Effect of Degreasing Rabbit Bone Micro Powder on the Characteristics of Dough and Noodles

-

摘要: 为扩展兔骨的应用范围,将项目组前期研制的兔骨微细粉(degreasing rabbit bone micro powder,DRBM)添加至小麦粉中,研究DRBM对面团及面条特性的影响。结果表明,随着DRBM的添加比例增大,面团的白度呈下降趋势,蓝黄值显著增大(P<0.05),添加比例在8%以内色泽变化较小;从微观结构上看,DRBM添加量达到12%时会对面筋网络结构产生明显破坏;Mixolab混合实验仪结果表明,DRBM的添加能改善面团的耐揉性,提升面团的强度和糊化速度,延缓面团的老化,但会降低面团的吸水率、糊化热胶的稳定性、淀粉酶酶解等,DRBM添加量小于12%时,混合粉的流变学特性在可接受范围内;DRBM的添加显著提高了面条的矿物质及赖氨酸含量(P<0.05),同时加快面条糊化速度,缩短煮面时间,但DRBM的添加将引起面条蒸煮特性的降低,结合感官评分与质构分析,DRBM添加量在8%以内时,面条品质较优,当添加量超过12%,面条表观状态趋于不好。综上,在不添加品质改善剂的情况下,DRBM应用于面条加工的添加比例不应超过12%。Abstract: In order to expand the application scope of rabbit bone, the degreasing rabbit bone micro powder (DRBM) which was previously studied by the project group was added into wheat flour to study the effect of DRBM on the properties of dough and noodles. The results showed that, with the increasing of DRBM, the whiteness of the mixed dough decreased, and the blue yellow value increased significantly(P<0.05), and the range of color change was small when the proportion of DRBM was less than 8%. The microstructure of the dough showed that the bone meal particles began to destroy the gluten network structure obviously when the addition amount reached 12%. The results of Mixolab mixing tester showed that, the addition of DRBM could improve the kneading resistance, the strength and gelatinization speed of dough, and delayed the aging of dough, but reduced the water absorption of dough and the stability of gelatinized hot glue, as well as the enzymatic hydrolysis of amylase. The rheological properties of mixed powder were within an acceptable range when the addition of DRBM was less than 12%. The addition of DRBM significantly improved the mineral and lysine content of noodles (P<0.05), accelerated the gelatinization speed and shortened the cooking time. However, the mixing of DRBM would reduce the cooking characteristics of noodles. Combined with sensory score and texture analysis, the quality of noodles were better when the addition amount of DRBM was less than 8%, and the apparent state of noodles inclined to be bad while the addition amount was more than 12%. In conclusion, the addition ratio of DRBM in noodle processing should not exceed 12% without adding quality improver.

-

Keywords:

- rabbit bone /

- micro powder /

- proportion /

- dough properties /

- noodles properties

-

由于特殊的风味、质地及营养特性,兔肉越来越受到世界各国消费者的喜爱[1-3],兔产业蓬勃发展。伴随兔肉的加工,兔骨等大量副产品产生,这对企业经济效益和环境造成压力。目前,对兔骨的加工研究仍处于初步阶段。有报道显示,兔骨营养丰富,且利用球磨、高频振动等技术将兔骨微细化,能显著提高兔骨粉的粉体特性及钙的生物利用率等[4-7]。此外,将兔骨粉加入肉糜中,可使肉制品具有特殊的骨香味及高钙的特点[8-9]。

项目组前期利用高频振动粉碎等技术[7,10],高效制备出平均粒径(D0.5)为16.92±0.15 µm兔骨微细粉(degreasing rabbit bone micro powder,DRBM)。DRBM粉体色泽白,是一种天然的钙源,具有高矿物质的营养特点,若将其应用于主食化面制品中,不仅可以增强面制品的营养功能,还能扩展动物骨的应用。小麦粉与水混合后,在和面过程中,由于面筋蛋白形成的网络结构,使得面粉形成具有粘弹性的面团,这是面粉能够蒸制馒头、烘焙面包、煮制面条等面制品的物质基础[11]。动物骨粉中虽含有大量的蛋白质类物质,却不是面筋蛋白,且其中大量的无机盐可能会影响面团的网络结构。研究显示,将罗非鱼鱼骨粉、牦牛骨粉添加至小麦粉中制备骨粉面条,发现随着骨粉的添加,面条中面筋蛋白含量相对减少、面筋网络结构形成减少,面条的断条率和蒸煮损失率不断增加,而骨粉的添加量过少,又会降低面条的营养价值[12-13]。本研究通过对不同骨粉比例的面团进行色泽、微观结构、流变特性分析,研究兔骨微细粉DRBM对面团特性的影响,并在此基础上制备相应的兔骨粉面条,研究DRBM对面条蒸煮特性、感官品质及化学成分的影响,为兔骨在面制品中的应用提供数据支撑。

1. 材料与方法

1.1 材料与仪器

伊拉兔四肢骨 重庆市阿兴记原种兔养殖基地;福临门家宴牌小麦粉(蛋白质含量9.5%)、晶心牌食用盐 市售;丙酮、戊二醇、浓盐酸、浓硫酸、石油醚(30~60 ℃)等 均为分析纯,成都科龙化工试剂厂;氨基酸混合标准品、茚三酮、磺基水杨酸、氨基酸分析仪缓冲液等 赛卡姆( 北京) 科学仪器有限公司。

ASM-PE1210A和面机 北美电器(ACA);JYS-N6自动面条机 九阳股份有限公司;CM-2300d 分光测色计 日本柯尼卡美能达控股公司;XT-48BN 白度测定仪 杭州研特科技有限公司;LyoQuest冻干机 西班牙Telstar公司;ProX扫描电子显微镜 荷兰飞纳公司;Mixolab混合实验仪 法国肖邦技术公司;DSC 25差式扫描量热仪 美国TA仪器有限公司;B-81 脂肪抽提测定仪 瑞士步琪公司;KJELTEC 8400 全自动凯氏定氮仪 丹麦福斯公司;SX-4-10 马弗炉 北京中兴伟业仪器有限公司;S433D 全自动氨基酸分析仪 德国赛卡姆公司;iCAP 6000电感耦合等离子体发射光谱仪 美国赛默飞公司;Milli-q reference 超纯水系统 美国密理博公司。

1.2 实验方法

1.2.1 样品制备

1.2.1.1 兔骨微细粉制备

根据项目组前期的工艺[7],对兔骨进行120 ℃高温蒸煮软化2 h、粗粉碎、乙酸乙酯液料比5.3:1超声辅助脱脂、液料比3:1水洗脱色、振动磨微粉碎10 min,制备得到平均粒径(D0.5)为16.92±0.15 µm,兔骨微细粉DRBM(脂肪含量为1.73%,灰分含量为84.21 g/100 g,钙含量为17.55 g/100 g,磷的含量为8.56 g/100 g,镁的含量为555.63 mg/100 g,锌的含量为22.09 mg/100 g)。

1.2.1.2 面团制备

将DRBM按0、4%、8%、12%、16%、20%添加于小麦粉中,配方如表1所示,置于和面机中(额定功率1200 W),1档和面1 min,期间缓慢加入超纯水,5档和面5 min,暂停2 min,4档和面2 min,取出面团,手工整形成表面光滑后,常温醒发20 min,得到面团样品。

表 1 面团配方Table 1. Recipe of dough添加比例

(%)DRBM添加量

(g)面粉添加量

(g)超纯水添加量

(mL)0 0 200 120 4 8 192 120 8 16 184 120 12 24 176 120 16 32 168 120 20 40 160 120 1.2.1.3 面条制备

将DRBM按0、4%、8%、12%、16%、20%添加于小麦粉中,加粉体总重2%的食盐,混匀后,倒入和面机中,1档和面5 min,按料液比3:1(g:g)逐步加入适量超纯水,和面结束后将絮状面团倒入面条机中,选取2 mm模头,“手动制面”模式下出面,室温下悬挂晾干至水分含量小于14.0%,取下后切成15 cm长的面条备用。化学成分测定时,需将面条用粉碎机粉碎,过60目筛,取筛下粉末为测试样品。

1.2.2 色泽测定

面团的色泽用白度及色差来表示:将面团样品放入样品盒中,压实,表面无缝隙及气泡,置于经校正后的白度测定仪检测口进行白度(W)测定,记录各个样品的ISO白度值(R457);取适量面团样品放入透明自封袋中,排除表面气泡,然后置于经过校正后的色差仪检测口进行色差测定,记录各个样品的L*、a*、b*值。

1.2.3 扫描电镜观察

将揉好的面团切成0.5 cm3的小方块,于培养皿中用3.5%的戊二醛固定24 h,再先后用浓度梯度30%、50%、70%、90%、100%的丙酮(V/V)洗脱各20 min,丙酮常温挥发后,将面团块置于自封袋密封好后放入–21 ℃冰箱冷冻24 h,再置于冻干机中冻干20 h,得到固定化面团样品[14]。扫描电镜测试前,将面团切开,取中间部分切成1~2 mm薄片,用导电胶将样品粘在样品座上,样品喷金30 s后,用扫描电镜观察样品截面的形态特征,并在10 kV的加速电压下摄取放大1000倍、1500倍的照片。

1.2.4 流变学特性测定

按表1配方,将DRBM按0、4%、8%、12%、16%、20%添加于面粉中,样品充分混合均匀后取适量混粉样品置于Mixolab混合实验仪和面钵中,参数设定按照“Chopin+”标准,实验结束后获得力矩曲线,得到面团吸水率、C1~C5扭矩值、面团形成时间、面团稳定时间、糊化特性、回生特性等数据[11,15]。

1.2.5 面条蒸煮特性研究

1.2.5.1 最佳煮面时间测定

将面条置于微沸的超纯水中煮4 min,然后每隔10 s取样一次,将取出的面条切断,观察面条横截面内部白色的硬心,当白色硬心消失时,所记录的时间即为最佳煮面时间[16]。

1.2.5.2 断条率测定

按照最佳煮面时间用微沸水煮15根面条,煮面结束后记录完整长度面条的根数N,按下列公式推算出面条断条率[13]:

断条率(%)=(15−N15)×100 1.2.5.3 吸水率测定

按照最佳煮面时间用500 mL微沸超纯水煮10.00 g面条,煮面结束后捞出面条,沥干水分后称面条重量M(g),按下列公式计算面条吸水率:

吸水率(%)=(M−1010)×100 1.2.5.4 蒸煮损失测定

将测定面条吸水率后的面汤转入500 mL容量瓶中用超纯水定容,取100 mL置于250 mL干燥的烧杯中,在电炉上煮至微沸,快干时放入105 ℃烘箱中烘干至恒重,烧杯的增重计为m1(g),按下列公式计算面条蒸煮损失:

蒸煮损失(%)=5m110×100 1.2.6 面条感官评价

按照最佳煮面时间将兔骨粉面条煮熟后随机3位数编号,由15名感官评定员组成评定小组,样品评定间用清水漱口,各评定员单独评定相互间不交流。具体评分如表2所示:

表 2 面条感官评定标准(分)Table 2. Sensory evaluation standard of noodles(scores)项目 评价内容 分值 好 一般 差 色泽 均匀一致,明亮 10.0 10.0~8.5 8.4~6.1 6.0~1.0 外观 表面光滑、粗细均匀、无断条及形变 10.0 10.0~8.5 8.4~6.1 6.0~1.0 适口性 软硬适中,细腻不粗糙 20.0 20.0~17.1 17.1~12.1 12.0~1.0 韧性 有弹性、嚼劲 25.0 25.0~21.1 21.0~15.1 15.0~1.0 粘性 不粘牙 25.0 25.0~21.1 21.0~15.1 15.0~1.0 光滑性 表面光滑,口感滑爽 5.0 5.0~4.3 4.2~3.1 3.0~1.0 风味 无异味,具有本类产品特有香味 5.0 5.0~4.3 4.2~3.1 3.0~1.0 总分 100.0 100.0~84.3 84.2~60.1 60.0~1.0 1.2.7 面条化学组成分析

面条水分、灰分、蛋白质、脂肪含量的测定分别采用食品安全国家标准GB5009.3-2016《食品中水分的测定》、GB 5009.4-2016《食品中灰分的测定》、GB 5009.5-2016《食品中蛋白质的测定》、GB 5009.6-2016《食品中脂肪的测定》;矿物质的组成采用食品安全国家标准GB 5009.268-2016《食品中多元素的测定》第二法,电感耦合等离子体发射光谱法(ICP-OES);氨基酸测定参照GB 5009.124-2016《食品中氨基酸含量的测定》,样品前处理采用常规酸水解-厌氧管充氮密封水解法,略有改动[7],分析条件:流动相流速0.45 mL/min,茚三酮流速0.25 mL/min,柱温130 ℃。

1.3 数据处理

每组实验重复3次(n=3),采用Excel 2010和SPSS 19.0进行数据统计及差异性分析。

2. 结果与分析

2.1 添加DRBM对面团色泽的影响

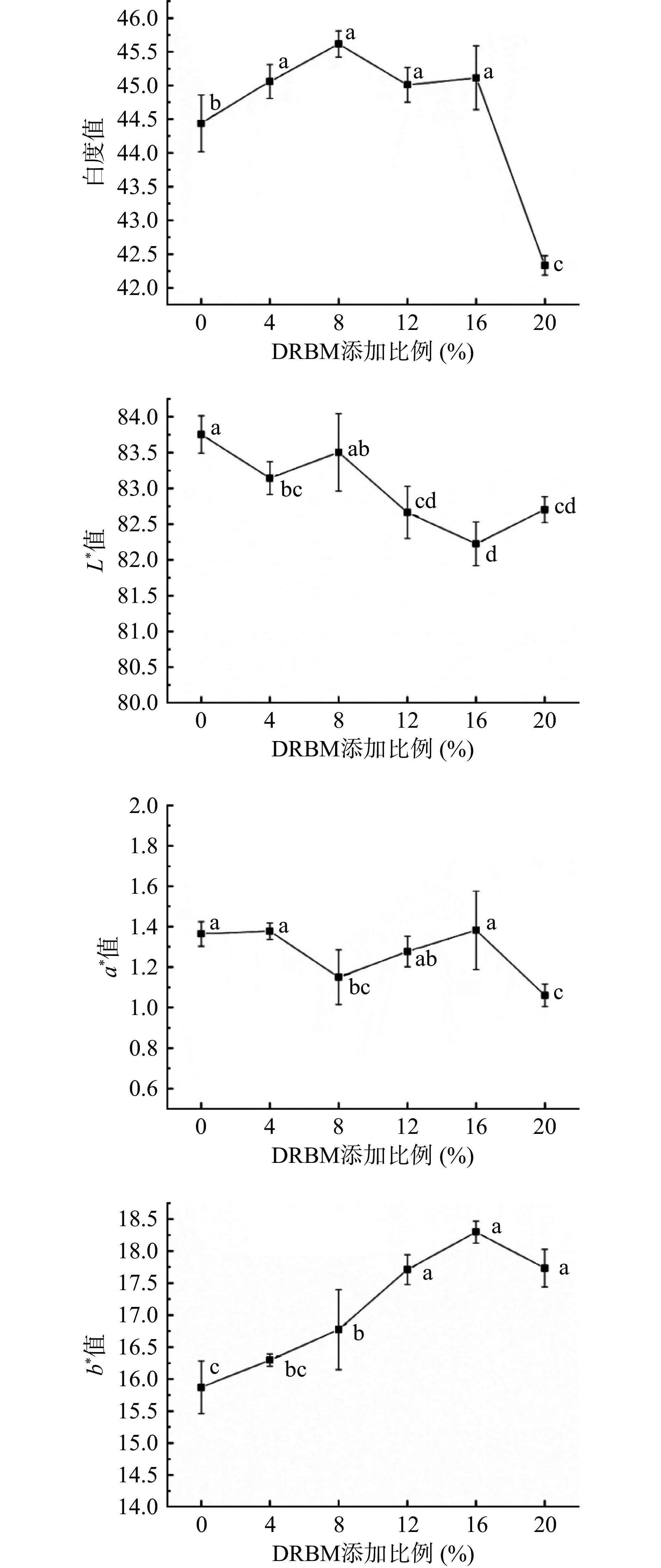

由图1可以看出,添加DRBM后,面团的白度先增加后降低,亮度、绿红值呈下降趋势,蓝黄值先升高后不变,说明面团颜色逐渐变黄,颜色变暗,这与肉眼观察一致。DRBM主要由白色的羟基磷灰石及少量残留的红褐色血红蛋白组成,与小麦粉相比,DRBM颜色偏黄、偏绿[7],因此添加到面粉中将一定程度地影响面团的色泽,DRBM的添加比例在16%以内,有助于提升面团的白度,但亮度及蓝黄值影响较大,添加比例在8%以内,色泽变化范围较小。

2.2 添加DRBM对面团微观结构的影响

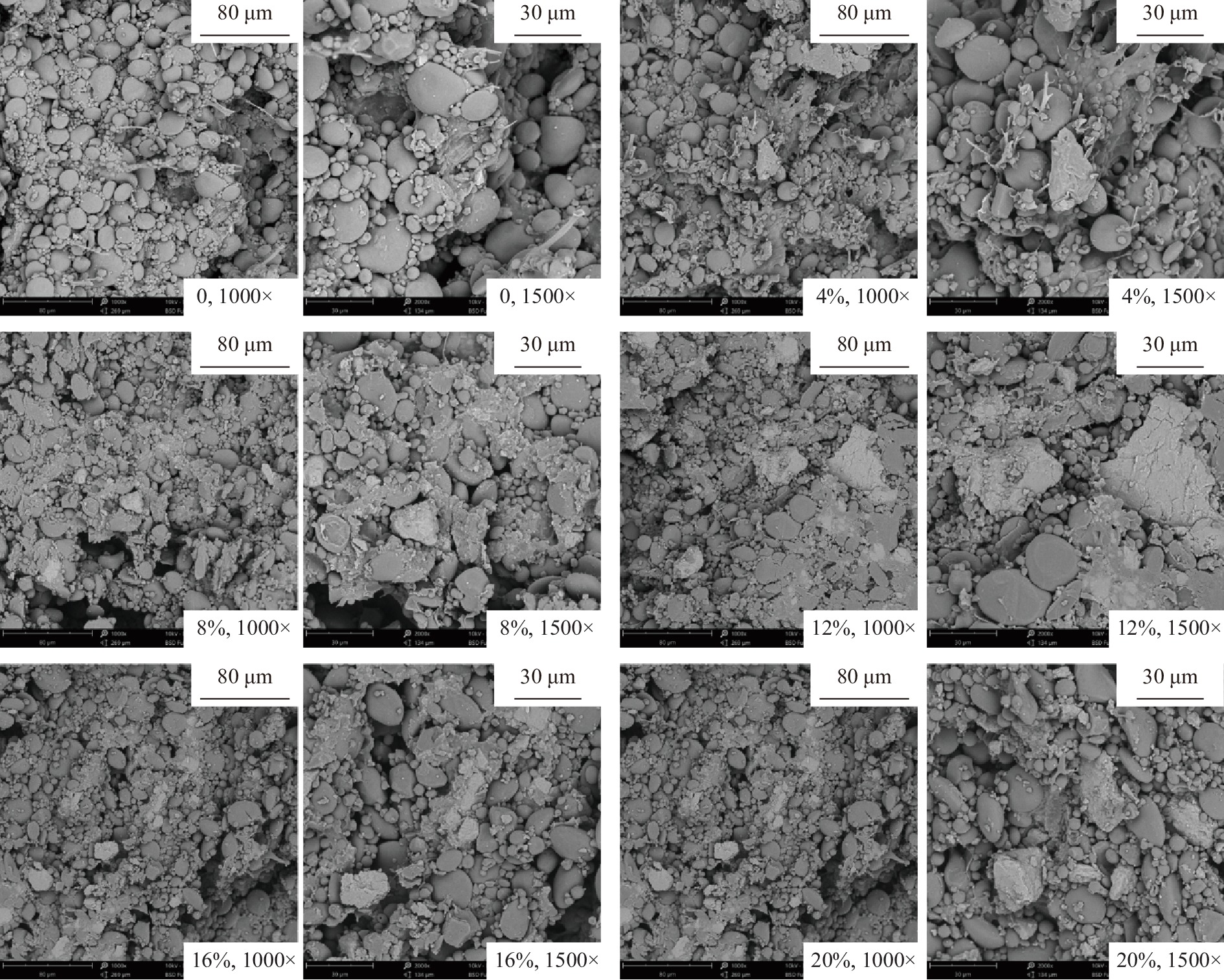

支撑面团的网络结构主要是由醇溶蛋白和谷蛋白组成的面筋蛋白构成[17],DRBM中虽含有较高的蛋白质,但不含面筋蛋白。由图2中可以看出,添加DRBM之前,呈圆球形的淀粉颗粒连续镶嵌在面筋蛋白的网络结构中,结构均匀紧密,而随着DRBM的添加,越来越多的呈不规则多角形的骨粉颗粒插入在面团网络结构中,原本致密的网络结构变得疏松,当添加量达到12%时,骨粉颗粒开始对面筋网络结构产生明显影响,面团微观结构中出现板结情况,面筋蛋白网络结构的连续性被打破,这可能与骨粉颗粒分布不均匀且团聚有关。段娇娇等[18]在添加了青稞全粉的小麦面团的微观结构中也观察到了这一现象,麸皮及紧密的青稞淀粉的存在破坏了面筋蛋白连续的网络结构,网络不够明显且有团聚板结。因此,DRBM的配粉比例不宜过高。

2.3 添加DRBM对面团流变学特性的影响

利用兼具粉质特性和糊化特性测定功能的Mixolab混合实验仪对面团进行流变特性分析,测试结果如表3所示。由表3中的数据可以看出,DRBM的添加对小麦粉的流变学特性产生了较大影响,随着DRBM添加比例的增加(0~8%),面团的吸水率显著降低(P<0.05),蛋白质的弱化、面团粘度、回生值、糊化速度、酶解速度等特性均发生显著变化(P<0.05)。

表 3 DRBM混合面团的Chopin+协议测试参数结果汇总Table 3. Chopin+ protocol test parameters results of DRBM mixed dough配粉比例(%) 0 4 8 12 16 20 吸水率(%) 59.00±0.01a 57.60±0.85b 56.01±0.01c 55.65±0.21c 55.25±0.35c 55.20±0.02c CS(Nm) 0.95±0.01b 1.02±0.06ab 1.04±0.00a 1.04±0.01a 1.03±0.04a 0.98±0.01ab C2(Nm) 0.33±0.00c 0.40±0.03b 0.43±0.01ab 0.45±0.01a 0.42±0.02ab 0.41±0.01b C3(Nm) 1.63±0.01c 1.78±0.09b 1.89±0.01a 1.85±0.01ab 1.86±0.03ab 1.89±0.01a C4(Nm) 1.41±0.02bc 1.48±0.08ab 1.51±0.01a 1.35±0.01c 1.25±0.05d 1.06±0.01e C5(Nm) 1.78±0.04a 1.80±0.06a 1.81±0.06a 1.60±0.05b 1.42±0.06c 1.23±0.01d C1-CS(Nm) 0.16±0.00a 0.10±0.01bc 0.08±0.00c 0.09±0.01bc 0.10±0.02bc 0.11±0.02b CS-C2(Nm) 0.62±0.01a 0.62±0.04a 0.61±0.01a 0.6±0.01ab 0.61±0.02a 0.57±0.02b C1-C2(Nm) 0.78±0.01a 0.71±0.04b 0.69±0.01b 0.69±0.01b 0.71±0.04b 0.68±0.03b C5-C4(Nm) 0.37±0.02a 0.32±0.02a 0.30±0.05ab 0.25±0.04b 0.17±0.01c 0.16±0.01c 形成时间(min) 1.53±0.04ab 1.67±0.02ab 2.68±1.35a 1.05±0.04b 1.13±0.01b 1.23±0.13b 稳定时间(min) 6.33±0.12d 9.05±0.49c 9.6±0.14bc 9.65±0.07bc 9.80±0.42b 10.45±0.21a α −0.07±0.01 −0.07±0.01 −0.07±0.00 −0.08±0.01 −0.08±0.00 −0.08±0.00 β 0.30±0.06b 0.26±0.02b 0.30±0.03b 0.62±0.03a 0.60±0.03a 0.65±0.01a γ −0.01±0.01a −0.03±0.02ab −0.05±0.01ab −0.05±0.03ab −0.05±0.00ab −0.05±0.00ab 注:同一行不同小写字母表示差异显著(P<0.05);表4同。 DRBM添加量0~8%时,混合面团吸水率一直显著下降(P<0.05),继续添加则下降趋势不显著(P>0.05),前期研究表明[7],DRBM的持水力显著低于小麦粉(P<0.05),这与DRBM的化学组成有关,面团中影响吸水率的主要成分是面筋蛋白[17],而DRBM中的羟基磷灰石及蛋白质吸水性不强,因此DRBM添加至面团中影响到混合面团的吸水率。

随着DRBM的添加,面团升温过程中稠度最小值C2显著上升(P<0.05),DRBM添加量至16%后C2有所降低,但仍优于纯小麦粉,热弱化值CS-C2、总弱化值C1-C2均降低,面团稳定时间升高,这都说明DRBM减少了机械搅拌和热作用下面团中蛋白质的弱化,面团的韧性提高,这可能与DRBM中羟基磷灰石颗粒的强度有关,面筋网络包埋DRBM中的羟基磷灰石使得面团的强度提高,搅拌刀叶片感受到较大的阻力,因此DRBM提升了面团的揉混强度。

面团升温过程中,DRBM的添加显著提升了(P<0.05)混粉面团的峰值粘度C3,面团变粘,这可能与DRBM中含有的胶原蛋白粘度有关[19],而淀粉糊化速度β显著提高(P<0.05),这可能与DRBM本身已经过高温处理有关。

在面团保温过程中,保持粘度C4随着DRBM的添加先显著上升(P<0.05),添加至12%时后显著下降(P<0.05),因此过量的DRBM将会影响面团淀粉糊化热胶的稳定性,而随着DRBM的添加混粉面团淀粉酶酶解速度γ降低,这可能与DRMB在混粉中替代面粉率提高有关,面粉中的淀粉酶对面制品品质提升有较大影响,淀粉酶有较强的耐热性[20-21],高温情况下仍能降解淀粉产生可溶性糊精、低聚糖及少量麦芽糖、葡萄糖等,这可以提高发酵面制品质量,使组织内部质构松软细腻,且能延缓面团的老化,提升延伸性和拉伸性[22-24]。

面团冷却过程中,DRBM的添加量至12%后,回生终点粘度C5显著降低(P<0.05),C5值与面制品的嚼劲呈正相关[25-26],因此,过量的DRBM会影响面制品嚼劲,但混粉面团C5-C4回生值随着DRMB的添加显著降低(P<0.05),面团老化速度减缓,这将有益于延长面制品货架期。

将表3中的指标做皮尔逊相关性分析,与DRBM添加量有显著相关性(P<0.05)的流变学特性指标按相关性由大至小依次为:回生值C5-C4>吸水率>回生终点粘度C5>淀粉糊化速度β>面团稳定时间>保持粘度C4>峰值粘度C3>总弱化值C1-C2>热弱化值CS-C2>酶解速度γ>稠度最小值C2。

其中,C5-C4、吸水率、C5、C4、与DRBM添加量呈极强负相关(皮尔逊相关系数绝对值>0.8),C1-C2、CS-C2、γ与DRBM添加量呈强负相关(皮尔逊相关系数绝对值0.6~0.8);β、稳定时间、C3与DRBM添加量呈极强正相关,C2与DRBM添加量呈强正相关。因此,随着DRBM的添加,面团吸水率降低、保持粘度及回生终点粘度降低、回生值降低、蛋白质的热弱化值和和总弱化值降低、酶解速度下降,说明DRBM提升了面团的强度,延缓了面团的老化速度,但会影响面团的吸水率、糊化热胶的稳定性、冷却过程糊化胶的粘度、淀粉酶的酶解;而面团峰值粘度上升、面团的稳定时间上升,淀粉糊化速度上升、稠度最小值上升,说明DRBM改善了面团的耐揉性、机械力和热过程中面团的强度,提升了面团的粘度及糊化速度。

综上所述,DRBM的添加不宜过高,DRBM添加量为4%时,对混合粉的流变学特性影响不大,当DRBM添加量在8%~12%时,混合粉的流变学特性也在可接受范围内,但当DRBM添加量增大到16%及以上时,对混合粉的流变学特性影响较大。

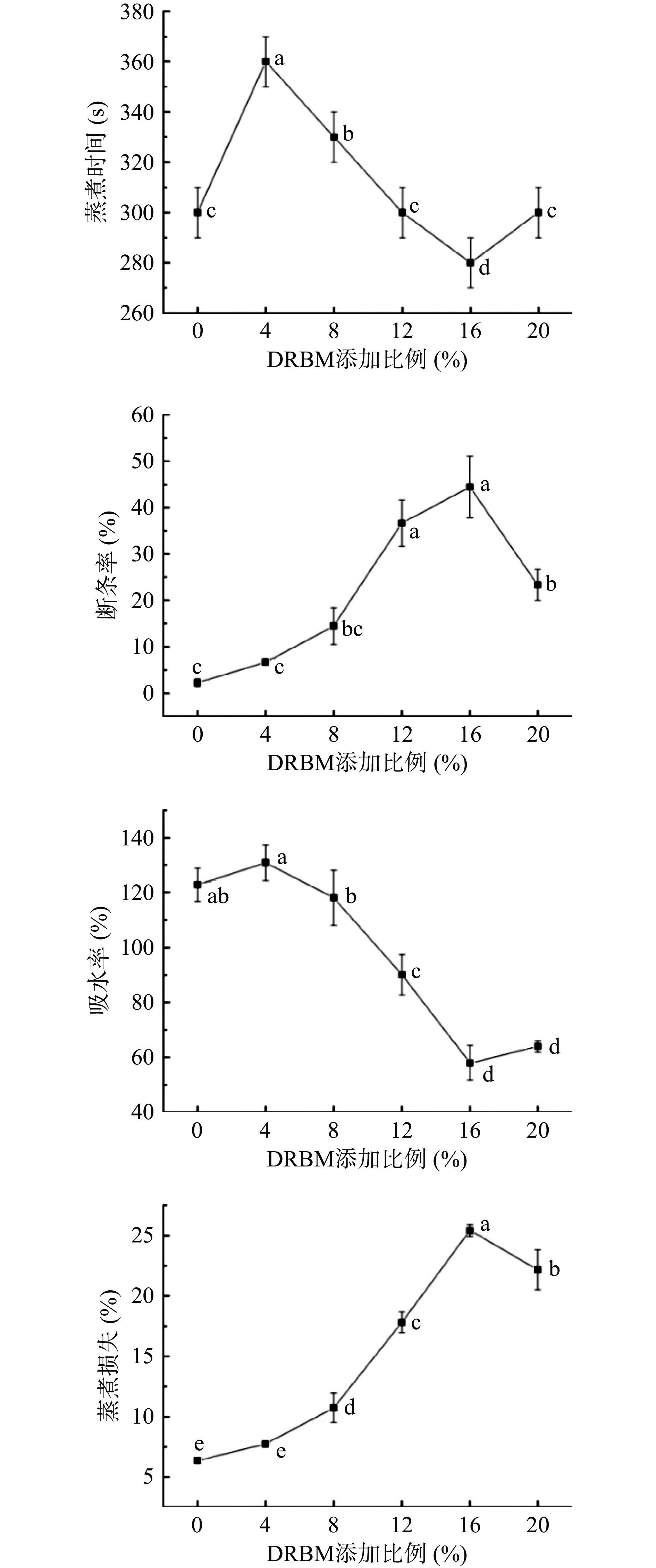

2.4 不同配粉比例对面条蒸煮特性的影响

不同骨粉比例对面条蒸煮特性的影响如图3所示,可以看出:随着DRBM的添加,面条煮面时间整体呈下降趋势,最佳煮面时间可以反映面条的糊化速度,这说明煮熟面条所需的时间变短,在2.3的研究结果中也表明,DRBM可以提高面团的糊化速度、降低糊化所需要的热量;面条断条率整体呈上升趋势,DRBM添加比例4%时,断条率变化不显著(P>0.05),仅为6%左右,但随着DRBM的继续添加(至12%),断条率显著上升(P<0.05),添加至20%时又有所下降,从图2可以看出,过多的DRBM使面筋蛋白的网络结构产生裂缝,这可能导致面条在蒸煮过程中发生断条现象,而添加至20%时,骨粉颗粒致密的团聚在一起,可能会增加面条的强度,导致断条率有所下降。

吸水率和蒸煮损失是评价面条品质的重要指标,面条吸水率大,面条出品率高,而烹煮损失小,淀粉流失少,面条不易糊汤[16,27]。随着DRBM配粉比例的提高,面条吸水率显著降低、蒸煮损失显著提高(P<0.05),面条吸水率的降低与DRBM的持水力有关,骨粉比例8%以内,面条吸水率变化不大,但添加至12%后,面条吸水率降低至100%以内,这会影响面条的膨胀及出品率;面条蒸煮损失增大与DRBM对面团网络结构的弱化有关,随着DRBM配粉比例的提高,面筋连续均匀的网络结构被打破,淀粉颗粒更易从面筋网络中游离出来、溶于面汤中,尤其在添加DRBM至12%后,面条蒸煮损失明显增大至15%以上,浑汤现象变严重。

综上,为保证较好的蒸煮特性,DRBM制作面条的配粉比例应控制12%以内。

2.5 不同配粉比例对面条感官特性的影响

由表4可看出,随着DRBM配粉比例的增大,面条感官评分逐渐降低:面条颜色变暗、变黄,色泽分值降低但变化不显著(P>0.05),添加量到16%时,分值低于8;添加量到12%时,面条表面明显变得不光滑,评分值低于8,面条煮后的外观可能与小麦粉中淀粉的溶出有关,DRBM的添加使得面筋网络结构被破坏,包裹在其中的淀粉颗粒流出,一方面导致面条表面凹凸不平,另一方面面筋蛋白的断裂还可能导致面条韧性降低、弹性降低[18,28],因此面条的韧、粘性得分也降低;与此同时,由于DRBM中的羟基磷灰石呈多角状、难溶于水,因此口感较粗糙,添加量过多会影响面条的适口性,面条会有明显的颗粒感;DRBM本身带有轻微的腥味,添加量4%时,面条有轻微骨粉味,可接受,添加量至8%时,骨粉味较明显,但得分仍较好,且面条无明显粗糙感,添加量至12%时,断条开始较为明显,骨粉味明显,当DRBM添加至16%时,面条中的骨粉气味令人产生不愉快的感受。综上,当DRBM添加量超过12%,熟面条的感官状态均趋于不好。

表 4 添加DRBM对面条感官品质的影响Table 4. Effect of DRBM addition on the sensory evaluation of noodles感官评分(分) 0 4% 8% 12% 16% 20% 色泽 9.50±0.71 9.25±1.06 9.00±0.71 8.65±0.92 7.90±1.27 7.35±1.20 外观 9.75±0.35a 9.75±0.35a 8.20±0.28b 6.75±0.35c 6.05±0.07d 6.00±0.00d 适口性 16.75±1.06a 17.75±1.06a 17.50±0.71a 12.00±0.00b 10.75±1.06b 11.00±1.41b 韧性 23.00±2.83a 22.50±0.71a 20.00±1.41ab 15.25±0.35bc 12.50±3.54c 12.50±3.54c 粘性 21.50±0.71a 21.50±0.71a 20.50±0.71a 15.25±0.35b 10.00±0.00c 9.00±0.00c 光滑性 4.75±0.35a 4.65±0.21a 4.00±0.00ab 3.05±0.07bc 2.50±0.71c 2.25±1.06c 风味 5.00±0.00a 4.90±0.14a 4.25±0.35ab 3.50±0.00b 2.50±0.71c 1.75±0.35c 总分 90.25±4.60a 90.30±3.25a 83.45±2.76a 64.45±1.34b 52.20±7.35bc 49.85±7.57c 2.6 不同配粉比例对面条化学组成的影响

由前期研究可知[7],DRBM是一种营养价值较高的天然资源,具有低脂、高蛋白、高矿物质的特点,添加DRBM将改变面条的化学组成,结果如表5所示。

表 5 添加DRBM对面条化学组成的影响Table 5. Effect of DRBM addition on chemical composition of noodles含量 0 4% 8% 12% 16% 20% 蛋白质 10.91±0.15 11.01±0.12 11.06±0.10 11.05±0.13 11.07±0.01 10.90±0.07 水分 13.85±0.37a 13.33±0.17ab 13.19±0.33b 11.84±0.10c 11.93±0.15c 11.97±0.19c 脂肪 0.78±0.23b 1.03±0.35ab 1.18±0.13ab 1.42±0.01a 1.33±0.04a 1.22±0.13ab 灰分 0.55±0.06f 3.84±0.33e 7.31±0.58d 10.34±0.64c 13.16±0.03b 17.11±0.21a 钙 0.06±0.00f 1.02±0.00e 1.88±0.00d 2.78±0.05c 3.60±0.05b 4.32±0.04a 磷 0.13±0.00f 0.69±0.00e 1.23±0.01d 1.82±0.03c 2.39±0.02b 2.90±0.01a 镁 29.10±0.08f 50.63±0.65e 66.11±0.39d 87.98±1.66c 106.98±0.57b 123.57±0.19a 锌 0.00±0.00f 0.23±0.04e 1.19±0.12d 2.21±0.09c 3.00±0.02b 4.07±0.12a 铁 0.22±0.07d 0.21±0.02d 1.17±0.01a 0.60±0.07c 0.67±0.08c 0.86±0.09b 甘氨酸 0.35±0.01e 0.40±0.01d 0.41±0.02cd 0.44±0.00bc 0.44±0.00b 0.48±0.01a 脯氨酸 1.82±0.07ab 1.89±0.00a 1.81±0.13ab 1.75±0.02ab 1.70±0.01b 1.76±0.05ab 羟脯氨酸 0.47±0.04b 0.49±0.02ab 0.53±0.00a 0.53±0.00a 0.52±0.00ab 0.54±0.01a 谷氨酸 3.46±0.02ab 3.52±0.12a 3.29±0.18abc 3.23±0.04bcd 3.00±0.00d 3.08±0.11cd 丙氨酸 0.30±0.01c 0.32±0.01bc 0.32±0.02bc 0.33±0.00ab 0.32±0.01bc 0.36±0.02a 天冬氨酸 0.26±0.01c 0.28±0.01abc 0.28±0.02bc 0.29±0.00ab 0.28±0.00abc 0.31±0.01a 丝氨酸 0.48±0.01a 0.49±0.02a 0.46±0.02ab 0.46±0.00ab 0.43±0.01b 0.46±0.01ab 赖氨酸 0.09±0.02b 0.12±0.00ab 0.13±0.02ab 0.16±0.01a 0.15±0.01a 0.15±0.02a 亮氨酸 0.66±0.01ab 0.69±0.02a 0.65±0.04ab 0.65±0.01ab 0.61±0.01b 0.65±0.03ab 苯丙氨酸 0.43±0.00ab 0.45±0.01a 0.44±0.03ab 0.43±0.01ab 0.40±0.01b 0.42±0.01ab 缬氨酸 0.35±0.01 0.38±0.01 0.37±0.02 0.36±0.00 0.35±0.00 0.37±0.01 苏氨酸 0.25±0.00 0.26±0.00 0.25±0.02 0.25±0.00 0.24±0.00 0.26±0.01 异亮氨酸 0.29±0.00ab 0.3±0.01a 0.29±0.01ab 0.29±0.00ab 0.27±0.00b 0.29±0.01ab 蛋氨酸 0.09±0.01 0.08±0.02 0.08±0.01 0.07±0.01 0.08±0.00 0.09±0.02 组氨酸 0.17±0.00 0.18±0.01 0.18±0.02 0.18±0.01 0.17±0.00 0.18±0.02 精氨酸 0.32±0.01 0.33±0.01 0.34±0.01 0.34±0.00 0.32±0.01 0.35±0.03 酪氨酸 0.19±0.03 0.16±0.02 0.21±0.01 0.20±0.01 0.17±0.00 0.20±0.02 胱氨酸 0.16±0.01a 0.14±0.01ab 0.15±0.01a 0.14±0.00ab 0.12±0.00b 0.14±0.01ab 氨基酸总量 10.14±0.12ab 10.50±0.16a 10.2±0.59ab 10.11±0.09ab 9.63±0.05b 10.08±0.36ab 注:同一行数据标有不同小写字母表示差异显著(P<0.05);各指标单位为:蛋白质(g/100 g),水分(g/100 g),脂肪(g/100 g),灰分(g/100 g),钙(g/100g),磷(g/100 g),镁(mg/100 g),锌(mg/100 g),铁(mg/100 g),氨基酸(g/100 g)。 随着DRBM的添加,面条水分含量、谷氨酸含量等有所降低,这与DRBM的水分含量、谷氨酸含量低有关,且DRBM的吸水性低,这也可能导致面条中的水分含量低。DRBM的脂肪含量为1.73%,略高于面粉的脂肪含量,因此DRBM的添加增加了面条中的脂肪含量,但增加幅度较小,DRBM面条制品的脂肪含量低于1.50%。

DRBM中的灰分含量高达84.21 g/100 g、钙含量17.55 g/100 g、磷含量8.56 g/100 g、镁含量555.63 mg/100 g、锌含量22.09 mg/100 g,因此DRBM的混入显著提升了面条的矿物质含量(P<0.05),DRBM添加量为4%时,面条中的钙含量达1.02 g/100 g,远高于牛奶中的钙含量(约0.12 g/100 mL),与此同时,还赋予了面条高锌、高镁的营养特点。

DRBM的添加对面条氨基酸总量的影响不大,但显著提高了面条中赖氨酸的含量(P<0.05),赖氨酸是一种人体必需氨基酸,其参与机体蛋白质合成、葡萄糖和酮体、脂肪的代谢等,在促进机体生长发育、提供能量等方面都具有积极的营养学意义[29]。

3. 结论

本试验将小麦粉中添加不同比例的DRBM后,对混粉面团在色泽、微观结构、流变学特性、热特性等方面进行了分析,并试制兔骨面条并进行品质评价,得出如下结论:DRBM的添加能改善面团耐揉性、提高糊化速度、延缓老化,但会破坏面筋蛋白网络结构,并且影响面团的色泽、吸水率、糊化热胶的稳定性、淀粉酶酶解、回生终点粘度等,DRBM添加量不宜超过12%;DRBM缩短了面条煮制时间,并且提高了面条的营养特性,添加4% DRBM的面条钙含量达1.02±0.00 g/100 g,镁含量达50.63±0.65 mg/100 g,锌含量达0.23±0.04 mg/100 g,赖氨酸含量达0.12±0.00 g/100 g,但DRBM的添加将引起面条色泽变化、蒸煮特性降低,结合感官评分,DRBM添加量在8%以内时面条品质较优,当添加量超过12%,面条表观状态趋于不好。

因此,DRBM应用于面条生产的添加比例最高不应超过12%。而如何提高DRBM的适口性、天然亲水多糖及生物酶等改良剂在骨粉面制品中的使用等,还需要进一步研究,从而使动物骨粉能够更好地在主食化产品中推广应用。

-

表 1 面团配方

Table 1 Recipe of dough

添加比例

(%)DRBM添加量

(g)面粉添加量

(g)超纯水添加量

(mL)0 0 200 120 4 8 192 120 8 16 184 120 12 24 176 120 16 32 168 120 20 40 160 120 表 2 面条感官评定标准(分)

Table 2 Sensory evaluation standard of noodles(scores)

项目 评价内容 分值 好 一般 差 色泽 均匀一致,明亮 10.0 10.0~8.5 8.4~6.1 6.0~1.0 外观 表面光滑、粗细均匀、无断条及形变 10.0 10.0~8.5 8.4~6.1 6.0~1.0 适口性 软硬适中,细腻不粗糙 20.0 20.0~17.1 17.1~12.1 12.0~1.0 韧性 有弹性、嚼劲 25.0 25.0~21.1 21.0~15.1 15.0~1.0 粘性 不粘牙 25.0 25.0~21.1 21.0~15.1 15.0~1.0 光滑性 表面光滑,口感滑爽 5.0 5.0~4.3 4.2~3.1 3.0~1.0 风味 无异味,具有本类产品特有香味 5.0 5.0~4.3 4.2~3.1 3.0~1.0 总分 100.0 100.0~84.3 84.2~60.1 60.0~1.0 表 3 DRBM混合面团的Chopin+协议测试参数结果汇总

Table 3 Chopin+ protocol test parameters results of DRBM mixed dough

配粉比例(%) 0 4 8 12 16 20 吸水率(%) 59.00±0.01a 57.60±0.85b 56.01±0.01c 55.65±0.21c 55.25±0.35c 55.20±0.02c CS(Nm) 0.95±0.01b 1.02±0.06ab 1.04±0.00a 1.04±0.01a 1.03±0.04a 0.98±0.01ab C2(Nm) 0.33±0.00c 0.40±0.03b 0.43±0.01ab 0.45±0.01a 0.42±0.02ab 0.41±0.01b C3(Nm) 1.63±0.01c 1.78±0.09b 1.89±0.01a 1.85±0.01ab 1.86±0.03ab 1.89±0.01a C4(Nm) 1.41±0.02bc 1.48±0.08ab 1.51±0.01a 1.35±0.01c 1.25±0.05d 1.06±0.01e C5(Nm) 1.78±0.04a 1.80±0.06a 1.81±0.06a 1.60±0.05b 1.42±0.06c 1.23±0.01d C1-CS(Nm) 0.16±0.00a 0.10±0.01bc 0.08±0.00c 0.09±0.01bc 0.10±0.02bc 0.11±0.02b CS-C2(Nm) 0.62±0.01a 0.62±0.04a 0.61±0.01a 0.6±0.01ab 0.61±0.02a 0.57±0.02b C1-C2(Nm) 0.78±0.01a 0.71±0.04b 0.69±0.01b 0.69±0.01b 0.71±0.04b 0.68±0.03b C5-C4(Nm) 0.37±0.02a 0.32±0.02a 0.30±0.05ab 0.25±0.04b 0.17±0.01c 0.16±0.01c 形成时间(min) 1.53±0.04ab 1.67±0.02ab 2.68±1.35a 1.05±0.04b 1.13±0.01b 1.23±0.13b 稳定时间(min) 6.33±0.12d 9.05±0.49c 9.6±0.14bc 9.65±0.07bc 9.80±0.42b 10.45±0.21a α −0.07±0.01 −0.07±0.01 −0.07±0.00 −0.08±0.01 −0.08±0.00 −0.08±0.00 β 0.30±0.06b 0.26±0.02b 0.30±0.03b 0.62±0.03a 0.60±0.03a 0.65±0.01a γ −0.01±0.01a −0.03±0.02ab −0.05±0.01ab −0.05±0.03ab −0.05±0.00ab −0.05±0.00ab 注:同一行不同小写字母表示差异显著(P<0.05);表4同。 表 4 添加DRBM对面条感官品质的影响

Table 4 Effect of DRBM addition on the sensory evaluation of noodles

感官评分(分) 0 4% 8% 12% 16% 20% 色泽 9.50±0.71 9.25±1.06 9.00±0.71 8.65±0.92 7.90±1.27 7.35±1.20 外观 9.75±0.35a 9.75±0.35a 8.20±0.28b 6.75±0.35c 6.05±0.07d 6.00±0.00d 适口性 16.75±1.06a 17.75±1.06a 17.50±0.71a 12.00±0.00b 10.75±1.06b 11.00±1.41b 韧性 23.00±2.83a 22.50±0.71a 20.00±1.41ab 15.25±0.35bc 12.50±3.54c 12.50±3.54c 粘性 21.50±0.71a 21.50±0.71a 20.50±0.71a 15.25±0.35b 10.00±0.00c 9.00±0.00c 光滑性 4.75±0.35a 4.65±0.21a 4.00±0.00ab 3.05±0.07bc 2.50±0.71c 2.25±1.06c 风味 5.00±0.00a 4.90±0.14a 4.25±0.35ab 3.50±0.00b 2.50±0.71c 1.75±0.35c 总分 90.25±4.60a 90.30±3.25a 83.45±2.76a 64.45±1.34b 52.20±7.35bc 49.85±7.57c 表 5 添加DRBM对面条化学组成的影响

Table 5 Effect of DRBM addition on chemical composition of noodles

含量 0 4% 8% 12% 16% 20% 蛋白质 10.91±0.15 11.01±0.12 11.06±0.10 11.05±0.13 11.07±0.01 10.90±0.07 水分 13.85±0.37a 13.33±0.17ab 13.19±0.33b 11.84±0.10c 11.93±0.15c 11.97±0.19c 脂肪 0.78±0.23b 1.03±0.35ab 1.18±0.13ab 1.42±0.01a 1.33±0.04a 1.22±0.13ab 灰分 0.55±0.06f 3.84±0.33e 7.31±0.58d 10.34±0.64c 13.16±0.03b 17.11±0.21a 钙 0.06±0.00f 1.02±0.00e 1.88±0.00d 2.78±0.05c 3.60±0.05b 4.32±0.04a 磷 0.13±0.00f 0.69±0.00e 1.23±0.01d 1.82±0.03c 2.39±0.02b 2.90±0.01a 镁 29.10±0.08f 50.63±0.65e 66.11±0.39d 87.98±1.66c 106.98±0.57b 123.57±0.19a 锌 0.00±0.00f 0.23±0.04e 1.19±0.12d 2.21±0.09c 3.00±0.02b 4.07±0.12a 铁 0.22±0.07d 0.21±0.02d 1.17±0.01a 0.60±0.07c 0.67±0.08c 0.86±0.09b 甘氨酸 0.35±0.01e 0.40±0.01d 0.41±0.02cd 0.44±0.00bc 0.44±0.00b 0.48±0.01a 脯氨酸 1.82±0.07ab 1.89±0.00a 1.81±0.13ab 1.75±0.02ab 1.70±0.01b 1.76±0.05ab 羟脯氨酸 0.47±0.04b 0.49±0.02ab 0.53±0.00a 0.53±0.00a 0.52±0.00ab 0.54±0.01a 谷氨酸 3.46±0.02ab 3.52±0.12a 3.29±0.18abc 3.23±0.04bcd 3.00±0.00d 3.08±0.11cd 丙氨酸 0.30±0.01c 0.32±0.01bc 0.32±0.02bc 0.33±0.00ab 0.32±0.01bc 0.36±0.02a 天冬氨酸 0.26±0.01c 0.28±0.01abc 0.28±0.02bc 0.29±0.00ab 0.28±0.00abc 0.31±0.01a 丝氨酸 0.48±0.01a 0.49±0.02a 0.46±0.02ab 0.46±0.00ab 0.43±0.01b 0.46±0.01ab 赖氨酸 0.09±0.02b 0.12±0.00ab 0.13±0.02ab 0.16±0.01a 0.15±0.01a 0.15±0.02a 亮氨酸 0.66±0.01ab 0.69±0.02a 0.65±0.04ab 0.65±0.01ab 0.61±0.01b 0.65±0.03ab 苯丙氨酸 0.43±0.00ab 0.45±0.01a 0.44±0.03ab 0.43±0.01ab 0.40±0.01b 0.42±0.01ab 缬氨酸 0.35±0.01 0.38±0.01 0.37±0.02 0.36±0.00 0.35±0.00 0.37±0.01 苏氨酸 0.25±0.00 0.26±0.00 0.25±0.02 0.25±0.00 0.24±0.00 0.26±0.01 异亮氨酸 0.29±0.00ab 0.3±0.01a 0.29±0.01ab 0.29±0.00ab 0.27±0.00b 0.29±0.01ab 蛋氨酸 0.09±0.01 0.08±0.02 0.08±0.01 0.07±0.01 0.08±0.00 0.09±0.02 组氨酸 0.17±0.00 0.18±0.01 0.18±0.02 0.18±0.01 0.17±0.00 0.18±0.02 精氨酸 0.32±0.01 0.33±0.01 0.34±0.01 0.34±0.00 0.32±0.01 0.35±0.03 酪氨酸 0.19±0.03 0.16±0.02 0.21±0.01 0.20±0.01 0.17±0.00 0.20±0.02 胱氨酸 0.16±0.01a 0.14±0.01ab 0.15±0.01a 0.14±0.00ab 0.12±0.00b 0.14±0.01ab 氨基酸总量 10.14±0.12ab 10.50±0.16a 10.2±0.59ab 10.11±0.09ab 9.63±0.05b 10.08±0.36ab 注:同一行数据标有不同小写字母表示差异显著(P<0.05);各指标单位为:蛋白质(g/100 g),水分(g/100 g),脂肪(g/100 g),灰分(g/100 g),钙(g/100g),磷(g/100 g),镁(mg/100 g),锌(mg/100 g),铁(mg/100 g),氨基酸(g/100 g)。 -

[1] ZOTTE A D, SZENDRÖ Z. The role of rabbit meat as functional food[J]. Meat Science,2011,88(3):319−331. doi: 10.1016/j.meatsci.2011.02.017

[2] WANG Z M, HE Z F, EMARA A M, et al. Effects of malondialdehyde as a byproduct of lipid oxidation on protein oxidation in rabbit meat[J]. Food Chemistry,2019,288:405−412. doi: 10.1016/j.foodchem.2019.02.126

[3] DAL-BOSCO A, MATTIOLI S, CULLERE M, et al. Effect of diet and packaging system on the oxidative status and polyunsaturated fatty acid content of rabbit meat during retail display[J]. Meat Science,2018,143:46−51. doi: 10.1016/j.meatsci.2018.04.004

[4] 李少博, 李洪军, 贺稚非. 纳米级兔骨粉球磨法制备工艺优化究[J]. 农业工程学报,2017,33(14):300−306. [LI S B, LI H J, HE Z F. Optimization of preparation process of nanometer rabbit bone meal by ball milling[J]. Transactions of the Chinese Society of Agricultural Engineering,2017,33(14):300−306. doi: 10.11975/j.issn.1002-6819.2017.14.040 [5] 任灿, 贺稚非, 李杨梅, 等. 超细微兔骨理化性质的研究[J]. 食品与发酵工业,2017,43(2):226−231. [REN C, HE Z F, LI Y M, et al. The physical and chemical properties of ultra-fine rabbit bone[J]. Food and Fermentation Industries,2017,43(2):226−231. [6] 李少博, 贺稚非, 邓大川, 等. 不同粒度兔骨粉营养特性和理化特性的研究[J]. 食品与发酵工业,2017,43(10):74−79. [LI S B, HE Z F, DENG D C, et al. Nutritional characteristics and physicochemical characteristics of different size rabbit bone meal[J]. Food and Fermentation Industries,2017,43(10):74−79. [7] 李雪, 贺稚非, 许晶冰, 等. 高频振动式微粉碎对兔骨粉体特性的影响[J/OL]. 食品与发酵工业: 1−10 [2021-02-03]. https: //doi. org/10.13995/j. cnki. 11-1802/ts. 026226. LI X, HE Z F, XU J B, et al. Effect of high frequency vibration micro comminution on powder characteristics of rabbit bone[J/OL]. Food and Fermentation Industries: 1−10 [2021-02-03].https://doi.org/10.13995/j.cnki.11-1802/ts.026226.

[8] 任灿. 超微兔骨与高钙兔糜凝胶的制备及其理化特性研究[D]. 重庆: 西南大学, 2017. REN C. Studies on production and physicochemical property of superfine rabbit bone and the high calcium rabbit mi gel[D]. Chongqing: Southwest Universtiy, 2017.

[9] LI S B, HE Z F, LI H J. Effect of nano-scaled rabbit bone powder on physicochemical properties of rabbit meatbatter[J]. Journal of the Science of Food and Agriculture,2018,98(12):4533−4541. doi: 10.1002/jsfa.8981

[10] 许晶冰, 李雪, 贺稚非, 等. 超声波辅助兔骨粉脱脂工艺优化[J]. 食品与发酵工业,2020,46(17):145−150. [XU J B, LI X, HE Z F, et al. Optimization of ultrasonic assisted degreasing process of rabbit bone meal[J]. Food and Fermentation Industries,2020,46(17):145−150. [11] 黄莲燕, 张小爽, 张君慧, 等. 不同谷物麸皮对面团流变学特性及面筋蛋白结构的影响[J]. 食品科学,2017,38(23):1−6. [HUANG L Y, ZHANG X S, ZHANG J H, et al. Effect of different cereal brans on dough rheological properties and gluten secondary structure[J]. Food Science,2017,38(23):1−6. doi: 10.7506/spkx1002-6630-201723001 [12] 张钟, 刘海招. 罗非鱼鱼骨粉面条的研制[J]. 粮食与饲料工业,2017(3):22−28. [ZHANG Z, LIU H Z. Noodles of tilapia bone meal[J]. Cereal & Feed Industry,2017(3):22−28. [13] 胡拖萧. 牦牛骨粉挂面制作技术研究[D]. 雅安: 四川农业大学, 2016. HU T X. Study on producing technology of yak bone powder dry noodles[D]. Sichuan Agricultural University, 2016.

[14] 袁永利, 黄卫宁, 邹奇波, 等. 食品酶制剂对冷冻面团流变学和微观结构的影响[J]. 食品与机械,2006,22(6):30−33. [YUAN Y L, HUANG W N, ZOU Q B, et al. Effect of food enzymes on rheological and micro structural properties of frozen doughs[J]. Food and Machinery,2006,22(6):30−33. doi: 10.3969/j.issn.1003-5788.2006.06.009 [15] MARCO C, ROSELL C M. Breadmaking performance of protein enriched, gluten-free breads[J]. European Food Research and Technology,2008,227(4):1205−1213. doi: 10.1007/s00217-008-0838-6

[16] 张玲, 赵国华, 曾志红, 等. 微细化苦荞全粉在面条加工中的应用[J]. 食品与发酵工业,2018,44(11):222−228. [ZHANG L, ZHAO G H, ZENG Z H, et al. The application of micronized tartary buckwheat flour in noodle processing[J]. Food and Fermentation Industries,2018,44(11):222−228. [17] 张玲, 赵国华, 高飞虎, 等. 微细化苦荞全粉对面团特性的影响[J]. 食品与发酵工业,2017,43(10):177−181. [ZHANG L, ZHAO G H, GAO F H, et al. Effect of micronized tartary buckwheat flour on its dough properties[J]. Food and Fermentation Industries,2017,43(10):177−181. [18] 段娇娇, 覃小丽, 金剑波, 等. 不同品种青稞全粉对重组粉面团流变学性质及面条品质的影响[J]. 食品与发酵工业,2019,45(16):208−215. [DUAN J J, TAN X L, JIN J B, et al. , et al. Effects of highland barley varieties on rheological properties ofreconstituted dough and the quality of noodles[J]. Food and Fermentation Industries,2019,45(16):208−215. [19] LI X, HE Z F, XU J B, et al. Effect of nanoprocessing on the physicochemical properties of bovine, porcine, chicken, and rabbit bone powders[J]. Food Science & Nutrition,2021,9(7):3580−3592.

[20] 张首玉, 曾洁, 孙俊良. α-淀粉酶对馒头品质的影响及抑制回生的机理研究[J]. 食品工业,2014,35(3):31−33. [ZHANG S Y, ZENG J, SUN J L. Effect of α-amylase on qualities of steamed bread and its inhibition mechanismto retrogradation[J]. The Food Industry,2014,35(3):31−33. [21] STEFFOLANI M E, RIBOTTA P D, PÉREZGT, et al. Combinations of glucose oxidase, α-amylase and xylanase affect dough properties and bread quality[J]. International Journal of Food Science & Technology,2012,47(3):525−534.

[22] 杨末, 于雷, 赵安琪, 等. α-淀粉酶对绿豆面包品质的影响[J]. 粮食与油脂,2018,31(5):31−34. [YANG M, YU L, ZHAO A Q, et al. Effect of α-amylase on mung bean bread's quality[J]. Cereals and Oils,2018,31(5):31−34. doi: 10.3969/j.issn.1008-9578.2018.05.010 [23] JI H K, MAEDA T, MORITA N. Effect of fungal α-amylase on the dough properties and bread quality of wheat flour substituted with polished flours[J]. Food Research International,2006,39(1):117−126. doi: 10.1016/j.foodres.2005.06.008

[24] 赵景艳, 冯海涛, 王圣宝. 淀粉酶对面团流变学特性的影响[J]. 现代面粉工业,2013,26(9):20−23. [ZHAO J Y, FENG H T, WANG S B. Effect of amylase on rheological properties of dough[J]. Modern Flour Milling Industry,2013,26(9):20−23. [25] 杨文建, 俞杰, 孙勇, 等. 添加金针菇、茶树菇粉对面团流变学特性的影响[J]. 食品科学,2014,35(23):43−47. [YANG W J, YU J, SUN Y, et al. Effect of flammulinavelutipes and agrocybeaegirit powders on rheological properties of dough[J]. Food Science,2014,35(23):43−47. doi: 10.7506/spkx1002-6630-201423009 [26] 陶虹伶, 王丹, 马宁, 等. 松茸粉对面团流变特性及饼干品质的影响[J]. 食品科学,2019,40(5):51−56. [TAO H L, WANG D, MA N, et al. Effect of tricholoma matsutake powder on rheological properties of dough and quality characteristics[J]. Food Science,2019,40(5):51−56. [27] 彭芸, 陈洁, 吕莹果, 等. 苦荞粉添加量对面团性质及馒头品质的影响[J]. 粮油食品科技,2015,23(1):47−50. [PENG H L, CHEN J, LV Y G, et al. Effect of addition amount of buckwheat on the dough properties and steamed bread quality[J]. Science and Technology of Cereals, Oils and Foods,2015,23(1):47−50. doi: 10.3969/j.issn.1007-7561.2015.01.012 [28] HONG T, ZHANG Y, XU D, et al. Effect of sodium alginate on the quality of highland barley fortified wheat noodles[J]. LWT-Food Science and Technology,2020,140:110719.

[29] CULLERE M, DALLE-ZOTTE A. Rabbit meat production and consumption: State of knowledge and future perspectives[J]. Meat Science,2018,143:137−146. doi: 10.1016/j.meatsci.2018.04.029

-

期刊类型引用(3)

1. 李亚俐,王雪莉,石柳,吴文锦,陈胜,陈朗,郭晓嘉,熊光权,汪兰,孙智达. 壳聚糖-绿原酸复合保鲜剂对冷藏鮰鱼片食用品质的影响. 肉类研究. 2025(01): 42-50 .  百度学术

百度学术

2. 武玫怡,焦文娟,赵甜甜,刘俊,周芳,刘伟峰,张业辉,南海军,陈晓瑛,黄利华. 高静水压与水煮处理对热带海参品质的影响. 肉类研究. 2025(01): 25-33 .  百度学术

百度学术

3. 崔燕,刘韩欣,朱麟,尚海涛,林旭东,陈曙颖,宣晓婷. 超高压杀菌对大黄鱼理化性质及滋味、风味的影响. 食品工业科技. 2025(05): 44-55 .  本站查看

本站查看

其他类型引用(3)

下载:

下载:

下载:

下载: