Effects of Hydrocolloids Coating Pretreatment on the Drying Kinetics and Quality Attributes of Heat Pump Dried Scallop Adductors

-

摘要: 为提高扇贝柱热泵干燥效率,改善干制品品质,研究了低甲氧基果胶(LMP)和壳聚糖(CTS)等2种成膜预处理对扇贝柱干燥动力学与品质特性(质构、复水比、收缩率、色泽)的影响。结果表明,扇贝柱含水率随干燥时间延长而降低,扇贝柱干燥过程处于降速干燥阶段,干燥进程受内部水分扩散控制;LMP和CTS处理均提高了扇贝柱干燥速率。相比于CK,LMP和CTS成膜处理使扇贝柱有效水分扩散系数分别提高了11.08%和26.73%。相比于CK,LMP处理可降低扇贝柱收缩率、色差、硬度和韧性,提高干制品复水率;CTS处理降低了扇贝柱收缩率,提高了扇贝柱复水率、韧性和硬度,但对扇贝柱色差无影响。采用8种数学模型拟合干燥动力学数据,Midilli et al.为描述扇贝柱热泵干燥过程的最适模型。亲水胶体成膜预处理在提高扇贝柱热泵干燥效率、改善干制品品质方面具有显著效果。本研究可为水产品的热泵干燥提供一定的理论基础和实践参考。Abstract: In order to improve the heat pump drying efficiency of scallop adductors and improve the quality of dried products, the effects of low methoxy pectin (LMP) and chitosan (CTS) on drying kinetics and quality characteristics (texture, rehydration rate, shrinkage rate, color) of scallop adductors were investigated. The results showed that moisture content of scallop adductors was decreased with increasing drying time. The drying process of scallop adductors was in the falling rate stage, and the drying process was controlled by internal water diffusion. The drying rate was increased by LMP and CTS treatments. Compared with CK, LMP and CTS pretreatment could increase the effective water diffusion coefficient by 11.08% and 26.73%, respectively. Compared with CK, LMP treatment reduced the shrinkage rare, total color difference, hardness and toughness of scallop adductors, and improved the rehydration rate of dried products. CTS treatment decreased shrinkage rate, and enhanced the rehydration rate, toughness and hardness, but showed no effect on total color difference. Eight mathematical models were used to fit the drying kinetics data. The Midilli et al. was the most suitable model to describe the drying process of scallop adductors. Hydrocolloid’s coating pretreatment has a significant effect on improving the drying efficiency of scallop adductors during heat pump drying and enhancing the quality of dried products. The findings provide theoretical basis and practical reference for heat pump drying of aquatic products.

-

Keywords:

- scallop adductors /

- low methoxyl pectin /

- chitosan /

- coating pretreatment /

- heat pump /

- drying kinetics /

- quality attributes

-

扇贝(Argopecten irradias)富含蛋白质、不饱和脂肪酸和微量元素等营养物质和多糖、牛磺酸、胆碱等生物活性成分,具有丰富的营养价值和较高的保健功能[1-2]。但是,鲜活扇贝含水率高,内源酶种类繁多而且活性较高,加之容易遭受微生物侵染,导致其货架期短[3]。干燥是降低水分活度,提高水产品货架期常用方式。传统干燥方法主要为自然晾晒和热风干燥,但干燥效率低、产品质量差[4]。热泵干燥能效高、参数易于调控,尤其适用果蔬、水产品等热敏性物料的干燥[5]。但是,热泵干燥中后期效率低、能耗高是限制该领域发展的瓶颈[6]。

预处理是提高干燥效率、改善干制品品质的有效方式。化学预处理可以提高干燥效率,但是存在试剂残留导致的安全隐患;热力处理可以钝化酶,抑制微生物,强化干燥效率,但是营养成分损失率高[7]。非热力预处理(如冻融、渗透脱水、超声波、超高压和脉冲电场)不但可以提高干燥速率,而且还可以钝化酶,抑制微生物,显著降低干燥过程中色泽变化和营养成分损失[8]。

成膜预处理是一种新颖的非热力预处理方式。研究表明,成膜预处理不仅降低了果蔬干燥过程中色泽和营养成分的损失[9-12],而且不影响其干燥速率[9-10],有些甚至提高了果蔬干燥过程中的有效水分扩散系数[11-12]。但是,成膜预处理在水产品干燥领域则鲜有报道。Tian等[13]研究表明,成膜预处理可调控扇贝柱渗透脱水过程中的固形物增加量,提高扇贝柱渗透脱水效率。Shi等[1]研究表明,海藻酸钠成膜预处理提高了扇贝柱热泵干燥过程中的有效水分扩散系数,降低了干燥过程中所需的活化能。近年来,亲水胶体因具有良好的功能特性和较高的营养价值而成为食品科学领域的研究热点[14]。基于此,本文探讨低甲氧基果胶(LMP)和壳聚糖(CTS)等2种亲水胶体成膜预处理对扇贝柱热泵干燥动力学及品质特性的影响,旨在为水产品尤其扇贝柱热泵干燥提供理论基础和技术参考。

1. 材料与方法

1.1 材料与仪器

鲜活扇贝 淄博水产市场,扇贝清洗、取柱,所得扇贝柱质量和直径分别为(2.792±0.752)g, (1.686±0.263)cm;扇贝柱湿基含水率、蛋白质、脂肪和灰分含量分别为82.23%±0.62%、12.23%±1.15%,2.13%±0.18%,1.38%±0.12%;低甲氧基果胶(LMP)、壳聚糖(CTS) 食品级,上海权旺生物科技有限公司;吐温80、醋酸、CaCl2 AR,国药集团化学试剂有限公司。

1HP-5热泵除湿干燥成套设备 青岛欧美亚科技有限公司;DHG-9140A电热鼓风干燥箱 上海一恒科学仪器有限公司;TMS-2000质构仪 美国FTC公司;WSC-S色差计 上海仪电物理光学仪器有限公司;PL203电子天平 梅特勒-托利多仪器有限公司。

1.2 实验方法

1.2.1 成膜预处理

分别配制(w/v) 2% LMP、2% CaCl2和1% CTS(将CTS溶解在体积比为1%的醋酸溶液中,然后加入体积比为1%的吐温80)溶液。采用3种方式处理扇贝柱:①LMP成膜预处理:扇贝柱置于2% LMP溶液5 min,然后取出,放于2% CaCl2溶液中30 min;②CTS成膜预处理:扇贝柱置于1% CTS溶液30 s,取出并静置30 min;③对照组(CK):未经成膜预处理的扇贝柱。预处理后的扇贝柱,置于不锈钢丝网沥干30 min,用滤纸擦干表面水备用。

1.2.2 热泵干燥

成膜预处理和CK扇贝柱在温度30 ℃,风速2.0 m/s进行热泵干燥。干燥过程中,定期取样称量,当扇贝柱干基含水率为0.67 kg/kg时,干燥结束。

1.3 干燥动力学与数学模型

1.3.1 含水率和水分比

采用常压干燥法测定扇贝柱含水率[15]。水分比(MR)指扇贝柱在一定干燥条件下未被干燥去除的水分,计算式[16]:

MR=Mt−MeM0−Me (1) 式中:M0、Mt分别为干燥时间为0与t时刻的干基含水率,kg/kg。Me为扇贝柱的平衡干基含水率,kg/kg。由于干燥时间较长,Me与M0、Mt相比,可忽略不计。因此,式(1)简化为[16]:

MR=MtM0 (2) 1.3.2 干燥速率

干燥速率(DR)计算式[1]:

DR=−Md,i+1−Md,iti+1−ti (3) 式中:ti、ti+1分别为干燥时间i和i+1;Md, i、Md,i+1分别为干燥时间i和i+1时刻扇贝柱的干基含水率,kg/kg。

1.3.3 干燥数学模型

采用表1所示的8种常见的农产品薄层干燥数学模型拟合试验数据。模型拟合精度采用决定系数(R2)、卡方(χ2)、均方根误差(RMSE)来衡量,R2越高,χ2和RMSE越低,模型拟合精度越高[16]。

模型名称 模型表达式 Lewis MR=exp(−kt) Page MR=exp(−ktn) Modified Page MR=exp(−kt)n Henderson and Pabis MR=a exp(−kt) Logarithmic MR=a exp(−kt)+c Two term model MR=aexp(−k0t)+bexp(−k1t) Wang and singh MR=1+at+bt2 Midilli et al. MR=aexp(−ktn)+bt 注:MR为水分比(无量纲),a、b、c、k、k0、k1、n均为数学模型的参数。 1.3.4 有效水分扩散系数

扇贝柱热泵干燥过程中,有效水分扩散系数(Deff)可以Fick扩散方程的简化对数形式(推导过程略)计算[1]:

lnMR=ln[6π2]−[π2Deffr2]t (4) 式中:Deff为有效水分扩散系数,m2/s;r为扇贝柱的半径,m;t为干燥时间,s。由此可知,lnMR与t呈线性关系,Deff可根据直线的斜率计算得到。

1.4 指标测定

1.4.1 色泽

采用色差计测定干燥前后样品的色泽,扇贝柱色差(ΔE)计算式[1]:

ΔE=√(L−L0)2+(a−a0)2+(b−b0)2 (5) 式中:L,a,b表示干燥后扇贝柱色泽;L0,a0,b0表示扇贝柱干燥前色泽参数值。

1.4.2 收缩率(SR)

利用甲苯置换法测定[17]。

SR(%)=V1−V2V1×100 (6) 其中:V1和V2分别代表扇贝柱干燥前和干燥后的体积,mL。

1.4.3 复水率(Rf)

称取一定质量的扇贝柱,置于100 ℃蒸馏水中,维持10 min,然后取出扇贝柱,沥干表面水,称量[1]。

Rf(%)=mfmg×100 (7) 式中:mf为复水后的质量,g;mg为复水前的质量,g。

1.4.4 质构特性

采用质构仪测定样品的剪切力和压缩力(测试样本容量n=10),分析扇贝柱的硬度与韧性[5]。剪切试验参数:刀片厚度20 mm,运行速度50 mm/min。单轴压缩试验参数:圆柱探针直径66 mm,运行速率50 mm/min,压缩至原样品厚度的50%。

1.5 数据处理

扇贝柱热泵干燥试验和干制品指标测定都平行3次,试验数据用“平均值±标准差”表示。采用Matlab 7.1软件进行线性和非线性回归分析,利用SPSS 19.0软件进行单因素方差分析,差异显著者进行Duncan’s多重比较。

2. 结果与分析

2.1 成膜预处理对扇贝柱热泵干燥动力学特性影响

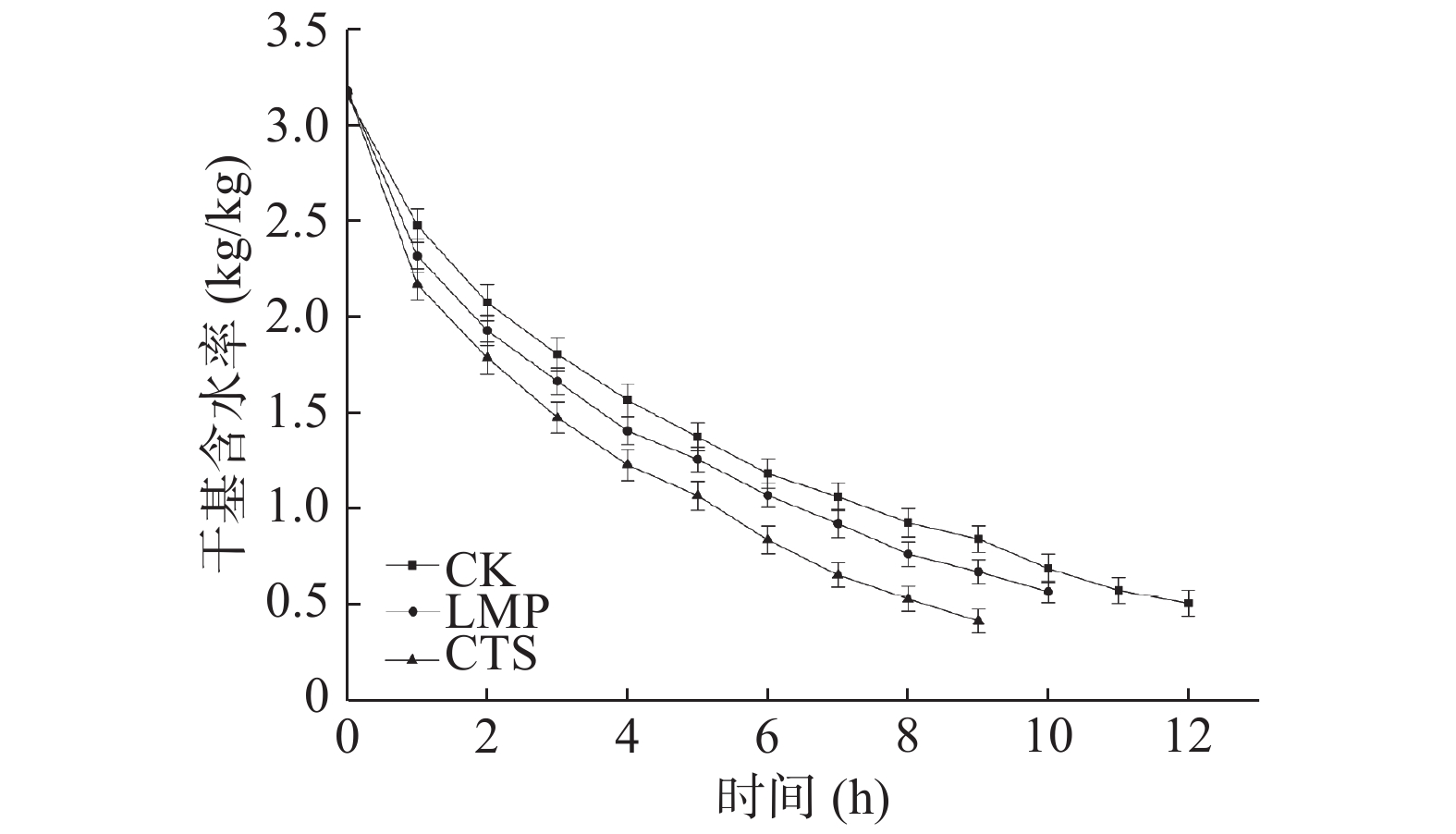

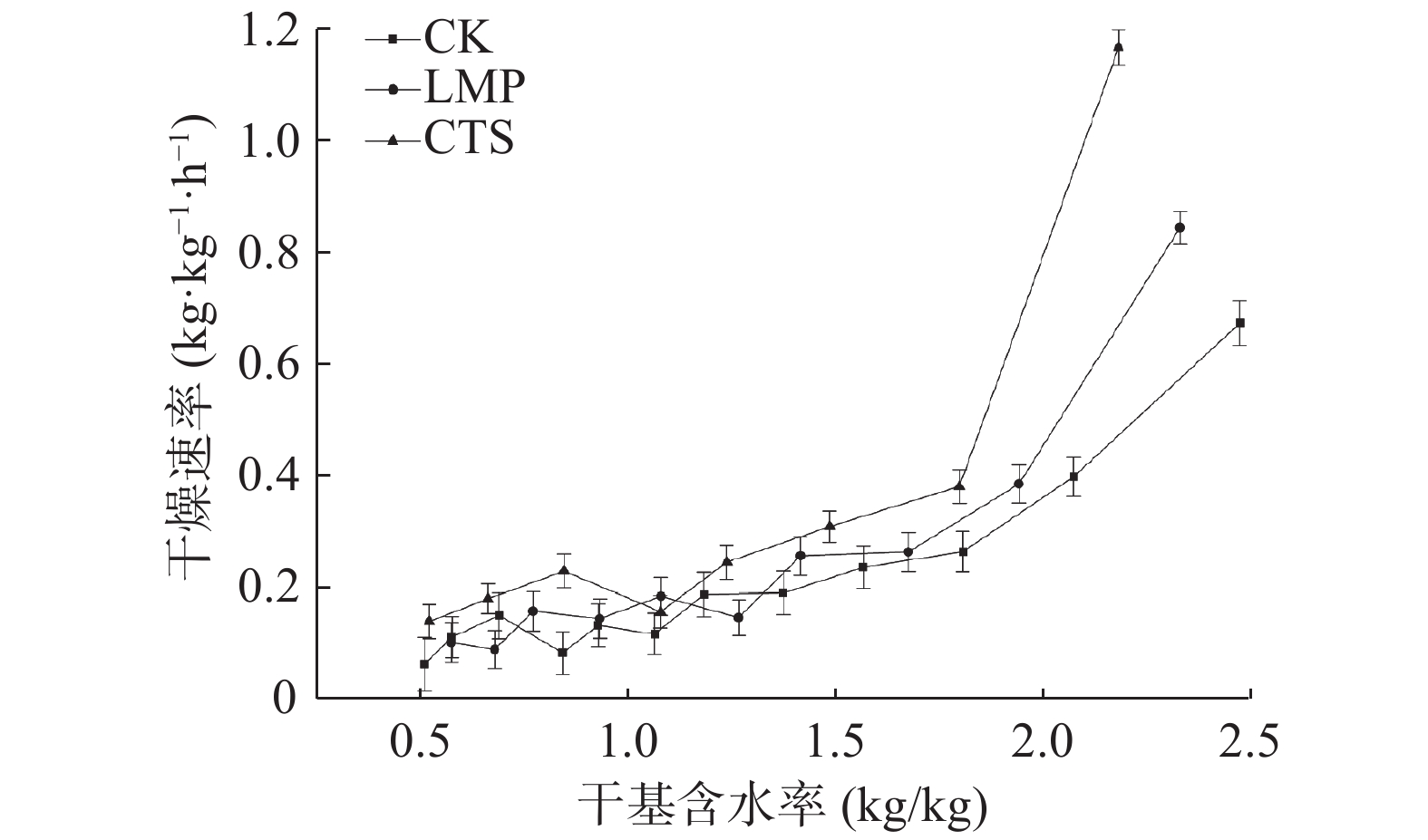

成膜预处理扇贝柱的干燥动力学特性影响如图1和图2所示。由图1可知,随着干燥时间的增加,扇贝柱干基含水率逐渐减低。与CK相比,成膜处理扇贝柱含水率下降趋势更明显。相同干燥时间下,成膜处理扇贝柱含水率低。例如,扇贝柱干燥8 h,CK、LMP和CTS的含水率分别降低至0.93、0.76和0.53 kg/kg。由图2可知,扇贝柱热泵干燥过程主要为降速干燥,内部扩散机制为扇贝柱干燥过程的主要驱动力。干燥前期,干燥速率迅速降低;而干燥中后期,干燥速率变化平缓,干燥动力不足。成膜预处理有效提高了扇贝柱干燥速率,干燥初期和中期尤为明显;而干燥后期,这种强化干燥效率效果呈减缓趋势,这可能是由于蛋白质变性,导致扇贝柱体积严重收缩,妨碍水分逸出通道所致。水产品热泵干燥过程中,细胞与细胞间隙的水势梯度是水分迁移的推动力[18],水势梯度和组织膨压随干燥进行逐渐降低,内外压力失衡产生收缩应力,进而引起体积收缩[19],导致干燥速率降低,能耗比升高。成膜预处理避免物料表面水分快速蒸发、引起局部过热而形成的表面硬化,使扇贝柱组织维系一定的水势梯度,降低肌肉组织收缩应力,减缓甚至抑制扇贝柱干燥过程中的体积收缩现象[1]。此外,亲水胶体具有极性基团,水溶液中聚合物分子链通过氢键结合,形成的膜具有高极性和水透过性能,干燥过程中传质阻力小[1,12],促进了扇贝柱内部水分向表面扩散,进而强化了扇贝柱干燥效率。

2.2 数学模型拟合

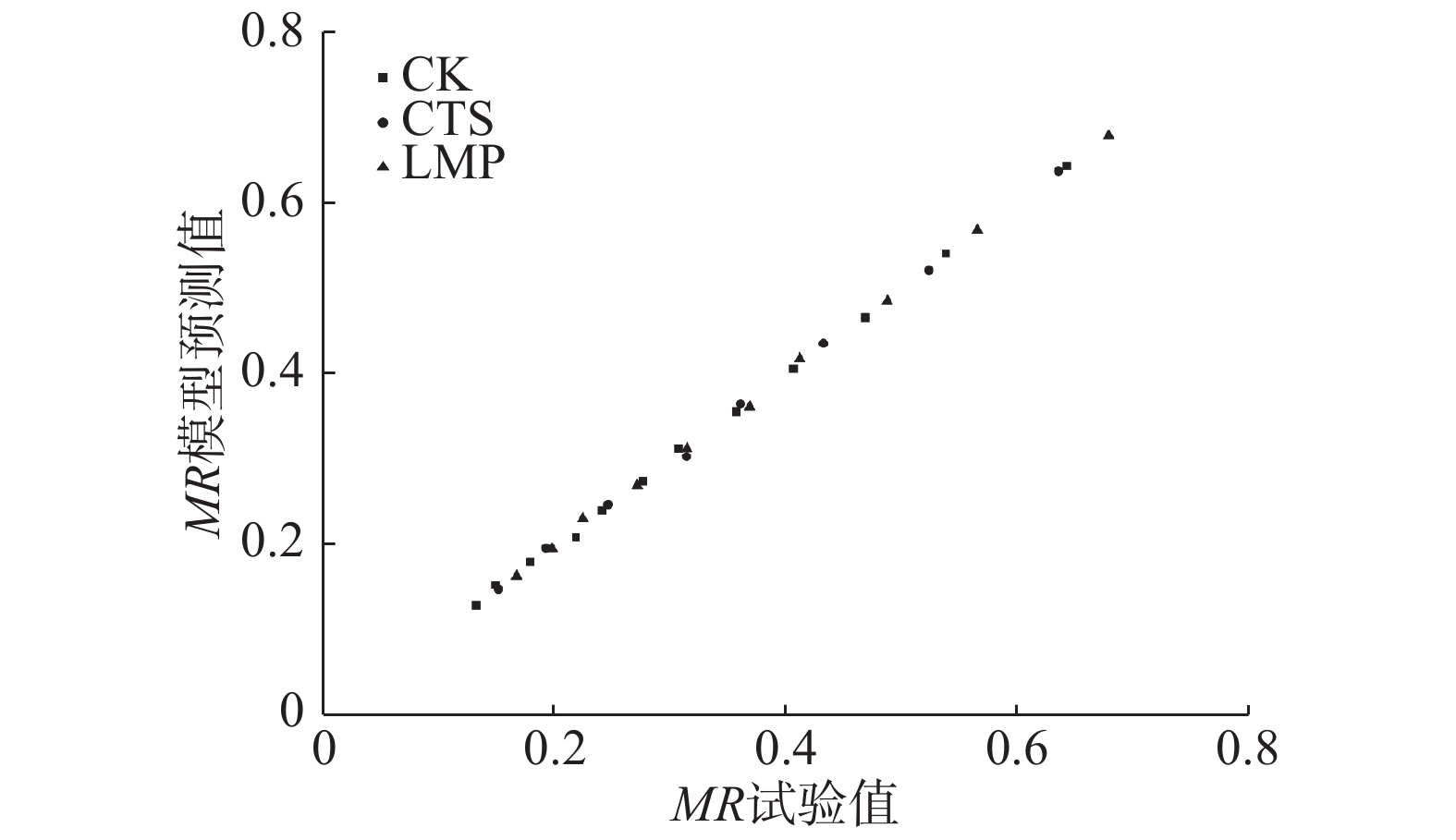

将扇贝柱干燥过程中干基含水率转换成MR,采用表1所示的8种数学模型拟合MR,模型拟合结果如表2所示。通过模型间参数比较可知,Midilli et al.模型R2最高,χ2和RMSE最低,R2、χ2和RMSE的范围分别为0.998~0.999,0.0002~0.0005,0.0046~0.0089。因此,Midilli et al.是描述扇贝柱热泵干燥过程的最适模型。为了验证Midilli et al.模型的准确性,对3组不同预处理扇贝柱干燥过程中MR值与模型预测的MR值进行对比,结果如图3所示。可以看出,数据点紧密分布在45°直线附近,表明Midilli et al.模型所得MR预测值和试验值具有较高的一致性,所得数学模型可靠,可用于预测扇贝柱热泵干燥特性。

表 2 数学模型拟合及评估参数值Table 2. Estimated parameters of mathematical models数学模型 处理 模型常数 评价参数 R2 χ2 RMSE CK k=0.208 0.772 0.0651 0.0769 Lewis LMP k=0.210 0.857 0.0364 0.0636 CTS k=0.264 0.855 0.0282 0.0635 CK k=0.296, n=0.621 0.989 0.0031 0.0176 Page LMP k=0.353, n=0.677 0.993 0.0019 0.0152 CTS k=0.409, n=0.688 0.985 0.0030 0.0022 Modified Page CK k=0.346, n=0.696 0.988 0.0349 0.0591 LMP k=0.321, n=0.734 0.993 0.0133 0.0408 CTS k=0.356, n=0.781 0.983 0.0286 0.0691 Henderson and Pabis CK a=0.725, k=0.140 0.998 0.0006 0.0080 LMP a=0.782, k=0.154 0.999 0.0004 0.0069 CTS a=0.775, k=0.193 0.997 0.0006 0.0103 CK a=0.254, k=0.149, c=0.019 0.997 0.0006 0.0082 Logarithmic LMP a=0.768, c=0.0194, k=0.162 0.999 0.0004 0.0071 CTS a=0.848, c=0.097, k=0.152 0.998 0.0003 0.0083 CK a=0.023, b=0.145, k0=0.703, k1=0.140 0.998 0.0006 0.0089 Two term LMP a=30.200, b=8.599, k0=0.777, k1=0.153 0.999 0.0003 0.0070 CTS a=8.222, b=13.730, k0=0.775, k1=0.193 0.997 0.0006 0.0127 Wang and Singh CK a=−0.180, b=0.009 0.705 0.0845 0.0919 LMP a=−0.192, b=0.011 0.834 0.0419 0.0724 CTS a=−0.236, b=0.017 0.811 0.0369 0.0784 Midilli et al. CK a=0.888, b=−0.009, k=0.308, n=0.590 0.999 0.0002 0.0046 LMP a=0.025, b=−0.029, k =−3.366, n=−0.065 0.998 0.0005 0.0089 CTS a=0.963, b=−0.025, k=0.374, n=0.475 0.999 0.0002 0.0066 2.3 有效水分扩散系数

相比于CK,亲水胶体成膜预处理提高了扇贝柱热泵干燥过程中的有效水分扩散系数(Deff)。例如,未经成膜预处理(CK)扇贝柱热泵干燥过程中的Deff为1.534×10−10 m2/s,而采用LMP和CTS预处理后,Deff分别提高至1.704×10−10和1.944×10−10 m2/s,这与扇贝柱热泵干燥动力学特性吻合。Silva等[10]、Filho等[12]分别采用LMP成膜预处理菠萝片和南瓜片,得到了相似的结论。亲水胶体预处理提高干燥效率的可能原因是:首先,亲水性胶体具有强亲水特性,膜的Deff远高于扇贝柱组织中的水分扩散系数[1];其次,亲水胶体成膜预处理降低了扇贝柱肌肉组织的收缩,促进了干燥过程中的水分迁移,因此提高了干燥效率。

2.4 成膜预处理对扇贝柱热泵干燥品质特性的影响

成膜预处理对扇贝柱热泵干燥品质特性的影响如表3所示。预处理方式对扇贝柱品质特性影响显著。干制品重要指标之一是色泽,成膜预处理对扇贝柱色泽变化的影响取决于成膜材料。与CK相比较,经LMP成膜后,扇贝柱的色差值由22.63±0.12显著(P<0.05)降低至17.80±1.02,色差减少了21.34%;而CTS处理后,扇贝柱色差值降低至22.19±0.03,但处理间无显著差异(P>0.05)。水产品干燥过程中,色泽变化主要是由于酶促/非酶褐变所致[20-21],酶促褐变需要氧气参与,成膜预处理将扇贝柱肌肉与干燥介质中氧气隔离,进而起到抑制酶促褐变作用[20];此外,成膜处理提高了干燥效率,缩短了干燥时间,也在一定程度上降低了非酶促褐变速度及程度,因此,提高了扇贝柱的色泽。CTS处理与CK色泽间无明显差异,一方面由于LMP和CTS形成的膜对氧气的透过性有所差异;另一方面由于CTS成膜后自身颜色变化妨碍了扇贝柱的色泽,具体原因尚需进一步探究。

表 3 成膜预处理对扇贝柱热泵干燥品质特性的影响Table 3. Effect of coating pretreatments on the quality attributes of heat pump dried scallop adductors处理 ΔE SR (%) Rf (%) 韧性(N) 硬度(N) CK 22.63 ± 0.12a 49.46 ± 2.56a 113.86 ± 0.44c 96.00 ± 3.51b 3680.0 ± 8.9b LMP 17.80 ± 1.02b 32.50 ± 6.61c 122.62 ± 0.97a 82.67 ± 3.33c 3583.7 ± 6.6c CTS 22.19 ± 0.03a 40.46 ± 3.85b 118.61 ± 0.79b 111.67 ± 3.67a 3813.8 ± 13.8a 注:同一列中,不同上标小写字母代表显著性差异(P<0.05)。 收缩率和复水率是评价干制品品质的重要指标,取决于物料干燥过程中细胞和结构破坏的程度[21]。成膜预处理显著降低了扇贝柱干燥过程中的体积收缩现象,提高了扇贝柱的复水能力(表3)。与CK相比,LMP和CTS预处理使扇贝柱体积收缩率由49.46%±2.56%显著(P<0.05)降低至32.50% ± 6.61%和40.46%±3.85%,体积收缩率分别降低了4.29%和18.20%。此外,LMP和CTS预处理使扇贝柱复水率由113.86%±0.44%显著(P<0.05)增加至122.62%±0.97%和118.61%±0.79%;与CK相比,复水率分别提高了7.69%和4.17%。Islam等[22]和Dehsheikh等[23]分别采用淀粉和羟甲基纤维素成膜预处理番木瓜和香蕉片,探究成膜处理对脱水木瓜和香蕉品质的影响,得到了相似的结论。

质构是衡量干制品品质特性的另一重要指标。由表3可知,相比于CK,扇贝柱LMP预处理后,干制品韧性由(96.00±3.51)N显著(P<0.05)降低至(82.67±3.33)N,硬度值则由(3680.00±8.90)N降低至(3583.70±6.60)N,韧性和硬度值分别降低了13.89%和2.6%。但是,扇贝柱CTS预处理后,相比于CK,干制品的韧性和硬度值分别增加了16.32%和3.64%。由于LMP显著降低了扇贝柱体积收缩,缩短了干燥时间,LMP处理剪切力和硬度显著(P<0.05)降低。韩飞等[24]采用瓜尔豆胶和黄原胶浸渍预处理扇贝柱,经冷风干燥后,扇贝柱硬度显著降低。CTS预处理提高了扇贝柱硬度和剪切力,这可能是由于壳聚糖分子与扇贝柱肌原纤维蛋白形成了共价或非共价键作用,从而改变了扇贝柱的质构。Yuan等[25]采用壳聚糖涂膜保鲜白对虾,提高了虾肉的硬度和韧性,并将其归因于虾肉肌原纤维蛋白和壳聚糖形成新的价键。

综上,亲水胶体成膜预处理显著影响(P<0.05)扇贝柱干制品品质,其可能原因:其一,成膜预处理提高了干燥速率,缩短了干燥时间,减少了蛋白质变性程度;其二,成膜预处理抑制了干燥过程中扇贝柱和氧气的接触,降低了氧气参与的相关反应;其三,扇贝柱干燥过程中,成膜预处理影响扇贝柱干燥过程中水分状态和水分分布,进而影响扇贝柱肌原纤维蛋白聚集、胶凝等功能特性,具体原因亟需进一步探究。

3. 结论

扇贝柱热泵干燥主要为降速干燥阶段,水分内扩散起主导作用,LMP和CTS成膜处理均可以提高扇贝柱干燥速率。Midilli et al.模型为描述扇贝柱热泵干燥进程的最适模型。相比于CK,LMP处理提高了扇贝柱复水率,降低了扇贝柱色泽变化、收缩率、韧性和硬度;CTS预处理提高了扇贝柱复水率、韧性和硬度,降低了体积收缩,而对色泽变化无显著影响。综合考虑,LMP预处理可提高扇贝柱热泵干燥效率,改善干制品品质。本研究为水产品尤其扇贝柱热泵干燥中后期能效低、品质差提供了一种新颖的解决思路;未来研究应偏重成膜预处理对扇贝柱热泵干燥过程中水分状态分布和迁移规律,探究水分状态变化与蛋白质功能特性之间的内在联系,进而阐明成膜预处理提高扇贝柱干燥效率及品质机制。

-

模型名称 模型表达式 Lewis MR=exp(−kt) Page MR=exp(−ktn) Modified Page MR=exp(−kt)n Henderson and Pabis MR=a exp(−kt) Logarithmic MR=a exp(−kt)+c Two term model MR=aexp(−k0t)+bexp(−k1t) Wang and singh MR=1+at+bt2 Midilli et al. MR=aexp(−ktn)+bt 注:MR为水分比(无量纲),a、b、c、k、k0、k1、n均为数学模型的参数。 表 2 数学模型拟合及评估参数值

Table 2 Estimated parameters of mathematical models

数学模型 处理 模型常数 评价参数 R2 χ2 RMSE CK k=0.208 0.772 0.0651 0.0769 Lewis LMP k=0.210 0.857 0.0364 0.0636 CTS k=0.264 0.855 0.0282 0.0635 CK k=0.296, n=0.621 0.989 0.0031 0.0176 Page LMP k=0.353, n=0.677 0.993 0.0019 0.0152 CTS k=0.409, n=0.688 0.985 0.0030 0.0022 Modified Page CK k=0.346, n=0.696 0.988 0.0349 0.0591 LMP k=0.321, n=0.734 0.993 0.0133 0.0408 CTS k=0.356, n=0.781 0.983 0.0286 0.0691 Henderson and Pabis CK a=0.725, k=0.140 0.998 0.0006 0.0080 LMP a=0.782, k=0.154 0.999 0.0004 0.0069 CTS a=0.775, k=0.193 0.997 0.0006 0.0103 CK a=0.254, k=0.149, c=0.019 0.997 0.0006 0.0082 Logarithmic LMP a=0.768, c=0.0194, k=0.162 0.999 0.0004 0.0071 CTS a=0.848, c=0.097, k=0.152 0.998 0.0003 0.0083 CK a=0.023, b=0.145, k0=0.703, k1=0.140 0.998 0.0006 0.0089 Two term LMP a=30.200, b=8.599, k0=0.777, k1=0.153 0.999 0.0003 0.0070 CTS a=8.222, b=13.730, k0=0.775, k1=0.193 0.997 0.0006 0.0127 Wang and Singh CK a=−0.180, b=0.009 0.705 0.0845 0.0919 LMP a=−0.192, b=0.011 0.834 0.0419 0.0724 CTS a=−0.236, b=0.017 0.811 0.0369 0.0784 Midilli et al. CK a=0.888, b=−0.009, k=0.308, n=0.590 0.999 0.0002 0.0046 LMP a=0.025, b=−0.029, k =−3.366, n=−0.065 0.998 0.0005 0.0089 CTS a=0.963, b=−0.025, k=0.374, n=0.475 0.999 0.0002 0.0066 表 3 成膜预处理对扇贝柱热泵干燥品质特性的影响

Table 3 Effect of coating pretreatments on the quality attributes of heat pump dried scallop adductors

处理 ΔE SR (%) Rf (%) 韧性(N) 硬度(N) CK 22.63 ± 0.12a 49.46 ± 2.56a 113.86 ± 0.44c 96.00 ± 3.51b 3680.0 ± 8.9b LMP 17.80 ± 1.02b 32.50 ± 6.61c 122.62 ± 0.97a 82.67 ± 3.33c 3583.7 ± 6.6c CTS 22.19 ± 0.03a 40.46 ± 3.85b 118.61 ± 0.79b 111.67 ± 3.67a 3813.8 ± 13.8a 注:同一列中,不同上标小写字母代表显著性差异(P<0.05)。 -

[1] Shi Q, Tian Y, Zhu L, et al. Effects of sodium alginate-based coating pretreatment on drying characteristics and quality of heat pump dried scallop adductors[J]. Journal of the Science of Food and Agriculture,2019,99(10):4781−4792. doi: 10.1002/jsfa.9728

[2] 郭洁, 白凤岐, 李笑颜, 等. 低盐处理对扇贝柱热风干燥品质的影响[J]. 食品工业科技,2015,36(14):303−307. [3] 隋笑乐, 朱智壮, 张欣, 等. 基于LF-NMR探究冻融对压差膨化扇贝柱水分分布与品质影响[J]. 食品与发酵工业,2019,45(23):115−120. [4] Zhang M, Chen H, Mujumdar A S, et al. Recent developments in high-quality drying of vegetables, fruits, and aquatic products[J]. Critical Reviews in Food Science and Nutrition,2017,57(6):1239−1255. doi: 10.1080/10408398.2014.979280

[5] 石启龙, 赵亚, 魏彦君. 热泵干燥南美白对虾品质特性与玻璃化转变关系研究[J]. 农业机械学报,2017,48(1):297−302. doi: 10.6041/j.issn.1000-1298.2017.01.039 [6] Shi Q, Zheng Y, Zhao Y. Optimization of combined heat pump and microwave drying of yacon (Smallanthus sonchifolius) using response surface methodology[J]. Journal of Food Processing and Preservation,2014,38(5):2090−2098. doi: 10.1111/jfpp.12189

[7] Deng L, Mujumdar A S, Zhang Q, et al. Chemical and physical pretreatment of fruits and vegetables: Effects on drying characteristics and quality attributes-a comprehensive review[J]. Critical Reviews in Food Science and Nutrition,2019,59(9):1408−1432. doi: 10.1080/10408398.2017.1409192

[8] Osae R, Essilfie G, Alolga R N, et al. Application of non-thermal pretreatment techniques on agricultural products prior to drying: A review[J]. Journal of the Science of Food and Agriculture,2020,100(6):2585−2599. doi: 10.1002/jsfa.10284

[9] Canizares D, Mauro M A. Enhancement of quality and stability of dried papaya by pectin-based coatings as air-drying pretreatment[J]. Food and Bioprocess Technology,2015,8(6):1187−1197. doi: 10.1007/s11947-015-1483-2

[10] Silva K S, Garcia C C, Amado L R, et al. Effects of edible coatings on convective drying and characteristics of the dried pineapple[J]. Food and Bioprocess Technology,2015,8(7):1465−1475. doi: 10.1007/s11947-015-1495-y

[11] Garcia C C, Caetano L C, de Souza Silva K, et al. Influence of edible coating on the drying and quality of papaya (Carica papaya)[J]. Food and Bioprocess Technology,2014,7(10):2828−2839. doi: 10.1007/s11947-014-1350-6

[12] Filho M L, Frascareli E C, Mauro M A. Effect of an edible pectin coating and blanching pretreatments on the air-drying kinetics of pumpkin (Cucurbita moschata)[J]. Food and Bioprocess Technology,2016,9(5):859−871. doi: 10.1007/s11947-016-1674-5

[13] Tian Y, Zhao Y, Shi Q. Appropriate coating pretreatment enhancing osmotic dehydration efficiency of scallop adductors[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE),2016,32(17):266−273.

[14] Li J, Nie S. The functional and nutritional aspects of hydrocolloids in foods[J]. Food Hydrocolloids,2016,53:46−61. doi: 10.1016/j.foodhyd.2015.01.035

[15] 纪家笙, 黄志斌, 杨运华, 等. 水产品工业手册[M]. 北京: 中国轻工业出版社, 1999: 595-596. [16] Shi Q, Zheng Y, Zhao Y. Mathematical modeling on thin-layer heat pump drying of yacon (Smallanthus sonchifolius) slices[J]. Energy Conversion and Management,2013,71:208−216. doi: 10.1016/j.enconman.2013.03.032

[17] Tarafdar A, Shahi N C. Application and comparison of genetic and mathematical optimizers for freeze-drying of mushrooms[J]. Journal of Food Science and Technology,2018,55:2945−2954. doi: 10.1007/s13197-018-3212-0

[18] 石启龙, 赵亚, 李兆杰, 等. 热泵干燥过程中竹荚鱼水分迁移特性[J]. 农业机械学报,2010,41(2):122−126. doi: 10.3969/j.issn.1000-1298.2010.02.025 [19] Nguyen T K, Khalloufi S, Mondor M, Ratti C. Shrinkage and porosity evolution during air-drying of non-cellular food systems: experimental data versus mathematical modelling[J]. Food Research International,2018,103:215−225. doi: 10.1016/j.foodres.2017.10.013

[20] Sui X, Zhao Y, Zhang X, et al. Hydrocolloid coating pretreatment makes explosion puffing drying applicable in protein-rich foods-A case study of scallop adductors[J/OL]. Drying Technology, https://www.tandfonline. com/doi/full/10.1080/07373937.2020.1768108.

[21] Li M, Wu Y, Guan Z, et al. Effect of physical osmosis methods on quality of tilapia fillets processed by heat pump drying[J]. Polish Journal of Food and Nutrition Sciences,2017,67(2):145−150. doi: 10.1515/pjfns-2016-0016

[22] Islam M Z, Saha T, Monalisa K, et al. Effect of starch edible coating on drying characteristics and antioxidant properties of papaya[J]. Journal of Food Measurement and Characterization,2019,13(4):2951−2960. doi: 10.1007/s11694-019-00215-3

[23] Dehsheikh F N, Dinani S T. Coating pretreatment of banana slices using carboxymethyl cellulose in an ultrasonic system before convective drying[J]. Ultrasonics Sonochemistry,2019,52:401−413. doi: 10.1016/j.ultsonch.2018.12.018

[24] 韩飞, 唐伟伟, 常永波, 等. 扇贝柱预处理工艺优化及干燥过程中品质变化评价[J]. 食品工业科技,2017,38(3):221−226. [25] Yuan G, Lv H, Tang W, et al. Effect of chitosan coating combined with pomegranate peel extract on the quality of Pacific white shrimp during iced storage[J]. Food Control,2016,59(1):818−823.

-

期刊类型引用(3)

1. 乔常宏,陈翔宇,刘宝玲,罗琴,刘丁语,何振文,王晓虎,陈晶,张翩,黄元,白挨泉,王刚,蔡汝健. 多组学视角下中药抗菌机制研究进展. 中国畜牧兽医. 2025(01): 52-59 .  百度学术

百度学术

2. 蓝蔚青,赵家欣,谢晶. 香芹酚纳米乳液制备及其对腐败希瓦氏菌的抑制作用. 广东海洋大学学报. 2024(03): 128-135 .  百度学术

百度学术

3. 王亚哲,赵永强,王迪,陈胜军,于刚,冯阳,王悦齐,李春生. 多组学视角下植物精油抑菌机理的研究进展. 食品科学. 2024(17): 348-356 .  百度学术

百度学术

其他类型引用(1)

下载:

下载:

下载:

下载: