Preparation and Properties of Hydrophobically Modified Whey Protein Isolate-Pullulan Composite Aerogel

-

摘要: 目的:对易吸湿的蛋白/多糖类气凝胶进行疏水改性并对其性能进行评估。方法:对乳清分离蛋(whey protein isolate,WPI)-普鲁兰多糖(pullulan,PUL)复合气凝胶进行低温等离子体处理,使其羟基充分暴露后,使用硅烷偶联剂进行表面接枝处理,获得具有疏水性能的复合气凝胶,并研究其吸湿性、疏水疏油性、抗压性能、热失重、精油装载与缓释性能等。结果:甲基三甲氧基硅烷(methyltrimethoxysilane,MTMS)改性后复合气凝胶的平衡吸湿率为(9.67%±0.323%),十八烷基三甲氧基硅烷(octadecyltrimethoxysilane,OTMS)改性后复合气凝胶平衡吸湿率为(9.34%±0.276%),相比为改性前(11.41%±0.506%)均明显降低;改性前,复合气凝胶水接触角为(40.14°±2.16°),油接触角为(28.07°±2.43°);MTMS改性后水接触角为(82.10°±4.78°),油接触角为(56.14°±3.25°);OTMS改性后水接触角为(85.21°±4.61°),油接触角为(74.63°±3.08°);改性后疏水疏油性均有所提升,且OTMS改性处理效果更好。改性前复合气凝胶压缩模量(21.745±1.982)MPa,MTMS改性后(17.655±3.034)MPa,OTMS改性后(18.412±3.513)MPa。改性后抗压强度略有降低,但不影响正常使用。改性前复合气凝胶丁香精油的最大装载率为(254.26%±5.585%),MTMS疏水改性后丁香精油最大装载率(241.57%±5.214%),OTMS组则为(223.31%±4.436%)。丁香精油装载率有所下降但缓释性能均有所提升,且MTMS改性缓释效果更好。热稳定性方面均有所提升,且OTMS组热稳定性更好。结论:综上所述,硅烷接枝疏水改性处理可以显著提升复合气凝胶的疏水性并提高其亲油性。适用于油脂类活性物质的装载与缓释应用,拓宽了WPI-PUL复合气凝胶的应用领域。Abstract: Objective: To modify hydrophobicity of protein/polysaccharide aerogels and evaluate their properties. Methods: The whey protein isolate(WPI)- pullulan(PUL) composite aerogels were treated by low temperature plasma treatment. After exposure to hydroxyl groups, silane coupling agents were used for surface grafting. Hydrophobic composite aerogels were obtained, and their hygroscopicity, hydrophobicity, oil content, compression resistance, thermal weightlessness, loading and slow release properties of essential oils were studied. Results: The equilibrium moisture absorption rate of the composite aerogel modified by methyltrimethoxy silane(methyltrimethoxysilane, MTMS) was (9.67%±0.323%), eighteen alkyl trimethoxy silane(octadecyltrimethoxysilane, OTMS) modified composite aerogel equilibrium moisture absorption rate of (9.34%±0.276%), compared with before modification(11.41%±0.506%). It was significantly reduced; Before modification, the contact angle of composite gas gel was (40.14°±2.16°), the oil contact angle was (28.07°±2.43°); The contact angle of water after MTMS modification was (82.10°±4.78°), the oil contact angle was (56.14°±3.25°); The contact angle of water after OTMS modification was (85.21°±4.61°), the oil contact angle was (74.63°±3.08°); The hydrophobic and oil drainage properties of the modified products were improved, and the effect of OTMS was better. Compression modulus of modified composite aerogel(21.745±1.982) MPa, (17.655±3.034) MPa after MTMS modification, (18.412±3.513) MPa after OTMS modification. The compressive strength of the modified material decreased slightly, but it did not affect the normal use. The maximum loading rate of the modified composite aerogel clove essential oil was (254.26%±5.585%), after MTMS hydrophobic modification, the maximum loading rate of clove essential oil was (241.57%±5.214%) and OTMS group (223.31%±4.436%). The loading rate of clove essential oil had decreased, but the sustained release property had been improved, and the MTMS modified slow-release effect was better. The thermal stability of OTMS group was better. Conclusion: Silane graft hydrophobic modification can significantly enhance the hydrophobicity and enhance the hydrophobicity of composite aerogels. It is suitable for loading and slow releasing applications of active oils, which widens the application field of WPI-PUL composite aerogels.

-

Keywords:

- aerogels /

- whey proteinisolate /

- pullulan /

- hydrophobicity modification /

- essential oil release

-

蛋白、多糖类气凝胶由于含有较多的亲水性基团,如-COOH、-NH2、-OH等,加上自身多孔的结构及比表面积大的特点,使其容易吸收空气中的水分。吸水后的气凝胶可能会使得气凝胶结构软化、吸附能力降低、装载的活性物质活性下降,此外,水蒸发时产生的力还会影响气凝胶的结构[1-5]。综上所述,为了拓宽复合气凝胶的应用范围,降低其亲水性显得尤为重要。

在常温下,通过气体放电法[6]对空气进行电离得到等离子体,此时,等离子体处于一种非热平衡状态,等离子体的电子温度远高于离子和中性粒子温度,是一种高能电子[7-8]。当高能电子与中性原子发生碰撞后,会将能量传递给中性原子使其跃迁为激发态或形成自由基,这一特性有利于气凝胶表面接枝或聚合反应的进行[7, 9]。同时,等离子的刻蚀作用可以使光滑的气凝胶表面变得粗糙,为疏水改性提供了良好的结构支持[10-12]。

硅烷偶联剂,如甲基三甲氧基硅烷(Methyltrimethoxysilane,MTMS)[13-14]、十八烷基三甲氧基硅烷(Octadecyltrimethoxysilane,OTMS)[15-16]等是近年来常用的疏水改性剂,其主要原理是:在溶液中硅烷偶联剂水解失去烷基基团,使得-OH暴露出来形成硅烷醇类。硅烷醇类彼此继续脱水缩合形成长链,在此过程中富含-OH的气凝胶可以参与其缩合反应而在表面形成一种疏水分子层[17]。FENG等[18]使用MTMS对纤维素气凝胶进行改性处理,得到了具有超强吸油能力的疏水亲油性气凝胶。李玉岐[19]通过将OTMS修饰的TiO2喷涂在再生纤维素气凝胶上制备出超疏水气凝胶,油水分离率高达99%。

目前对于蛋白、多糖类气凝胶的疏水改性研究相对较少,且改性手段相对单一。本研究针对WPI和PUL原料易改性的特点,采用低温等离子体(Plasma)-硅烷偶联剂接枝复合处理手段。在前期实验基础上制备WPI-PUL复合气凝胶[20],对其进行Plasma处理,使其羟基充分暴露后,再使用硅烷偶联剂进行表面接枝处理,以获得具有疏水性能的复合气凝胶。以吸湿性、表面润湿性对其疏水性进行评估,以广谱抑菌精油——丁香精油(主要成分丁香酚)[21]为活性物质测试其装载及缓释性能,并对复合气凝胶的其他应用性能进行测试,旨在拓宽WPI-PUL复合气凝胶的应用领域。

1. 材料与方法

1.1 材料与仪器

乳清分离蛋白 美国ISOPURE公司;普鲁兰多糖(纯度>98%,MW:342-710000) 上海萨恩化学技术有限公司;丁香精油 吉安市中香天然植物有限公司;食品级食用油 益海嘉里金龙鱼粮油食品股份有限公司;盐酸、氢氧化钠、氯化钠、溴化钾 国药集团上海化学试剂有限公司;甲基三甲氧基硅烷、十八烷基三甲氧基硅烷、正己烷 上海麦克林生化科技有限公司;去离子水 实验室自制;以上试剂除注明外均为分析纯。

TA.XTPlus质构仪 英国SMS公司;SU5000热场发射扫描电镜 Hitachi(日立)公司;PiezobrushPZ2等离子处理仪 德国RelyonPlasmaGmbH公司;U-3900紫外分光光度计 日本日立高新技术科学公司;JC2000C接触角测量仪 上海中晨数字技术设备有限公司;DF-101S型集热式恒温加热磁力搅拌器 河南省巩义市科瑞仪器有限公司;SCIENTZ-10N型真空冷冻干燥机 宁波新芝生物科技股份有限公司;DZF-6050型真空干燥箱 上海精宏实验设备有限公司;NicoletiZ10型傅立叶变换显微红外成像光谱仪 ThermoScientific有限公司;LHS-500HC-II型恒温恒湿箱、YP202N型电子天平、雷磁PHS-3CpH计 上海精密科学有限公司。

1.2 实验方法

1.2.1 WPI-PUL复合气凝胶的制备

用电子天平称取20 g WPI粉末置于烧杯中,添加5.5 g PUL粉末与100 mL去离子水在25 ℃水浴条件下充分搅拌使之混合。以肉眼不可见白色悬浮物后再继续搅拌5 min作为混匀标准。混匀后密封,于4 ℃冰箱静置12 h,使其充分水合。后加入0.585 g NaCl,并用1 mol/L的HCl或NaOH溶液调节其溶液pH至7.9,再于25 ℃恒温水浴搅拌30 min。将搅拌后分散均匀的悬浮液除去溶液上层泡沫后倒入2 mL离心管,84 ℃条件下水浴加热30 min使之充分形成WPI-PUL水凝胶,−20 ℃冰箱冷冻12 h。将冷冻完全的样品置于真空冷冻干燥机进行干燥(规程:−45 ℃,15 Pa,2 d),制得WPI-PUL复合气凝胶。

1.2.2 疏水改性处理

用功率30 W的Plasma等离子处理仪对制备好的复合气凝胶处理10 min后置于疏水剂修饰溶液(硅烷偶联剂:正己烷=1:2)中,常温下浸泡24 h使之充分反应。后将处理完成的样品60 ℃真空干燥6 h,制得疏水改性复合气凝胶(MTMS组、OTMS组)[19, 22]。另设未疏水改性组作为空白组进行对照实验。

1.2.3 吸湿性能测试

通过重量法测定气凝胶的吸湿率,参照SU等[23]的方法并作修改,将气凝胶置于相对湿度为83.6%,温度为30 ℃的恒温恒湿箱中,测量间隔为1 h,重量动态平衡即为测试终点。气凝胶吸湿率按式(1)计算:

(1) 式中,H-吸湿率,%;W-吸湿一定时间后气凝胶的质量,g;W0-未吸湿前气凝胶的初始质量,g。

1.2.4 油/水接触角

切取气凝胶样品平整部位的表面置于接触角测量仪的样品台,从针头中分别将蒸馏水、食用油缓缓挤出滴落至样品表面,对水滴照片进行采集并用五点拟合法分析其接触角大小,每个样品至少取五个部分进行测试[24]。

1.2.5 抗压性能测试

将气凝胶切成高度为1 cm,直径0.8 cm的圆柱状样品。选用P25平面探头,质构仪参数设定为:测前速度1.0 mm/s,测试速度0.1 mm/s,测后速度1.0 mm/s,形变75%为测试终点。在得到的应力-应变曲线上,取应变范围8%~15%线性区域,记其斜率为气凝胶的压缩模量[25]。

1.2.6 精油装载

采用AHMADI等[25]的方法并作修改,将等体积的气凝胶样品浸入丁香精油中,在30 ℃恒温密封条件下浸泡3 h,使精油逐渐吸附到气凝胶的通道中。后取出置于敞开培养皿上,30 ℃恒温使其充分挥发至恒重,装载率按(2)式计算:

(2) 式中,T-装载率,%;m0-未浸入精油前气凝胶的初始质量,g;mt-挥发至恒重气凝胶的质量,g。

1.2.7 精油释放

根据国标GB31604.1-2015[26],以95%乙醇溶液和蒸馏水作为食品模拟液。将载有精油的WPI-PUL复合气凝胶样品(等体积)分别完全浸入50 mL 95%乙醇溶液和蒸馏水中,密封好后25 ℃水浴条件下磁力搅拌,每隔10 min取样3 mL溶液,并补充3 mL对应溶剂。293 nm下对取出液进行紫外分光光度检测,对照组为同等处理的未载油气凝胶样品浸泡液,通过标准曲线计算精油释放浓度[27]。释放率R按式(3)计算:

(3) 式中:R-释放率,%;Ci-第i次取样时精油浓度,g/mL;m-精油装载量,g。

1.2.8 扫描电镜分析

将气凝胶样品沿横切面切成1 mm厚的薄片,粘于导电胶上喷金120 s后,使用26 kV加速电压扫描电镜观察气凝胶表面的微观结构[28]。

1.2.9 傅里叶红外光谱分析

分别将各组样品碾碎后,与KBr混合。混合比例为1:100(质量比)。再进行研磨,压片。傅里叶红外光谱的扫描范围为450~4000 cm−1,分辨率为4 cm−1。

1.2.10 热重分析(TG)

将气凝胶样品(5~10 mg)置于Al2O3坩埚中,保护气为氮气,流速设定为20 mL/min,升温速率10 ℃/min,测定其在30~600 ℃恒升温速率加热过程中的质量损失[29]。

1.3 数据处理

文中数据均为3次平行实验平均值,采用SPSS25软件进行数据处理与分析并用Orgin 2019软件绘图。

2. 结果与分析

2.1 吸湿性能分析

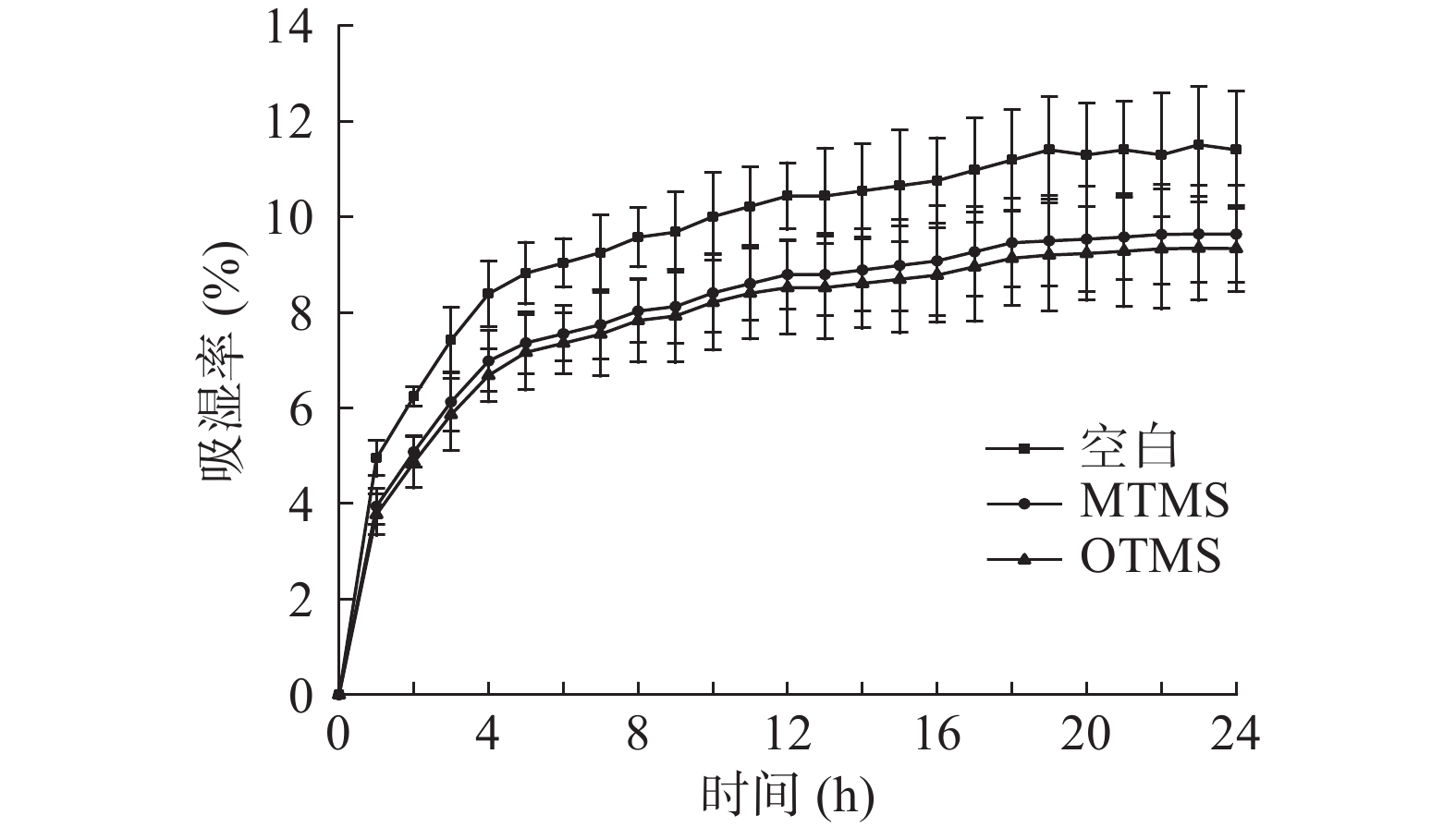

单位时间内吸湿率的差异可以反应吸湿速率的快慢。如图1所示,两种疏水剂处理后复合气凝胶相对于空白组吸湿过程明显变缓,其中MTMS组的平衡吸湿率为(9.67%±0.323%),OTMS组的平衡吸湿率为(9.34%±0.276%),均明显低于未改性组的(11.41%±0.506%)。说明疏水改性处理可以抑制气凝胶对空气的水分的吸附作用,从而明显的降低气凝胶的吸湿性。

2.2 油/水接触角

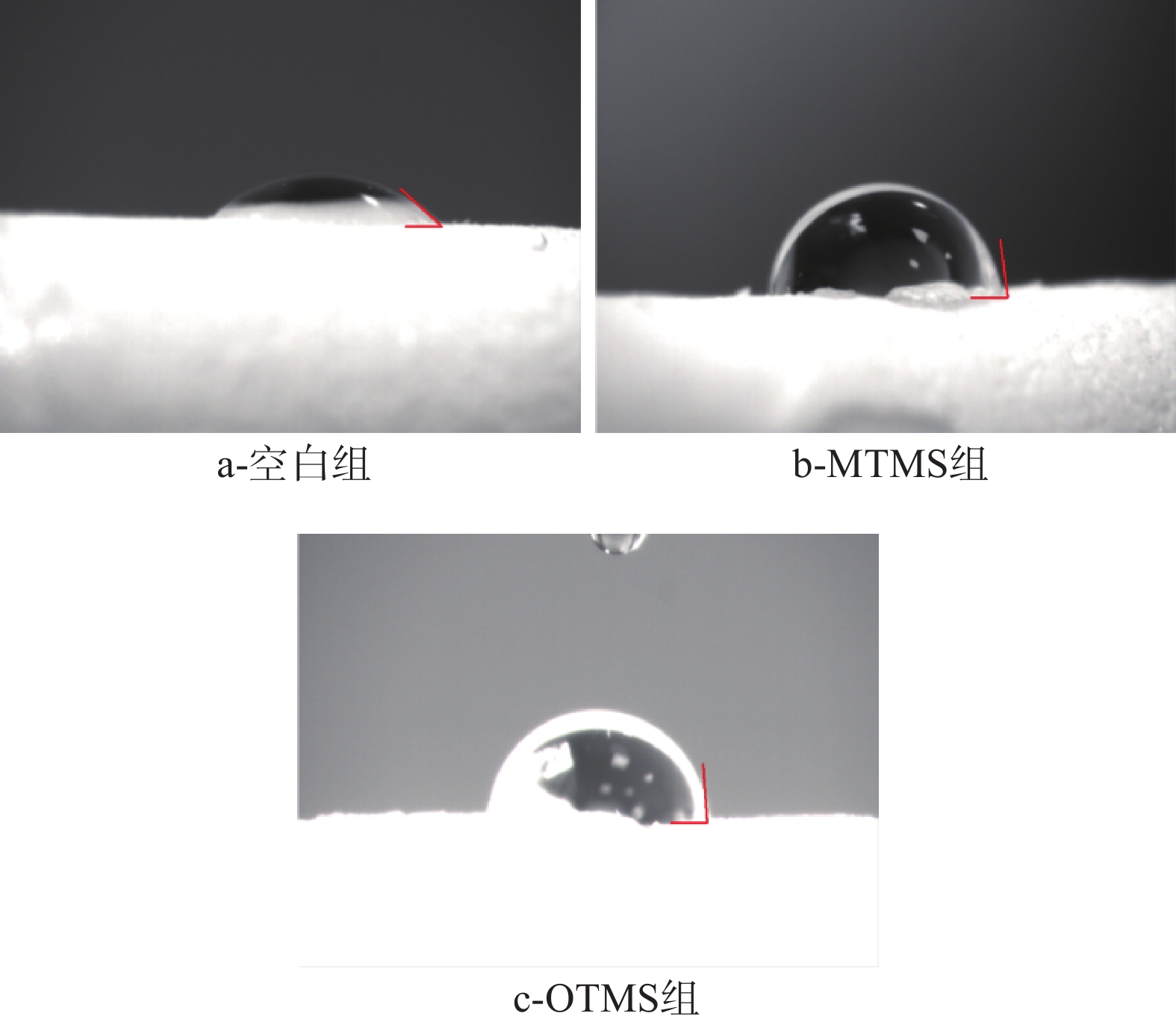

水(油)接触角的大小反映了气凝胶的表面疏水(油)性,接触角越大则材料的疏水(油)性越好。水接触角实验结果如图2所示,图a为改性处理前,其接触角(40.14°±2.16°),亲水性较高。图b为MTMS改性处理后,接触角(82.10°±4.78°),图c为OTMS改性后,接触角(85.21°±4.61°),疏水改性后,水珠的表面张力变大,变得更难以浸润气凝胶表面,使得气凝胶的亲水性均明显下降。

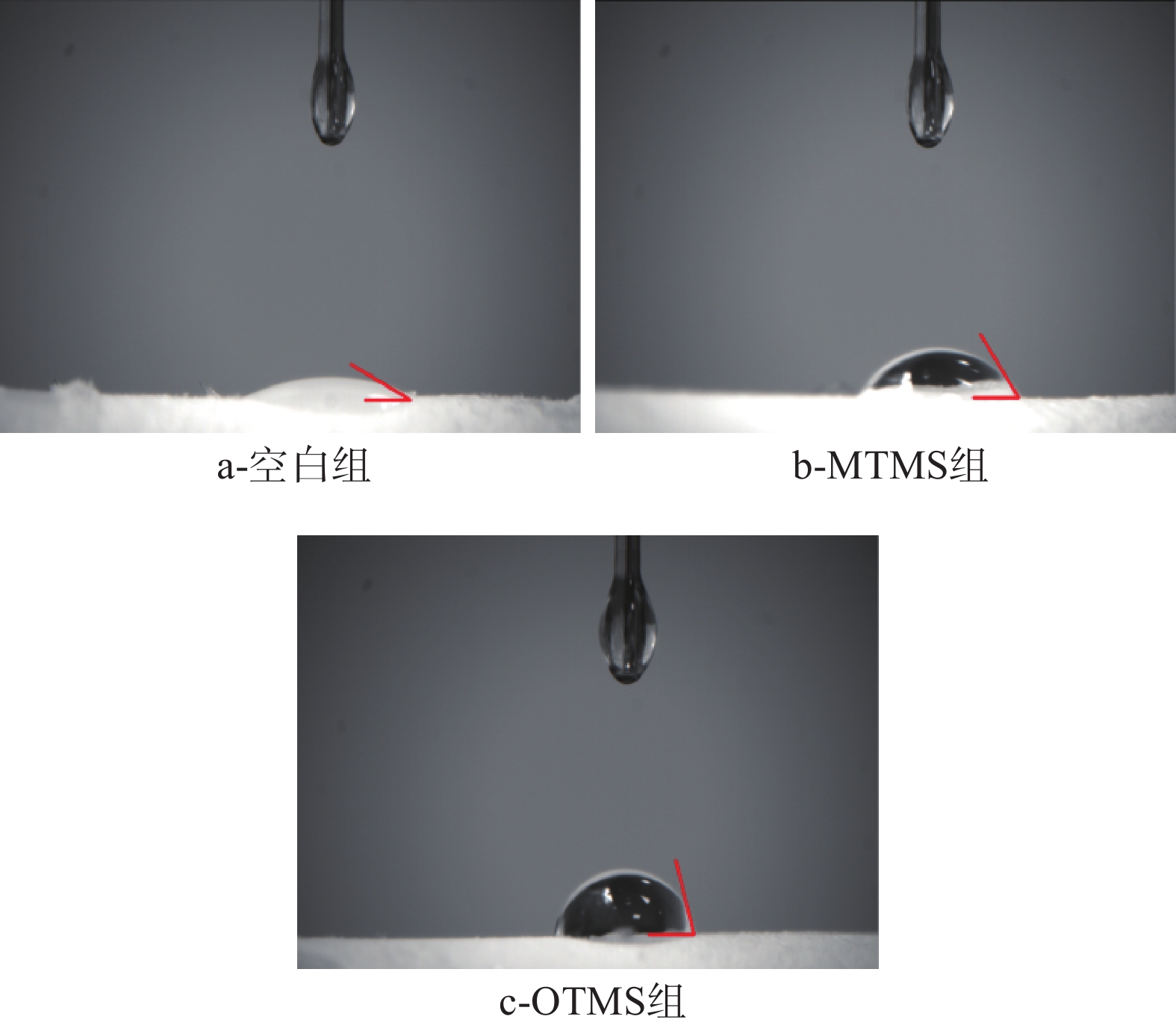

油接触角实验结果如图3所示,图a为改性处理前,其接触角(28.07°±2.43°),亲油性高。图b为MTMS改性处理后,接触角(56.14°±3.25°),图c为OTMS改性后,接触角(74.63°±3.08°),改性后亲油性亦明显下降。其中OTMS改后疏油效果明显更好,这可能是由于OTMS具有更长的烷基支链,其形成的表面分子层更为致密所致。

2.3 抗压性能分析

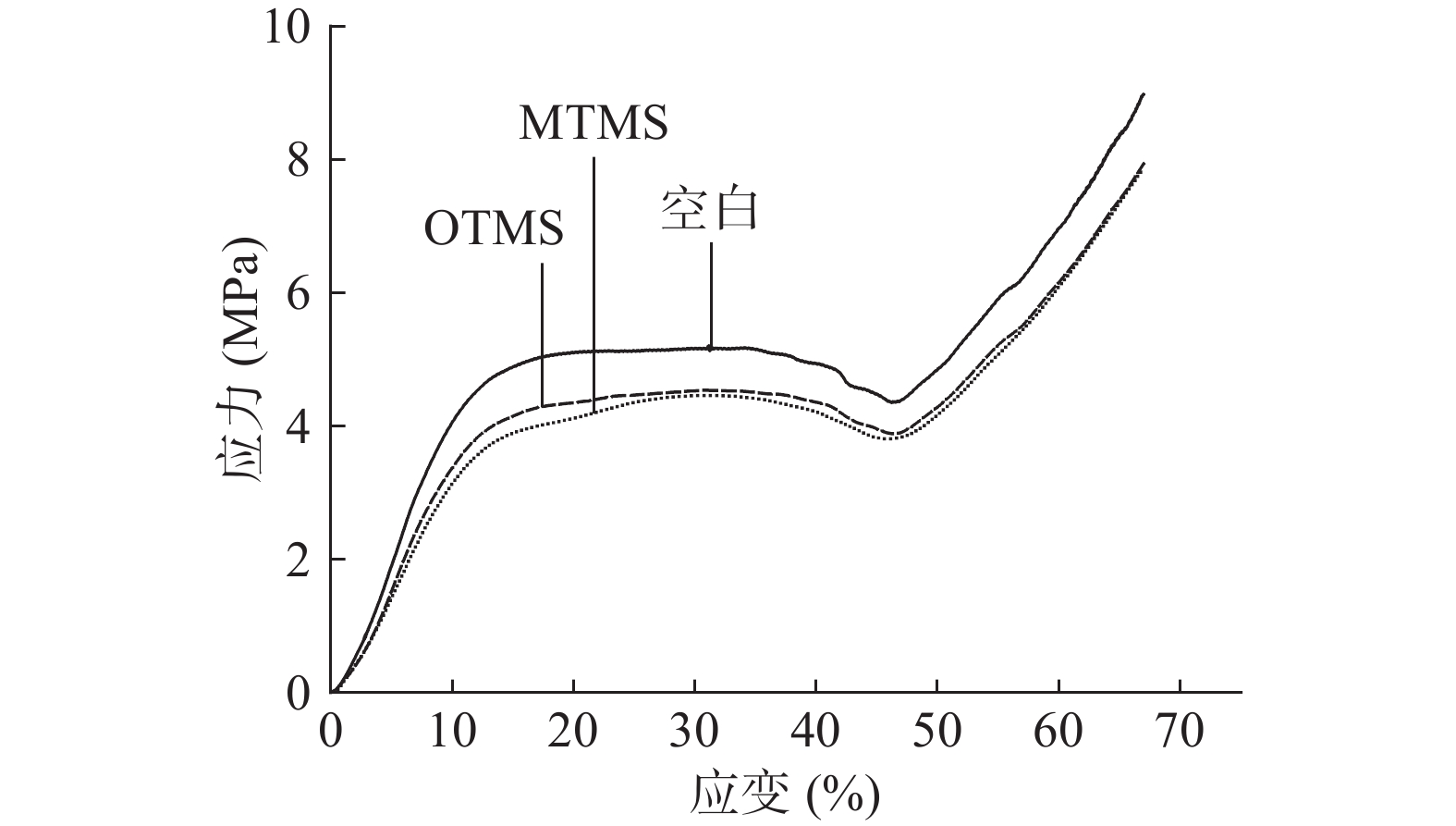

图4反映了改性前后的复合气凝胶在匀速形变过程中应力的变化情况。未改性的气凝胶压缩模量为(21.745±1.982)MPa,抗压性能优良。改性后其压缩模量略有所下降,MTMS疏水改性后抗压性能为(17.655±3.034)MPa,OTMS组则为(18.412±3.513)MPa,这可能是由于等离子体刻蚀作用使得气凝胶结构形变,进而使其抗压性能下降。

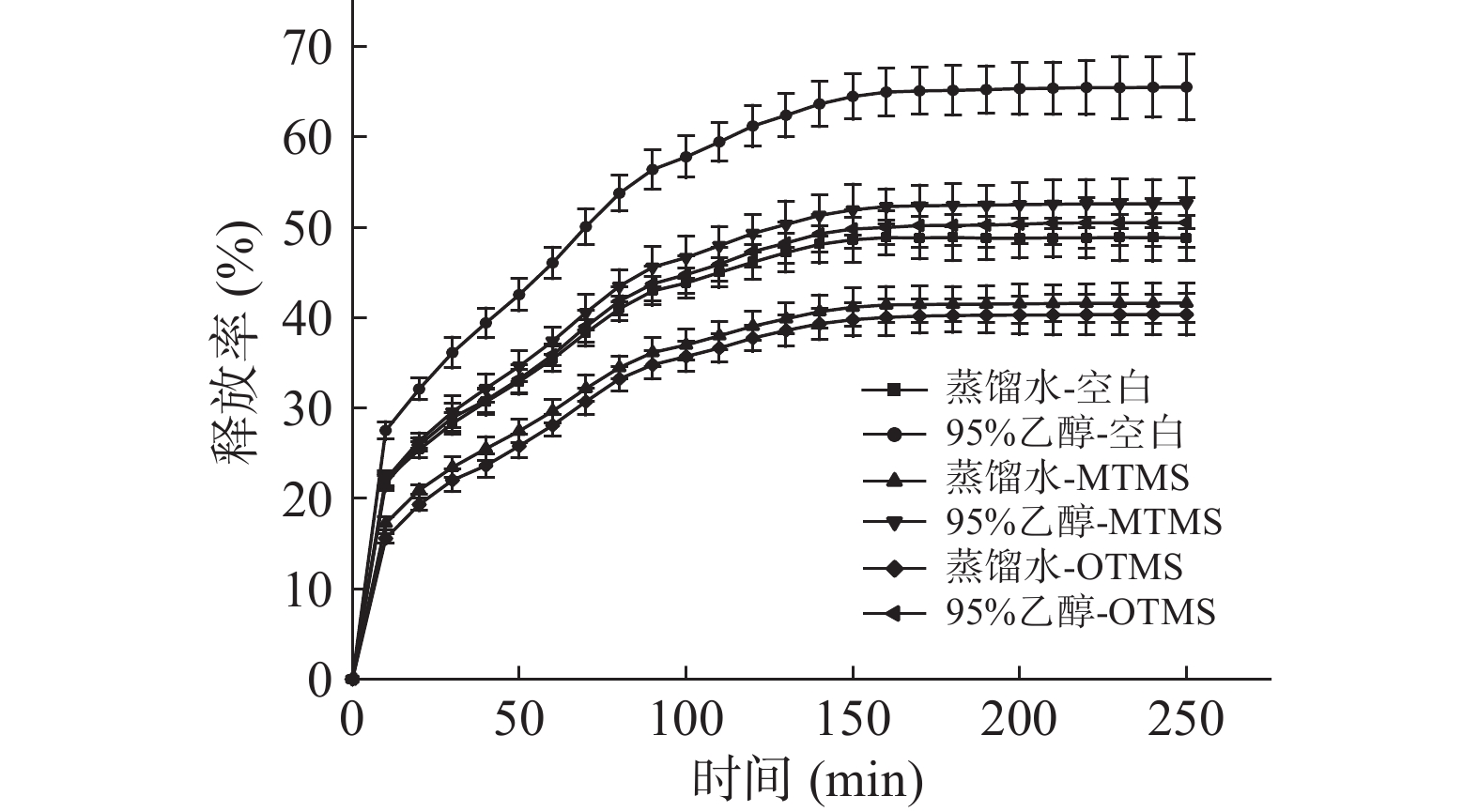

2.4 精油释放

经过装载精油实验发现,疏水改性处理前丁香精油的最大装载率为(254.26%±5.585%),MTMS疏水改性后丁香精油最大装载率(241.57%±5.214%),OTMS组则为(223.31%±4.436%)。最大装载率的降低可能与气凝胶改性后的疏油性提升相关,这与一些疏油型油水分离材料性能类似[30-31]。图5为装载丁香精油的复合气凝胶改性前后分别在蒸馏水及95%乙醇中,丁香精油的动态释放曲线。实验发现,无论是在水或是95%乙醇体系中,疏水改性后的复合气凝胶单位时间内丁香精油释放率相对于空白组降低,缓释性能提升,其中MTMS组缓释性能优于OTMS组。但改性后总释放率低于空白组,这可能是由于疏水改性后复合气凝胶表面的分子层对于精油从内往外扩散亦有阻隔性,导致更难释放出来。拟合各释放曲线得到的模拟方程如表1所示。

表 1 气凝胶疏水改性前后丁香精油释放率的非线性模拟方程Table 1. Nonlinear simulation equation of the release rate of clove essential oil before and after hydrophobic modification of aerogel样品 模拟液 拟合方程(t≠0) 决定系数R2 空白 蒸馏水 r=6.456E-6t3−0.004t2+0.647t+9.339 0.951 空白 95%乙醇 r=8.106E−6t3−0.005t2+0.850t+11.359 0.961 MTMS 蒸馏水 r=5.0401E−6t3−0.003t2+0.552t+7.259 0.963 MTMS 95%乙醇 r=6.749E−6t3−0.004t2+0.692t+9.286 0.960 OTMS 蒸馏水 r=4.980E−6t3−0.003t2+0.533t+6.326 0.969 OTMS 95%乙醇 r=6.494E−6t3−0.004t2+0.659t+9.273 0.955 2.5 扫描电镜分析

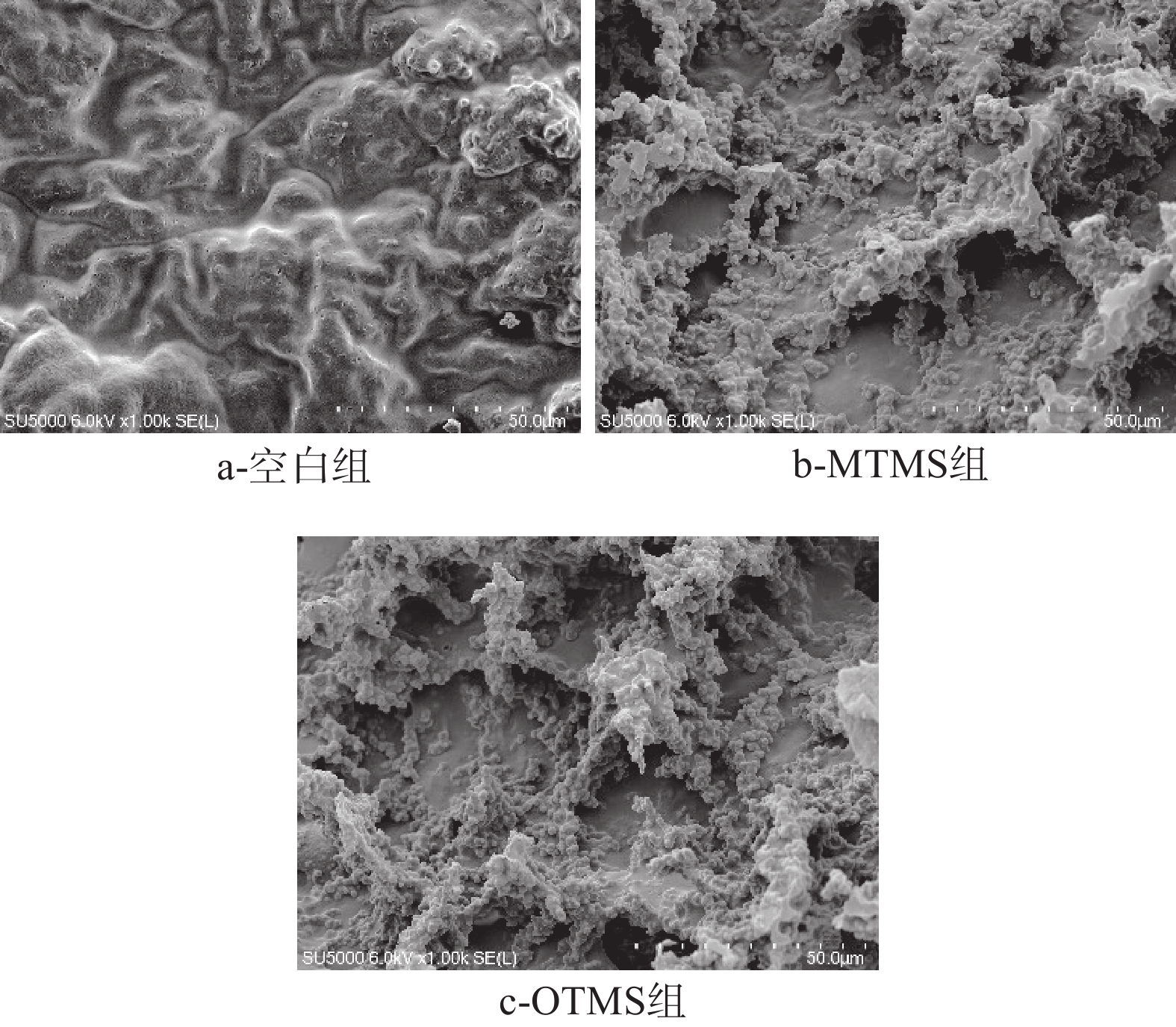

图6a是改性前复合气凝胶表面的扫描电镜图,表面较为光滑,结构致密。图6b为MTMS改性组,图6c为OTMS改性组,可以清楚地看到改性后气凝胶表面粗糙度增加。这可能是由于等离子体的刻蚀与改性剂分子接枝的共同作用使得气凝胶表面粗糙度增加,从物理结构和化学性能上两方面提高了气凝胶表面的疏水性,降低了气凝胶的吸湿性。

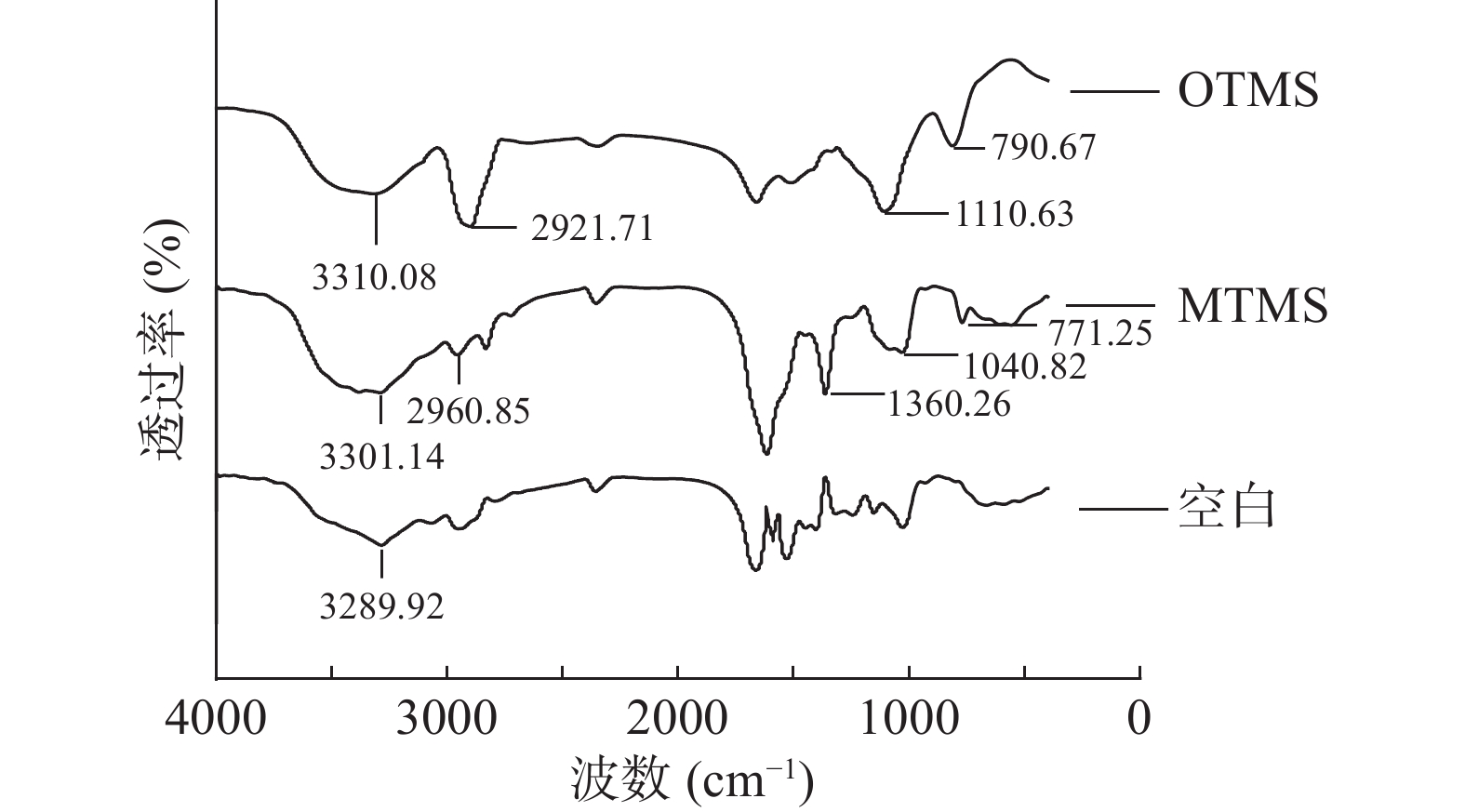

2.6 傅里叶红外分析

图7是气凝胶疏水改性前后的傅里叶红外波谱图。MTMS处理组中1360.26 cm−1为MTMS中C-C单键的骨架振动,2960.85 cm−1处为-CH3的伸缩振动,1040.82 cm−1处为Si-O-Si的特征峰,771.25 cm−1为Si-CH3特征峰[32];OTMS处理组2921.71 cm−1为-CH2-的伸缩振动,1110.63 cm−1处为Si-O-Si的特征峰,790.67 cm−1为Si-CH3特征峰。各特征峰的存在说明疏水剂已经成功地接枝到气凝胶上,Si-O-Si与C-O-C峰的重叠则是聚硅氧烷化反应的结果。各组分3300 cm−1附近吸收峰的变宽及偏移反映了新的-OH生成,这是Plasma处理后的结果。

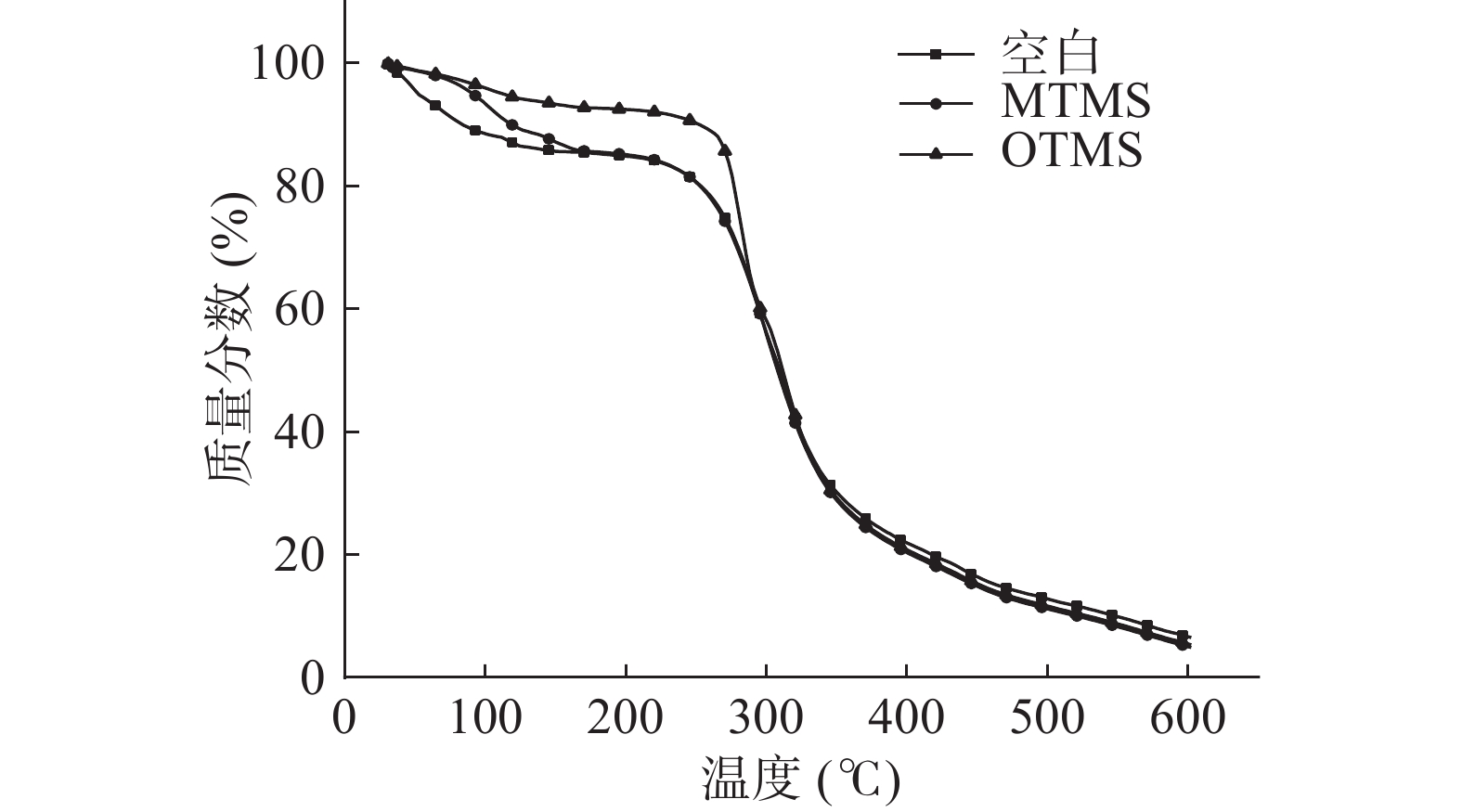

2.7 热重分析

图8为复合气凝胶改性前后的热失重曲线(30~600 ℃温度范围)。30~80 ℃阶段,这一阶段主要是吸湿过程气凝胶所吸附水分的逸出,三组曲线差距则反映出不同组分吸湿性的差异,OTMS改性组质量损失小于MTMS组,二者均明显小于空白组,侧面证明两种改性手段均能明显降低复合气凝胶的吸湿性。MTMS组在80~130 ℃,质量损失加快,这是MTMS的挥发导致的;三组在110~290 ℃的变化差异则是由于PUL的部分分解;290~350 ℃三组曲线基本重合,这阶段则是WPI与PUL的大规模裂解,复合气凝胶质量损失约为70%。温度高于350 ℃之后,质量损失速度减缓,这部分损失是剩余残渣碳化使得氮氧元素丢失造成的。综合来看,改性处理不仅可以降低复合气凝胶的吸湿性,还能提高其常温范围的热稳定性,且热稳定性方面OTMS组优于MTMS组。

3. 结论

在前期实验的基础上以最优制备条件(PUL添加量55 mg/mL,pH7.9,凝胶温度84 ℃)制备WPI-PUL复合气凝胶,并对其进行疏水改性处理。疏水改性后,复合气凝胶表面形成了一层疏水层,MTMS改性后平衡吸湿率为(9.67%±0.323%),水接触角(82.10°±4.78°);OTMS改性后平衡吸湿率为(9.34%±0.276%),水接触角(85.21°±4.61°),疏水性能得到明显提升。与此同时,疏水改性后的气凝胶疏油性能也有所提升,且OTMS改性处理效果更好。改性后抗压强度略有降低,但不影响正常使用;疏水改性处理后,丁香精油装载率有所下降但缓释性能均有所提升,且MTMS改性缓释效果更好;常温下热稳定性方面均有所提升,且OTMS组热稳定性更好。

综上所述,硅烷接枝疏水改性处理可以显著提升复合气凝胶的疏水性并提高其亲油性。适用于油脂类活性物质的装载与缓释应用,拓宽了WPI-PUL复合气凝胶的应用领域。

-

表 1 气凝胶疏水改性前后丁香精油释放率的非线性模拟方程

Table 1 Nonlinear simulation equation of the release rate of clove essential oil before and after hydrophobic modification of aerogel

样品 模拟液 拟合方程(t≠0) 决定系数R2 空白 蒸馏水 r=6.456E-6t3−0.004t2+0.647t+9.339 0.951 空白 95%乙醇 r=8.106E−6t3−0.005t2+0.850t+11.359 0.961 MTMS 蒸馏水 r=5.0401E−6t3−0.003t2+0.552t+7.259 0.963 MTMS 95%乙醇 r=6.749E−6t3−0.004t2+0.692t+9.286 0.960 OTMS 蒸馏水 r=4.980E−6t3−0.003t2+0.533t+6.326 0.969 OTMS 95%乙醇 r=6.494E−6t3−0.004t2+0.659t+9.273 0.955 -

[1] 陈当家. 柔性桥联型硅氧烷气凝胶的常压制备及性能调控[D]. 北京: 北京科技大学, 2019. CHEN D J. Ambient pressure preparation and performance regulation of flexible bridged siloxane aerogels[D]. Beijing: University of Science and Technology, 2019.

[2] 黄健, 房猛, 张爱满, 等. 疏水性SiO2气凝胶常压干燥制备与表征[J]. 硅酸盐通报,2018,37(1):96−102. [HUANG J, FANG M, ZHANG A M, et al. Preparation of superhydrophobic elastic of SiO2 aerogels and adsorption properties[J]. Bulletin of the Chinese Ceramic Society,2018,37(1):96−102. [3] 曹庆龙, 雷桥, 吴浩, 等. 影响普鲁兰多糖气凝胶性能的工艺参数[J]. 食品与发酵工业,2020,46(23):108−115. [CAO Q L, LEI Q, WU H, et al. Effect of process parameters on pullulan aerogel properties[J]. Food and Fermentation Industries,2020,46(23):108−115. [4] 张亚娟. 疏水性SiO2气凝胶与Ag/SiO2复合气凝胶的制备及性能研究[D]. 西安: 陕西师范大学, 2011. ZHANG Y J. Preparation and properties of hydrophobic SiO2 aerogels and Ag/SiO2 composite aerogels[D]. Xi'an: Shaanxi Normal University.

[5] YAN J, DU H, ZHU G W, et al. Application of atmospheric pressure low temperature plasma in cotton fabric desizing[J]. Journal of Physics: Conference Series,2021,1790(1):12060−12066.

[6] 李帅星, 王一男, 王莉. 大气压脉冲调制射频氩气放电等离子体特性的数值研究[J/OL]. 核聚变与等离子体物理: 1−7[2021-10-19]. http://kns.cnki.net/kcms/detail/51.1151.TL.20210607.0934.002.html. LI S X, WANG Y N, WANG L. Numerical study on pulse modulated RF argon dischargeat atmospheric pressure [J/OL]. Nuclear Fusion and Plasma Physics: 1−7[2021-10-19]. http://kns.cnki.net/kcms/detail/51.1151.TL.20210607.0934.002.html.

[7] KIM J E, LEE D, MIN S C. Microbial decontamination of red pepper powder by cold plasma[J]. Food Microbiology,2014,38(apr.):128−136.

[8] 杨文芳, 顾振亚. 低温等离子体技术在纺织品中的应用[J]. 针织工业,2000(6):53−55. [YANG W F, GU Z Y. Application of low temperature plasma technology in textiles[J]. Knitting Industries,2000(6):53−55. doi: 10.3969/j.issn.1000-4033.2000.06.008 [9] GÜLEÇ H A, SARIOGˇLU K, MUTLU M. Modification of food contacting surfaces by plasma polymerisation technique. Part I: Determination of hydrophilicity, hydrophobicity and surface free energy by contact angle method[J]. Journal of Food Engineering, 2005, 75(2).

[10] SONG J, XU W, LU Y. One-step electrochemical machining of superhydrophobic surfaces on aluminum substrates[J]. Journal of Materials Science,2012,47(1):162−168. doi: 10.1007/s10853-011-5783-2

[11] 杨玉山, 沈华杰, 秦磊, 等. 木材表面遗态仿生构建类荷叶自清洁超疏水微/纳米结构[J]. 林业工程学报,2020,5(5):63−68. [YANG Y S, SHEN H J, QIN L, et al. Biomimetic fabrication of lotus-leaf-like self-cleaning superhydrophobic woodsurface with micro/nano-biomimetic structures using morph-genetic method[J]. Journal of Forestry Engineering,2020,5(5):63−68. [12] 徐雷秋, 万晓峰, 董菁, 等. 盐酸-激光复合刻蚀+SA修饰制备镁合金表面超疏水结构的耐腐蚀性能[J]. 机械工程材料,2019,43(10):6−10. [XU L Q, WAN X F, DONG J, et al. Corrosion resistance of superhydrophobic structure on magnesium alloy surfaceprepared by hydrochloric acid-laser composite etching and SA modification[J]. Materials for Mechanical Engineering,2019,43(10):6−10. doi: 10.11973/jxgccl201910002 [13] LIU Y, HAN X, KUERBANJIANG B, et al. Effect of sodium bicarbonate solution on methyltrimethoxysilane-derived silica aerogels dried at ambient pressure[J]. Frontiers of Chemical Science and Engineering,2021(1-2):1−6.

[14] WANG L, FENG J, JIANG Y, et al. Elastic methyltrimethoxysilane based silica aerogels reinforced with polyvinylmethyldimethoxysilane[J]. RSC Advances,2019,9(19):10948−10957. doi: 10.1039/C9RA00970A

[15] VIDON S, LEBLANC R M. Langmuir study of octadecyltrimethoxysilane behavior at the airwater interface[J]. Journal of Physical Chemistry B,2016,102(7):1279−1286.

[16] ZENG J, LIU H, CHEN J, Et al. Octadecyltrimethoxysilane functionalized ZnO nanorods as a novel coating for solid-phase microextraction with strong hydrophobic surface[J]. Analyst,2012,137(18):4295−4301. doi: 10.1039/c2an35542f

[17] 李贞. 废报纸基纤维素复合气凝胶的制备及吸附性能研究[D]. 西安: 西安理工大学, 2019. LI Z. Preparation and adsorption properties of waste newspaper based cellulose composite aerogels[D]. Xi'an: Xi'an University of Technology, 2019.

[18] FENG J, NGUYEN S T, FAN Z, et al. Advanced fabrication and oil absorption properties of super-hydrophobic recycled cellulose aerogels[J]. Chemical Engineering Journal,2015:270.

[19] 李玉歧. 多糖基气凝胶的制备及其水处理性能[D]. 福州: 福建农林大学, 2017. LI Y Q. Preparation of polysaccharide-based aerogels and their performance in water treatment[D]. Fuzhou: Fujian Agriculture and Forestry University, 2017.

[20] 曹庆龙, 雷桥, 吴浩, 等. 乳清分离蛋白-普鲁兰多糖复合气凝胶的制备及性能优化[J]. 食品与发酵工业,2021,47(16):181−187. [CAO Q L, LEI Q, WU H, et al. Preparation and performance optimization of whey protein isolate pullulan composite aerogel[J]. Food and Fermentation Industries,2021,47(16):181−187. [21] JI H, KHB A, YE S, et al. Synergistic bactericidal effect of clove oil and encapsulated atmospheric pressure plasma againstEscherichia coli O157: H7 and Staphylococcus aureus and its mechanism of action[J]. Food Microbiology,2020,93:103611.

[22] YI C, LU L, ZHANG W, et al. Reinforced low density alginate-based aerogels: Preparation, hydrophobic modification and characterization[J]. Carbohydrate Polymers,2012,88(3):1093−1099. doi: 10.1016/j.carbpol.2012.01.075

[23] SU J, HUANG Z, ZHAO Y, et al. Moisture sorption and water vapor permeability of soy protein isolate/poly(vinyl alcohol)/glycerol blend films[J]. Industrial Crops & Products,2010,31(2):266−276.

[24] YUAN Y, LEE T R. Contact angle and wetting properties[J]. Springer Berlin Heidelberg,2013,51:3−34.

[25] AHMADI M , MADADLOU A , SABOURY A A. Whey protein aerogel as blended with cellulose crystalline particles or loaded with fish oil[J]. Food Chemistry,2016,196:1016−1022. doi: 10.1016/j.foodchem.2015.10.031

[26] GB 31604.1-2015 食品安全国家标准食品接触材料及制品迁移试验通则[S]. 2015. GB 31604.1-2015 National food safety standards general rules for migration test of food contact materials and products[S]. 2015.

[27] 夏天利. 乳清蛋白气凝胶的制备、改性及应用研究[D]. 无锡: 江南大学, 2018. XIA T L. Study on the preparation, modification and application of whey protein aerogel[D]. Wuxi: Jiangnan University, 2018.

[28] 张勇. 三聚氰胺基复合气凝胶制备与性能研究[D]. 合肥: 中国科学技术大学, 2017. ZHANG Y. Preparation and properties of melamine based composite aerogel[D]. Hefei: University of Science and Technology of China, 2017.

[29] 焦晨璐. 微晶纤维素基气凝胶的制备及对重金属、染料的吸附降解性研究[D]. 苏州: 苏州大学, 2017. JIAO C L. Preparation of microcrystalline cellulose based aerogel and its application on adsorption of heavy metals and degradation of dyes[D]. Suzhou: Suzhou University, 2017.

[30] 李晨. 超亲水/水下超疏油聚丙烯膜的制备及性能研究[D]. 武汉: 武汉纺织大学, 2020. LI C. Fabrication and performance research of superhydrophilic/underwater superoleophobic polypropylene membrane[D]. Wuhan: Wuhan Textile University, 2020.

[31] 崔久云. 超亲水/水下超疏油PVDF复合膜的制备及油/水乳液分离性能研究[D]. 镇江: 江苏大学, 2020. CUI J Y. Fabrication of superhydrophilic/underwater superoleophobic PVDF composite membraneand study on separation performance of oil/wateremulsion[D]. Zhenjiang: Jiangsu University, 2020.

[32] 史彦龙. 基于POSS无机/有机杂化光电材料的合成及性质研究[D]. 兰州: 兰州交通大学, 2015. SHI Y L. Synthesis and properties of poss-based organic/inorganic hybrid photoelectric materials[D]. Lanzhou: Lanzhou Jiaotong University , 2015.

下载:

下载:

下载:

下载: