温度加快结构吸水和淀粉吸水溶胀,促使冻干米线软化速度加快,硬度值降低。同一复水水温下FDRN10在整个复水过程中硬度值始终最低,原因在于FDRN10内部组织孔隙大、结构疏松,结构吸水能力较强,硬度值降低较快。随着复水过程的延续,三种冻干米线的硬度值趋于一致,说明随着水分的渗入,淀粉吸水溶胀,复水趋于结束。

![]() 图 5 冻干米线复水过程中硬度的变化注:A:FDRN10;B:FDRN20;C:FDRN40;图6同。Figure 5. Hardness changes of freeze-dried rice noodles after rehydration in different temperature

图 5 冻干米线复水过程中硬度的变化注:A:FDRN10;B:FDRN20;C:FDRN40;图6同。Figure 5. Hardness changes of freeze-dried rice noodles after rehydration in different temperature2.5 冻干米线复水后胶粘度的变化

复水过程也是淀粉吸水溶胀的过程,水分进入米线组织与淀粉结合会产生具有粘弹性的胶体,随着水分进入量的增加,胶体中水分含量升高、分布均匀,胶粘度降低,因此胶粘度的高低反映了米线组织内部水分含量的多少[38]。三种冻干米线复水后的胶粘度如图6所示,随着复水时间的延长三种冻干米线组织内胶体中水分含量逐渐增加并且分布趋于均匀,粘度值逐渐降低。复水水温50 ℃时三种冻干米线的胶粘度在10 min前下降迅速,10 min后下降减慢,水温70和90 ℃时整个复水过程胶粘度下降趋势明显,表明高温促进了水分在冻干米线组织内的均匀分布。FDRN10在复水水温50 ℃时胶粘度值低于70和90 ℃,表明FDRN10即使在较低的温度下也能快速吸水。FDRN20和FDRN40在较高的复水水温下由酥脆的固体开始吸水,开始时吸水不均匀,外层吸水较快但内层还较干燥,胶粘度值偏高,随着水分渗透,淀粉吸水溶胀形成大量胶体,胶粘度值快速降低。

在FDRN40的胶粘度曲线中出现了一个小峰,推测可能的原因是FDRN40组织孔隙较小、结构均匀致密、淀粉回生程度低,当水温较高时(90 ℃)复水初期米线表层吸水快、组织软化快,导致胶粘度值降低;之后水分快速与淀粉颗粒结合形成均匀致密的凝胶网络结构[31],当这种凝胶的形成占主导地位时胶粘度值会升高,故在复水8 min时胶粘度值形成了一个小峰,随着淀粉继续吸水溶胀,凝胶中游离水增加、结构松散,胶粘度值继续下降[39]。由此推测FDRN40复水前期以结构吸水为主,后期则以淀粉吸水溶胀为主导。

2.6 复水冻干米线与鲜湿米线的质构特性比较

作为速食方便食品,冻干米线除了复水快以外,浸泡的水温和复水后的品质也是影响方便米线开发的重要因素。研究中发现不同冻干米线复水后品质也存在差异,因此进一步比较三种冻干米线复水过程中的质构特性。将冻干米线质构特性与鲜湿米线最接近时所需复水时间和水温作为最佳的复水条件,在此复水条件下冻干米线的质构特性于表2列出,其中FDRN10在70 ℃热水中浸泡8 min的质构特性与鲜湿米线最为接近,FDRN20和FDRN40则要在90 ℃热水中浸泡10 min才与鲜湿米线接近。食味品质与粘度和硬度的比值存在正相关性[40],在一定条件下,粘度和硬度比值即平衡度越高食味品质越好[41],口感也越好。四种米线中FDRN10的平衡度最高、食味品质最好。虽然FDRN20和FDRN40的平衡度也高于鲜湿米线,但这两种米线的表面均已出现龟裂,咀嚼性降低,感官品质欠佳。

表 2 冻干米线在最佳复水条件复水后的质构特性Table 2. Texture properties of rehydrated freeze-dried rice noodles under optimum rehydration conditions复水条件 硬度(N) 粘度(N.sec) 弹性 胶粘性 咀嚼性 平衡度(粘度/硬度) 鲜湿米线 − 16.74±1.16a 0.020±0.00c 1.24±0.09a 4.27±0.83b 9.58±1.46a 0.0010a FDRN10 70 ℃/8 min 17.79±3.25a 0.065±0.11a 1.32±0.10a 7.23±3.29a 9.64±1.80a 0.0037a FDRN20 90 ℃/10 min 14.30±1.71b 0.023±0.05c 1.30±0.06a 6.37±1.02a 8.32±1.68b 0.0016a FDRN40 90 ℃/10 min 17.02±1.22a 0.034±0.05b 1.24±0.07a 6.06±0.87a 7.55±1.42c 0.0020a 注:结果以平均值±标准差的形式表示,同列不同小写字母表示差异显著(P<0.05)。 3. 结论

冻结温度和复水水温是冻干米线复水品质形成的关键因素,较高的冻结温度和复水水温可以加快冻干米线的复水速度、改善复水品质。结合微观结构和质构特性分析结果,−10 ℃冻结温度制备、70 ℃水温复水8 min的冻干米线FDRN10,具有大而疏松的组织结构,复水机制是以结构吸水为主导,复水速率高、质构特性与鲜湿米线最为接近,复水品质最佳。

在冻干米线制备时,需较高的冻结温度来增加孔隙,需较低的冻结温度来抑制淀粉回生,这个过程存在矛盾,很难统一,较高的复水温度只能起到缓解的作用,还需从改善米线的品质特性上来改进。因此,进一步的研究可通过加入抗老化添加剂,如抗性淀粉、酶等,延缓冻结时米淀粉的回生程度,改善冻干米线的复水品质,开发复水快、品质好的冻干米线。

-

图 5 冻干米线复水过程中硬度的变化

注:A:FDRN10;B:FDRN20;C:FDRN40;图6同。

Figure 5. Hardness changes of freeze-dried rice noodles after rehydration in different temperature

表 1 冻干米线孔隙大小的对比

Table 1 Comparison of pore of the freeze-dried rice noodles

FDRN10 FDRN20 FDRN40 外表面孔隙(µm) 72.58±6.97a 36.07±2.78b 18.01±1.46c 横截面孔隙(µm) 32.35±2.89a 33.12±2.29a 22.94±1.66b 注:结果以平均值±标准差的形式表示;同行不同小写字母表明差异显著(P<0.05)。 表 2 冻干米线在最佳复水条件复水后的质构特性

Table 2 Texture properties of rehydrated freeze-dried rice noodles under optimum rehydration conditions

复水条件 硬度(N) 粘度(N.sec) 弹性 胶粘性 咀嚼性 平衡度(粘度/硬度) 鲜湿米线 − 16.74±1.16a 0.020±0.00c 1.24±0.09a 4.27±0.83b 9.58±1.46a 0.0010a FDRN10 70 ℃/8 min 17.79±3.25a 0.065±0.11a 1.32±0.10a 7.23±3.29a 9.64±1.80a 0.0037a FDRN20 90 ℃/10 min 14.30±1.71b 0.023±0.05c 1.30±0.06a 6.37±1.02a 8.32±1.68b 0.0016a FDRN40 90 ℃/10 min 17.02±1.22a 0.034±0.05b 1.24±0.07a 6.06±0.87a 7.55±1.42c 0.0020a 注:结果以平均值±标准差的形式表示,同列不同小写字母表示差异显著(P<0.05)。 -

[1] AHMED I, QAZI I M, LI Z X, et al. Rice noodles: Materials, processing and quality evaluation[J]. Pakistan Academy of Sciences: B Life and Environmental Sciences,2016,53(3):215−238.

[2] 刘鑫. 方便米线品质改良的研究及营养米线产品的开发[D]. 杭州: 浙江工商大学, 2012. LIU X. Research on quality improvement of convenient rice noodles and development of nutritious rice noodles products[D]. Hangzhou: Zhejiang Gongshang University, 2012.

[3] 叶敏, 章焰, 谭汝成. 方便湿米粉的加工工艺研究[J]. 粮食与饲料工业,2005(11):15−17. [YE M, ZHANG Y, TAN R C. A study on processing technology for production of instant wet rice noodle[J]. Cereal & Feed Industry,2005(11):15−17. doi: 10.3969/j.issn.1003-6202.2005.11.008 [4] 刘鑫, 陈杰, 孟岳成, 等. 干燥型方便米线品质影响因素及其营养强化研究进展[J]. 食品科学,2011,32(3):296−300. [LIU X, CHEN J, MENG Y C, et al. Research progress in quality factors and nutrition fortification of dry-type instant rice noodles[J]. Food Science,2011,32(3):296−300. [5] 赵思明, 刘友明, 熊善柏. 高温高湿干燥对方便米粉品质的影响[J]. 粮食与饲料工业,2003(2):16−17. [ZHAO S M, LIU Y M, XIONG S B. Effect of high-temperature and high-moisture drying on the quality of instant rice noodles[J]. Cereal & Feed Industry,2003(2):16−17. doi: 10.3969/j.issn.1003-6202.2003.02.005 [6] 吕莹果, 高静丹, 陈洁, 等. 米粉干燥工艺的研究[J]. 粮食与饲料工业,2012(6):25−27. [LÜ Y G, GAO J D, CHEN J, et al. Research on drying technology of rice noodles[J]. Cereal & Feed Industry,2012(6):25−27. doi: 10.3969/j.issn.1003-6202.2012.06.009 [7] 刘成梅, 艾亦旻, 万婕, 等. 方便米粉微波干燥特性的研究[J]. 中国粮油学报,2014,29(10):1−5, 22. [LIU C M, AI Y M, WANG J, et al. Mathematical modeling on thin layer microwave drying of instant rice noodles[J]. Journal of the Chinese Cereals and Oils Association,2014,29(10):1−5, 22. [8] 熊柳, 孙庆杰. 干燥方式对方便米线复水性影响的研究[J]. 食品工业科技,2009(7):157−159. [XIONG L, SUN Q J. Study on effect of drying method on rehydration of instant rice noodle[J]. Science and Technology Food Industry,2009(7):157−159. [9] WANG X Y. Instant rice noodles and its production method: China, CN20031038704[P]. 2003-06-23.

[10] LI C M, YOU Y X, CHEN D, et al. A systematic review of rice noodles: Raw material, processing method and quality improvement[J]. Trends in Food Science & Technology,2021,107:389−400.

[11] LIU T N, WANG K, XUE W, et al. In vitro starch digestibility, edible quality and microstructure of instant rice noodles enriched with rice bran insoluble dietary fiber[J]. LWT-Food Science and Technology,2021,142:111008. doi: 10.1016/j.lwt.2021.111008

[12] CHEN J, YANG S, ZHANG M, et al. Effects of potato starch on the characteristics, microstructures and quality attributes of indica rice flour and instant rice noodles[J]. International Journal of Food Science and Technology,2022,57(4):2285−2297. doi: 10.1111/ijfs.15580

[13] CHOIL M H, KIML K H, CHOI C U, et al. Quality characteristics and antioxidant activities of instant rice noodles amended with Perilla leaf powder[J]. Journal of the Korean Society of Food Science and Nutrition,2019,48(4):424−432. doi: 10.3746/jkfn.2019.48.4.424

[14] 贺清辉, 黄文华, 王红刚. 真空冷冻干燥食品的加工工艺研究[J]. 中国食品,2022(5):128−130. [HE Q H, HUANG W H, WANG H G. Study on the processing technology of vacuum freeze-drying food[J]. China Food,2022(5):128−130. doi: 10.3969/j.issn.1000-1085.2022.05.063 [15] 毕金峰, 冯舒涵, 金鑫, 等. 真空冷冻干燥技术与产业的发展及趋势[J]. 核农学报,2022,36(2):414−421. [BI J F, FENG S H, JIN X, et al. Development and trend of vacuum freeze-drying technology and industry[J]. Journal of Nuclear Agricultural Sciences,2022,36(2):414−421. doi: 10.11869/j.issn.100-8551.2022.02.0414 [16] 廖超, 谢勇, 覃小丽, 等. 不同干燥方式对发芽青稞活性成分的影响[J]. 食品与发酵工业,2020,46(21):139−146. [LIAO C, XIE Y, QIN X L, et al. Effects of different drying methods on active constituents of germinated highland barley[J]. Food and Fermentation Industries,2020,46(21):139−146. [17] 陈腊梅, 金鑫, 毕金峰, 等. 超声辅助糖液渗透处理对真空冷冻干燥桃脆片干制品品质及吸湿性的影响[J]. 食品科学,2020,41(15):177−185. [CHEN L M, JIN X, BI J F, et al. Effect of ultrasound-assisted sugar osmosis treatment on the quality and hygroscopicity of vacuum freeze-drying peach crisp[J]. Food Science,2020,41(15):177−185. doi: 10.7506/spkx1002-6630-20190730-403 [18] 张婷, 何强. 真空冷冻干燥技术在黄秋葵加工中的应用[J]. 食品安全质量检测学报,2019,10(13):4290−4294. [ZHANG T, HE Q. Application of vacuum freeze-drying technology in Processing okra[J]. Journal of Food Safety and Quality Inspection,2019,10(13):4290−4294. doi: 10.3969/j.issn.2095-0381.2019.13.044 [19] 马娇, 唐远菊. 云南野生菌真空冷冻干燥技术研究[J]. 现代食品,2020,17:105−107. [MA J, TANG Y J. Study on vacuum freeze-drying technology of wild mushroom in Yunnan[J]. Modern Food,2020,17:105−107. [20] 邢颖, 张月, 徐怀德, 等. 不同干燥方法对生姜叶活性成分和抗氧化活性的影响[J]. 食品工业科技,2020,41(18):75−80, 86. [XING Y, ZHANG Y, XU H D, et al. Different drying methods on the ginger leaves the active ingredient and the effects of antioxidant activity[J]. Journal of Food Science and Technology,2020,41(18):75−80, 86. [21] TRAN P H L, LEE B J, TRAN T T D. Strategies and formulations of freeze-dried tablets for controlled drug delivery[J]. International Journal of Pharmaceutics,2021,597:120373. doi: 10.1016/j.ijpharm.2021.120373

[22] 周国燕, 胡琦玮, 李红卫, 等. 冻干技术的特点及在方便主食中的应用[J]. 食品工业科技,2010,82(3):389−392. [ZHOU G Y, HU Q W, LI H W, et al. Characteristics of freeze-drying technology and its application in convenient staple food[J]. Science and Technology of Food Industry,2010,82(3):389−392. [23] 陈天鹏, 李里特, 钱平. 冻干方便米饭复水品质的研究[J]. 中国粮油学报,2006,21(4):1−5. [CHEN T P, LI L T, QIAN P. The re-hydration quality of freeze dried instant rice[J]. Journal of the Chinese Cereals and Oils Association,2006,21(4):1−5. doi: 10.3321/j.issn:1003-0174.2006.04.001 [24] 李新建, 王辉, 彭菲菲. 真空冷冻干燥糯米方便粥的工艺研究[J]. 食品工业,2019,40(1):74−78. [LI X J, WANG H, PENG F F. Study on the process of vacuum freeze-drying glutinous rice instant porridge[J]. The Food Industry,2019,40(1):74−78. [25] 陈树俊, 郭琪. 真空冷冻干燥制备即食小米粥工艺优化[J]. 中国粮油学报,2021,36(7):146−154. [CHEN S J, GUO Q. Optimization of vacuum freeze-drying preparation of instant millet porridge[J]. Journal of the Chinese Cereals and Oils Association,2021,36(7):146−154. [26] GETACHEW A, EDMUNDOBRITO-DE F, FRANCO J M, et al. The importance of understanding the freezing step and its impaction on freeze drying process performance[J]. Journal of Pharmaceutical Sciences,2019,108(4):1378−1395. doi: 10.1016/j.xphs.2018.11.039

[27] 龙成. 超高压处理对籼米淀粉性质影响的研究[D]. 合肥: 安徽农业大学, 2020. LONG C. Effect of ultra high pressure (UHP) treatment on the physicochemical properties of indica rice starch[D]. Hefei: Anhui Agricultural University, 2020.

[28] 张玮, 陈洁, 陈玲. 鲜湿米粉储存过程中的品质变化规律[J]. 食品科技,2019,44(7):191−195. [ZHANG W, CHEN J, CHEN L. Quality changes of fresh wet rice noodles during storage[J]. Food Science and Technology,2019,44(7):191−195. [29] 杨榕. 大米制品适宜加工精度研究[D]. 南昌: 南昌大学, 2020. YANG R. Research on the appropriate degree of milling of rice products[D]. Nanchang: Nanchang University, 2020.

[30] LUANGMALAWATA P, PRACHAYAWARAKORN S, NATHAKARANAKULE A, et al. Effect of temperature on drying characteristics and quality of cooked rice[J]. LWT-Food Science and Technology,2008,41(4):716−723. doi: 10.1016/j.lwt.2007.04.010

[31] 陈小聪, 肖满凤, 林莹. 水分对淀粉糊化度及鲜湿米粉品质的影响[J]. 粮食与油脂,2018,31(3):41−44. [CHEN X C, XIAO M F, LIN Y. Effect of water addition on starch gelatinization degree and quality of fresh and wet rice flour[J]. Cereals & Oils,2018,31(3):41−44. doi: 10.3969/j.issn.1008-9578.2018.03.011 [32] COSTAS G B, JANINER R T. Influence of lipids on the thermal and mechanical properties of concentrated starch gels[J]. Journal of Agricultural and Food Chemistry,1991,39(5):833−840. doi: 10.1021/jf00005a003

[33] 冀智勇, 吴荣书, 刘智梅. 影响方便米线复水性及常见问题的若干因素研究[J]. 粮油加工,2005(1):75−77, 80. [JI Z Y, WU R S, LIU Z M. Study on several factors affecting rehydration and problems of instant rice noodles[J]. Cereals and Oils Processing,2005(1):75−77, 80. [34] FU Z Q, WANG L J, LI D, et al. The effect of partial gelatinization of corn starch on its retrogradation[J]. Carbohydrate Polymers,2013,97(2):512−517. doi: 10.1016/j.carbpol.2013.04.089

[35] 韩雪, 井雪萍, 张莉丽, 等. 大米淀粉回生特性及控制技术研究进展[J]. 哈尔滨工业大学学报,2016,48(2):126−130. [HAN X, JING X P, ZHANG L L, et al. Review on retrogradation properties and control technology of rice starch[J]. Journal of Harbin Institute of Technology,2016,48(2):126−130. [36] 王睿. 即食方便米饭的抗老化研究及工艺改进[D]. 无锡: 江南大学, 2007. WANG R. Studies on retrogradation of instant rice and improvement of processing[D]. Wuxi: Jiangnan University, 2007.

[37] 王婷婷, 冯霞, 连喜军. 淀粉回生动力学研究进展[J]. 粮食加工,2016,41(1):39−43. [WANG T T, FENG X, LIAN X J. Review of recent research on the dynamics of starch retrogradation[J]. Grain Processing,2016,41(1):39−43. [38] KANG M J, BAE I Y, LEE H G. Rice noodle enriched with okara: Cooking property, texture, and in vitro starch digestibility[J]. Food Bioscience,2018,22:178−183. doi: 10.1016/j.fbio.2018.02.008

[39] 蔡永艳. 米粉干法生产工艺及品质改良研究[D]. 郑州: 河南工业大学, 2011. CAI Y Y. Studies on drying technology and quality improving of rice noodles[D]. Zhengzhou: Henan University of Technology, 2011.

[40] BELLO M, BAEZA R, TOLABA M P. Quality characteristics of milled and cooked rice affected by hydrothermal treatment[J]. Journal of Food Engineering,2006,72(2):124−133. doi: 10.1016/j.jfoodeng.2004.11.026

[41] 郑志, 张原箕, 罗水忠, 等. 添加剂对方便米饭特性的影响[J]. 食品科学,2010,31(24):120−123. [ZHENG Z, ZHANG Y Q, LUO S Z, et al. Effect of food additive on properties of instant rice[J]. Food Science,2010,31(24):120−123.

下载:

下载:

下载:

下载: