Optimization of Preparation of Seafood Flavor Condiment Base from Tuna Cooking Liquor by Fermentation

-

摘要: 本文采用提取蛋白和油脂后的金枪鱼蒸煮液为原料,以感官评定、氨基酸态氮含量为测定指标,同时辅以电子鼻分析发酵液的气味变化,对酵母发酵制备海鲜调味品基料进行评定。通过单因素实验研究酵母种类、酵母添加量、发酵时间、盐度对发酵产物的影响,在此基础上通过响应面设计进一步确定最佳发酵工艺。结果表明,金枪鱼蒸煮液发酵的最佳条件为:酵母71B,酵母添加量4.5‰,发酵时间6 h,盐度0.26 mol/L,此条件下,发酵液的感官评分为9.31,发酵后鲜味氨基酸(天冬氨酸、谷氨酸),甜味氨基酸(甘氨酸、丙氨酸)均有上升,苦味氨基酸(缬氨酸、组氨酸)明显下降。Abstract: The tuna cooking liquor obtained by extracting protein and oil was used as the raw material to produce the seafood condiment base through yeast fermentation. Sensory evaluation and amino acid nitrogen of the reaction products were determined and odor changes were analyzed using electronic nose. Through single-factor experiments, the influence of yeast type, added amount of yeast, fermentation time, and salinity on fermentation degree and product was studied. The optimal fermentation process was further determined through response surface design. The results showed that the optimal conditions for fermentation of bonito cooking liquor were: Yeast 71B, yeast addition amount 4.5‰, fermentation time 6 h, salinity 0.26 mol/L. Under this condition, the sensory score of the fermentation broth was 9.31. The amino acid composition showed that after fermentation, umami amino acids (Asp, Glu), sweet amino acids (Gly, Ala) all increased, and bitter amino acids (Val, His) decreased significantly.

-

Keywords:

- tuna /

- fermentation /

- amino acid nitrogen /

- sensory evaluation /

- electronic nose

-

我国是水产品捕捞和加工大国,每年都有数以万吨的水产品出口海外,2019年我国水产品出口额占农产品出口总额比重达30%,其中金枪鱼出口又占据了重要的地位,因为鱼肉罐头受到各国人民的喜爱,在国外十分畅销。蒸煮液是金枪鱼罐头加工过程中产生的废弃物,富含大量蛋白质、核苷酸、氨基酸等营养成分和风味物质[1]。由于加工技术的限制导致蒸煮液大量流失,不仅造成了极大的资源浪费,而且给企业污水处理增加了成本[2]。因此,对金枪鱼蒸煮液的高值化利用是金枪鱼加工企业亟待解决的问题。

目前,国内对金枪鱼蒸煮液在食品领域的应用研究不多。杨小克等[3]、何键东等[4]采用酶解法从金枪鱼蒸煮液中提取鱼油;陈启航等[5]采用酶解蒸煮液法制备风味海鲜调味汁;李可欣等[6]以金枪鱼蒸煮汁为原料研制金枪鱼风味沙拉酱。然而研究发现酶解法不易消除其固有的腥味[7-8],酵母是一种天然发酵剂[9],具有较好的脱腥效果[10-11]和重金属离子吸附作用[12],目前已有一些研究将活性干酵母应用到海鲈鱼片、草鱼、牡蛎酶解液、鲟鱼肉等脱腥工艺上[13-16]。本文以金枪鱼蒸煮液为原料,加入酵母进行发酵制备海鲜调味品基料,通过响应面设计确定最佳发酵工艺,对最优条件下的发酵液进行氨基酸组成分析,以期为金枪鱼蒸煮液的深度加工利用以及调味品的开发提供理论依据。

1. 材料与方法

1.1 材料与仪器

金枪鱼蒸煮液 浙江省舟山市某金枪鱼罐头加工企业;无水乙醇、乙酸、无水乙酸钠、甲醇、乙酰丙酮等 均为分析纯;活性干酵母:黄酒酵母、啤酒酵母、葡萄酒酵母、复合功能菌酵母 安琪酵母股份有限公司;面包酵母 乐斯福有限公司;71B酵母 曼森商贸有限公司。

AR224CN电子分析天平 奥豪斯仪器(上海)有限公司;CT14RDⅡ高速台式冷冻离心机 上海天美科学仪器有限公司;RE-52AA旋转蒸发仪 上海亚荣生化仪器厂;智能恒温培养振荡器 天津欧诺仪器股份有限公司;PEN 3型电子鼻 德国Airsense公司;L-8900全自动氨基酸分析仪 日本日立公司。

1.2 实验方法

1.2.1 单因素实验

本实验选用感官评定、电子鼻分析、氨基酸态氮含量三项指标来评估酵母种类、酵母添加量、时间、盐度对发酵的影响。感官评定可以较为直观地反映人对不同条件发酵液的接受程度[17],电子鼻主要通过气味指纹信息对气体或挥发性成分做定性或定量的检测[18-19],可对感官评定结果进行验证,氨基酸态氮含量的高低表示游离氨基酸的丰富程度,也可在一定程度上反应物质风味特点[20-21]。

1.2.1.1 酵母种类

分别取30 mL盐度为0.20 mol/L的待发酵液,按2‰的添加量加入黄酒酵母、啤酒酵母、葡萄酒酵母、71B酵母、面包酵母、复合功能菌酵母,置于35 ℃条件下反应12 h,随后进行感官评定、氨基酸态氮测定、电子鼻分析。

1.2.1.2 酵母添加量

分别取30 mL盐度为0.20 mol/L的待发酵液,按不同的添加量(w/v,2‰、4‰、6‰、8‰)加入71B酵母,置于35 ℃条件下反应12 h,随后进行感官评定、氨基酸态氮测定、电子鼻分析。

1.2.1.3 发酵时间

分别取30 mL盐度为0.20 mol/L的待发酵液,按4‰的添加量加入71B酵母,置于35 ℃条件下分别发酵6、12、18 h(预实验发现发酵24 h和36 h后,发酵液呈现明显的硫化氢臭味,故未对该时间发酵液进行其他指标测定),随后进行感官评定、氨基酸态氮测定、电子鼻分析。

1.2.1.4 盐度

分别取30 mL不同盐度(0.15、0.25、0.35、0.45 mol/L)的待发酵液,按4‰的添加量加入71B酵母,置于35 ℃条件下反应12 h,随后进行感官评定、氨基酸态氮测定、电子鼻分析。

1.2.2 响应面设计

在单因素实验的基础上,以感官评分为评价指标,选取酵母添加量、发酵时间、盐度3个因素进行Box-Behnken设计,各因素水平见表1。

表 1 响应面试验设计Table 1. Response surface design水平 因素 酵母添加量A(‰) 发酵时间B(h) 盐度C(mol/L) −1 2 6 0.20 0 4 12 0.30 1 6 18 0.40 1.2.3 感官评定

参考靳艳芬等[22]对鲍复合调味品的感官评定方法,由10位评价人员组成评价小组对样品进行感官评定,评定采用1~10分制,取10名评价人员的平均分数为最终结果。感官评分参照调味料行业标准,以总体可接受度为最终评价结果,从产品色泽、香气、滋味(权重比为3:4:3)进行感官评定,感官评分标准见表2。

表 2 感官评分标准Table 2. Sensory scoring standards指标 分类标准 很好 较好 好 一般 差 色泽 10~9 8~7 6~5 4~3 1~2 香气 10~9 8~7 6~5 4~3 1~2 滋味 10~9 8~7 6~5 4~3 1~2 1.2.4 电子鼻分析

参考吴靖娜[23]的方法并做适当修改,电子鼻传感器阵列由10个金属氧化物传感器组成:1号传感器W1C对芳香成分灵敏;2号传感器W5S对氮氧化合物很灵敏;3号传感器W3C对氨水、芳香成分灵敏;4号传感器W6S对氢气有选择性;5号传感器W5C对烷烃芳香成分灵敏;6号传感器W1S对甲烷灵敏;7号传感器W1W对硫化物灵敏;8号传感器W2S对乙醇灵敏;9号传感器W2W对芳香成分、有机硫化物灵敏;10号传感器W3S对烷烃灵敏。

测定条件为:传感器清洗时间100 s,归零时间10 s,样品准备时间5 s,样品测试时间150 s,内部流量300 mL/min。选取测定过程中144~146 s的数据用于后续分析。

1.2.5 氨基酸态氮含量测定

氨基酸态氮含量参考GB 5009.235-2016《食品中氨基酸态氮的测定》[24]第二法测定。

氨基酸态氮增量采用式(1)计算:

(1) 其中,Y为氨基酸态氮增量,A1为发酵后氨基酸态氮含量,A0为发酵液初始氨基酸态氮含量。

1.2.6 氨基酸组成分析

氨基酸组成参考GB/T 5009.124-2016《食物中氨基酸的测定》[25],使用氨基酸分析仪进行测定。

1.3 统计与分析

实验结果采用平均值±标准差表示,每个实验平行3次。采用Excel和Design Expert 8数据处理系统进行数据分析,利用Origin 8.5软件作图。

2. 结果与分析

2.1 单因素实验

2.1.1 酵母种类对发酵的影响

由图1A可知,71B酵母发酵后体系感官评分最高,结合电子鼻分析可知,71B酵母对传感器2、6的响应值较小,说明经71B酵母发酵后,发酵液中氮氧化合物和甲烷含量较低,从而呈现较好的风味。虽然黄酒酵母和啤酒酵母发酵液的氨基酸态氮含量较高,但在发酵过程中也产生了乙醇,使得感官评分较低。因此,选择71B酵母用于后续发酵,并对其发酵条件进行优化。

2.1.2 酵母添加量对发酵的影响

由图2A可知,酵母添加量为4‰时,感官评分最高,添加量超过4‰后,感官评分呈现下降趋势,可能因为酵母浓度的增加,引起微生物的竞争性抑制,减缓了腥味物质的分解[11]。结合图2B,酵母添加量为4‰的发酵液对传感器2、7、9的响应值均最小,说明发酵液中氮氧化物、硫化物最少。氨基酸态氮含量的变化与感官评分一致,在4‰时最高。

2.1.3 发酵时间对发酵的影响

由图3A可知,随发酵时间延长,体系感官评分呈现先增加后降低的趋势,结合电子鼻分析(图3B)可知,随发酵时间延长,体系中氮、硫化物含量非常高,呈现不愉悦的气味。由图3C可知,发酵时间为12 h时,氨基酸态氮含量最高。发酵过程中蛋白质逐渐被降解成肽、氨基酸和其他小分子,但发酵后期随着降解的进行,部分小分子肽、氨基酸被继续分解成氮氧化物,从而导致氨基酸态氮的含量减少,感官评分降低[26]。因此,发酵时间选择12 h作为最优条件。

2.1.4 盐度对发酵产物的影响

由于不同批次不同厂家的蒸煮液中含盐量(以NaCl计)存在差异,且钠盐的浓度会影响微生物的生长代谢,进而影响蛋白质的降解[27-28]。因此,研究蒸煮液盐度对发酵脱腥工艺的影响十分重要。由图4可知,盐度为0.25 mol/L时,样品的感官评分和氨基酸态氮增量最高,发酵效果最好。且在此条件下,体系对传感器2、7、9的响应值较小。前期实验结果表明当蒸煮液盐度为0.3 mol/L和0.25 mol/L时,其发酵液感官评分差距较小,而蒸煮液实际盐度为0.3 mol/L,因此响应面试验的盐度以0.3 mol/L为中心点。

2.2 响应面设计优化

2.2.1 响应面试验结果

结合单因素实验可知,氨基酸态氮含量和感官评分结果具有一定的相关性,且不同盐度的初始氨基酸态氮含量不同,在响应面不同设计组中不易表征,因此以感官评分为评价指标,选择酵母添加量、发酵时间、盐度三因素三水平,进行Box-Behnken试验设计和响应面分析,以确定海鲜调味基料的最佳制备工艺条件,试验设计及结果见表3。

表 3 响应面试验结果Table 3. The test results of response surface序号 酵母添加量(‰) 发酵时间(h) 盐度(mol/L) 感官评分 1 0 −1 1 7.18 2 0 0 0 9.16 3 −1 1 0 7.83 4 0 0 0 9.08 5 1 1 0 7.97 6 0 1 −1 7.14 7 −1 0 −1 9.23 8 1 0 1 8.16 9 1 0 −1 7.27 10 0 −1 −1 8.32 11 1 −1 0 8.84 12 −1 −1 0 8.51 13 0 0 0 9.04 14 0 0 0 9.21 15 0 0 0 8.88 16 0 1 1 6.94 17 −1 0 1 7.68 2.2.2 方差分析

由表4可知,P=0.0014可知模型极显著(P<0.01),失拟项P=0.1256,差异不显著(P>0.05),决定系数R2=0.9428。各因素对感官评分的影响依次为B(发酵时间)>C(盐度)>A(酵母添加量)。其中,模型的极显著因子项(P<0.01)有B、AC、B2和C2,显著的因子项(P<0.05)为C,可知感官评分受发酵时间的影响最大。

表 4 方差分析结果Table 4. The ANOVA results来源 平方和 自由度 均方 F P>F 模型 9.88 9 1.1 12.81 0.0014 A 0.13 1 0.13 1.49 0.2621 B 1.1 1 1.1 12.86 0.0089 C 0.5 1 0.5 5.83 0.0464 AB 9.03E-03 1 9.03E-03 0.11 0.755 AC 1.49 1 1.49 17.37 0.0042 BC 0.22 1 0.22 2.58 0.1524 A2 9.80E-03 1 9.80E-03 0.11 0.7451 B2 2.29 1 2.29 26.78 0.0013 C2 3.73 1 3.73 43.48 0.0003 残差 0.6 7 0.086 失拟项 0.54 3 0.18 11.03 0.1256 净误差 0.065 4 0.016 总离差 10.48 16 2.2.3 响应面分析

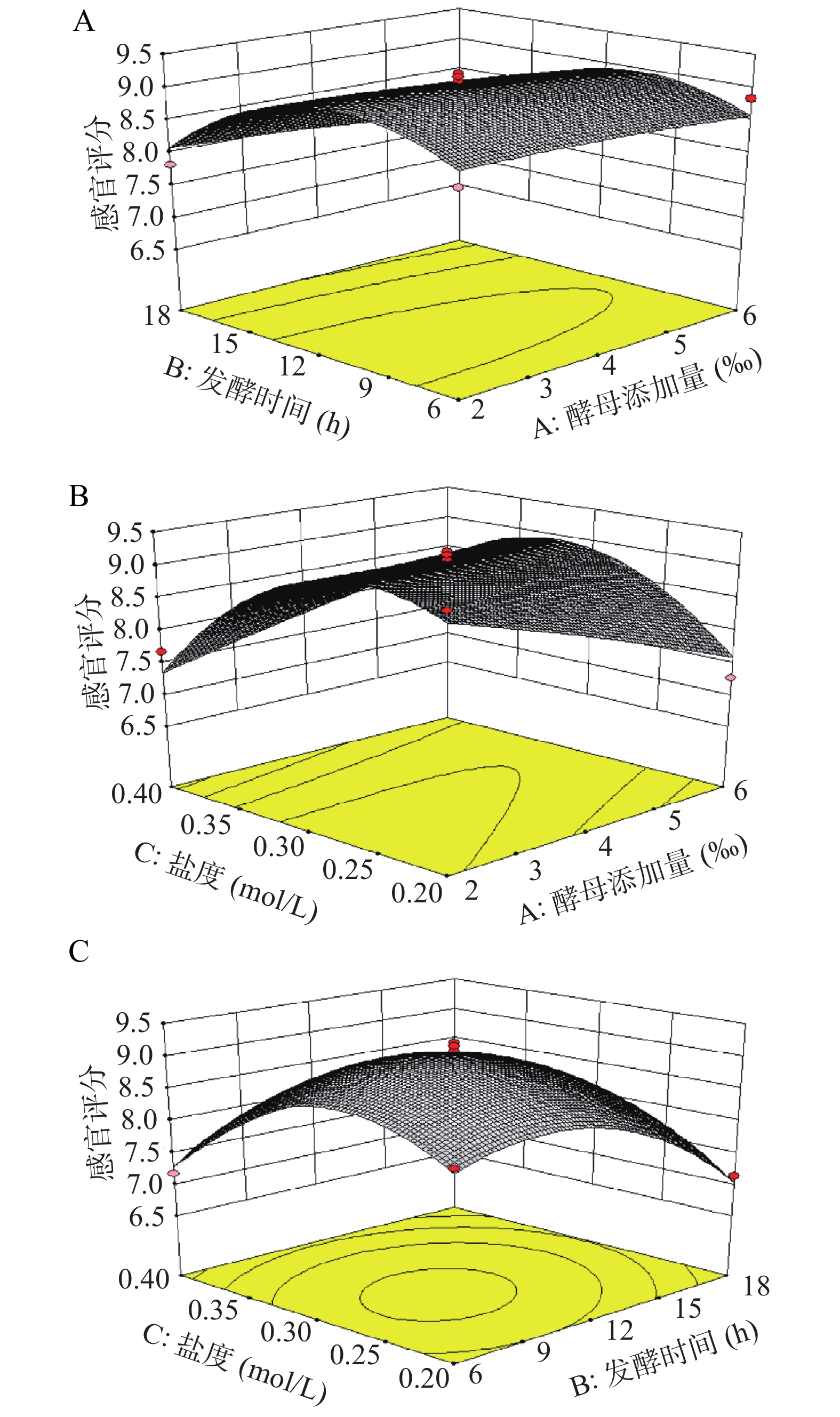

响应面图是回归方程的图形表述,从响应面图中可快速找到最佳参数[29]。由图5可知,各因素对响应面的陡峭程度影响由大到小依次为:发酵时间>盐度>酵母添加量,这与方差分析结果一致。当酵母添加量固定不变时(图5A),随发酵时间延长,发酵液感官评分呈现先升高后下降的趋势;当盐度固定不变时(图5B),酵母添加量小于4.5‰时,感官评分上升,添加量超过4.5‰时,感官评分随即下降;当发酵时间固定不变时(图5C),随着盐度的增加,发酵液感官评分也是先上升后下降。

2.2.4 最佳工艺条件的预测与验证

由Design-Expert 8.0软件预测得出发酵制备海鲜调味基料最优工艺条件为:酵母添加量4.5‰,发酵时间6 h,盐度0.26 mol/L,感官评分9.45。在修正条件下进行3次平行验证实验,感官评分9.31±0.32。与理论预测值相符,说明该优化结果可靠,可进一步利用开发为新型调味品。

2.3 氨基酸组成分析

蒸煮液经酵母发酵后,其中一部分蛋白质可水解为低分子肽类和氨基酸[30]。氨基酸是一种重要的呈味物质,氨基酸组成与滋味的形成关系密切。根据氨基酸的味觉强度可大致分为鲜味、甜味、苦味和无味四大类[31]。同时氨基酸还可作为美拉德反应的前体物质,与糖作用生成特殊的香味物质[32]。因此,游离氨基酸是衡量发酵产品风味的一个重要指标。

上述实验发现71B酵母发酵后发酵液的感官评分最高,这与其呈味氨基酸的变化密切相关。如表5所示,发酵后溶液中天冬氨酸(Asp)、谷氨酸(Glu)、甘氨酸(Gly)、丙氨酸(Ala)等几种呈味氨基酸的含量均有明显上升,其中Gly和Glu的含量相对较高,使发酵液呈现柔和的甜味和较强的鲜味。此外,缬氨酸(Val)、组氨酸(His)的含量明显下降,可能是微生物生长繁殖利用,或是与发酵体系中的还原糖发生了美拉德反应,从而导致其含量降低。由于Val和His是苦味氨基酸,所以其含量的降低也有利于发酵液呈现较好的风味。

表 5 发酵液中的氨基酸组成Table 5. The amino acid composition of fermentation products编号 氨基酸 未发酵(%) 71B发酵(%) 1 牛磺酸(Tau) 10.0696 8.1039 2 天冬氨酸(Asp) 2.9464 6.3496 3 苏氨酸(Thr) 1.8973 3.6556 4 丝氨酸(Ser) 1.8787 3.4918 5 谷氨酸(Glu) 6.0867 10.047 6 甘氨酸(Gly) 5.8748 11.169 7 丙氨酸(Ala) 3.9514 6.7758 8 色氨酸(Trp) 3.4672 4.3456 9 缬氨酸(Val) 26.846 3.6821 10 甲硫氨酸(Met) 1.4025 2.0943 11 异亮氨酸(Ile) 1.4071 2.475 12 亮氨酸(Leu) 2.2444 4.7655 13 酪氨酸(Tyr) 1.0251 1.6249 14 苯丙氨酸(Phe) 1.1605 2.1039 15 赖氨酸(Lys) 3.4141 5.7122 16 组氨酸(His) 21.545 12.867 17 精氨酸(Arg) 2.4431 5.3744 18 脯氨酸(Pro) 2.6925 6.6544 3. 结论

金枪鱼蒸煮液发酵制备海鲜调味品基料的最佳工艺条件为:酵母71B,酵母添加量4.5‰,发酵时间6 h,盐度0.26 mol/L,最优条件下,感官评分9.31±0.32,与理论预测值相符。对发酵液进行氨基酸组成分析,发现其天冬氨酸、谷氨酸、甘氨酸和丙氨酸含量明显上升,缬氨酸、组氨酸含量明显下降。研究结果表明蒸煮液经酵母发酵后可用于制备海鲜调味品基料,并且该发酵工艺简单,适合在产业中应用,从而提升金枪鱼蒸煮液的附加值。

-

表 1 响应面试验设计

Table 1 Response surface design

水平 因素 酵母添加量A(‰) 发酵时间B(h) 盐度C(mol/L) −1 2 6 0.20 0 4 12 0.30 1 6 18 0.40 表 2 感官评分标准

Table 2 Sensory scoring standards

指标 分类标准 很好 较好 好 一般 差 色泽 10~9 8~7 6~5 4~3 1~2 香气 10~9 8~7 6~5 4~3 1~2 滋味 10~9 8~7 6~5 4~3 1~2 表 3 响应面试验结果

Table 3 The test results of response surface

序号 酵母添加量(‰) 发酵时间(h) 盐度(mol/L) 感官评分 1 0 −1 1 7.18 2 0 0 0 9.16 3 −1 1 0 7.83 4 0 0 0 9.08 5 1 1 0 7.97 6 0 1 −1 7.14 7 −1 0 −1 9.23 8 1 0 1 8.16 9 1 0 −1 7.27 10 0 −1 −1 8.32 11 1 −1 0 8.84 12 −1 −1 0 8.51 13 0 0 0 9.04 14 0 0 0 9.21 15 0 0 0 8.88 16 0 1 1 6.94 17 −1 0 1 7.68 表 4 方差分析结果

Table 4 The ANOVA results

来源 平方和 自由度 均方 F P>F 模型 9.88 9 1.1 12.81 0.0014 A 0.13 1 0.13 1.49 0.2621 B 1.1 1 1.1 12.86 0.0089 C 0.5 1 0.5 5.83 0.0464 AB 9.03E-03 1 9.03E-03 0.11 0.755 AC 1.49 1 1.49 17.37 0.0042 BC 0.22 1 0.22 2.58 0.1524 A2 9.80E-03 1 9.80E-03 0.11 0.7451 B2 2.29 1 2.29 26.78 0.0013 C2 3.73 1 3.73 43.48 0.0003 残差 0.6 7 0.086 失拟项 0.54 3 0.18 11.03 0.1256 净误差 0.065 4 0.016 总离差 10.48 16 表 5 发酵液中的氨基酸组成

Table 5 The amino acid composition of fermentation products

编号 氨基酸 未发酵(%) 71B发酵(%) 1 牛磺酸(Tau) 10.0696 8.1039 2 天冬氨酸(Asp) 2.9464 6.3496 3 苏氨酸(Thr) 1.8973 3.6556 4 丝氨酸(Ser) 1.8787 3.4918 5 谷氨酸(Glu) 6.0867 10.047 6 甘氨酸(Gly) 5.8748 11.169 7 丙氨酸(Ala) 3.9514 6.7758 8 色氨酸(Trp) 3.4672 4.3456 9 缬氨酸(Val) 26.846 3.6821 10 甲硫氨酸(Met) 1.4025 2.0943 11 异亮氨酸(Ile) 1.4071 2.475 12 亮氨酸(Leu) 2.2444 4.7655 13 酪氨酸(Tyr) 1.0251 1.6249 14 苯丙氨酸(Phe) 1.1605 2.1039 15 赖氨酸(Lys) 3.4141 5.7122 16 组氨酸(His) 21.545 12.867 17 精氨酸(Arg) 2.4431 5.3744 18 脯氨酸(Pro) 2.6925 6.6544 -

[1] 鲍伟, 刘雅婷, 王小凤, 等. 基于电子鼻、电子舌和GC-MS分析饲料中添加金枪鱼蒸煮液对巴马香猪猪肉气味和滋味的影响[J]. 食品工业科技,2019,40(23):229−234. [Bao Wei, Liu Yating, Wang Xiaofeng, et al. Based on electronic nose, electronic tongue and GC-MS analysis of the effect of adding tuna cooking liquid in feed on the smell and taste of Bama pig pork[J]. Food Industry Science and Technology,2019,40(23):229−234. [2] 步营, 祝伦伟, 何玮, 等. 蓝蛤蒸煮液与酶解液的风味改善作用研究[J]. 现代食品科技,2020,36(1):253−261, 234. [Bu Ying, Zhu Lunwei, He Wei, et al. Study on the flavor improvement effect of blue clam cooking liquid and enzymatic hydrolysate[J]. Modern Food Science and Technology,2020,36(1):253−261, 234. [3] 杨小克, 李晓琳, 江晓路, 等. 金枪鱼乳化液中脂肪酸提取及组成分析[J]. 食品工业,2012,33(1):118−120. [Yang Xiaoke, Li Xiaolin, Jiang Xiaolu, et al. Fatty acid extraction and composition analysis of tuna emulsion[J]. Food Industry,2012,33(1):118−120. [4] 何键东. 金枪鱼蒸煮废水制备功能性鱼油及其微胶囊化研究[D].舟山: 浙江海洋学院, 2012. He Jiandong. Study on the preparation of functional fish oil from tuna cooking waste water and its microencapsulation[D]. Zhoushan: Zhejiang Ocean University, 2012.

[5] 陈启航, 朱秀花, 俞珺, 等. 金枪鱼蒸煮液酶解工艺优化及风味海鲜调味汁的制备[J]. 食品工业科技,2018,39(9):124−130. [Chen Qihang, Zhu Xiuhua, Yu Jun, et al. Optimization of enzymatic hydrolysis of tuna cooking liquid and preparation of flavored seafood sauce[J]. Food Industry Science and Technology,2018,39(9):124−130. [6] 李可欣, 丁慧璞, 周旭静, 等. 金枪鱼蒸煮汁的抗氧化性、脱腥处理及其风味沙拉酱的研制[J]. 食品工业科技,2020,41(4):153−160. [Li Kexin, Ding Huipu, Zhou Xujing, et al. Antioxidant, deodorizing treatment of tuna cooking juice and development of flavor salad dressing[J]. Food Industry Science and Technology,2020,41(4):153−160. [7] 于学娟, 姜竹茂, 陈英乡. 响应面法优化金枪鱼下脚料双菌发酵制备防腐功能海鲜风味调料的研究[J]. 中国调味品,2020,45(7):101−107. [Yu Xuejuan, Jiang Zhumao, Chen Yingxiang. Response surface methodology to optimize the fermentation of tuna scraps with two bacteria to prepare antiseptic seafood flavor seasonings[J]. Chinese Condiments,2020,45(7):101−107. doi: 10.3969/j.issn.1000-9973.2020.07.023 [8] Chen J, Li L, Yi R, et al. Release kinetics of Tilapia scale collagen I peptides during tryptic hydrolysis[J]. Food Hydrocolloids,2018,77:931−936. doi: 10.1016/j.foodhyd.2017.11.040

[9] 郑银桦, 彭聪, 吴秀峰, 等. 酵母酶解物对大口黑鲈生长性能、脂类代谢及肠道组织结构的影响[J]. 动物营养学报,2015,27(5):1605−1612. [Zheng Yinhua, Peng Cong, Wu Xiufeng, et al. Effects of yeast enzymatic hydrolysate on growth performance, lipid metabolism and intestinal tissue structure of largemouth bass[J]. Journal of Animal Nutrition,2015,27(5):1605−1612. doi: 10.3969/j.issn.1006-267x.2015.05.033 [10] 武利刚,谢广深,段杉. 活性炭和酵母粉对虾头虾壳蛋白水解液脱腥脱苦的比较研究[J]. 现代食品科技,2008,24(12):1243−1246. [Wu Ligang, Xie Guangshen, Duan Shan. Comparative study on the deodorization and debittering of activated carbon and yeast powder to the hydrolysate of shrimp head and shrimp shell protein[J]. Modern Food Science and Technology,2008,24(12):1243−1246. [11] 钱攀, 马旭婷, 许刚, 等. 美国鲢鱼挥发性成分和脱腥方法研究[J]. 中国食品学报,2016,16(12):169−176. [Qian Pan, Ma Xuting, Xu Gang, et al. Study on volatile components and deodorization methods of American silver carp[J]. Chinese Journal of Food Science,2016,16(12):169−176. [12] 李颖, 杨立华, 郭建华. 利用啤酒酵母吸附重金属离子的研究进展[J]. 啤酒科技,2012(5):18−21. [Li Ying, Yang Lihua, Guo Jianhua. Research progress on the adsorption of heavy metal ions by brewer's yeast[J]. Beer Science and Technology,2012(5):18−21. [13] 张海燕, 吴燕燕, 李来好, 等. 响应面法优化海鲈鱼片脱腥工艺[J]. 食品与发酵工业,2019,45(11):143−149. [Zhang Haiyan, Wu Yanyan, Li Laihao, et al. Optimization of deodorization process for sea bass fillets by response surface methodology[J]. Food and Fermentation Industries,2019,45(11):143−149. [14] Guttman L, Van Rijn J. 2-Methylisoborneol and geosmin uptake by organic sludge derived from a recirculating aquaculture system[J]. Water Research,2009,43(2):474−480. doi: 10.1016/j.watres.2008.10.018

[15] 刘艳, 段振华, 蔡彦, 等. 牡蛎酶解液的脱腥工艺研究[J]. 食品研究与开发,2015,36(21):95−99. [Liu Yan, Duan Zhenhua, Cai Yan, et al. Study on the deodorization process of oyster enzymatic hydrolysate[J]. Food Research and Development,2015,36(21):95−99. doi: 10.3969/j.issn.1005-6521.2015.21.025 [16] 苏怡, 夏文水, 姜启兴. 不同脱腥方法对鲟鱼肉脱腥效果比较研究[J]. 食品科技,2019,44(10):138−146. [Su Yi, Xia Wenshui, Jiang Qixing. Comparative study on the effect of different deodorizing methods on sturgeon meat[J]. Food Science and Technology,2019,44(10):138−146. [17] Civille G V, Oftedal K N. Sensory evaluation techniques-make "good for you" taste "good"[J]. Physiology & Behavior,2012,107(4):598−605.

[18] Musatov V Y, Sysoev V V, Sommer M, et al. Assessment of meat freshness with metal oxide sensor microarray electronic nose: A practical approach[J]. Sensors and Actuators B: Chemical,2010,144(1):99−103. doi: 10.1016/j.snb.2009.10.040

[19] Barbri E, Amari A, Vinaixa M, et al. Building of a metal oxide gas sensor-based electronic nose to assess the freshness of sardines under cold storage[J]. Sensors and Actuators B: Chemical,2007,128(1):235−244. doi: 10.1016/j.snb.2007.06.007

[20] 赵华杰, 杨荣华, 戴志远. 贻贝蒸煮液发酵调味品的感官评价及呈味成分的分析[J]. 中国食品学报,2009,9(4):185−191. [Zhao Huajie, Yang Ronghua, Dai Zhiyuan. Sensory evaluation and analysis of flavor components of fermented condiments from mussel cooking liquor[J]. Chinese Journal of Food Science,2009,9(4):185−191. doi: 10.3969/j.issn.1009-7848.2009.04.030 [21] Byun M W, Lee K H, Kim D H. Effects of gamma radiation on sensory qualities, microbiological and chemical properties of salted and fermented squid[J]. Journal of Food Protection,2000,63(7):934. doi: 10.4315/0362-028X-63.7.934

[22] 靳艳芬, 吴靖娜, 路海霞, 等. 鲍蒸煮液复合调味品制作配方和工艺研究[J]. 渔业现代化,2017,44(1):45−50, 58. [Jin Yanfen, Wu Jingna, Lu Haixia, et al. Study on the formula and technology of making compound condiment of abalone cooking liquid[J]. Fishery Modernization,2017,44(1):45−50, 58. [23] 吴靖娜, 靳艳芬, 陈晓婷, 等. 鲍鱼蒸煮液美拉德反应制备海鲜调味基料工艺优化[J]. 食品科学,2016,37(22):69−76. [Wu Jingna, Jin Yanfen, Chen Xiaoting, et al. Process optimization of seafood seasoning base prepared by Maillard reaction of abalone cooking liquid[J]. Food Science,2016,37(22):69−76. doi: 10.7506/spkx1002-6630-201622010 [24] 中华人民共和国国家卫生和计划生育委员会.GB 5009.235-2016食品中氨基酸态氮的测定[S]. 2016. National Health and Family Planning Commission of the People's Republic of China: GB 5009.235-2016 Determination of amino acid nitrogen in food[S]. 2016.

[25] 中华人民共和国国家卫生和计划生育委员会. GB/T 5009.124-2016食物中氨基酸的测定[S]. 2016. National Health and Family Planning Commission of the People's Republic of China: GB/T 5009.124-2016 Determination of amino acids in food[S]. 2016.

[26] 陈丽丽, 袁美兰, 张树峰, 等. 草鱼和鳗鱼内脏发酵鱼露的理化成分比较[J]. 中国调味品,2020,45(2):16−18, 22. [Chen Lili, Yuan Meilan, Zhang Shufeng, et al. Comparison of physicochemical components of fermented fish sauce from grass carp and eel offal[J]. China Seasoning,2020,45(2):16−18, 22. doi: 10.3969/j.issn.1000-9973.2020.02.004 [27] Su G, Wang S, Yuan Z, et al. Enhanced volatile fatty acids production of waste activated sludge under salinity conditions: Performance and mechanisms[J]. Journal of Bioscience and Bioengineering,2016,121(3):293−298. doi: 10.1016/j.jbiosc.2015.07.009

[28] Zhao J, Liu Y, Wang D, et al. Potential impact of salinity on methane production from food waste anaerobic digestion[J]. Waste Management,2017,67:308−314. doi: 10.1016/j.wasman.2017.05.016

[29] Huidrom S, Deka M. In vitro characterization of lactic acid bacteria isolated from the infant faeces as potential probiotic[J]. International Journal of Pharma & Bio ences,2014,5(2):B390−B399.

[30] 冯霞, 赵欣, 宋家乐. 传统酿造酱油的品质特性及其氨基酸组成研究[J]. 中国调味品,2014,39(2):16−19. [Feng Xia, Zhao Xin, Song Jiale. Study on the quality characteristics and amino acid composition of traditional brewed soy sauce[J]. Chinese Condiments,2014,39(2):16−19. doi: 10.3969/j.issn.1000-9973.2014.02.004 [31] Tseng Y H, Lee Y L, Li R C. Non-volatile flavor components of Ganoderma tsugae[J]. Food Chemistry,2005,90(3):109−115.

[32] 武俊瑞, 顾采东, 田甜, 等. 豆酱自然发酵过程中蛋白质和氨基酸的变化规律[J]. 食品科学,2017,38(8):139−144. [Wu Junrui, Gu Caidong, Tian Tian, et al. Changes of protein and amino acids during the natural fermentation of soybean paste[J]. Food Science,2017,38(8):139−144. doi: 10.7506/spkx1002-6630-201708022 -

期刊类型引用(3)

1. 雷军,胡悦. 在线凝胶渗透色谱-气质联用法测定腌制鱼中7种N-亚硝胺类化合物的一测多评研究. 中国调味品. 2025(01): 201-205+215 .  百度学术

百度学术

2. 杨军林,田栋伟,王佳,赵雯宇,黄河鸥,范恩帝,朱安然,尤小龙,吴成,胡建锋,汪地强. 超高效液相色谱-质谱-一测多评法结合质量控制图在高温大曲生产过程品控分析中的应用. 食品与发酵工业. 2024(08): 290-302 .  百度学术

百度学术

3. 王彦蕊,潘立超,任玉龑,郭晓鹏,任海伟,范文广,李志忠. 基于Web of Science和CNKI的羊肚菌研究文献计量分析. 中国食用菌. 2022(07): 1-12 .  百度学术

百度学术

其他类型引用(4)

下载:

下载:

下载:

下载: