Volatile Flavor Compounds Analysis in Lateolabrax japonicus Fish Floss Fried with Three Vegetable Oils Based on GC-IMS

-

摘要: 本研究以海鲈鱼鱼松为研究对象,通过感官评分、色差和质构确定了植物油最佳添加量为3%。在此基础上,采用气相色谱-离子迁移谱(Gas Chromatography-Ion Mobility Spectroscopy,GC-IMS)技术深入分析了三种植物油(花生油、棕榈油和葵花籽油)炒制鱼松过程中挥发性风味物质的组成情况。结果表明,三种植物油炒制的鱼松中共鉴定出40种挥发性风味物质,包括醛类、醇类、酯类和酮类化合物等,其中,花生油、棕榈油和葵花籽油炒制鱼松中醛类的相对含量最高,分别为63.33%、57.58%和43.75%。不同植物油炒制鱼松中存在特征风味物质,其中,丙醛、苯甲醛分别只存在于花生油、棕榈油炒制鱼松中;3-甲基-1-丁醇和己醛同时存在于花生油和葵花籽油炒制鱼松中。本研究结果表明根据GC-IMS建立的三种植物油炒制鱼松指纹图谱相似度较低,能有效区分炒制鱼松的植物油来源,可作为植物油炒制鱼松的鉴定及掺伪鉴别的有效手段。Abstract: On the basis of sensory scoring, color difference and texture of the optimal amount of vegetable oil to be added to 3%, compositions of volatile flavor compounds in Lateolabrax japonicus fish floss during frying process with three kinds of vegetable oils (peanut oil, palm oil and sunflower oil) were thoroughly evaluated by gas chromatography-ion mobility spectroscopy (GC-IMS) in this study. The results showed that 40 volatile substances were identified in the three kinds of vegetable oils fried fish floss, including aldehydes, alcohols, esters, and ketones compounds. The highest relative content of aldehydes was respectively 63.33%, 57.58% and 43.75% in peanut oil, palm oil and sunflower oil fried fish floss. There were characteristic flavor components of fish floss fried with different vegetable oils, which propanal and benzaldehyde were detected in fish floss fried with peanut oil and palm oil respectively; 3-methylbutan-1-ol and hexanal in fish floss fried with peanut oil and sunflower oil. The results indicated that the fingerprints of the three vegetable oil fried fish floss had low similarity established according to GC-IMS, which could effectively distinguish the vegetable oil source of fried fish floss, and could be used as the identification of vegetable oil fried fish floss and the identification of adulteration.

-

Keywords:

- Lateolabrax japonicus /

- fish floss /

- vegetable oil /

- volatile flavor compounds

-

海鲈鱼(Lateolabrax japonicas),学名为日本真鲈,又称花鲈,俗称海鲈鱼[1]。其鱼肉纯白细腻,口味鲜甜,蛋白质含量略高于其他优质鱼类,还含有维生素、必需氨基酸、矿物质等营养物质,特别是富含钙和微量元素锌等,深受人们的喜爱[2-3]。近年来,鲈鱼养殖规模越来越大,产量不断增加,《2021中国渔业年鉴》最新统计显示,2020年我国鲈鱼养殖年产量约19万吨,比上一年增长了8.37%[4-5]。鱼松是我国传统的一类鱼肉加工产品,它是用蒸煮后的鱼类肌肉加入植物油炒制一定程度制得的金黄色绒毛状调味干制品[6]。市售鱼松常通过添加植物油来赋予鱼松酥脆的口感,植物油含有脂溶性维生素和其他有益健康成分,可补充人体所需的能量,因而添加植物油对保持鱼松风味和强化鱼松营养具有重要作用[7-9]。

鱼松风味的形成主要受温度、植物油添加量和蛋白质的影响。鱼肉中蛋白质较丰富,在加工过程中加入植物油,高温炒制过程中由于水分蒸发、蛋白质变性和油脂氧化等因素的影响,鱼松在加工时产生香味物质,增加了鱼肉的风味[10-11]。花生油、棕榈油和葵花籽油等植物油是目前市场上较为常见的鱼松炒制用油,在炒制过程中补充鱼松营养价值的同时可赋予其独特风味,但肉眼难以区分掺入添加量一致、种类不同的植物油炒制的鱼松产品。气相色谱-离子迁移谱(Gas Chromatography-Ion Mobility Spectroscopy,GC-IMS)能够快速准确地检测出挥发性风味物质的组成和含量[12],陈辉等[13]利用气相色谱质谱联用技术建立橄榄油、大豆油和掺入大豆油的橄榄油的指纹图谱,快速辨识橄榄油与掺伪橄榄油。

本文以三种植物油炒制的海鲈鱼鱼松为研究对象,通过色度、质构和感官评价得出植物油的最佳添加量,在植物油最佳添加量下采用GC-IMS技术研究三种植物油对海鲈鱼鱼松挥发性风味物质的影响,建立三种植物油炒制鱼松中挥发性风味指纹图谱,旨在为较好地区分不同植物油炒制的海鲈鱼鱼松产品提供一定的理论参考。

1. 材料与方法

1.1 材料与仪器

鲜冻海鲈鱼 每尾长(35.0±5.0)cm,重约1.5 kg,由福建闽威实业养殖基地提供;棕榈油、花生油、葵花籽油、料酒 福州永辉超市,均符合食品卫生标准。

BS 224S型电子天平 赛多利斯科学仪器(北京)有限公司;WK2102电磁炉 美的集团股份有限公司;WSC-S测色色差计 上海申光仪器仪表有限公司;TA.XT EXpressC物性分析仪 英国SMS公司;FlavourSpec®风味分析仪(配有LAV(Laboratory Analytical Viewer)分析软件和GC×IMS Library Search定性软件) 德国G.A.S公司;Checkmate3顶空分析仪 丹麦Densensor公司。

1.2 实验方法

1.2.1 鱼松制作工艺流程

解冻→预处理→去腥→蒸煮→去皮去骨→碾压脱水→添加植物油→炒制→冷却→密封包装[14-15]。

将解冻的鲜冻海鲈鱼进行清洗,沥水后加入料液比1:2(g/mL)料酒腌制20 min去腥,后置于电磁炉1600 W,200 ℃蒸20 min,冷却后去除鱼皮、鱼刺,按鱼肉纤维组织手撕鱼肉至条、块状,揉搓打开鱼肉纤维;将揉搓好的鱼肉中加入一定量的植物油使其分布均匀,倒入不粘锅中电磁炉300 W,100 ℃炒制10 min,去除鱼肉表面水分,转电磁炉120 W,60 ℃继续炒制25 min,直到鱼肉纤维呈金黄色绒毛状为止,冷却至室温将鱼松密封包装。

1.2.2 植物油添加量对炒制鱼松品质的影响

鱼松制备过程同1.2.1,分别添加花生油、棕榈油和葵花籽油1%、2%、3%、4%、5%于揉搓好的鱼肉中,炒制鱼松,研究植物油添加量对鱼松色度、质构和感官品质的影响。

1.2.3 不同植物油对炒制鱼松挥发性物质的影响

鱼松制备过程同1.2.1,分别加入添加量3%的花生油、棕榈油和葵花籽油炒酥,研究不同植物油对炒制鱼松挥发性风味物质的影响。

1.2.4 色度测定

采用色差计对鱼松色泽进行分析,以白色标准板和光阱校正。以b*值为指标,记录色度值(b*值越大表示颜色越偏黄[16]),比较不同条件对鱼松金黄色泽的影响。每组鱼松随机选择3个样品,每个样品测量3次后取平均值。

1.2.5 质构测定

利用质构仪对鱼松制品的质构特性(硬度)进行测定,使用探头P/36R,采用全质构(TPA)模式进行测试,测试前速度:2.0 mm/s,测试速度:2.0 mm/s,测试后速度:5.0 mm/s;应变为75%,触发力1.0 g。每个样品测量重复3次,取平均值。

1.2.6 感官评价

感官评定采用加权评分检验法,根据鱼松色泽、组织形态、风味、口感等四个方面进行综合评分(满分以100分计)。由10名经过专业训练的人员组成评定小组,随机抽取样品,于室温环境下进行评分,评定标准见表1所示。

表 1 鱼松感官评定标准Table 1. Sensory evaluation standard of fish floss指标 权重 标准 评分(分) 色泽 25% 金黄,颜色均匀,有光泽 81~100 浅金黄色,颜色稍不均匀,稍无光泽 61~80 浅黄或深褐色,颜色不均匀,无光泽 0~60 形态 25% 纤维分明疏松,无颗粒 81~100 纤维疏松,稍有颗粒 61~80 纤维少,颗粒多 0~60 风味 25% 香味纯正,无异味 81~100 香味较纯正,稍有鱼腥味 61~80 香味淡,有鱼腥味 0~60 口感 25% 口感好,有酥脆 81~100 口感一般,稍有酥脆 61~80 口感差,较硬或较软 0~60 1.2.7 GC-IMS检测挥发性风味物质

称取1.0 g样品,置于20 mL顶空瓶中待分析。测定三种植物油炒制鲈鱼鱼松中挥发性风味物质的组成。

1.2.7.1 气相-离子迁移谱单元

分析时间:25 min;色谱柱类型:FS-SE-54-CB-1 (15 m×0.53 mm);柱温:60 ℃;载气/漂移气:N2;IMS温度:45 ℃。

1.2.7.2 自动顶空进样单元

进样体积:500 μL;孵育时间:15 min;孵育温度:90 ℃;进样针温度:85 ℃;孵化转速:500 r/min。

气相色谱条件:0~2 min:漂移气150 mL/min,载气2 mL/min;2~10 min:漂移气150 mL/min,载气2 mL/min提升到10 mL/min;10~20 min:漂移气150 mL/min,载气10 mL/min 提升到100 mL/min;20~25 min:漂移气150 mL/min,载气100 mL/min 提升到150 mL/min。

1.3 数据处理

采用Origin 2018软件、IBM SPSS 23软件进行数据处理及显著性分析,P<0.05为差异显著。鱼松样品中的挥发性物质采用仪器配套的LAV(Laboratory Analytical Viewer)分析软件和Library Search软件进行采集和分析。利用LAV分析谱图并进行定量分析;通过Reporter和Gallery Plot插件对比指纹图谱的差异;利用Dynamic PCA插件对样品进行聚类分析,以确定未知样品的种类;利用VOCal软件查看分析谱图和数据的定性定量,应用软件内置的NIST数据库和IMS数据库可对物质进行定性分析。

2. 结果与分析

2.1 植物油添加量对鱼松色度、质构及感官的影响

2.1.1 植物油添加量对鱼松色度的影响

植物油添加量对鱼松品质至关重要。植物油在炒制时与鱼松相互接触,会以薄膜的形式在短时间内被高温加热,期间因较大的比表面积而被氧化发生一系列的物理、化学变化,包括色泽加深等[17]。三种植物油添加量对鱼松色度b*的影响见表2。

表 2 三种植物油添加量对鱼松b*的影响Table 2. Effect of three kinds of vegetable oils on the b* of fish floss植物油添加量(%) b* 花生油 棕榈油 葵花籽油 1 20.16±1.52c 24.78±1.40d 21.34±1.50c 2 25.46±1.20b 29.34±1.11c 23.08±0.99c 3 27.51±0.12a 31.66±1.44bc 28.17±0.86b 4 28.47±1.18a 32.84±2.18b 29.29±0.39ab 5 28.71±0.47a 39.02±0.83a 30.78±0.75a 注:同列不同小写字母代表差异显著(P<0.05)。 如表2所示,不同植物油炒制时鱼松的色度b*随着植物油添加量的增加而增大。棕榈油中添加量为2%和3%、3%和4%间差异不显著;葵花籽油中1%和2%、3%和4%、4%和5%之间差异不显著(P>0.05),花生油炒制鱼松在添加量为3%、4%、5%时色度无明显差异(P>0.05)。这是因为不同种类的植物油在相同条件下发生物理、化学变化的趋势、快慢都不同,可能是由于其脂肪酸组成不同和内源性抗氧化剂含量不同而导致炒制鱼松的色度不同[18]。其中,当添加量大于3%时,鱼松色度b*虽随着植物油添加量的增加而逐渐升高但差异不显著。

2.1.2 植物油添加量对鱼松质构的影响

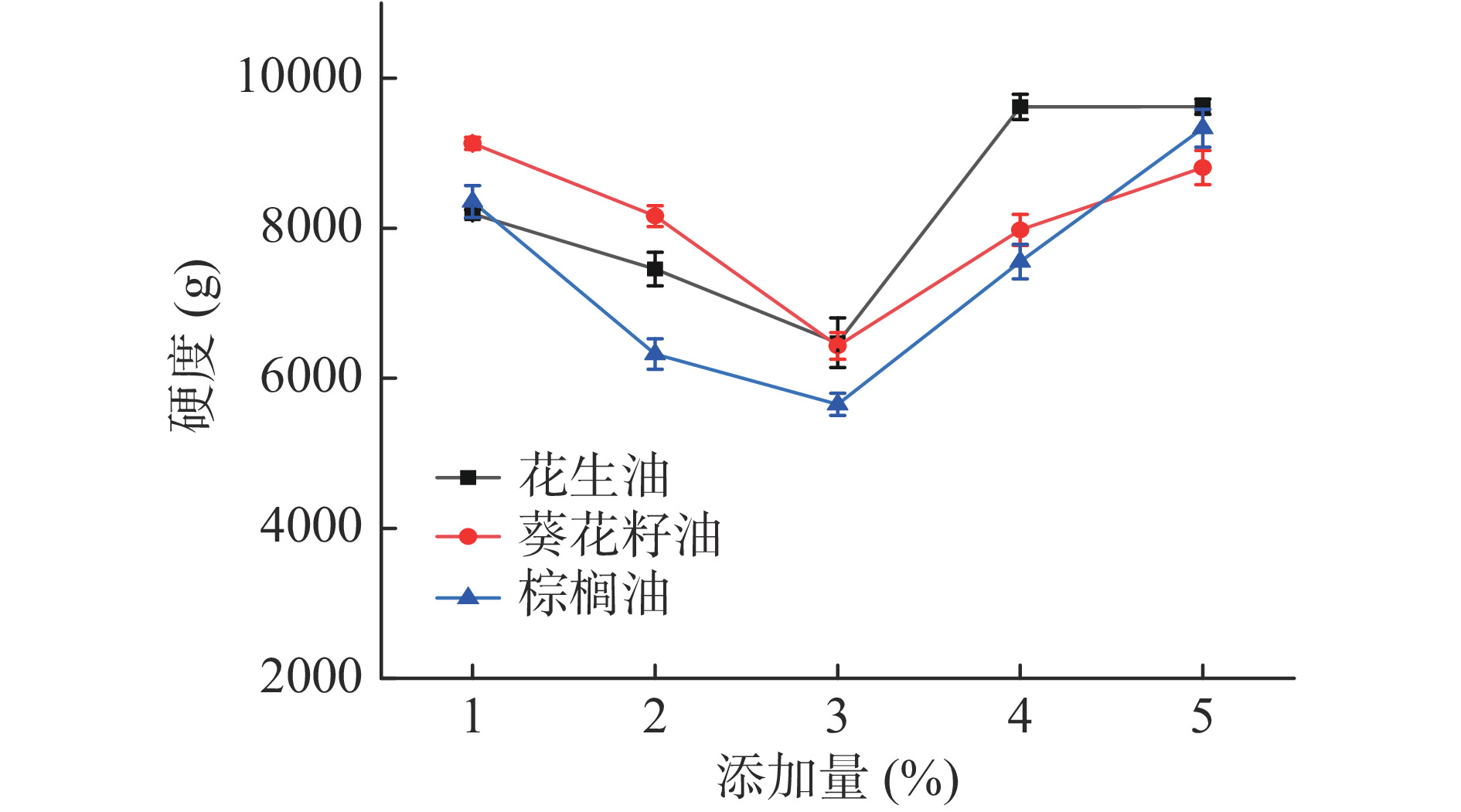

当温度不变,植物油添加量增加时,鱼肉外层水分在炒制过程中快速蒸发,过多的植物油会使鱼肉表面形成壳[19],三种植物油添加量对鱼松质构(硬度)的影响见图1。

如图1所示,三种植物油炒制的鱼松硬度随添加量的增大而呈现先减小后增大的趋势,其中,当植物油的添加量为3%时鱼松硬度最低。导致上述现象的原因可能是植物油添加量太多,炒制中较多的植物油使鱼肉里层水分不容易蒸发,纤维易断裂,容易造成成品变硬、酥性差、口感不佳且油脂味重,呈现出较差的品质[20]。

2.1.3 植物油添加量对鱼松感官评分的影响

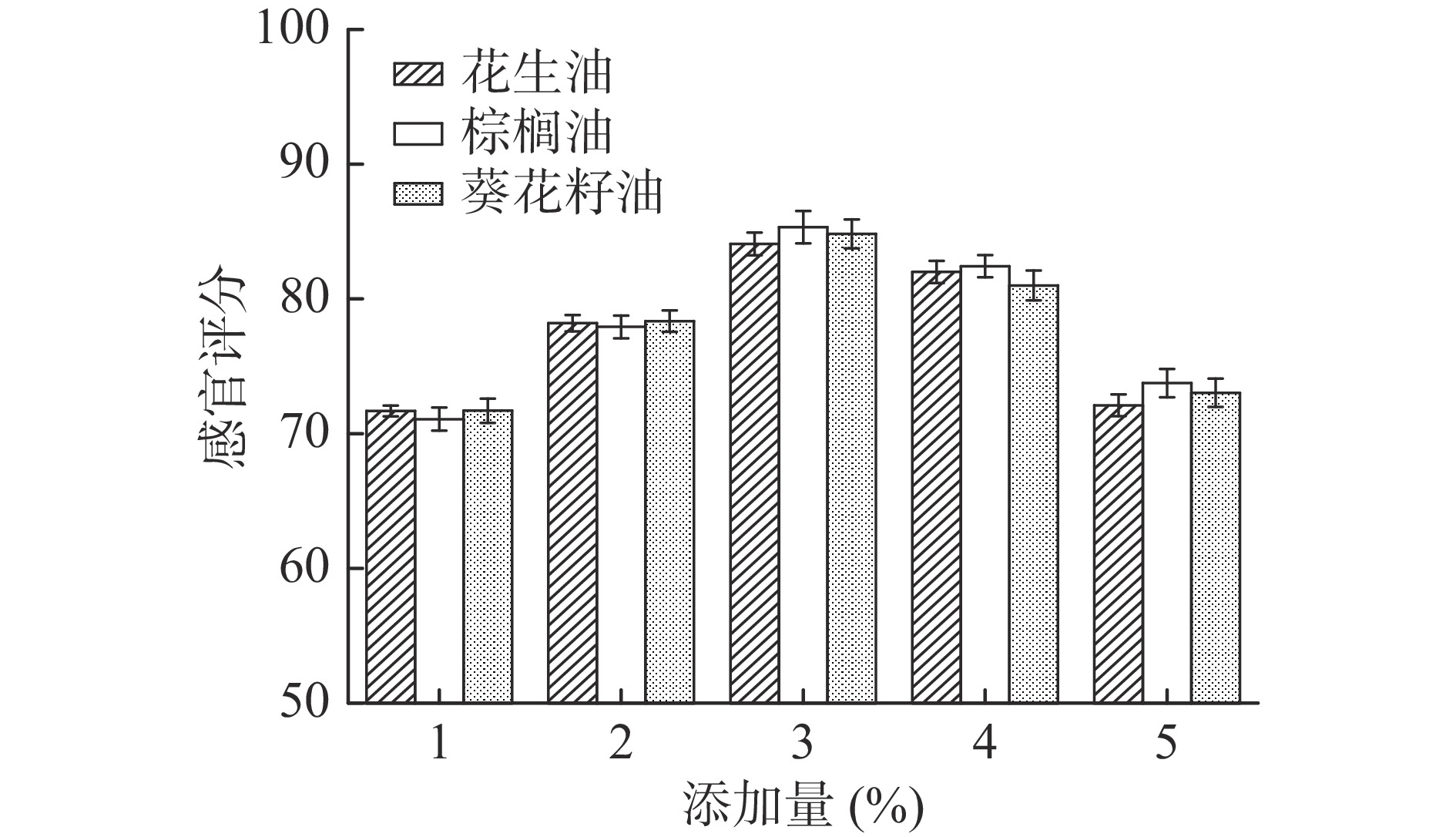

植物油虽具有重要的生理功能,但在炒制过程中不饱和脂肪酸会发生热氧化裂变和热氧化分解,产生高聚合物及醛、酮、酸类小分子化合物等,当使用量较大时该现象明显,易引起炒制物的感官变化[17],三种植物油添加量对鱼松感官评分的影响见图2。

如图2所示,鱼松的感官评分随着植物油添加量的增加而增加,添加量为3%时评分最高,之后再增加植物油的添加量时,口感、风味等均有下降,感官评分降低。结合上述色度和质构的变化情况,说明鱼松形态、风味、色泽、口感等都会随着植物油添加量的增加而趋于较优的感官品质,最后变化不明显,由此,采用3%为最优的植物油添加量水平。其中,棕榈油是一种饱和脂肪酸和不饱和脂肪酸各约占50%的油脂,较其他植物油脂具有更好的氧化稳定性,其在炒制过程不易发生氧化分解、聚合等反应,品质随添加量变化较稳定[15]。

2.2 三种植物油炒制鲈鱼鱼松挥发性风味物质组成分析

2.2.1 三种植物油炒制鲈鱼鱼松挥发性风味物质成分谱图分析

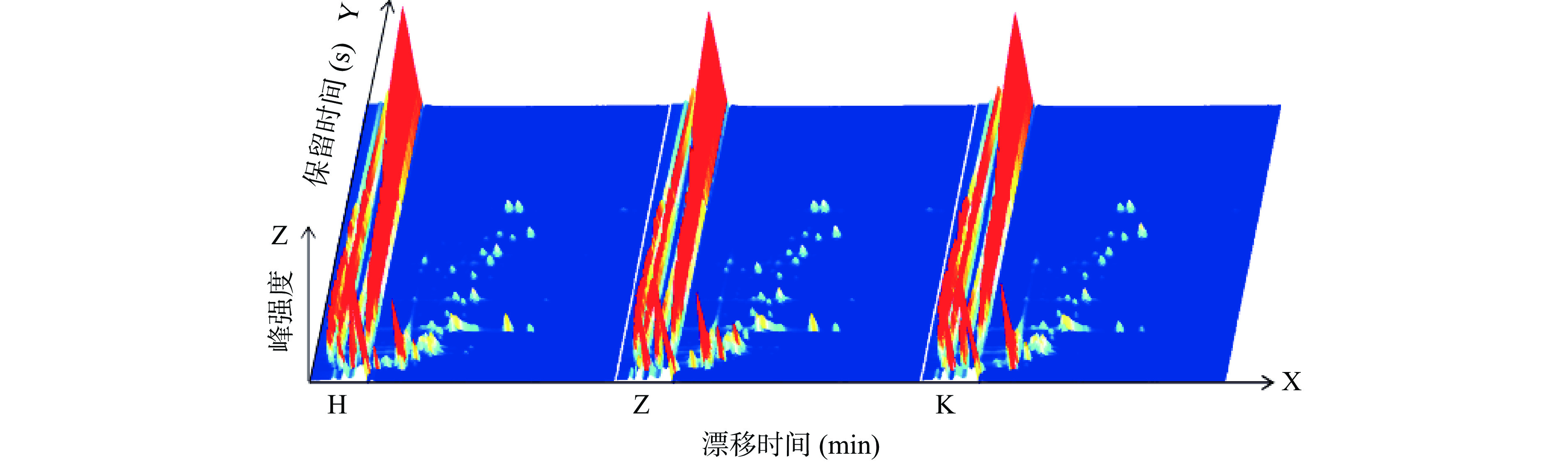

图3是三种鱼松气相色谱离子迁移三维谱图。受到挥发性物质含量和状态的影响,谱图离子峰上每个化合物可能会有1~3个斑点(指示单体或二聚体或三聚体)[21-22]。图3中挥发性成分3D谱图从左到右分别为花生油、棕榈油、葵花籽油炒制的鱼松样品。从3D谱图外观可见,不同植物油炒制鱼松样品中挥发性风味物质肉眼不容易直接区分。

图4中不同植物油炒制鱼松表现出相对特征性的GC-IMS谱图,不同植物油炒制的鱼松样品挥发性风味成分通过GC-IMS技术可以得到较好地识别与分离,能直观对比分析花生油、棕榈油、葵花籽油炒制鱼松中挥发性风味物质的细微差别。本文利用GC-IMS技术对三种植物油炒制鱼松中挥发性风味成分差异进行检测,如图4所示,浅蓝色点和红色点的数量在三种植物油炒制鱼松样品中有明显的增加或减少,说明三种鱼松样品中某些挥发性成分浓度的升高或降低。该现象可能是由于炒制过程中植物油受高温加热而发生的一系列物理、化学等综合因素变化,导致不同植物油物质溶出或氧化分解速率不同,炒制产品风味物质呈现较明显差异[17,23]。

2.2.2 三种植物油炒制鲈鱼鱼松挥发性风味物质定性分析

利用GC-IMS技术对海鲈鱼肉的挥发性风味物质进行分析鉴定。图5表示三种植物油炒制鲈鱼鱼松GC-IMS差异谱图。横坐标代表离子迁移时间(ms),纵坐标代表保留时间(s),图中1.0处红色竖线表示反应离子峰(RIP峰),每个样品的迁移时间约为2.08 ms左右,各种风味物质的保留时间集中分布在100~380 s。RIP峰两侧的每个点反映了离子流的信号强度,代表一种挥发性物质,点的颜色及面积表示物质含量的大小,点的颜色越深、面积越大反映离子流的信号越强,物质浓度越高,反之越低[24-26]。当以花生油炒制鱼松样本谱图为参照时,发现棕榈油炒制样本谱图中会出现红色和蓝色斑点,葵花籽油炒制的样本中大都是蓝色斑点,即花生油炒制样本或是棕榈油炒制样本中都有含量较高的挥发性风味物质,葵花籽油炒制的样本中几乎没有,即葵花籽油炒制的鱼松样本中挥发性物质少于另外两种植物油炒制鱼松样本。

为了进一步分析三种植物油炒制鲈鱼鱼松挥发性风味物质的变化,利用Vocal软件查看分析谱图和数据的定性定量,应用软件内置的NIST数据库和IMS数据库可对物质进行定性分析[27]。三种植物油炒制鱼松样本鉴定到的样本中挥发性物质如表3所示。鉴定出的挥发性物质的碳链普遍集中在C3~C10之间,包括醛类物质21种,醇类物质6种,酯类物质3种,酮类物质2种,其它物质8种,其中,醛类物质种类最多。醛类物质多呈刺激性或清香果香味,可有效掩盖鱼肉本身的腥臭味,说明植物油的添加对鱼松产品风味的产生具有很大的影响。

表 3 三种鱼松中鉴定出的挥发性物质Table 3. Volatile compounds identified from three kinds of fish floss编号 类别 风味化合物名称 分子式 保留指数 保留时间(s) 迁移时间(ms) 气味描述[28-30] 1 醛类 Propanal(丙醛) C3H6O 511.1 97.128 1.05199 刺激性味 2 2-methyl-propanal(2-甲基丙醛) C4H8O 533.5 106.809 1.09629 刺激性气味 3 3-methylbutanal(3-甲基丁醛) C5H10O 651.8 157.925 1.41059 苹果香 4 Pentanal M(戊醛M) C5H10O 695.0 179.028 1.18249 刺激性味 5 Pentanal D(戊醛D) C5H10O 695.0 179.028 1.42647 6 Hexanal M(己醛M) C6H12O 791.2 258.718 1.25424 青草、葡萄酒味 7 Hexanal D(己醛D) C6H12O 792.9 260.575 1.33926 8 Hexanal T(己醛T) C6H12O 792.0 259.572 1.56613 9 (E)-2-hexenal((E)-2-己烯醛) C6H10O 848.4 321.200 1.18619 清香、果香 10 Heptanal M(庚醛M) C7H14O 900.4 383.331 1.3285 蜡脂、果香 11 Heptanal D(庚醛D) C7H14O 901.6 385.462 1.40284 12 Heptanal T(庚醛T) C7H14O 900.9 384.185 1.69767 13 (E)-2-heptenal((E)-2-庚烯醛) C7H12O 957.2 482.975 1.26025 青草香 14 Benzaldehyde(苯甲醛) C7H6O 972.5 509.913 1.15574 杏仁味 15 Octanal M(辛醛M) C8H16O 1011.2 581.346 1.40276 强烈果香 16 Octanal D(辛醛D) C8H16O 1010.9 580.891 1.46204 17 Octanal T(辛醛T) C8H16O 1009.5 577.932 1.8271 18 Phenylacetaldehyde(苯乙醛) C8H8O 1064.2 687.286 1.25377 鲜花、水果 19 n-Nonanal M(壬醛M) C9H18O 1105.7 770.312 1.46958 玫瑰、油脂 20 n-Nonanal D(壬醛D) C9H18O 1106.0 770.957 1.51551 21 n-Nonanal T(壬醛T) C9H18O 1104.8 768.377 1.9476 22 醇类 3-methylbutan-1-ol(3-甲基-1-丁醇) C5H12O 722.4 201.150 1.23947 不愉快的气味 23 3-Methyl-3-buten-1-ol(3-甲基-3-丁烯-1-醇) C5H10O 770.7 240.195 1.2852 辛辣、不愉快味 24 2,3-Butanediol(2,3-丁二醇) C4H10O2 846.8 319.422 1.37207 特殊香味 25 2-Octanol(2-辛醇) C8H18O 956.4 481.613 1.44958 特殊味 26 2-Ethyl-1-hexanol(2-乙基-1-己醇) C8H18O 1043.2 645.331 1.39704 刺激性气味 27 1-Octanol(1-辛醇) C8H18O 1066.0 690.961 1.461 特殊气味 28 酮类 1-hydroxy-2-propanone(羟基丙酮) C3H6O2 691.5 176.125 1.22335 刺激性香味 29 Cyclohexanone(环己酮) C6H10O 899.0 380.889 1.15717 薄荷味 30 酸类 Propanoic acid(丙酸) C3H6O2 695.6 179.510 1.26808 刺激性气味 31 酯类 n-Propyl acetate(乙酸丙酯) C5H10O2 728.7 206.228 1.16401 特殊的水果香味 32 Isoamyl acetate(乙酸异戊酯) C7H14O2 866.9 341.352 1.3059 香蕉、梨味 33 Ethyl hexanoate(己酸乙酯) C8H16O2 972.4 509.710 1.34542 曲香、菠萝香 34 烯类 alpha-Phellandrene(α-水芹烯) C10H16 974.6 513.508 1.22075 香辛料香气 35 Limonene M(双戊烯M) C10H16 1036.1 631.118 1.2204 柠檬香味 36 Limonene D(双戊烯D) C10H16 1035.2 629.292 1.29169 37 苯胺类 Trimethylamine M(三甲胺M) C3H9N 575.1 124.775 0.95337 鱼腥味 38 Trimethylamine D(三甲胺D) C3H9N 545 111.782 1.15499 39 Benzeneamine M(苯胺M) C6H7N 992.8 545.47 1.16059 强烈气味 40 Benzeneamine D(苯胺D) C6H7N 991.7 543.671 1.43701 注:Monomer为单体;Dimer为二聚体;Tripolymer为三聚体。 2.2.3 三种植物油炒制鲈鱼鱼松挥发性风味物质指纹谱图

利用Gallery Plot插件框选所有挥发性组分信号峰,形成各样品指纹图谱进行对比,如图6所示。图中每一行代表一个样品中选取的全部信号峰,每一列代表同一挥发性组分在不同样品中的信号峰,若为数字则表示该物质在谱库中匹配度较低未被鉴定出[31-32]。观察指纹图谱可知,红框中框出的丙醛、戊醛、3-甲基丁醛、(E)-2-庚烯醛、辛醛、3-甲基-3-丁烯-1-醇、双戊烯等物质在花生油炒制鱼松样品中含量较高,绿框中框出的2-甲基丙醛、(E)-2-己烯醛、己醛、庚醛、壬醛、苯甲醛、羟基丙酮、环己酮、2,3-丁二醇、1-辛醇、α-水芹烯、己酸乙酯、丙酸等物质在棕榈油炒制鱼松样品中含量较高,葵花籽油炒制的鱼松样品中挥发性物质较少。其中,只有花生油炒制鱼松中有丙醛,棕榈油炒制鱼松中有苯甲醛;花生油和葵花籽油炒制鱼松中都有己醛和3-甲基-1-丁醇,说明三种植物油炒制的海鲈鱼鱼松挥发性风味物质的成分有较明显的区别。

为了更好表征各类挥发性化合物的变化,根据化合物在指纹图谱上的信号强度,换算得到三种植物油炒制海鲈鱼鱼松中挥发性风味物质的相对含量变化如图7所示。由图可知,花生油、棕榈油、葵花籽油炒制鱼松的挥发性成分以醛类(63.33%、57.58%、43.75%)、酯类(3.33%、6.06%、6.25%)、酮类(6.67%、6.06%、18.75%)、醇类(10.00%、12.12%、12.50%)为主,其中,醛类物质在三种植物油炒制的鱼松中相对含量最高。醛类物质主要为脂肪氧化的产物,阈值较低,对鱼松总体挥发性风味影响较大;酮类和醇类物质也来源于脂肪酸的氧化降解,其阈值高于醛类,带有一定浓香的风味;酯类物质主要是酸类和醇类物质酯化反应的产物[33-35]。含量不同的挥发性成分赋予了不同植物油炒制鱼松的差异性风味。

2.2.4 三种植物油炒制鲈鱼鱼松挥发性风味物质主成分分析

利用GC-IMS技术对挥发性成分数据采用主成分分析,探究不同条件对样品区分的可行性[36]。根据主成分分析在双标图上的距离来反映样品中挥发性组分与样品之间的相关性,每组样品风味物质谱图数据相对集合一处,使得不同处理样品实现较好的分类[37]。由图8可知,植物油炒制鱼松挥发性物质两个主成分PC1和PC2叠加贡献率可达92%,同种植物油炒制鱼松风味物质谱图数据相对集合一处,使得不同植物油炒制鱼松分类明显。花生油、棕榈油、葵花籽油炒制的海鲈鱼鱼松在挥发性风味上差异明显,棕榈油和葵花籽油炒制的鱼松样品相对较好地聚集在一处,均一性好,而花生油炒制的鱼松样品均一性较差,究其原因是花生油富含不饱和脂肪酸,其不饱和脂肪酸含量高达80%以上,因此,煎炸烹炒后裂变程度大[38]。

3. 结论

本研究利用色度、质构和感官评分确定植物油炒制海鲈鱼鱼松的最佳添加量为3%,采用GC-IMS技术对花生油、棕榈油、葵花籽油炒制的海鲈鱼鱼松中挥发性风味物质进行分析,共鉴定出40种挥发性物质,包括醛类、酮类、醇类、酸类、酯类和其它物质,其中,醛类物质的相对含量最高,其次是醇类和酮类物质。不同植物油炒制的海鲈鱼鱼松风味物质组成存在明显差异,其中,花生油炒制的鱼松中辛醛、丙醛、3-甲基-3-丁烯-1-醇、戊醛、双戊烯、3-甲基丁醛、(E)-2-庚烯醛相对含量较高,棕榈油炒制鱼松中壬醛、己醛、丙酸、2-甲基丙醛、羟基丙酮、庚醛、苯甲醛、环己酮、α-水芹烯、2,3-丁二醇、己酸乙酯、1-辛醇、(E)-2-己烯醛相对含量较高,葵花籽油炒制鱼松风味物质含量较少。因而,结合GC-IMS分析得出的风味物质,能较好地区分不同植物油炒制的海鲈鱼鱼松产品。

-

表 1 鱼松感官评定标准

Table 1 Sensory evaluation standard of fish floss

指标 权重 标准 评分(分) 色泽 25% 金黄,颜色均匀,有光泽 81~100 浅金黄色,颜色稍不均匀,稍无光泽 61~80 浅黄或深褐色,颜色不均匀,无光泽 0~60 形态 25% 纤维分明疏松,无颗粒 81~100 纤维疏松,稍有颗粒 61~80 纤维少,颗粒多 0~60 风味 25% 香味纯正,无异味 81~100 香味较纯正,稍有鱼腥味 61~80 香味淡,有鱼腥味 0~60 口感 25% 口感好,有酥脆 81~100 口感一般,稍有酥脆 61~80 口感差,较硬或较软 0~60 表 2 三种植物油添加量对鱼松b*的影响

Table 2 Effect of three kinds of vegetable oils on the b* of fish floss

植物油添加量(%) b* 花生油 棕榈油 葵花籽油 1 20.16±1.52c 24.78±1.40d 21.34±1.50c 2 25.46±1.20b 29.34±1.11c 23.08±0.99c 3 27.51±0.12a 31.66±1.44bc 28.17±0.86b 4 28.47±1.18a 32.84±2.18b 29.29±0.39ab 5 28.71±0.47a 39.02±0.83a 30.78±0.75a 注:同列不同小写字母代表差异显著(P<0.05)。 表 3 三种鱼松中鉴定出的挥发性物质

Table 3 Volatile compounds identified from three kinds of fish floss

编号 类别 风味化合物名称 分子式 保留指数 保留时间(s) 迁移时间(ms) 气味描述[28-30] 1 醛类 Propanal(丙醛) C3H6O 511.1 97.128 1.05199 刺激性味 2 2-methyl-propanal(2-甲基丙醛) C4H8O 533.5 106.809 1.09629 刺激性气味 3 3-methylbutanal(3-甲基丁醛) C5H10O 651.8 157.925 1.41059 苹果香 4 Pentanal M(戊醛M) C5H10O 695.0 179.028 1.18249 刺激性味 5 Pentanal D(戊醛D) C5H10O 695.0 179.028 1.42647 6 Hexanal M(己醛M) C6H12O 791.2 258.718 1.25424 青草、葡萄酒味 7 Hexanal D(己醛D) C6H12O 792.9 260.575 1.33926 8 Hexanal T(己醛T) C6H12O 792.0 259.572 1.56613 9 (E)-2-hexenal((E)-2-己烯醛) C6H10O 848.4 321.200 1.18619 清香、果香 10 Heptanal M(庚醛M) C7H14O 900.4 383.331 1.3285 蜡脂、果香 11 Heptanal D(庚醛D) C7H14O 901.6 385.462 1.40284 12 Heptanal T(庚醛T) C7H14O 900.9 384.185 1.69767 13 (E)-2-heptenal((E)-2-庚烯醛) C7H12O 957.2 482.975 1.26025 青草香 14 Benzaldehyde(苯甲醛) C7H6O 972.5 509.913 1.15574 杏仁味 15 Octanal M(辛醛M) C8H16O 1011.2 581.346 1.40276 强烈果香 16 Octanal D(辛醛D) C8H16O 1010.9 580.891 1.46204 17 Octanal T(辛醛T) C8H16O 1009.5 577.932 1.8271 18 Phenylacetaldehyde(苯乙醛) C8H8O 1064.2 687.286 1.25377 鲜花、水果 19 n-Nonanal M(壬醛M) C9H18O 1105.7 770.312 1.46958 玫瑰、油脂 20 n-Nonanal D(壬醛D) C9H18O 1106.0 770.957 1.51551 21 n-Nonanal T(壬醛T) C9H18O 1104.8 768.377 1.9476 22 醇类 3-methylbutan-1-ol(3-甲基-1-丁醇) C5H12O 722.4 201.150 1.23947 不愉快的气味 23 3-Methyl-3-buten-1-ol(3-甲基-3-丁烯-1-醇) C5H10O 770.7 240.195 1.2852 辛辣、不愉快味 24 2,3-Butanediol(2,3-丁二醇) C4H10O2 846.8 319.422 1.37207 特殊香味 25 2-Octanol(2-辛醇) C8H18O 956.4 481.613 1.44958 特殊味 26 2-Ethyl-1-hexanol(2-乙基-1-己醇) C8H18O 1043.2 645.331 1.39704 刺激性气味 27 1-Octanol(1-辛醇) C8H18O 1066.0 690.961 1.461 特殊气味 28 酮类 1-hydroxy-2-propanone(羟基丙酮) C3H6O2 691.5 176.125 1.22335 刺激性香味 29 Cyclohexanone(环己酮) C6H10O 899.0 380.889 1.15717 薄荷味 30 酸类 Propanoic acid(丙酸) C3H6O2 695.6 179.510 1.26808 刺激性气味 31 酯类 n-Propyl acetate(乙酸丙酯) C5H10O2 728.7 206.228 1.16401 特殊的水果香味 32 Isoamyl acetate(乙酸异戊酯) C7H14O2 866.9 341.352 1.3059 香蕉、梨味 33 Ethyl hexanoate(己酸乙酯) C8H16O2 972.4 509.710 1.34542 曲香、菠萝香 34 烯类 alpha-Phellandrene(α-水芹烯) C10H16 974.6 513.508 1.22075 香辛料香气 35 Limonene M(双戊烯M) C10H16 1036.1 631.118 1.2204 柠檬香味 36 Limonene D(双戊烯D) C10H16 1035.2 629.292 1.29169 37 苯胺类 Trimethylamine M(三甲胺M) C3H9N 575.1 124.775 0.95337 鱼腥味 38 Trimethylamine D(三甲胺D) C3H9N 545 111.782 1.15499 39 Benzeneamine M(苯胺M) C6H7N 992.8 545.47 1.16059 强烈气味 40 Benzeneamine D(苯胺D) C6H7N 991.7 543.671 1.43701 注:Monomer为单体;Dimer为二聚体;Tripolymer为三聚体。 -

[1] CAI L, WU X, LI X, et al. Effects of different freezing treatments on physicochemical responses and microbial characteristics of Japanese sea bass (Lateolabrax japonicas) fillets during refrigerated storage[J]. LWT-Food Science and Technology,2014,59(1):122−129. doi: 10.1016/j.lwt.2014.04.062

[2] LIU F, HUANG H, LIN W, et al. Effects of temperature on the denaturation and aggregation of (Lateolabrax japonicus) myosin from Seabass surimi[J]. Journal of Food Processing and Preservation,2021,45(5):e15417.

[3] 吴燕燕, 李冰, 朱小静, 等. 养殖海水和淡水鲈鱼的营养组成比较分析[J]. 食品工业科技,2016,37(20):348−352. [WU Y Y, LI B, ZHU X J, et al. Comparison of nutrient composition of cultured sea bass and cultured fresh-water bass, Lateolabrax japonicas and Micropterus salmoides[J]. Science and Technology of Food Industry,2016,37(20):348−352. WU Y Y, LI B, ZHU X J, et al. Comparison of nutrient composition of cultured sea bass and cultured fresh-water bass, Lateolabrax japonicas and Micropterus salmoides[J]. Science and Technology of Food Industry, 2016, 37(20): 348-352.

[4] 李金星, 吴燕燕, 王悦齐, 等. 响应面法优化海鲈鱼小片的品质改良工艺技术[J]. 上海海洋大学学报,2021:1−14. [LI J X, WU Y Y, WANG Y Q, et al. Response surface methodology to optimize the quality improvement technology of Lateolabrax japonicassmall slices[J]. Journal of Shanghai Ocean University,2021:1−14. LI J X, WU Y Y, WANG Y Q, et al. Response surface methodology to optimize the quality improvement technology of Lateolabrax japonicassmall slices[J]. Journal of Shanghai Ocean University, 2021: 1-14.

[5] 农业农村部渔业渔政管理局. 《2021中国渔业统计年鉴》[M]. 北京: 中国农业出版社, 2021. Fishery and Fishery Administration of the Ministry of Agriculture and Rural Affairs. "China Fishery Statistics Yearbook"[M]. China Agriculture Press, 2021.

[6] 王玮琼, 熊光权, 鉏晓艳. 响应面法优化鲈鱼鱼松加工工艺[J]. 湖北农业科学,2017,56(4):716−721. [WANG W Q, XIONG G Q, CHU X Y. Optimization of processing techniques by response surface for Micropterus salmoides dried fish floss[J]. Hubei Agricultural Sciences,2017,56(4):716−721. WANG W Q, XIONG G Q, CHU X Y. Optimization of processing techniques by response surface for Micropterus salmoides dried fish floss[J]. Huibei Agricultural Sciences, 2017, 56(4): 716-721.

[7] 林亚楠, 王海星, 阳丽红, 等. 磷脂茶多酚复合物的制备及其对淡水鱼松的抗氧化作用[J]. 中国食品学报,2020,20(1):205−211. [LI Y N, WANG H X, YANG L H, et al. Preparation of phospholipid tea polyphenol complex and its antioxidant effect on fresh-water fish floss[J]. Journal of Chinese Institute of Food Science and Technology,2020,20(1):205−211. LI Y N, WANG H X, YANG L H, et al. Preparation of phospholipid tea polyphenol complex and its antioxidant effect on fresh-water fish floss[J]. Journal of Chinese Institute of Food Science and Technology, 2020, 20(1): 205-211.

[8] 符兵, 王绥涛, 李培佳, 等. 鱼类肌肉品质影响因素的研究进展[J]. 广东饲料,2021,30(5):41−45. [FU B, WANG S T, LI P J, et al. Research progress of the influencing factors of fish muscle quality[J]. Guangdong Feed,2021,30(5):41−45. doi: 10.3969/j.issn.1005-8613.2021.05.011 FU B, WANG S T, LI P J, et al. Research progress of the influencing factors of fish muscle quality[J]. Guangdong Feed, 2021, 30(5): 41-45. doi: 10.3969/j.issn.1005-8613.2021.05.011

[9] 肖新生, 周旭, 蒋黎艳. 植物油加工工艺对风味物质影响的研究进展[J]. 中国油脂,2021,46(9):51−56. [XIAO X S, ZHOU X, JIANG L Y. Progress on influence of vegetable oil processing technology on flavor compounds[J]. China Oils and Fats,2021,46(9):51−56. XIAO X S, ZHOU X, JIANG L Y. Progress on influence of vegetable oil processing technology on flavor compounds[J]. China Oils and Fats, 2021, 46(9): 51-56.

[10] 刘兴义, 夏文云, 盖圣美, 等. 肉松品质研究进展[J]. 食品安全质量检测学报,2020,11(16):5547−5553. [LIU X Y, XIA W Y, GAI S M, et al. Research progress on quality of dried meat floss[J]. Journal of Food Safety & Quality,2020,11(16):5547−5553. LIU X Y, XIA W Y, GAI S M, et al. Research progress on quality of dried meat floss[J]. Journal of Food Safety & Quality, 2020, 11(16): 5547-5553.

[11] ZHANG Q, LIU C, SUN Z, et al. Authentication of edible vegetable oils adulterated with used frying oil by fourier transform infrared spectroscopy[J]. Food Chem,2012,132(3):1607−1613. doi: 10.1016/j.foodchem.2011.11.129

[12] LIEDTKEB S, SEIFERTA L, AHLMANNA N, et al. Coupling laser desorption with gas chromatography and ion mobility spectrometry for improved olive oil characterisation[J]. Food Chemistry,2018,255:323−331. doi: 10.1016/j.foodchem.2018.01.193

[13] 陈辉, 戚建良, 李玉华, 等. 利用GC-MS指纹图谱技术快速检测掺伪大豆油的橄榄油[J]. 粮油加工(电子版),2014(9):46−47. [CHEN H, QI J L, LI Y H, et al. Rapid detection of aduteratied olive oil by GC-MS fingerprint analysis[J]. Cereals and Oils Processing (Electronic Version),2014(9):46−47. CHEN H, QI J L, LI Y H, et al. Rapid detection of aduteratied olive oil by GC-MS fingerprint analysis[J]. Cereals and Oils Processing (Electronic Version) , 2014(9): 46-47.

[14] 林亚楠. 膳食纤维纳米乳覆膜鱼松的研制及货架期研究[D]. 杭州: 浙江工商大学, 2019. LIN Y N. Development and shelf life study of nanoemulsion coated fish floss with dietary fiber[D]. Hangzhou: Zhejiang Gongshang University, 2019.

[15] 张静, OOI Cheng Keat, 牛跃庭, 等. 棕榈油在油酥肉松中的应用研究[J]. 食品与发酵科技,2014,50(5):49−53. [ZHANG J, OOI C K, NIU Y T, et al. Study on the application of the palm oil in the meat floss[J]. Food and Fermentation Technology,2014,50(5):49−53. ZHANG J, OOI C K, NIU Y T, et al. Study on the application of the palm oil in the meat floss[J]. Food and Fermentation Technology, 2014, 50(5): 49-53.

[16] 林华坚, 张梓豪, 孟江, 等. 干姜及其炮制品色差值与活性成分含量的相关性研究[J]. 中国药房,2020,31(10):1197−1202. [LIN H J, ZHANG Z H, MENG J, et al. Correlation study of color difference values and active constituent contents in crude and processed Zingiber officinale[J]. China Pharmacy,2020,31(10):1197−1202. doi: 10.6039/j.issn.1001-0408.2020.10.08 LIN H J, ZHANG Z H, MENG J, et al. Correlation study of color difference values and active constituent contents in crude and processed Zingiber officinale[J]. China Pharmacy, 2020, 31(10): 1197-1202. doi: 10.6039/j.issn.1001-0408.2020.10.08

[17] 刘素君, 任炳旭, 杨会军, 等. 4种食用油煎炒过程中品质变化研究[J]. 中国油脂,2018,43(10):26−31. [LIU S J, REN B X, YANG H J, et al. Quality change of four kinds of edible oils during pan-and stir-frying processes[J]. China Oils and Fats,2018,43(10):26−31. doi: 10.3969/j.issn.1003-7969.2018.10.006 LIU S J, REN B X, YANG H J, et al. Quality change of four kinds of edible oils during pan-and stir-frying processes[J]. China Oils and Fats, 2018, 43(10): 26-31. doi: 10.3969/j.issn.1003-7969.2018.10.006

[18] 章海风, 李辉, 周晓燕, 等. 三种食用油在鸡排煎制中的品质变化[J]. 扬州大学烹饪学报,2013,30(1):27−30. [ZHANG H F, LI H, ZHOU X Y, et al. Quality change of three cooking oils in chicken chops[J]. Culinary Science Journal of Yangzhou University,2013,30(1):27−30. ZHANG H F, LI H, ZHOU X Y, et al. Quality change of three cooking oils in chicken chops[J]. Culinary Science Journal of Yangzhou University, 2013, 30(1): 27-30.

[19] 陈军明, 陆唯哲, 张汁. 无糖肉松的加工工艺[J]. 肉类工业,2014(1):7−8. [CHEN J M, LU W Z, ZHANG Z. Processing technology of sugar-free pork floss[J]. Meat Industry,2014(1):7−8. doi: 10.3969/j.issn.1008-5467.2014.01.003 CHEN J M, LU W Z, ZHANG Z. Processing technology of sugar-free pork floss[J]. Meat Industry, 2014(1): 7-8. doi: 10.3969/j.issn.1008-5467.2014.01.003

[20] 康雪梅, 李桂华, 刘斌, 等. 葵花籽油在油条煎炸过程中的品质变化研究[J]. 粮油食品科技,2014,22(5):25−28. [KANG X M, LI G Y, LIU B, et al. Changes in the quality of sunflower oil during frying dough sticks[J]. Science and Technology of Cereals, Oils and Foods,2014,22(5):25−28. doi: 10.3969/j.issn.1007-7561.2014.05.007 KANG X M, LI G Y, LIU B, et al. Changes in the quality of sunflower oil during frying dough sticks[J]. Science and Technology of Cereals, Oils and Foods, 2014, 22(5): 25-28. doi: 10.3969/j.issn.1007-7561.2014.05.007

[21] 孙达锋, 胡小松, 张沙沙. 电子鼻结合气相-离子迁移谱联用技术分析兰茂牛肝菌气调贮藏期间挥发性风味物质的变化[J]. 食品工业科技,2021,42(21):111−117. [SUN D F, HU X S, ZHANG S S. Changes in volatile compounds of Lanmaoa asiatica during controlled atmosphere storage using electronic nose combined with gas chromatography-ion mobility spectroscopy[J]. Science and Technology of Food Industry,2021,42(21):111−117. SUN D F, HU X S, ZHANG S S. Changes in volatile compounds of Lanmaoa asiatica during controlled atmosphere storage using electronic nose combined with Gas Chromatography-Ion Mobility Spectroscopy[J]. Science and Technology of Food Industry, 2021, 42(21): 111-117.

[22] LI H, LIU J, WANG Z, et al. Process optimization of chili flavor beef tallow and analysis of its volatile compounds by GC-IMS[J]. International Journal of Food Engineering,2021,17(7):507−516. doi: 10.1515/ijfe-2020-0246

[23] 金文刚, 别玲玲, 裴金金, 等. 基于GC-IMS技术分析炖煮过程中大鲵头汤挥发性风味物质[J]. 食品工业科技,2021,42(19):307−313. [JIN W G, BIE L L, PEI J J, et al. Volatile flavor compounds of giant salamander (Andrias davidianus) head soup during stewing based on GC-IMS technology[J]. Science and Technology of Food Industry,2021,42(19):307−313. JIN W G, BIE L L, PEI J J, et al. Volatile flavor compounds of giant salamander (Andrias davidianus) head soup during stewing based on GC-IMS technology[J]. Science and Technology of Food Industry, 2021, 42(19): 307-313.

[24] 杨晓芳, 焦茹媛, 朱新梦, 等. 抗生素发酵制药工程中异味的特征与关键污染物识别[J]. 环境工程学报,2020,14(8):2020−2029. [YANG X F, JIAO R Y, ZHU X M, et al. Profiling and identification of fermentation odorants from industrial production of antibiotics[J]. Chinese Journal of Environmental Engineering,2020,14(8):2020−2029. doi: 10.12030/j.cjee.202005121 YANG X F, JIAO R Y, ZHU X M, et al. Profiling and identification of fermentation odorants from industrial production of antibiotics[J]. Chinese Journal of Environmental Engineering, 2020, 14(8): 2020-2029. doi: 10.12030/j.cjee.202005121

[25] 林良静, 蔡惠钿, 包涵, 等. 潮汕特色佛手香黄的特征挥发性风味成分分析[J]. 现代食品科技,2021,37(7):238−249. [LIN L J, CAI H D, BAO H, et al. Analysis of the characteristic volatile flavor components of preserved Lao-xiang-huang of Chaozhou[J]. Modern Food Science and Technology,2021,37(7):238−249. LIN L J, CAI H D, BAO H, et al. Analysis of the characteristic volatile flavor components of preserved Lao-xiang-huang of Chaozhou[J]. Modern Food Science and Technology, 2021, 37(7): 238-249.

[26] 陈瑶, 朱凯悦, 张玉莹, 等. 基于气相-离子迁移谱分析不同品种鱼子酱挥发性成分差异[J]. 食品与发酵工业,2021,47(24):1−9. [CHEN Y, ZHU K Y, ZHANG Y Y, et al. Analysis of volatile components in various caviars based on gas chromatography-ion mobility spectroscopy[J]. Food and Fermentation Industries,2021,47(24):1−9. CHEN Y, ZHU K Y, ZHANG Y Y, et al. Analysis of volatile components in various caviars based on Gas Chromatography-Ion Mobility Spectroscopy[J]. Food and Fermentation Industries, 2021, 47(24): 1-9.

[27] WANG F, GAO Y, WANG H, et al. Analysis of volatile compounds and flavor fingerprint in Jingyuan lamb of different ages using gas chromatography-ion mobility spectrometry (GC-IMS)[J]. Meat Science,2021,175:108449. doi: 10.1016/j.meatsci.2021.108449

[28] ZOU J, XU M, ZOU Y, et al. Chemical compositions and sensory characteristics of pork rib and silkie chicken soups prepared by various cooking techniques[J]. Food Chemistry,2021,345:128755. doi: 10.1016/j.foodchem.2020.128755

[29] 虞舟. 一种墨鱼仔制品的脱腥方法: 中国, 202010266347. 6[P]. 2020-08-18. YU Z. A method for removing fishy smell from cuttlefish roe product: China, 202010266347. 6[P]. 2020-08-18.

[30] 金文刚, 赵萍, 金晶, 等. 基于气相-离子迁移色谱分析大鲵不同可食部位挥发性成分指纹差异[J]. 食品科学,2021,43(2):1−11. [JIN W G, ZHAO P, JIN J, et al. Volatile component fingerprint analysis of giant salamander (Andrias davidiauns) from different edible parts based on gas chromatography-ion mobility spectroscopy[J]. Food Science,2021,43(2):1−11. doi: 10.7506/spkx1002-6630-20200116-198 JIN W G, ZHAO P, JIN J, et al. Volatile component fingerprint analysis of giant salamander (Andrias davidiauns) from different edible parts based on Gas Chromatography-Ion Mobility Spectroscopy[J]. Food Science, 2021, 43(2): 1-11. doi: 10.7506/spkx1002-6630-20200116-198

[31] GE S, CHEN Y, DING S, et al. Changes in volatile flavor compounds of peppers during hot air drying process based on headspace-gas chromatography-ion mobility spectrometry (HS-GC-IMS)[J]. Journal of the Science of Food and Agriculture,2020,100(7):3087−3098. doi: 10.1002/jsfa.10341

[32] 金文刚, 陈小华, 耿敬章, 等. 基于气相-离子迁移谱分析不同产地“汉中仙毫”气味指纹差异[J]. 食品与发酵工业,2021,47(5):231−237. [JIN W G, CHEN X H, GENG J Z, et al. Analysis of “HanzhongXianhao”odor finger-prints from different places based on GC-IMS[J]. Food and Fermentation Industries,2021,47(5):231−237. JIN W G, CHEN X H, GENG J Z, et al. Analysis of “HanzhongXianhao”odor finger-prints from different places based on GC-IMS[J]. Food and Fermentation Industries, 2021, 47(5): 231-237.

[33] ZHAN H, HAYAT K, CUI P, et al. Characterization of flavor active non-volatile compounds in chicken broth and correlated contributing constituent compounds in muscle through sensory evaluation and partial least square regression analysis[J]. LWT-Food Science and Technology,2020,118:108786. doi: 10.1016/j.lwt.2019.108786

[34] XU N, YE J, LI L, et al. Exploration of flavor and taste of soft-boiled chicken at different post-mortem aging time: Based on GC-IMS and multivariate statistical analysis[J]. Food Bioscience,2021,43:101326. doi: 10.1016/j.fbio.2021.101326

[35] 周晨曦, 郑福平, 孙宝国. 离子迁移谱技术在食品风味分析中的应用研究进展[J]. 食品工业科技,2019,40(18):309−318. [ZHOU C X, ZHENG F P, SUN B G. Research progress on the application of ion mobility spectrometry (IMS) in food flavor analysis[J]. Science and Technology of Food Industry,2019,40(18):309−318. ZHOU C X, ZHENG F P, SUN B G. Research progress on the application of Ion Mobility Spectrometry (IMS) in food flavor analysis[J]. Science and Technology of Food Industry, 2019, 40(18): 309-318.

[36] 于亚辉, 陈沁雯, 李晓婷, 等. 基于HS-SPME-GC-MS和PCA的不同萃取头对鸡肉香精香气成分萃取效果比较[J]. 食品研究与开发,2021,42(1):159−165. [YU Y H, CHEN Q W, LI X T, et al. Comparison of the extraction effect of chicken flavors by different extraction heads based on HS-SPME-GC-MS and PCA[J]. Food Research and Development,2021,42(1):159−165. YU Y H, CHEN Q W, LI X T, et al. Comparison of the extraction effect of chicken flavors by different extraction heads based on HS-SPME-GC-MS and PCA[J]. Food Research and Development, 2021, 42(1): 159-165.

[37] YANG Y, WANG B, FU Y, et al. HS-GC-IMS with PCA to analyze volatile flavor compounds across different production stages of fermented soybean whey tofu[J]. Food chemistry,2021,346:128880. doi: 10.1016/j.foodchem.2020.128880

[38] 厉玉婷, 于艳艳, 杨振东, 等. 基于方差分析研究4种食用植物油煎炸过程品质变化规律[J]. 中国油脂,2021:1−9. [LI Y T, YU Y Y, YANG Z D, et al. Research on quality changes of 4 kinds of edible vegetable oil during frying based on analysis of variance[J]. China Oils and Fats,2021:1−9. LI Y T, YU Y Y, YANG Z D, et al. Research on quality changes of 4 kinds of edible vegetable oil during frying based on analysis of variance[J]. China Oils and Fats, 2021: 1-9.

-

期刊类型引用(7)

1. 刘冀黔,旦正杰,韩丽娟,桂林生,侯生珍,王志有,杨葆春. 不同月龄黑藏羊肉品质及风味评价分析. 饲料研究. 2024(13): 105-111 .  百度学术

百度学术

2. 宁舒娴,曾金秀,沙小梅,丁红秀. 不同生境来源的鳙鱼肉挥发性物质组成比较分析. 食品工业科技. 2024(18): 265-272 .  本站查看

本站查看

3. 董平,范文教,朱开宪,吴华昌,邓静. 不同复热方式对咸烧白风味的影响. 食品科技. 2023(02): 122-129 .  百度学术

百度学术

4. 陈方雪,邓祎,谌玲薇,李冬生,乔宇,吴文锦,熊光权,汪兰,李新,石柳,丁安子. 预制冷风风干武昌鱼干制过程中的品质变化及香气形成. 现代食品科技. 2023(02): 9-17 .  百度学术

百度学术

5. 张蓝月,孙万成,罗毅皓. 基于气相色谱-离子迁移谱分析不同地区羊肉的挥发性风味化合物. 食品与发酵工业. 2023(10): 265-272 .  百度学术

百度学术

6. 火玉明,柯汉杰,吴晨昕,姜红贺,梁鹏,汪晴,陈小辉. 海鲈鱼鱼松加工工艺研究. 食品安全质量检测学报. 2022(10): 3367-3374 .  百度学术

百度学术

7. 戴振庭,周惠敏,殷泽生,周瑜,陈舜胜. 添加植物油对鲣鱼鱼松滋味的影响. 甘肃农业大学学报. 2022(06): 227-234 .  百度学术

百度学术

其他类型引用(5)

下载:

下载:

下载:

下载: