Effects of Saccharomyces cerevisiae and Lactobacillus plantarum Co-fermentation on the Storage Characteristics of Noodles

-

摘要: 为探究酿酒酵母与植物乳杆菌复合发酵对面条储藏特性的影响。采用质构仪(TA)、低场脉冲核磁共振仪(LF-NMR)、X-射线衍射仪(XRD)对面条在4 ℃储藏期间的品质变化进行分析。结果表明,与空白组相比,发酵面条的断条率低,吸水率无显著性差异(P>0.0.5),pH下降,可滴定酸(TTA)值上升;在相同储藏时间内发酵面条的硬度和咀嚼性均低于空白组,黏聚性随时间延长呈下降趋势,在10~15 d黏聚性低于空白组,弹性先增加后减小;复合菌种发酵面条与空白组相比,强结合水对应的弛豫时间呈减小趋势,所有样品经低温储藏后,强结合水所占比例呈下降趋势;X射线衍射图谱显示,空白组面条低温储藏15 d后,相对结晶度(RC)为16.77%,发酵60 min面条的相对结晶度为12.10%,与空白组相比RC值显著降低(P<0.05),说明发酵延缓淀粉老化,适度发酵通过增加体系水分的稳定性及抑制淀粉老化,从而延缓面条低温储藏时的品质劣变。Abstract: To investigate the influence of S. cerevisiae and L. plantarum co-fermentation on the storage characteristics of noodles. Texture analyzer (TA), low field pulsed nuclear magnetic resonance (LF-NMR) and X-ray diffraction (XRD) were used to analyze the quality changes of noodles during storage at 4 ℃. The main research results were as follows: The breakage rate and pH of fermented noodles were lower than these of blank group, there was no significant difference in water absorption rate among different samples(P>0.05), titratable acid (TTA) value increased with fermentation time prolonging. At the same storage time, the hardness and chewiness of the fermented noodles was lower than that of blank group. The cohesiveness decreased with time and was lower than that of blank group after 10~15 days storage. The elasticity first increased and then decreased during the storage duration. Compared with the blank group, the relaxation time of strongly bound water showed a descending trend. After stored at low temperature, the proportion of strongly bound water decreased. The X-ray diffraction pattern illustrated that the relative crystallinity (RC) of the blank group noodles was 16.77% after low temperature storage for 15 days, and the RC value of noodles fermented for 60 min was 12.10%, which was significantly lower than the blank group (P<0.05), indicating that fermentation delayed the starch retrogradation, and moderate fermentation delayed the quality deterioration of noodles during low temperature storage by increasing the stability of water in the system and inhibiting the retrogradation of starch.

-

面食深受我国北方地区人们喜爱,每年约有40%小麦被用来制作面条[1],可见面条需求量之大。随着经济快速发展,速冻食品、自热食品等已成为开发研究的重点。其中自热面条等自热食品更是主食工业化推广的重要载体形式之一。但面条作为淀粉质食品,在储藏过程中极易发生老化,使面条硬度变大,口感变差。而发酵会对面条中直链和支链淀粉含量以及面筋蛋白的结构产生一定影响,进而影响面条微观结构[2]。

酿酒酵母和植物乳杆菌是馒头及面包制作过程中最常用的微生物,是酸面团中的优势菌种。Zhang等[3]探究了内蒙古西部地区酸面团中的微生物组成,结果发现植物乳杆菌和酿酒酵母是主要的菌种。杨浣漪等[4]对河南地区的传统面食发酵剂进行微生物组成分析,发现酿酒酵母和植物乳杆菌为优势菌种。有研究发现酵母菌[5]或乳酸菌发酵[6]可缩短面团发酵时间,提升面条风味及营养特性。李芸[7]研究表明,包含植物乳杆菌在内的混合菌种对大米粉的感官品质有影响。阳盈盈[8]研究发现,自然发酵的发糕及其发酵米浆中的优势菌株为乳酸菌和酵母菌。在面团发酵过程中,酵母菌的作用是产气、产生风味物质等,乳酸菌的作用是产酸和风味物质[9]。两者复合发酵时,不仅可以促进酸性物质与醇类物质反应,形成具有特殊风味的酯类物质,还可以改善发酵产品的质构及抗老化特性[10]。但是目前市场上的米面制品大多采用单一菌种发酵,发酵风味和香气不够浓郁,口感相对单一[11-12],对于使用复合菌种来制作面条的研究相对较少。

因此,本研究将植物乳杆菌和酿酒酵母应用于面条的制备,研究复合菌种发酵对面条储藏过程中品质特性的影响,为即食面条的新品研发提供依据。

1. 材料与方法

1.1 材料与仪器

小麦粉 中粮面业集团;植物乳杆菌(Lactobacillus plantarum)GIM1.191 中国微生物菌种保藏中心;酿酒酵母(Saccharomyces cerevisiae)GIM2.133 广东省微生物菌种保藏中心;MRS肉汤培养基、麦芽汁培养基 北京奥博星生物技术有限责任公司。

DDQ-A30G5型和面机 佛山市小熊厨房电器有限公司;全钢型DSS160型压面机 拜杰电器有限公司;XY-FD-18冷冻干燥机 上海欣谕仪器有限公司;TA-XT plus物性分析仪 美国TA公司;NM120低场核磁共振分析仪 上海纽曼电子科技有限公司;D8 ADVANCE多功能X射线衍射仪 德国布鲁克公司;TG-16-WS高速冷冻离心机 湘仪仪器有限公司。

1.2 实验方法

1.2.1 植物乳杆菌的活化及扩大培养

参考张丽华等[13]的方法略有改动。配制MRS肉汤培养基100 mL,121 ℃灭菌15 min,冷却。然后将植物乳杆菌按接种量1%(v/v)转入培养基中,于(37±1)℃培养48 h。按上述步骤连续活化2次,将所得菌悬液离心(4 ℃,3382×g,10 min),倒去上层培养基,用无菌水洗涤沉淀3次后得到菌泥,与无菌水按1:10(w/v)比例混匀,活菌数达108 CFU/mL。

1.2.2 酿酒酵母的活化及扩大培养

配制麦芽汁培养基100 mL,121 ℃灭菌15 min,冷却。然后将酿酒酵母按接种量1%(v/v)转入培养基中,于(28±1)℃培养48 h。按上述步骤连续活化2次,将所得菌悬液离心(4 ℃,5500×g,10 min),倒去上层培养基,用无菌水洗涤沉淀3次后得到菌泥,与无菌水按1:10(w/v)比例混匀,活菌数达108 CFU/mL。

1.2.3 面条配方及制作方法

将植物乳杆菌和酿酒酵母的菌泥按100:1比例混合[14],然后按面粉质量的1%接种,同时加入35 g水,和面10 min,之后于室温下分别发酵10、20、40、60、120 min后,安装1.5 mm圆面刀,压片切条。将湿面条煮3 min捞出,于冰水冷却1 min,用PET/NY/AL/CPP袋真空包装,4 ℃贮藏15 d。空白对照组不加菌种发酵,其他条件相同。

1.2.4 面条蒸煮特性测定

参考陈舒涵等[15]的方法。取20根长20 cm面条称重(m1, g),于500 mL沸水煮3 min,冰水冷却1 min,用竹筷将面条轻轻挑出,记录完整的面条根数N,吸干表面水分,称重(m2, g);面汤冷却至常温后,定容到500 mL,取50 mL面汤加入已恒重的烧杯中(m3, g),于电炉加热蒸发掉大部分水后,在105 ℃干燥箱中烘至恒重(m4, g)。

1.2.5 pH与可滴定酸度(TTA)测定

参考闫博文[16]的方法。称10 g生面条样品,加到90 mL蒸馏水中,搅拌10 min至样品与水完全混合。以酸度计测定该悬浊液的pH,即为样品的pH。以0.1 mol/L的NaOH溶液滴定该悬浊液至pH为8.5,所消耗NaOH体积(mL)为该样品TTA值。每份样品平行测定3次。

1.2.6 质构测定

参考肖东[17]的方法。取三根储藏不同时间(0、5、10、15 d)面条,平行放置于载物台,每种试样重复5次。探头:P/36R;参数设定:测前速度1.0 mm/s,测试速度2.0 mm/s,测后速度2.0 mm/s,压缩率60%,起点感应力5 g,两次压缩时间间隔为5 s。

1.2.7 低场脉冲核磁共振分析

参考李立华等[18]的方法略有改动。取3 g储藏不同时间(0、5、10、15 d)面条进行检测。检测参数:采样点数320066,重复扫描8次,弛豫衰减时间1000 ms。利用CPMG脉冲序列测定样品的横向弛豫时间T2。每个样品重复5次。

1.2.8 X-射线衍射分析

参考修琳等[19]的方法。样品经干燥粉碎后过筛,利用X-射线衍射仪测定样品相对结晶度。测定条件:扫描速度4 °/min,扫描区域3°~40°,采样步宽0.02°。

1.3 数据处理

用Origin 8.5,MDI Jade 5.0,Excel 2019和SPSS 23.0分析数据,P<0.05表示差异显著。

2. 结果与分析

2.1 复合菌种发酵对面条品质的影响

2.1.1 复合菌种发酵对面条蒸煮特性的影响

经煮制后,面筋蛋白吸收水分形成网络结构,阻止水分和淀粉从面条中溶出,蒸煮特性是评价面条品质的重要指标[20]。由表1可知,复合菌种发酵面条的断条率均低于空白组,说明复合菌种发酵后面条的面筋网络连续性好,断条率低。在蒸煮过程中,面条干物质的溶出与面条结构有很大关联,溶出越少,品质越高,发酵120 min的面条蒸煮损失率最低,但断条率为3.33%,可能是因为发酵时间过长,淀粉链被深度降解、打断,使面条容易被煮烂,从而导致断条率升高。而发酵20 min的面条断条率显著降低(P<0.05),吸水率升高,蒸煮损失率较低,因此综合三个指标选出发酵20 min的面条品质较好。

表 1 复合菌种发酵时间对面条蒸煮特性的影响Table 1. Effects of fermentation time of compound strains on cooking characteristics of noodles发酵时间(min) 断条率(%) 吸水率(%) 蒸煮损失率(%) CK 6.67±2.89a 98.71±3.66a 6.50±0.55ab 10 0.00±0.00b 99.66±6.83a 6.73±1.00ab 20 0.00±0.00b 100.14±1.83a 6.90±0.69ab 40 3.33±2.89ab 98.20±3.93a 7.63±1.57a 60 3.33±2.89ab 98.57±7.64a 6.94±0.37ab 120 3.33±2.89ab 97.96±2.74a 5.60±0.51b 注:CK代表空白样品。上标字母或组合字母不同表示差异显著(P<

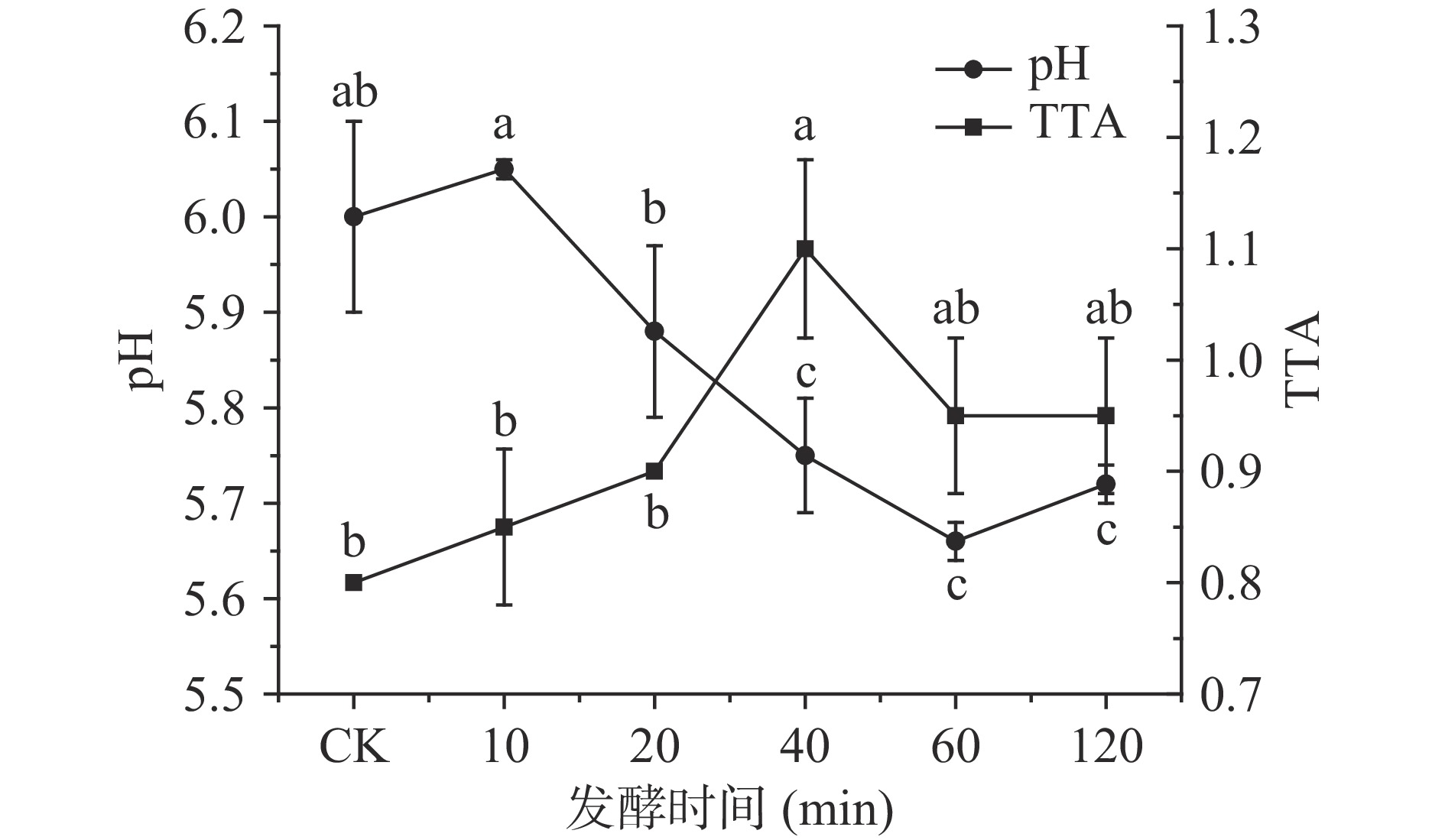

0.05);若比较的两组之间存在字母相同或组合内某一字母相同的情况,则表明差异不显著(P>0.05)。表2~表4、图1同。2.1.2 复合菌种发酵对面条pH和TTA的影响

pH和TTA值是面团发酵过程中的重要指标。pH会影响面团中各种酶的活性、微生物的生长以及发酵面食最终的品质,TTA值可以表征面团的酸味程度。由图1可知,复合菌种发酵面条的pH随时间延长呈下降趋势,与空白组相比发酵40~120 min的面条pH显著下降(P<0.05),而TTA值变化趋势正好相反,其中发酵40 min面条的TTA值显著高于空白组(P<0.05)。这主要是因为酵母菌和乳酸菌的大量生长繁殖会产生如CO2、乳酸、醋酸等代谢物质[21],使发酵面条中出现pH下降,TTA相应增加的现象。

2.2 复合菌种发酵对面条储藏特性的影响

2.2.1 复合菌种发酵对面条在低温储藏过程中质构特性的影响

应用质构仪评价面条的质构特性是探究其品质的重要手段之一。由表2可知,在低温储藏过程中(0~15 d),空白组面条硬度呈增大趋势,在相同储藏时间内(5~15 d)发酵面条硬度显著(P<0.05)低于空白组,这是因为淀粉质食品在储藏过程中极易发生老化,而发酵产生的脂肪酶及乳酸等物质可以延缓老化,降低面条硬度。相比于空白组,在0~5 d复合菌种发酵面条的弹性均较高,随后无明显规律性变化,这是因为在短期老化过程中,发酵使直链淀粉含量增加,强化凝胶网络,增强保水性[22],使面条弹性增加,其中发酵20 min面条弹性较高。黏聚性表示测试时面条与表面接触的黏附力,数值越小表明面条越爽口顺滑[23],在储藏期内黏聚性随时间延长呈下降趋势,在0~5 d复合菌种发酵面条的黏聚性基本上均高于空白组,在10~15 d黏聚性低于空白组。10~15 d复合菌种发酵面条的咀嚼性低于空白组。

表 2 复合菌种发酵面条在4 ℃储藏期内的质构特性变化Table 2. Changes of texture characteristics of noodles fermented by compound strains during storage at 4 ℃储藏时

间(d)发酵时

间(min)硬度(g) 弹性 黏聚性 咀嚼性 0 CK 1789.72±66.40a 0.86±0.00c 0.59±0.00b 941.02±58.24a 10 1744.90±61.70ab 0.88±0.01bc 0.60±0.00b 918.80±12.20a 20 1543.65±48.58c 0.90±0.01b 0.61±0.01b 834.26±51.66ab 40 1448.30±44.68c 0.88±0.01bc 0.60±0.01b 764.66±45.62b 60 1653.49±84.53b 0.92±0.00a 0.61±0.01b 892.64±72.29a 120 1829.38±73.40a 0.87±0.01bc 0.63±0.00a 932.25±94.36a 5 CK 1823.60±57.47a 0.90±0.01bc 0.56±0.01bc 973.72±29.45a 10 1540.59±84.42de 1.01±0.01a 0.59±0.01a 918.88±26.82a 20 1731.66±32.77b 0.95±0.08abc 0.55±0.02c 913.03±36.56a 40 1646.65±21.37c 0.88±0.02c 0.56±0.00bc 825.77±1.28b 60 1479.65±4.72e 0.92±0.06abc 0.60±0.01a 807.77±88.76b 120 1571.48±33.57cd 0.99±0.07ab 0.58±0.02ab 951.47±44.37a 10 CK 1930.14±130.20a 0.89±0.07ab 0.56±0.00a 946.40±87.68a 10 1674.94±48.88b 0.95±0.07a 0.54±0.02ab 767.83±33.41bc 20 1459.74±127.13c 0.91±0.01ab 0.53±0.00b 671.97±65.18cd 40 1492.21±59.34c 0.86±0.06ab 0.53±0.01b 615.72±27.50d 60 1672.19±53.97b 0.84±0.04b 0.54±0.01ab 763.12±52.27bc 120 1818.18±108.35ab 0.85±0.03ab 0.53±0.00b 803.01±21.41b 15 CK 1895.40±38.32a 0.90±0.02a 0.56±0.00a 932.82±14.90a 10 1643.24±55.42b 0.89±0.03a 0.53±0.01c 816.42±61.06b 20 1480.64±41.53c 0.83±0.01b 0.55±0.01b 672.21±2.83c 40 1627.25±17.14b 0.90±0.00a 0.56±0.01a 890.17±79.80ab 60 1607.71±50.62b 0.81±0.01b 0.52±0.00d 687.66±1.72c 120 1655.83±71.51b 0.79±0.04b 0.55±0.00ab 860.14±11.52ab 2.2.2 复合菌种发酵对面条在低温储藏过程中水分分布的影响

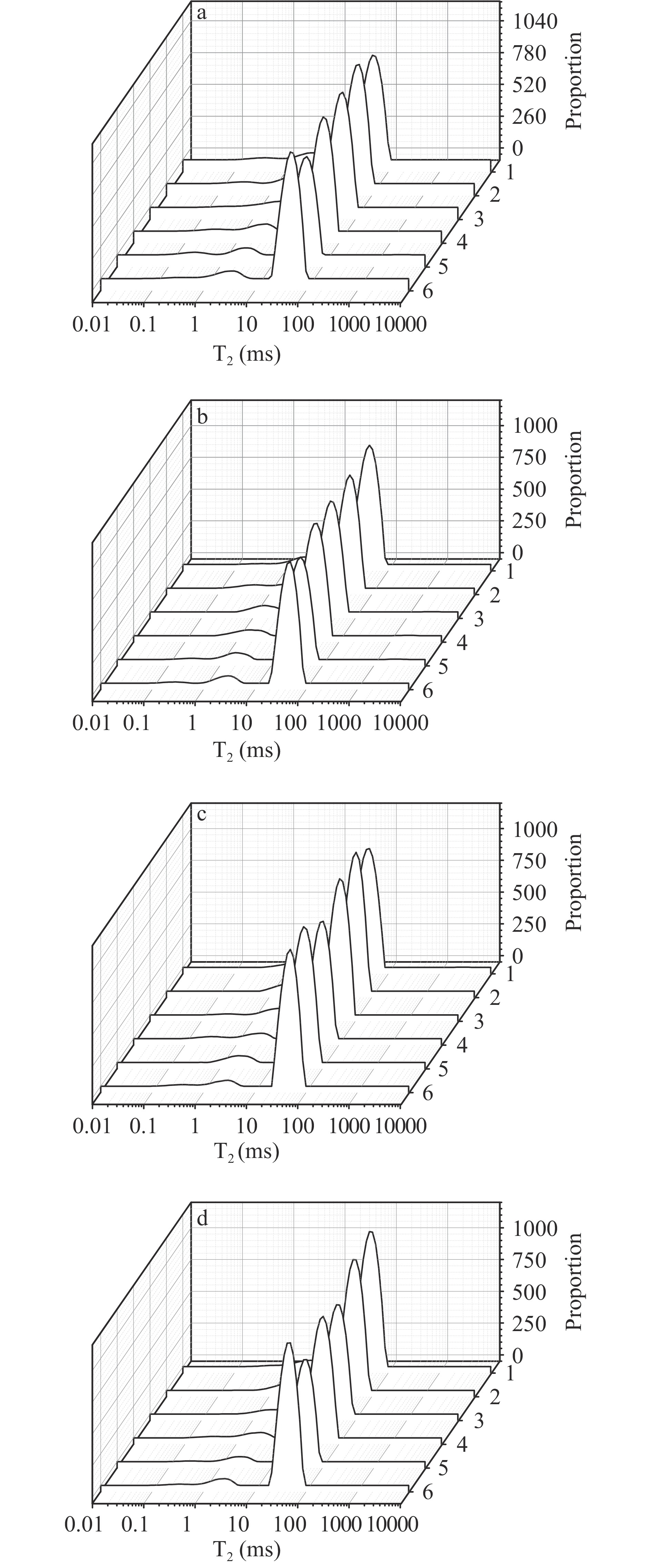

采用低场核磁共振技术对面条中的水分分布进行研究,检测到两个主要质子群(T21和T22)。T21代表结合水,T22代表不易流动水。A21和A22分别代表了氢质子相对含量和疏水组分的吸水性[24]。由图2可知,复合菌种发酵面条煮制后主要存在结合水和不易流动水,其中结合水是水通过无定形空间进入支链淀粉双螺旋结构的紧密结合区,不易流动水是在煮面过程中进入面条结构中淀粉无定形空间的水[25]。

横向弛豫时间反映了与水的结合能力,横向弛豫时间越短,水结合能力越强[26],由表3可知,复合菌种发酵面条与空白组相比,结合水对应的弛豫时间呈减小趋势,不易流动水对应的弛豫时间变化无明显规律。在0 d时,复合菌种发酵面条其结合水所占比例高于空白组,不易流动水所占比例减小,而经低温储藏相同时间后结合水所占比例减小,不易流动水所占比例增加,说明面条中水分状态发生了变化,可能是因为发酵后水分子与淀粉和蛋白质中的OH、NH2和SH基团之间的质子交换影响了水在面条中组分之间的交换[27]。总体来看,所有样品经低温储藏后,强结合水所占比例呈下降趋势,这是因为淀粉发生老化,与大分子紧密结合的水一部分向不易流动水转换。

表 3 复合菌种对面条水分流动性及水分状态含量的影响Table 3. Influence of compound strains on moisture fluidity and moisture state content of noodles时间(d) 发酵时间(min) T21(ms) T22(ms) A21(%) A22(%) 0 CK 3.71±0.57a 49.77±0.00b 6.94±0.39c 93.06±0.39a 10 4.04±0.00a 57.22±0.00a 7.61±0.37b 92.39±0.37b 20 3.86±0.30a 57.22±0.00a 8.54±0.51a 91.46±0.51c 40 3.40±0.70a 49.77±0.00b 7.31±0.09bc 92.69±0.09ab 60 3.40±0.23a 49.77±0.00b 8.79±0.23a 91.21±0.23c 120 3.51±0.00a 49.77±0.00b 7.34±0.07bc 92.66±0.07ab 5 CK 2.83±0.62a 45.45±3.74a 7.76±0.58a 92.24±0.58b 10 2.57±0.53a 39.53±3.26a 7.59±0.85a 92.41±0.85b 20 1.83±0.15b 36.01±2.83b 6.76±0.28ab 93.24±0.28ab 40 1.67±0.13b 34.38±2.83b 7.01±0.82ab 92.99±0.82ab 60 1.76±0.24b 36.01±2.83b 6.92±0.20ab 93.08±0.20ab 120 3.05±0.00a 49.77±0.00a 6.44±0.05b 93.56±0.05a 10 CK 3.05±0.00a 43.29±0.00b 7.04±0.09a 92.96±0.09b 10 2.56±0.43a 49.77±0.00a 5.88±0.09b 94.12±0.09a 20 2.57±0.53a 49.77±0.00a 6.80±0.26a 93.20±0.26b 40 2.96±0.61a 49.77±0.00a 5.91±0.48b 94.09±0.48a 60 3.05±0.00a 47.61±3.74a 6.59±0.10a 93.41±0.10b 120 2.81±0.43a 49.77±0.00a 5.60±0.11b 94.40±0.11a 15 CK 3.05±0.43a 43.29±3.74c 6.71±0.52a 93.29±0.52b 10 2.36±0.60b 49.77±0.00a 5.80±0.23b 94.20±0.23a 20 2.92±0.23ab 45.45±3.74bc 5.88±0.09b 94.12±0.09a 40 3.05±0.00a 47.61±3.74ab 5.90±0.30b 94.10±0.30a 60 2.57±0.53ab 49.77±0.00a 5.74±0.09b 94.26±0.09a 120 2.66±0.00ab 49.77±0.00a 5.53±0.30b 94.47±0.30a 2.2.3 复合菌种发酵对面条在低温储藏过程中淀粉结晶的影响

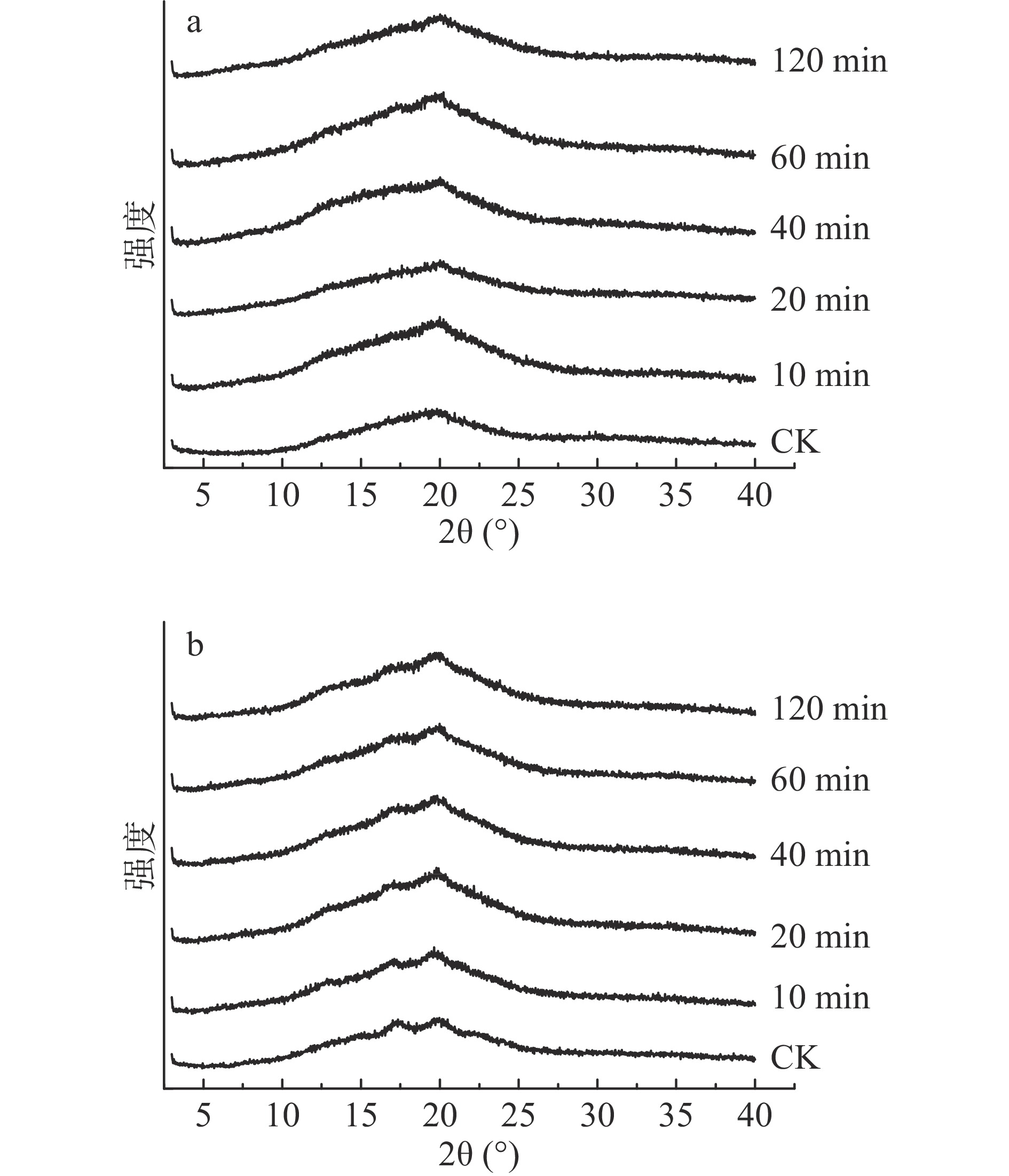

根据支链淀粉侧链的双螺旋结构,淀粉结晶结构通常分为A、B或C型,X射线衍射仪也显示出V型晶体结构[28]。图3分别为面条在4 ℃储藏0和15 d的X射线衍射图谱。由图3a可知,所有样品在20°均出现一个明显的衍射峰,表明淀粉V型结构的存在,复合菌种发酵面条与空白组相比结晶类型无变化,说明发酵对淀粉的结晶类型没有影响。由图3b可知,储藏15 d后,样品在17°附近均有明显的衍射峰,其中空白组衍射峰较为尖锐,结晶度高,老化程度明显,而复合菌种发酵面条的峰值较弱,其老化程度明显降低。由表4可知,储藏15 d后,空白组相对结晶度为16.77%,复合菌种发酵60 min面条的相对结晶度为12.10%,与空白组相比RC值显著降低(P<0.05),可能是因为发酵破坏了淀粉的微晶结构,抑制了支链淀粉外部短链的重排结晶,使淀粉分子内部聚合变慢,从而降低相对结晶度,抑制淀粉老化,这与Odey等[29]和Wahyuni等[30]的研究结果类似。其研究发现木薯淀粉结晶度随发酵时间的增加而增加,说明样品的晶体结构在发酵过程中变得更加无定形。

表 4 复合菌种发酵面条储藏期内的相对结晶度Table 4. Relative crystallinity of noodles fermented by compound strains during storage period储藏时间

(d)RC(%) CK 10 min 20 min 40 min 60 min 120 min 0 13.50±0.20a 11.37±0.15cd 11.93±0.23b 10.77±0.15e 11.07±0.15de 11.60±0.10c 15 16.77±0.15a 13.73±0.15b 12.97±0.21c 12.83±0.12c 12.10±0.20d 12.80±0.10c 3. 结论

酿酒酵母与植物乳杆菌复合发酵面条与空白组面条的品质存在明显差异。经复合菌种发酵的面条断条率低,pH下降,TTA增加。在4 ℃储藏过程中,与空白组相比,发酵面条硬度显著(P<0.05)下降,强结合水所占比例呈下降趋势,RC值显著降低(P<0.05)。说明发酵能够破坏淀粉微晶结构,抑制支链淀粉重排结晶,延缓老化。适度发酵能够改善面条品质,延缓面条低温储藏时的品质劣变。其中发酵20 min面条的蒸煮特性和储藏特性相对较好。

-

表 1 复合菌种发酵时间对面条蒸煮特性的影响

Table 1 Effects of fermentation time of compound strains on cooking characteristics of noodles

发酵时间(min) 断条率(%) 吸水率(%) 蒸煮损失率(%) CK 6.67±2.89a 98.71±3.66a 6.50±0.55ab 10 0.00±0.00b 99.66±6.83a 6.73±1.00ab 20 0.00±0.00b 100.14±1.83a 6.90±0.69ab 40 3.33±2.89ab 98.20±3.93a 7.63±1.57a 60 3.33±2.89ab 98.57±7.64a 6.94±0.37ab 120 3.33±2.89ab 97.96±2.74a 5.60±0.51b 注:CK代表空白样品。上标字母或组合字母不同表示差异显著(P<

0.05);若比较的两组之间存在字母相同或组合内某一字母相同的情况,则表明差异不显著(P>0.05)。表2~表4、图1同。表 2 复合菌种发酵面条在4 ℃储藏期内的质构特性变化

Table 2 Changes of texture characteristics of noodles fermented by compound strains during storage at 4 ℃

储藏时

间(d)发酵时

间(min)硬度(g) 弹性 黏聚性 咀嚼性 0 CK 1789.72±66.40a 0.86±0.00c 0.59±0.00b 941.02±58.24a 10 1744.90±61.70ab 0.88±0.01bc 0.60±0.00b 918.80±12.20a 20 1543.65±48.58c 0.90±0.01b 0.61±0.01b 834.26±51.66ab 40 1448.30±44.68c 0.88±0.01bc 0.60±0.01b 764.66±45.62b 60 1653.49±84.53b 0.92±0.00a 0.61±0.01b 892.64±72.29a 120 1829.38±73.40a 0.87±0.01bc 0.63±0.00a 932.25±94.36a 5 CK 1823.60±57.47a 0.90±0.01bc 0.56±0.01bc 973.72±29.45a 10 1540.59±84.42de 1.01±0.01a 0.59±0.01a 918.88±26.82a 20 1731.66±32.77b 0.95±0.08abc 0.55±0.02c 913.03±36.56a 40 1646.65±21.37c 0.88±0.02c 0.56±0.00bc 825.77±1.28b 60 1479.65±4.72e 0.92±0.06abc 0.60±0.01a 807.77±88.76b 120 1571.48±33.57cd 0.99±0.07ab 0.58±0.02ab 951.47±44.37a 10 CK 1930.14±130.20a 0.89±0.07ab 0.56±0.00a 946.40±87.68a 10 1674.94±48.88b 0.95±0.07a 0.54±0.02ab 767.83±33.41bc 20 1459.74±127.13c 0.91±0.01ab 0.53±0.00b 671.97±65.18cd 40 1492.21±59.34c 0.86±0.06ab 0.53±0.01b 615.72±27.50d 60 1672.19±53.97b 0.84±0.04b 0.54±0.01ab 763.12±52.27bc 120 1818.18±108.35ab 0.85±0.03ab 0.53±0.00b 803.01±21.41b 15 CK 1895.40±38.32a 0.90±0.02a 0.56±0.00a 932.82±14.90a 10 1643.24±55.42b 0.89±0.03a 0.53±0.01c 816.42±61.06b 20 1480.64±41.53c 0.83±0.01b 0.55±0.01b 672.21±2.83c 40 1627.25±17.14b 0.90±0.00a 0.56±0.01a 890.17±79.80ab 60 1607.71±50.62b 0.81±0.01b 0.52±0.00d 687.66±1.72c 120 1655.83±71.51b 0.79±0.04b 0.55±0.00ab 860.14±11.52ab 表 3 复合菌种对面条水分流动性及水分状态含量的影响

Table 3 Influence of compound strains on moisture fluidity and moisture state content of noodles

时间(d) 发酵时间(min) T21(ms) T22(ms) A21(%) A22(%) 0 CK 3.71±0.57a 49.77±0.00b 6.94±0.39c 93.06±0.39a 10 4.04±0.00a 57.22±0.00a 7.61±0.37b 92.39±0.37b 20 3.86±0.30a 57.22±0.00a 8.54±0.51a 91.46±0.51c 40 3.40±0.70a 49.77±0.00b 7.31±0.09bc 92.69±0.09ab 60 3.40±0.23a 49.77±0.00b 8.79±0.23a 91.21±0.23c 120 3.51±0.00a 49.77±0.00b 7.34±0.07bc 92.66±0.07ab 5 CK 2.83±0.62a 45.45±3.74a 7.76±0.58a 92.24±0.58b 10 2.57±0.53a 39.53±3.26a 7.59±0.85a 92.41±0.85b 20 1.83±0.15b 36.01±2.83b 6.76±0.28ab 93.24±0.28ab 40 1.67±0.13b 34.38±2.83b 7.01±0.82ab 92.99±0.82ab 60 1.76±0.24b 36.01±2.83b 6.92±0.20ab 93.08±0.20ab 120 3.05±0.00a 49.77±0.00a 6.44±0.05b 93.56±0.05a 10 CK 3.05±0.00a 43.29±0.00b 7.04±0.09a 92.96±0.09b 10 2.56±0.43a 49.77±0.00a 5.88±0.09b 94.12±0.09a 20 2.57±0.53a 49.77±0.00a 6.80±0.26a 93.20±0.26b 40 2.96±0.61a 49.77±0.00a 5.91±0.48b 94.09±0.48a 60 3.05±0.00a 47.61±3.74a 6.59±0.10a 93.41±0.10b 120 2.81±0.43a 49.77±0.00a 5.60±0.11b 94.40±0.11a 15 CK 3.05±0.43a 43.29±3.74c 6.71±0.52a 93.29±0.52b 10 2.36±0.60b 49.77±0.00a 5.80±0.23b 94.20±0.23a 20 2.92±0.23ab 45.45±3.74bc 5.88±0.09b 94.12±0.09a 40 3.05±0.00a 47.61±3.74ab 5.90±0.30b 94.10±0.30a 60 2.57±0.53ab 49.77±0.00a 5.74±0.09b 94.26±0.09a 120 2.66±0.00ab 49.77±0.00a 5.53±0.30b 94.47±0.30a 表 4 复合菌种发酵面条储藏期内的相对结晶度

Table 4 Relative crystallinity of noodles fermented by compound strains during storage period

储藏时间

(d)RC(%) CK 10 min 20 min 40 min 60 min 120 min 0 13.50±0.20a 11.37±0.15cd 11.93±0.23b 10.77±0.15e 11.07±0.15de 11.60±0.10c 15 16.77±0.15a 13.73±0.15b 12.97±0.21c 12.83±0.12c 12.10±0.20d 12.80±0.10c -

[1] 王磊鑫, 吕莹果, 陈洁, 等. 发酵拉制面条发酵工艺及品质研究[J]. 河南工业大学学报(自然科学版),2018,39(6):36−40, 46. [WANG L X, LV Y G, CHEN J, et al. Study on fermentation technology and quality of fermented hand-pulled noodles[J]. Journal of Henan University of Technology(Natural Science Edition),2018,39(6):36−40, 46. [2] LIU T, LI Y, SADIQ F A, et al. Predominant yeasts in Chinese traditional sourdough and their influence on aroma formation in Chinese steamed bread[J]. Food Chemistry,2018,242:404−411. doi: 10.1016/j.foodchem.2017.09.081

[3] ZHANG J C, LIU W J, SUN Z H, et al. Diversity of lactic acid bacteria and yeasts in traditional sourdoughs collected from western region in Inner Mongolia of China[J]. Food Control,2011,22(5):767−774. doi: 10.1016/j.foodcont.2010.11.012

[4] 杨浣漪, 张国华, 何国庆. 传统面食发酵剂中菌群多样性的研究[J]. 现代食品科技,2013,29(9):2115−2119. [YANG H Y, ZHANG G H, HE G Q. Biodiversity of microorganisms in Chinese traditional starter cultures ecosystem[J]. Modern Food Science and Technology,2013,29(9):2115−2119. [5] 张杰, 张文刚, 党斌, 等. 乳酸菌和米根霉混合固态发酵对黑青稞生化成分的动态变化[J]. 食品工业科技,2019,40(24):88−93. [ZHANG J, ZHANG W G, DANG B, et al. Dynamic changes of biochemical composition of black highland barley by mixed solid-state fermentation with lactic acid bacteria and rhizopus oryzae[J]. Science and Technology of Food Industry,2019,40(24):88−93. [6] 李晓娜, 亓鑫, 赵卉, 等. 植物乳杆菌改性玉米粉制作玉米面条的工艺及品质分析[J]. 食品与发酵工业,2019,45(5):185−189. [LI X N, QI X, ZHAO H, et al. Processing technique and quality analysis of corn noodles made from Lactobacillus plantarum modified corn flour[J]. Food and Fermentation Industries,2019,45(5):185−189. [7] 李芸. 发酵米粉生产过程中的菌相变化及发酵对米粉品质的影响[D]. 北京: 中国农业大学, 2015. LI Y. Microbial succession during rice noodle processing and influence of fermentation on quality of rice noodle[D]. Beijing: China Agricultural University, 2015.

[8] 阳盈盈. 自然发酵米发糕微生物分析及其优势菌的应用[D]. 长沙: 湖南农业大学, 2014. YANG Y Y. Analysis of microbe in naturally fermented rice cake and application of its dominant strains[D]. Changsha: Hunan Agricultural University, 2014.

[9] DE V L, HARTH H, VAN K S. Yeast diversity of sourdoughs and associated metabolic properties and functionalities[J]. International Journal of Food Microbiology,2016,239:26−34. doi: 10.1016/j.ijfoodmicro.2016.07.018

[10] LI N, ZHANG B, ZHAO S, et al. Influence of Lactobacillus/Candida fermentation on the starch structure of rice and the related noodle features[J]. International Journal of Biological Macromolecules,2019,121:882−888. doi: 10.1016/j.ijbiomac.2018.10.097

[11] 李慧东, 刘冠勇. 用乳酸菌和酵母共同发酵法生产面包的研究[J]. 食品工业,2007(6):25−26. [LI H D, LIU G Y. Research on producing bread by collective fermentation process using Lactobacillus and yeast[J]. The Food Industry,2007(6):25−26. [12] 杨秀琴, 邹奇波, 黄卫宁. 酵母菌对自然发酵酸面团面包中风味物质影响的研究[J]. 食品与机械,2006,22(3):37−43. [YANG X Q, ZOU Q B, HUANG W N. Studies on the effect of adding yeast on volatile flavor compounds in sourdough breads[J]. Food and Machinery,2006,22(3):37−43. doi: 10.3969/j.issn.1003-5788.2006.03.012 [13] 张丽华, 李珍珠, 乜晓爽, 等. 植物乳杆菌发酵杜仲鲜叶饮料的研制[J]. 食品科技,2019,44(2):129−133. [ZHANG L H, LI Z Z, NIE X S, et al. The process technology of Eucommia ulmoides leaves beverage fermented by Lactobacillus plantarum[J]. Food Science and Technology,2019,44(2):129−133. [14] CORSETTI A. Technology of sourdough fermentation and sourdough applications[M]. Handbook on sourdough biotechnology. Boston: Springer, 2013: 85−103.

[15] 陈舒涵. 乳清浓缩蛋白对面条品质的影响研究[D]. 无锡: 江南大学, 2020: 11−12. CHEN S H. Effect of whey protein concentrate on noodle quality[D]. Wuxi: Jiangnan University, 2020: 11−12.

[16] 闫博文. 老面酵头微生物菌群多样性差异分析及其对馒头风味特性的影响[D]. 无锡: 江南大学, 2019: 24−25. YAN B W. Variation analysis of microbial diversity in sourdough and its influence on the flavor of Chinese steamed bread[D]. Wuxi: Jiangnan University, 2019: 24−25.

[17] 肖东. 鲜湿面储藏期内老化机理及抗老化研究[D]. 长沙: 中南林业科技大学, 2016: 39−40. XIAO D. Research of retrogradation mechanism for fresh wet noodle and inhibition of retrogradation during storage period[D]. Changsha: Central South University of Forestry and Technology, 2016: 39−40.

[18] 李立华, 周文化, 邓航. 乳化剂对鲜湿面货架期内水分迁移及热力学影响[J]. 食品科学,2018,39(12):140−145. [LI L H, ZHOU W H, DENG H. Effects of emulsififiers on moisture migration and thermodynamics in fresh noodles during shelf life[J]. Food Science,2018,39(12):140−145. doi: 10.7506/spkx1002-6630-201812022 [19] 修琳, 姜南, 郑明珠, 等. 复配改良剂对玉米面条老化特性的影响[J]. 食品工业,2016,37(2):77−80. [XIU L, JIANG N, ZHENG M Z, et al. Influence of compound inhibiter on corn noodles aging characteristics[J]. Food Industry,2016,37(2):77−80. [20] 葛珍珍, 张圆圆, 陈淑慧, 等. 谷朊粉对面条质构及微观结构的影响[J]. 食品科技,2019,44(9):160−165. [GE Z Z, ZHANG Y Y, CHEN S H, et al. Effects of gluten on the texture and microstructure of noodles[J]. Food Science and Technology,2019,44(9):160−165. [21] 王雪婷. 复合发酵菌种对麸皮馒头品质提升的研究[D]. 重庆: 西南大学, 2017: 4−5. WANG X T. Quality promotion of the bran-enriched steamed bread with mixed strains from sourdoughs[D]. Chongqing: Southwest University, 2017: 4−5.

[22] 袁美兰, 鲁战会, 李里特. 自然发酵对玉米淀粉分子结构的影响[J]. 食品科技,2010,35(8):290−293. [YUAN M L, LU Z H, LI L T. Effect of spontaneous fermentation on the molecular structure of corn starch[J]. Food Science and Technology,2010,35(8):290−293. [23] MUDGIL D, BARAK S, KHATKAR B S. Optimization of textural properties of noodles with soluble fiber, dough mixing time and different water levels[J]. Journal of Cereal Science,2016,69:104−110. doi: 10.1016/j.jcs.2016.02.015

[24] LEI M X, HUANG J H, TIAN X L, et al. Effects of insoluble dietary fiber from wheat bran on noodle quality[J]. Grain & Oil Science and Technology,2020,4(1):1−9.

[25] LING X W, TANG N, ZHAO B, et al. Study on the water state, mobility and textural property of Chinese noodles during boiling[J]. International Journal of Food Science & Technology,2020,55(4):1716−1724.

[26] WU L R, ZHANG L, ZHANG Y Q, et al. Water state and distribution in noodle dough using low-field nuclear magnetic resonance and differential scanning calorimetric[J]. Transactions of the Chinese Society of Agricultural Engineering,2015,31(9):288−294.

[27] WANG X, CHOI S G, KERR W L. Water dynamics in white bread and starch gels as affected by water and gluten content[J]. LWT-Food Science and Technology,2003,37(3):377−384.

[28] ZHANG B J, CHEN L, ZHAO Y, et al. Structure and enzymatic resistivity of debranched high temperature-pressure treated high-amylose corn starch[J]. Journal of Cereal Science,2013,57(3):348−355. doi: 10.1016/j.jcs.2012.12.006

[29] ODEY G N, LEE W Y. Evaluation of the quality characteristics of flour and pasta from fermented cassava roots[J]. International Journal of Food Science & Technology,2020,55(2):813−822.

[30] WAHYUNI S. Physico-chemical properties of wikau maombo flour from cassava (Manihot esculenta Crantz)[J]. Journal of Food Measurement and Characterization,2017,11(1):329−336. doi: 10.1007/s11694-016-9401-5

-

期刊类型引用(0)

其他类型引用(2)

下载:

下载:

下载:

下载: