Effects of High-pressure Processing on the Storage Properties of Yak Meat

-

摘要: 牦牛肉分别经200、400、600 MPa超高压处理480 s,测定4 °C条件下贮藏0、4、8、12、16 d后感官、pH、微生物、色泽、蛋白质与脂质氧化情况,以探讨超高压处理对牦牛肉贮藏期内品质的影响。结果表明:超高压处理可以显著降低贮藏期内牦牛肉的菌落总数、总挥发性盐基氮含量(total volatile basic nitrogen, TVB-N)(P<0.05),延长保质期,且经贮藏4~8 d后能良好保持牦牛肉的感官品质。经超高压处理后牦牛肉L*值、b*值显著增大(P<0.05),a*值在400 MPa时显著增大(P<0.05)并在贮藏期内维持在最高水平,且400 MPa组各类肌红蛋白(Myoglobin, Mb)含量也表现出良好的肉色稳定性,但a*值在其他压力处理后显著减小(P<0.05)。但经超高压处理后牦牛肉肌原纤维蛋白(Myofibrillar Protein, MP)羰基含量与表面疏水性增高、巯基含量降低,TBARS值升高。Pearson相关性分析结果也表示超高压处理后牦牛肉品质的变化与压力、蛋白质氧化、脂质氧化和微生物相关(P<0.05)。综上,超高压处理虽加速了蛋白质和脂质氧化,而合理利用适当的压力有利于维持牦牛肉的肉色稳定性和感官品质,提高牦牛肉的贮藏特性,这对超高压处理牦牛肉的生产应用提供参考。

-

关键词:

- 超高压处理(HHP) /

- 肉色 /

- 蛋白质氧化 /

- 脂质氧化 /

- 牦牛肉

Abstract: To investigate the effect of high-pressure processing (HPP) on the quality of yak meat, yak meat was processed under pressure at 200, 400, and 600 MPa for 480 seconds, respectively, and the sensory, pH, microorganism, color, protein, and lipid oxidation of yak meat stored at 4 °C for 0, 4, 8, 12, and 16 days was determined. The results showed that HPP significantly lowered the total number of colonies and total volatile basic nitrogen (TVB-N) during storage (P<0.05), and extended the shelf life of yak meat. Yak meat was well preserved for 4~8 days from sensory perception. The L* and b* values of yak meat with HPP increased significantly (P<0.05). The a* value increased significantly at 400 MPa (P<0.05) and remained at the highest level throughout storage, and the contents of various myoglobin (Mb) in the 400 MPa group also demonstrated excellent meat color stability. Whereas the a* values decreased significantly under other pressure conditions (P<0.05). The carbonyl content and surface hydrophobicity of yak meat myofibrillar protein (MP) were increased, while sulfhydryl content were decreased, and TBARS of yak meat were elevated. According to Pearson correlation analysis, pressure, protein oxidation, lipid oxidation, and microbes were all associated with changes in yak meat quality under HHP (P<0.05). In conclusion, although HPP accelerated the oxidation of protein and lipids, the use of appropriate pressure was conducive to maintaining the meat color stability and sensory quality of yak meat, providing a reference for the application of yak meat with HPP.-

Keywords:

- high pressure processing (HHP) /

- meat color /

- protein oxidation /

- lipid oxidation /

- yak meat

-

牦牛肉具有高蛋白、低脂肪、肉色好和风味独特等特点[1],但是,牦牛肉在屠宰、加工、运输等环节仍存在肉色与质地劣变、异味产生等诸多问题。目前,各类加工与贮藏方法被用来改善牦牛肉品质和提高经济价值。其中,超高压技术是一项新兴的非热加工技术,广泛用于食品加工与保鲜等领域[2]。据报道,100~1000 MPa压力处理可达到不同程度的灭菌效果,能有效提高肉制品的品质、保留营养成分并延长保质期[3]。此外,超高压处理还能有效改善蛋白质的功能特性[4-5]。但是,过高压力处理下肉制品会产生结构改变、氧化变质等不利影响[6],使超高压技术在肉制品方面的应用受到限制。例如,当压力超过300 MPa时,肉色会出现“增白效应”[7],压力超过400 MPa时,肉色呈灰棕色[8]。有研究表明,约在200 MPa时肌动球蛋白变性,400 MPa时Mb变性[9],高于400 MPa时氧合肌红蛋白(Oxymyoglobin, OMb)氧化,高铁肌红蛋白(Methemoglobin, MMb)比例急剧上升[8]。同时,当压力大于300 MPa时,虽然有效抑制了微生物的繁殖,但是显著促进了脂质氧化[3,10-11],蛋白结构也发生不可逆的变化,使蛋白氧化产物增加[12]。Guyon等[12]认为高压可以诱导脂质和蛋白质等成分的修饰,并通过促进自由基的形成来加速氧化,导致品质变化和营养损失。

目前,关于猪肉[13]、牛肉[12]、鸡肉[14]等经超高压处理后贮藏过程中品质变化的研究有较多报道,但是,尚未见有关牦牛肉经超高压处理后贮藏过程中的品质、理化特性以及微生物变化的研究。由于肉制品的体系复杂,不同品种的肉制品体系呈现出的变化不同,而目前品质变化的相关机制仍不明确。因此,本研究以不同压力处理牦牛肉,通过测定贮藏过程中牦牛肉的理化特性、蛋白和脂质氧化以及微生物的变化,探讨牦牛肉经超高压处理后贮藏0、4、8、12、16 d的理化品质变化规律,为超高压在牦牛肉保鲜以及牦牛肉制品中的应用提供参考价值。

1. 材料与方法

1.1 材料与仪器

牦牛肉 购于四川省阿坝州红原县永源肉业,牦牛在红原县集中屠宰,取背长肌,经冷却排酸处理后,−4 ℃运回实验室储藏于4 ℃的环境中;Na2HPO4·12H2O、NaH2PO4·2H2O、MgCl2、EGTA、2,4-二硝基苯肼(DNPH)、氯仿、溴酚蓝、三氯乙酸、硼酸 分析纯,成都科隆化学品有限公司;盐酸胍、SDS、尿素 分析纯,德国BioFroxx公司;2-硫代巴比妥酸(TBA)、5,5-二硫基-2,2-二硝基苯甲酸(DTNB) 分析纯,上海源叶生物有限公司;平板计数琼脂 杭州微生物试剂有限公司;尼龙真空袋(12×22 cm)、立式铝箔袋(35×50 cm) 成都鹏世达公司。

HPP 3-5L超高压灭菌设备 包头科发高压科技有限责任公司;TA-XT Plus质构仪 英国Stable Micro Systems公司;CR-700d/600d色差仪 日本Konica Minolta公司;Centrifuge 5804R高速冷冻离心机 德国Eppendorf公司;T-25高速匀浆机 德国IKA公司;UV1810S紫外分光光度计、PHS-3C 酸度计 上海佑科仪器仪表有限公司;DHP-9052 电热恒温培养箱 上海齐欣科学仪器有限公司。

1.2 实验方法

1.2.1 样品前处理

参考Wang等[11]的方法并略作修改,对牦牛肉进行超高压处理。取牦牛肉背肌去脂肪、筋膜,分割成2.5×2.5×3.0 cm左右大小的肉块,采用尼龙真空袋真空包装,每袋50 g,测定时每组取3袋样品进行平行测定。对照组不进行处理,处理组样品置于超高压设备中,压力分别设定为200、400、600 MPa,常温下保压480 s,传压介质为水(温度保持在20±1 ℃)。处理完毕后用吸水纸吸干包装表面水分,置于立式铝箔袋中避光贮存于4 ℃冰箱中,分别测定0、4、8、12、16 d的肉品品质。

1.2.2 感官评价

感官评分标准参考李文东等[15]的方法并略作修改。感官评分小组由10名食品专业的研究生组成,每次评定前经过培训,熟悉评价内容和打分标准(见表1);评价时感官人员单独进行,相互不接触交流。

表 1 感官评分标准Table 1. Sensory scoring criteria项目 评分标准 评分 色泽

(10)肉色深红且均匀,有光泽 9~10 肉色鲜红且均匀,有光泽 6~8 肉色红色较浅或为呈浅褐色,光泽较暗 3~5 肉色灰白或深褐色,无光泽 1~2 组织状态

(10)肌肉纹理清晰,外表微干或略微湿润,不黏手 9~10 肌肉纹理清晰,外表稍有出水现象,不黏手 6~8 肌肉纹理较为不清晰,外表明显出水,黏手 3~5 肌肉纹理模糊不可辨,外表出水多,黏手严重 0~2 弹性

(10)弹性好,指压后凹陷立即恢复 9~10 弹性较好,指压后凹陷短时间内恢复 6~8 弹性一般,指压后凹陷基本不能恢复 3~5 无弹性,指压后凹陷明显 0~2 气味

(10)具有新鲜牦牛肉独特气味,无异臭、味 9~10 具有牦牛肉正常气味,无异味 6~8 牦牛肉气味较淡,略微异臭、味 3~5 异臭、味明显 0~2 总体

可接受度

(10)可接受性高 9~10 可接受性较好 6~8 接受性一般 3~5 不能接受 0~2 1.2.3 pH的测定

参考Huang等[16]的方法略作修改,取3 g样品加入30 mL去离子水(pH7.0)中,10000 r/min均质30 s后测定,每个样品3次重复测定。

1.2.4 TVB-N含量的测定

参考李锦锦等[17]的方法,准确称取5 g肉样与22.5 mL 2.2%三氯乙酸匀浆(12000 r/min, 60 s)后离心(4 ℃, 8000×g, 10 min),取上清液5 mL置于扩散皿外室中,3 mL硼酸吸收液于扩散皿内室中,用带缺口毛玻璃将扩散皿密封,于外室中再加入5 mL碳酸钾溶液(10 g/L),密封,37 ℃孵育2 h。使用0.01 mol/L盐酸滴定内室中的硼酸液体,直到其恢复至原始颜色。通过消耗的盐酸量计算样品中TVB-N含量(mg/100 g)。

1.2.5 菌落总数的测定

参考GB 4789.2-2016《食品安全国家标准食品微生物学检验菌落总数测定》。

1.2.6 色差的测定

参考Tomasevic等[18]的方法并稍作修改。色差仪采用D65光源,8 mm孔径,近似角度10°,经零校正、白板校正后使用。样品去除包装,无隙置于白色载物板上,随机选取6个测定位置进行测定,记录样品的L*,a*,b*值。

1.2.7 Mb含量及状态的测定

参考Krzywicki[19]的方法并稍作修改,取10 g肉样,加入5倍体积(v/w)的0.04 mol/L的磷酸钠缓冲液(pH6.8),室温下10800 r/min匀浆10 s,冰浴1 h后离心(4 ℃, 1000×g, 30 min),过滤上清液,在525、545、565、572 nm处测定吸光度。

DMb(%)=(0.369R1+1.140R2−0.941R3+0.015)×100

OMb(%)=(0.882R1−1.267R2+0.809R3−0.361)×100

MMb(%)=(−2.514R1+0.777R2+0.800R3+1.098)×100

式中,DMb、OMb、MMb分别表示脱氧肌红蛋白含量、氧合肌红蛋白含量、高铁肌红蛋白含量,R1、R2和R3分别代表吸光度比值:A572/A525;A565/A525;A545/A525。

1.2.8 肌原纤维蛋白(Myofibrillar Protein, MP)的提取

参考Wang等[20]方法,将4倍体积(v/w)的10 mmol/L磷酸盐缓冲溶液(含0.1 mol/L NaCl、2 mmol/L MgCl2、1 mmol/L EGTA,pH7.0)添加到10 g肉中,冰浴条件下10000 r/min匀浆1 min,离心(4 ℃, 2000×g, 15 min),弃去上清液,重复该过程两次。在与上述相同条件下用4倍体积(v/w)的0.1 mol/L NaCl洗涤沉淀并离心2次,第三次均质液通过4层纱布过滤去除结缔组织,滤液用0.1 mol/L HCl调pH至6.0,离心后弃上清液,所得沉淀即为MP。双缩脲法测定蛋白浓度,MP保存在4 ℃冰箱内的密闭瓶中,18 h内使用。

1.2.9 MP羰基含量的测定

参考王琳琳等[21]的方法。取0.5 mL 蛋白溶液(5 mg/mL)中加入0.5 mL含0.02 mol/L DNPH的2 mol/L HCl 溶液,空白组加入0.5 mL 2 mol/L HCl溶液,混匀后在25 ℃下反应40 min。此后,加入2.0 mL 20%三氯乙酸并离心(4 ℃, 10000 r/min, 5 min),除去上清液,沉淀用1.0 mL乙醇-乙酸乙酯溶液(V:V, 1:1)洗涤3次。加入3.0 mL 6.0 mol/L盐酸胍溶液,在37 ℃条件下水浴保温30 min溶解沉淀,以空白组为对照。在370 nm波长处测定吸光度,以摩尔吸光系数22000 mol/(L·cm)计算总羰基含量(nmol/mg)。

1.2.10 MP巯基含量的测定

参考王琳琳等[21]的方法,取0.5 mL蛋白溶液(2 mg/mL)依次加入2 mL尿素-SDS溶液(含8.0 mol/L尿素,30 g/L SDS,0.1 mol/L磷酸钠缓冲液,pH8.0)和0.5 mL 10 mmol/L DTNB溶液(溶解于0.1 mol/L磷酸钠缓冲液,pH 8.0),空白组不含DTNB,室温下反应15 min后,412 nm处测定吸光度,以摩尔吸光系数11400 mol/(L·cm)计算巯基含量(nmol/mg)。

1.2.11 MP表面疏水性的测定

参考王琳琳等[21]的方法,向1.0 mL蛋白溶液(5.0 mg/mL)中加入200 μL 1.0 mg/mL溴酚蓝溶液,混匀离心(6000 r/min,15 min),取上清液进行10倍稀释,以无蛋白的磷酸盐溶液为空白对照,在595 nm波长处测定吸光度,以溴酚蓝结合量来表示表面疏水性指数(μg)。

1.2.12 硫代巴比酸值(TBARS)的测定

参考Huang等[16]的方法,取0.3 g肉样,加入3 mL 1% TBA溶液和17 mL TCA-HCl溶液均质,90 ℃水浴40 min,冷却后加入5 mL氯仿,离心(4 ℃, 3000 r/min, 5 min),取上清液在532 nm下测定吸光值,结果表示为每千克肉样中丙二醛(MDA)的毫克数。摩尔消光系数为152000 mol/(L·cm)。

1.3 数据处理

所有指标重复测定3次,结果以平均值±标准差表示;原始数据统计采用Excel 2019,采用SPSS 24.0进行平均值、标准差、ANOVA方差分析;处理组平均数之间采用Duncan多重比较进行显著性分析,显著水平为P˂0.05;采用Pearson相关性分析对指标相关性分析;所有图由Origin 2019b 绘制。

2. 结果与分析

2.1 超高压处理对牦牛肉感官品质的影响

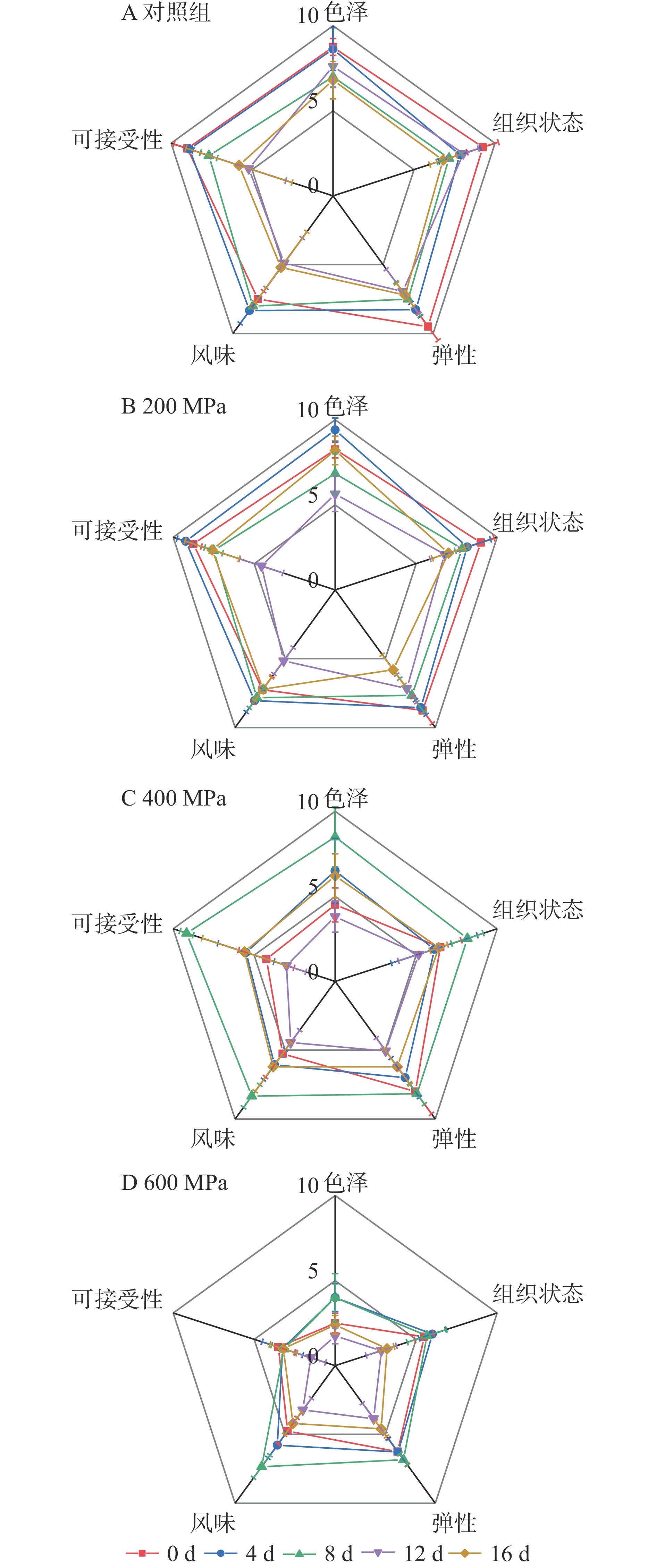

感官评价是最简便直接的评价肉制品的方法。由图1可知,经超高压处理的牦牛肉,在不同贮藏时间感官品质有所变化。经超高压处理后牦牛肉的感官评分随着压力增大而减小;色泽随着压力增大由深红变为粉红(200~400 MPa),当压力较高时(600 MPa),牦牛肉色泽变为棕褐色,与前人的研究结果吻合[7-8]。400 MPa组牦牛肉在贮藏8 d后感官品质相较其他组更佳,这说明适当的加压处理能改善肉品品质,但具体原因需要进一步确定。与对照组相比,当压力为200和400 MPa时,牦牛肉虽保留了良好的色泽和组织状态,但12 d后微生物的过度生长,脂质过氧化分解并产生异常气味[22]降低了可接受度。当压力为600 MPa时,牦牛肉在第0 d时就出现明显劣变,如组织结构松散,这可能是高压使蛋白碎片化导致[23]。

2.2 超高压处理对牦牛肉pH的影响

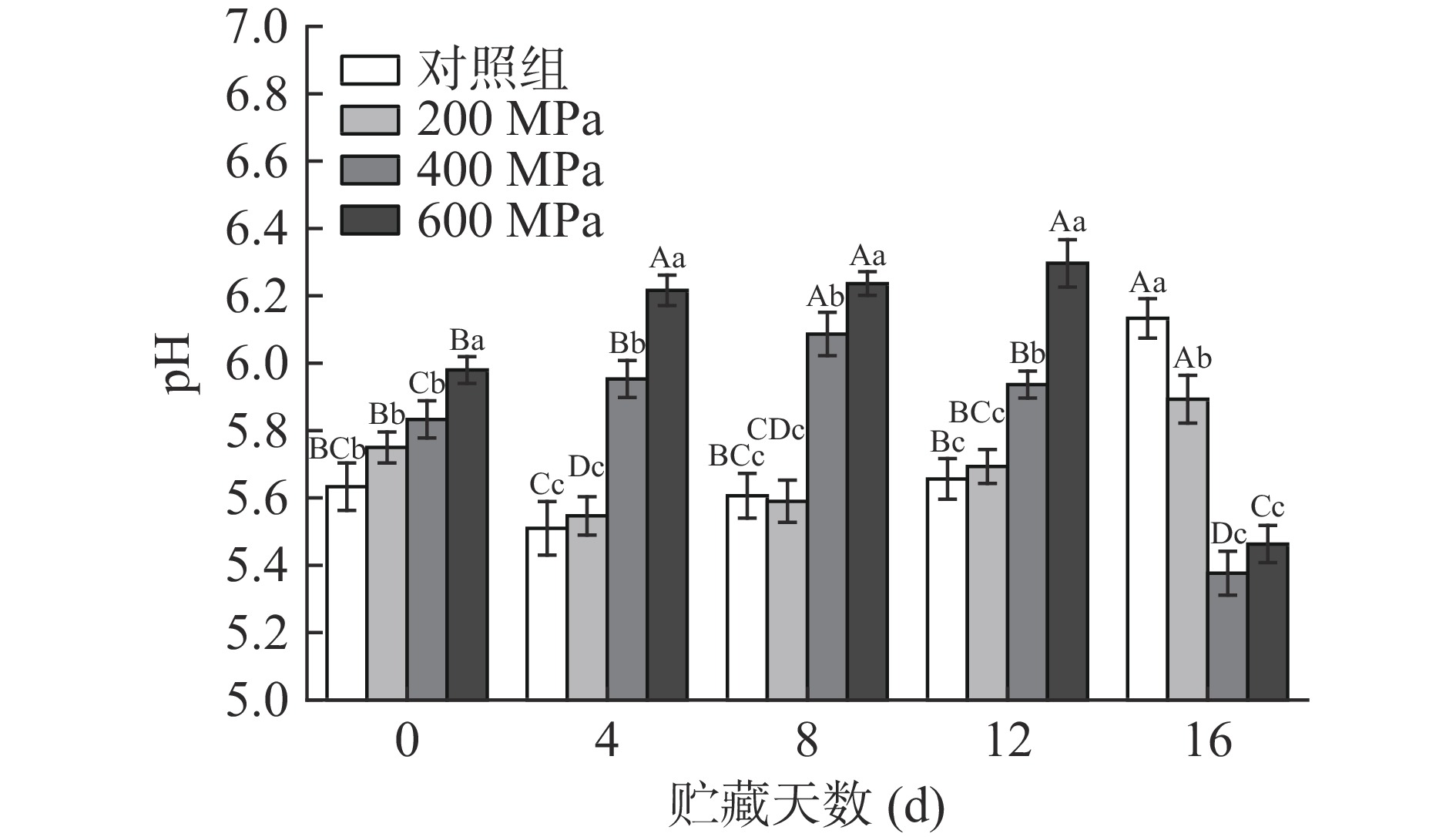

pH是影响色泽、持水力、嫩度和微生物生长等的主要因素[24]。由图2可知,与对照组相比,随着压力的增大,牦牛肉pH显著上升(P˂0.05)。这是由于超高压处理使蛋白结构发生变化,酸性基团被包埋,同时自由氨基酸进入细胞使含氮物质增加,氨基酸在压力作用下电解,导致pH升高[25]。

在贮藏前期,对照组和200 MPa组牦牛肉的pH略有下降,这可能是排酸不彻底,乳酸积累所致。随着贮藏时间的延长,对照组和200 MPa组pH显著增大(P˂0.05)。这是因为微生物在肉表面积聚、活动加快,产生氨、胺等碱性物质,同时在酶的作用下蛋白质分解,pH升高[24]。400 MPa组与600 MPa组牦牛肉的pH随时间增加先上升后下降。贮藏前期pH上升可能是由于蛋白质变性与脂质氧化加剧[26],而16 d时400 MPa组和600 MPa组的pH剧烈下降可能是由于细菌在受到损伤后逐渐恢复活性,生长繁殖分泌了有机酸、酮等腐败物质[27-28]。

2.3 超高压处理对牦牛肉新鲜度的影响

TVB-N和菌落总数常用于评判肉制品新鲜程度[29]。由图3A和图3B可知,超高压处理降低了牦牛肉的TVB-N含量和菌落总数,与Chen等[30]和Soladoye等[31]的描述相吻合。随着贮藏时间的延长,牦牛肉的菌落总数和TVB-N含量均显著增大(P<0.05)。这是由于微生物生长导致蛋白降解产生胺类物质,菌落总数增加,TVB-N含量升高[29]。贮藏16 d时,对照组TVB-N含量达15.68 mg/100 g,超过15.0 mg/100 g,而各处理组牦牛肉TVB-N含量均低于15 mg/100 g。同时,对照组和200 MPa组12 d时菌落总数远高于6 lg(CFU/g),分别达7.57、7.16 lg(CFU/g),而400 MPa组12 d时菌落总数达5.92 lg(CFU/g),600 MPa组16 d时菌落总数达5.83 lg(CFU/g),说明较高压力下杀菌效果更佳。综上,超高压处理能有效提高牦牛肉新鲜度、延长其保质期。

2.4 超高压处理对牦牛肉色泽的影响

色泽直接影响了消费者的购买意愿。由图4可知,随着压力增大,牦牛肉L*、b*值增大,当压力过高(600 MPa)时,a*值减小;贮藏过程中各组L*、b*值变化逐渐趋于稳定,a*值逐渐减小。0 d时,较高压力下(400 MPa和600 MPa),牦牛肉L*、b*值显著增大(P˂0.05),并在整个贮藏期内都维持在较高的水平(见图4A、图4C),这与Bak等[32]的研究结果相似。这可能是超高压处理使纤维结构疏松和表面性质变化,导致肉表面光学反射率改变[7]。贮藏0 d时,随着压力升高,牦牛肉a*值升高后显著降低(P˂0.05)(见图4B)。该结果与Kruk等[33]的报道相似。这或许与MMb含量变化有关,中等压力(200~400 MPa)下减少MMb的酶系统可能被激活,而较高压力(600 MPa)下酶系统和MMb的形成受到干扰[34]。贮藏8 d时,200 MPa组牦牛肉a*值显著下降(P˂0.05)。研究表明MMb的积累是a*值下降的主要原因[35];同时脂质氧化与肌红蛋白氧化之间相互促进,使肉表面a*值降低、色泽褐变[36]。

2.5 超高压处理对牦牛肉Mb氧化的影响

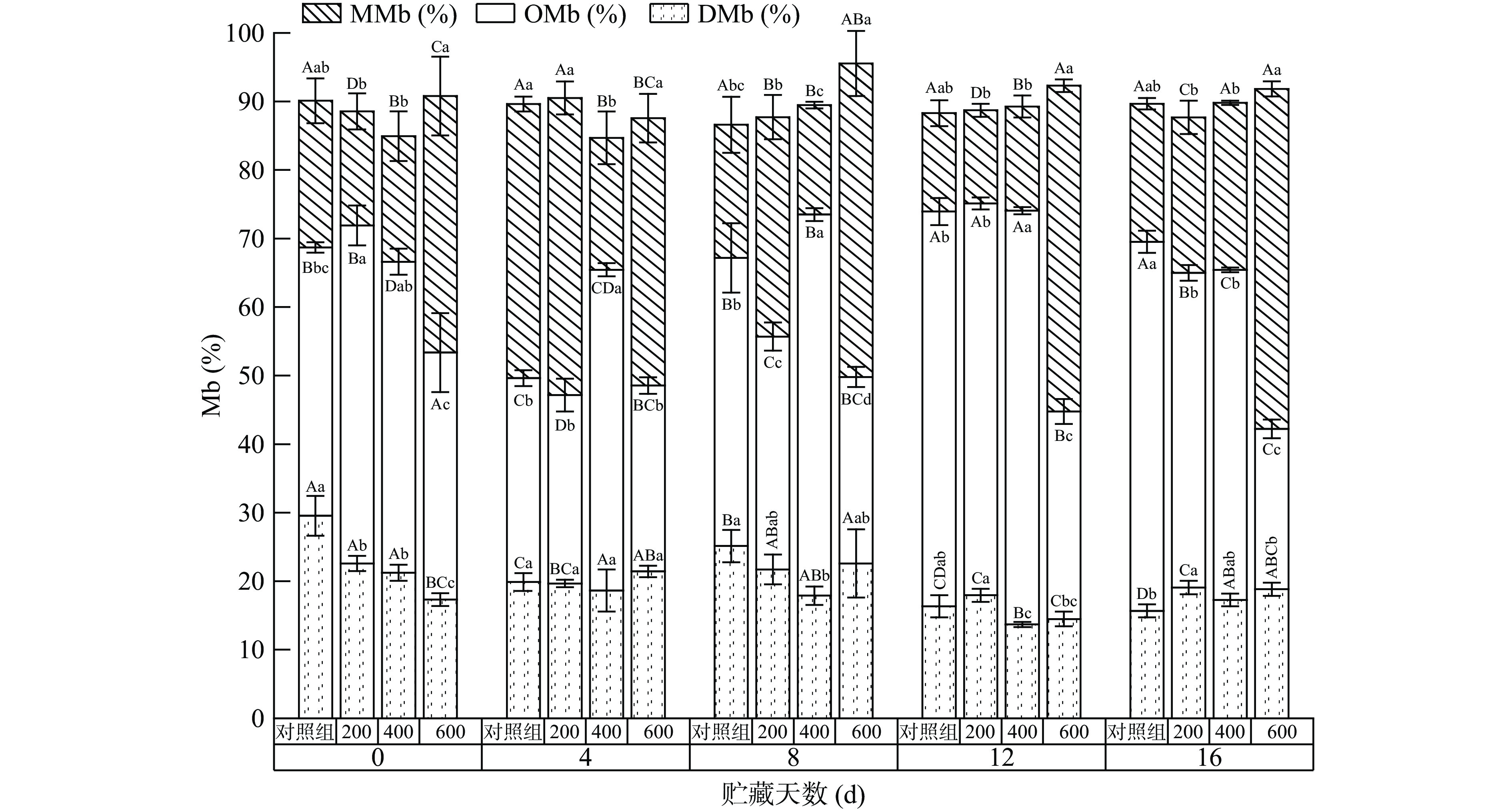

色泽的变化与肌肉中水分的状态、Mb的氧化状态等有关,压力对Mb影响显著[7]。由图5可知,与对照组相比,处理组DMb含量减少,OMb、MMb含量增多,说明超高压促进Mb氧化。贮藏过程对照组DMb含量减少、OMb含量先减少后增多、MMb含量增多后减少。200 MPa组和对照组的变化趋势相似,贮藏4 d时MMb含量明显增多,而后显著降低(P˂0.05)。这或许是因为:线粒体耗氧及真空条件形成了厌氧环境,同时线粒体与OMb的相互作用使氧气转移,促进了DMb的形成、MMb的减少[37];MMb可能进一步氧化形成铁酰肌红蛋白而质子化,与蛋白质形成血红素-蛋白交联物质[35]。经超高压处理后,400 MPa组OMb含量增多,600 MPa组MMb含量增多,且两者在贮藏期内均维持在较高水平。这可能与还原酶系统的激活和破坏、蛋白与脂质氧化对Mb的氧化诱导、蛋白变性等因素有关[7]。综上,超高压显著促进了Mb的氧化,400 MPa组肉色稳定性良好。

2.6 超高压处理对牦牛肉MP氧化的影响

2.6.1 羰基含量变化

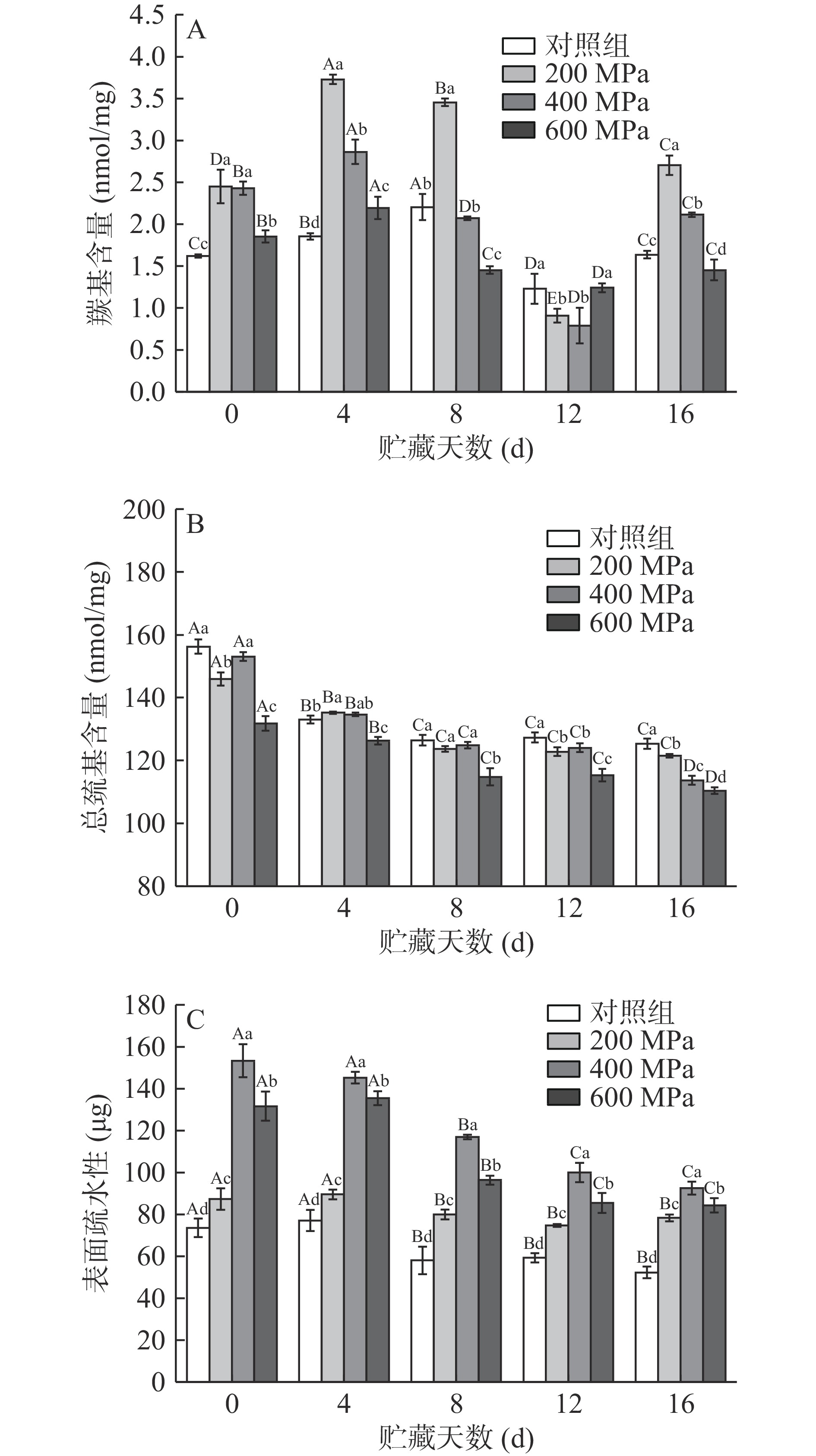

羰基是评估蛋白氧化的相关标志物,蛋白氧化程度越高,羰基含量越高[38]。由图6A可知,0 d时,与对照组相比,处理组羰基含量显著增多(P˂0.05),即超高压处理促进了蛋白质氧化。在处理组内,羰基含量随着压力升高而降低(P<0.05),可能是更高的压力使蛋白系统缩至更小的摩尔体积,形成较大的不溶性蛋白聚集体,影响了蛋白结构[7]。贮藏4 d时各组羰基含量相比0 d时显著增加(P<0.05),可能与Mb和脂质的氧化诱导有关[7,37,39]。对照组羰基含量增量比处理组小,可能是由于抗氧化蛋白的存在[40];处理组羰基含量增量随着压力增大而减小,可能与蛋白结构的变性程度有关[7]。8~12 d内各组羰基含量随时间延长而下降,可能原因有:贮藏过程中蛋白质被降解[41];或蛋白羰基进一步氧化,形成Strecker醛等[39]。在贮藏16 d时,各组羰基含量显著增大(P˂0.05),可能是随时间延长蛋白羰基化严重导致羰基含量再次增加。整个贮藏期内羰基含量的变化与Zhang等[42]辐照处理新鲜猪肉时的结果相似,说明超高压处理对羰基化合物的形成与降解影响显著。

2.6.2 总巯基含量变化

在MP表面及内部含有大量巯基,容易氧化形成二硫键,使巯基含量下降,因此巯基含量的变化也反映了蛋白氧化情况[39]。由图6B可知,相比对照组,处理组总巯基含量减少,即超高压促进了蛋白氧化。0 d时,200 MPa压力下活性巯基被加速氧化使总巯基含量显著减少(P<0.05);400 MPa组总巯基含量与对照组无显著差异(P>0.05),而600 MPa组总巯基含量显著减少(P˂0.05),可能是蛋白内部的巯基在适当压力下暴露,而过高压力下巯基基团在蛋白重折叠过程中被包裹[43]。Nicolas等[44]也报道了约400 MPa的压力下兔的MP活性巯基含量有所增加。随着贮藏时间的延长,总巯基含量显著减少(P<0.05),这可能是由于蛋白质氧化使结构展开,巯基基团暴露被氧化[45]。

2.6.3 表面疏水性变化

表面疏水性的变化反映了蛋白质三级结构的变化[46]。由图6C可知,相比对照组,处理组表面疏水性升高,可能是由于超高压处理使非极性氨基酸暴露[45]。在处理组内,随着压力的升高,表面疏水性升高后降低。研究表明,当压力超过400 MPa时,表面疏水性开始下降[46]。200~400 MPa内,表面疏水性随着压力升高而升高,与Zhang等[4]的结果吻合。600 MPa组表面疏水性显著降低(P<0.05)。这可能是高压力下疏水区域的暴露促进了疏水相互作用,使未折叠的蛋白重新结合或聚集[47]。贮藏过程中,表面疏水性显著下降(P˂0.05),可能是蛋白结构过度变性所致[45]。

2.6.4 超高压处理对牦牛肉MP氧化的影响

MP是肌肉蛋白中的主要成分,多项研究表明当压力超过一定阈值后,MP的物理化学特性会受到影响[46,48]。由2.6.1~2.6.3结果可知,当压力≥400 MPa时,超高压会显著促进牦牛肉MP的氧化,主要表现为羰基含量的增多、巯基含量的减少与表面疏水性的升高。

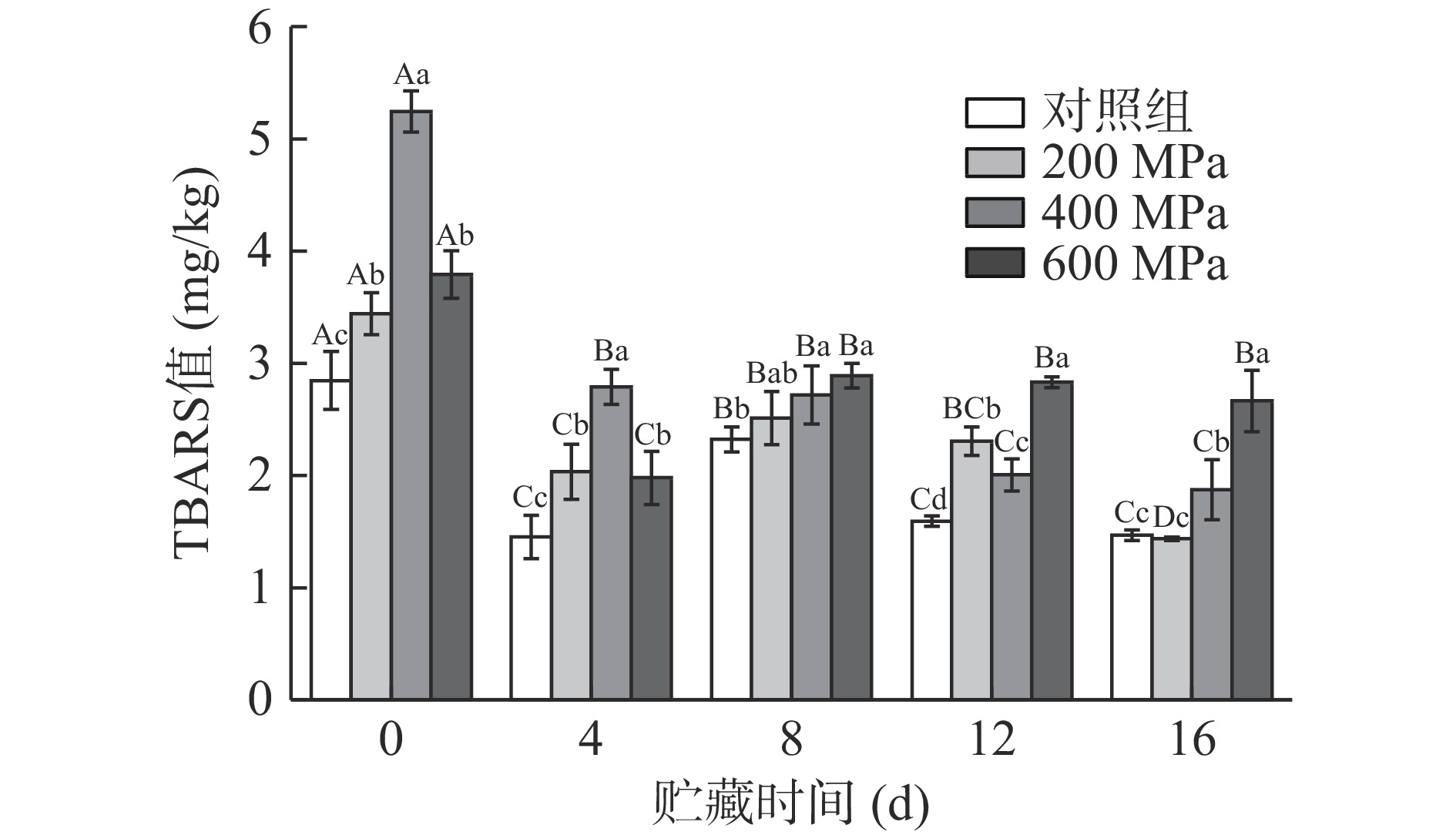

2.7 超高压处理对牦牛肉TBARS值的影响

TBARS值广泛用于衡量肉制品的脂质氧化程度[10]。由图7可知,与对照组相比,处理组牦牛肉TBABS值显著增大(P<0.05)。400 MPa组TBARS值最大,说明400 MPa极大地促进了脂质氧化的发生,这与多项研究结果相符[10]。600 MPa组TBARS值较400 MPa组小。Orlien等[49]发现TBARS的形成与压力高度相关,600、700 MPa压力下反而抑制了氧化的发生。在贮藏过程中,贮藏4 d时TBARS值显著减小后维持在较低水平(P<0.05),这与以往研究结果有些不同,脂质氧化是一个动态过程,氧化产物不断产生和降解,醛类可与蛋白质的亲核基团反应形成Schiff碱或Michael加成化合物等[35]。Şayin Sert等[50]将牛肉糜经加压后贮藏过程中TBARS值的降低归因于真空包装后的低氧、肉中抗氧化肽释放产生作用和丙二醛高度氧化降解成醇和酸。关于其具体原因需要进一步研究确认。

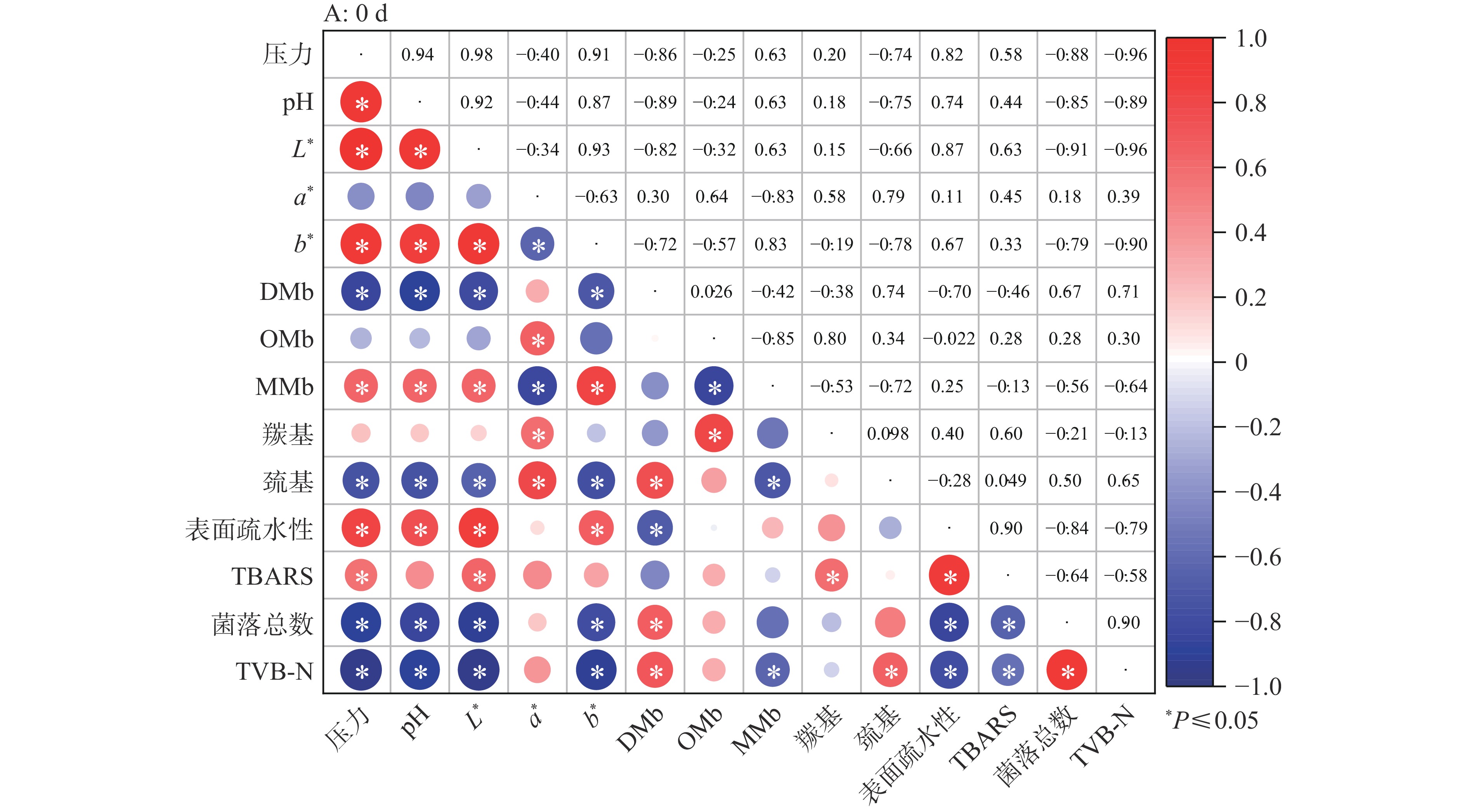

2.8 各指标间相关性分析

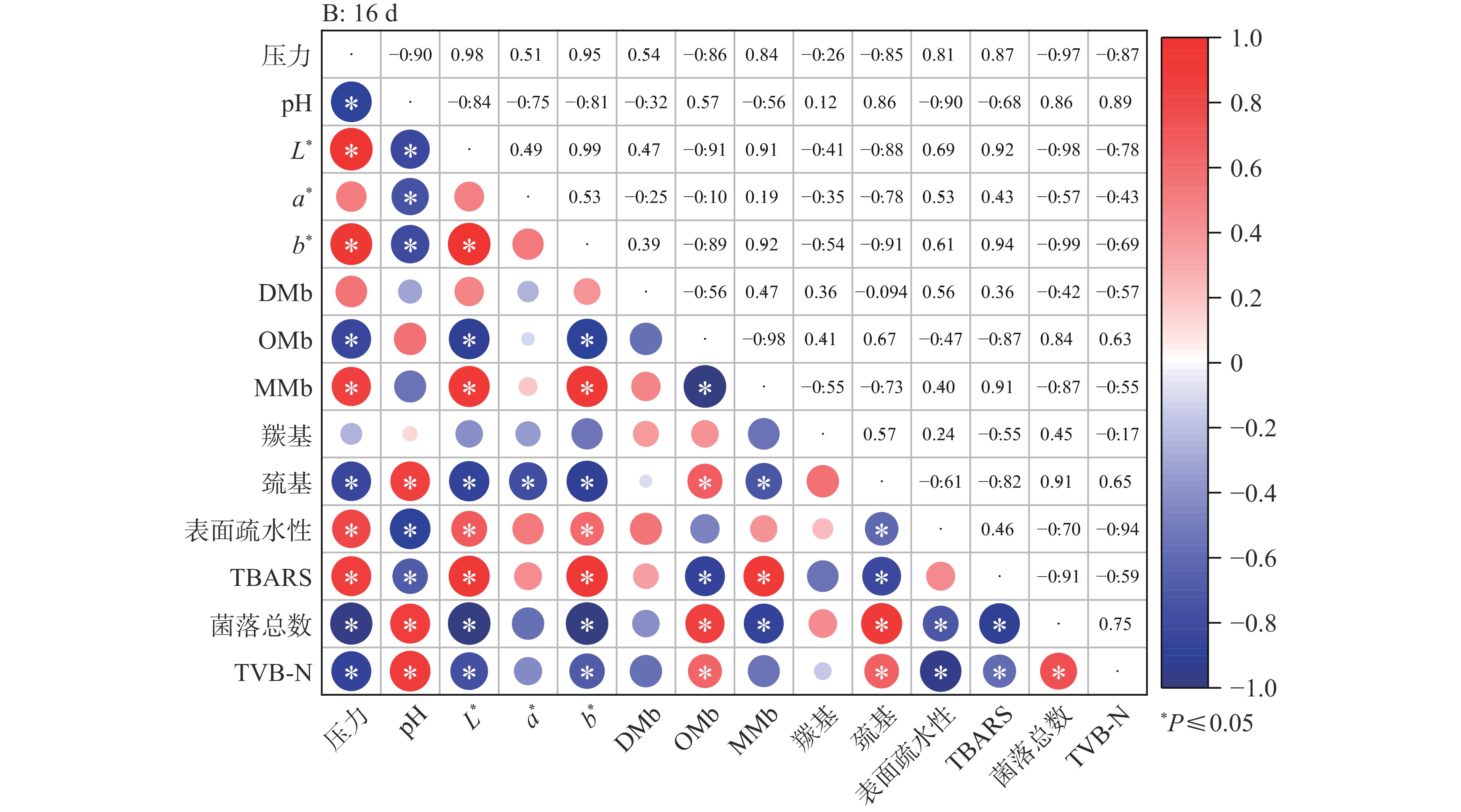

Pearson相关性分析结果见图8。由图8A可知,0 d时,随着压力的增大,牦牛肉的L*值与b*值强正相关(r=0.93, P<0.05),且均与pH、MMb含量、表面疏水性、TBARS值正相关,与DMb含量、巯基含量、菌落总数、TVB-N含量负相关;而a*值与OMb含量、羰基含量、巯基含量正相关,与MMb含量负相关(P<0.05)。说明色泽与蛋白质和脂质氧化、微生物情况相关。其中OMb与羰基含量正相关(r=0.80, P<0.05),MMb与巯基含量负相关(r=−0.72, P<0.05),表面疏水性与TBARS值强正相关(r=0.90, P<0.05),菌落总数、TVB-N含量均与DMb、表面疏水性、TBARS值相关(P<0.05)。说明压力可能导致蛋白质结构变化和微生物数量的减少,引起脂质和蛋白质氧化,使pH升高、色泽改变。

由图8B可知,贮藏16 d后牦牛肉a*值与肌红蛋白氧化状态无显著相关性(P>0.05),而OMb含量与L*值、b*值的负相关性加强(r=−0.91、−0.89, P<0.05),与TBARS值出现负相关性(r=−0.84, P<0.05)。羰基与其他指标间相关性不再显著(P>0.05)。TBARS值不再与表面疏水性相关(P>0.05),而与巯基出现负相关性(r=−0.82, P<0.05),同时与菌落总数的负相关性增强(r由−0.64增长为−0.91)。说明经贮藏后色泽的变化可能主要是脂质氧化引起的。0与16 d牦牛肉各指标的相关性异同说明:牦牛肉品质变化仍与蛋白质和脂质氧化、微生物情况相关,超高压处理可能影响了其变化机制。

3. 结论

超高压处理显著延长了牦牛肉的保质期,主要表现为TVB-N含量和菌落总数的降低,但超高压处理也降低了感官品质,导致肉色劣变。进一步分析发现,超高压处理导致加速了脂质和蛋白质氧化,主要表现为OMb和MMb含量的增多、MP羰基含量、表面疏水性的上升和总巯基含量的减少、TBARS值的增大。其中,适当的氧化有利于牦牛肉的品质,牦牛肉贮藏4~8 d后超高压处理组保持更好的品质,且400 MPa下牦牛肉的肉色稳定性更佳。Pearson相关性结果表示经超高压处理后牦牛肉品质变化与压力显著相关,且色泽的变化与蛋白氧化、脂质氧化、微生物之间存在关联。

由于高寒低氧的生存环境,牦牛肉肌红蛋白含量高、肉色好。研究表明肉及肉制品色泽与压力、蛋白质和脂质氧化有关,关于微生物的作用却少有提及。因此,关于超高压处理后牦牛肉中在贮藏过程中的肌红蛋白自氧化、蛋白质氧化、脂质氧化、微生物与肉色的关系需要深入研究,以期为牦牛肉的保鲜与加工提供可靠参考意见。

-

表 1 感官评分标准

Table 1 Sensory scoring criteria

项目 评分标准 评分 色泽

(10)肉色深红且均匀,有光泽 9~10 肉色鲜红且均匀,有光泽 6~8 肉色红色较浅或为呈浅褐色,光泽较暗 3~5 肉色灰白或深褐色,无光泽 1~2 组织状态

(10)肌肉纹理清晰,外表微干或略微湿润,不黏手 9~10 肌肉纹理清晰,外表稍有出水现象,不黏手 6~8 肌肉纹理较为不清晰,外表明显出水,黏手 3~5 肌肉纹理模糊不可辨,外表出水多,黏手严重 0~2 弹性

(10)弹性好,指压后凹陷立即恢复 9~10 弹性较好,指压后凹陷短时间内恢复 6~8 弹性一般,指压后凹陷基本不能恢复 3~5 无弹性,指压后凹陷明显 0~2 气味

(10)具有新鲜牦牛肉独特气味,无异臭、味 9~10 具有牦牛肉正常气味,无异味 6~8 牦牛肉气味较淡,略微异臭、味 3~5 异臭、味明显 0~2 总体

可接受度

(10)可接受性高 9~10 可接受性较好 6~8 接受性一般 3~5 不能接受 0~2 -

[1] TIAN J, HAN L, YU L, et al. Changes in tenderness and cathepsins activity during post mortem ageing of yak meat[J]. Canadian Journal of Animal Science,2013,93(3):321−328. doi: 10.4141/cjas2012-102

[2] de OLIVEIRA F A, NETO O C, SANTOS L M R D, et al. Effect of high pressure on fish meat quality – A review[J]. Trends in Food Science & Technology,2017,66:1−19.

[3] GARCÍA-PARRA J, RAMÍREZ R. New preservations technologies: Hydrostatic high pressure processing and high pressure thermal processing: Encyclopedia of food security and sustainability [M]. Oxford: Elsevier, 2019: 473−480.

[4] ZHANG Z, YANG Y, ZHOU P, et al. Effects of high pressure modification on conformation and gelation properties of myofibrillar protein[J]. Food Chemistry,2017,217:678−686. doi: 10.1016/j.foodchem.2016.09.040

[5] ROOBAB U, KHAN A W, LORENZO J M, et al. A systematic review of clean-label alternatives to synthetic additives in raw and processed meat with a special emphasis on high-pressure processing (2018~2021) [J]. Food Research International, 2021, 150(Part A): 110792.

[6] 刘泽超, 罗欣, 张一敏, 等. 宰后成熟对生鲜肉品质影响的研究进展[J]. 食品科学,2021,42(21):202−212. [LIU Z C, LUO X, ZHANG Y M, et al. Progress in research on the effect of postmortem aging on the quality of fresh meat[J]. Food Science,2021,42(21):202−212. doi: 10.7506/spkx1002-6630-20200710-147 [7] BAK K H, BOLUMAR T, KARLSSON A H, et al. Effect of high pressure treatment on the color of fresh and processed meats: A review[J]. Critical Reviews in Food Science and Nutrition,2019,59(2):228−252. doi: 10.1080/10408398.2017.1363712

[8] 马汉军, 周光宏, 徐幸莲, 等. 高压处理对牛肉肌红蛋白及颜色变化的影响[J]. 食品科学,2004(12):36−39. [MA H J, ZHOU G H, XUE X L, et al. Effects of high pressure treatment on myoglobin changes and color changes in minced beef[J]. Food Science,2004(12):36−39. doi: 10.3321/j.issn:1002-6630.2004.12.002 [9] MA H J, LEDWARD D A. High pressure processing of fresh meat — Is it worth it?[J]. Meat Science,2013,95(4):897−903. doi: 10.1016/j.meatsci.2013.03.025

[10] GUYON C, MEYNIER A, de LAMBALLERIE M. Protein and lipid oxidation in meat: A review with emphasis on high-pressure treatments[J]. Trends in Food Science & Technology,2016,50:131−143.

[11] WANG Q, ZHAO X, REN Y, et al. Effects of high pressure treatment and temperature on lipid oxidation and fatty acid composition of yak (Poephagus grunniens) body fat[J]. Meat Science,2013,94(4):489−494. doi: 10.1016/j.meatsci.2013.03.006

[12] GUYON C, le VESSEL V, MEYNIER A, et al. Modifications of protein-related compounds of beef minced meat treated by high pressure[J]. Meat Science,2018,142:32−37. doi: 10.1016/j.meatsci.2018.03.019

[13] 郜娜. 超高压和L-抗坏血酸互作调控冷却肉色泽的分子机制与应用研究[M]. 合肥: 合肥工业大学, 2021. GAO N. Study on the molecular mechanism and application of the interaction between ultra-high pressure and L-ascorbic acid in regulating the color of chilled meat[D]. Hefei: Hefei University of Technology, 2021.

[14] MARIANA C, PAOLA F P, DIEGO F, et al. Effect of high hydrostatic pressure on Salmonella spp inactivation and meat-quality of frozen chicken breast[J]. LWT,2020,118(C):108873.

[15] 李文东, 韩玲, 余群力, 等. 冷却方式对牦牛肉贮藏过程中品质变化的影响[J]. 食品与发酵工业,2020,46(20):199−207. [LI W D, HAN L, YU Q L, et al. Effect of chilling methods on the quality of yak meat during storage[J]. Food and Fermentation Industries,2020,46(20):199−207. doi: 10.13995/j.cnki.11-1802/ts.023957 [16] HUANG Q, DONG K, WANG Q, et al. Changes in volatile flavor of yak meat during oxidation based on multi-omics[J]. Food Chemistry,2022,371:131103. doi: 10.1016/j.foodchem.2021.131103

[17] 李锦锦, 莫然, 李琼帅, 等. 超声波解冻功率对猪肝品质及脂质氧化特性的影响[J]. 食品与发酵工业,2022,48(8):113−119, 127. [LI J J, MO R, LI Q S, et al. Effects of ultrasonic thawing power on quality and lipid oxidation properties of porcine liver[J]. Food and Fermentation Industries,2022,48(8):113−119, 127. doi: 10.13995/j.cnki.11-1802/ts.027680 [18] TOMASEVIC I, DJEKIC I, FONT I F M, et al. Recent advances in meat color research[J]. Current Opinion in Food Science,2021,41:81−87. doi: 10.1016/j.cofs.2021.02.012

[19] KRZYWICKI K. The determination of hem pigments in meat[J]. Meat Science,1982,7(1):29−36. doi: 10.1016/0309-1740(82)90095-X

[20] WANG H H, SONG Y Y, LIU Z Q, et al. Effects of iron-catalyzed and metmyoglobin oxidizing systems on biochemical properties of yak muscle myofibrillar protein[J]. Meat Science,2020:166.

[21] 王琳琳, 陈炼红, 李璐倩, 等. 解冻方式对牦牛肉蛋白氧化、功能特性及新鲜度的影响[J]. 农业机械学报,2021,52(5):342−349. [WANG L L, CHEN L H, LI L Q, et al. Effects of thawing methods on protein oxidation, protein functional properties and freshness of yak meat[J]. Transactions of the Chinese Society for Agricultural Machinery,2021,52(5):342−349. doi: 10.6041/j.issn.1000-1298.2021.05.038 [22] 周彬静, 刘小花, 彭菁, 等. 荧光假单胞菌和热杀索丝菌对低温贮藏期间猪肉品质变化的影响[J]. 食品科学,2022,43(19):208−214. [ZHOU B J, LIU X H, PENG J, et al. Effects of Pseudomonas fluorescens and Brochothrix thermosphacta on quality changes of pork during low-temperature storage[J]. Food Science,2022,43(19):208−214. doi: 10.7506/spkx1002-6630-20211010-093 [23] BARBHUIYA R I, SINGHA P, SINGH S K. A comprehensive review on impact of non-thermal processing on the structural changes of food components[J]. Food Research International,2021,149:110647. doi: 10.1016/j.foodres.2021.110647

[24] SUJIWO J, KIM D, JANG A. Relation among quality traits of chicken breast meat during cold storage: Correlations between freshness traits and torrymeter values[J]. Poultry Science,2018,97(8):2887−2894. doi: 10.3382/ps/pey138

[25] DONG K, LUO X, LIU L, et al. Effect of high-pressure treatment on the quality of prepared chicken breast[J]. International Journal of Food Science and Technology,2021,56(4):1597−1607. doi: 10.1111/ijfs.14776

[26] HUANG Y, LI H, HUANG T, et al. Lipolysis and lipid oxidation during processing of Chinese traditional smoke-cured bacon[J]. Food Chemistry,2014,149:31−39. doi: 10.1016/j.foodchem.2013.10.081

[27] WANG Z, TU J, ZHOU H, et al. A comprehensive insight into the effects of microbial spoilage, myoglobin autoxidation, lipid oxidation, and protein oxidation on the discoloration of rabbit meat during retail display[J]. Meat Science,2021,172:108359. doi: 10.1016/j.meatsci.2020.108359

[28] SHAO L, CHEN S, WANG H, et al. Advances in understanding the predominance, phenotypes, and mechanisms of bacteria related to meat spoilage[J]. Trends in Food Science & Technology, 2021, 118(Part B): 822−832.

[29] BEKHIT A E A, HOLMAN B W B, GITERU S G, et al. Total volatile basic nitrogen (TVB-N) and its role in meat spoilage: A review[J]. Trends in Food Science & Technology,2021,109:280−302.

[30] CHEN L, JIAO D, LIU H, et al. Effects of water distribution and protein degradation on the texture of high pressure-treated shrimp (Penaeus monodon) during chilled storage[J]. Food Control,2022,132:108555. doi: 10.1016/j.foodcont.2021.108555

[31] SOLADOYE O P, PIETRASIK Z. Utilizing high pressure processing for extended shelf life meat products: Reference module in food science[M]. Elsevier, 2018.

[32] BAK K H, LINDAHL G, KARLSSON A H, et al. Effect of high pressure, temperature, and storage on the color of porcine longissimus dorsi[J]. Meat Science,2012,92(4):374−381. doi: 10.1016/j.meatsci.2012.02.002

[33] KRUK Z A, YUN H, RUTLEY D L, et al. The effect of high pressure on microbial population, meat quality and sensory characteristics of chicken breast fillet[J]. Food Control,2010,22(1):6−12. doi: 10.15358/0935-0381-2010-1-6

[34] JUNG S, GHOUL M, DE LAMBALLERIE-ANTON M. Influence of high pressure on the color and microbial quality of beef meat[J]. LWT - Food Science and Technology,2003,36(6):625−631. doi: 10.1016/S0023-6438(03)00082-3

[35] WANG Z, HE Z, EMARA A M, et al. Effects of malondialdehyde as a byproduct of lipid oxidation on protein oxidation in rabbit meat[J]. Food Chemistry,2019,288:405−412. doi: 10.1016/j.foodchem.2019.02.126

[36] FAUSTMAN C, SUN Q, MANCINI R, et al. Myoglobin and lipid oxidation interactions: Mechanistic bases and control[J]. Meat Science,2010,86(1):86−94. doi: 10.1016/j.meatsci.2010.04.025

[37] SUMAN S P, JOSEPH P. Myoglobin chemistry and meat color[J]. Annual Review of Food Science and Technology,2013,4(1):79−99. doi: 10.1146/annurev-food-030212-182623

[38] ESTÉVEZ M. Protein carbonyls in meat systems: A review[J]. Meat Science,2011,89(3):259−279. doi: 10.1016/j.meatsci.2011.04.025

[39] SOLADOYE O P, JUÁREZ M L, AALHUS J L, et al. Protein oxidation in processed meat: Mechanisms and potential implications on human health[J]. Comprehensive Reviews in Food Science and Food Safety,2015,14(2):106−122. doi: 10.1111/1541-4337.12127

[40] JOSEPH P, SUMAN S P, RENTFROW G, et al. Proteomics of muscle-specific beef color stability[J]. Journal of Agricultural and Food Chemistry,2012,60(12):3196−3203. doi: 10.1021/jf204188v

[41] ZHANG X, HUANG W, XIE J. Effect of different packaging methods on protein oxidation and degradation of grouper (Epinephelus coioides) during refrigerated storage[J]. Food,2019,8(8):325. doi: 10.3390/foods8080325

[42] ZHANG M, HE L, LI C, et al. Effects of gamma ray irradiation-induced protein hydrolysis and oxidation on tenderness change of fresh pork during storage[J]. Meat Science,2020,163:108058. doi: 10.1016/j.meatsci.2020.108058

[43] 何轩辉. 超高压对花生分离蛋白凝胶特性的影响及其机理研究[D]. 北京: 中国农业科学院, 2013: 108. HE X H. Study on the effects of ultra-high pressure on the gelation properties of peanut protein isolates and its mechanism[D]. Beijing: Chinese Academy of Agricultural Sciences, 2013: 108

[44] NICOLAS J C, MARIE I D L. Changes in myofibrillar proteins interactions and rheological properties induced by high-pressure processing[J]. European Food Research and Technology, 2003, 216(6): 470-476.

[45] JIANG S, ZHAO D, NIAN Y, et al. Ultrasonic treatment increased functional properties and in vitro digestion of actomyosin complex during meat storage[J]. Food Chemistry,2021,352:129398. doi: 10.1016/j.foodchem.2021.129398

[46] LIU H, XU Y, ZU S, et al. Effects of high hydrostatic pressure on the conformational structure and gel properties of myofibrillar protein and meat quality: A review[J]. Foods,2021,10(8):1872. doi: 10.3390/foods10081872

[47] JIN Y, DENG Y, QIAN B, et al. Allergenic response to squid (Todarodes pacificus) tropomyosin Tod p1 structure modifications induced by high hydrostatic pressure[J]. Food and Chemical Toxicology,2015,76:86−93. doi: 10.1016/j.fct.2014.12.002

[48] YAMIRA C, MAURICIO O, ANJA E M J, et al. Effects of high hydrostatic pressure (HHP) on protein structure and digestibility of red abalone (Haliotis rufescens) muscle[J]. Innovative Food Science and Emerging Technologies,2020,60(C):102282.

[49] ORLIEN V, HANSEN E, SKIBSTED L H. Lipid oxidation in high-pressure processed chicken breast muscle during chill storage: Critical working pressure in relation to oxidation mechanism[J]. European Food Research and Technology,2000,211(2):99−104. doi: 10.1007/s002179900118

[50] ŞAYIN SERT T, COŞKUN F. The effects of high-pressure processing on pH, thiobarbituric acid value, color and texture properties of frozen and unfrozen beef mince[J]. Molecules,2022,27(13):3974. doi: 10.3390/molecules27133974

下载:

下载:

下载:

下载: