Effect of Ultra-high Pressure Sterilization and Pasteurization on the Quality of Passion Fruit Juice during Storage

-

摘要: 本文研究了超高压杀菌(Ultra-High Pressure Sterilization,600 MPa/6 min)和巴氏杀菌(Pasteurization,80 ℃/30 s)对百香果果汁贮藏期菌落总数、理化指标、抗氧化活性、营养成分及挥发性成分的影响。结果表明:两种处理方式均使百香果汁达到商业无菌的状态,贮藏期结束后,巴氏杀菌和超高压杀菌菌落总数小于100 CFU/mL。巴氏杀菌使果汁总色差显著升高(P<0.05),且始终高于超高压处理,说明超高压杀菌对保持百香果汁色泽更有效。超高压处理对百香果汁可溶性糖、总酸、蛋白质含量无显著性影响(P>0.05)。贮藏期结束后,巴氏杀菌果汁的总酚、维生素C、总黄酮含量显著低于(P<0.05)超高压杀菌处理。巴氏杀菌处理后果汁的挥发性化合物酯类、醇类、酮类、醛类、烯烃类保留率低于超高压处理,且保留率与贮藏期呈负相关。综上,传统巴氏杀菌会降低百香果汁感官品质和营养品质,超高压杀菌对百香果汁品质的保持有显著优势。Abstract: The effects of ultra-high pressure sterilization (UHP, 600 MPa/6 min) and pasteurization (80 ℃/30 s) on the total number of colonies, physical and chemical indexes, antioxidant activity, nutritional components and volatile components of passion fruit juice during storage were studied. The results showed that the passion fruit juice were commercially sterile under these two treatments. After the storage period, the total number of bacterial colonies of pasteurization and ultra-high pressure sterilization were less than 100 CFU/mL. Pasteurization significantly increased the total color difference of passion fruit juice (P<0.05) and was always higher than that of ultra-high pressure treatment, indicating that ultra-high pressure sterilization was more effective in maintain the color of passion fruit juice. Ultra-high pressure treatment had no significant effect on the soluble sugar, total acid and protein content of passion fruit juice (P>0.05). After the end of storage period, the contents of total phenols, vitamin C and total flavonoids in pasteurization juice was significantly lower than those in ultra-high pressure sterilization (P<0.05). The retention rates of volatile compounds esters, alcohols, ketones, aldehydes and alkenes in pasteurized juice were lower than that in ultra-high pressure treatment, and all retention rates were negatively correlated with storage period. In conclusion, traditional pasteurization can reduce the sensory quality and nutritional quality of passion fruit juice, and ultra-high pressure sterilization has obvious advantages in maintaining the quality of passion fruit juice.

-

百香果(Passiflora edulis Sims),西番莲科西番莲属草质藤本植物,又名鸡蛋果、巴西果,主要有黄果和紫果两大类。百香果果瓤多汁,酸甜可口,气味芳香浓郁,含有丰富的氨基酸、维生素C、类胡萝卜素等物质[1-2],多酚、黄酮和生物碱等生物活性物质具有良好的抗炎、抗菌和抗氧化作用[3-5],近年来百香果逐渐成为国内外研究的热点。

百香果除了鲜食,还可加工成果醋、果酒、果汁等。果蔬饮品上市前都需经过杀菌处理以延长其货架期,杀菌方式主要有热杀菌和非热杀菌[6]。巴氏杀菌(Pasteurization,PT)因其设备简单,成本低,杀灭微生物的效果理想,是生产上常用的热杀菌方式,但易破坏食品的感官品质和营养物质[7-8]。柑橘类果汁经巴氏杀菌后会产生蒸煮味,同时苦味物质含量显著增加[9]。陈旋等[10]研究发现,巴氏杀菌会使胡柚百香果复合果汁维生素C和总酚含量显著下降,柚皮苷含量上升。研究表明,热杀菌处理的果汁营养物质被裂解,可滴定酸度、抗氧化活性含量下降,褐变度增加[11-12]。Reis等[13]对橙色西番莲汁进行巴氏杀菌,发现贮藏期间杀菌后的果汁褐变度增加,维生素原A、α-胡萝卜素、β-胡萝卜素含量下降。

超高压杀菌(Ultra-High Pressure Sterilization,UHP)是将产品密封于软包装中,以流水作为传压介质,施加100~1000 MPa的压力,在常温或较低温度下保压一定时间后,达到钝化食物内源酶活性,杀灭细菌的目的,可以很好地保持食品色泽、风味、营养品质[14-15]。邓红等[16]对猕猴桃汁进行超高压和高温短时(High Temperature Short-time,HTST)杀菌,结果发现,UHP杀菌后的猕猴桃汁总酸、抗氧化活性保留率都高于HTST杀菌。唐美玲等[17]发现200/500 MPa低高压组合,保压12 min能有效杀灭复合饮料的细菌,同时较好地保持饮料的色、香、味。Pandraju等[18]对甘蔗汁进行杀菌,发现超高压处理的果汁比巴氏杀菌处理的果汁保质期长55 d。目前对百香果的研究多集中于与其他水果复配的复合果汁的杀菌比较[10,17],超高压杀菌的百香果果汁贮藏期品质变化的研究尚待开展,牛慧慧等[19]对比UHP、HTST、PT后发现,UHP处理能较好地保持百香果汁感官和营养品质,但没有对杀菌后百香果汁贮藏期品质变化深入研究。有研究对比了巴氏杀菌和新鲜百香果果汁的品质差异并对冷藏环境下的果汁进行保质期评价[20-21],但未对整个过程芳香化合物的变化进行分析。

随着人们对果汁的消费需求越来越高,果汁贮藏期品质问题成为水果加工产业关注的焦点。本试验以紫色百香果为材料,研究了巴氏杀菌和超高压杀菌后百香果汁在4 ℃、25 d贮藏期内,糖、酸、色泽、芳香化合物等与感官品质相关指标的变化,测定了抗氧化活性及总酚、黄酮、抗坏血酸等生物活性物质,为百香果果汁货架期的评估和产业化生产提供一定的参考。

1. 材料与方法

1.1 材料与仪器

新鲜紫色百香果 产地为江西省赣州市寻乌县,2021年10月8日采收后立即运回实验室于4 ℃冰箱内储存,2 d内进行原料处理;酵母浸膏、胰蛋白胨、考马斯亮蓝G250、蒽酮 上海国药集团化学试剂有限公司;果胶酶(10万U/g) 诺维信生物科技有限公司;福林酚、芦丁、二水合氯化亚锡 光华生物科技有限公司;2,6-二氯靛酚钠盐 上海麦克林生化科技有限公司;2,4,6-三吡啶基三嗪(TPTZ)、2,2-二苯基-1-吡啶并肼基(DPPH) 上海源叶生物科技有限公司;没食子酸、2,2-联氮-二(3-乙基-苯并噻唑-6-磺酸)二铵盐(ABTS) 北京索来宝科技有限公司;以上所用有机试剂均为分析纯;丙酮、二氯甲烷 色谱纯,德国Merck公司。

FE20/EL20试验室pH计 上海梅特勒-托利多仪器有限公司;爱拓PAL-1显数测糖仪 广州市深华生物技术有限公司;S-HPP-8.8 L超高压设备 山西力德福科技有限公司;RT500(SP60)积分球式表面色差仪 天津特鲁斯科技有限公司;UV-1800型紫外分光光度计 北京瑞利分析仪器有限公司;KQ-500DB数控超声波清洗器 昆山市超声仪器有限公司;Spark 10M多功能酶标仪 南昌君辉科技有限公司;GC7890B/MS5977A气相色谱-质谱联用仪 美国Agilent公司。

1.2 实验方法

1.2.1 百香果汁的制备

1.2.2 超高压杀菌处理

预实验后,将分装于PET瓶的百香果果汁放入超高压设备杀菌,处理条件:600 MPa/6 min/22 ℃;杀菌后将样品置于4 ℃冰箱内贮藏,期间每隔5 d取样一次(样品检测到微生物则停止取样),储藏周期为25 d,测定1.2.5中各指标。

1.2.3 巴氏杀菌处理

参照文献[22]和预试验,确定巴氏杀菌条件为80 ℃/30 s。将分装于锡箔袋的百香果果汁进行巴氏杀菌,杀菌结束后0 ℃冰浴迅速冷却至室温,贮藏于4 ℃冰箱内,25 d内每5 d定期取样一次,测定1.2.5中各指标。

1.2.4 对照组处理

以未杀菌百香果果汁为对照组,贮藏条件及取样时间与1.2.2一致。

1.2.5 指标测定

1.2.5.1 微生物指标的测定

参照GB 4789.2-2016《食品微生物学检验 菌落总数测定》,测定样品中菌落总数[23]。

1.2.5.2 pH的测定

室温下用FE20/EL20试验室pH计测定其pH,测定前用pH4.01和6.86的缓冲液校正仪器。

1.2.5.3 总可溶性固形物的测定

采用日本PAL-1测糖仪测定可溶性固形物(Total Soluble Solids,TSS),测定结果的单位为ºBrix。

1.2.5.4 色度的测定

室温下采用RT500(SP60)积分球式表面色差仪测定样品色差,将样品摇匀后置于比色杯中(约15 mL),在反射模式下测定L*、a*、b*值。总色差的计算公式如下:

ΔE=√(L∗−L)2+(a∗−a)2+(b∗−b)2 (1) 式中:L、a、b分别为未处理百香果原汁测定值;L*、a*、b*为杀菌处理后百香果汁测定值;ΔE为总色差。

1.2.5.5 可溶性糖的测定

采用蒽酮-硫酸显色法测定[24],以葡萄糖配制标准溶液,得到标准曲线为:y=0.0069x+0.0194(R²=0.9927)。

1.2.5.6 总酸的测定

参照GB 12456-2021中酸碱指示剂滴定法测定总酸,以柠檬酸换算系数进行计算。

1.2.5.7 蛋白质的测定

参照SN/T 3926-2014中考马斯亮蓝法测定蛋白质,以牛血清白蛋白为标准品,其标准曲线方程为:y=0.4055x+0.0096(R²=0.9947)。

1.2.5.8 DPPH·清除率的测定

参考蔡萌等[25]的方法测定DPPH·清除率,并略作修改。配制0.02 mmol/L的DPPH溶液,每个样品取三支试管,A0管加入1 mL无水乙醇和1 mL DPPH,A1管加入1 mL样液和1 mL DPPH,A2管加入1 mL样液和1 mL无水乙醇,纯溶剂无水乙醇调零,在暗处反应30 min,在517 nm处测定吸光值。按下列公式计算DPPH·清除率。

DPPH⋅ 清除率 (%)=(1−A1−A2 A0)×100 (2) 1.2.5.9 铁离子还原能力的测定

参照Iris等[26]的方法测定铁离子还原能力,稍作修改。

标准曲线制作:将300 mmol/L,pH为3.6的CH3COONa溶液与10 mmol/L的TPTZ及20 mmol/L的FeCl3溶液按10:1:1混合均匀后得FRAP工作液,37 ℃水浴备用。

取0.1 mL不同浓度(800、400、200、100、50、25 μmol/L)的FeSO4溶液于10 mL比色管,加入3 mL FRAP工作液及2 mL超纯水,混合均匀避光反应50 min,在593 nm下测吸光值。其拟合方程为:y=0.0008x+0.0619(R²=0.9995)。

样品测定方法同上,将所得吸光值代入标准曲线得铁离子还原能力。

1.2.5.10 ABTS+·清除率的测定

参考Aati等[27]的报道,并稍加修改测定。各取0.2 mL ABTS储备液(7.4 mmol/L)+K2S2O8储备液(2.6 mmol/L)置于试管中,混合均匀,置于室温黑暗环境12 h,再用无水乙醇稀释,使A734 nm=0.7±0.02,得ABTS工作液。取1 mL ABTS工作液与50 μL百香果汁混合,振荡10 s,静置6 min,在734 nm处测得吸光值为A;以无水乙醇代替果汁在734 nm处测得吸光值为B,按下式计算ABTS+·清除率

ABTS+⋅ 清除率 (%)=B−AB×100 (3) 1.2.5.11 总酚的测定

采用福林酚法测定[28],以没食子酸为标准品,标准曲线方程为:y=0.4157x+0.0448(R²=0.9923)。

1.2.5.12 抗坏血酸的测定

参照GB 5009.86-2016中2,6-二氯靛酚滴定法测定。

1.2.5.13 总黄酮的测定

采用亚硝酸钠-硝酸铝比色法测定[29],以芦丁为标准品,标准曲线方程为:y=0.0927x−0.0018(R²=0.9951)。

1.2.6 香气的测定

1.2.6.1 样品前处理

参考刘文菁等[30]的方法,具体操作如下:加入5 mL百香果汁、玻璃珠于50 mL离心管中,涡旋混合仪处理7 min,加入5 mL二氯甲烷萃取剂,室温下5000 r/min离心5 min,静置分层,吸取中间层液体于玻璃瓶中,使用旋转蒸发仪在35 ℃水浴下减压旋蒸浓缩至近干,再加800 μL二氯甲烷,用移液枪吸取液体反复吹打玻璃瓶壁,得萃取液1 mL。将萃取液过0.22 μm有机系微孔滤膜,进行GC-MS分析。

1.2.6.2 色谱条件

参照韩素芳等[31]气相色谱-质谱(GC-MS)联用分析法,并略作修改。

采用HP-5MS毛细管柱(30 m×0.25 mm,0.25 μm),进样口温度230 ℃;柱温采用程序升温:初始柱温80 ℃,保持3 min,以15 ℃/min升至260 ℃,保持5 min;载气为氦气,采用不分流,流速1.0 mL/min。

1.2.6.3 质谱条件

电子轰击离子源(EI),检测器电压350 V,离子源温度260 ℃,接口温度280 ℃,电子能量70 eV,扫描/秒为2.8;阈值150,扫描质量范围33~550 amu。

对百香果汁进行GC-MS分析后,利用NIST质谱库进行检索,结合相对保留时间和相关文献确定香气成分。用峰面积归一法确定各成分相对含量。

1.3 数据处理

每个指标做三次平行测定,所得数据以平均值±标准差表示,用Excel进行数据处理和作图,SPSS 25.0软件对数据进行方差分析。

2. 结果与分析

2.1 超高压和巴氏杀菌处理百香果汁总菌落的变化

由表1可知,对照组的初始菌落总数为723 CFU/mL,两种杀菌处理均能使百香果汁达到商业无菌状态。随着贮藏期的延长,巴氏杀菌的果汁在15 d后开始出现微生物,25 d后,微生物含量为76 CFU/mL。超高压杀菌果汁菌落出现时间比巴氏杀菌处理晚10 d,25 d后微生物含量为17 CFU/mL,这可能是由于果汁内耐高压的芽孢杆菌未被完全消灭,继续繁殖,但菌落总数小于100 CFU/mL,仍符合国家安全标准。柳青等[32]对草莓汁杀菌后发现,超高压处理比热处理的草莓汁细菌增长慢,与本研究具有相似的结果。

表 1 超高压和巴氏杀菌对百香果汁总菌落的影响Table 1. Effects of UHP and PT on total bacterial colonies of passion fruit juice以上分析表明,超高压处理的百香果果汁杀菌效果优于巴氏杀菌。

2.2 超高压和巴氏杀菌处理百香果汁贮藏期pH、TSS的变化

由表2可知,贮藏期0 d时,与对照相比,超高压杀菌的百香果汁pH没有显著性差异(P>0.05),巴氏杀菌后pH显著升高(P<0.05)。李靖等[33]对刺梨汁进行超高压(500 MPa/10 min)和传统热杀菌(90 ℃/15 min)处理后发现热杀菌使刺梨汁的pH显著上升(P<0.05)。黄晓玲等[34]对橙汁进行HTST和UHP杀菌后,也发现类似结果,可能是由于高温加速酚酸、维生素C等氧化损伤有关。在贮藏期0 d时,两杀菌处理组的TSS含量略高于对照组,推测是温度和高压可促进果汁中内容物的流出,使果汁TSS含量提高,研究人员在对苹果汁不同杀菌处理后,也发现了相似结果[35]。两种杀菌处理的pH、TSS含量在各贮藏阶段均无显著性差异(P>0.05)。

表 2 超高压和巴氏杀菌对百香果汁贮藏期pH、TSS的影响Table 2. Effect of UHP and PT on pH, TSS of passion fruit juice during storage处理条件 贮藏期(d) pH TSS(ºBrix) CK 0

5

10

15

20

253.09±0.04cdef

3.07±0.02ef

3.11±0.02bcdef

3.07±0.01ef

3.09±0.02cdef

3.07±0.02ef18.47±0.25ab

18.40±0.20bc

18.33±0.21bcde

18.20±0.03defgh

18.10±0.10efghi

17.77±0.06hi巴氏杀菌 0

5

10

15

20

253.20±0.20ab

3.22±0.05a

3.18±0.04abc

3.25±0.07a

3.18±0.06abcd

3.17±0.02abcde18.66±0.25a

18.40±0.20bcd

18.28±0.26bcdef

18.16±0.27efghi

17.87±0.29ghi

17.68±0.12i超高压杀菌 0

5

10

15

20

253.02±0.04f

3.03±0.02f

3.08±0.01def

3.06±0.01ef

3.07±0.01ef

3.08±0.02def18.73±0.06a

18.53±0.25ab

18.23±0.06bcdef

18.03±0.06fghi

17.80±0ghi

17.63±0.12i表 3 超高压和巴氏杀菌对百香果汁贮藏期颜色的影响Table 3. Effect of UHP and PT on the color of passion fruit juice during storage处理条件 贮藏时间(d) L* a* b* ΔE CK 0 45.60±0.99bc 1.71±0.07bcd 3.97±0.26a 0l 5 45.5±0.13bcd 1.55±0.04e 3.93±0.01a 0.21±0.09k 10 45.76±0.38b 1.68±0.06d 3.78±0.05b 0.40±0.02j 15 45.23±0.08cde 1.69±0.02cd 3.58±0.09cde 0.55±0.05i 20 45.11±0.02cde 1.53±0.03e 3.46±0.03ef 0.73±0.03gh 25 44.99±0.07e 1.50±0.03e 3.43±0.02f 0.83±0.06f 巴氏杀菌 0 46.36±0.06a 1.73±0.09abcd 3.63±0.07c 0.84±0.03ef 5 46.35±0.03a 1.79±0.02a 3.45±0.04ef 0.91±0.02e 10 46.43±0.05a 1.78±0.01a 3.43±0.01f 0.99±0.03d 15 46.41±0.03a 1.77±0.02ab 3.21±0.05g 1.11±0.06c 20 46.45±0.03a 1.74±0.03abc 3.46±0.03ef 1.25±0.05b 25 46.52±0.03a 1.74±0.01abc 3.43±0.02f 1.38±0.07a 超高压杀菌 0 45.55±0.03bc 1.68±0.01cd 3.60±0.02cd 0.38±0.02j 5 45.59±0.16bc 1.78±0.01a 3.57±0.01cde 0.43±0.01j 10 45.26±0.06cde 1.78±0.02a 3.49±0.03def 0.59±0.05i 15 45.20±0.10cde 1.74±0.01abc 3.43±0.02f 0.67±0.07h 20 45.04±0.03de 1.77±0.02ab 3.39±0.02f 0.80±0.02fg 25 45.02±0.04de 1.76±0.01ab 3.39±0.02f 0.82±0.02f 表 4 超高压和巴氏杀菌对百香果汁贮藏期抗氧化能力的影响Table 4. Effect of UHP and PT on antioxidant activity of passion fruit juice during storage处理条件 贮藏时间(d) 铁离子还原能力(μmol/L) DPPH·清除率(%) ABTS+·清除率(%) CK 0 252.63±3.39b 19.90±1.31b 88.00±2.22a 5 202.72±5.12c 5.86±0.67e 73.60±1.30cd 10 177.56±1.43d 5.12±1.17ef 73.57±1.69cd 15 171.53±1.75def 4.70±0.10ef 73.19±1.76cde 20 168.19±1.96efg 2.61±0.19gh 75.49±1.55c 25 177.19±5.10d 1.90±0.14h 73.73±0.70cd 巴氏杀菌 0 250.17±2.60b 19.15±0.21b 72.93±0.17cde 5 176.06±9.35d 12.97±0.75d 70.90±2.36e 10 173.00±2.24de 4.63±0.29ef 72.91±1.07cde 15 152.91±1.67h 3.90±0.06fg 72.04±3.30de 20 150.66±7.06h 2.42±0.02gh 73.99±0.68cd 25 150.72±3.89h 1.54±0.15h 74.09±1.03cd 超高压杀菌 0 264.10±1.46a 23.53±0.62a 84.27±0.95b 5 206.19±3.80c 22.24±1.57a 73.70±0.81cd 10 174.91±2.71d 22.41±1.95a 73.70±0.81cd 15 176.06±9.35d 20.26±0.52b 75.24±0.69c 20 164.34±3.51g 15.79±1.40c 74.76±1.47cd 25 166.53±2.04fg 14.22±1.25d 73.81±2.57cd 综上,超高压杀菌可更好地保持百香果果汁pH,两种杀菌处理均可提高百香果果汁TSS含量。

2.3 超高压和巴氏杀菌对百香果汁贮藏期颜色的影响

由表3可知,与对照相比,超高压杀菌的百香果汁亮度L*无显著变化(P>0.05),这可能是由于超高压会使果汁内源酶钝化,抑制酶促褐变,减缓果汁的褐变进程[36]。与对照相比,两杀菌处理百香果汁的红绿指标a*无显著差异(P>0.05),黄蓝指标b*显著降低(P<0.05),说明百香果汁黄色变淡;与巴氏杀菌相比,超高压处理组的百香果汁ΔE变化小,说明超高压处理能更好地保持百香果汁的色泽,这与Hu等[37]的研究结果相似。各处理的L*随贮藏期延长无显著性变化(P>0.05)。总色差随储藏期延长而增大,且巴氏杀菌处理后果汁总色差显著大于超高压处理(P<0.05),可能是由于热杀菌伴随的焦糖化、美拉德反应及抗氧化物质VC等降解使百香果汁发生褐变[38-39]。

综上,超高压杀菌会减缓果汁褐变,贮藏期巴氏杀菌果汁总色差比超高压杀菌大。

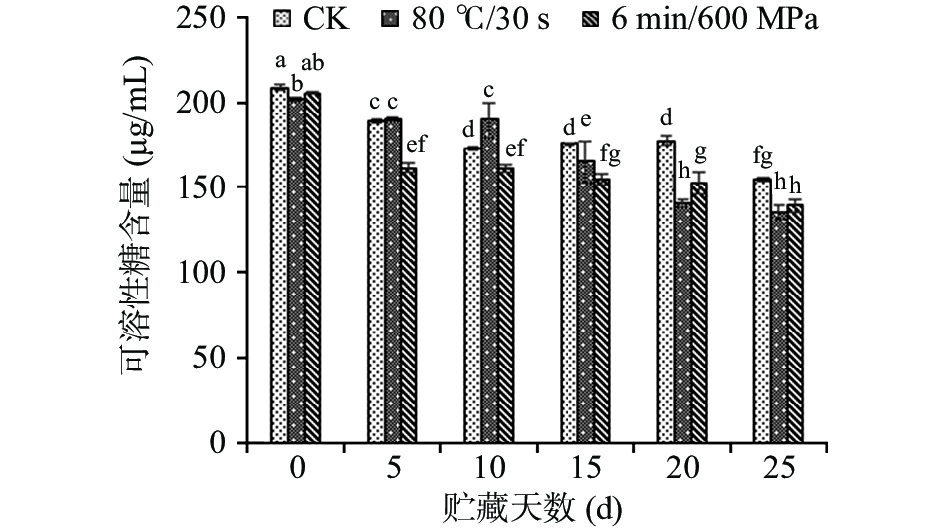

2.4 超高压和巴氏杀菌对百香果汁贮藏期可溶性糖含量的影响

如图1所示,刚杀菌处理完(贮藏0 d时),巴氏杀菌的百香果汁可溶性糖含量与对照组相比显著降低(P<0.05),为201.13 μg/mL,超高压处理组与对照组相比无显著性差异(P>0.05)。相比贮藏期0 d时,巴氏杀菌处理组百香果汁可溶性糖含量在贮藏期显著下降(P<0.05),超高压杀菌的果汁可溶性糖含量在贮藏期各阶段也显著降低(P<0.05),可能与耐高温、高压的芽孢杆菌继续繁殖消耗可溶性糖有关[40]。

综上,贮藏0 d时,超高压杀菌可更好地保持果汁可溶性糖含量,贮藏期内两种杀菌处理均使百香果果汁可溶性糖含量下降。

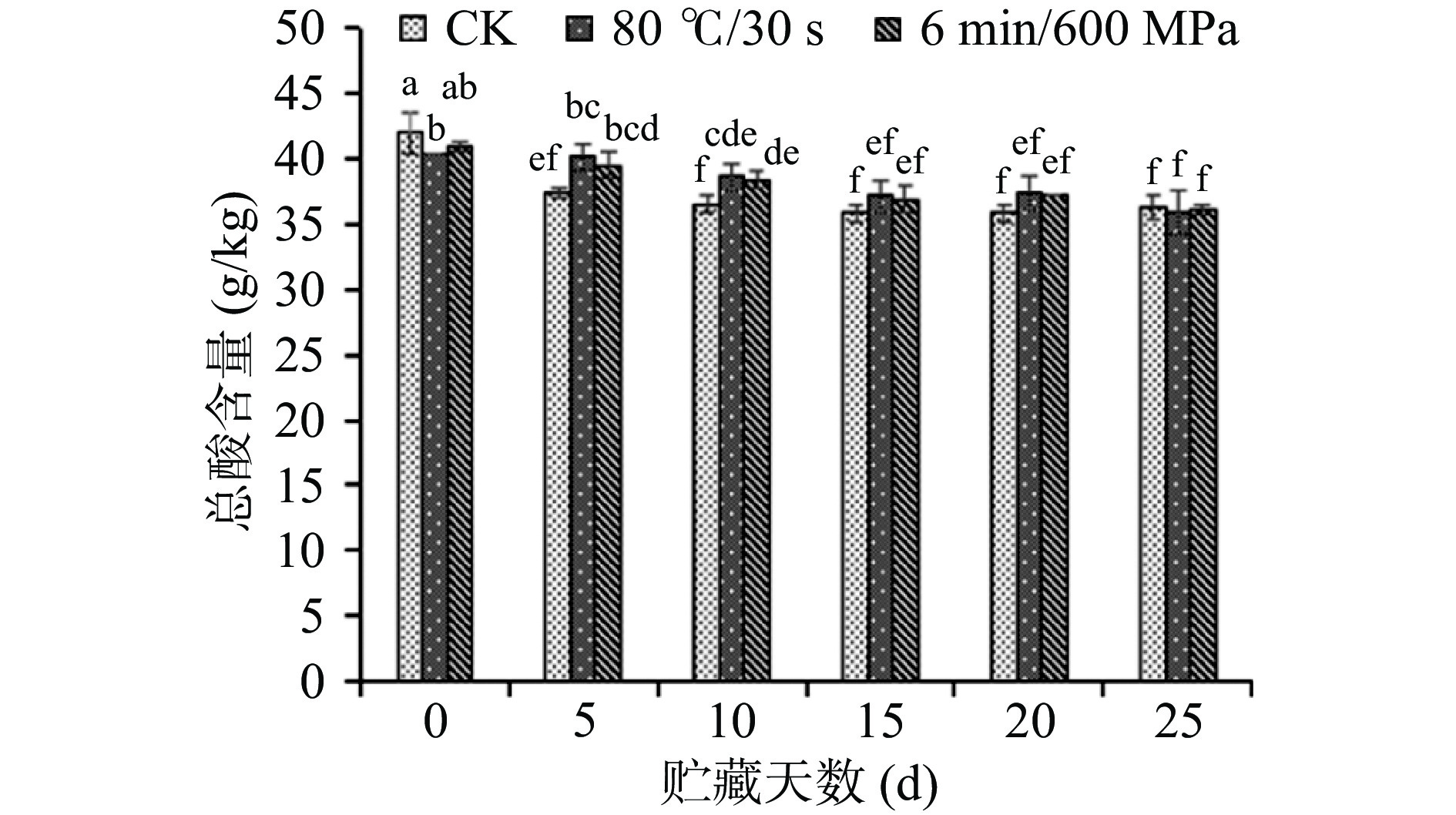

2.5 超高压和巴氏杀菌对百香果汁贮藏期总酸含量的影响

食品中酸性成分,包括H+、酸式盐浓度等对总酸度有一定影响。如图2所示,贮藏期0 d时,超高压杀菌处理的百香果汁总酸含量与对照无显著差异(P>0.05),巴氏杀菌处理百香果汁总酸含量显著降低(P<0.05),说明超高压杀菌能更好保持果汁总酸含量。贮藏期内,两种杀菌方式导致百香果汁总酸含量虽有下降但两处理间没有显著性差异(P>0.05),李根等[41]对NFC苹果汁进行微波和巴式热杀菌后,发现总酸含量变化不显著(P>0.05),与本研究结果相似。

综上,超高压可更好保持百香果果汁总酸含量,两种杀菌方式均使贮藏期百香果汁总酸含量下降。

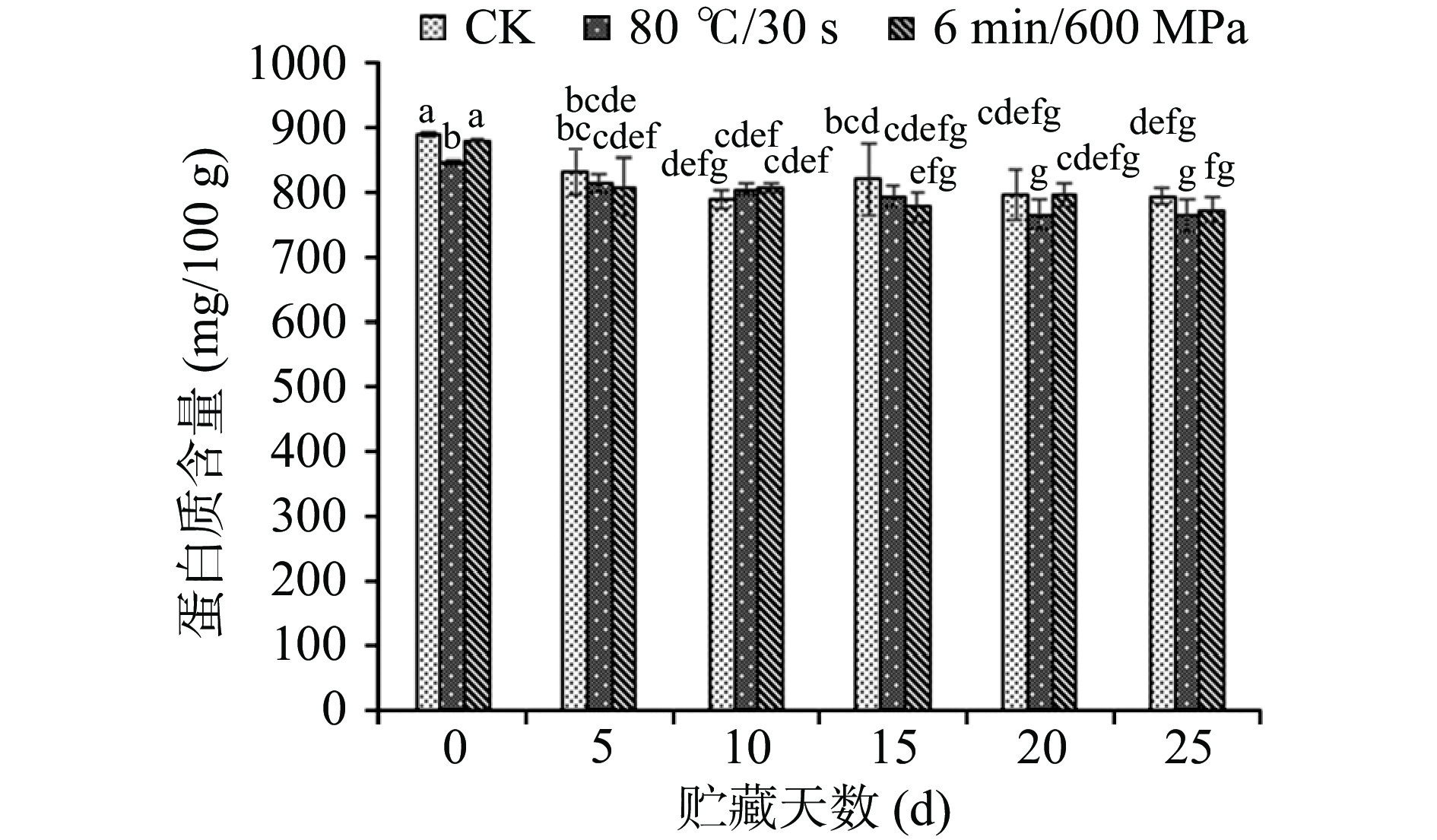

2.6 超高压和巴氏杀菌对百香果汁贮藏期蛋白质含量的影响

由图3可知,贮藏0 d时,对照组百香果汁蛋白质含量为890.35 mg/100 g,超高压与对照无显著性差异(P>0.05),巴氏杀菌显著降低百香果汁蛋白质含量(P<0.05),推测可能是高温使蛋白质变性。贮藏期5 d时,超高压处理的果汁蛋白质含量显著下降(P<0.05)。推测是由于蛋白质是有三维结构的生物高分子,具有离子键、氢键等较弱的结合键,高压会破坏弱的结合键使蛋白质变性[42],因此含量下降。

综上,贮藏0 d时,超高压杀菌可较好保留果汁蛋白质,巴氏杀菌会使果汁蛋白质变性含量下降,但高压会破坏弱的结合键导致贮藏期内果汁蛋白质含量下降。

2.7 超高压和巴氏杀菌处理对百香果汁贮藏期抗氧化能力的影响

由表4可知,与对照相比,在贮藏期0 d时,超高压处理的铁离子还原能力和DPPH·清除能力显著提高了4.54%、18.24%,彭思嘉等[43]在对樱桃汁500 MPa/2 min的超高压处理后,发现樱桃汁的抗氧化能力升高,康欢等[44]超高压处理南瓜复合果汁得到了相似结论,推测是由于静水高压促使果汁组织细胞发生改变,使胞内抗氧化物质释放到胞外环境,增加抗氧化能力。刚杀菌处理完,巴氏杀菌的百香果汁的ABTS+·清除率下降程度比超高压处理更显著(P<0.05),这可能是由于高温会加速果汁抗氧化成分的降解[33]。贮藏期间,两种杀菌处理的铁离子还原能力与DPPH·清除能力均呈显著下降趋势(P<0.05),推测可能与果汁内维生素C、多酚、花色苷、生物碱等抗氧化活性物质发生降解有关[45],贮藏25 d时,超高压处理组的果汁铁离子还原能力和DPPH·清除能力显著高于(P<0.05)巴氏杀菌处理组。

以上分析表明,超高压杀菌能更好地保持百香果果汁抗氧化能力。

2.8 超高压和巴氏杀菌对百香果汁贮藏期总酚、VC含量的影响

如图4所示,贮藏期前20 d内,超高压杀菌的百香果果汁总酚含量与对照无显著差异(P>0.05),可能是由于瞬间高压破坏细胞壁,使酚类物质的流出量增加,更易被提取、测定,且高压不会破坏分子内部共价键,所以超高压处理能更好的保留百香果汁的总酚[46-47]。在贮藏期第10 d时,巴氏杀菌的百香果汁总酚含量显著降低21.59%(P<0.05),辛明等[48]在研究不同杀菌方式对龙眼汁品质的影响中发现巴氏杀菌下龙眼汁的总酚损失率更高。

图5中,与对照组相比,0 d时巴氏杀菌VC含量显著降低(P<0.05),损失率为16.91%,0 d时超高压杀菌组VC含量与总酚变化一致,虽有小幅度上升但与对照无显著差异(P>0.05)。与0 d时相比,巴氏杀菌的百香果汁在贮藏期各阶段VC损失率分别为1.75%、6.43%、11.10%、15.79%、34.49%;贮藏期25 d后,超高压处理的果汁VC损失率为20.00%,损失率比巴氏杀菌处理组低14.49%,这可能是由于维生素C化学性质不稳定,特殊的连烯二醇结构极易受光、温度、湿度等因素影响,对热尤其敏感[49],而高压对共价键不具有破坏作用,可以使小分子维生素C更好地保存下来。张琪等[50]比较不同的杀菌方式对沙棘果浆品质的影响,发现巴氏杀菌后,沙棘果浆VC含量显著下降,与本研究结果相似。

综上所述,贮藏期各阶段,超高压杀菌处理的百香果汁总酚、维C保留率均高于巴氏杀菌处理。

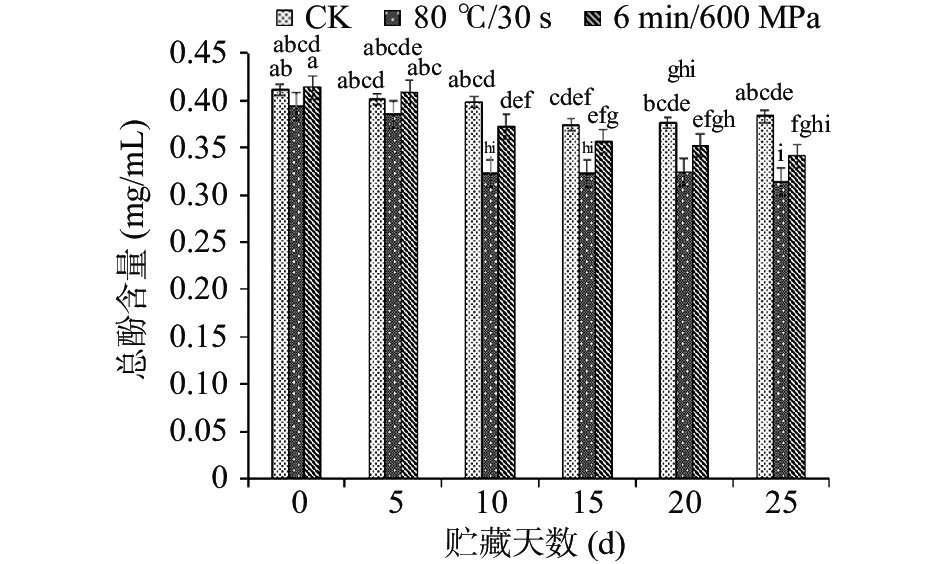

2.9 超高压和巴氏杀菌对百香果汁贮藏期总黄酮的影响

由图6可以看出,与对照组相比,贮藏期0 d时,巴氏杀菌和超高压杀菌处理总黄酮含量分别降低16.12%和10.98%,总黄酮含量与贮藏时间呈负相关,贮藏期5 d时,各处理总黄酮含量下降显著(P<0.05)。贮藏期结束后,巴氏杀菌百香果汁总黄酮保留率为63.49%,超高压处理的总黄酮保留率为82.57%,可能是由于巴氏杀菌产生的热效应会使百香果汁中黄酮成分被破坏。吴振等[51]对蓝莓果汁进行不同温度巴氏杀菌后,发现处理温度越高,贮藏初始阶段总多酚和总黄酮下降越明显。在贮藏后期,与CK相比,超高压处理组百香果汁总黄酮含量较高,推测是由于高压处理对植物组织形成机械冲击,使果汁内容物多酚、黄酮流出,稳定性提高[52]。

综上所述,巴氏杀菌的热效应对百香果汁黄酮成分有破坏作用,超高压处理可更好地保持百香果汁总黄酮稳定性。

2.10 超高压和巴氏杀菌处理后百香果汁贮藏期挥发性化合物的变化

由表5可知,贮藏期0 d时,对照组百香果果汁共检测出27种挥发性成分,两种杀菌处理后,有28种挥发性物质检出,研究者对番木瓜果汁进行巴氏杀菌(85 ℃/15 min)和高温短时杀菌后,发现巴氏杀菌的番木瓜汁挥发性成分增多[53],与本实验有相似结果。

表 5 杀菌处理后百香果汁贮藏期挥发性化合物的变化Table 5. Changes of volatile compounds in passion fruit juice after sterilization during storage序号 CAS号 名称 相对含量(%) 0C 0P 0H 5C 5P 5H 10C 10P 10H 15C 15P 15H 20C 20P 20H 25C 25P 25H 1 141-78-6 乙酸乙酯 6.31 6.19 6.21 5.98 5.89 6.17 5.46 5.86 6.02 5.13 5.79 6.11 4.87 5.76 3.98 4.52 5.23 3.77 2 79-20-9 乙酸甲酯 1.50 1.42 1.42 1.38 1.25 1.33 1.19 0.96 1.07 1.13 0.76 1.19 0.98 0.53 1.06 — — 0.97 3 105-54-4 丁酸乙酯 10.97 9.65 10.56 9.98 11.03 10.32 9.67 9.87 9.98 9.03 8.65 8.99 8.77 8.37 8.96 8.11 7.98 8.13 4 106-32-1 辛酸乙酯 1.02 0.98 1.00 0.89 0.75 0.85 0.64 0.56 0.65 0.56 0.23 0.62 0.23 — 0.45 0.19 — 0.32 5 6378-65-0 己酸己酯 4.32 4.36 4.25 4.08 3.78 4.16 3.76 3.21 3.98 3.34 2.34 3.76 2.71 1.61 3.23 2.13 1.35 3.12 6 109-20-6 异戊酸香叶基酯 0.53 0.47 0.45 0.41 — 0.38 0.32 — 0.29 0.19 — 0.27 — — — — — — 7 1259-10-5 环芳基乙酸酯 7.62 6.54 7.27 7.13 5.98 7.02 6.56 3.56 6.78 5.87 3.25 6.53 5.13 2.98 5.37 4.87 2.54 5.21 8 301-00-8 亚麻酸甲酯 2.31 1.37 2.16 2.14 — 1.52 1.97 — 1.39 1.23 — 0.97 0.67 — 0.92 0.33 — 0.88 9 109-43-3 癸二酸二丁酯 — 2.20 2.97 — 2.98 — — 3.98 — — 3.58 — — 1.47 2.37 — 1.32 2.16 10 93789-66-3 异胆酸乙酯 — 1.76 2.61 — 2.23 2.08 — 3.07 2.01 — 2.48 2.68 — 2.08 2.53 — 1.97 2.13 11 123-51-3 异戊醇 5.30 5.04 4.63 4.87 — 4.03 4.16 — 3.78 3.98 — 3.12 3.46 — 3.08 2.97 — 2.76 12 469-39-6 环六烯醇 3.52 3.29 3.33 3.57 3.32 3.87 3.69 4.21 4.78 3.67 3.98 4.92 3.93 3.07 4.57 4.12 2.76 4.34 13 83-47-6 谷甾醇 4.32 — — 3.12 3.17 — 1.97 3.17 — 1.42 3.07 — — 2.36 — — 2.34 — 14 106-69-4 1,2,6-己三醇 5.67 5.13 5.37 5.13 4.36 4.74 4.78 — 3.78 4.32 — 3.54 3.45 — 2.97 2.77 — 2.76 15 1449-09-8 环芳醇 5.85 9.04 9.34 5.87 6.7 8.76 5.33 5.32 7.54 5.15 5.17 6.35 4.98 4.85 5.37 4.73 4.56 4.78 16 78-70-6 芳樟醇 3.31 2.76 3.09 3.12 — 2.97 2.97 — 2.15 2.86 — 2.16 2.13 — 1.98 1.85 — 1.76 17 111-27-3 正己醇 1.42 1.00 1.32 1.33 0.45 1.03 1.12 — 0.78 1.01 — 0.56 0.78 — 0.32 0.53 — — 18 78-83-1 异丁醇 1.37 1.07 1.24 0.73 — 0.67 0.41 — — 0.17 — — — — — — — — 19 541-57-1 4-羟基-2,5-二甲基-

3(2H)呋喃酮6.18 5.51 6.02 6.02 5.74 5.52 5.79 5.82 4.67 5.67 5.13 3.77 5.12 4.47 2.46 4.87 4.68 1.93 20 79-77-6 β-紫罗兰酮 3.36 3.08 3.13 3.23 3.32 2.9 3.10 2.64 1.98 2.87 2.37 1.62 2.89 2.06 1.97 2.67 2.66 0.87 21 110-43-0 2-庚酮 0.93 0.81 0.89 0.76 0.34 0.42 0.34 — 0.23 — — 0.15 — — — — — — 22 3796-70-1 香叶基丙酮 0.77 0.69 0.73 0.54 0.53 0.55 0.43 — 0.37 0.28 — 0.33 — — — — — — 23 78-85-3 异丁烯醛 3.12 2.65 2.98 2.76 2.13 2.31 2.33 2.35 1.87 1.98 2.31 1.89 1.47 2.11 1.73 1.21 1.97 1.56 24 111-02-4 反式角鲨烯 4.13 4.26 4.03 3.98 4.09 3.82 3.76 3.69 4.17 3.24 3.5 3.57 2.98 3.34 2.81 2.76 2.98 1.87 25 18835-33-1 十六碳烯 0.52 0.34 0.32 0.43 — 0.37 0.36 — 0.56 0.27 — 0.67 — — 1.02 — — 1.39 26 621-82-9 肉桂酸 1.27 1.12 1.72 1.02 — 1.43 0.98 — 0.87 0.52 — 1.98 — — 2.21 — — 1.89 27 2091-29-4 棕榈油酸 — — — — 4.08 1.59 — 3.21 1.78 1.56 3.65 1.05 1.32 3.52 1.83 1.77 3.42 1.93 28 57-10-3 棕榈酸 6.11 4.47 4.87 6.07 5.88 5.02 5.92 6.03 4.83 5.13 6.76 5.04 4.76 5.44 4.81 3.96 3.66 4.8 29 463-40-1 亚麻酸 3.97 5.04 3.66 3.87 3.68 4.64 3.97 5.56 5.32 4.76 6.07 5.16 5.13 5.23 5.32 5.07 5.6 4.67 30 57-11-4 硬脂酸 4.28 3.29 4.39 4.12 — 3.79 3.97 4.21 3.42 4.13 4.32 3.84 4.22 3.72 4.17 4.16 2.32 3.89 注:“—”表示未检出该指标;“0、5、10、15、20、25”分别代表贮藏天数;“C、P、H”分别代表对照、巴氏杀菌和超高压杀菌。 由表6可知,各处理百香果汁的挥发性物质相对含量最高的是酯类,相对含量较低的为醛类和烯烃类物质。

表 6 百香果汁贮藏期间挥发性化合物的种类及相对含量Table 6. Types and relative contents of volatile compounds in passion fruit juice during storage化合物类别 相对含量(%) 0C 0P 0H 5C 5P 5H 10C 10P 10H 15C 15P 15H 20C 20P 20H 25C 25P 25H 酯类 34.58 34.93 38.92 31.99 33.89 33.83 29.57 31.07 32.17 26.48 27.08 31.12 23.36 22.80 28.87 20.15 20.39 26.69 醇类 30.77 27.34 28.33 27.74 18.00 26.07 24.43 12.70 22.81 22.58 12.22 20.65 18.73 10.28 18.29 16.97 9.66 16.40 酮类 11.24 10.09 10.77 10.55 9.93 9.39 9.66 8.46 7.25 8.82 7.5 5.87 8.01 6.53 4.43 7.54 7.34 2.8 醛类 3.12 2.65 2.98 2.26 4.13 2.31 2.33 2.35 1.87 1.98 2.31 1.89 1.47 2.11 1.73 1.21 1.97 1.56 烯烃类 4.65 4.61 4.35 4.41 4..09 4.19 4.12 3.69 4.73 3.51 3.5 4.24 2.98 3.34 3.83 2.76 2.98 3.26 酸类 15.63 15.55 14.65 15.08 13.64 16.47 14.84 19.01 16.22 16.1 20.80 17.07 15.43 17.91 18.34 14.96 15.00 17.18 注:“0、5、10、15、20、25”分别代表贮藏天数;“C、P、H”分别代表对照、巴氏杀菌和超高压杀菌。 在酯类物质中,含量最高的是具有甜果香的丁酸乙酯,它可能是百香果汁重要的呈香物质。环芳香乙酸酯、乙酸乙酯(略带酒香)含量次之,乙酸甲酯、辛酸乙酯(白兰地酒香味)、异戊酸香叶基酯相对含量较低。有研究报道百香果果肉共有77种挥发性化合物,其主要挥发性化合物有丁酸乙酯,丁酸丁酯,己酸丁酯等[54]。由表5可知,贮藏期0 d时,巴氏杀菌和超高压杀菌处理的果汁丁酸乙酯相对含量分别下降12.03%、3.74%,说明巴氏杀菌造成百香果汁特征香气损失大。

醇类物质是影响百香果果汁香味的第二大类化合物,本实验共检测出8种醇类物质,相对含量最高的是环芳醇,其次是异戊醇、1,2,6-己三醇。贮藏期0 d时,与CK相比,巴氏和超高压杀菌组环芳醇含量明显上升,环芳醇可使果汁的花香味更丰裕;与对照相比,具有铃兰香气的芳樟醇、略带酒香的正己醇、异丁醇在巴氏杀菌处理后相对含量降低比率比UHP处理大。

百香果汁酮类物质相对含量约10%左右。其中4-羟基-2,5-二甲基-3(2H)呋喃酮有焦糖香气、浓郁的果香味、果酱味,稀释后具有覆盆子香味,β-紫罗兰酮带有特殊的花香味,这两种酮类物质的存在使百香果汁气味更加馥郁。表5中,与对照组相比,两种杀菌处理后百香果汁四种酮类化合物相对含量均减少,可能是杀菌过程中酮类物质发生化合反应生成其他物质有关[16]。龙倩倩[55]在对西番莲果汁加工过程中,通过巴氏杀菌和微波杀菌,发现巴氏杀菌后β-紫罗兰酮、芳樟醇等香气成分大量丧失,与本试验有相似的结果。

醛类物质带有一定的硫化气味,大多数热带水果都含有醛类物质,异丁烯醛含量过多则可能影响百香果整体风味,两种杀菌处理后,异丁烯醛类物质含量有所降低。

此次试验共检出反式角鲨烯、十六碳烯两种烯烃类化合物,角鲨烯具有令人愉悦的香味。刘纯友等[56]利用HS-SPME-GC-MS技术检测出三种百香果汁中有β-月桂烯、D-柠檬烯等典型的香气化合物,本试验未检测出这些物质,可能是由于这两种物质具有低挥发性,本实验前处理未能提取出。

由表6可知,酸类成分含量占总挥发性化合物的15%左右。表5中,棕榈酸、亚麻酸、硬脂酸含量较高,在巴氏杀菌后,棕榈酸含量随贮藏期先升高后下降,棕榈油酸在贮藏期出现,相对含量随贮藏期延长而下降。牛慧慧[19]在对百香果汁杀菌处理的研究中检测出硬脂酸,酸类物质会有脂肪味、蜡味等特征,产生不愉快的嗅感。肉桂酸是一种不饱和芳香酸,具有香脂气、微有桂皮气味,巴氏杀菌处理后肉桂酸含量降低,超高压杀菌后肉桂酸含量随贮藏期延长先下降后升高。

两种杀菌处理后,酯类、醇类、酮类、醛类和烯烃类挥发性化合物的相对含量随贮藏期的延长而逐渐降低。表6中,与贮藏期0 d相比,巴氏杀菌、超高压杀菌处理的果汁的醇类物质相对含量在贮藏期25 d时分别下降了64.67%、42.11%,说明超高压更有利于醇类挥发性物质的保留。25 d后,巴氏杀菌处理果汁醛类物质含量比超高压杀菌处理高26.28%,这可能是由于热杀菌处理造成醛类物质增加,醛类物质含量会影响果汁的风味[57]。两种处理的酸类物质相对含量会随贮藏期延长而增加,巴氏杀菌和超高压杀菌处理的果汁酸类物质相对含量在第10 d分别增加了22.25%、10.72%,第15 d分别增加了33.76%、16.52%,但巴氏杀菌引起酸类物质增加比例大,这些化合物的增加可能与不饱和脂肪酸、类胡萝卜素等发生降解有关[58]。

综上所述,超高压杀菌对百香果汁的酯类(含量最高)、醇类(第二大类呈香物质)的保留率均大于巴氏杀菌处理,且巴氏杀菌还会引起百香果汁贮藏期内醛类、酸类物质增加,造成不愉快的嗅感,因此超高压杀菌可更好的保留百香果汁的原有风味。

3. 结论

经超高压和巴氏杀菌处理后,百香果汁均能达到商业无菌状态,超高压杀菌处理可延长果汁的货架期;巴氏杀菌后果汁pH显著升高(P<0.05),超高压杀菌果汁的pH与对照组无显著差异(P>0.05)。两杀菌处理的TSS含量与对照无显著性差异(P>0.05),随贮藏期延长巴氏杀菌处理的百香果汁TSS含量下降,巴氏杀菌处理后果汁总色差大于超高压处理。超高压处理会显著提高百香果汁的铁离子还原能力和DPPH·清除能力(P<0.05),这两种抗氧化活性都会随贮藏期延长而下降。与超高压处理相比,巴氏杀菌降低百香果汁ABTS+·清除能力更显著(P<0.05)。两杀菌处理对果汁总酚含量无显著性影响(P>0.05),贮藏期内巴氏杀菌的果汁总酚损失率高于超高压处理;巴氏杀菌会使百香果果汁维生素C含量显著降低16.91%,贮藏期25 d时,巴氏杀菌比超高压杀菌的百香果汁维生素C损失率高14.49%。

巴氏杀菌处理会明显降低百香果汁总黄酮、蛋白质、可溶性糖、总酸含量,超高压处理对百香果汁可溶性糖、总酸、蛋白质含量无显著性影响(P>0.05);贮藏期间,两种杀菌处理的上述四个指标含量均有所降低,贮藏期结束后,超高压处理果汁的总黄酮含量远高于巴氏杀菌处理。超高压杀菌处理后果汁某些含量较高的酯类(丁酸乙酯)、醇类(环芳醇)保留率高于巴氏杀菌处理。巴氏杀菌后酸类、醛类物质含量比超高压杀菌处理高,且酸类物质在贮藏中期升高,会影响果汁风味。

综上,与巴氏杀菌相比,超高压杀菌可有效杀灭百香果汁微生物,延长货架期;有效保持百香果汁理化性质,增强抗氧化能力,可减少百香果汁营养物质损失,更益于挥发性成分的保留。因此,相比巴氏杀菌,超高压杀菌可更好地保持百香果果汁的品质。

-

表 1 超高压和巴氏杀菌对百香果汁总菌落的影响

Table 1 Effects of UHP and PT on total bacterial colonies of passion fruit juice

表 2 超高压和巴氏杀菌对百香果汁贮藏期pH、TSS的影响

Table 2 Effect of UHP and PT on pH, TSS of passion fruit juice during storage

处理条件 贮藏期(d) pH TSS(ºBrix) CK 0

5

10

15

20

253.09±0.04cdef

3.07±0.02ef

3.11±0.02bcdef

3.07±0.01ef

3.09±0.02cdef

3.07±0.02ef18.47±0.25ab

18.40±0.20bc

18.33±0.21bcde

18.20±0.03defgh

18.10±0.10efghi

17.77±0.06hi巴氏杀菌 0

5

10

15

20

253.20±0.20ab

3.22±0.05a

3.18±0.04abc

3.25±0.07a

3.18±0.06abcd

3.17±0.02abcde18.66±0.25a

18.40±0.20bcd

18.28±0.26bcdef

18.16±0.27efghi

17.87±0.29ghi

17.68±0.12i超高压杀菌 0

5

10

15

20

253.02±0.04f

3.03±0.02f

3.08±0.01def

3.06±0.01ef

3.07±0.01ef

3.08±0.02def18.73±0.06a

18.53±0.25ab

18.23±0.06bcdef

18.03±0.06fghi

17.80±0ghi

17.63±0.12i表 3 超高压和巴氏杀菌对百香果汁贮藏期颜色的影响

Table 3 Effect of UHP and PT on the color of passion fruit juice during storage

处理条件 贮藏时间(d) L* a* b* ΔE CK 0 45.60±0.99bc 1.71±0.07bcd 3.97±0.26a 0l 5 45.5±0.13bcd 1.55±0.04e 3.93±0.01a 0.21±0.09k 10 45.76±0.38b 1.68±0.06d 3.78±0.05b 0.40±0.02j 15 45.23±0.08cde 1.69±0.02cd 3.58±0.09cde 0.55±0.05i 20 45.11±0.02cde 1.53±0.03e 3.46±0.03ef 0.73±0.03gh 25 44.99±0.07e 1.50±0.03e 3.43±0.02f 0.83±0.06f 巴氏杀菌 0 46.36±0.06a 1.73±0.09abcd 3.63±0.07c 0.84±0.03ef 5 46.35±0.03a 1.79±0.02a 3.45±0.04ef 0.91±0.02e 10 46.43±0.05a 1.78±0.01a 3.43±0.01f 0.99±0.03d 15 46.41±0.03a 1.77±0.02ab 3.21±0.05g 1.11±0.06c 20 46.45±0.03a 1.74±0.03abc 3.46±0.03ef 1.25±0.05b 25 46.52±0.03a 1.74±0.01abc 3.43±0.02f 1.38±0.07a 超高压杀菌 0 45.55±0.03bc 1.68±0.01cd 3.60±0.02cd 0.38±0.02j 5 45.59±0.16bc 1.78±0.01a 3.57±0.01cde 0.43±0.01j 10 45.26±0.06cde 1.78±0.02a 3.49±0.03def 0.59±0.05i 15 45.20±0.10cde 1.74±0.01abc 3.43±0.02f 0.67±0.07h 20 45.04±0.03de 1.77±0.02ab 3.39±0.02f 0.80±0.02fg 25 45.02±0.04de 1.76±0.01ab 3.39±0.02f 0.82±0.02f 表 4 超高压和巴氏杀菌对百香果汁贮藏期抗氧化能力的影响

Table 4 Effect of UHP and PT on antioxidant activity of passion fruit juice during storage

处理条件 贮藏时间(d) 铁离子还原能力(μmol/L) DPPH·清除率(%) ABTS+·清除率(%) CK 0 252.63±3.39b 19.90±1.31b 88.00±2.22a 5 202.72±5.12c 5.86±0.67e 73.60±1.30cd 10 177.56±1.43d 5.12±1.17ef 73.57±1.69cd 15 171.53±1.75def 4.70±0.10ef 73.19±1.76cde 20 168.19±1.96efg 2.61±0.19gh 75.49±1.55c 25 177.19±5.10d 1.90±0.14h 73.73±0.70cd 巴氏杀菌 0 250.17±2.60b 19.15±0.21b 72.93±0.17cde 5 176.06±9.35d 12.97±0.75d 70.90±2.36e 10 173.00±2.24de 4.63±0.29ef 72.91±1.07cde 15 152.91±1.67h 3.90±0.06fg 72.04±3.30de 20 150.66±7.06h 2.42±0.02gh 73.99±0.68cd 25 150.72±3.89h 1.54±0.15h 74.09±1.03cd 超高压杀菌 0 264.10±1.46a 23.53±0.62a 84.27±0.95b 5 206.19±3.80c 22.24±1.57a 73.70±0.81cd 10 174.91±2.71d 22.41±1.95a 73.70±0.81cd 15 176.06±9.35d 20.26±0.52b 75.24±0.69c 20 164.34±3.51g 15.79±1.40c 74.76±1.47cd 25 166.53±2.04fg 14.22±1.25d 73.81±2.57cd 表 5 杀菌处理后百香果汁贮藏期挥发性化合物的变化

Table 5 Changes of volatile compounds in passion fruit juice after sterilization during storage

序号 CAS号 名称 相对含量(%) 0C 0P 0H 5C 5P 5H 10C 10P 10H 15C 15P 15H 20C 20P 20H 25C 25P 25H 1 141-78-6 乙酸乙酯 6.31 6.19 6.21 5.98 5.89 6.17 5.46 5.86 6.02 5.13 5.79 6.11 4.87 5.76 3.98 4.52 5.23 3.77 2 79-20-9 乙酸甲酯 1.50 1.42 1.42 1.38 1.25 1.33 1.19 0.96 1.07 1.13 0.76 1.19 0.98 0.53 1.06 — — 0.97 3 105-54-4 丁酸乙酯 10.97 9.65 10.56 9.98 11.03 10.32 9.67 9.87 9.98 9.03 8.65 8.99 8.77 8.37 8.96 8.11 7.98 8.13 4 106-32-1 辛酸乙酯 1.02 0.98 1.00 0.89 0.75 0.85 0.64 0.56 0.65 0.56 0.23 0.62 0.23 — 0.45 0.19 — 0.32 5 6378-65-0 己酸己酯 4.32 4.36 4.25 4.08 3.78 4.16 3.76 3.21 3.98 3.34 2.34 3.76 2.71 1.61 3.23 2.13 1.35 3.12 6 109-20-6 异戊酸香叶基酯 0.53 0.47 0.45 0.41 — 0.38 0.32 — 0.29 0.19 — 0.27 — — — — — — 7 1259-10-5 环芳基乙酸酯 7.62 6.54 7.27 7.13 5.98 7.02 6.56 3.56 6.78 5.87 3.25 6.53 5.13 2.98 5.37 4.87 2.54 5.21 8 301-00-8 亚麻酸甲酯 2.31 1.37 2.16 2.14 — 1.52 1.97 — 1.39 1.23 — 0.97 0.67 — 0.92 0.33 — 0.88 9 109-43-3 癸二酸二丁酯 — 2.20 2.97 — 2.98 — — 3.98 — — 3.58 — — 1.47 2.37 — 1.32 2.16 10 93789-66-3 异胆酸乙酯 — 1.76 2.61 — 2.23 2.08 — 3.07 2.01 — 2.48 2.68 — 2.08 2.53 — 1.97 2.13 11 123-51-3 异戊醇 5.30 5.04 4.63 4.87 — 4.03 4.16 — 3.78 3.98 — 3.12 3.46 — 3.08 2.97 — 2.76 12 469-39-6 环六烯醇 3.52 3.29 3.33 3.57 3.32 3.87 3.69 4.21 4.78 3.67 3.98 4.92 3.93 3.07 4.57 4.12 2.76 4.34 13 83-47-6 谷甾醇 4.32 — — 3.12 3.17 — 1.97 3.17 — 1.42 3.07 — — 2.36 — — 2.34 — 14 106-69-4 1,2,6-己三醇 5.67 5.13 5.37 5.13 4.36 4.74 4.78 — 3.78 4.32 — 3.54 3.45 — 2.97 2.77 — 2.76 15 1449-09-8 环芳醇 5.85 9.04 9.34 5.87 6.7 8.76 5.33 5.32 7.54 5.15 5.17 6.35 4.98 4.85 5.37 4.73 4.56 4.78 16 78-70-6 芳樟醇 3.31 2.76 3.09 3.12 — 2.97 2.97 — 2.15 2.86 — 2.16 2.13 — 1.98 1.85 — 1.76 17 111-27-3 正己醇 1.42 1.00 1.32 1.33 0.45 1.03 1.12 — 0.78 1.01 — 0.56 0.78 — 0.32 0.53 — — 18 78-83-1 异丁醇 1.37 1.07 1.24 0.73 — 0.67 0.41 — — 0.17 — — — — — — — — 19 541-57-1 4-羟基-2,5-二甲基-

3(2H)呋喃酮6.18 5.51 6.02 6.02 5.74 5.52 5.79 5.82 4.67 5.67 5.13 3.77 5.12 4.47 2.46 4.87 4.68 1.93 20 79-77-6 β-紫罗兰酮 3.36 3.08 3.13 3.23 3.32 2.9 3.10 2.64 1.98 2.87 2.37 1.62 2.89 2.06 1.97 2.67 2.66 0.87 21 110-43-0 2-庚酮 0.93 0.81 0.89 0.76 0.34 0.42 0.34 — 0.23 — — 0.15 — — — — — — 22 3796-70-1 香叶基丙酮 0.77 0.69 0.73 0.54 0.53 0.55 0.43 — 0.37 0.28 — 0.33 — — — — — — 23 78-85-3 异丁烯醛 3.12 2.65 2.98 2.76 2.13 2.31 2.33 2.35 1.87 1.98 2.31 1.89 1.47 2.11 1.73 1.21 1.97 1.56 24 111-02-4 反式角鲨烯 4.13 4.26 4.03 3.98 4.09 3.82 3.76 3.69 4.17 3.24 3.5 3.57 2.98 3.34 2.81 2.76 2.98 1.87 25 18835-33-1 十六碳烯 0.52 0.34 0.32 0.43 — 0.37 0.36 — 0.56 0.27 — 0.67 — — 1.02 — — 1.39 26 621-82-9 肉桂酸 1.27 1.12 1.72 1.02 — 1.43 0.98 — 0.87 0.52 — 1.98 — — 2.21 — — 1.89 27 2091-29-4 棕榈油酸 — — — — 4.08 1.59 — 3.21 1.78 1.56 3.65 1.05 1.32 3.52 1.83 1.77 3.42 1.93 28 57-10-3 棕榈酸 6.11 4.47 4.87 6.07 5.88 5.02 5.92 6.03 4.83 5.13 6.76 5.04 4.76 5.44 4.81 3.96 3.66 4.8 29 463-40-1 亚麻酸 3.97 5.04 3.66 3.87 3.68 4.64 3.97 5.56 5.32 4.76 6.07 5.16 5.13 5.23 5.32 5.07 5.6 4.67 30 57-11-4 硬脂酸 4.28 3.29 4.39 4.12 — 3.79 3.97 4.21 3.42 4.13 4.32 3.84 4.22 3.72 4.17 4.16 2.32 3.89 注:“—”表示未检出该指标;“0、5、10、15、20、25”分别代表贮藏天数;“C、P、H”分别代表对照、巴氏杀菌和超高压杀菌。 表 6 百香果汁贮藏期间挥发性化合物的种类及相对含量

Table 6 Types and relative contents of volatile compounds in passion fruit juice during storage

化合物类别 相对含量(%) 0C 0P 0H 5C 5P 5H 10C 10P 10H 15C 15P 15H 20C 20P 20H 25C 25P 25H 酯类 34.58 34.93 38.92 31.99 33.89 33.83 29.57 31.07 32.17 26.48 27.08 31.12 23.36 22.80 28.87 20.15 20.39 26.69 醇类 30.77 27.34 28.33 27.74 18.00 26.07 24.43 12.70 22.81 22.58 12.22 20.65 18.73 10.28 18.29 16.97 9.66 16.40 酮类 11.24 10.09 10.77 10.55 9.93 9.39 9.66 8.46 7.25 8.82 7.5 5.87 8.01 6.53 4.43 7.54 7.34 2.8 醛类 3.12 2.65 2.98 2.26 4.13 2.31 2.33 2.35 1.87 1.98 2.31 1.89 1.47 2.11 1.73 1.21 1.97 1.56 烯烃类 4.65 4.61 4.35 4.41 4..09 4.19 4.12 3.69 4.73 3.51 3.5 4.24 2.98 3.34 3.83 2.76 2.98 3.26 酸类 15.63 15.55 14.65 15.08 13.64 16.47 14.84 19.01 16.22 16.1 20.80 17.07 15.43 17.91 18.34 14.96 15.00 17.18 注:“0、5、10、15、20、25”分别代表贮藏天数;“C、P、H”分别代表对照、巴氏杀菌和超高压杀菌。 -

[1] CARMO S J T, CRISTINA P F, CASTRO T E, et al. Brazilian native passion fruit (Passiflora tenuifila Killip) is a rich source of proanthocyanidins, carotenoids, and dietary fiber[J]. Food Research International,2021,147(12):110521.

[2] ZERAIK M L, YARIWAKE J H. Quantification of isoorientin and total flavonoids in Passiflora edulis fruit pulp by HPLC-UV/DAD[J]. Microchemical Journal,2010,96(1):86−91. doi: 10.1016/j.microc.2010.02.003

[3] 代义闯, 马伊萨兰, 潘雨阳, 等. 百香果鲜榨汁对6种食源性致病菌的抑菌效果及被膜形成的影响[J]. 中国食品学报,2018,18(12):195−202. [DAI Y C, MA Y S L, PAN Y Y, et al. Antibacterial activity of citrus passiflora fresh juice and its effect on biofilm formation to six common foodborne pathogens[J]. Journal of Chinese Institute of Food Science and Technology,2018,18(12):195−202. doi: 10.16429/j.1009-7848.2018.12.025 [4] 李欣燃, 张华兴, 翁贵英, 等. 百香果黄酮提取工艺优化及其抗氧化活性研究[J]. 食品工业科技,2020,41(24):106−112. [LI X R, ZHANG H X, WENG G Y, et al. Optimization of extraction process of total flavonoids from passion fruit and its antioxidant activity[J]. Science and Technology of Food Industry,2020,41(24):106−112. doi: 10.13386/j.issn1002-0306.2020020275 [5] VUOLO M M, LIMA G C, BATISTA Â G, et al. Passion fruit peel intake decreases inflammatory response and reverts lipid peroxidation and adiposity in diet-induced obese rats[J]. Nutrition Research,2020,76(8):106−117.

[6] 周永升, 覃浩锋, 谭凯丹, 等. 4种杀菌方式对桑葚露酒品质的影响[J]. 食品安全质量检测学报,2021,12(20):8105−8112. [ZHOU Y S, QIN H F, TAN K D, et al. Effect of 4 kinds of different sterilization methods on the quality of integrated alcoholic beverages of mulberry[J]. Journal of Food Safaty and Quality,2021,12(20):8105−8112. doi: 10.19812/j.cnki.jfsq11-5956/ts.2021.20.028 [7] YOU Y, LI N, HAN X, et al. Influence of different sterilization treatments on the color and anthocyanin contents of mulberry juice during refrigerated storage[J]. Innovative Food Science and Emerging Technologies,2018,48(3):1−10.

[8] 冀晓龙, 王猛, 李环宇, 等. 不同杀菌方式对梨枣汁杀菌效果及理化性质的影响[J]. 食品与发酵工业,2013,39(4):91−95. [JI X L, WANG M, LI H Y, et al. Effect of different sterilization methods on physicochemical properties and sterilizing results of pear jujube juice[J]. Food and Fermentation Industries,2013,39(4):91−95. doi: 10.13995/j.cnki.11-1802/ts.2013.04.033 [9] 李宏飞. 热力杀菌对柑橘罐头品质影响的研究[D]. 南京: 南京农业大学, 2016 LI H F. Study on the effect of heat sterilization on the quality of canned citrus fruits[D]. Nanjing: Agricultural University Nanjing, 2016.

[10] 陈旋, 祝林虎, 孔梦洁, 等. 杀菌方式对胡柚百香果复合果汁挥发性成分的影响[J]. 华中农业大学学报,2020,39(2):112−121. [CHEN X, ZHU L H, KONG M J, et al. Effect of sterilization methods on volatile compound juice of grapefruit and Passiflora edulis Sims[J]. Journal of the Huazhong Agricultural University,2020,39(2):112−121. doi: 10.13300/j.cnki.hnlkxb.2020.02.015 [11] ZHANG Y, GAO B, ZHANG M W, et al. Pulsed electric field processing effects on physicochemical properties, flavor compounds and microorganisms of longan juice[J]. Journal of Food Processing and Preservation,2010,34(6):1121−1138. doi: 10.1111/j.1745-4549.2009.00441.x

[12] BIRHANG B, KUMAR N P, MOHAN C C, et al. Impact of thermo sonication and pasteurization on the pHysicochemical, microbiological and anti-oxidant properties of pomelo (Citrus maxima) juice[J]. International Journal of Fruit Science,2020,20(S3):S2056−S2073.

[13] REIS L C R, FACCO E M P, FLORES S H, et al. Stability of functional compounds and antioxidant activity of fresh and pasteurized orange passion fruit (Passiflora caerulea) during cold storage[J]. Food Research International,2018,106(1):481−486.

[14] 王寅. 超高压处理对蓝莓汁的品质影响研究[D]. 北京: 北京林业大学, 2013. WANG Y. Effect of ultra-high pressure treatment on the quality of blueberry juice[D]. Beijing: Beijing Forestry University, 2013.

[15] 杨培青, 王永涛, 吴晓蒙, 等.超高压和高温短时杀菌对沙棘汁品质的影响(英文)[J/OL].食品科学: 2021: 1−15[2022-03-23]. http://kns.cnki. net/kcms/detail/11.2206.TS.20210618.1754.066.html. YANG P Q, WANG Y T, WU X M, et al. Effect of high pressure processing and high temperature short time on sea buckthorn juices[J/OL]. Food Science, 2021: 1−15[2022-03-23]. http://kns.cnki.net/kcms/detail/11.2206.TS. 20210618.1754.066.html.

[16] 邓红, 刘旻昊, 马婧, 等. UHP与 HTST杀菌处理的猕猴桃NFC果汁贮藏期品质变化[J]. 食品工业科技,2020,41(9):269−277, 296. [DENG H, LIU M H, MA J, et al. Quality changes of kwifruit NFC juice during storage with UHP and HTST sterilization treatment[J]. Food Industry Technology,2020,41(9):269−277, 296. [17] 唐美玲, 段伟文, 段振华, 等. 超高压处理对百香果-火龙果复合饮料品质的影响及杀菌工艺优化[J]. 食品与机械,2020,36(2):182−186,236. [TANG M L, DUAN W W, DUAN Z H, et al. Effect of ultra high pressure treatment on the quality of passion fruit-pitaya compound beverage and opitimization of sterilization process[J]. Food & Machinery,2020,36(2):182−186,236. [18] PANDRAJU S, LAKSHMI E J, PAVULURI S R, et al. Application of high-pressure processing for extending the shelf life of sugarcane juice under refrigerated conditions[J]. Journal of Food Processing and Preservation,2020,44(12):e14957.

[19] 牛慧慧, 张慧云, 邹文惠, 等.不同杀菌方式对百香果汁感官和营养品质的影响[J/OL].食品与发酵工业2022:1−10 [2022-03-23]. DOI:10.13995/j.cnki.11-1802/ts.030598. NIU H H, ZHANG H Y, ZOU W H, et al. Effects of sterilization methods on the sensory related characteristics and nutritional quality of passion fruit juice[J/OL]. Food and Fermentation Industries, 2022:1−10 [2022-03-23]. DOI:10.13995/j.cnki.11-1802/ts.030598.

[20] LABOISSIÈRE L H E S, DELIZA R, BARROS-MARCELLINI A M, et al. Effects of high hydrostatic pressure (HHP) on sensory characteristics of yellow passion fruit juice[J]. Innovative Food Science and Emerging Technologies,2007,8(4):469−477. doi: 10.1016/j.ifset.2007.04.001

[21] JANZANTTI N S, SANTOS G C, MONTEIRO M. Shelf life of fresh and pasteurized organic passion fruit (Passiflora edulis F. Flavicarpa D eg.) pulp[J]. Journal of Food Processing and Preservation,2014,38(1):262−270. doi: 10.1111/j.1745-4549.2012.00772.x

[22] CHEN Y, YU L J, RUPASINGHE H V. Effect of thermal and non-thermal pasteurisation on the microbial inactivation and phenolic degradation in fruit juice: A mini-review[J]. Journal of the Science of Food & Agriculture,2013,93(5):981−986.

[23] 中华人民共和国国家卫生和计划生育委员会. GB 4789.2 -2016 食品微生物学检验菌落总数测定[S]. 北京: 国家食品药品监督管理总局, 2016 The national health and family planning commission of the PRC. GB 4789.2-2016 Total number of bacterial colonies were measured by food microbiological test[S]. Beijing: China Food and Drug Administration, 2016.

[24] 张述伟, 宗营杰, 方春燕, 等. 蒽酮比色法快速测定大麦叶片中可溶性糖含量的优化[J]. 食品研究与开发,2020,41(7):196−200. [ZHANG S W, ZONG Y J, FANG C Y, et al. Optimization of anthrone colorimetric method for rapid determination of soluble sugar in barley leaves[J]. Food Research and Development,2020,41(7):196−200. doi: 10.12161/j.issn.1005-6521.2020.07.033 [25] 蔡萌, 杜双奎, 柴岩, 等. 黄土高原小粒大豆抗氧化活性研究[J]. 中国食品学报,2014,14(8):108−115. [CAI M, DU S K, CAI Y, et al. Study on antioxidant activity of small soybean from the loess plateau[J]. Chinese Journal of Food Science,2014,14(8):108−115. doi: 10.16429/j.1009-7848.2014.08.015 [26] IRIS F F B, SRRAIN J J. The ferric reducing ability of plasma (FRAP) as a measure of “Antioxidant power”: The FRAP assay[J]. Analytical Biochemistry,1996,239(1):70−76. doi: 10.1006/abio.1996.0292

[27] AATI H, EL-GAMAL A, KAYSER O. Chemical composition and biological activity of the essential oil from the root of Jatropha pelargoniifolia Courb. native to Saudi Arabia[J]. Saudi Pharmaceutical Journal,2018,27(1):88−95.

[28] 谭荣华, 艾连中, 熊智强, 等. 冷藏对滇橄榄果汁的成分、颜色及抗氧化活性的影响研究[J]. 食品与发酵科技,2021,57(6):18−26. [TAN R H, AI L Z, XIONG Z Q, et al. Effects of cold storage on composition, color and antioxidant activity of Phyllanthus emblica L. juice[J]. Food and Fermentation Technology,2021,57(6):18−26. doi: 10.3969/j.issn.1674-506X.2021.06-004 [29] 孙雪皎, 史琳, 张旋, 等. 沙棘汁总黄酮测定方法的对比分析[J]. 沈阳农业大学学报,2019,50(1):120−127. [SUN X J, SHI L, ZHANG X, et al. Comparision on determing methods for the total flavonoids in sea buckyhorn juice[J]. Journal of Shenyang Agricultural University,2019,50(1):120−127. [30] 刘文菁, 戴明, 许文琪, 等. 气相色谱-质谱法测定福建大田东方美人茶中芳樟醇类物质的含量[J]. 福建分析测试,2021,30(6):7−11,17. [LIU W J, DAI M, XU W Q, et al. Determination of linalool compounts in oriental beauty tea from Fujian datian by gas chromatography-mass spectrometry[J]. Fujian Analysis & Testing,2021,30(6):7−11,17. doi: 10.3969/j.issn.1009-8143.2021.06.02 [31] 韩素芳, 丁明, 刘亚群, 等. 顶空固相微萃取-气相色谱-质谱测定百香果香气条件的优化[J]. 中国食品学报,2010,10(4):278−284. [HAN S F, DING M, LIU Y Q, et al. The optimization of determination condition of passion fruit odors by SPME-GC-MS[J]. Chinese Journal of Food Science,2010,10(4):278−284. doi: 10.3969/j.issn.1009-7848.2010.04.042 [32] 柳青, 赵晓燕, 张超, 等. 超高压处理对草莓汁贮藏期微生物及品质的影响[J]. 中国食品学报,2014,14(11):111−117. [LIU Q, ZHAO X Y, ZHANG C, et al. Effect of high hydrostatic pressure processing on microorganism and qualities of strawberry juice during storage[J]. Journal of Chinese Institute of Food Science and Technology,2014,14(11):111−117. doi: 10.16429/j.1009-7848.2014.11.023 [33] 李靖, 王嘉祥, 陈欢, 等.超高压与热杀菌对刺梨汁贮藏期品质的影响[J].食品科学: 2021, 41(20): 1−12 LI J, WANG J X, CHEN H, et al. Quality changes of Rosa roxburghii juice by ultra-high pressure and thermal processing during storage[J]. Food Science, 2021, 41(20):1−12

[34] 黄晓玲, 王永涛, 廖小军, 等. 超高压和高温短时杀菌对 NFC 橙汁品质的影响[J]. 食品工业科技,2021,42(6):1−8. [HUANG X L, WANG Y T, LIAO X J, et al. Effects of ultra-high pressure and high temperature short-time sterilization on the quality of NFC orange juice[J]. Science and Technology of Food Industry,2021,42(6):1−8. [35] ZHU D S, ZHANG Y Y, KOU C C, et al. Ultrasonic and other sterilization methods on nutrition and flavor of cloudy apple juice[J]. Ultrasonics Sonochemistry,2022,84(2):105975.

[36] 黄易安. 不同杀菌处理方式对苹果果汁饮料品质的影响研究[J]. 食品安全导刊,2021(12):143−144. [HUANG Y A. Effects of different sterilization treatments on the quality of apple juice drinks[J]. Food Safety Guide,2021(12):143−144. doi: 10.16043/j.cnki.cfs.2021.12.079 [37] HU Y H, WANG C Y Y, CHEN B Y. Effects of high-pressure processing and thermal pasteurization on quality and microbiological safety of jabuticaba (Myrciaria cauliflora) juice during cold storage[J]. Journal of Food Science and Technology,2020,57(9):3334−3344. doi: 10.1007/s13197-020-04366-w

[38] 吴琼, 冯卫敏, 蒋和体. 不同杀菌方式对桑葚原汁品质的影响[J]. 食品科学,2016,37(9):144−149. [WU Q, FENG W M, JIANG H T. Effect of sterilization methods on the quality of mulberry juice[J]. Food Science,2016,37(9):144−149. doi: 10.7506/spkx1002-6630-201609027 [39] 马婧. 猕猴桃NFC果汁的超高压杀菌处理及其贮藏期品质变化[D]. 西安: 陕西师范大学, 2019 MA J. Ultra-high pressure sterilization of actinidia NFC juice and its quality changes during storage[D]. Xi’an: Shaanxi Normal University, 2019.

[40] 李雨浩. 蓝莓复合果汁的研制及贮藏期内品质变化研究[D]. 北京: 北京林业大学, 2020 LI Y H. Study on preparation of blueberry compound juice and its quality changes during storage[D]. Beijing: Beijing Forestry University, 2020.

[41] 李根, 赵岩, 马寅斐, 等. 微波和巴氏杀菌对NFC苹果汁品质的影响[J]. 食品研究与开发,2019,40(8):96−100. [LI G, ZHAO Y, MA Y F, et al. Effect of microwave sterilization and pasteurization on the quality of NFC apple juice[J]. Food Research and Development,2019,40(8):96−100. doi: 10.3969/j.issn.1005-6521.2019.08.017 [42] SEBASTIANO P, ALESSANDRA B. Effects of ultra-high hydrostatic pressuretreatments on the quality of tomato juice[J]. Food Chemistry,1995,52(1):35−41. doi: 10.1016/0308-8146(94)P4178-I

[43] 彭思嘉, 侯志强, 徐贞贞, 等. 超高压和高温短时杀菌对樱桃汁品质的影响[J]. 食品工业科技,2018,39(17):71−78. [PENG S J, HOU Z Q, XU Z Z, et al. Effects of high pressure and high temperature short time sterilization on the quality of cherry juice[J]. Science and Technology of Food Industry,2018,39(17):71−78. doi: 10.13386/j.issn1002-0306.2018.17.012 [44] 康欢, 马涛, 户昕娜, 等. 超高压处理对南瓜复合汁杀菌效果与品质的影响[J]. 食品工业,2019,40(5):153−159. [KANG H, MA T, HU X N, et al. Effect of ultra high pressure treatment on the sterilization and quality of pumpkin juice[J]. The Food Industry,2019,40(5):153−159. [45] 殷晓翠, 马嫄, 苏凡, 等. 超高压和热处理对发酵石榴汁品质的影响[J]. 食品工业技,2019,40(12):31−37. [YIN X C, MA Y, SU F, et al. Effect of high hydrostatic pressure and thermal treatment on quality of fermented pomegranate juice[J]. Science and Technology of Food Industry,2019,40(12):31−37. [46] SUBASI B G, ALPAS H. Effect of high hydrostatic pressure processing and squeezing pressure on some quality propertiesof pomegranate juice against thermal treatment[J]. High Pressure Research,2017,37(1):78−92. doi: 10.1080/08957959.2016.1263840

[47] 马鹏利, 张馨予, 冬子众, 等. 超高压和热处理对混合果蔬汁品质影响的比较研究[J]. 食品研究与开发,2020,41(20):51−57. [MAP L, ZHANG X Y, DONG Z Z, et al. Comparison of effects of ultra-high pressure treatment and heat treatment on qualities of mixing fruit-vegetable juice beverage[J]. Food Research and Development,2020,41(20):51−57. [48] 辛明, 李昌宝, 孙健, 等. 不同杀菌方式对龙眼原汁品质的影响[J]. 热带作物学报,2018,39(6):1190−1194. [XIN M, LI C B, SUN J, et al. Effect of sterilization methods on the quality of longan juice[J]. Chinese Journal of Tropical Crops,2018,39(6):1190−1194. doi: 10.3969/j.issn.1000-2561.2018.06.023 [49] 王乐乐, 周小顺, 周绍琴. 不同杀菌方式对刺梨果汁品质的影响[J]. 安徽农业科学,2018,46(33):144−146. [WANG L L, ZHOU X S, ZHOU S Q. Effects of different sterilization methods on the quality of Rosa roxburghii Tratt juice[J]. Journal of Anhui Agricultural Sciences,2018,46(33):144−146. doi: 10.3969/j.issn.0517-6611.2018.33.046 [50] 张琪, 朱丹, 牛广财, 等. 不同杀菌方式对沙棘果浆品质的影响[J]. 食品与发酵工业,2019,45(19):166−172. [ZHANG Q, ZHU D, NIU G C, et al. Effects of different sterilization methods on fruit pulp quality of sea buckthorn[J]. Food and Fermentation Industries,2019,45(19):166−172. doi: 10.13995/j.cnki.11-1802/ts.021174 [51] 吴振, 李红, 王勇德, 等. 不同热处理温度对蓝莓果汁在冷藏过程中多酚和黄酮含量的影响[J]. 食品与发酵工业,2019,45(17):209−215. [WU Z, LI H, WANG Y D, et al. Effects of different thermal-treated temperatures on polyphenols and flavonoids of blueberry juice during cold storage[J]. Food and Fermentation Industries,2019,45(17):209−215. doi: 10.13995/j.cnki.11-1802/ts.020573 [52] WELLALA C K D, BI J F, LIU X, et al. Effect of high pressure homogenization on mixed juice stability, rheology, physicochemical properties and microorganism reduction[J]. Journal of Food Science and Technology,2020,57(5):1944−1953. doi: 10.1007/s13197-019-04230-6

[53] 孔祥琪, 施瑞城, 张彦军, 等. 不同热力杀菌方式对番木瓜果汁挥发性香气成分的影响[J]. 保鲜与加工,2018,18(2):55−60. [KONG X Q, SHI R C, ZHANG Y J, et al. Effects of different thermal sterilizations on volatile aroma components in papaya juice[J]. Storage and Process,2018,18(2):55−60. doi: 10.3969/j.issn.1009-6221.2018.02.010 [54] MACORIS M S, JANZANTTI N S, GATTUTID S, et al. Volatile compounds from organic and conventional passion fruit (Passiflora edulis F. Flavicarpa) pulp[J]. Food Science and Technology,2011,31(2):430−435. doi: 10.1590/S0101-20612011000200023

[55] 龙倩倩. 西番莲果汁加工过程中香气成分变化[D]. 广州: 华南农业大学, 2018 LONG Q Q. Changes of aroma components in processing of passionflower juice[D]. Guangzhou: South China Agricultural University, 2018.

[56] 刘纯友, 江素珍, 冯笑, 等. HS-SPME-GC-MS测定三种类型百香果果实挥发性风味成分[J]. 食品工业科技,2021,42(11):255−262. [LIU C Y, JIANG S Z, FENG X, et al. Study on volatile flavor compounds from three types of passion fruit using fruit using headspace solid phase micro-extraction gas chromatography mass spectrometry[J]. Science and Technology of Food Industry,2021,42(11):255−262. [57] ROUSEFF R L, RUIZ P C P, JABALPURWALA F. Historical review of citrus flavor research during the past 100 years[J]. Journal of Agricultural & Food Chemistry,2009,57(18):8115−8124.

[58] GONZÁLEZ-C F, GARCÍA-P J, RAMÍREZ R. Aroma profile of a red plum purée processed by high hydrostatic pressure and analysed by SPME-GC/MS[J]. Innovative Food Science & Emerging Technologies,2016,33(1):108−114.

-

期刊类型引用(6)

1. 韦啟球,王思思,梁柳春,闭爱艳,裴世成,伍善广,刘雪萍. 扛板归多糖对HepG2细胞增殖的体外抑制作用评价. 食品研究与开发. 2025(05): 10-15+37 .  百度学术

百度学术

2. 王冬晴,马长伟,王共明,刘芳,井月欣,赵云苹,张健,矫春娜,徐英江. 发酵技术在海藻功能性食品加工中的应用. 食品与发酵工业. 2024(12): 379-387 .  百度学术

百度学术

3. 韦啟球,黄敏怡,农秋冬,闭爱艳,裴世成,刘雪萍. 扛板归粗多糖抗氧化、抗炎、镇痛和抑菌活性研究. 食品工业科技. 2024(17): 57-64 .  本站查看

本站查看

4. 许波杰,闫培生. 褐藻多糖的提取及生物活性研究进展. 现代食品科技. 2024(07): 369-378 .  百度学术

百度学术

5. 赵迪,白淼,余萍,矫艳平,闵祥博,李丽娜,李晶,彭永振,陈雪. 决明子菊花本草酵素的制备及降血压作用研究. 食品与发酵科技. 2023(05): 64-70 .  百度学术

百度学术

6. 刘欣鑫,姚必君,刘昱宏,邵端阳,韩冠英. 碱蓬多糖长循环脂质体的制备. 锦州医科大学学报. 2023(05): 6-12 .  百度学术

百度学术

其他类型引用(3)

下载:

下载:

下载:

下载: